Double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting

A technology for compaction grouting and grouting, which is applied in the field of two-liquid quick-setting grout for well roadway grouting and soft soil compaction grouting, can solve the problem of poor stone body durability, poor water corrosion resistance and difficult grouting effect. Guarantee and other issues, to achieve the effect of easy operation, improved grouting process, and adjustable gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The two-liquid quick-setting slurry is composed of the following components: Liquid A: Portland cement 50%, water 49.475%, inorganic sodium salt 0.5%, organic alcohol early strength agent 0.025%; liquid B: fly ash 43.6%, Sodium silicate 20.05%, water 36.35%. The volume ratio of liquid A and liquid B is 1:1.

[0015] The calculus rate of the slurry in this embodiment is 100%, and the gel time is 36s, which has obvious characteristics of fast setting and high calculus rate.

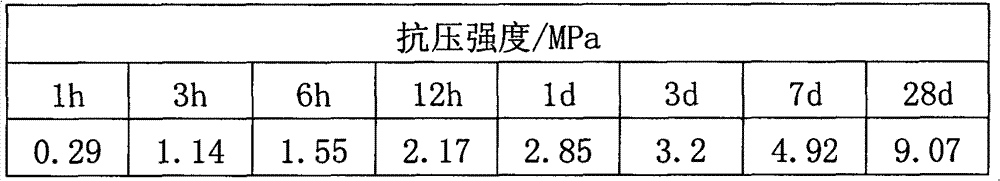

[0016] In order to characterize the early strength performance of the grout, the hourly compressive strength and later strength of the grout stone body were measured. The experimental results are shown in Table 1.

[0017] Early compressive strength of grout Table 1

[0018]

[0019] It can be seen from Table 1 that the slurry has strength within 1 hour, the compressive strength of the stone body can reach 1.5MPa at 6 hours, and the compressive strength can reach 9MPa at 28 days.

Embodiment 2

[0021] The two-liquid quick-setting slurry is composed of the following components: A liquid A: Portland cement 50%, water 49.45%, inorganic sodium salt 0.5%, organic alcohol early strength agent 0.05%; B liquid B: fly ash 46.2% %, sodium silicate 16.94%, water: 36.86%. The volume ratio of liquid A and liquid B is 1:1.

[0022] The calculus rate of the slurry in this embodiment is 100%, and the gel time is 82s, which has obvious characteristics of fast setting and high calculus rate.

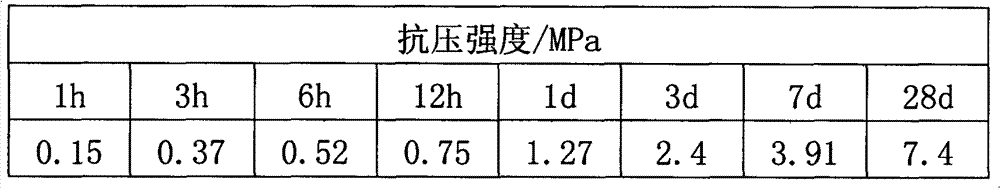

[0023] In order to further characterize the early strength performance of the slurry, the hourly compressive strength and later strength of the slurry stone body were measured. The experimental results are shown in Table 2.

[0024] Early compressive strength of grout Table 2

[0025]

Embodiment 3

[0027] The two-liquid quick-setting slurry is composed of the following components: A liquid A: Portland cement 50%, water 49.2%, inorganic sodium salt 0.75%, organic alcohol early strength agent 0.05%; B liquid B: fly ash 48.8% %, sodium silicate 13.9%, water 37.3%. The volume ratio of liquid A and liquid B is 1:1.

[0028] The calculus rate of the slurry in this embodiment is 100%, and the gel time is 124s, which has obvious characteristics of fast setting and high calculus rate.

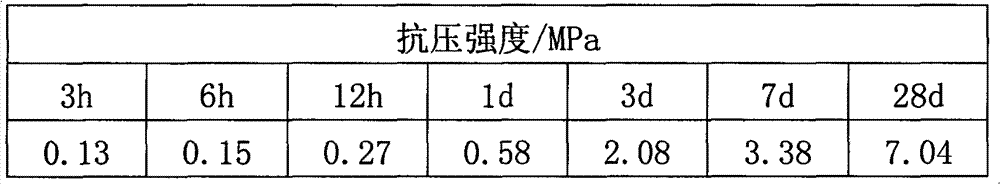

[0029] In order to further characterize the early strength performance of the slurry, the hourly compressive strength of the slurry stone body was measured. The experimental results are shown in Table 3.

[0030] Early compressive strength of grout Table 3

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com