Preparation method and application of catalytic cracking metal passivant

A metal passivator and catalytic cracking technology, which is applied in the direction of catalytic cracking, cracking, treatment equipment corrosion/fouling inhibition, etc., to achieve the effect of increasing the total liquid yield, high thermal decomposition temperature, and increasing the total liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

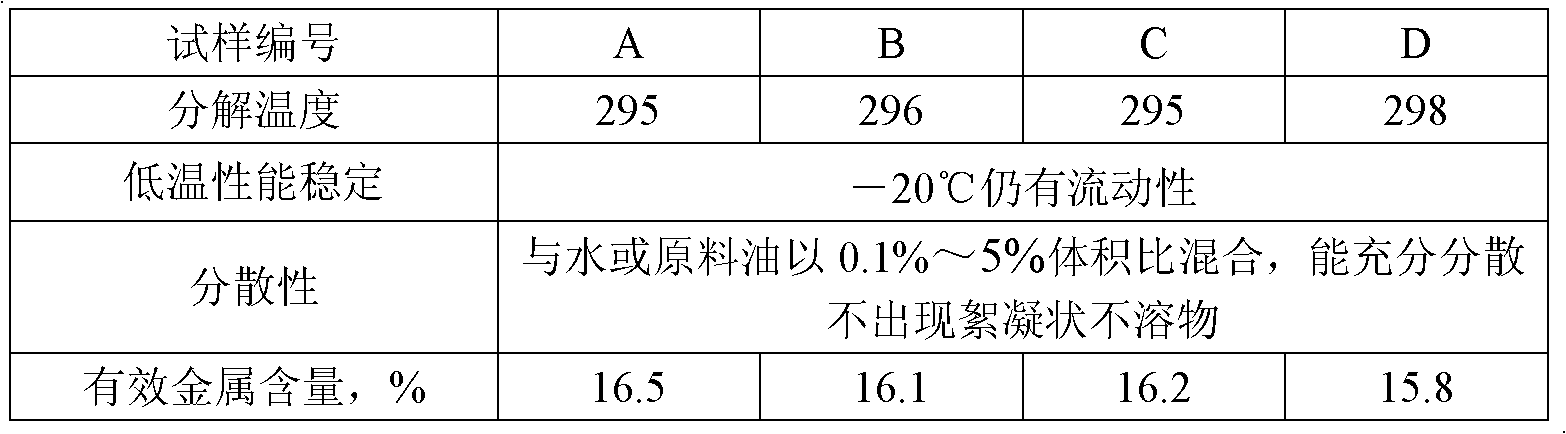

Embodiment 1

[0024] First, add 1000kg of diethanolamine into the stainless steel reaction kettle, raise the temperature to 70-90°C within 1 hour, stir, then add 2300kg of hydrogen peroxide and 1000kg of antimony trioxide in sequence, and keep it warm for 1-5 hours. After the oxidation reaction is completed, cool and add Ethylene glycol 500kg, carboxymethyl cellulose (2% aqueous solution) 100kg stir evenly and filter to remove impurities to obtain water-soluble metal deactivator A.

Embodiment 2

[0026] First add 1500kg of triethanolamine into the stainless steel reaction kettle, heat up to 70-90°C within 1 hour, stir, then add 1600kg of hydrogen peroxide, 800kg of antimony trioxide, 100kg of cerium oxide, 100kg of lanthanum oxide, and 300kg of 68% nitric acid to keep warm After 1 to 5 hours, after the oxidation reaction is finished, cool down, add 500 kg of glycerol and 100 kg of carboxymethyl cellulose (2% aqueous solution) and stir evenly, filter to remove impurities and obtain the water-soluble metal deactivator B.

Embodiment 3

[0028] First, add 1000kg of diethanolamine and 900kg of triethanolamine into the stainless steel reaction kettle, raise the temperature to 70-90°C within 1 hour, stir, then add 1500kg of hydrogen peroxide and 1000kg of antimony trioxide in sequence, and keep it warm for 1-5 hours. , cooling, add ethylene glycol 300kg, glycerol 200kg, carboxymethylcellulose (2% aqueous solution) 100kg and stir to get water-soluble metal deactivator C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com