Preparation method of fly maggot chitosan

A technology of fly maggot chitosan and chitosan, which is applied in the field of preparation of fly maggot chitosan, can solve the problems of large environmental pollution, low concentration of maggot pulp, smelly and deteriorated maggot pulp, and achieve low heavy metal content, separation The effect of high quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

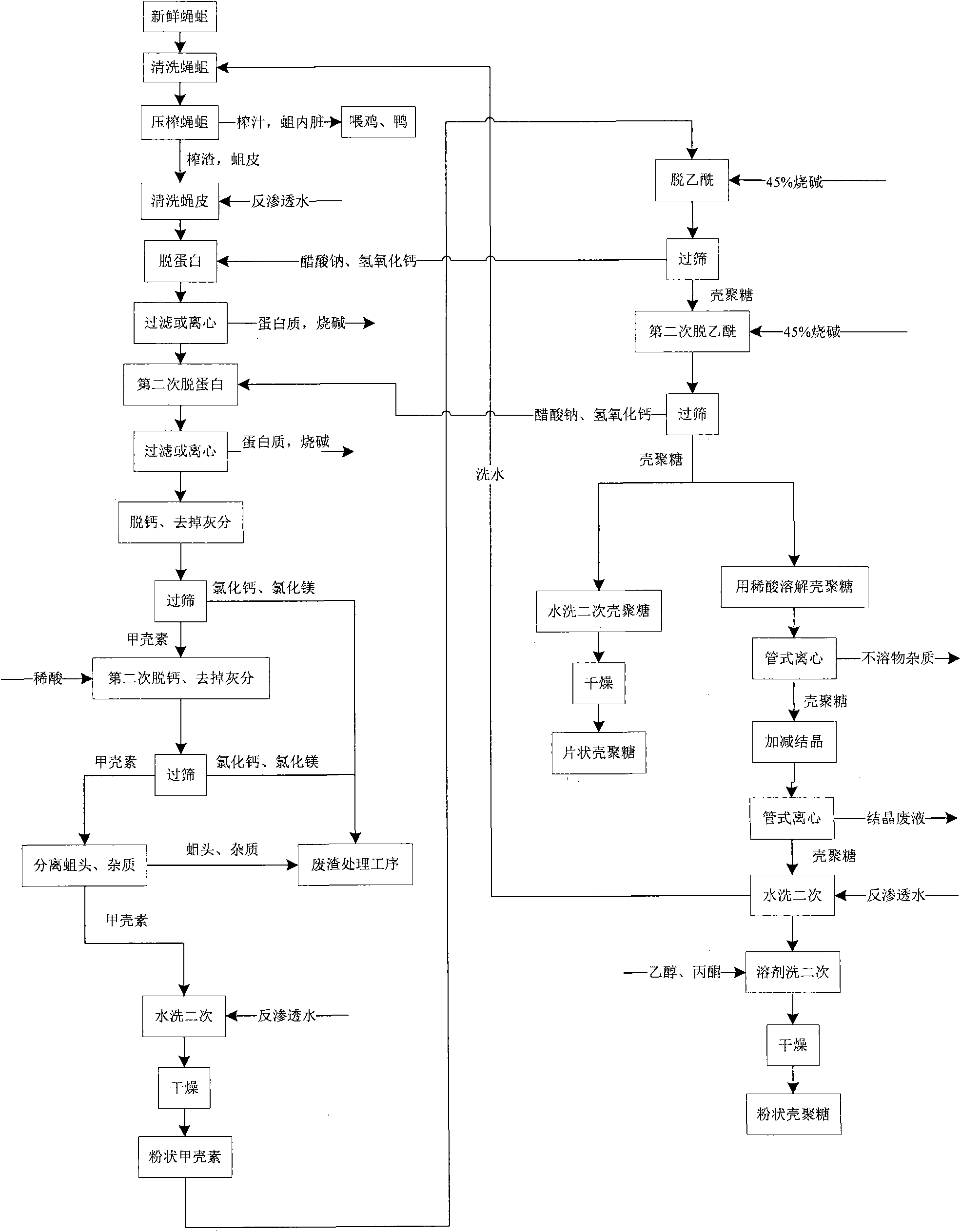

[0026] A detailed description will be given below of specific embodiments of the present invention. A kind of preparation method of fly maggot chitosan of the present invention, the method comprises the following steps:

