Patents

Literature

82results about How to "High in heavy metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

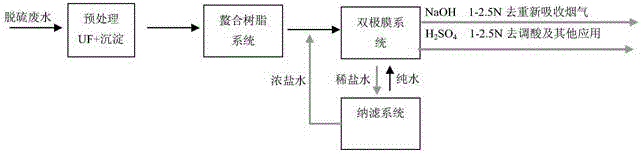

Cyclic utilization method of desulphurization waste water

ActiveCN105110521AEmission reductionReduce consumptionWaste water treatment from gaseous effluentsMultistage water/sewage treatmentFiltration membraneSulfate

The invention provides a cyclic utilization method of desulphurization waste water. A bipolar membrane is used for treating the desulphurization waste water, a bipolar membrane system is operated in a way that partial water is circulated and partial water is discharged, four solutions, namely, a salty solution, an acid solution, an alkaline solution and a polar solution are continuously circulated to obtain acid and alkali which have a given concentration, the alkaline solution is returned to a factory to absorb SO2 and SO3, and the acid solution is reused in a factory production process. The desulphurization waste water is treated by adopting a pretreatment and membrane integration technology, the waste salt is made into useful acid and alkali, the alkaline solution can be reused for absorbing sulfur-containing smoke to form sulfate, acid is directly used as a chemical raw material, the entire ecological circulation is completed, the desulphurization waste water is treated by utilizing the characteristics of ultrafiltration, a nano-filtration membrane and a bipolar membrane, the concentration solution is used for preparing acid and alkali, and comprehensive utilization is realized.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

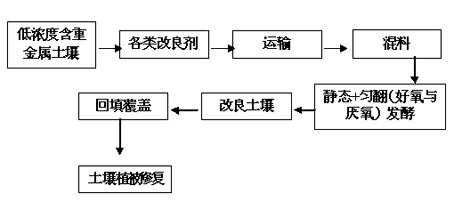

Method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of contaminated field

InactiveCN102319726AQuality improvementSimple structureContaminated soil reclamationSludgeAdditive ingredient

The invention relates to a method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of a contaminated field. The method comprises the following steps of: conveying of low-concentration soil after heavy metal-containing soil is detoxified, sludge and pulverized fuel ash; principal fermentation, mixing of various ingredients; primary fermentation; static state of post-fermentation (secondary fermentation); uniform turning (aerobic and anaerobic) fermentation; conveying of improved soil; and vegetation repairing (woody and herbaceous plants) planting for the contaminated soil. In the method, a modifier is added for modification, so that the content of heavy metals in the soil is reduced, the structure and pores of the damaged soil are repaired, and the permeation and air permeability of the soil are improved; and organic matters and other noxious matters in sludge and soil are decomposed and degraded in a certain condition by utilizing microbes in the sludge to reduce volume weight and compactness, so that the improved soil forms a substance similar to humus soil to serve as a biochemical process of the improved soil and fertilizer. According to the method, the planted vegetation growing environment of the land which uses the improved soil as a soil base material is ensured, so that the waste is used to treat waste, and the comprehensive utilization is improved.

Owner:姜桂荣 +1

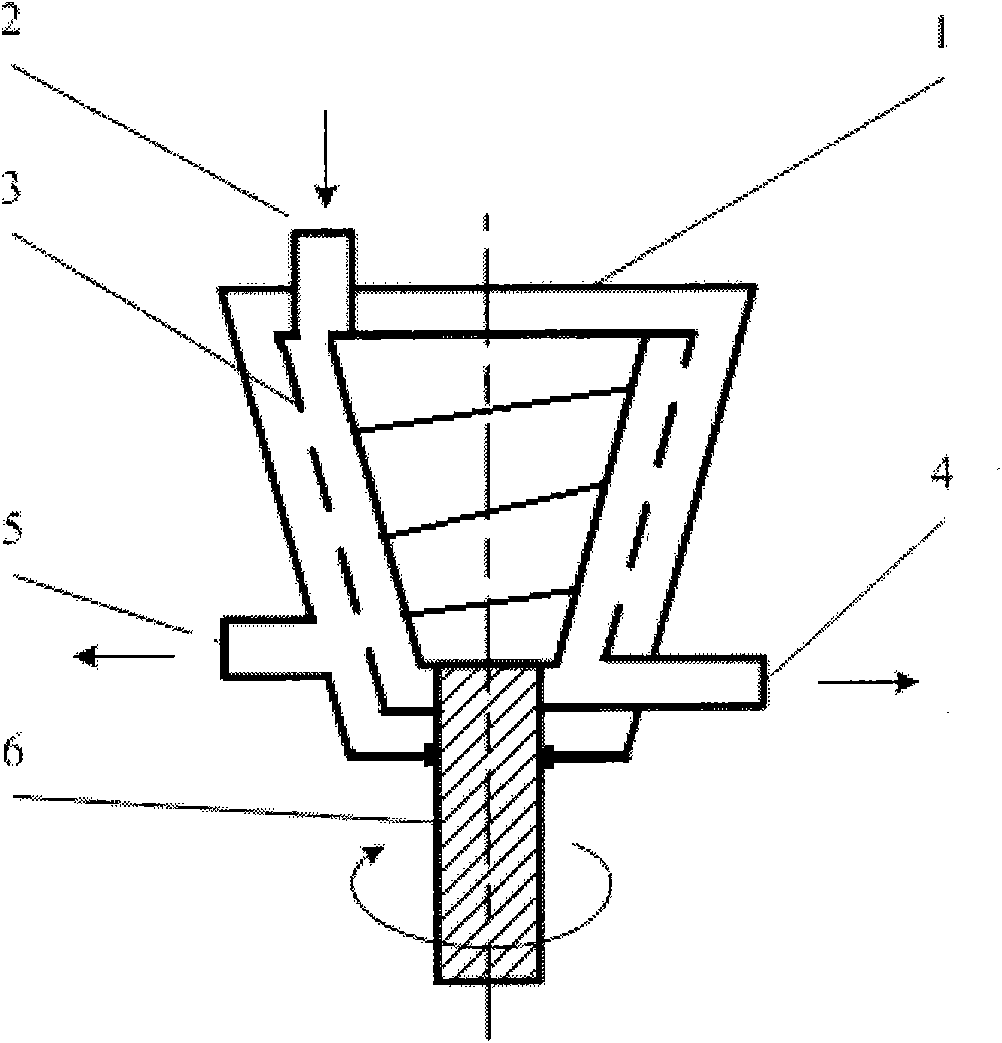

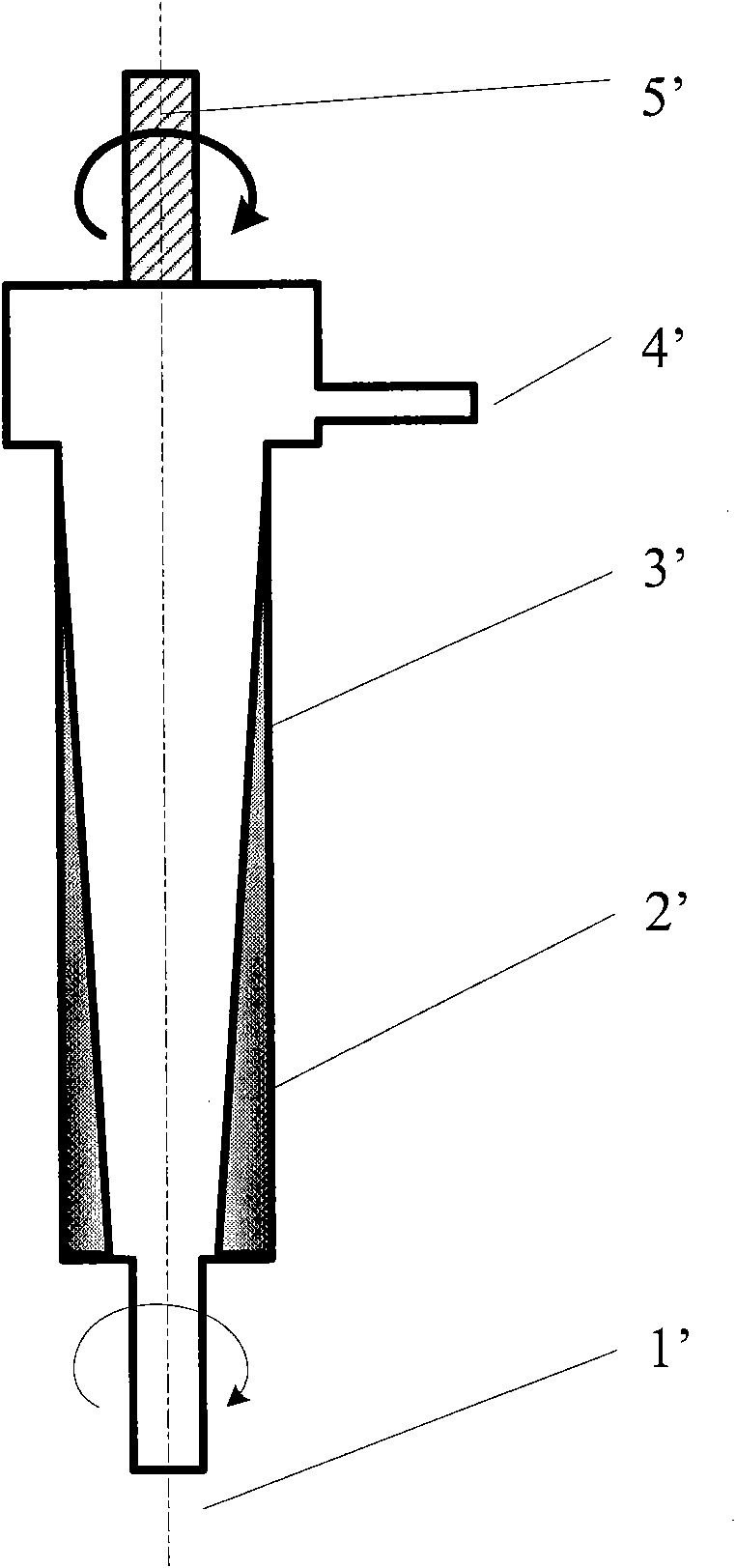

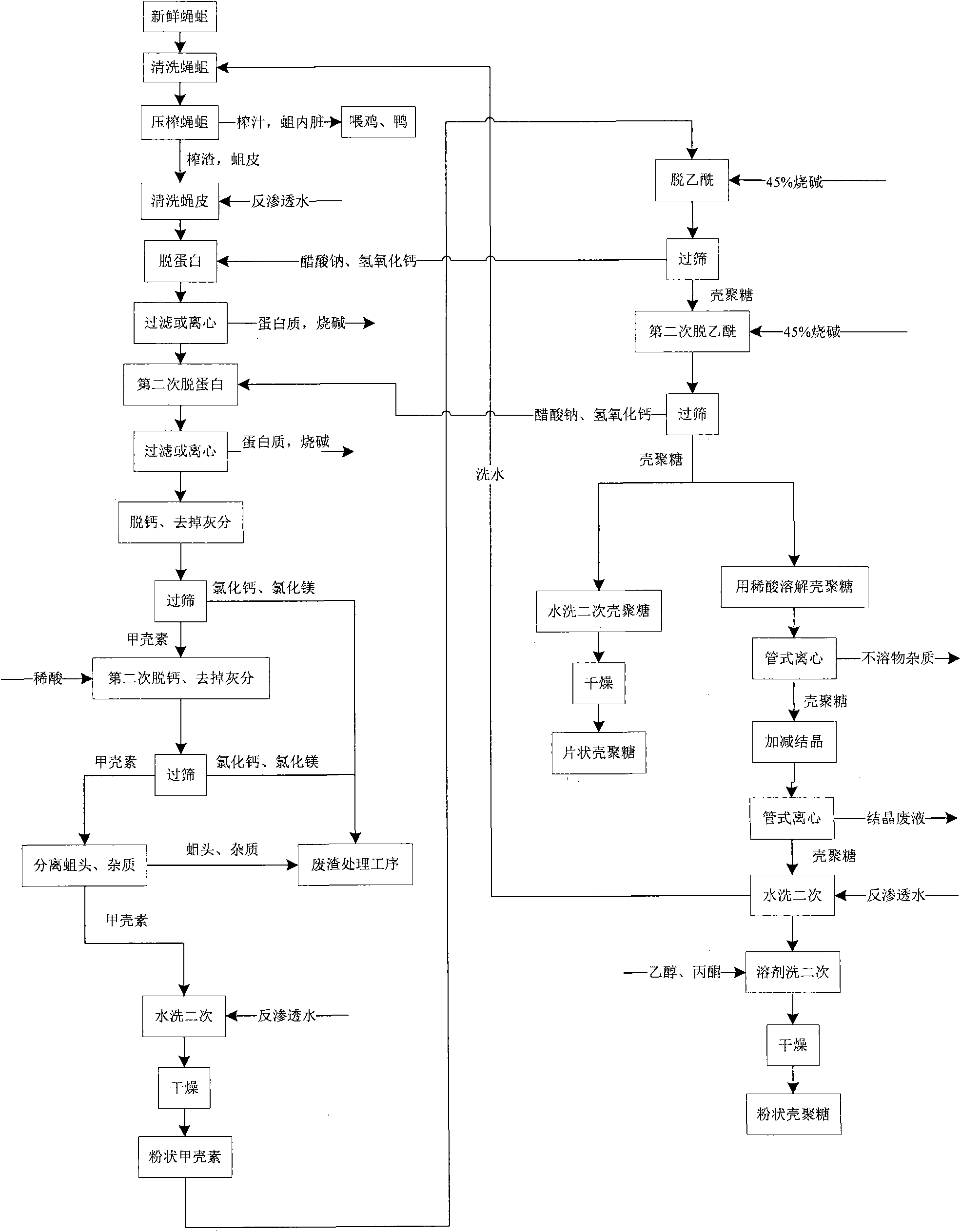

Preparation method of fly maggot chitosan

The invention relates to a method of preparing chitosan by using fly maggots, which comprises the followings steps that: firstly, the skin of a maggot is separated from entrails by pressing the fly maggot, an alkali solution is used to remove protein, a dilute acid solution is used to de-ash, and the impurities of the head of the maggot are removed by a physical method to obtain chitin; secondly, the chitin is deacetylated by 40-55% (W) of caustic soda solution, and then is separated to obtain a filter cake chitosan; and the chitosan is repeatedly washed until the PH value is equal to 7; thirdly, the cleaned chitosan adopts two processing methods: one method is to obtain flaky chitosan by drying, and the other method is that the chitosan is dissolved in dilute acid and centrifugally separated by a tube type centrifuge to obtain filtrate a chitosan solution; alkali is added in the filtrate until the PH value is equal 7-7.5, the chitosan is precipited and is separated by the tube type centrifuge to obtain a filter cake chitosan, and powdery chitosan is obtained after drying. The invention has the characteristics that: water can be saved, the chitosan product has low heavy metal content, low toxic content and stable product quality, the productivity is high and the production cost is low.

