Revivification method for catalytic cracking waste catalyst

A waste catalyst and catalytic cracking technology, which is applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited resurrection effect and complicated process, and achieve the reduction of coke yield and increase of liquid Yield, the effect of improving the yield of low-carbon olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

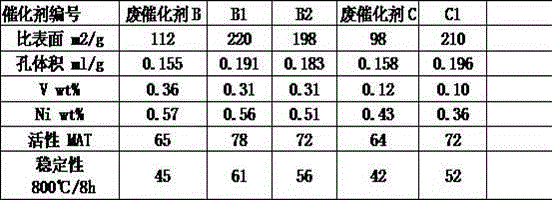

Embodiment 1

[0034] Take 500g of FCC spent catalyst A and place it in a 2000ml beaker, add 600ml of deionized water, add 100g of solid ammonium chloride, add 200ml of fluorosilicic acid solution with a concentration of 8%wt, add hydrochloric acid to adjust the pH value to 2.5, then stir and heat up to 80 ℃, constant temperature for 2 hours; filter and wash with 500ml of deionized water; add 600ml of rare earth chloride solution with rare earth oxide concentration of 100g / L, stir and mix for 30 minutes, filter and dry, and roast at 500℃ for 2 hours; Ammonium phosphate 1%wt solution, stirred for 30 minutes, filtered and dried to obtain the revived catalyst, record A1.

Embodiment 2

[0036] Take FCC waste catalyst A500g and place it in a 2000ml beaker, add 600ml of deionized water, add 100g of solid ammonium chloride, add 200ml of fluorosilicic acid solution with a concentration of 8%wt, add 50g of solid oxalic acid, add nitric acid to adjust the pH value to 2.8, and then Stir and heat up to 80°C, keep the temperature constant for 2 hours; filter, wash with 500ml of deionized water; add 500ml of rare earth chloride solution with a rare earth oxide concentration of 100g / L, stir and mix for 30 minutes, filter and dry, and roast at 500°C for 2 hours Add 400ml of solution containing ammonium phosphate 1%wt, add 500ml of deionized water, stir for 30 minutes, filter and dry to obtain the revived catalyst, record A2.

Embodiment 3

[0038] Take 500g of FCC waste catalyst A and place it in a 2000ml beaker, add 800ml of deionized water, add 130g of solid ammonium chloride, add 300ml of fluorosilicic acid solution with a concentration of 8%wt, add hydrochloric acid to adjust the pH value to 2.3, then stir and heat up to 80 ℃, constant temperature for 2 hours; filter and wash with 500ml deionized water; add 800ml of rare earth chloride solution with rare earth oxide concentration of 100g / L, stir and mix for 30 minutes, filter and dry, and roast at 500℃ for 2 hours; Ammonium phosphate 1%wt solution, stirred for 30 minutes, filtered and dried to obtain the revived catalyst, record A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com