Sewage treatment device and method integrating electric flocculation, magnetic flocculation and magnetic separation

A sewage treatment device and technology for sewage treatment, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. The process is complex and other problems, to achieve the effect of improving the flocculation effect and settling speed, broad development space and market prospects, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

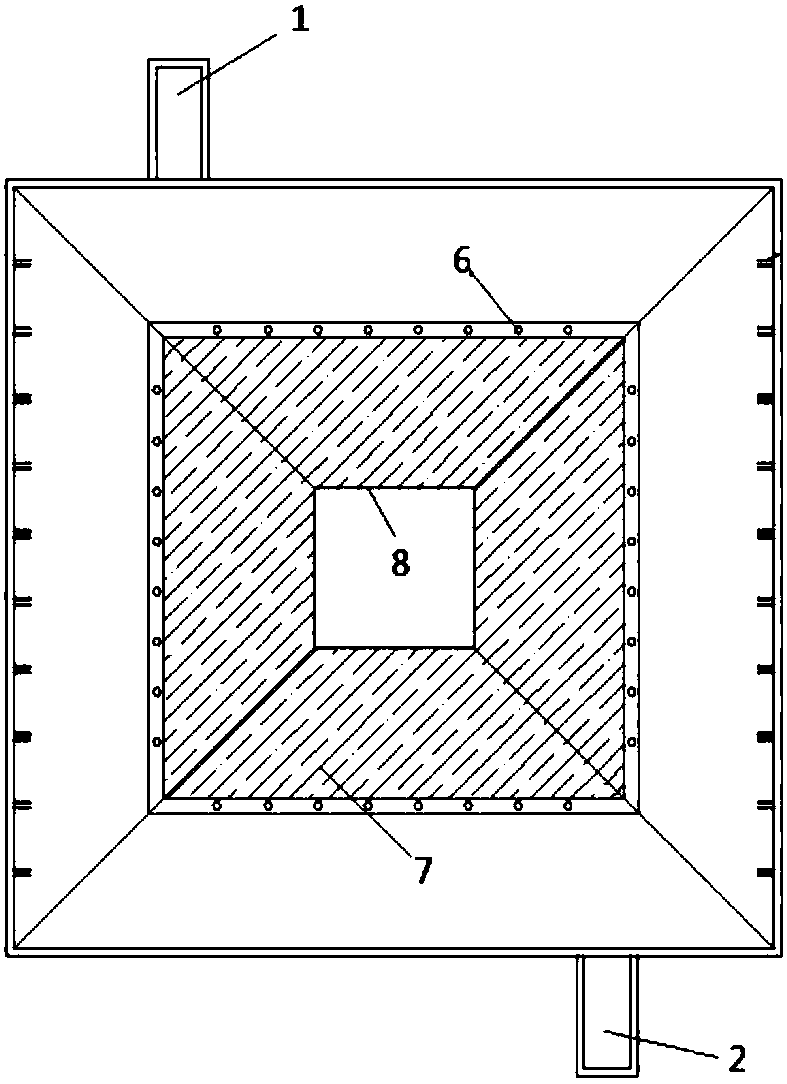

[0041] Such as figure 1 As shown, this embodiment provides a sewage treatment reaction tank 10 integrating electrocoagulation, magnetic flocculation and magnetic separation, including a water inlet 1 , a water outlet 2 , an aeration device 6 , an electromagnetic induction device 7 and a sludge discharge port 8 . The two side walls outside the reaction tank 10 are respectively provided with a water inlet 1 and a water outlet 2, the bottom side walls of the reaction tank 10 are respectively provided with an aeration device 6 and an electromagnetic induction device 7, and the center of the bottom of the reaction tank 10 is provided with a row mud mouth 8.

[0042] During use, the sewage enters the reaction tank 10 from the water inlet 1, and the reaction tank 10 is controlled to perform electric flocculation, the electromagnetic induction device 7 performs magnetic flocculation, and the aeration device 6 makes the mixing of the sewage more uniform during the flocculation process....