Owner:ZHEJIANG PUJIANG CHENGYUE PLANTATION +1

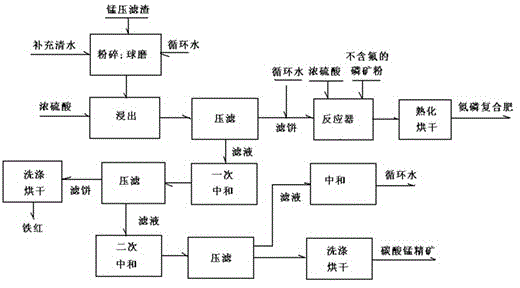

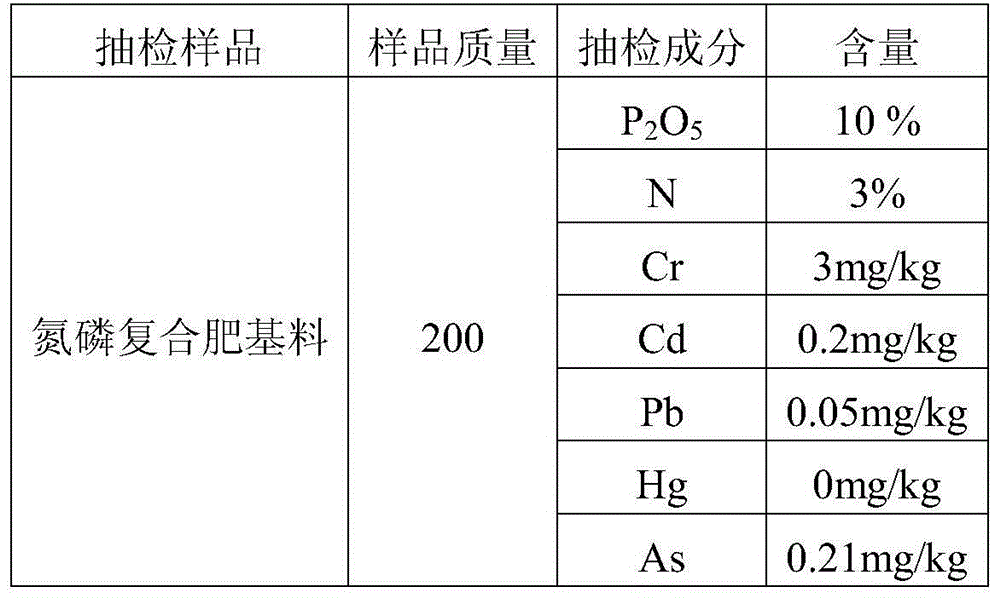

Method for recycling waste residue in manganese industry production

InactiveCN104480314AEfficient recyclingAvoid churnSilicon halogen compoundsProcess efficiency improvementWastewaterManganese

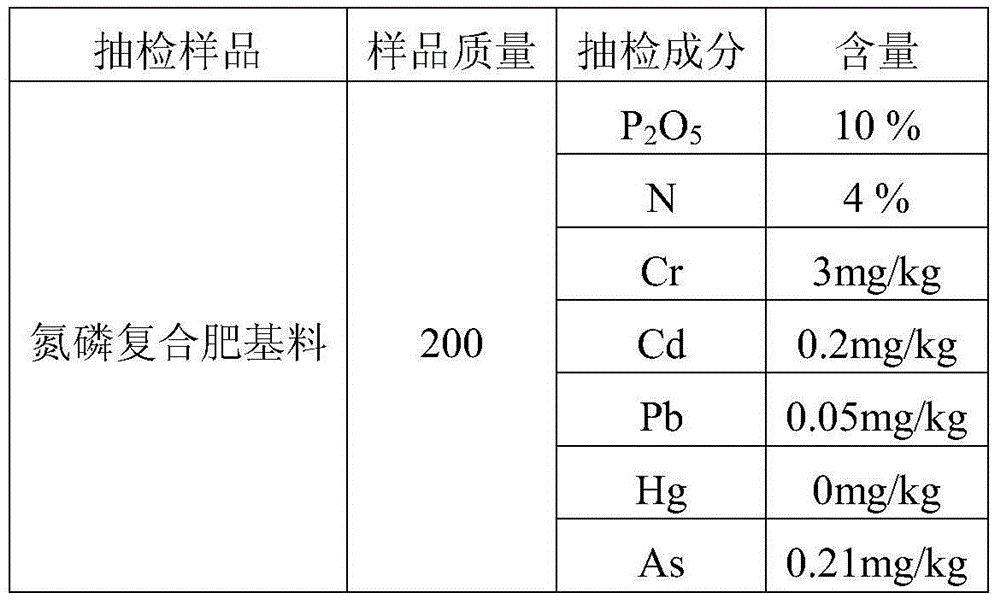

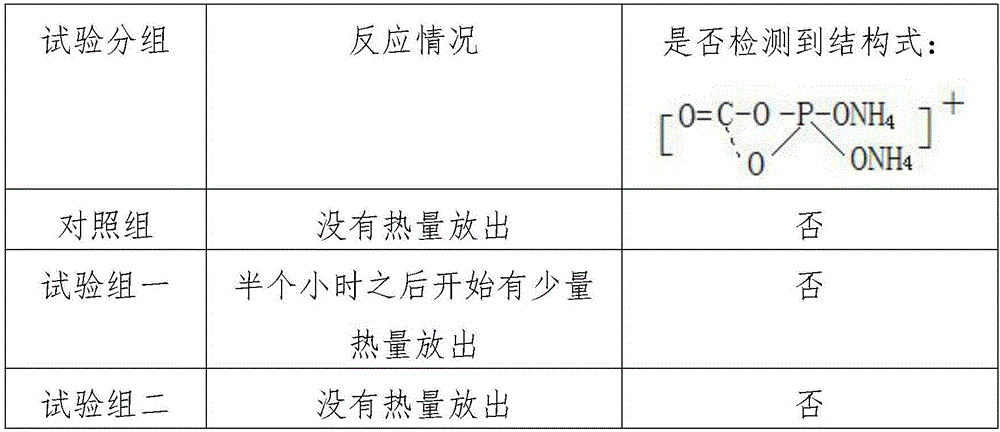

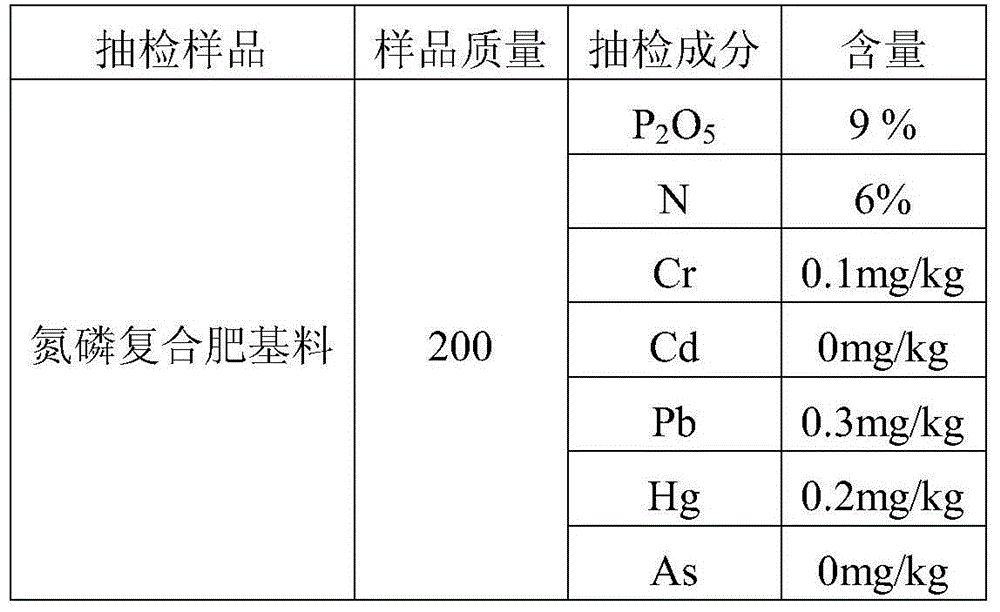

The invention relates to a method for recycling waste residue in manganese industry production. The method comprises the specific following steps: (1) pre-processing filter residue; (2) adding acid and leaching; (3) carrying out filtering and solid-liquid separation on ore slurry; (4) recovering hematite powder; (5) recovering manganese carbonate concentrate; and (6) preparing a nitrogen-phosphorus compound fertilizer base material. By the method, hematite powder, manganese carbonate concentrate and the nitrogen-phosphorus compound fertilizer base material can be recovered from leached press-filtered residue, the process is simple and is easy to achieve industrialization and meanwhile, the content of the heavy metal ingredients is in completely in conformity with national associated standards, treated wastewater and waste residue are free of harmful ingredients such as heavy metals, the environmental pressure is alleviated and the method has great promotional values.

Owner:大新县信锰矿业有限公司

Sweet tea kombucha

The invention discloses sweet tea kombucha. With sweet tea leaves as a main raw material, sweet tea is prepared; with the sweet tea as a culture medium and kombucha as a bacterial source, a novel and unique sweet tea kombucha beverage is prepared. Through implementation of the technical scheme, the sweet tea and the kombucha are organically combined and combined nutrients are richer; both the sweet tea and the kombucha have a significant health-care effect on human diseases, after the two are combined, the effects of the sweet tea and the kombucha are complementary, and the formed tea beverage has a more significant health-care effect and has a comprehensive effect far better than that of simple sweet tea leaves and that of the conventional kombucha beverage; the prepared sweet tea kombucha beverage is ideal in product form, well preserves original nutritional and functional components of sweet tea, can be easily digested and absorbed, is palatable in sweet and sour taste and very good in palatability, does not limit the application range, and is a dual-functional ecological health-care beverage having both beverage efficacy and medicinal efficacy.

Owner:何寒

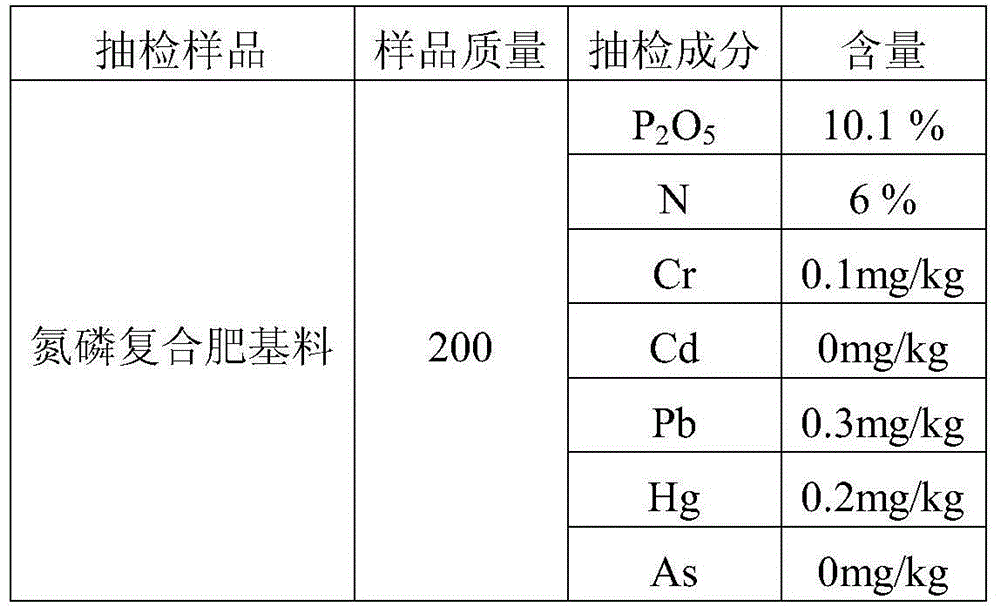

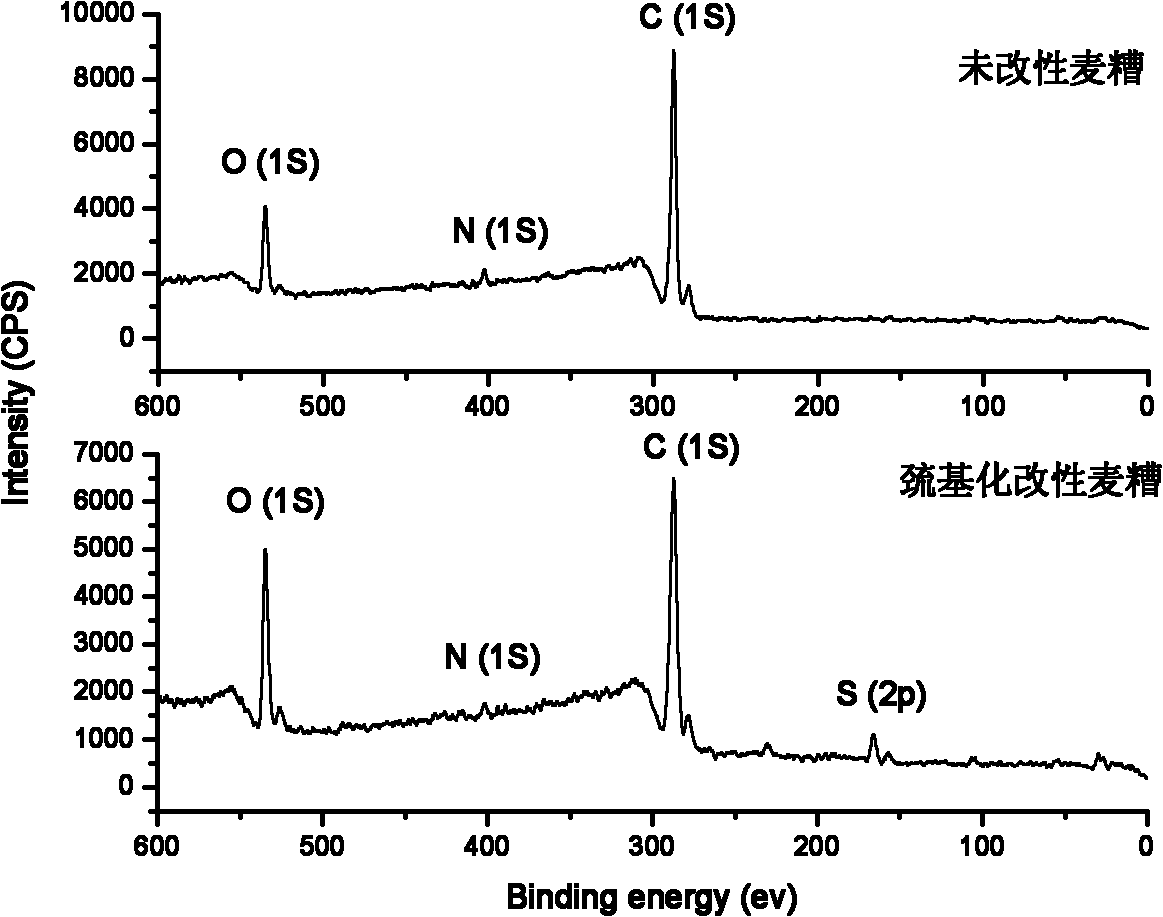

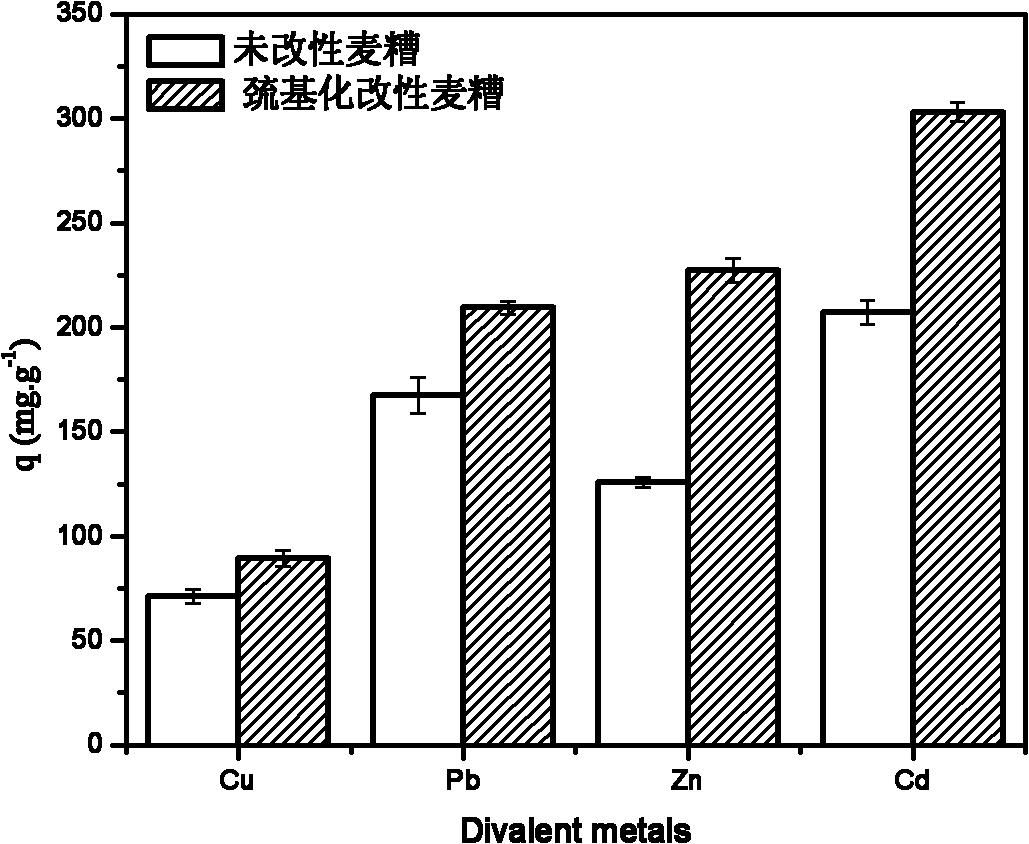

Heavy metal ion adsorbent and preparation and application method thereof

InactiveCN101804330AEasy to handleEasy to operateOther chemical processesWater/sewage treatment by sorptionPtru catalystSorbent

The invention discloses a heavy metal ion adsorbent and a preparation and application method thereof. Spent grain is adopted as material, mercaptoacetic acid is chosen as reagent for mercaptolation, NaHSO4.H2O is adopted as catalyst, N,N-dimethylformamide is adopted as reaction medium, mercaptolation is carried out, Na2S.9H2O is then added as reducing agent, aqueous ethanol is adopted as reaction medium, reduction reaction is carried out, and thereby the adsorbent is produced. Compared with the conventional sulfhydryl cotton preparation method, the method has the absolute advantages of high efficiency and quickness. The mercaptolated spend grain is rich in ester functional groups and mercapto functional groups, and can be used for the treatment of heavy metal wastewater. When the mercaptolated spend grain is used for treating mixed heavy metal wastewater containing Cu2 plus, Pb2 plus, Zn2 plus and Cd2 plus ions, effluent can meet National Integrated Wastewater Discharge Standard (GB8978-1996). The mercaptolated spend grain can be reused for at least three times, and therefore has a good application value.

