C70 high-strength concrete and preparation method thereof

A high-strength concrete and compressive strength technology, applied in the field of concrete, can solve problems such as low utilization rate, limited resource utilization of sulfur-fixed ash, and resource shortage, and achieve the effects of reducing water demand, rich hydration products, and high resource value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

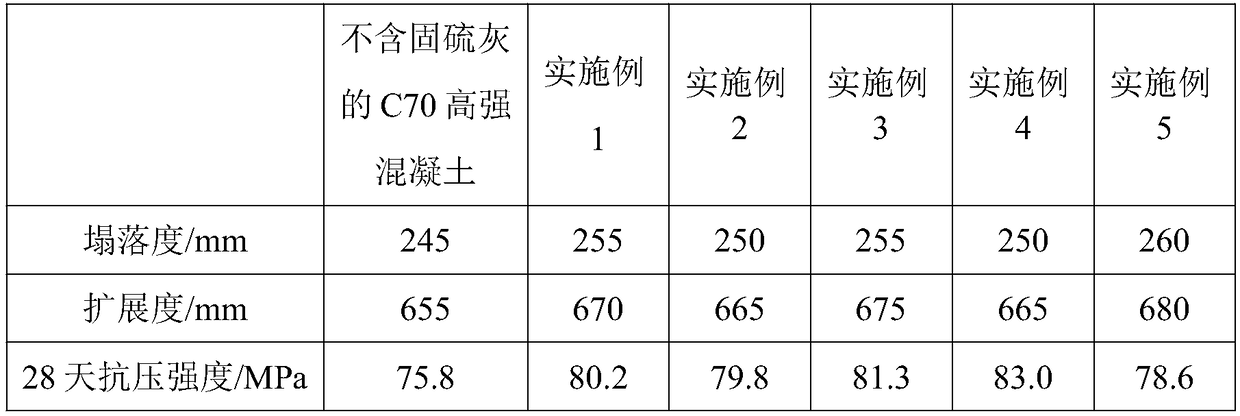

Examples

Embodiment 1

[0042] A C70 high-strength concrete composed of the following materials: 385 parts of cement, 80 parts of mineral powder, 30 parts of fly ash, 55 parts of sulfur ash, 1020 parts of coarse aggregate, 720 parts of fine aggregate, 3.6 parts of water reducing agent, 10 parts of rust inhibitor, 138 parts of water, in parts by weight.

[0043] The cement is selected from P.O 42.5 cement, provided by Dujiangyan Lafarge Cement Co., Ltd. The performance test results are as follows: standard consistency water requirement 26.7%, specific surface area 369m 2 ·Kg -1 , Initial setting time 170min, final setting time 246min, 3-day flexural strength 6.0MPa, 28-day flexural strength 8.3MPa, 3-day compressive strength 31.2MPa, 28-day compressive strength 50.1MPa, SO 3 The content is 2.03% (≤3.5%), the MgO content is 2.41% (≤5%), and the stability is qualified.

[0044] The slag powder is selected from S95 grade granulated blast furnace slag powder, which is provided by Chengdu Concrete New Building M...

Embodiment 2

[0056] A C70 high-strength concrete composed of the following materials: 372 parts of cement, 85 parts of mineral powder, 33 parts of fly ash, 60 parts of sulfur ash, 1020 parts of coarse aggregate, 720 parts of fine aggregate, 3.6 parts of water reducing agent, 10 parts of rust inhibitor, 138 parts of water, in parts by weight.

[0057] The cement is selected from P.O 42.5 cement, provided by Dujiangyan Lafarge Cement Co., Ltd. The performance test results are as follows: standard consistency water requirement 26.7%, specific surface area 369m 2 ·Kg -1 , Initial setting time 170min, final setting time 246min, 3-day flexural strength 6.0MPa, 28-day flexural strength 8.3MPa, 3-day compressive strength 31.2MPa, 28-day compressive strength 50.1MPa, SO 3 The content is 2.03% (≤3.5%), the MgO content is 2.41% (≤5%), and the stability is qualified.

[0058] The slag powder is selected from S95 grade granulated blast furnace slag powder, which is provided by Chengdu Concrete New Building M...

Embodiment 3

[0070] A C70 high-strength concrete composed of the following materials: 397 parts of cement, 75 parts of mineral powder, 28 parts of fly ash, 50 parts of sulfur-fixed ash, 1020 parts of coarse aggregate, 720 parts of fine aggregate, 3.6 parts of water reducing agent, 10 parts of rust inhibitor, 138 parts of water, in parts by weight.

[0071] The cement is selected from P.O 42.5 cement, provided by Dujiangyan Lafarge Cement Co., Ltd. The performance test results are as follows: standard consistency water requirement 26.7%, specific surface area 369m 2 ·Kg -1 , Initial setting time 170min, final setting time 246min, 3-day flexural strength 6.0MPa, 28-day flexural strength 8.3MPa, 3-day compressive strength 31.2MPa, 28-day compressive strength 50.1MPa, SO 3 The content is 2.03% (≤3.5%), the MgO content is 2.41% (≤5%), and the stability is qualified.

[0072] The slag powder is selected from S95 grade granulated blast furnace slag powder, which is provided by Chengdu Concrete New Buil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com