Red mud-containing briquette and preparation method thereof

A red mud and briquette technology, applied in the field of clean coal, can solve the problems of large land occupation and environmental pollution, and achieve the effects of reducing cultivated land occupation, low volatile matter, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

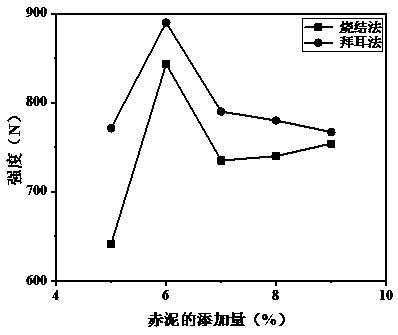

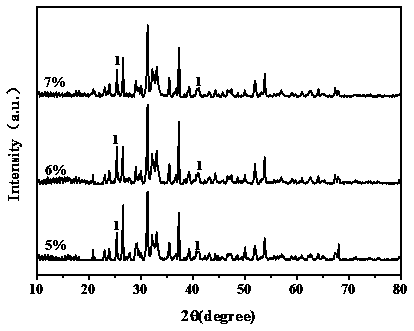

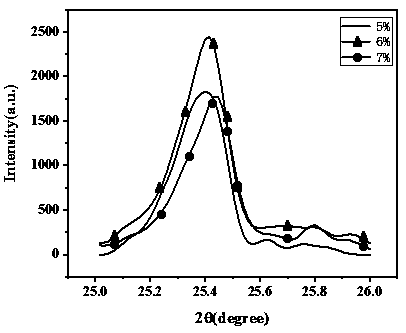

Embodiment 1

[0033] Take 65 parts of mixed coal, add 5 parts of sintering red mud or Bayer red mud, 2 parts of gelatinized starch, and 21 parts of 90°C water, and mix evenly.

[0034] The red mud is soaked in the dispersant solution before being mixed in.

[0035] The coal includes 5 parts of 4-2mm, 30 parts of 2-0.25mm and 30 parts of ≤0.25mm graded coal powder or coal slime.

[0036] After the mold is pressed, let it dry naturally.

Embodiment 2

[0038] Take 65 parts of mixed coal, add 6 parts of sintering red mud or Bayer red mud, 2 parts of gelatinized starch, and 21 parts of 90°C water, and mix evenly.

[0039] The red mud is soaked in the dispersant solution before being mixed in.

[0040] The coal includes 5 parts of 4-2mm, 30 parts of 2-0.25mm and 30 parts of ≤0.25mm graded coal powder or coal slime.

[0041] After the mold is pressed, let it dry naturally.

Embodiment 3

[0043] Take 65 parts of mixed coal, add 7 parts of sintering red mud or Bayer red mud, 2 parts of gelatinized starch, and 21 parts of 90°C water, and mix evenly.

[0044] The red mud is soaked in the dispersant solution before being mixed in.

[0045] The coal includes 5 parts of 4-2mm, 30 parts of 2-0.25mm and 30 parts of ≤0.25mm graded coal powder or coal slime.

[0046] After the mold is pressed, let it dry naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com