Owner:CENT SOUTH UNIV

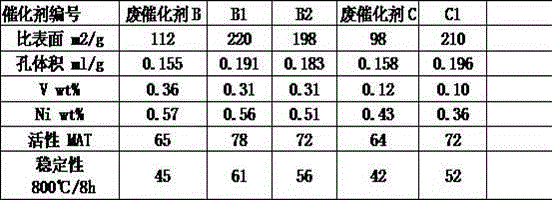

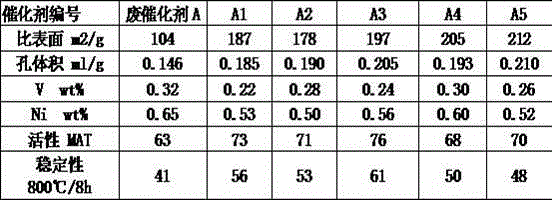

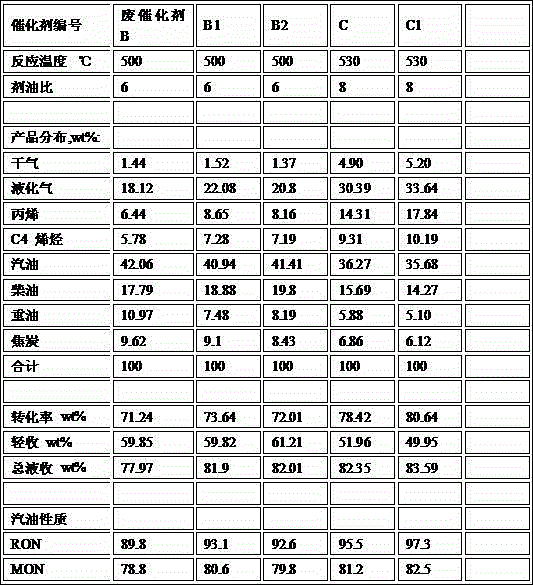

Revivification method for catalytic cracking waste catalyst

ActiveCN104815702AImprove liquid yieldReduce coke yieldCatalyst regeneration/reactivationPhosphoric acidChemistry

The invention relates to a revivification method for a catalytic cracking waste catalyst, which is characterized in that composite acid and ammonium salt are treated, and at least one of a supported rare earth treatment process and a phosphorus-containing acid treatment process is employed. a principle is characterized in that by improving a tunnel structure of the catalyst, composite acid is used for dredging the tunnel of the catalyst, a part of structure of molecular sieve is reconstructed through reaction and calcinations, acidity of the catalyst is adjusted by a rare earth compound-containing and / or phosphate-containing compound, so that waste catalyst performance can be recovered, the specific surface and activity of the recovered catalyst can be obviously increased, stability is obviously increased, good liquefied gas and low carbon olefin selectivity can be presented, green coke is reduced, liquid recovery is increased, gasoline RON is increased by 0.5-3 points, propylene and butylene yield can be respectively increased by more than 20-40% and 10-30%.

Owner:于向真

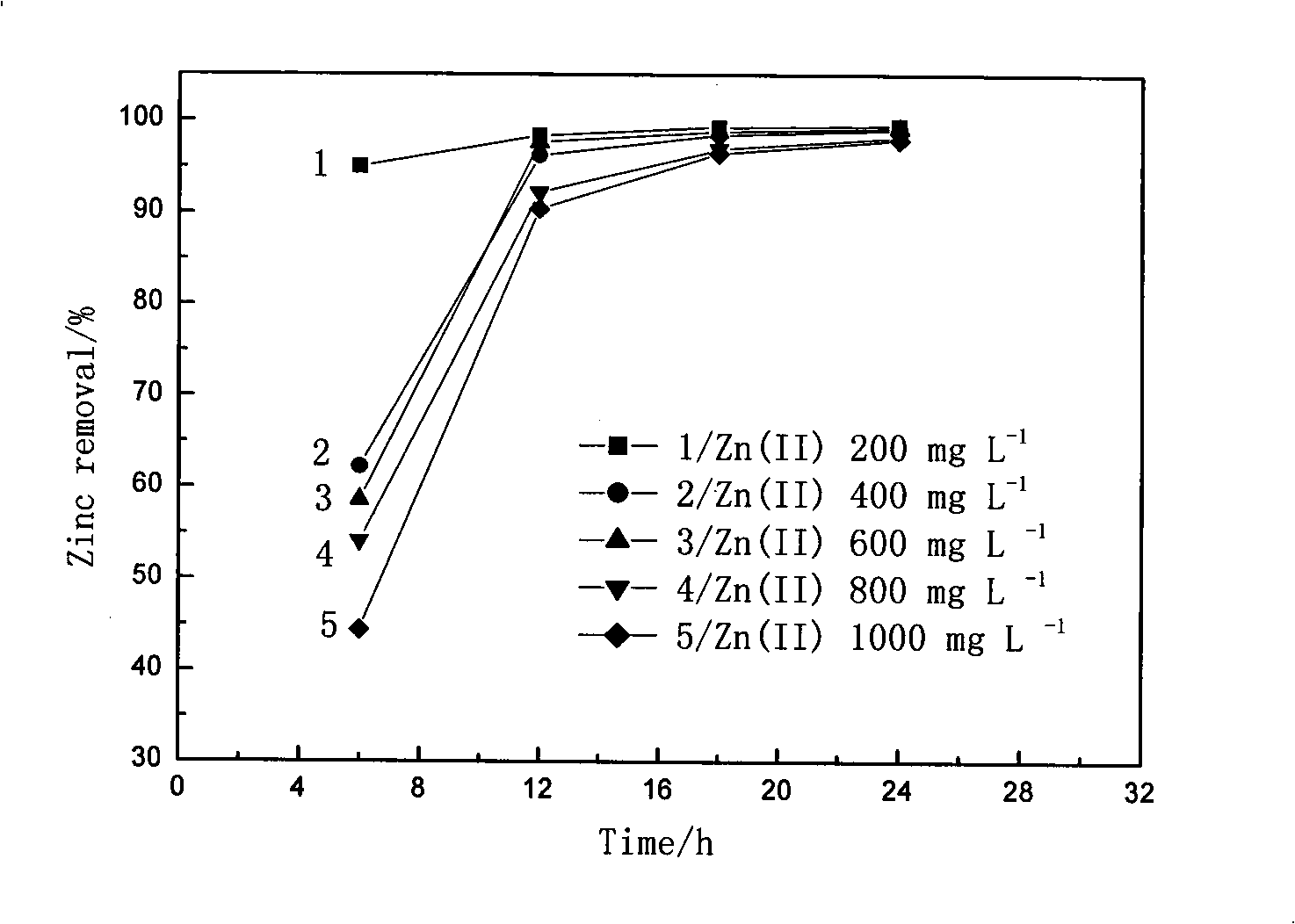

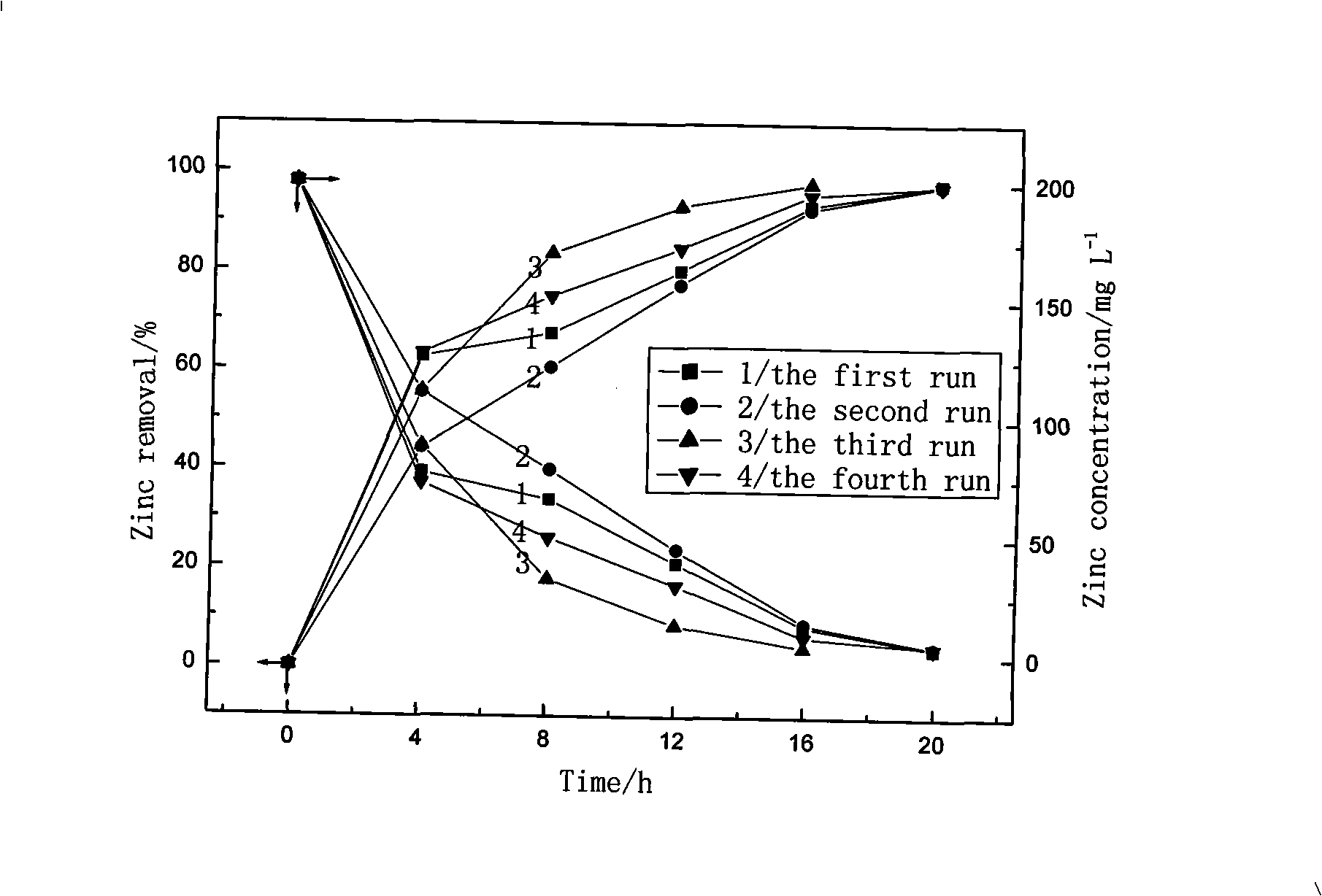

Cohesive action nutrient source SRB sewage sludge immobilization particle, production and uses in treating heavy metal wastewater thereof

ActiveCN101402485ATake advantage ofAvoid direct toxic effectsSustainable biological treatmentBiological water/sewage treatmentHigh concentrationSludge

The invention discloses a cohesive nutrient source SRB sludge immobilized particle, preparation thereof, and a method for heavy metal waste water treatment. In order to avoid the poison of high-concentration metallic ions to SRB and control the COD concentration of outputted water, SRB sludge and a carbon source fixing material are jointly embedded in the same particle pellet. The embedded pellet is used for treating heavy metal waste water after adsorbing the cohesive organic carbon source. The removal ratio of the metallic ions is as high as 99 percent, and the COD concentration in the outputted water is lower than 120mg / L. The concentration of the metallic ions in the inputted water is allowed to reach a g / L level; and the embedded pellet can be reused. The invention can be used for treating heavy metal waste water with high, medium and low concentration, and can also be used for the precipitation and recovery of the heavy metal in the water.

Owner:CENT SOUTH UNIV

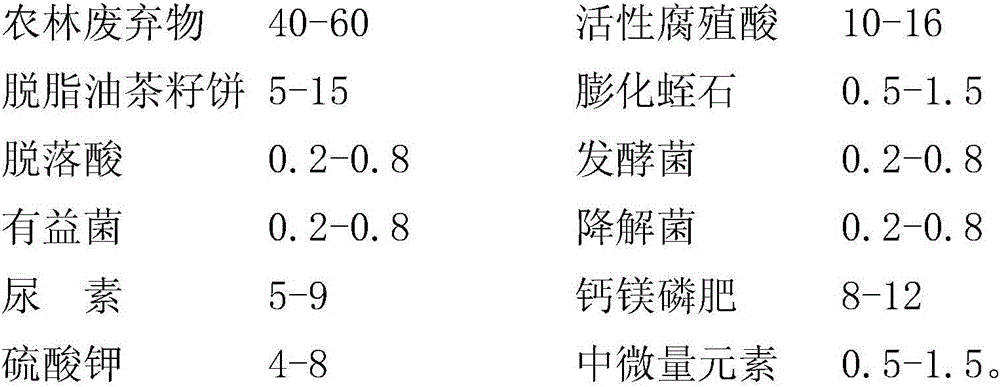

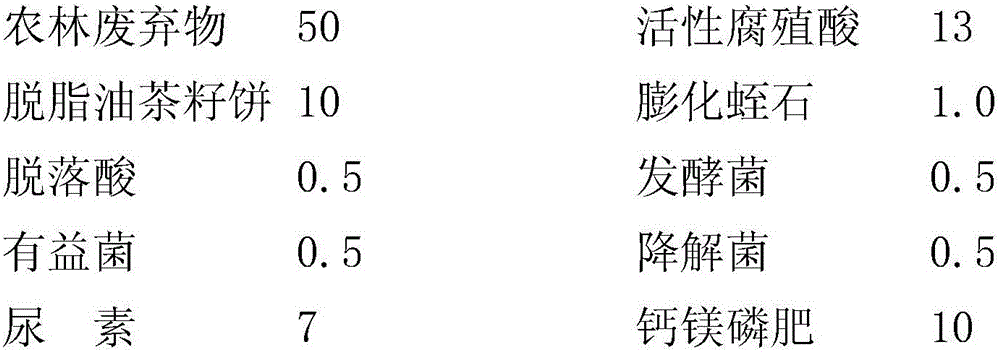

Multifunctional bio-organic fertilizer and preparation method thereof

PendingCN106810403AGood restorativeImprove water and fertilizer retention performanceCalcareous fertilisersBio-organic fraction processingAgricultural residuePlant growth

The invention discloses a multifunctional bio-organic fertilizer and a preparation method thereof, and relates to the technical field of agricultural fertilizers. The multifunctional bio-organic fertilizer is prepared from the following raw materials in parts by weight: 40-60 parts of forestry and agricultural residues, 10-16 parts of active humic acid, 5-15 parts of degreased tea-seed pancake, 0.5-1.5 parts of expanded vermiculite, 0.2-0.8 part of abscisic acid, 0.2-0.8 part of zymophyte, 0.2-0.8 part of beneficial bacterium, 0.2-0.8 part of degrading bacteria, 5-9 parts of urea, 8-12 parts of calcium magnesium phosphate fertilizer, 4-8 parts of potassium sulfate, and 0.5-1.5 parts of medium and trace element. The multifunctional bio-organic fertilizer has the characteristics that the nutritional elements for plant growing are contained; the organic substances are rich; in addition, the contaminated oil can be remediated; the soil structure can be activated; the multifunctional bio-organic fertilizer is applicable to the planting of crops such as rice of southern China, vegetables, watermelon, tobacco, fresh ginger, rape and tea, fruits such as naval orange, grapefruit and pear, garden nursery stock and flowers.

