Soil heavy metal activator and preparation method thereof

An activator and heavy metal technology, applied in the field of soil remediation, can solve the problems of soil structure and composition damage, unfavorable crop or plant growth, high price, etc., and achieve the effect of strong heavy metal binding ability, low use cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

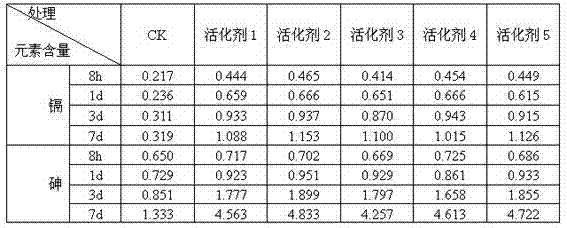

Image

Examples

Embodiment 1

[0054] 1) Stir and mix 100 parts of sodium acrylate or / and acrylic acid, 100 parts of sulfur-containing compounds (50 parts of sulfur, 50 parts of sodium sulfide), heat to 140°C, and react for 2 hours to obtain a solid mixture;

[0055] 2) After cooling to normal temperature, use a pulverizer to pulverize the solid mixed reaction product obtained in step 1) to 200 mesh;

[0056] 3) Mix 100 parts of organic materials (20 parts of rapeseed cake, 20 parts of rice straw, 20 parts of barley straw, 20 parts of rape straw), 50 parts of alkaline matter (20 parts of sodium hydroxide, 30 parts of quicklime), reduce Add 50 parts of the product (25 parts of sodium sulfite, 25 parts of sodium thiosulfate) and 50 parts of water to the pulverized product obtained in step 2), and stir evenly to obtain a mixture;

[0057] 4) Cook the mixture in step 3) in a steam bath for 1 hour to obtain a semi-finished activator;

[0058] 5) Place the semi-finished activator obtained in step 4) at 80°C or i...

Embodiment 2

[0061] 1) Stir and mix 110 parts of methyl acrylate and 450 parts of sulfur-containing compounds (100 parts of sodium hydrosulfide, 200 parts of potassium sulfide, and 150 parts of potassium hydrosulfide), heat to 250°C, and react for 3 hours to obtain a solid mixture;

[0062] 2) After cooling to normal temperature, use a pulverizer to pulverize the solid mixed reaction product obtained in step 1) to 300 mesh;

[0063] 3) Mix 550 parts of organic materials (50 parts of corn stalks, 50 parts of sorghum stalks, 100 parts of wood chips, 100 parts of weed straws, 250 parts of milk vetch straws), 250 parts of alkaline materials (150 parts of slaked lime, 100 parts of potassium hydroxide parts), 250 parts of reduced matter (50 parts of sodium hydrosulfite, 50 parts of reduced iron powder, 50 parts of reduced magnesium powder, 100 parts of reduced manganese powder) and 150 parts of water are added to the pulverized matter obtained in step 2), and stirred evenly, Obtain a solid-liqui...

Embodiment 3

[0068] 1) Stir and mix 120 parts of ethyl acrylate and 420 parts of sulfur-containing compound (20 parts of sulfur, 100 parts of sodium sulfide, 100 parts of sodium hydrosulfide, 100 parts of potassium sulfide and 100 parts of potassium hydrosulfide), and heat to 300°C , reacted for 0.5 hours to obtain a solid mixture;

[0069] 2) After cooling to normal temperature, use a pulverizer to pulverize the solid mixed reaction product of step 1) to 150 mesh;

[0070] 3) 800 parts of organic materials (100 parts of sawdust, 100 parts of weed straw, 100 parts of milk vetch straw, 100 parts of alfalfa straw, 100 parts of waste paper, 100 parts of water hyacinth, 200 parts of sugarcane chips), 400 parts of alkaline (100 parts of sodium hydroxide, 100 parts of quicklime, 100 parts of hydrated lime, 100 parts of potassium hydroxide), 260 parts of reducing substances (40 parts of sodium sulfite, 40 parts of sodium thiosulfate, 40 parts of hydrosulfite, 40 parts of reducing iron powder, Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com