Method for adjusting pH value of secondary circuit of nuclear power plant

A technology for the secondary circuit and adjustment method of a nuclear power plant, which is applied in the field of nuclear electrochemistry, can solve the problems of the inability to guarantee steam condensate at the vapor-liquid phase transition position, shorten the operation period of the condensate mixed bed, and increase the workload of operators, and achieves an improved cycle system. Effects of water volume, work load reduction, and corrosion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

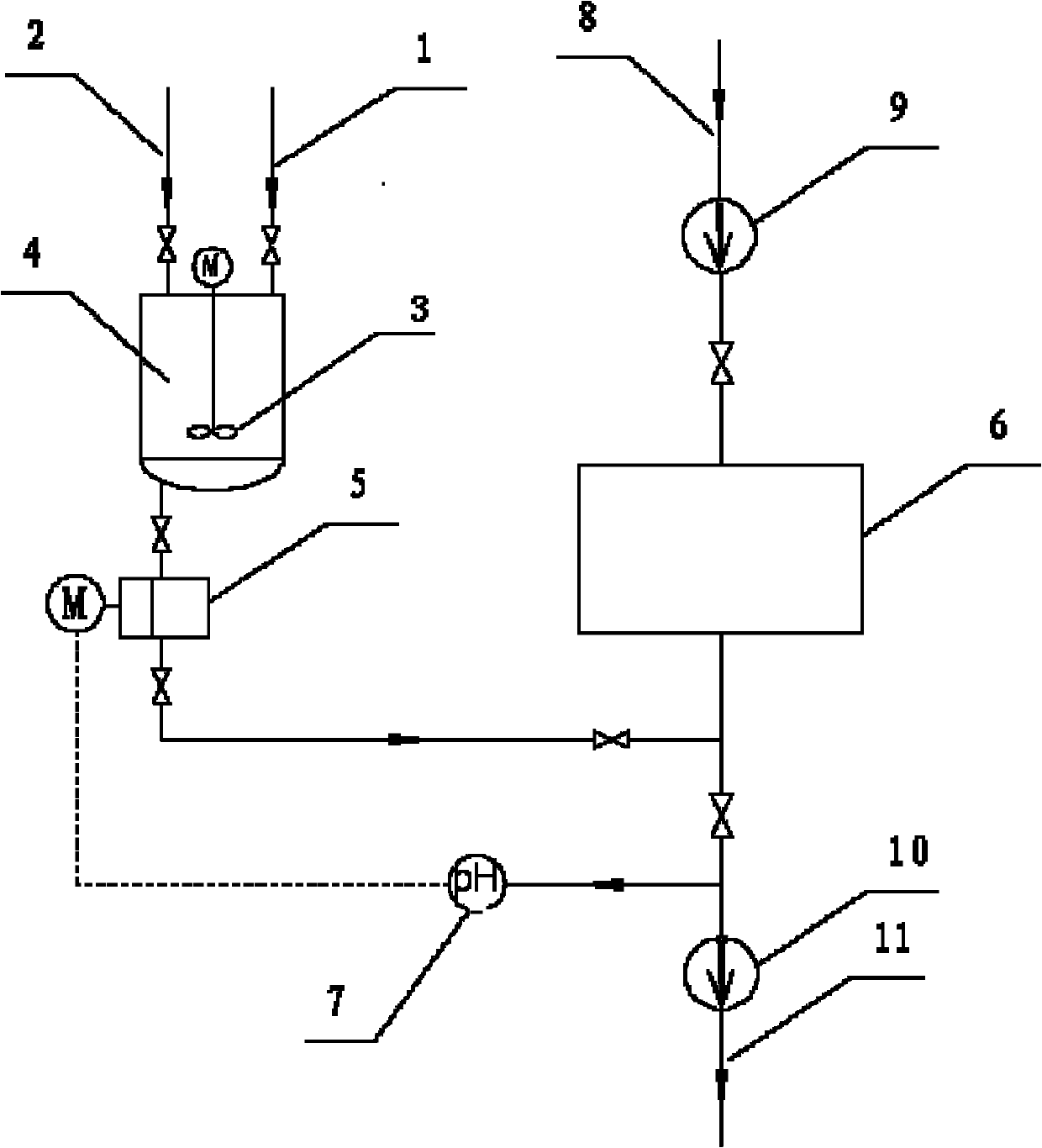

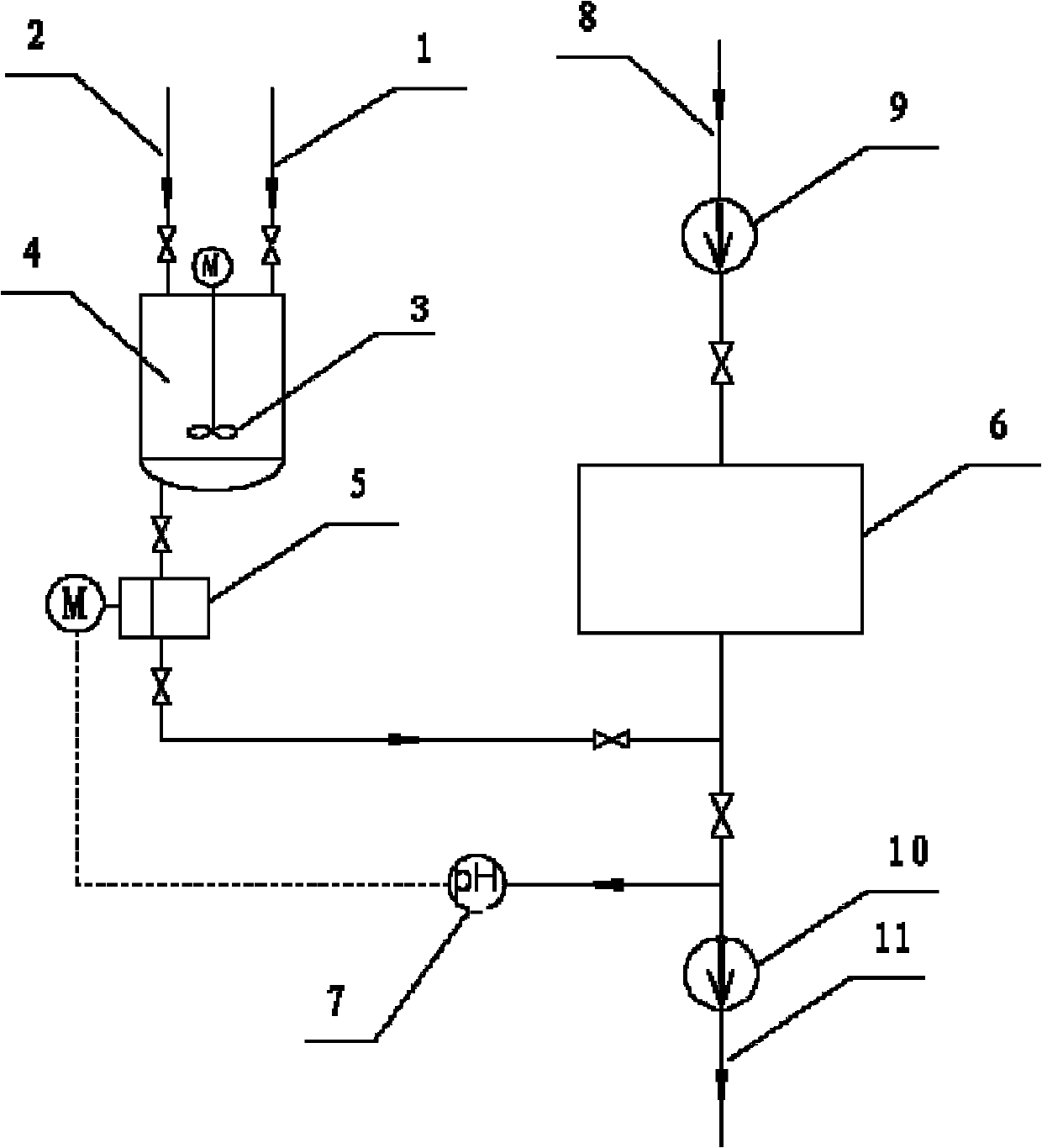

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

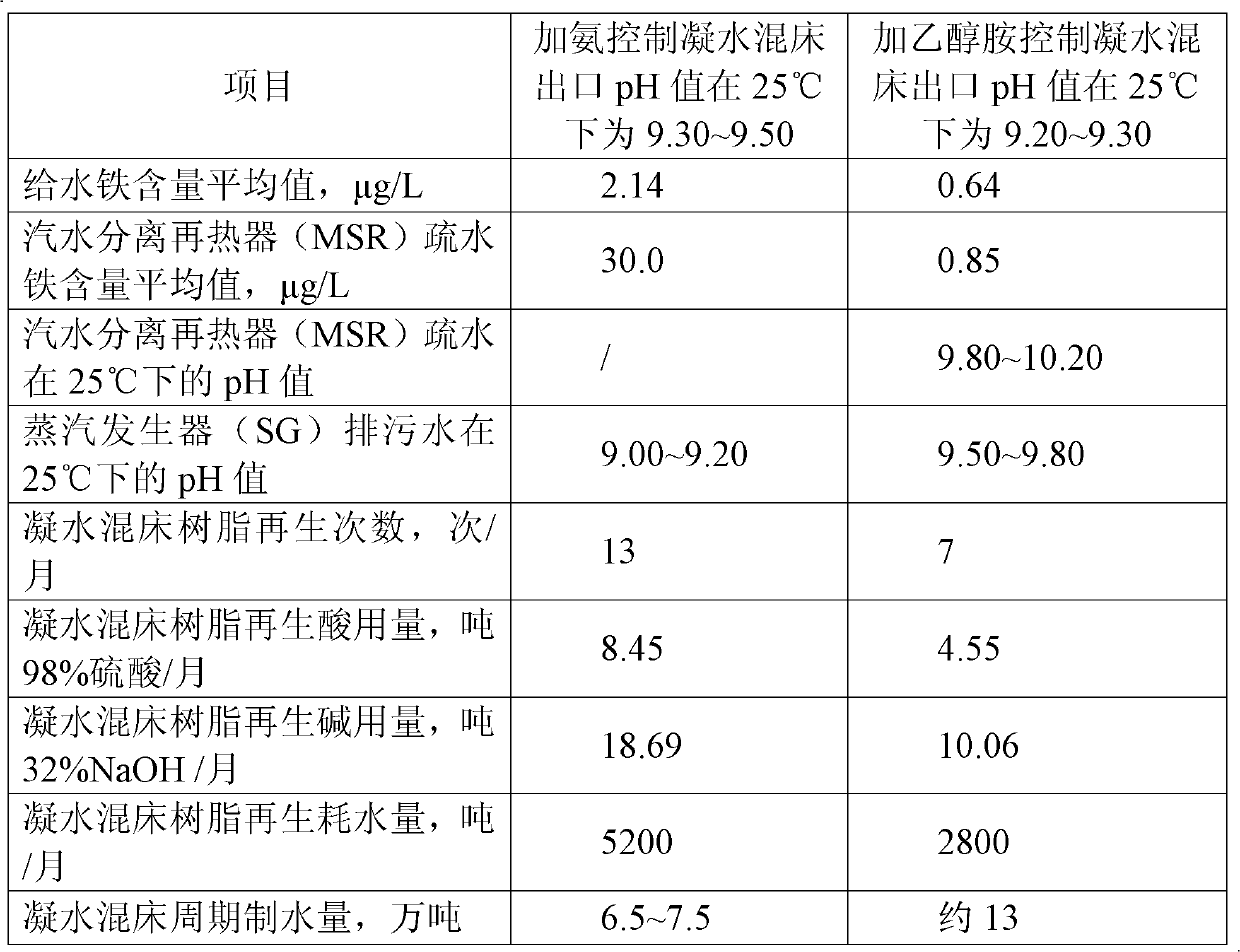

[0012] A kind of nuclear power plant secondary circuit pH value adjustment method of the present invention, its application such as figure 1 As shown, the flow rate of the condensed water from the outlet pipe 8 of the condenser is about 1200m 3 / h, all through the condensate pump 9 and the condensate polishing device 6 to carry out full-flow purification treatment; add about 75kg of ethanolamine (NH 2 CH 2 CH 2 OH), its purity is analytically pure, evaporation residue ≤ 0.2%, impurity content Fe ≤ 0.001%, Na ≤ 0.001%, Cu ≤ 0.001%, SO 4 ≤0.001%, Cl≤0.001%; then add about 1300kg of deionized water to the solution preparation box 4 by adding the deionized water pipeline 2, and the added ethanolamine and deionized water are mixed by the blade agitator 3 in the solution preparation box 4 Stir the water evenly to form an ethanolamine solution; then, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com