Owner:HUNAN ZHONGKE AGRI

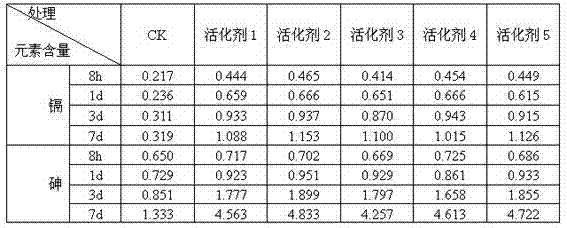

Soil heavy metal activator and preparation method thereof

InactiveCN104263378AImprove bindingStrong specificityOrganic fertilisersSoil conditioning compositionsSoil heavy metalsStrong binding

The invention discloses a soil heavy metal activator and a preparation method thereof, and belongs to the technical field of soil repairing. The activator is composed of the following raw materials in parts by weight: 60 to 140 parts of activating substance, 50 to 500 parts of sulfur-containing compound, 0 to 1000 parts of organic material assuming that the organic material has a water content of 10%, 0 to 500 parts of alkaline substance calculated by sodium hydroxide, 0 to 500 parts of reducing substance, and 0 to 200 parts of water. The activator has a strong binding force on heavy metals and extremely strong specificity. The heavy metal content in the soil solution is greatly improved after the activator is applied to the soil, especially the contents of cadmium, copper, and lead. Moreover the arsenic content in soil solution is greatly improved under a water flooding condition, and thus the activator can be directly applied to repairing of plants and soil polluted by heavy metals. During the application process, the operation is simple, the using amount is low, the price is cheap, the cost is low, and the activator can be used in Chinese dry lands polluted by cadmium in different degrees.

Owner:CHINA NAT RICE RES INST

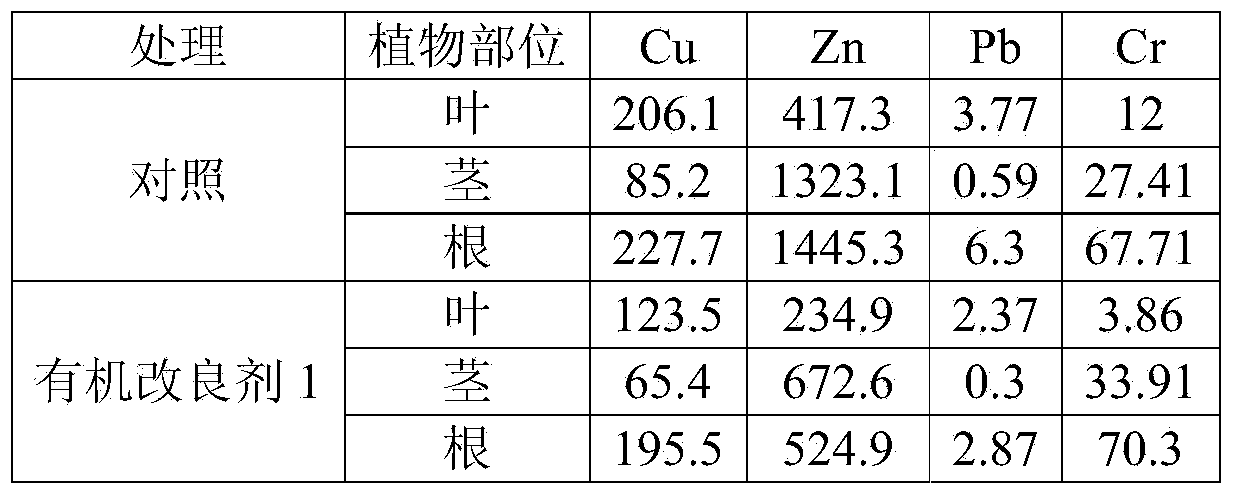

Organic amendment capable of passivating Cu, Zn and Pb in soil of vegetable field

ActiveCN104178178AGood characterOvercome obstacles to continuous croppingAgriculture tools and machinesOrganic fertilisersSoil propertiesOxidation state

The invention discloses an organic amendment capable of passivating Cu, Zn and Pb in soil of a vegetable field. The organic amendment is composed of the following components by mass percent: 10% to 50% of phosphate rock powder and 50% to 90% of wormcast. The organic amendment can be used for passivating heavy metals in contaminated soil, and especially used for passivating the Cu, the Zn and the Pb in the vegetable field soil which is moderately or slightly contaminated so as to decrease the content of the heavy metals in an acid extracting state, an oxidation state and other active states and increase the content of the heavy metals in an organic state, a residual state and other low active states, so that the content of the Cu, the Zn and the Pb in plants is obviously reduced, and a large quantity or an intermediate quantity of micronutrients required by the growth of the plants can be provided at the same time. Thus, the soil property is improved, the ecosystem health of the soil in the degraded vegetable field is restored, and the successive cropping obstacles of the soil are overcome. As a result, the yield and the quality of vegetables are improved.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

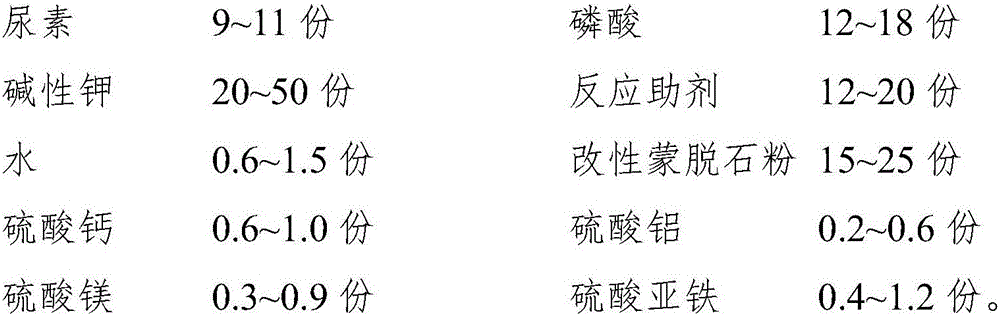

Fertilizer capable of fixing soil heavy metal and preparing method thereof

InactiveCN106631598AMeet growth needsReasonable formulaCalcareous fertilisersMagnesium fertilisersAluminium sulfatePhosphoric acid

The invention relates to the technical field of chemical engineering, and discloses a fertilizer capable of fixing soil heavy metal and a preparing method thereof. The fertilizer is prepared from, by weight, 9-11 parts of urea, 12-18 parts of phosphoric acid, 20-50 parts of alkaline potassium, 12-20 parts of reaction auxiliary, 0.6-1.5 parts of water, 15-25 parts of modified smectite powder, 0.6-1.0 part of calcium sulfate, 0.2-0.6 part of aluminum sulfate, 0.3-0.9 part of magnesium sulfate and 0.4-1.2 parts of ferrous sulfate. The used reaction auxiliary can be used as a catalyst when urea reacts with phosphoric acid and can be used for removing heavy metal ions in soil, impurity removal is omitted, no effluent or waste gas is exhausted, raw materials used in production are fully and reasonably used, and the fertilizer has remarkable environment protection benefits.

Owner:GUIZHOU UNIV

Method for preparing large-density foam glass

A preparation method of high-density foam glass, firstly put cullet powder with a density greater than 3.0g / cm3 and SiC or TiN into a ball mill jar and ball mill to below 200 mesh and add it into a heat-resistant steel mold, and finally move the mold into Firing in a foaming furnace; Foamed glass is obtained after foaming, rapid cooling and annealing. The present invention uses cullets with various densities greater than 3.0g / cm3 as raw materials; SiC or TiN as foaming agent; the foaming agent SiC or TiN helps foam glass to produce crystals in the preparation process, which is beneficial to improve the foam glass brick. mechanical properties. Therefore, the high-density cellular glass can absorb the shock wave energy during the explosion. The foam glass can be combined with cement, steel or other high-strength building materials, used in the interior and exterior façades of the key surfaces of buildings in high-risk areas of terrorist attacks, and has the advantage of a rigid structure. When facing shock waves, the said Bricks can absorb a major part of the explosion energy.

Owner:SHAANXI UNIV OF SCI & TECH

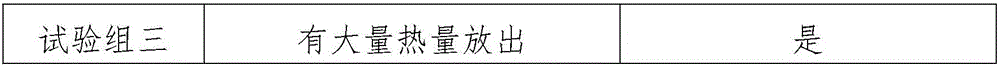

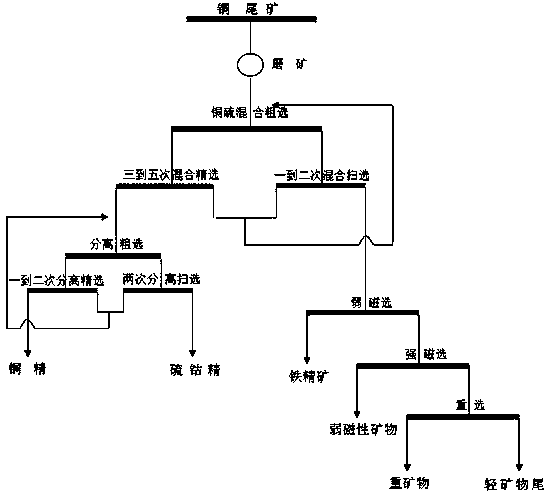

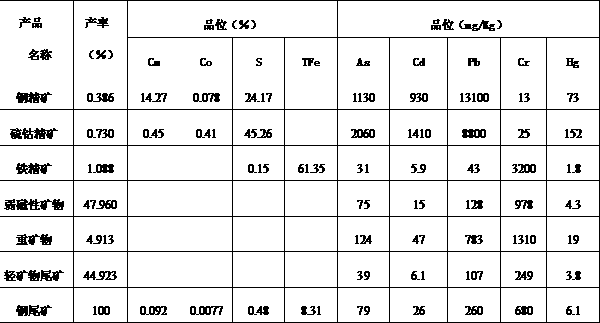

Physical ore dressing removal method for heavy metals in copper tailing

ActiveCN109174442ALow costNo secondary pollutionGlass recyclingSolid separationEcological environmentPollution

The invention discloses a physical ore dressing removal method for heavy metals in copper tailing, and relates to the field of the mine ecological environment and tailing resource reuse. The physicalore dressing technology of flotation-magnetic separation-gravity separation is adopted in the method, and the method comprises the steps of ore grinding, mixed flotation of sulphide ore, copper sulfurseparation flotation, low intensity magnetic separation, high intensity magnetic separation, gravity separation and the like. All kinds of heavy metals in the copper tailing can be effectively removed. Secondary resources are comprehensively recycled to produce copper concentrate with copper grade greater than 13%, cobalt sulphide concentrate with cobalt content greater than 0.35% and sulphur greater than 48%, and iron ore concentrate with iron grade greater than 60%. The weak magnetic and strong magnetic separation concentrate containing mass mica minerals can be used as a raw material for separation and recovery of mica. The method is simple and easy to conduct. The cost is low. Secondary pollution is avoided. In the process of innocuous treatment of the copper tailing, the secondary resources of the copper tailing can be recycled and utilized in a reasonable and comprehensive mode meanwhile. Economic benefits of mine enterprise disposal and utilization of the tailing can be improved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

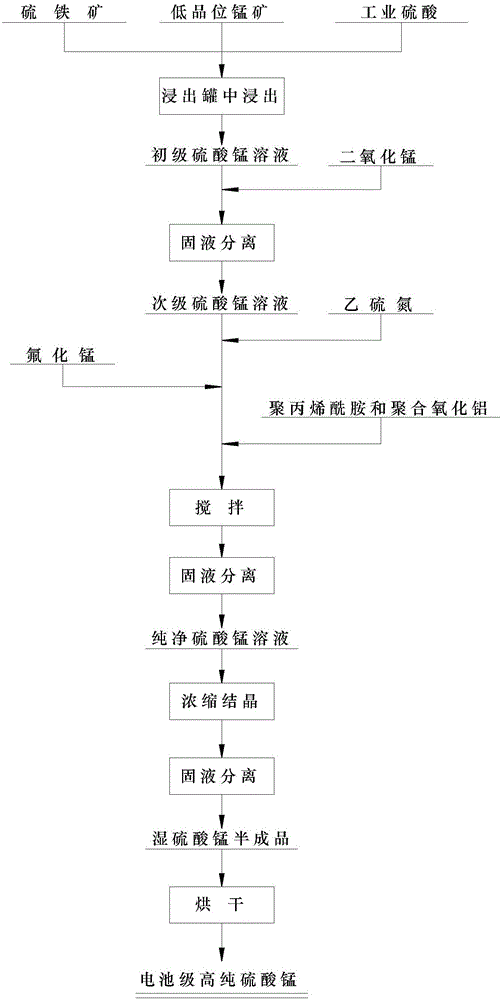

A method of preparing battery-grade high-purity manganese sulfate by utilizing low-grade manganese ore

The invention relates to a method of preparing battery-grade high-purity manganese sulfate by utilizing low-grade manganese ore. The method includes adding the low-grade manganese ore, pyrite and industrial sulfuric acid into a leaching tank, performing chemical leaching, performing solid liquid separation to obtain a primary manganese sulfate solution, then adding manganese dioxide into the primary manganese sulfate solution, adjusting the pH value of the solution, then performing solid liquid separation to obtain a secondary manganese sulfate solution, adding ethyl thiocarbamate, manganese fluoride, polyacrylamide and polyaluminum chloride into the secondary manganese sulfate solution, stirring the mixture for a certain period of time, performing solid liquid separation to obtain a purified manganese sulfate solution, adding the purified manganese sulfate solution into a crystallization kettle, performing concentration and crystallization, then performing solid liquid separation to obtain a wet manganese sulfate semi-finished product, and drying the wet manganese sulfate semi-finished product to obtain the battery-grade high-purity manganese sulfate. The method is simple in process and easy to operate. Addition of a large amount of agents is not needed in a preparing process. Secondary pollution to the environment is avoided and the production cost is low.

Owner:CENT SOUTH UNIV

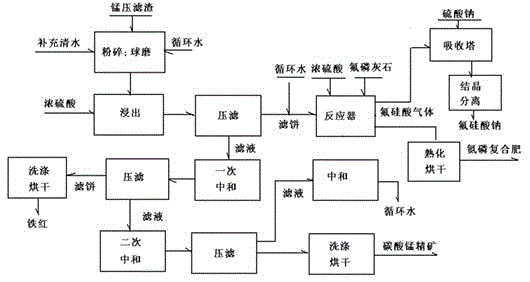

Method for recycling leached and press-filtered residues generated in production of electrolytic metal manganese and manganese dioxide

InactiveCN104480315AHigh in heavy metalsEfficient recyclingSilicon halogen compoundsFertilizer mixturesFertilizerHeavy metals

The invention relates to a method for recycling leached and press-filtered residues generated in production of electrolytic metal manganese and manganese dioxide. The method comprises the specific following steps: (1) pre-processing filter residues; (2) adding acid and leaching; (3) carrying out filtration and solid-liquid separation on ore pulp; (4) recovering hematite powder; (5) recovering manganese carbonate concentrate; (6) preparing a base material for a nitrogen / phosphorus compound fertilizer; and (7) preparing sodium fluosilicate. By the method, hematite powder, manganese carbonate concentrate, sodium fluosilicate and the base material for the nitrogen / phosphorus compound fertilizer can be recovered from the leached and press-filtered residues, the process is simple and easy to industrialize and meanwhile, the content of the heavy metals is in full compliance with national standards, further treated wastewater and waste residues are free of harmful ingredients such as heavy metals and thus the pressure on the environment is reduced and the method has great promotional values.

