Patents

Literature

56results about How to "Reduce coke yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

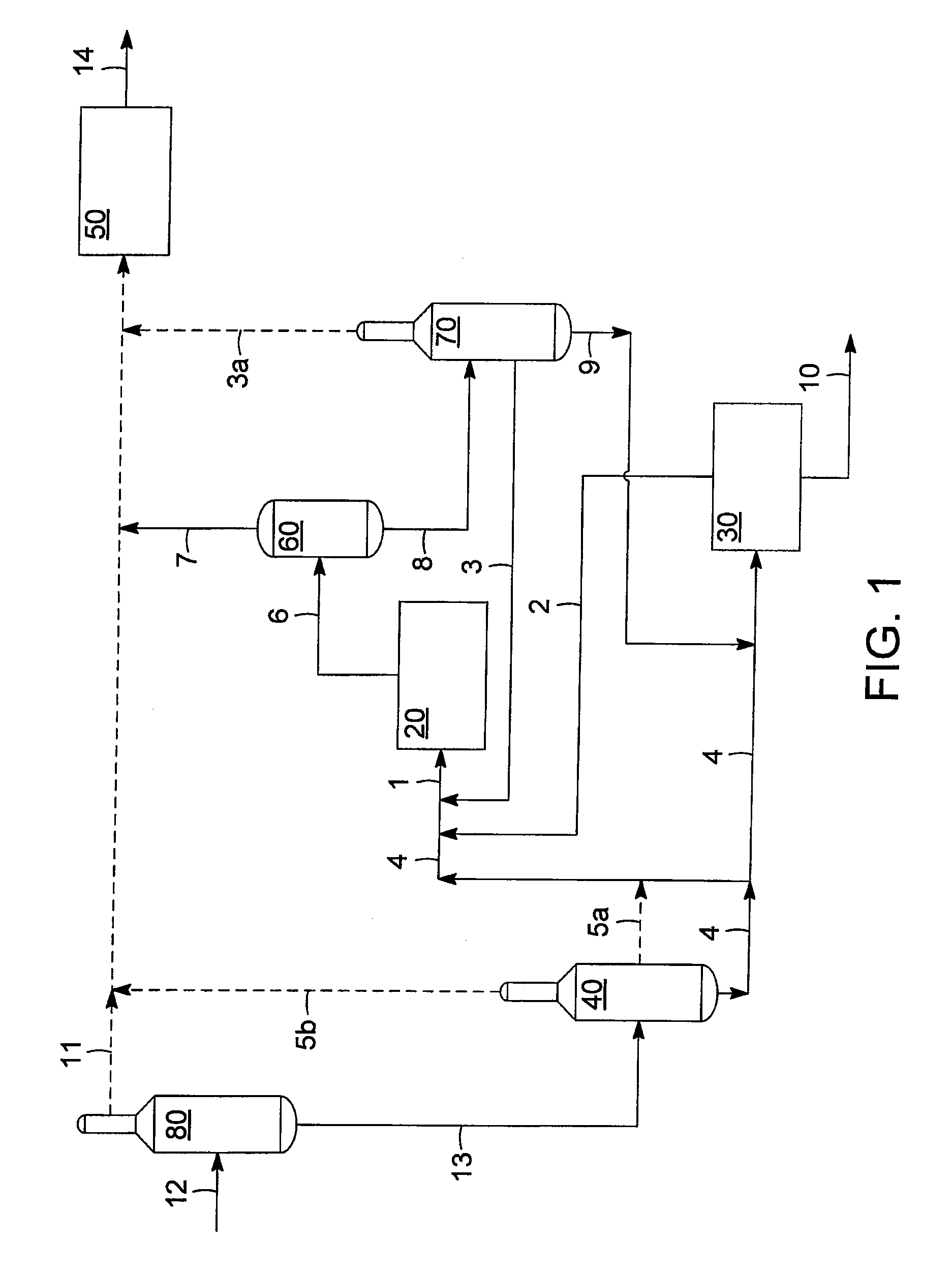

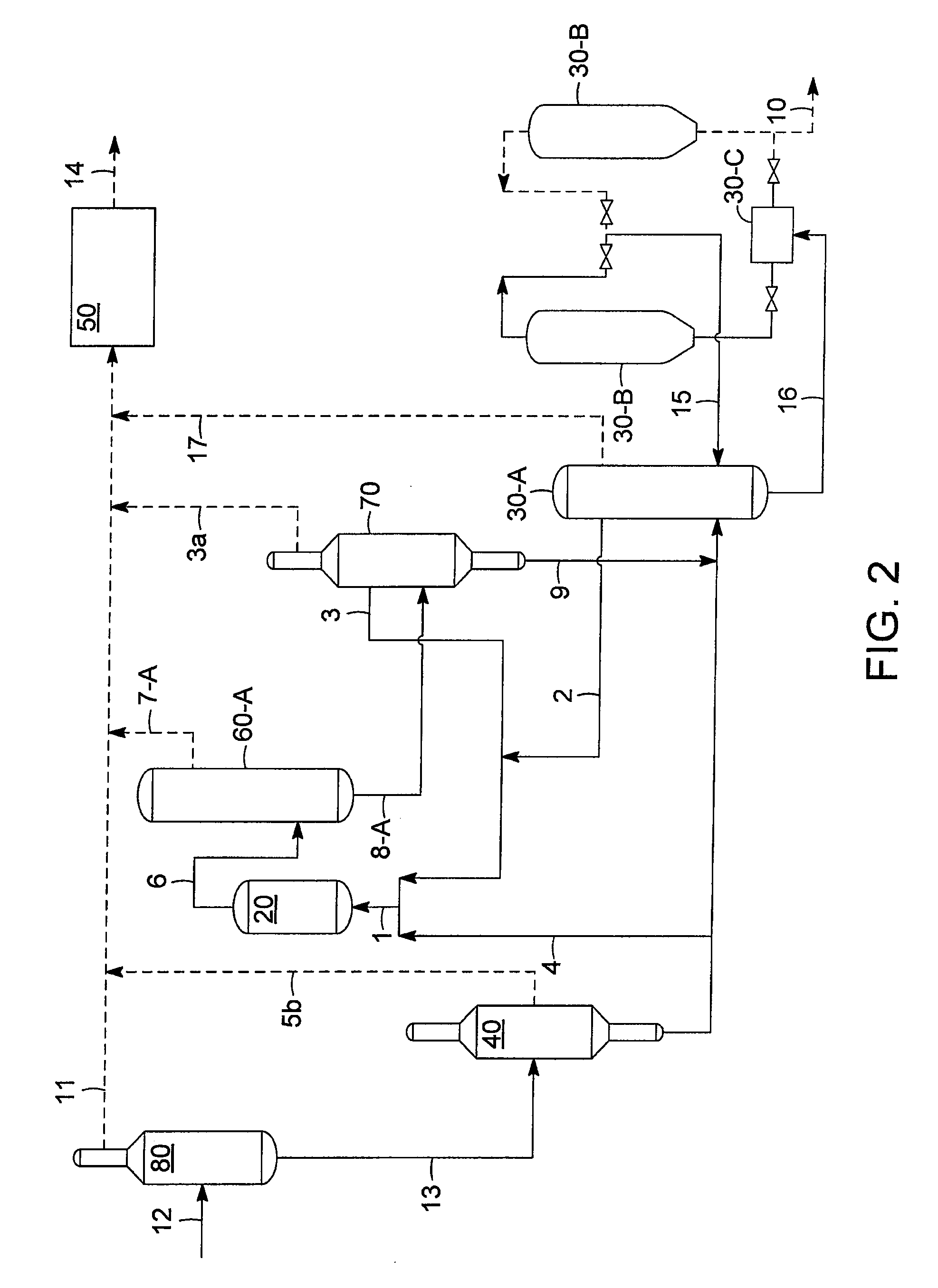

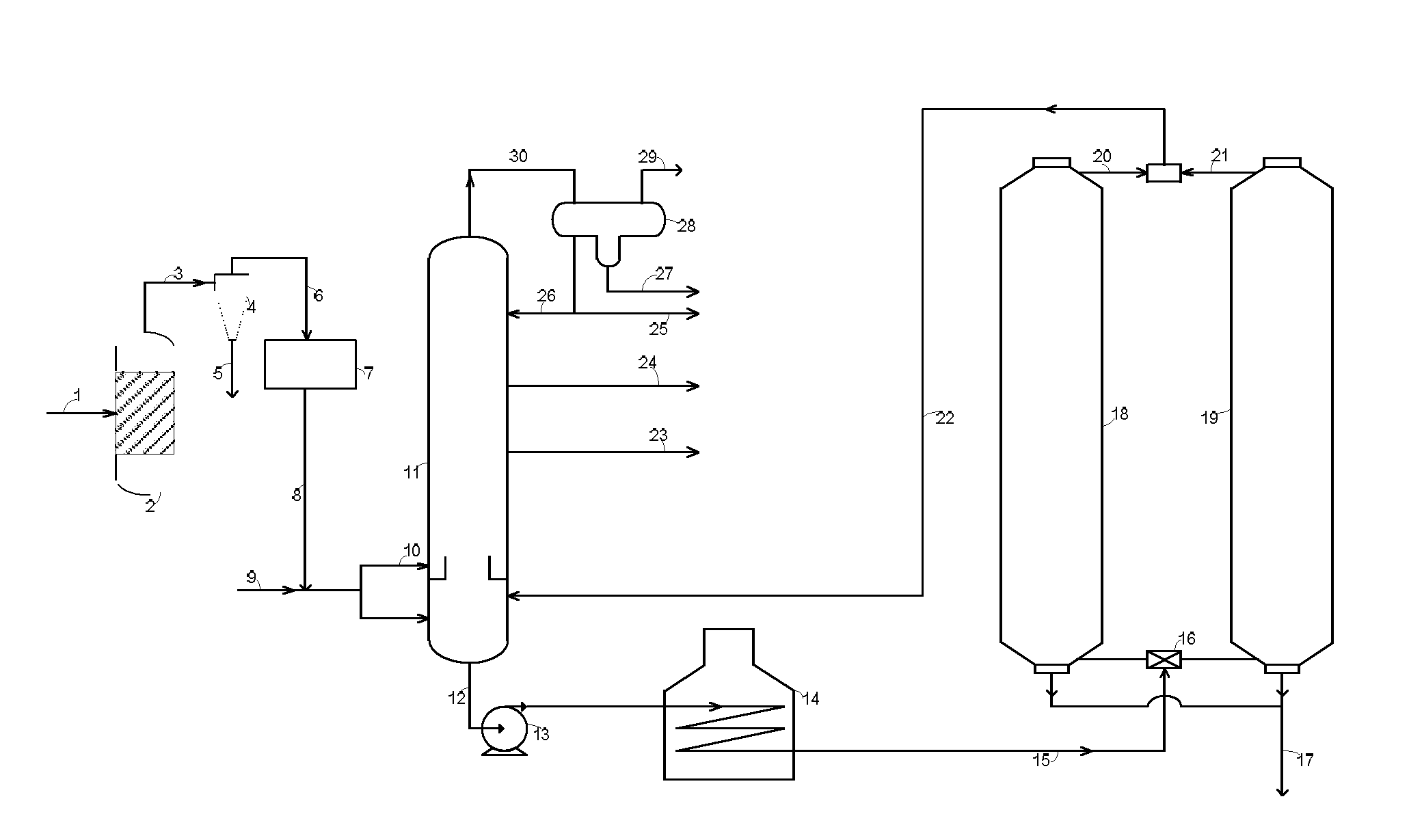

