Non-crystal type manganese oxide loaded nitrogen-doped carbon-based (MnOx/NC) catalyst, and preparation method thereof

A manganese oxide, nitrogen-doped carbon technology, used in electrochemical generators, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of decreased catalytic performance, poor electrical conductivity, easy aggregation, etc. , conducive to dispersion, the effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

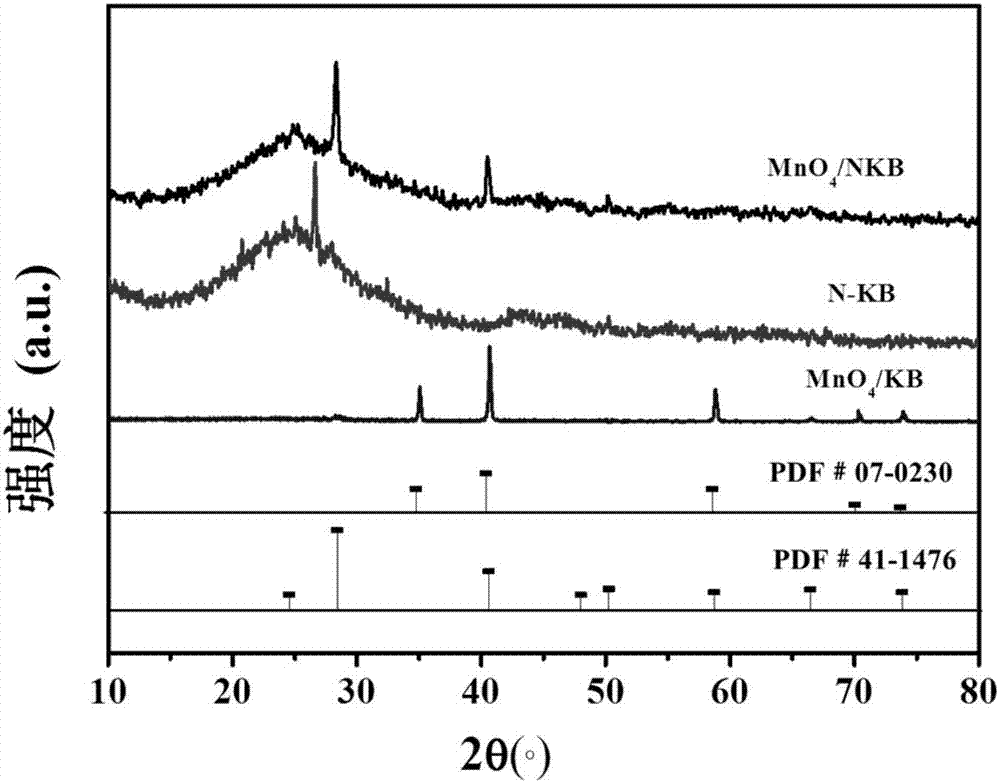

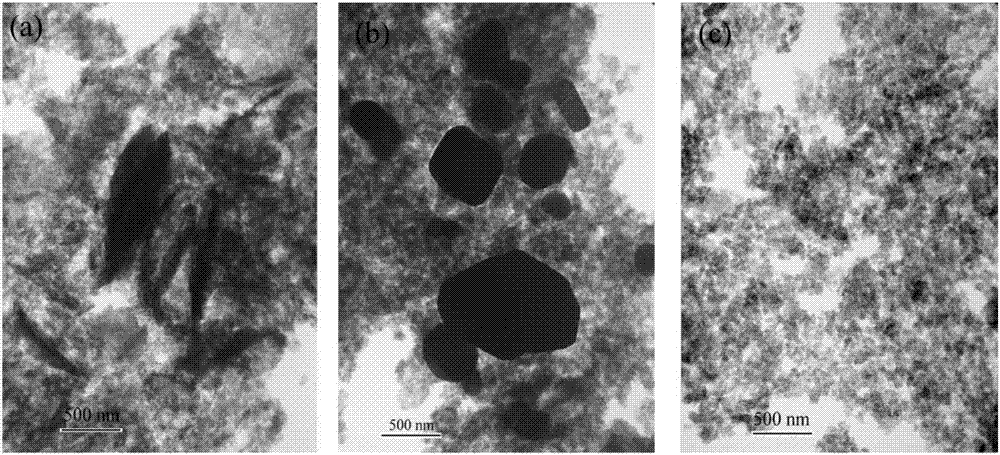

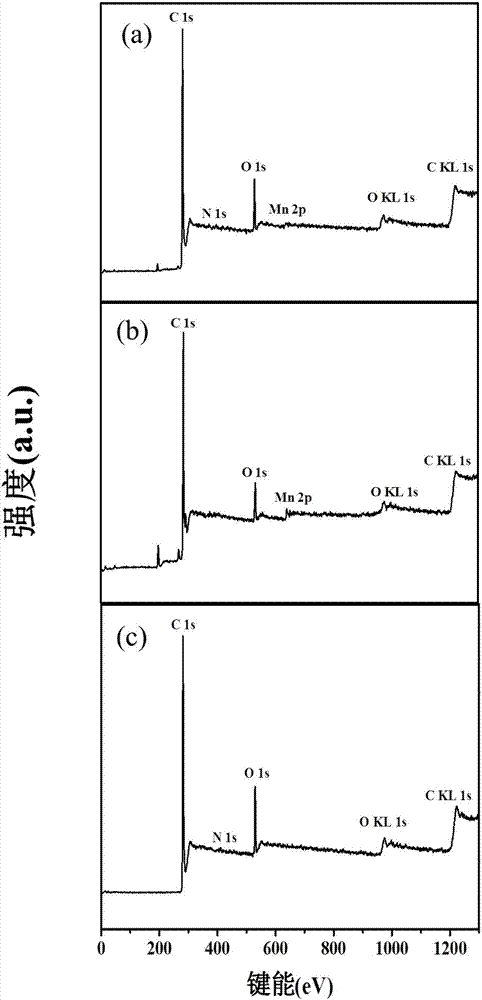

[0033] Example 1: MnO x / NC-15wt.%-900℃(MnO x / NC means that the prepared material is Ketjen carbon supported by nitrogen-doped amorphous manganese oxide, 15wt.% means that the mass of potassium permanganate charged accounts for 15% of the total mass of all raw materials, and 900°C means that the calcination temperature is 900°C)

[0034] Weigh 0.5g NH 4 Cl with 97.5mg KMnO 4 Put it in a mortar, mix the two evenly and grind them thoroughly for 10 minutes. Finally, add 50mg Ketjen carbon, mix well and set aside.

[0035] The mixture of the above three raw materials was placed in a ball mill jar and ground at a speed of 500 rpm for 1 h. Then put the above material in N 2 At 3°C min under atmosphere -1 The temperature was raised to 900°C, and kept at this temperature for 2 hours, and weighed after natural cooling, the obtained product was MnO x / NC catalyst.

Embodiment 2

[0036] Example 2: MnO x / NC-10wt.%-900℃(MnO x / NC means that the prepared material is Ketjen Carbon loaded with nitrogen and doped with amorphous manganese oxide, 10wt.% means that the mass of potassium permanganate is 10% of the total mass of all raw materials, and 900°C means that the calcination temperature is 900°C )