Owner:大新县信锰矿业有限公司

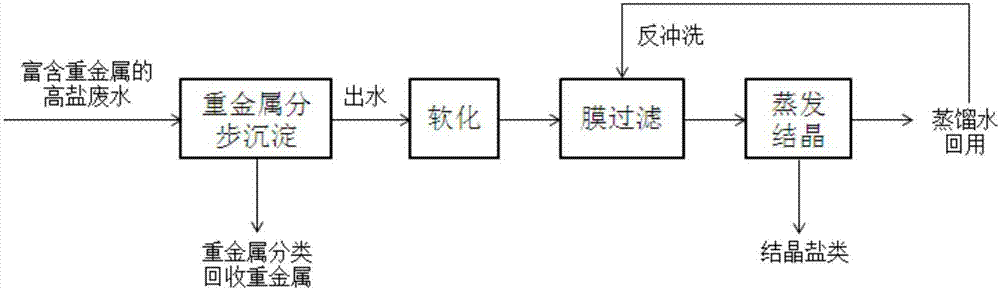

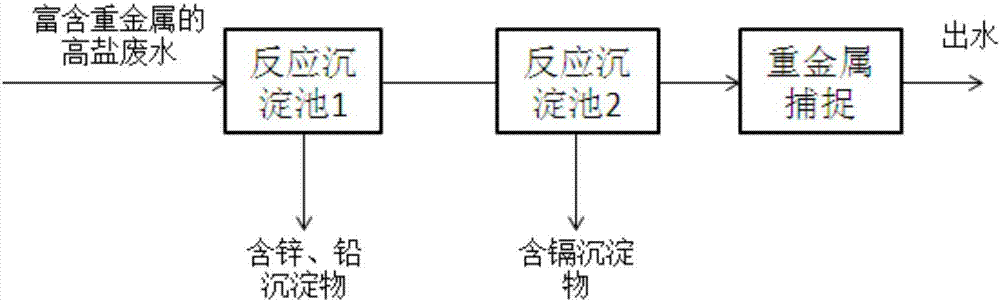

Zero-discharge method for strong brine containing high-concentration heavy metals

InactiveCN107162299AHigh in heavy metalsIncrease contentZinc oxides/hydroxidesWater contaminantsHigh concentrationFiltration

The invention discloses a zero-discharge method for strong brine containing high-concentration heavy metals. The zero-discharge method comprises the following steps: firstly, precipitation of heavy metals; secondly, softening; thirdly, tubular micro-filtration; fourthly, evaporation and crystallization. The zero-discharge method for the strong brine containing the high-concentration heavy metals, disclosed by the invention, is characterized in that in effluent obtained by fractional precipitation, namely evaporated and crystallized incoming water, the content of zinc is smaller than 1.0mg / L, the content of lead is smaller than 1.0mg / L, the content of cadmium is smaller than 1.0mg / L, the content of copper is smaller than 0.5mg / L, and the content of nickel is smaller than 1.0mg / L. In heavy metal sludge precipitated by the method disclosed by the invention, the contents of zinc and lead are high; the method can be used for recovering zinc oxide and lead oxide; in an evaporation and crystallization system disclosed by the invention, the salt separating rate is higher than or equal to 95 percent, the recovery rate of water is higher than or equal to 95 percent, and salts obtained by evaporating and crystalizing can be used as industrial salts for selling; distilled water is recycled for backwash of a water treatment system, medicine preparation and the like. According to the zero-discharge method disclosed by the invention, resources are recovered to the maximum extent while the difficult problems of high pollution and difficulty in discharge of high-salinity wastewater rich in the heavy metals generated by post treatment of a garbage power plant are solved, and near-zero discharge is realized.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

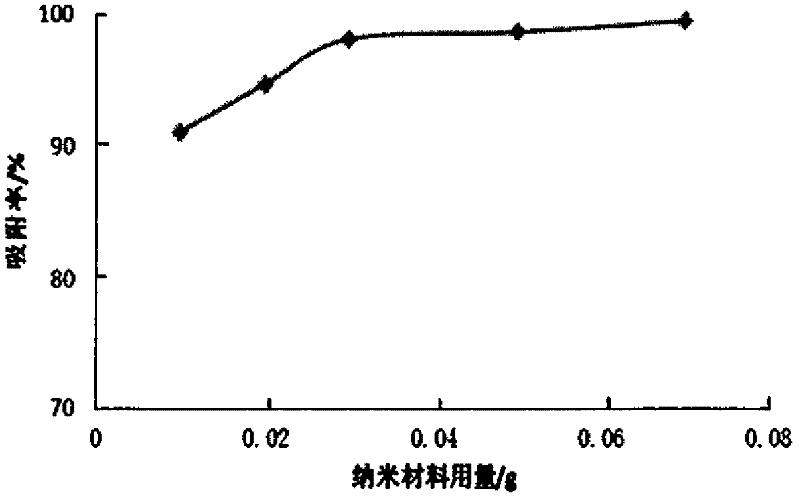

Method for determining trace lead in textile products

InactiveCN102455293AHigh in heavy metalsHigh measurement sensitivityPreparing sample for investigationAnalysis by thermal excitationPhysical chemistryInductively coupled plasma

The invention discloses a method for determining trace lead in textile products, which comprises the following steps of: after a heavy metal Pb in a textile product is extracted by using acidic perspiration, gathering a trace heavy metal Pb in an extracting solution by using nano TiO2; and then, carrying out determination by using an ICP-OES (inductively coupled plasma optical emission spectroscopy) method. Because the content of the heavy metal Pb in the solution subjected to gathering is high, the determination sensitivity is improved, and a determination operation can be performed by using an ICP (inductively coupled plasma) emission spectrum; and in the process of gathering, the salt content in a textile-product extracting solution is reduced, thereby reducing the matrix interference in the process of spectrum determination.

Owner:PEOPLES REPUBLIC OF CHINA BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