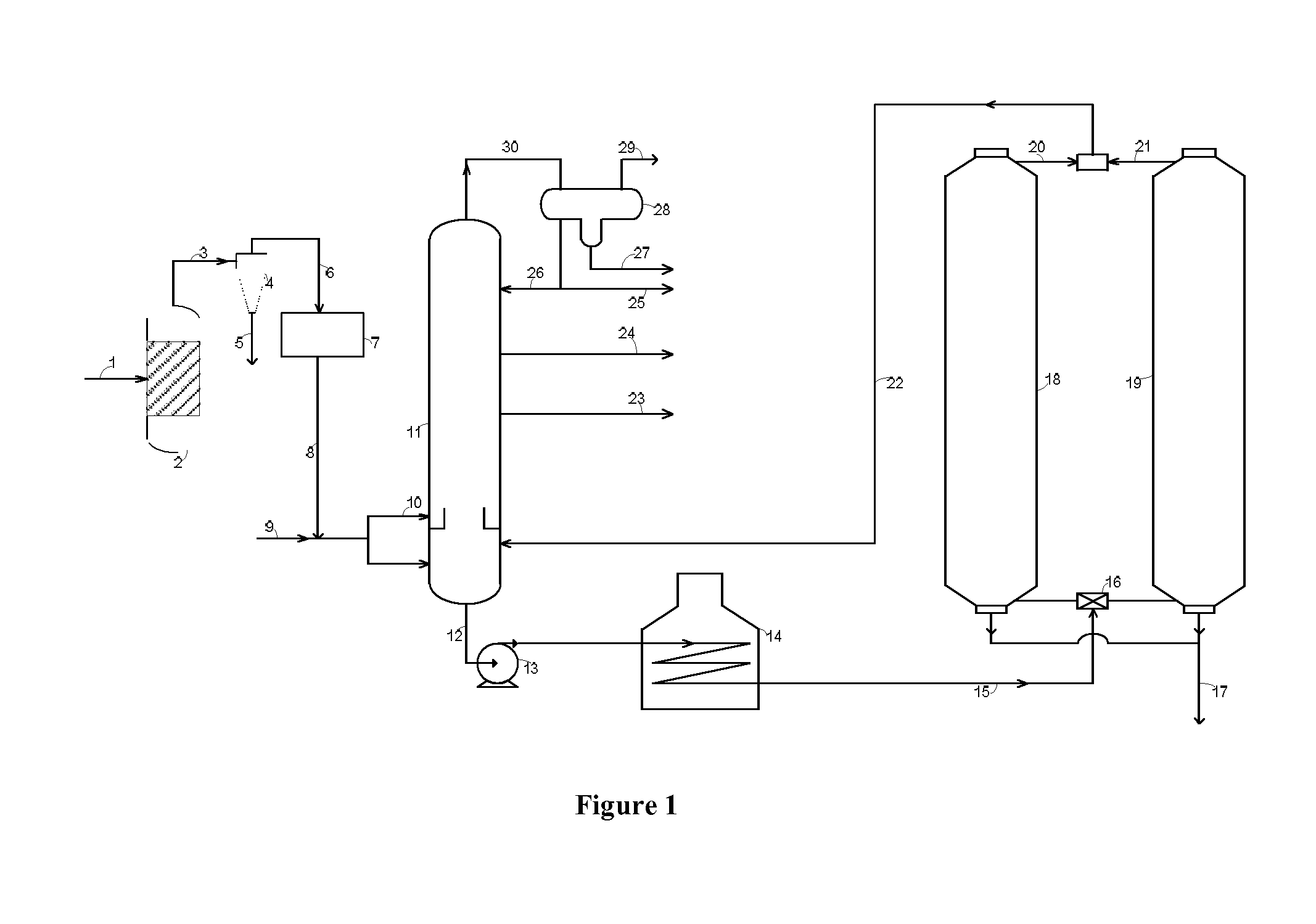

Process for delayed coking of whole crude oil

ActiveUS20120298552A1Enhance thermal cracking reactionReduce coke yieldThermal non-catalytic crackingCatalytic crackingNaphthaFractionating column