[0037] Weigh 0.5g NH 4 Cl with 62mg KMnO 4 Put it in a mortar, mix the two evenly and grind them thoroughly for 10 minutes. Finally, add 50mg Ketjen carbon, mix well and set aside.

[0038] The mixture of the above three raw materials was placed in a ball mill jar and ground at a speed of 500 rpm for 1 h. Then put the above material in N 2 At 3°C min under atmosphere -1 The temperature was raised to 900°C, and kept at this temperature for 2 hours, and weighed after natural cooling, the obtained product was MnO x / NC catalyst.

Embodiment 3

[0039] Example 3: MnO x / NC-5wt.%-900℃(MnO x / NC means that the prepared material is Ketjen Carbon loaded with nitrogen and doped with amorphous manganese oxide, 5wt.% means that the mass of potassium permanganate is 5% of the total mass of all raw materials, and 900°C means that the calcination temperature is 900°C )

[0040] Weigh 0.5g NH 4 Cl with 29mg KMnO 4 Put it in a mortar, mix the two evenly and grind them thoroughly for 10 minutes. Finally, add 50mg Ketjen carbon, mix well and set aside.

[0041] The mixture of the above three raw materials was placed in a ball mill jar and ground at a speed of 500 rpm for 1 h. Then put the above material in N 2 At 3°C min under atmosphere -1 The temperature was raised to 900°C, and kept at this temperature for 2 hours, and weighed after natural cooling, the obtained product was MnO x / NC catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com