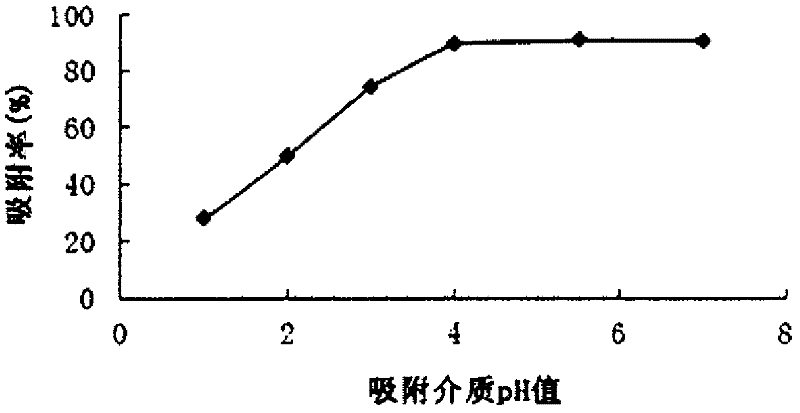

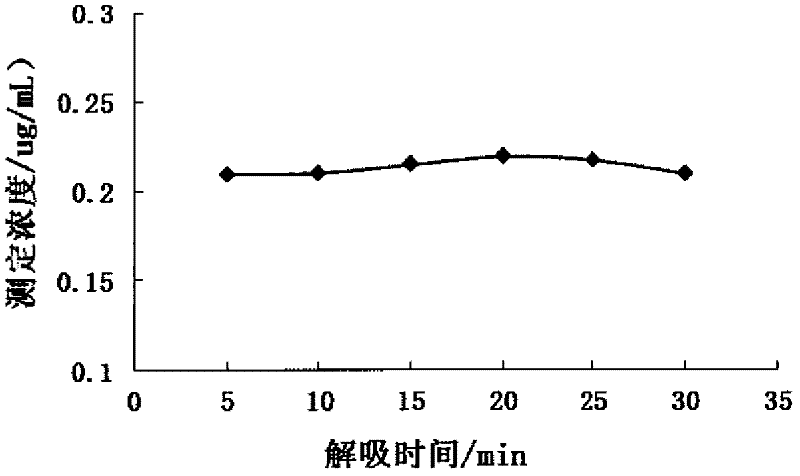

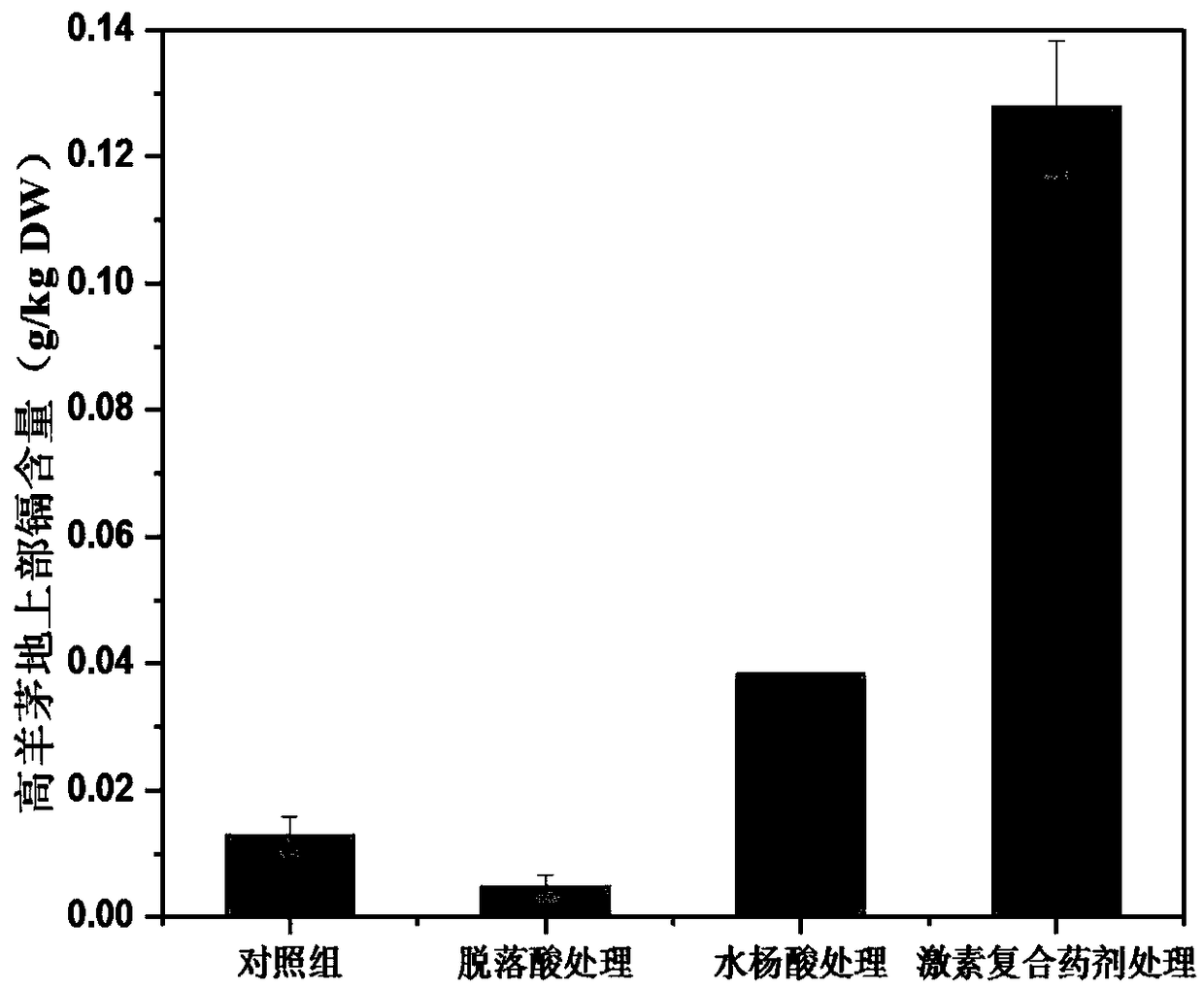

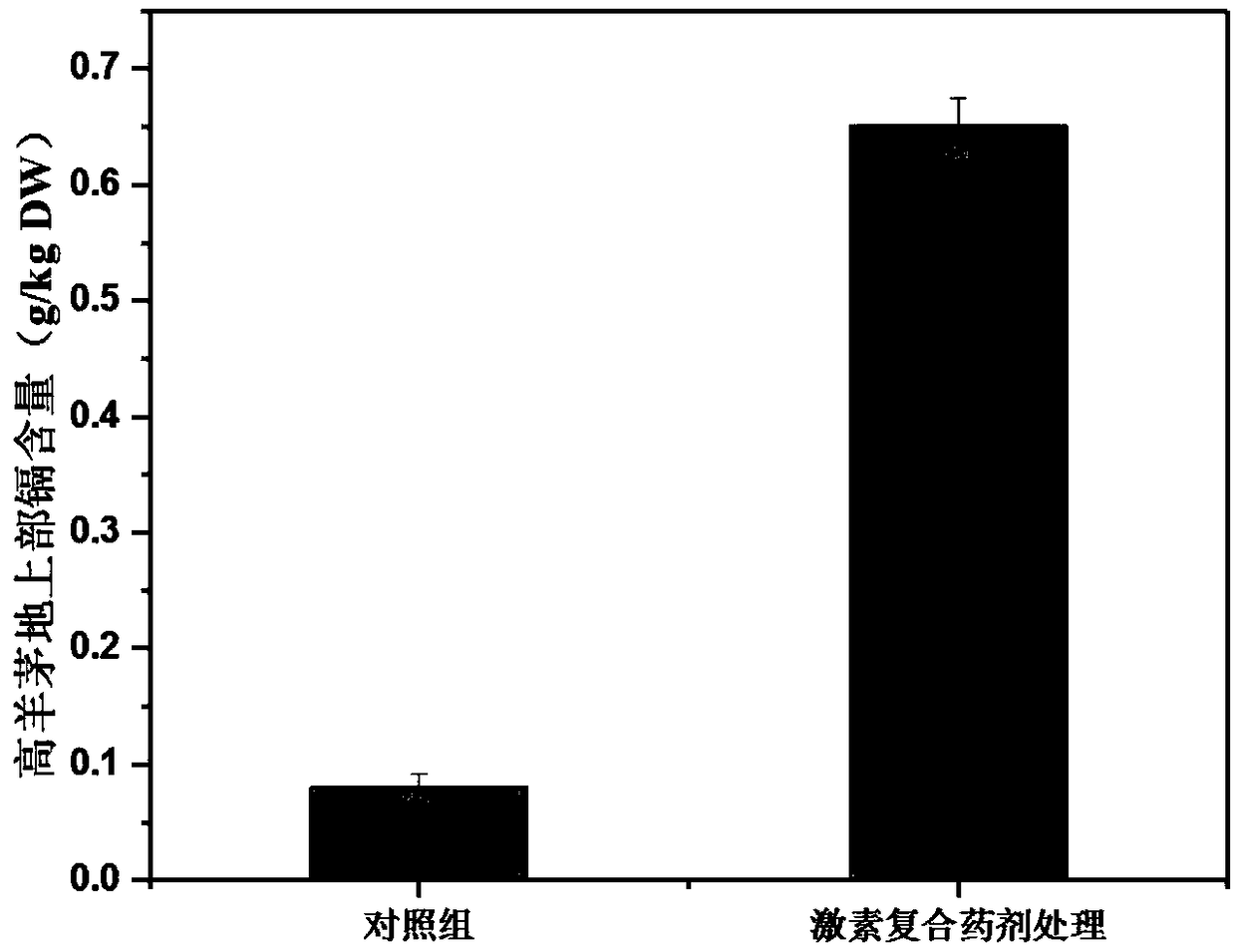

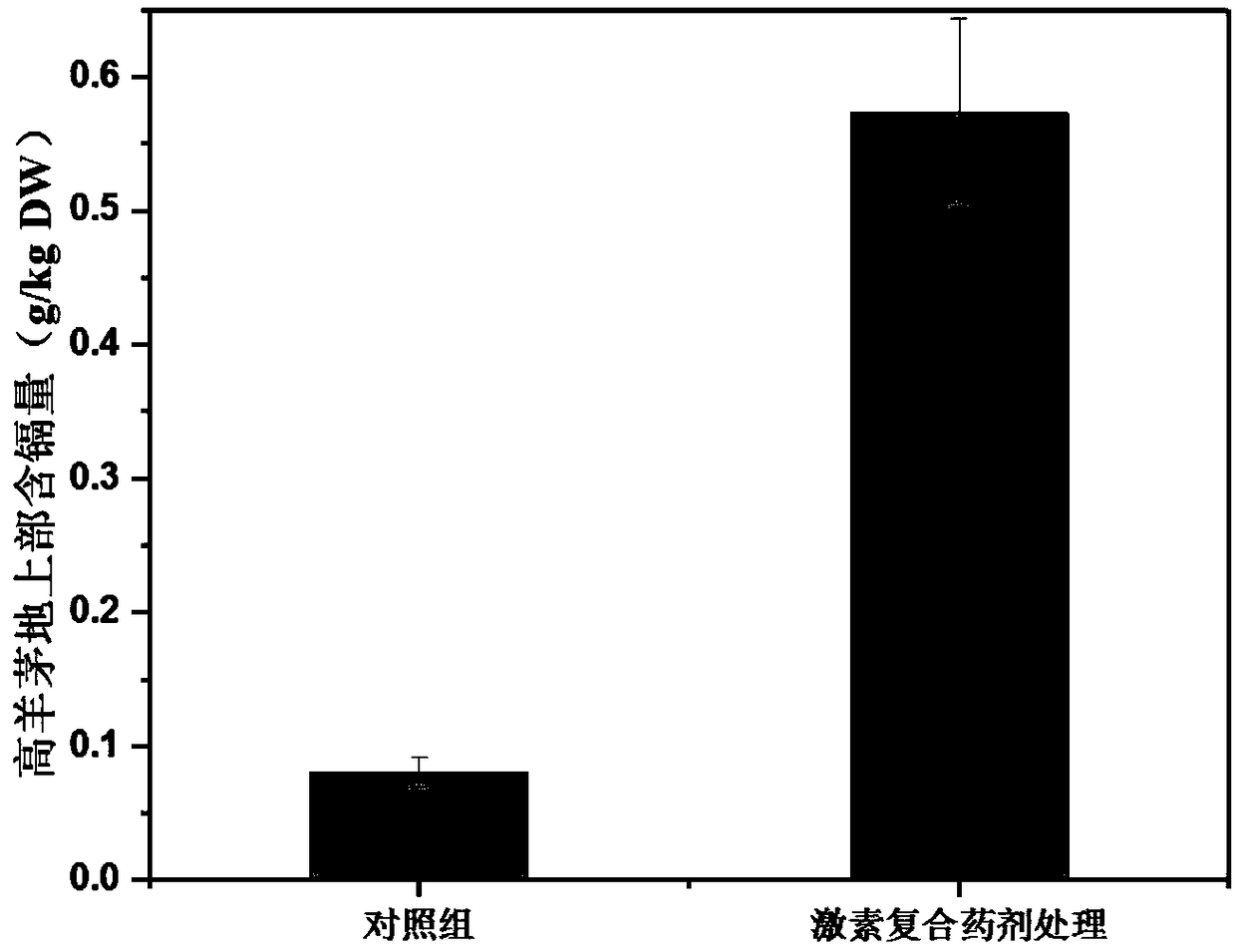

Compound agent for improving heavy metal absorption and transferring capacity of plants and preparation method and application of compound agent

ActiveCN108704928AFacilitate absorption and transport capacityImprove the transfer coefficientPlant growth regulatorsBiocideAbscisic acidSalicylic acid

The invention belongs to the field of remediation of environmental heavy metal pollution, and particularly discloses a compound agent for improving the heavy metal absorption and transferring capacityof plants and a preparation method and application of the compound agent. The composite agent is suitable for various kinds of soil or water bodies polluted by heavy metal. The composite agent comprises abscisic acid hormones and salicylic acid, abscisic acid hormones and salicylic acid are applied to the polluted soil or the water bodies where the plants are planted at the same time so that theabsorption and transferring capacity of the plants to the heavy metal can be effectively promoted, the transfer coefficient to the overground part is improved, harvesting and enrichment are facilitated, and the compound agent has wide application prospects.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

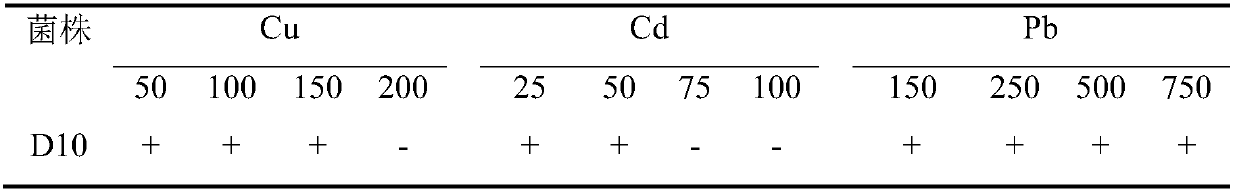

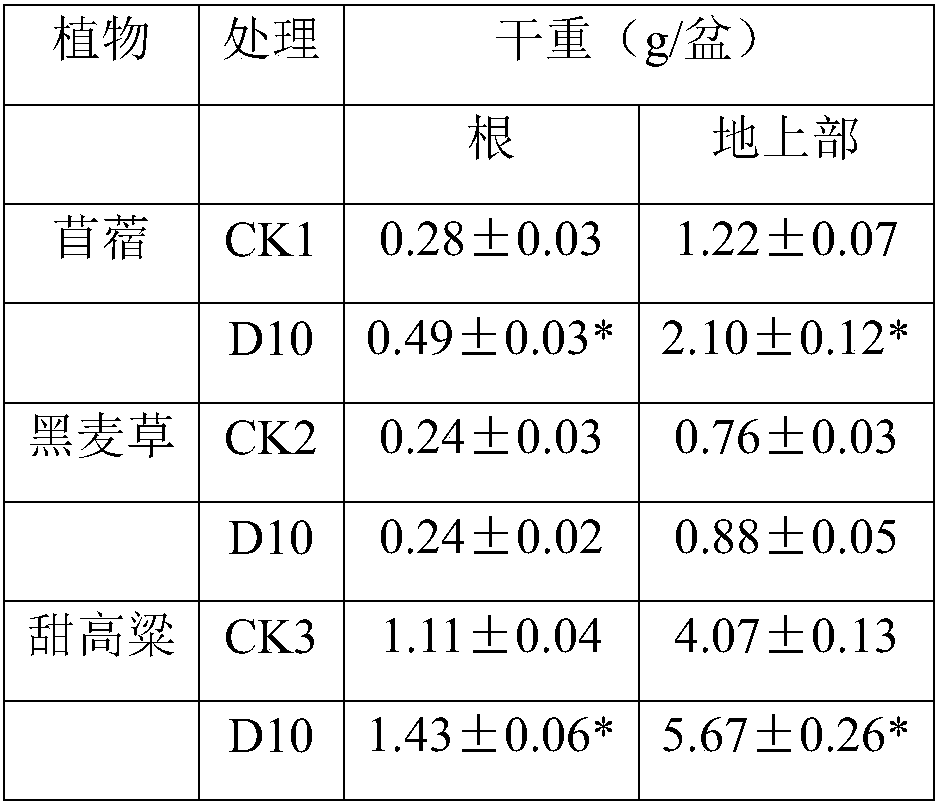

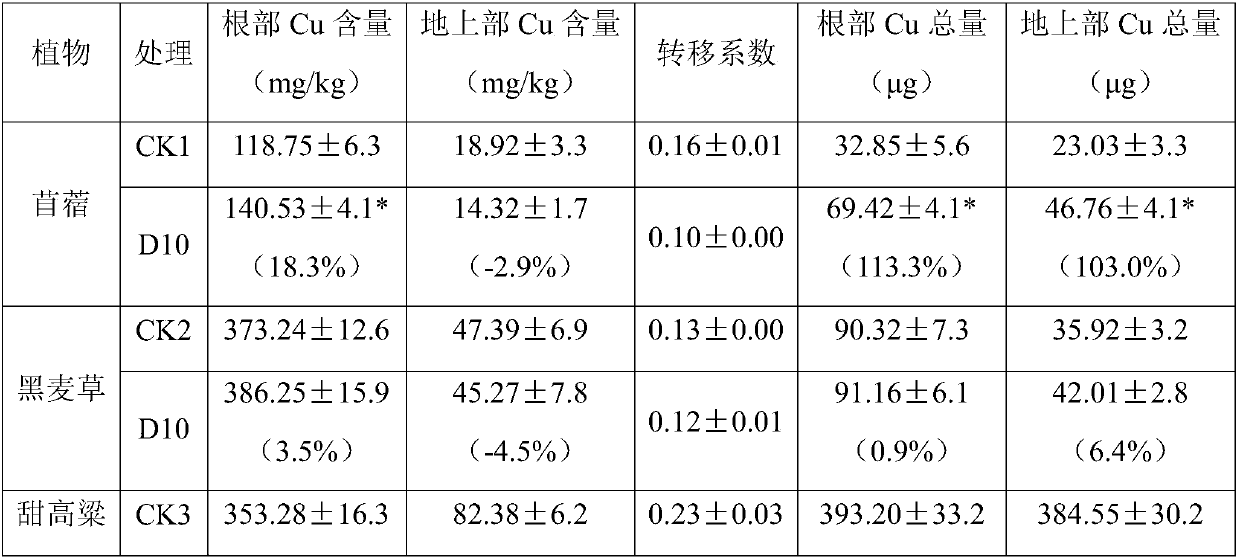

Bacterium D10 for improving validity of heavy metal and application of bacterium D10

ActiveCN107937302APromote growthHigh in heavy metalsBacteriaContaminated soil reclamationSweet sorghumFertility

The invention discloses bacterium D10 for improving the validity of heavy metal and an application of the bacterium D10. The bacterium D10 is named as Sinorhizobium meliloti D10 according to classification and is preserved at the China Center for Type Culture Collection with the culture preservation number being CCTCC NO: M 2016554. A D10 bacterial strain is taken as a raw material and is activated by a culture medium to prepare a bacterium suspending liquid. Soil polluted by heavy metal in a mining area is inoculated with the D10 bacterium suspending liquid, which can promote growth of energyplants, increases the extractable copper content of rhizosphere soil of plants, and improves the copper content and total copper absorptive amount of plant roots. Alfalfa and rye grass that are inoculated with D10 can fix and restore soil polluted by heavy metal, and sweet sorghum inoculated with D10 can perform fixed restoration and extraction restoration. After inoculation with the D10 bacterium suspending liquid, the content of IAA produced by rhizosphere microorganisms of plants is increased, and the fertility of soil is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for restoring heavy metal in sewage irrigation soil through NTA and 3-indoleacelic acid-enhanced festuca arundinacea

InactiveCN103865546AMitigate phytotoxicityPromote accumulationOrganic fertilisersHorticultureSoil heavy metalsFestuca elata

The invention discloses a method for restoring heavy metal in sewage irrigation soil through NTA and 3-indoleacelic acid (IAA)-enhanced festuca arundinacea. A mixture comprises chelating agent nitrilotriacetic acid and 3-indoleacelic acid in a mole ratio of 6-12mmol.kg<-1> to 2mg.kg<-1>. Experimental results show that under certain concentration, the plant toxicity of heavy metal and the chelating agent on festuca arundinacea can be relieved through the addition of IAA, and the accumulation of the plant on the heavy metal can be facilitated; the improvement of the above-ground biomass of the festuca arundinacea can be promoted through combination of the NTA and 3-indoleacelic acid. By comparing the combination of the IAA and NTA with the control group, the content of above-ground heavy metal of the festuca arundinacea can be increased, and therefore, more heavy metal can be extracted and accumulated by lawn plant, and the heavy metal-polluted soil can be restored to the maximum extent.

Owner:TIANJIN NORMAL UNIVERSITY

Sewage treatment device and method integrating electric flocculation, magnetic flocculation and magnetic separation

ActiveCN108545882ALow investment costEasy to operateWater treatment compoundsWater contaminantsElectricityFlocculation

The invention relates to a sewage treatment device and method integrating electric flocculation, magnetic flocculation and magnetic separation. The sewage treatment device comprises a water inlet tank, a reaction tank, a water outlet tank, an aeration device, a mud storage tank and a power module. A soluble electrode and an electromagnetic induction device are arranged in the reaction tank; when the device is used, a floc can be fully flocculated, and electric flocculation, magnetic flocculation and magnetic separation integration high-efficient treatment is realized. The device provided by the invention is energy saving, land saving, high in treatment capacity, fast in settling velocity, capable of greatly improving the treatment capacity and the settling velocity of electric flocculationand solving the problem of magnetic powder recovery of magnetic flocculation, and capable of being used for directly treating electroplating wastewater, desulfurization wastewater, mine wastewater and other industrial wastewater with a higher heavy metal content.

Owner:NANJING FORESTRY UNIV

Extraction technology of 98.5% lysine hydrochloride

ActiveCN103739508ASmall fluxEnsure clarityOrganic compound preparationAmino-carboxyl compound preparationAcid concentrationIon exchange

The invention belongs to the technical field of lysine production, and particularly relates to an extraction technology of 98.5% lysine hydrochloride. The extraction technology of 98.5% lysine hydrochloride comprises the following steps: (1) ceramic membrane separation; (2) continuous ion exchange; (3) acid concentration; (4) crystallization; (5) baking, namely baking wet crystals obtained in the step (4) through a dryer until the moisture content is smaller than or equal to 1.5%, then removing small particles in a multi-stage swinging screening manner, re-dissolving excessive overtails and siftage and then returning to the step (4) to crystallize. The technology is reasonable in design, and the extracted 98.5% lysine hydrochloride is regular in crystal shape, uniform in size and strong in compressive capacity.