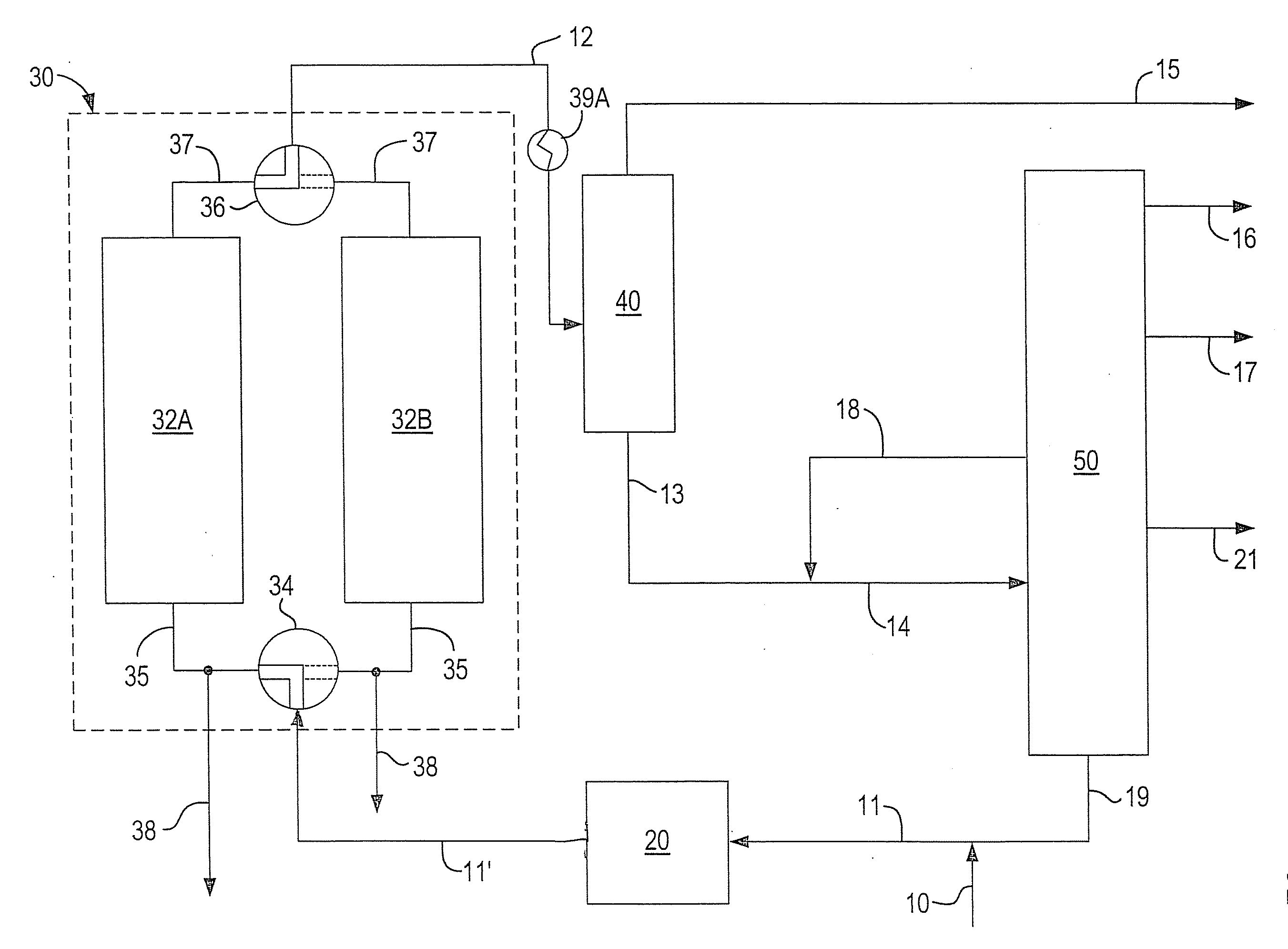

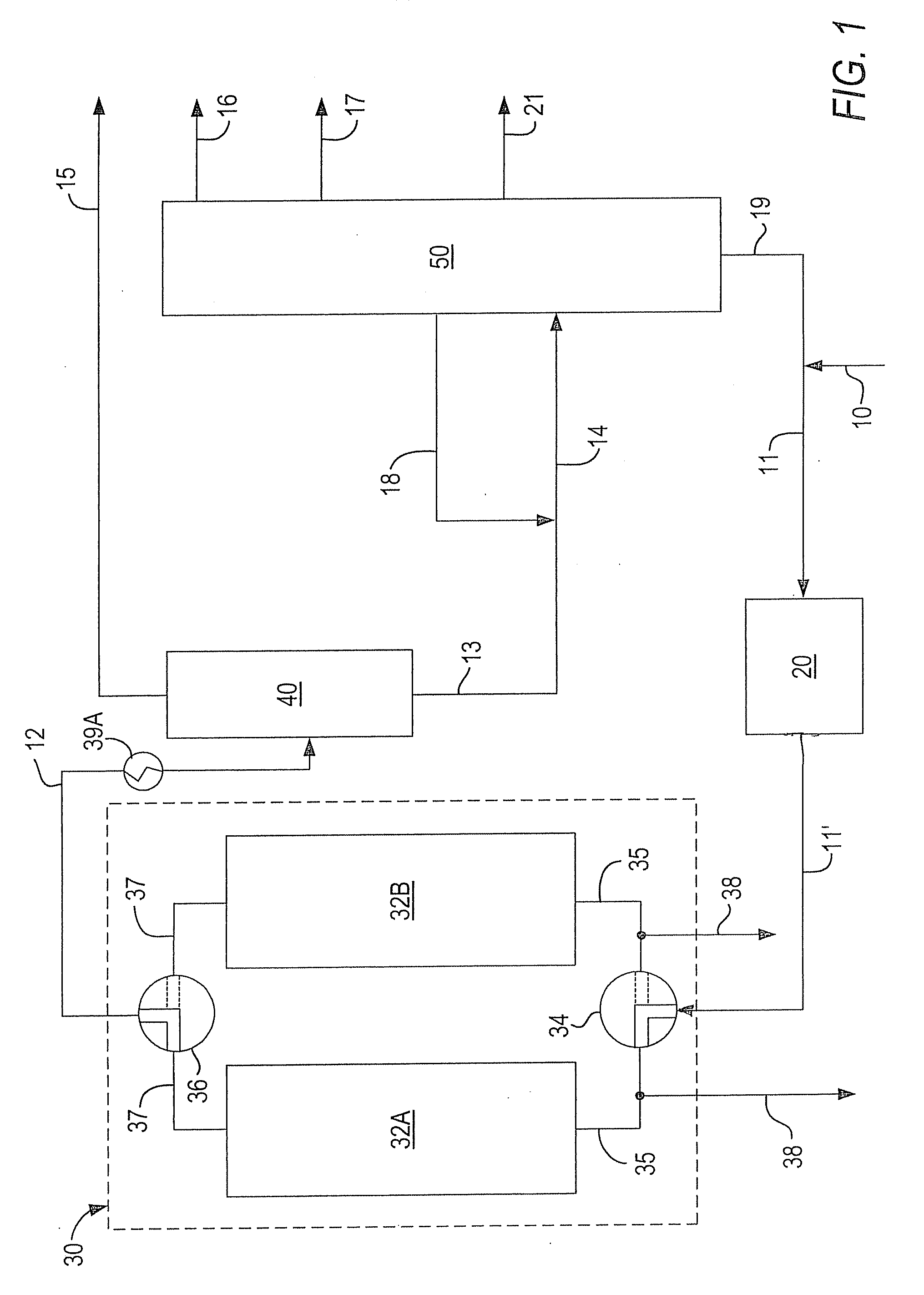

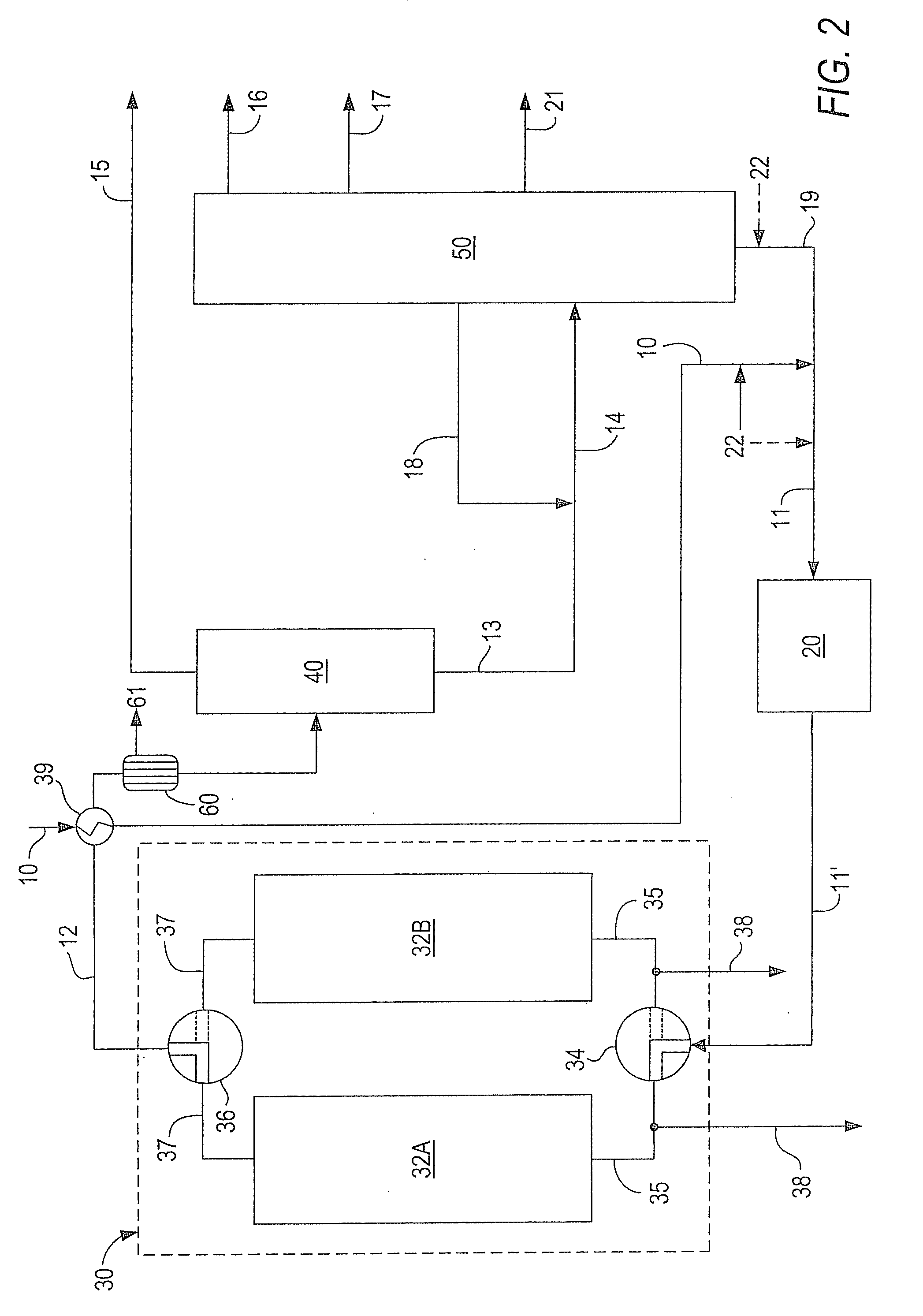

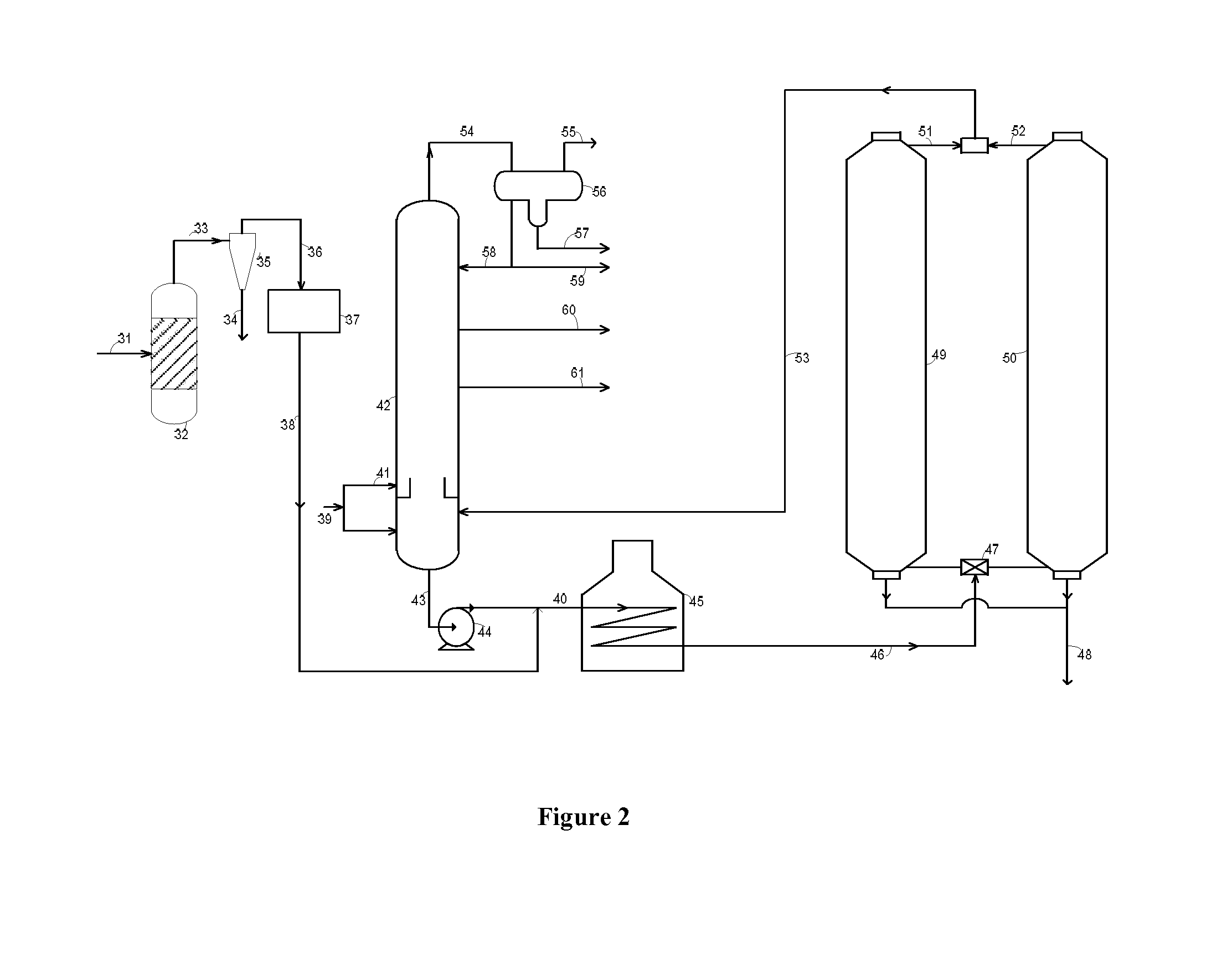

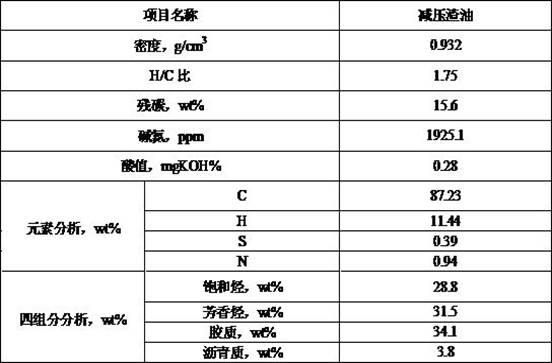

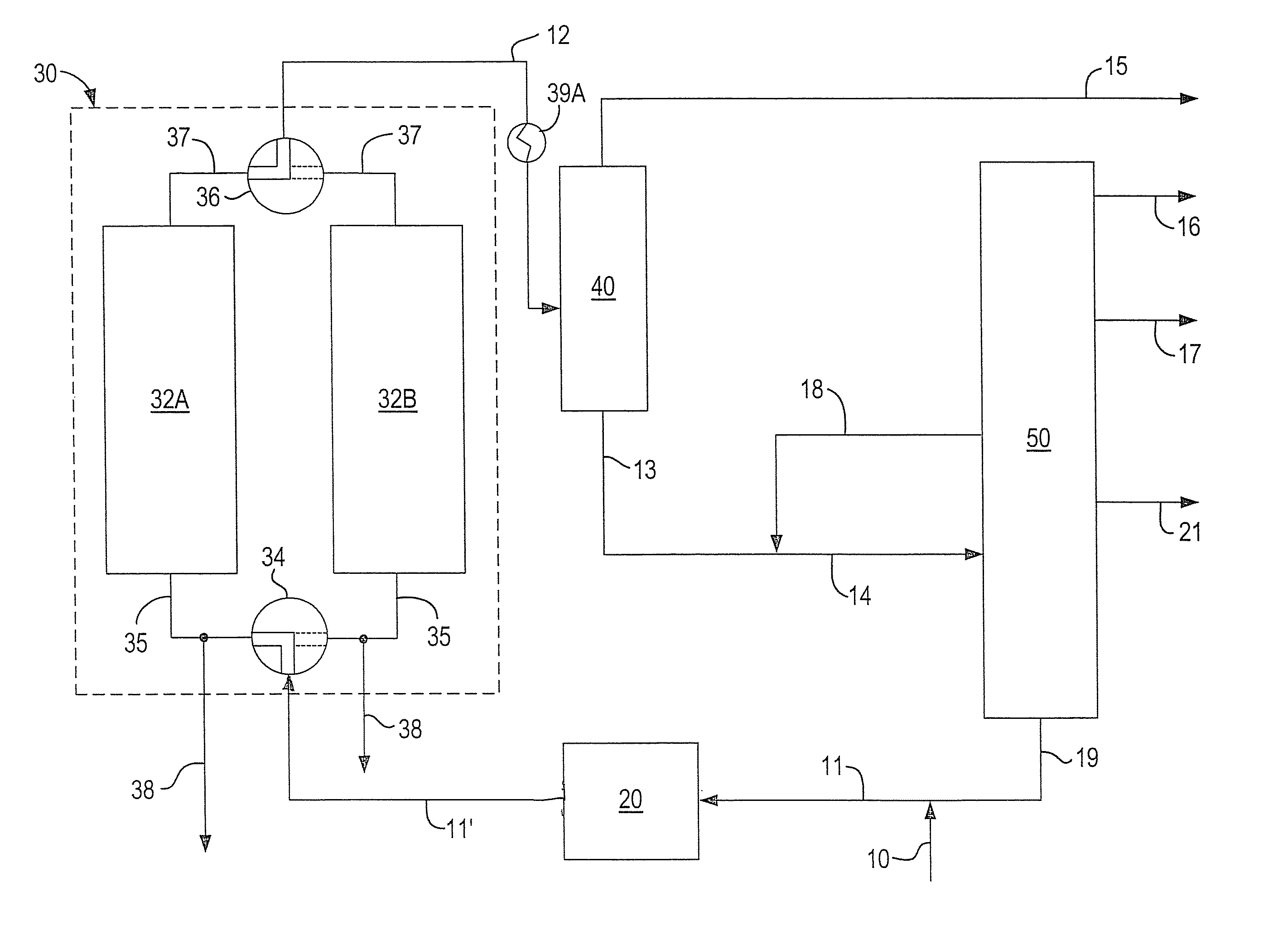

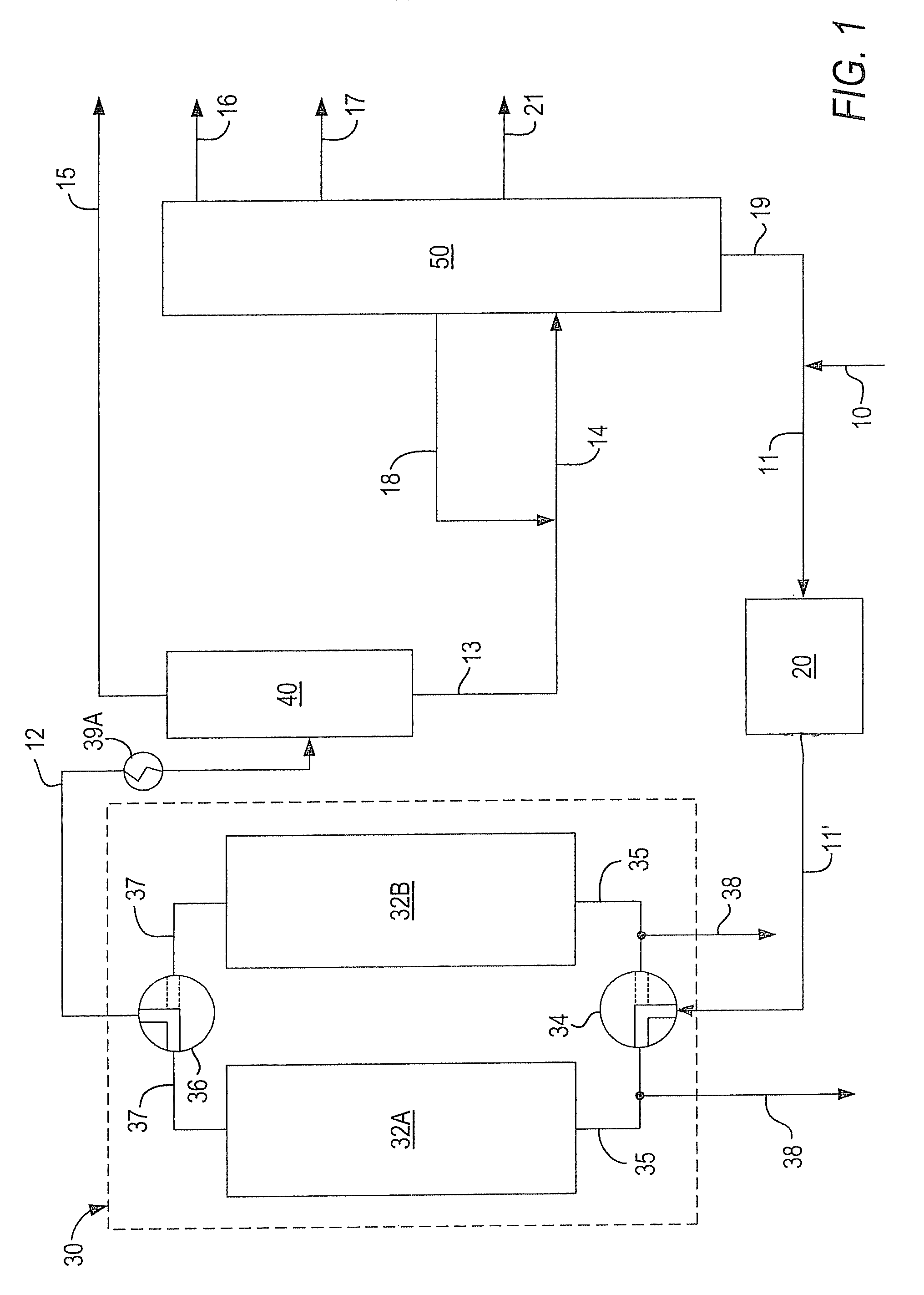

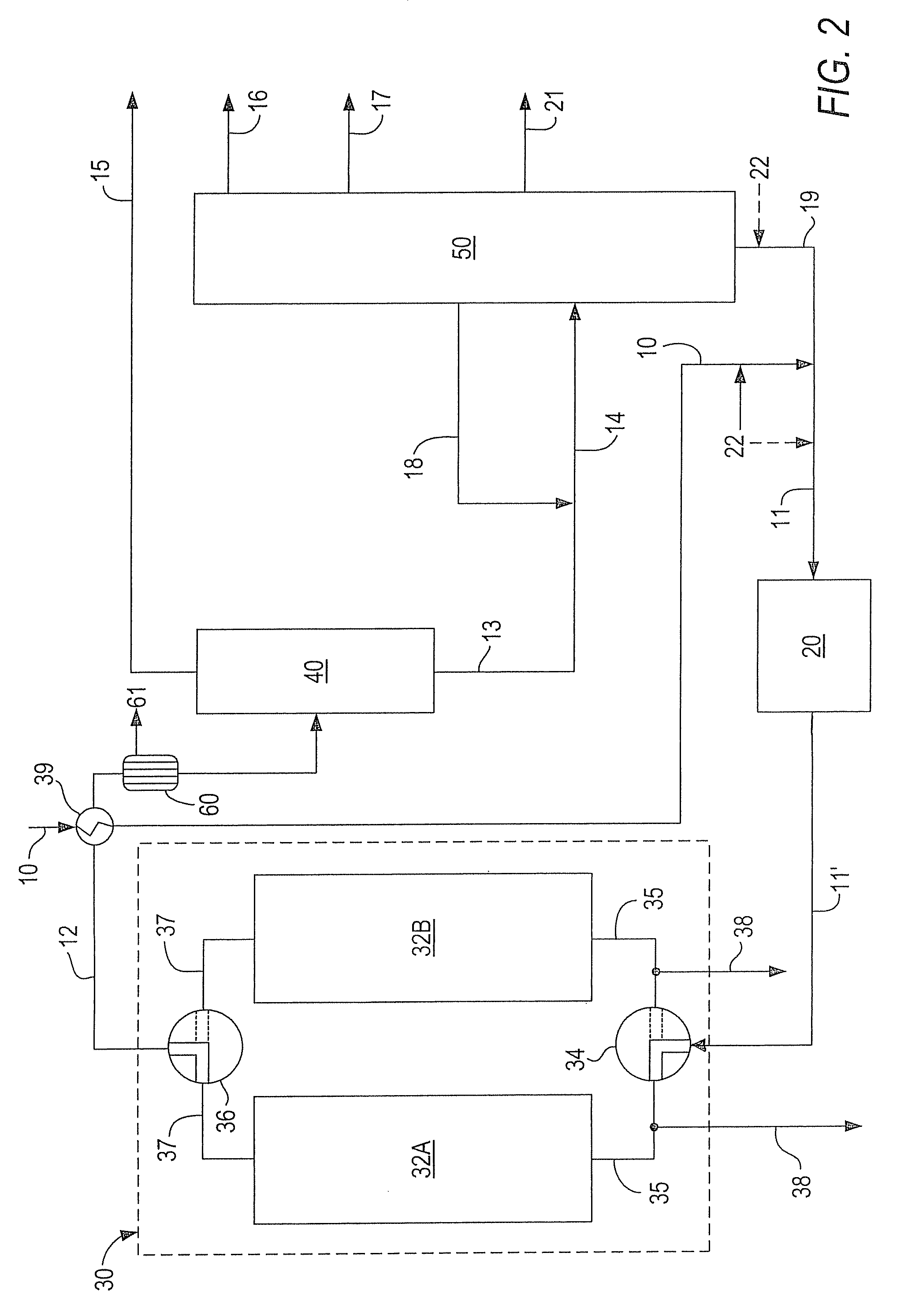

An improved delayed coking process utilizing a coking unit and a coking unit product fractionating column which includes the steps of:heating a mixture of a fresh whole crude oil feedstream and the bottoms from the coking unit product fractionator in a furnace to a coking temperature in the range of 480° C. to 530° C. / 896° F. to 986° F.;introducing the heated mixed whole crude oil and bottoms feedstream directly into the delayed coking unit;optionally passing the vaporized liquid and gaseous coking unit product stream into a flash unit;recovering a light product gas stream that includes H2S, NH3 and C1 to C4 hydrocarbons from the flash unit;transferring the bottoms from the flash unit to the coking unit product fractionating column;recovering as separate side streams from the fractionating column naphtha, light gas oil and heavy gas oil;recycling a portion of the heavy gas oil by introducing it into the fractionating column optionally with the bottoms from the flash unit;mixing the fractionating column bottoms with the whole crude oil feedstream to form the mixed feedstream; andintroducing the mixed whole crude oil and fractionating column bottoms feedstream into the furnace.

