Mineral admixture concrete and preparation method thereof

A mineral admixture and concrete technology, applied in the field of mineral admixture concrete and its preparation, and building materials, can solve the problems of difficult control of setting time, difficulty in achieving results, unfavorable transportation and storage, etc., and achieve obvious social and economic benefits Benefit, construction or use effect is good, the effect of overcoming instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

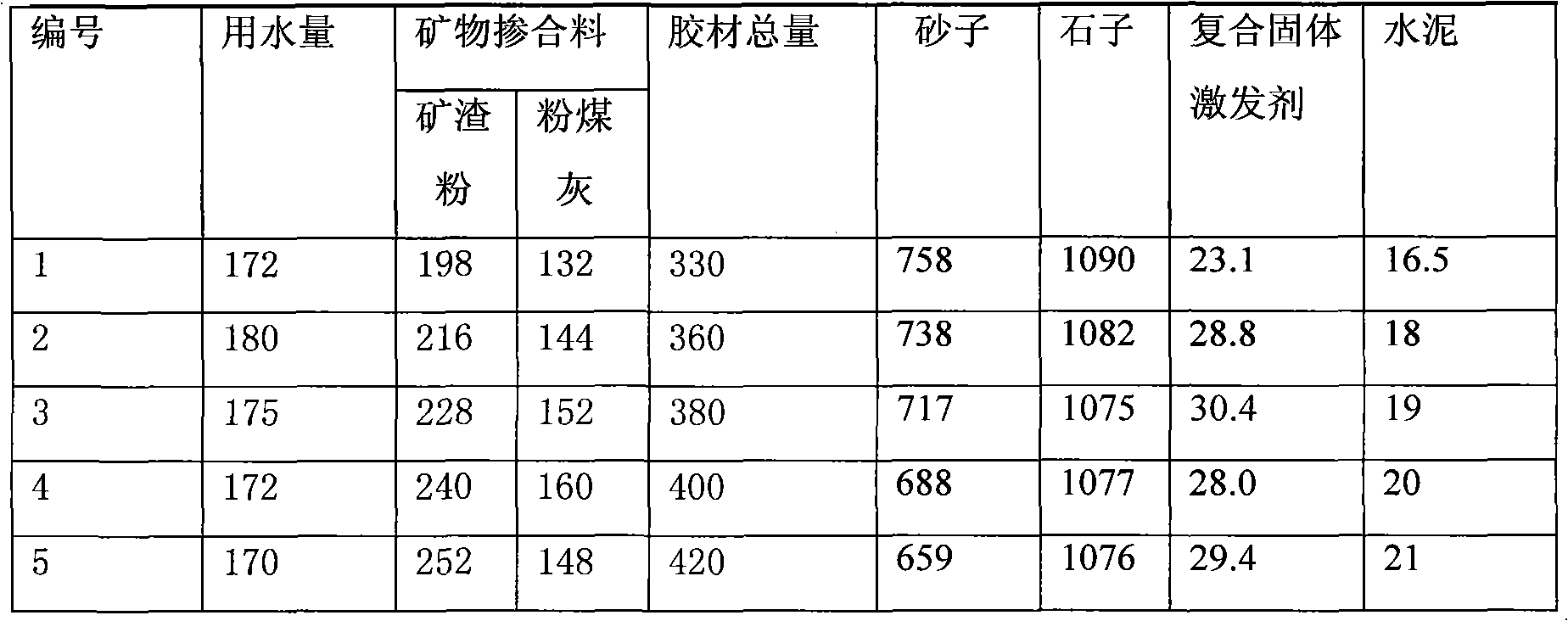

[0022] In the present invention, the mineral admixture is 14-18% by weight percentage, including 60wt% slag powder and 40wt% fly ash, the consumption of the composite solid activator is 1.0-1.3%, and the consumption of 425 ordinary Portland cement is 0.7-0.9%, the amount of sand is 28-32%, the sand uses medium sand with a modulus of 2.8, and the mud content is 2%; the amount of gravel is 45%, and the gravel with continuous grading of 5-31.5mm is used, and the water consumption is 7.2 ~7.5%;

[0023] The raw material composition weight ratio of composite solid activator is: sodium hydroxide 25%, modulus is 2.5, Baume degree is 65% of the liquid water glass of 46 degrees, sodium carbonate 10%, modifier polyacrylamide 0.2%, above-mentioned After the raw materials are fully mixed, they are aged and digested under vacuum conditions for 36 hours, dried at 150°C, and ground to a specific surface area of 305m 2 / kg to obtain a solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com