Embodiment 2

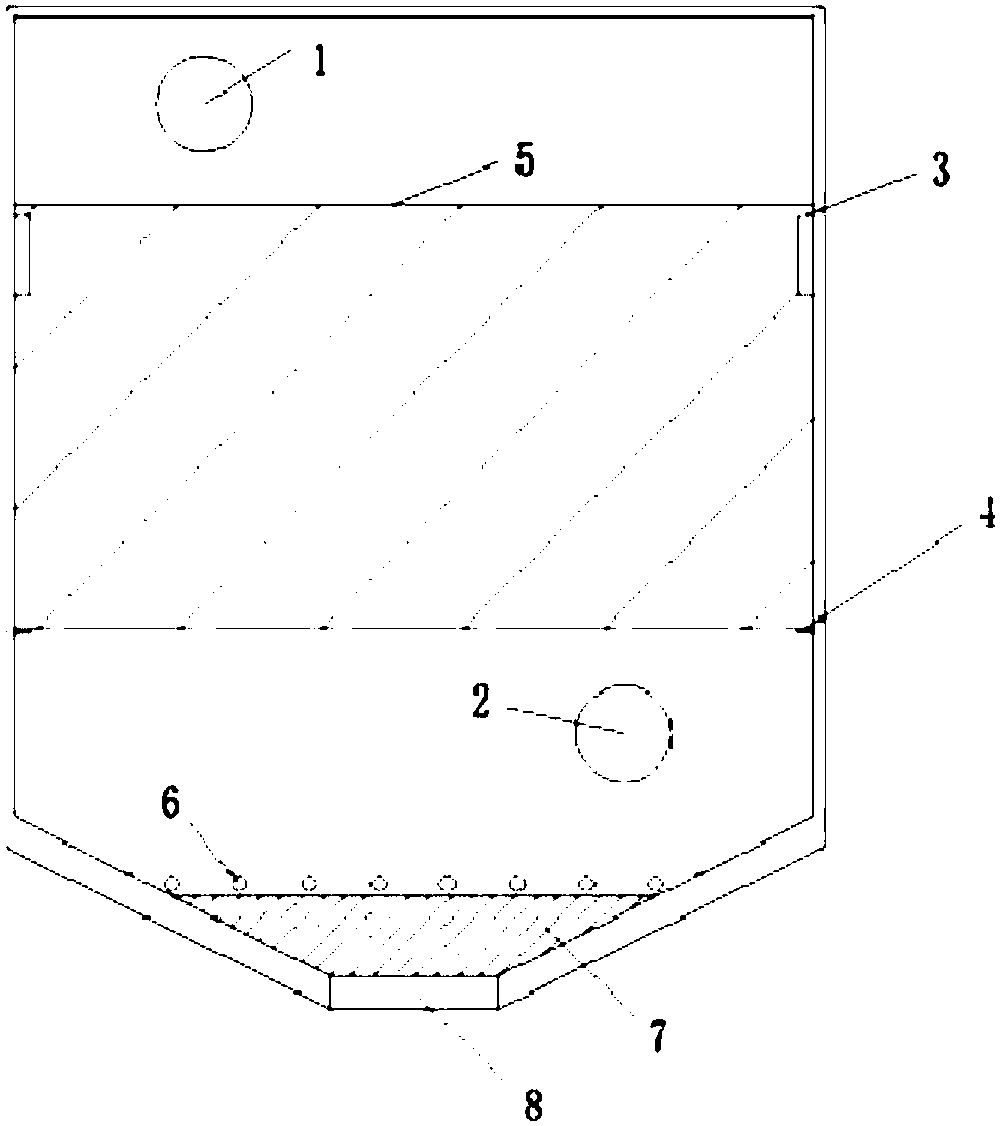

[0044] Such as figure 2 As shown, this embodiment provides a sewage treatment reaction tank 10 integrating electrocoagulation, magnetic flocculation and magnetic separation, including a water inlet 1, a water outlet 2, an electrode slot 3, an electrode support 4, a soluble electrode 5, an exposure Gas device 6, electromagnetic induction device 7 and mud discharge port 8. Wherein, the water inlet 1 and the water outlet 2 are respectively located on the two side walls outside the reaction tank 10, and the position of the water inlet 1 is higher than the position of the water outlet 2, and the electrode clamping groove 3 is located on two opposite surfaces inside the reaction tank 10. , the soluble electrode 5 is placed in the electrode card slot 3 and supported by the electrode support 4, the bottom side wall in the reaction tank 10 is respectively provided with an aeration device 6 and an electromagnetic induction device 7, and the center of the bottom of the reaction tank 10 ...