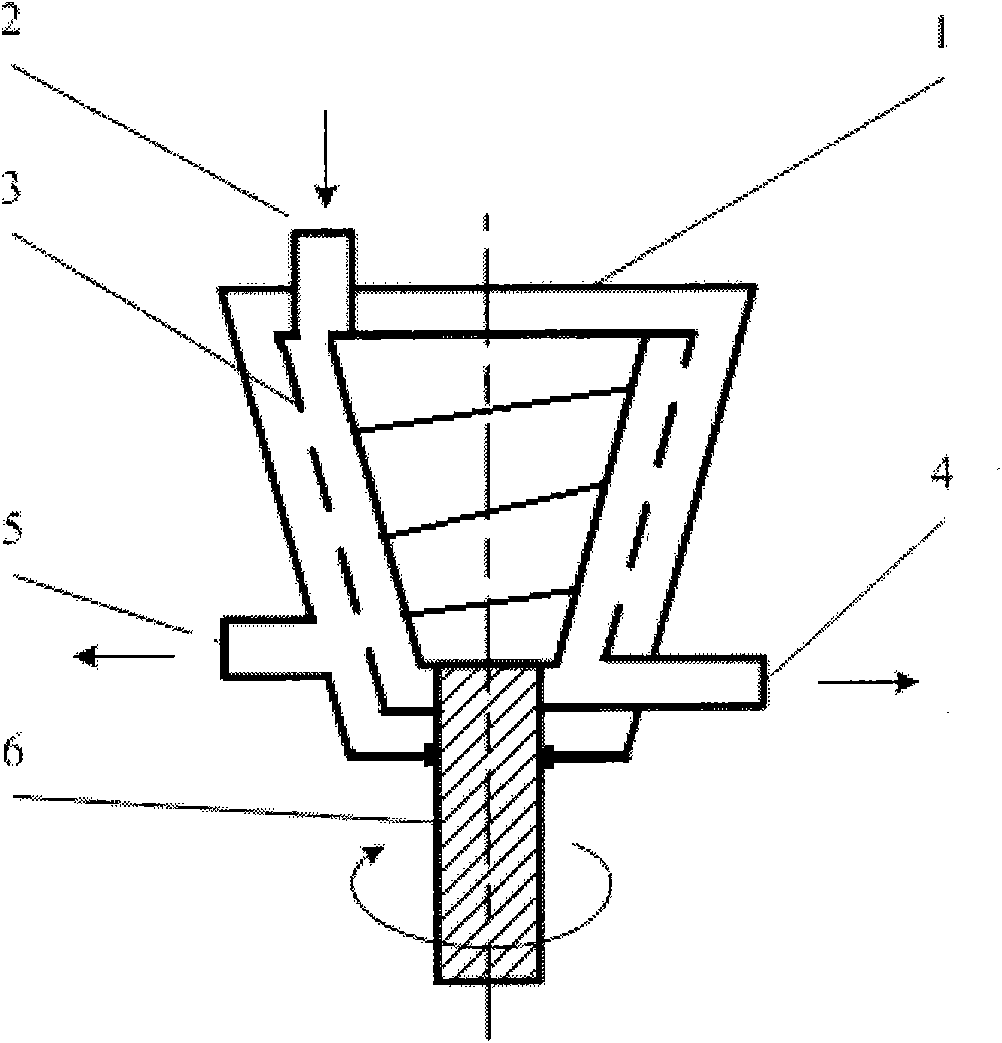

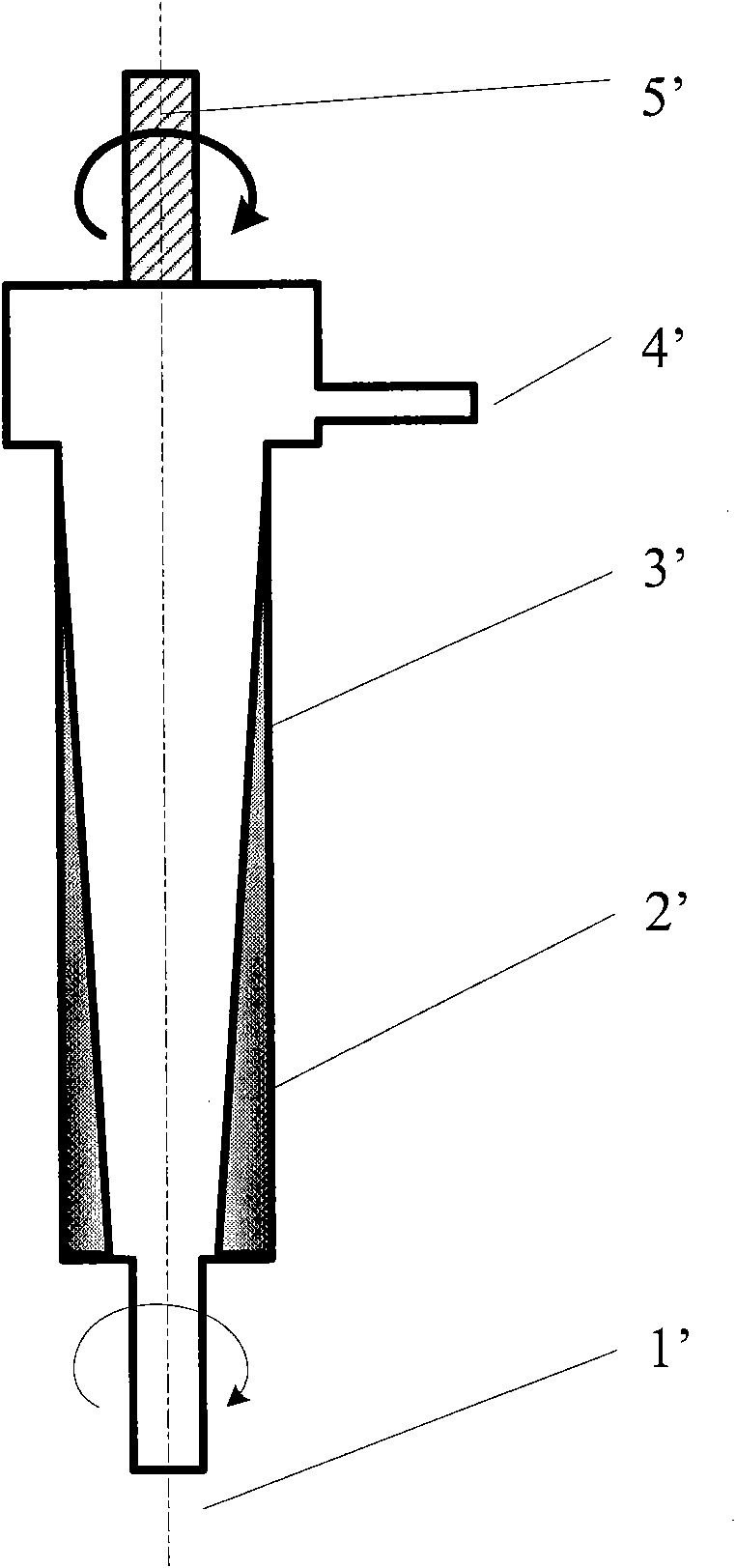

[0027] First, the fly maggots are cleaned to remove debris. Put the fly maggots into the juice extractor to separate the maggot skin and the maggot viscera by squeezing the juice. The fly maggots are fed through the feeding port, and the juice is squeezed by the screw push wheel to separate the maggot viscera. The maggot viscera is discharged from the slurry outlet through the screen holes; the maggot skin is flake and cannot pass through the screen and is discharged from the filter residue outlet. Wash the maggot skin 2 times with a small amount of reverse osmosis water. The maggot viscera exported from the juice extractor is directly used as feed to feed chickens and ducks.

[0028] The maggot skin after the above-mentioned cleaning is put into a specia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com