Fertilizer capable of fixing soil heavy metal and preparing method thereof

A technology for heavy metals and fertilizers, applied in the chemical industry, can solve problems such as heavy metal pollution and increase crop yield, and achieve the effects of cost reduction, enhancement of cation exchange, strong cation exchange capacity and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

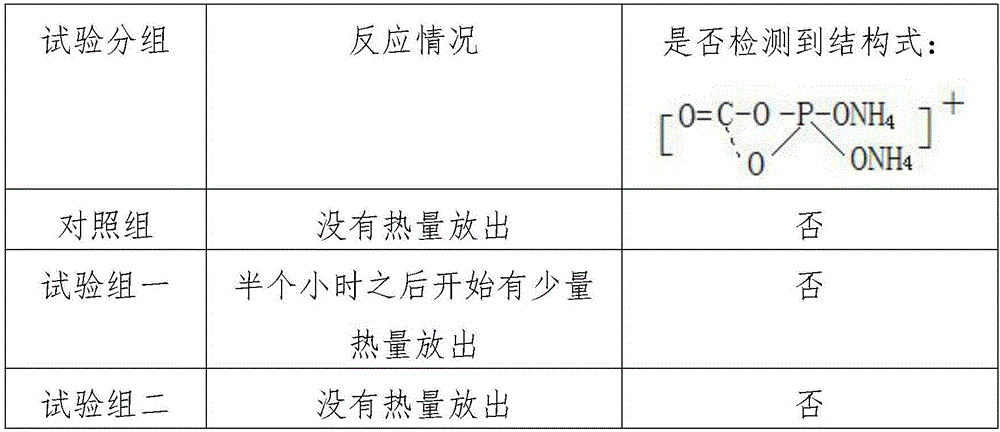

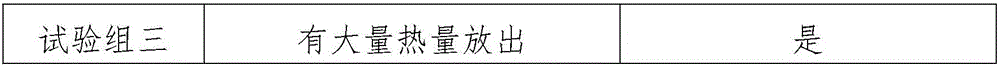

Method used

Image

Examples

Embodiment 1

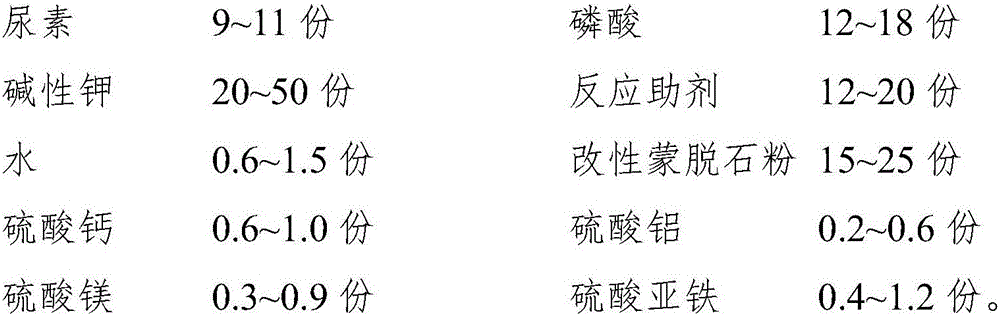

[0033] raw material:

[0034] Urea 9kg, phosphoric acid 12kg, potassium carbonate 20kg, reaction aid 12kg, water 0.6kg, modified montmorillonite powder 15kg, calcium sulfate 0.6kg, aluminum sulfate 0.2kg, magnesium sulfate 0.3kg and ferrous sulfate 0.4kg.

[0035] Preparation:

[0036] (1) Pulverization: after mixing urea, phosphoric acid and potassium carbonate uniformly, pulverize to obtain solid particle powder with uniform particle size;

[0037] (2) Dry reaction: put the solid particle powder into the reaction kettle, use a sprinkler to spray the reaction auxiliary agent and water on the surface of the solid particle, so that the reaction auxiliary agent and the solid particle material are evenly mixed, and adjust the humidity in the reaction kettle After reacting at room temperature for 20 minutes, add calcium sulfate, aluminum sulfate, magnesium sulfate and ferrous sulfate to the reaction kettle, and stir evenly to obtain the primary fertilizer product;

[0038] (3) R...

Embodiment 2

[0049] raw material:

[0050] Urea 11kg, phosphoric acid 18kg, potassium hydroxide 50kg, reaction aid 20kg, water 1.5kg, modified montmorillonite powder 25kg, calcium sulfate 1.0kg, aluminum sulfate 0.6kg, magnesium sulfate 0.9kg and ferrous sulfate 1.2kg.

[0051] Preparation:

[0052] (1) Pulverization: Mix urea, phosphoric acid and potassium hydroxide uniformly and then pulverize to obtain solid particle powder with uniform particle size;

[0053] (2) Dry reaction: put the solid particle powder into the reaction kettle, use a sprinkler to spray the reaction aid and water on the surface of the solid particle, so that the reaction aid and the solid particle material are evenly mixed, and adjust the humidity in the reaction kettle After reacting at room temperature for 60 minutes, add calcium sulfate, aluminum sulfate, magnesium sulfate and ferrous sulfate to the reaction kettle, and stir evenly to obtain the primary fertilizer product;

[0054] (3) Rolling: Mix the primary ...

Embodiment 3

[0065] raw material:

[0066] Urea 10kg, phosphoric acid 15kg, potassium hydroxide 35kg, reaction aid 16kg, water 1kg, modified montmorillonite powder 20kg, calcium sulfate 0.8kg, aluminum sulfate 0.4kg, magnesium sulfate 0.6kg and ferrous sulfate 0.9kg.

[0067] Preparation:

[0068] (1) Pulverization: Mix urea, phosphoric acid and potassium hydroxide uniformly and then pulverize to obtain solid particle powder with uniform particle size;

[0069] (2) Dry reaction: put the solid particle powder into the reaction kettle, use a sprinkler to spray the reaction aid and water on the surface of the solid particle, so that the reaction aid and the solid particle material are evenly mixed, and adjust the humidity in the reaction kettle After reacting at room temperature for 40 minutes, calcium sulfate, aluminum sulfate, magnesium sulfate and ferrous sulfate were added to the reaction kettle, and the primary fertilizer product was obtained after stirring evenly;

[0070] (3) Rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com