Embodiment 3

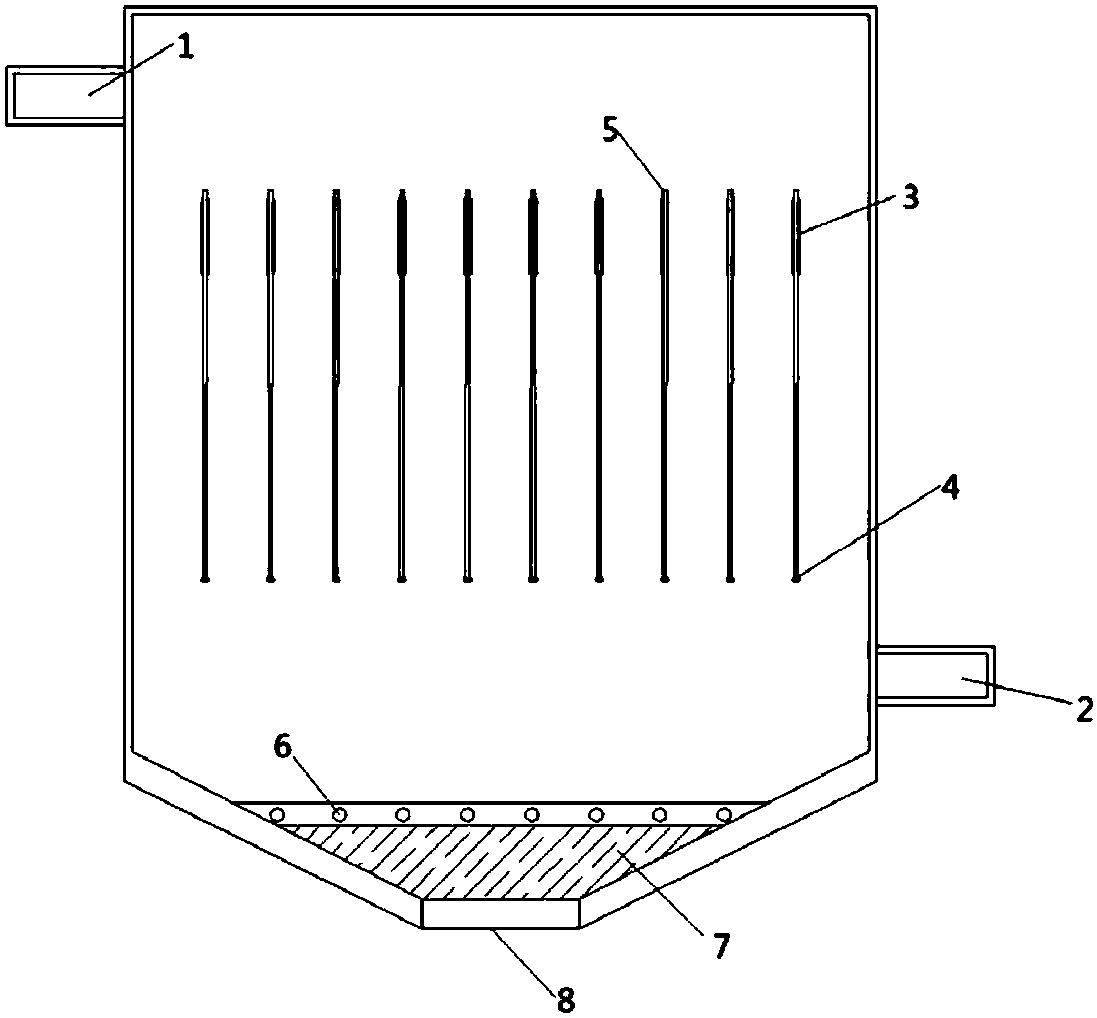

[0049] Such as image 3 As shown, this embodiment provides a sewage treatment reaction tank 10 integrating electrocoagulation, magnetic flocculation and magnetic separation, including: water inlet 1, water outlet 2, electrode card slot 3, electrode support 4, soluble electrode 5, The aeration device 6, the electromagnetic induction device 7 and the mud discharge port 8, wherein the water inlet 1 and the water outlet 2 are respectively located on both sides of the reaction tank 10, and the position of the water inlet 1 is higher than the position of the water outlet 2, and the electrode is stuck in the slot 3 are located on two opposite surfaces inside the reaction tank 10. The soluble electrode 5 is placed in the electrode card slot 3 and supported by the electrode support 4. An aeration device 6 is provided at the middle of the inclined tank wall at the bottom of the reaction tank 10. A mud outlet 8 is provided in the middle of the bottom of the reaction tank 10 , and an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com