Owner:ZHUCHENG DONGXIAO BIOTECH

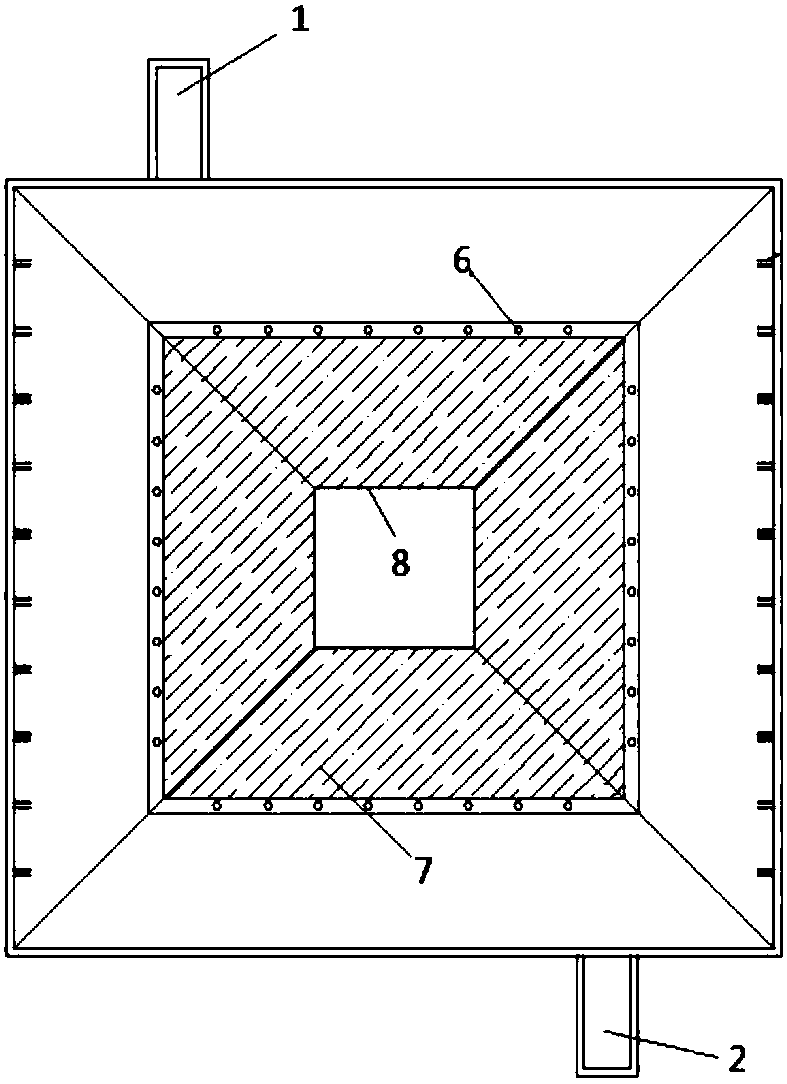

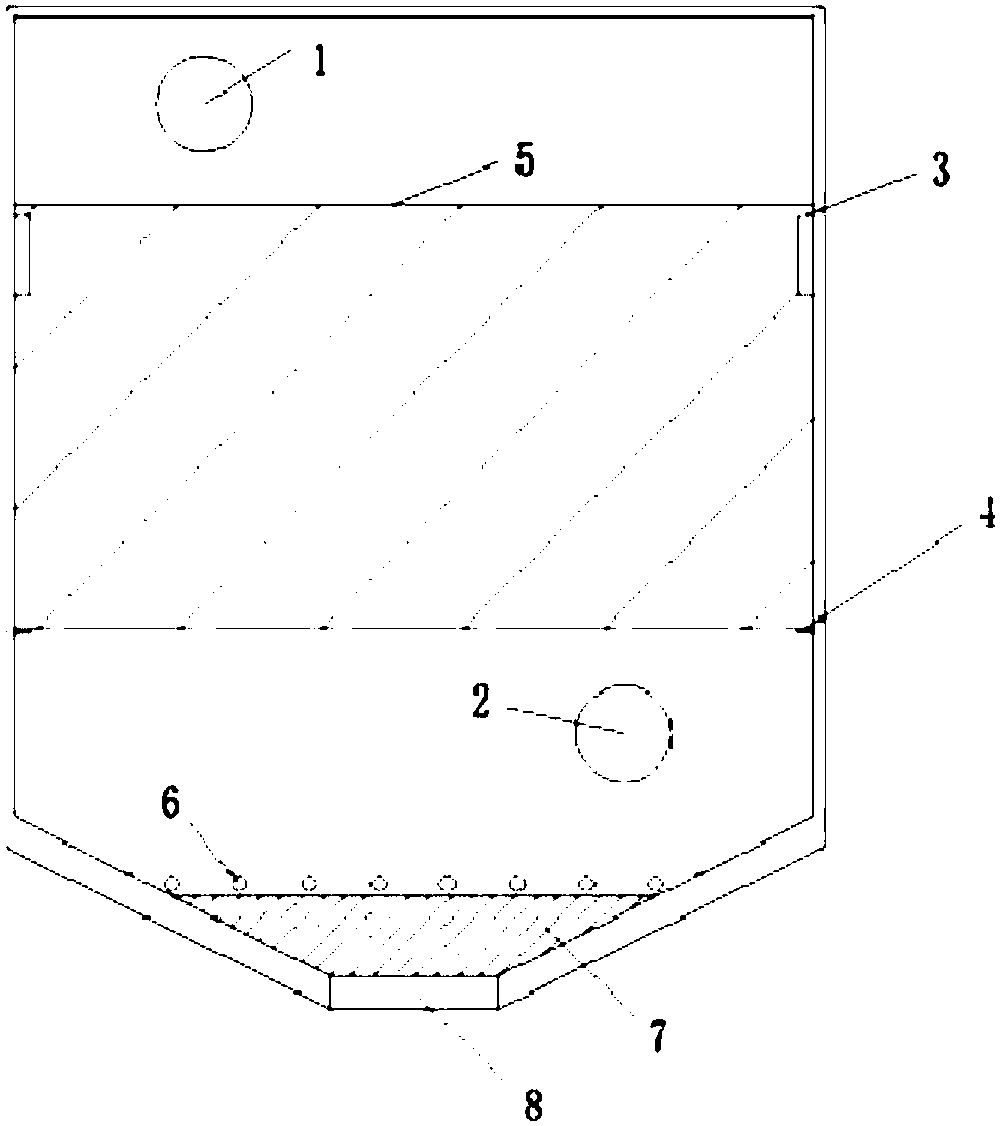

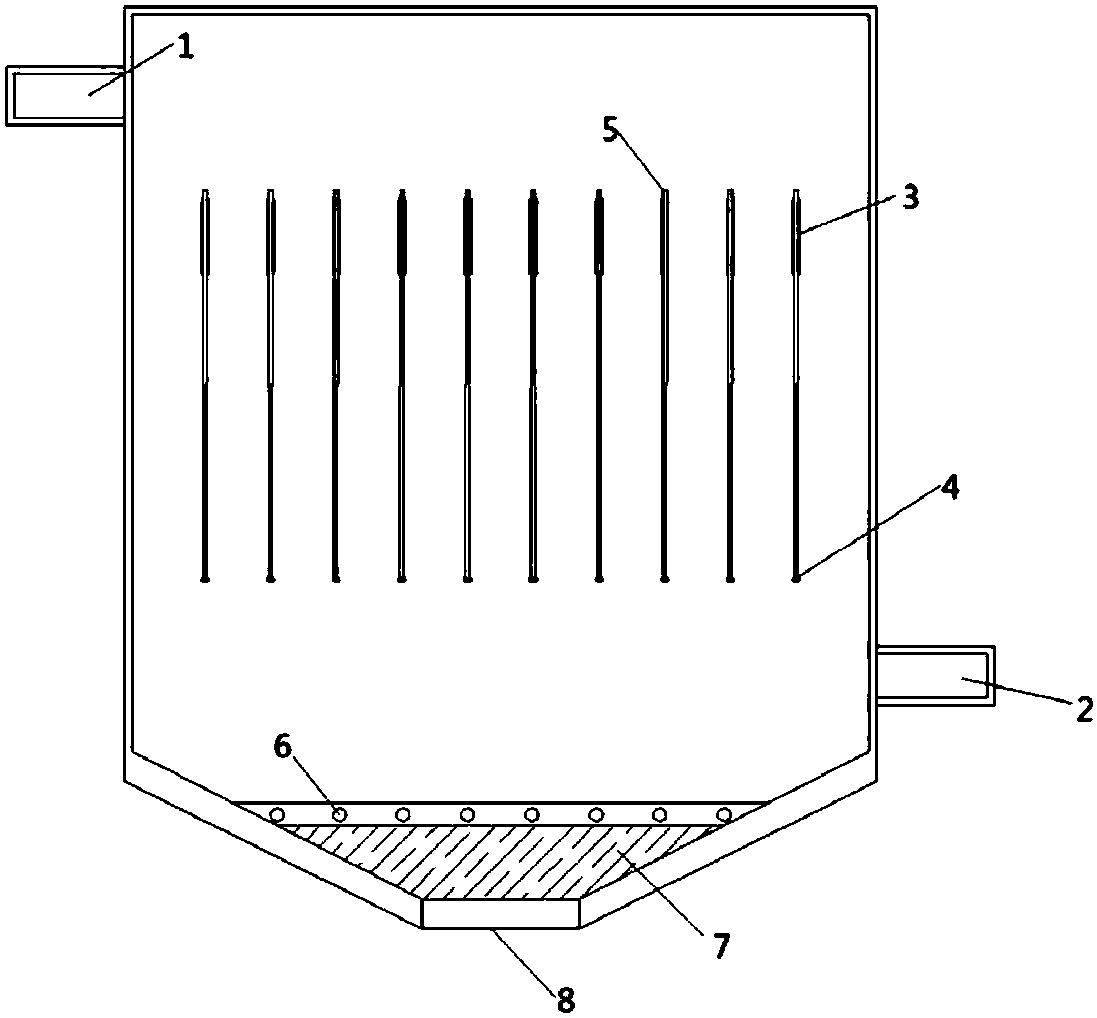

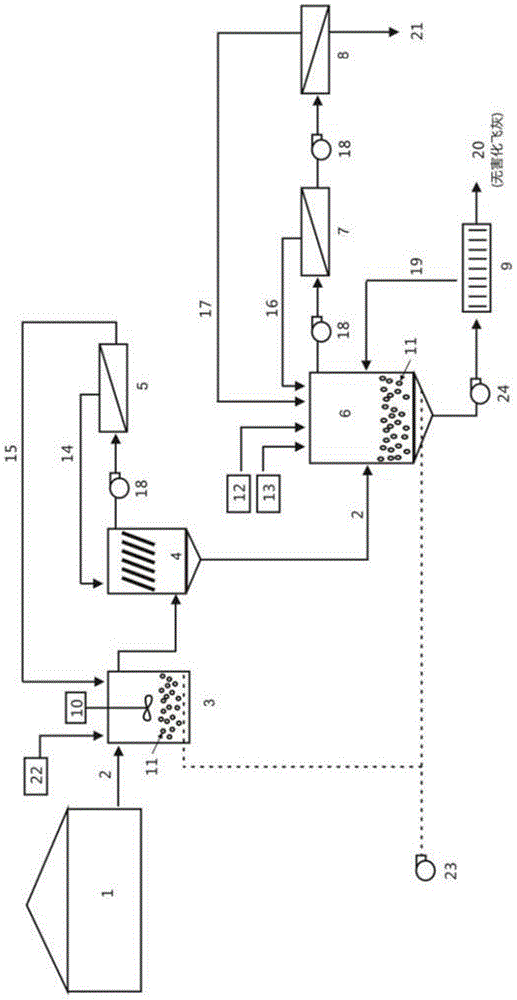

Film separation and concentration system for removing heavy metals in garbage incineration fly ash

ActiveCN105080946AImprove cleaning efficiencyImprove extraction efficiencySolid waste disposalAeration systemLitter

The invention relates to a film separation and concentration system for removing heavy metals in garbage incineration fly ash. The system comprises a cleaning tank (3), a settling tank (4), a leaching tank (6) and a press filter (9), wherein a stirring device (10) and a fine aeration system (11) are arranged in the cleaning tank (3); the cleaning tank (3) is connected with the settling tank (4); the settling tank (4) is connected with a first-grade film filter system (5), and is connected with the leaching tank (6); the fine aeration system (11) is arranged in the leaching tank (6); the leaching tank (6) is provided with an acid pouring port and a surface active agent pouring port, and is connected with a second-grade film filter system (7); the second-grade film filter system (7) is connected with a three-grade film concentration system (8); and a fly ash outlet of the leaching tank (6) is connected with the press filter (9). The system can realize the recycling of waste water and leaching liquid in the film system, and generates no secondary waste water and waste liquid; and the fly ash and the leaching liquid achieve high-efficiency separation through a film technology.

Owner:JOJOTECH ENVIRONMENTAL TECH LTD

Method for preparing feedstuff grade of defluorination tricalcium phosphate by two times of agglomeration

InactiveCN1415536AContinuous productionStable productionPhosphorus compoundsPhosphoritePhosphoric acid

A process for preparing feed-class defluorinated tricalcium phosplate by sintering twice includes such steps as sintering the high-F phosphorus ore at 1280-1350 deg.c in rotary kiln using water gas as fuel, grinding, proportionally mixing it with sodium carbonate (or sulfate) and lime stone powder, adding hot phosphonic acid, granulating, sintering at 1460-1530 deg.C, and grinding. Advantages: qualified product greater than 98%, less production cost.