Owner:SAUDI ARABIAN OIL CO

Method of raising liquid yield during delayed coking

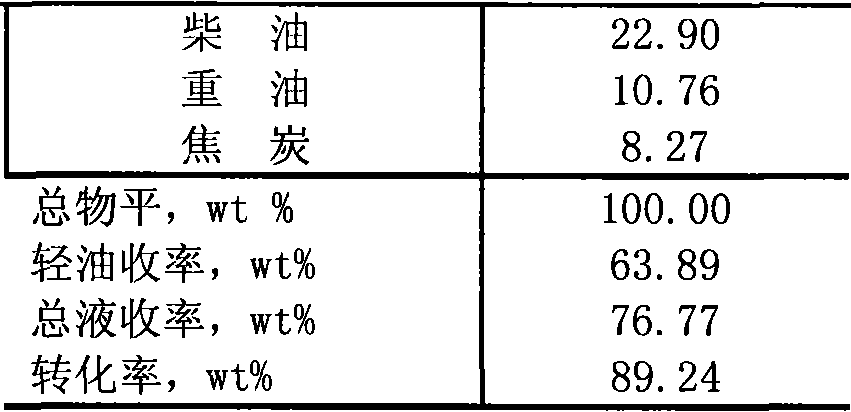

The method of raising liquid yield during delayed coking is to add one kind of low-boiling point evaporant capable of shortening the setting period of distillate oil in coking tower, and reducing the possibility of secondary cracking and re-condensation of hydrocarbon to form coke. The evaporatn may be gasoline, hydrogenated coked gasoline, organic alcohol, gaseous hydrocatbon or their mixture; and may be added into the fed material before coking tower, into the distillate oil in the back of coking tower and / or into the coking tower. The present invention can raise liquid yield by 2-8% and lower coke yield by over 2%.

Owner:曹炳铖

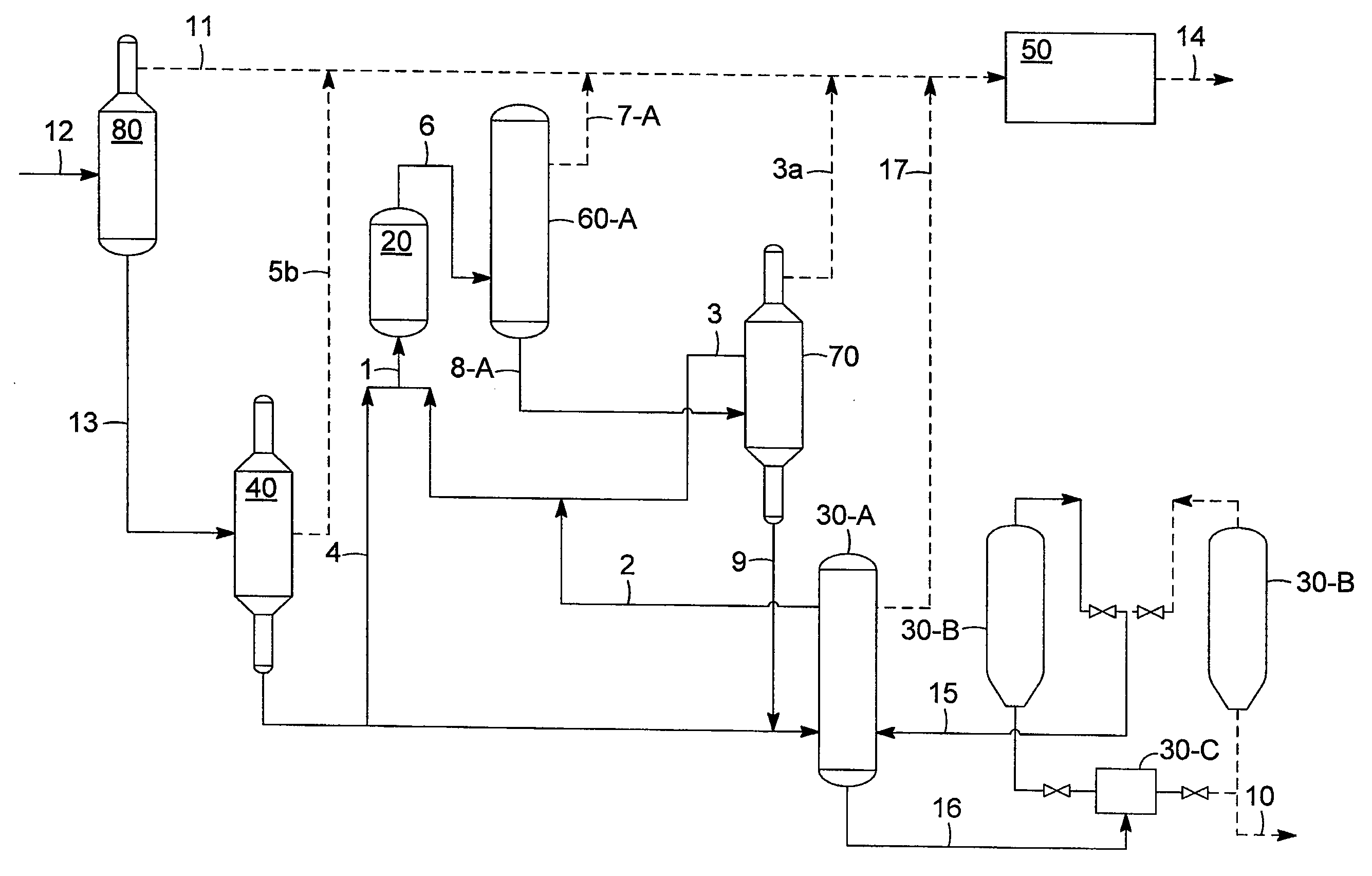

Integrated Slurry Hydrocracking and Coking Process

InactiveUS20100122932A1High value distillateIncrease valueThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesHydrogen

Integrated slurry hydrocracking (SHC) and coking methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a recycle SHC gas oil, a coker gas oil, a vacuum column resid, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Recovery of an SHC pitch from fractionation of the SHC reaction zone effluent provides an additional possibility for integration with the coker, and particularly via the upgrading of the SHC pitch in the coker to provide coke and lighter hydrocarbons such as SHC vacuum gas oil (VGO).