Owner:TUOFU PHOSPHOR & CALCIUM KAIYANG GUIZHOU

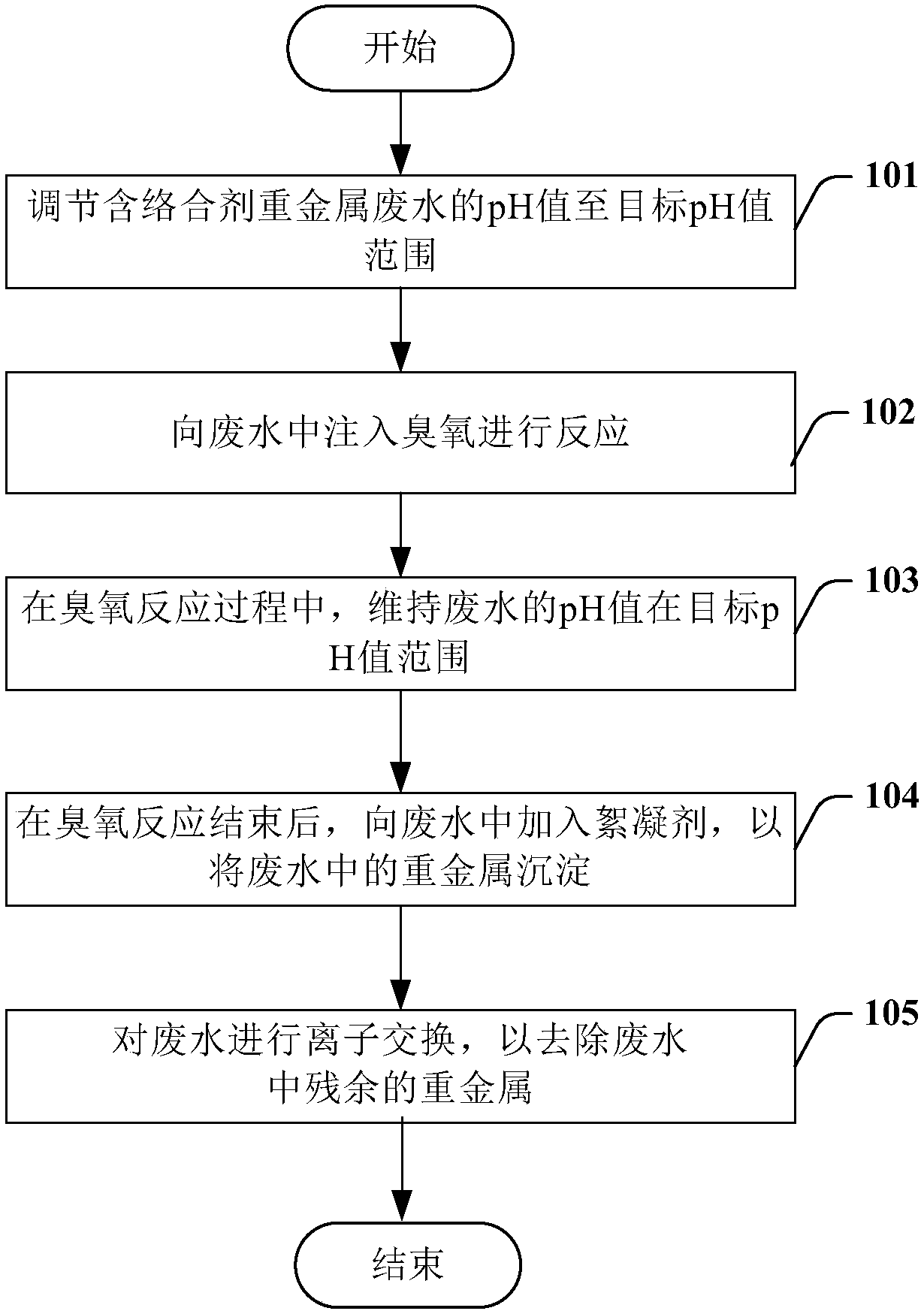

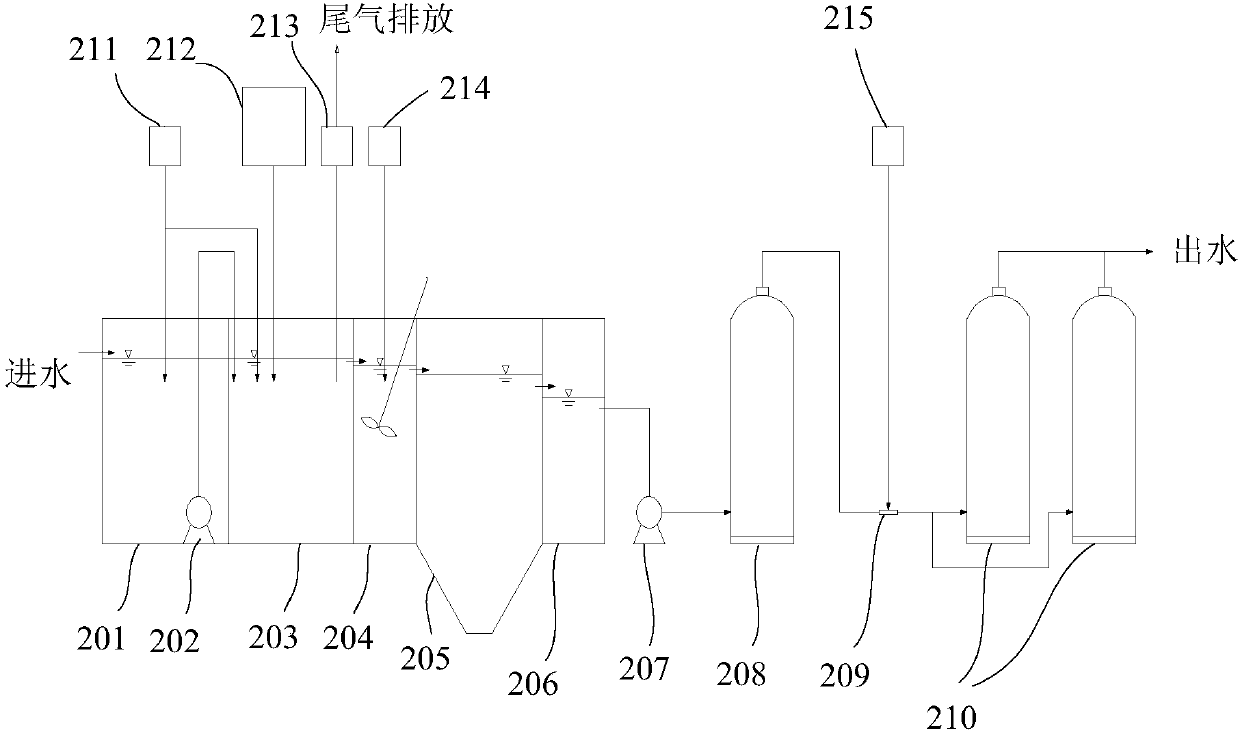

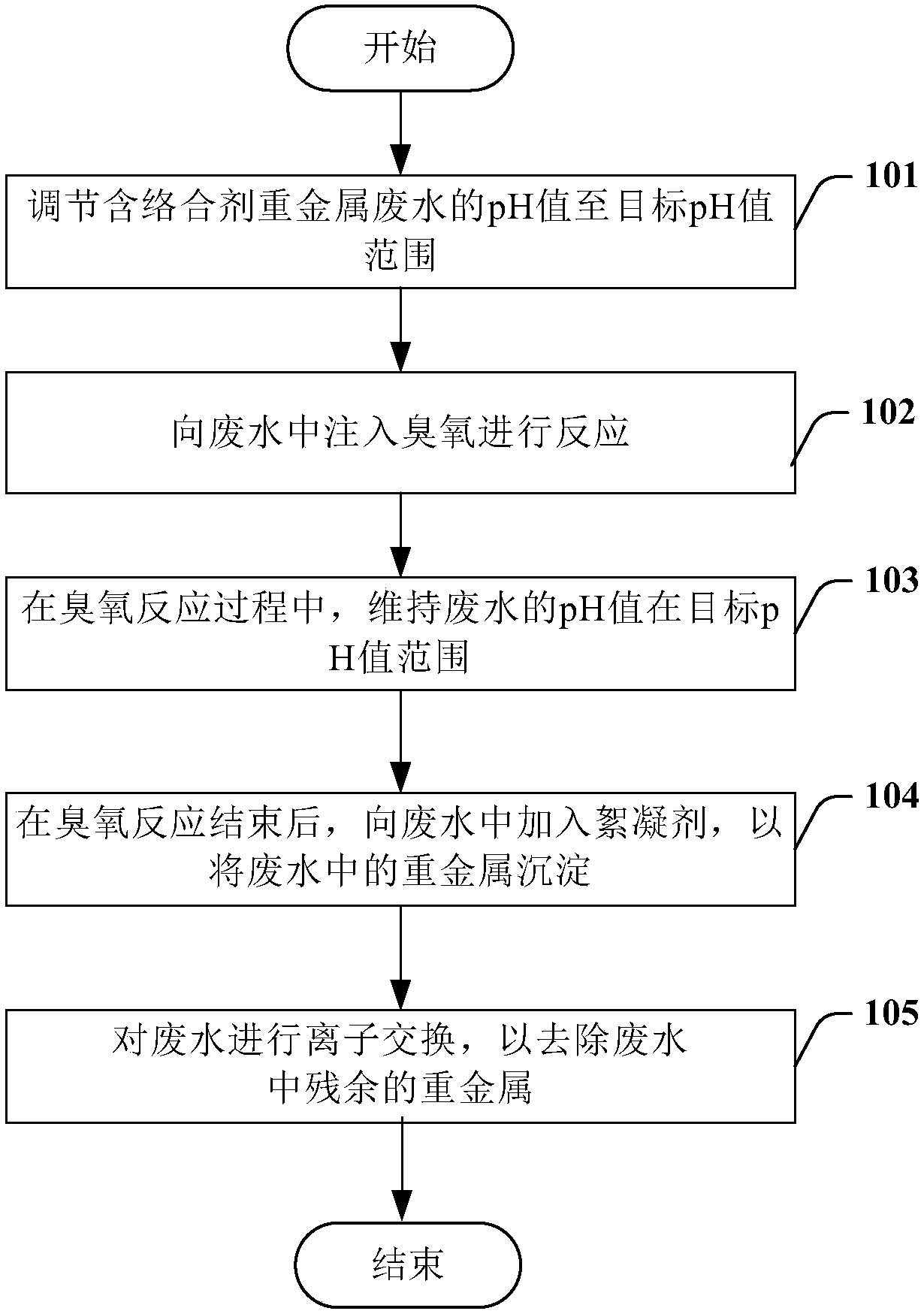

Processing method and equipment of complexing agent containing heavy metal waste water

PendingCN109987736AHas strong oxidizing propertiesSignificant decomplexation effectWater contaminantsWaste water treatment from metallurgical processIon exchangeWastewater

The invention provides a processing method and equipment of complexing agent containing heavy metal waste water. The processing method comprises following steps: the pH value of the complexing agent containing heavy metal waste water is adjusted to be in a target pH value range; ozone is introduced into the waste water for reaction, wherein in ozone reaction process, the pH value of the waste water is maintained in the target pH value range; after ozone reaction, a flocculating agent is added into the waste water for precipitation of heavy metal in the waste water; and the waste water is subjected to ion exchange to remove residual heavy metal in the waste water.

Owner:SHANGHAI LIGHT IND RES INST

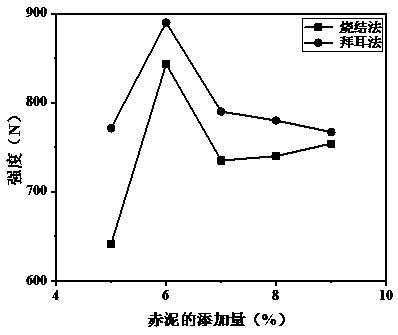

Red mud-containing briquette and preparation method thereof

The invention provides a red mud-containing briquette and a preparation method thereof. The red mud-containing briquette comprises, by weight, 60-70 parts of coal, 5-9 parts of red mud, 1-5 parts of adispersant and 2-5 parts of gelatinized starch, the dispersant is a naphthalene dispersant, and the coal is semi-coke or anthracite. The energy-saving, emission-reducing and environmentally-friendlybriquette is prepared by using pulverized coal as a main body and the red mud as a sulfur fixing agent and adding other substances such as a binding agent and the like, so the problem of red mud utilization can be solved, the problem of environmental pollution caused by the red mud and fire coal can also be solved, and the effect of treating wastes with wastes is achieved.

Owner:HENAN CHANGXING IND CO LTD

Method for preparing and using low-heavy-metal-content chlorella cultivation raw material mother solution

InactiveCN104496654AImprove solubilityControl exposureCalcareous fertilisersMagnesium fertilisersDissolutionChlorella

The invention provides a method for preparing and using a low-heavy-metal-content chlorella cultivation raw material mother solution. The method is characterized by comprising the following steps: pretreating humic acid used as a main material to obtain liquid fulvic acid and solid humic acid; mixing the liquid fulvic acid with a micro-element raw material to prepare a mother solution, and promoting dissolution of the microelement; mixing the solid humic acid with a high-heavy-metal-content raw material mother solution, and adsorbing heavy metals by using humic acid to reduce the heavy metal content of the raw material mother solution, thereby obtaining a solid part namely humic acid with the adsorbed heavy metals; and removing the heavy metals from humic acid with the adsorbed heavy metal by virtue of an acid cleaning method to realize regeneration. The microelement cultivation raw material mother solution containing humic acid and the constant cultivation raw material mother solution without the heavy metals, which are proportioned according to certain used amounts, can be used for cultivating various chlorella, and the method is low in cost, simple to operate, capable of effectively reducing the heavy metal content of chlorella cultivation raw materials, and capable of effectively promoting the growth of chlorella and effectively improving the product quality and yield of chlorella.

Owner:东莞市绿安奇生物工程有限公司

Restoration amendment for heavy metal-contaminated soil of metal mine

InactiveCN106381149AImproved agglomeration structureImprove water and fertilizer retention performanceOrganic fertilisersSoil conditioning compositionsTreatment effectPotassium

The invention provides a soil amendment. The soil amendment comprises the following active components: elemental nitrogen, elemental potassium, elemental phosphorus, humic acid, organic matters and microbes. According to the invention, agricultural waste can be used as the restoration amendment for heavy metal contamination of a metal mine, so the soil amendment provided by the invention is convenient in preparation of raw materials, low in cost, simple to operate and good in applicability; the soil amendment has synergistic and complementary effect and exerts additive restoration and treatment effect; and the soil amendment realizes comprehensive utilization of the waste, is free of secondary pollution, accords with the concept of ecological environmental protection, achieves the purpose of recycling of resources and produces ecological, economical and social benefits.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

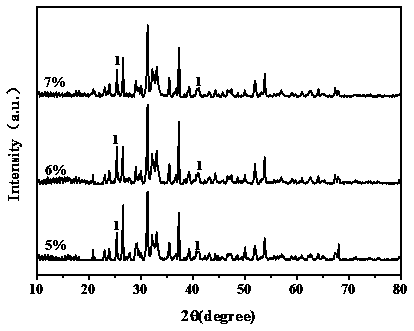

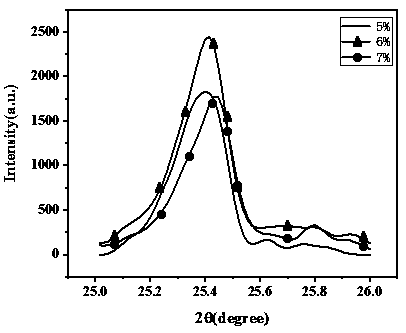

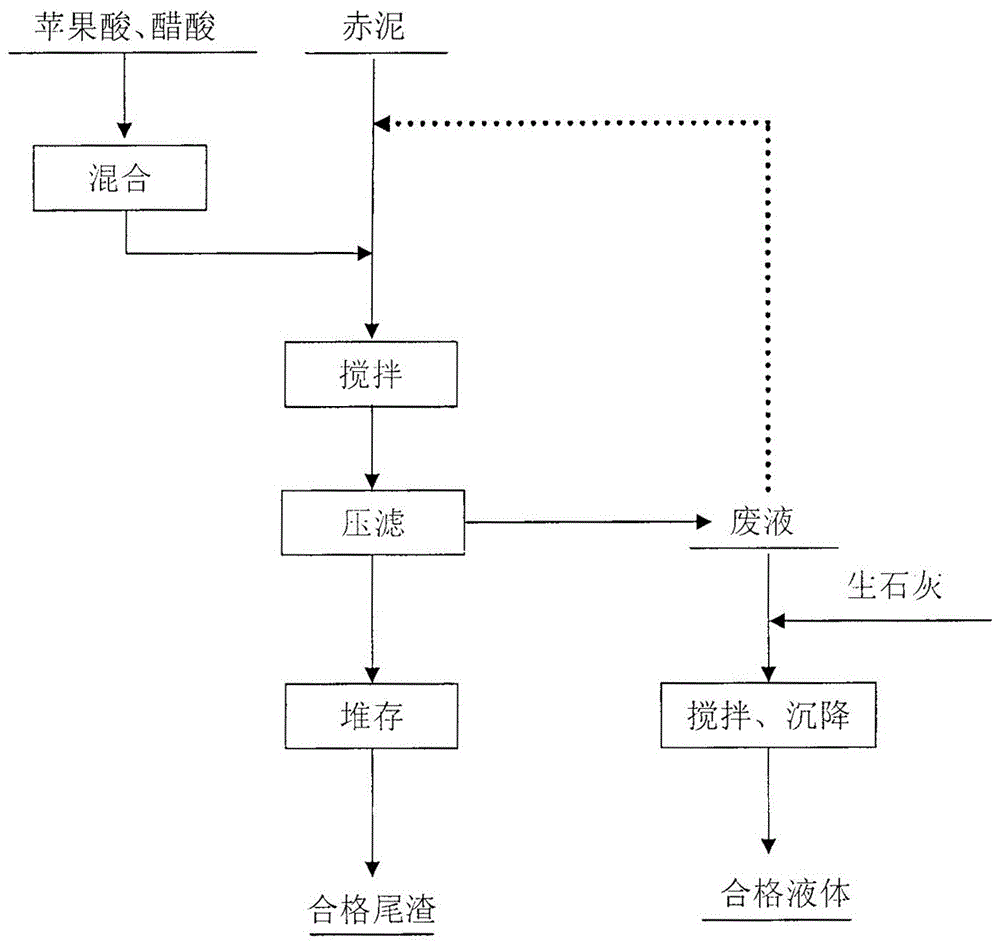

Method for removing zirconium, zinc and chromium in red mud

The invention discloses a method for removing zirconium, zinc and chromium in red mud. The method includes the steps that malic acid and acetic acid are mixed at first to be prepared into mixed organic acid, and then the mixed acid and the red mud are mixed and stirred; qualified tailings and waste liquor are obtained after filter pressing; and when heavy metal of the waste liquor is removed through recycle leaching until the pH value of the liquor is larger than 6, quick lime is added into the waste liquor for stirring, and a qualified solution can be obtained after filtering. The zirconium content in the qualified tailings is lower than 10 mg / kg, the chromium content is smaller than 5 mg / kg, the zinc content is smaller than 1 mg / kg, the residual organic acid can achieve biodegradation, harm to people, livestock and plants is avoided, and thus the qualified tailings can be used as a modifying agent for alkaline soil. The pH value of the qualified solution is 7-8.5, and the concentration of the zirconium, chromium and zinc is lower than 0.02 mg / L. The mixed organic acid is used for removing heavy metal in the red mud, and hence the method has the characteristics that chemical consumption is small, the removal rate of the heavy metal is high, the tailings can be used directly after treatment, the waste liquor can be recycled, the pH value of the waste liquor is high, the heavy metal content of the waste liquor is high and treatment and recycling of the waste liquor are easy.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com