Owner:UOP LLC

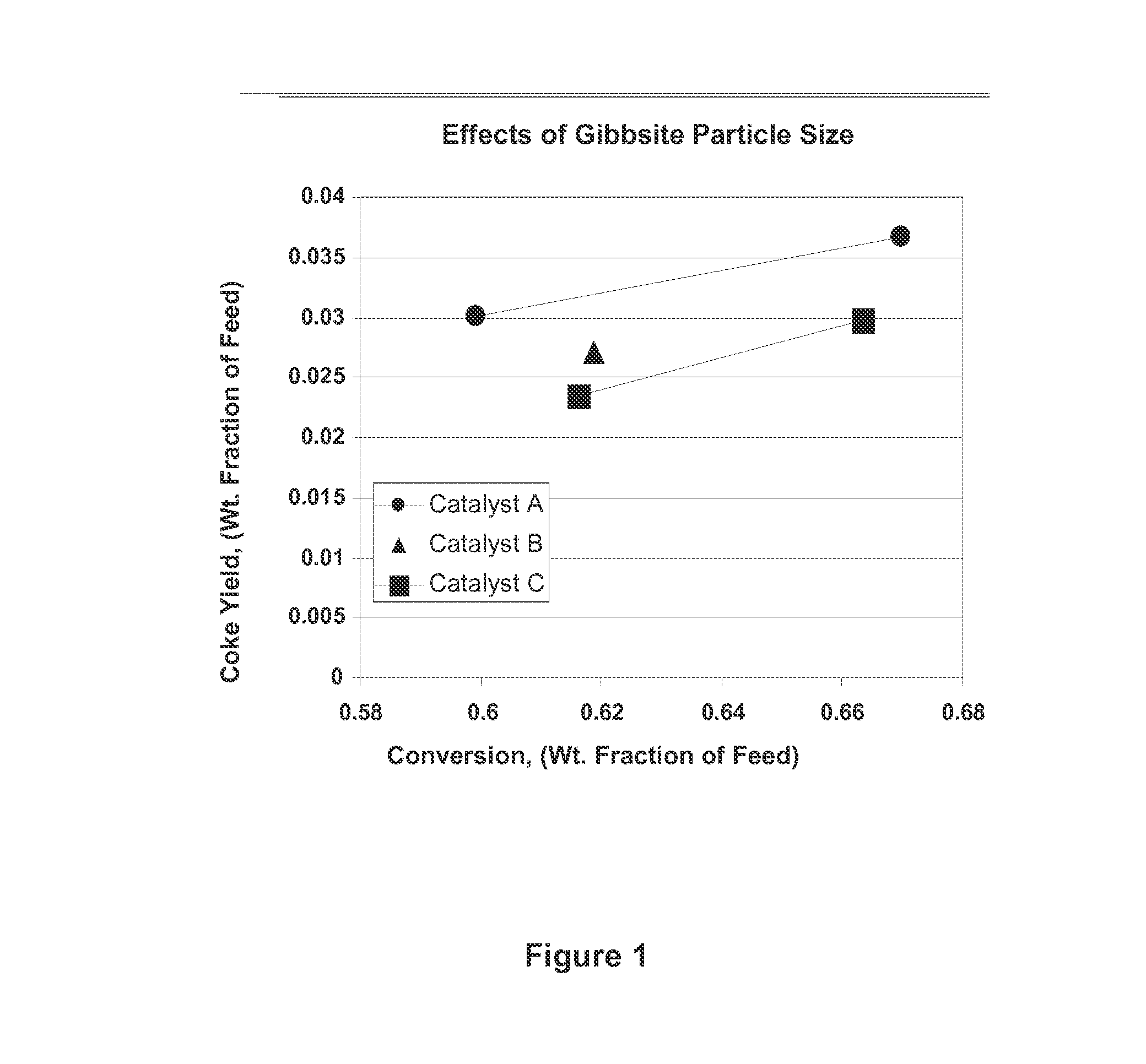

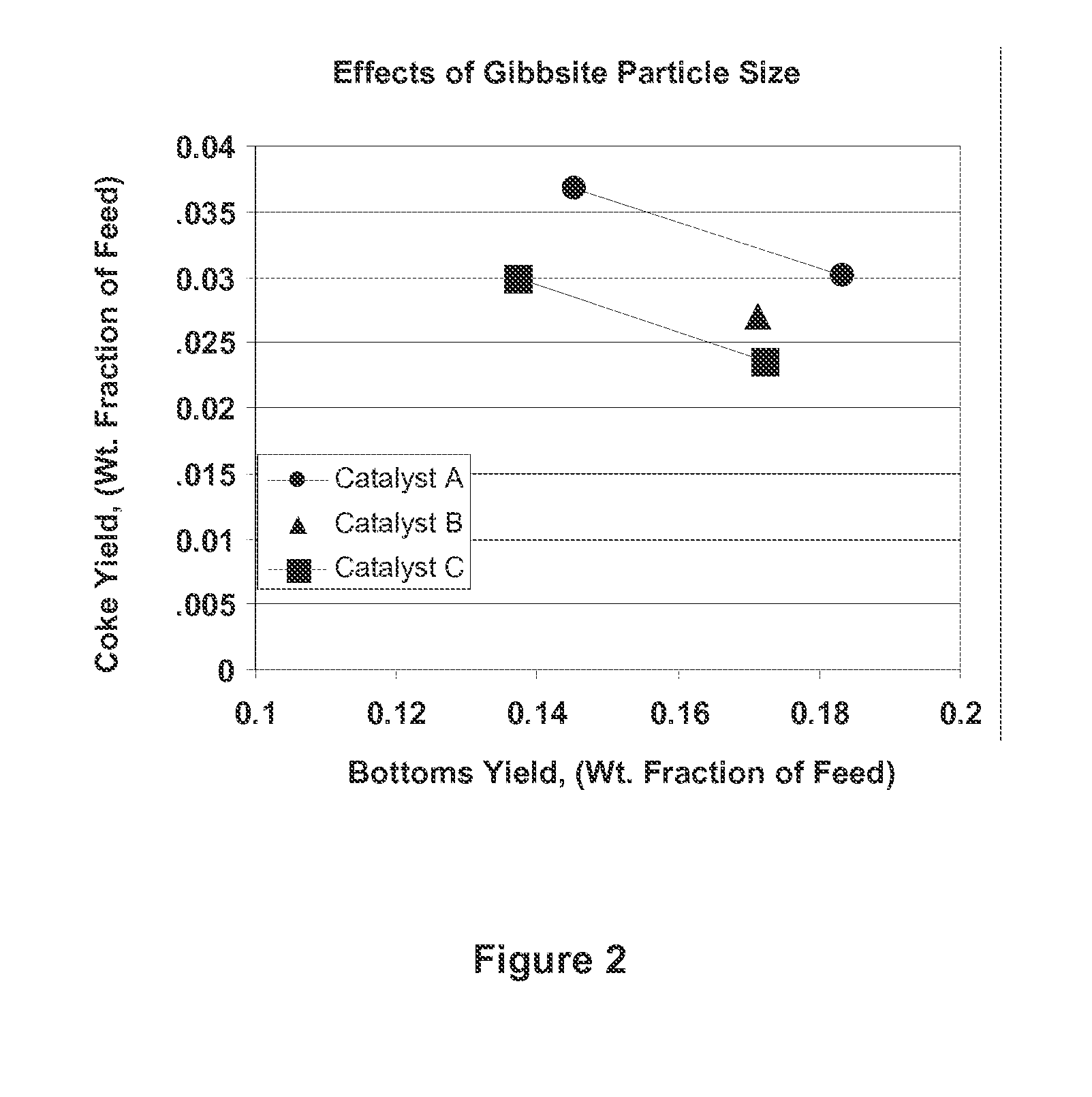

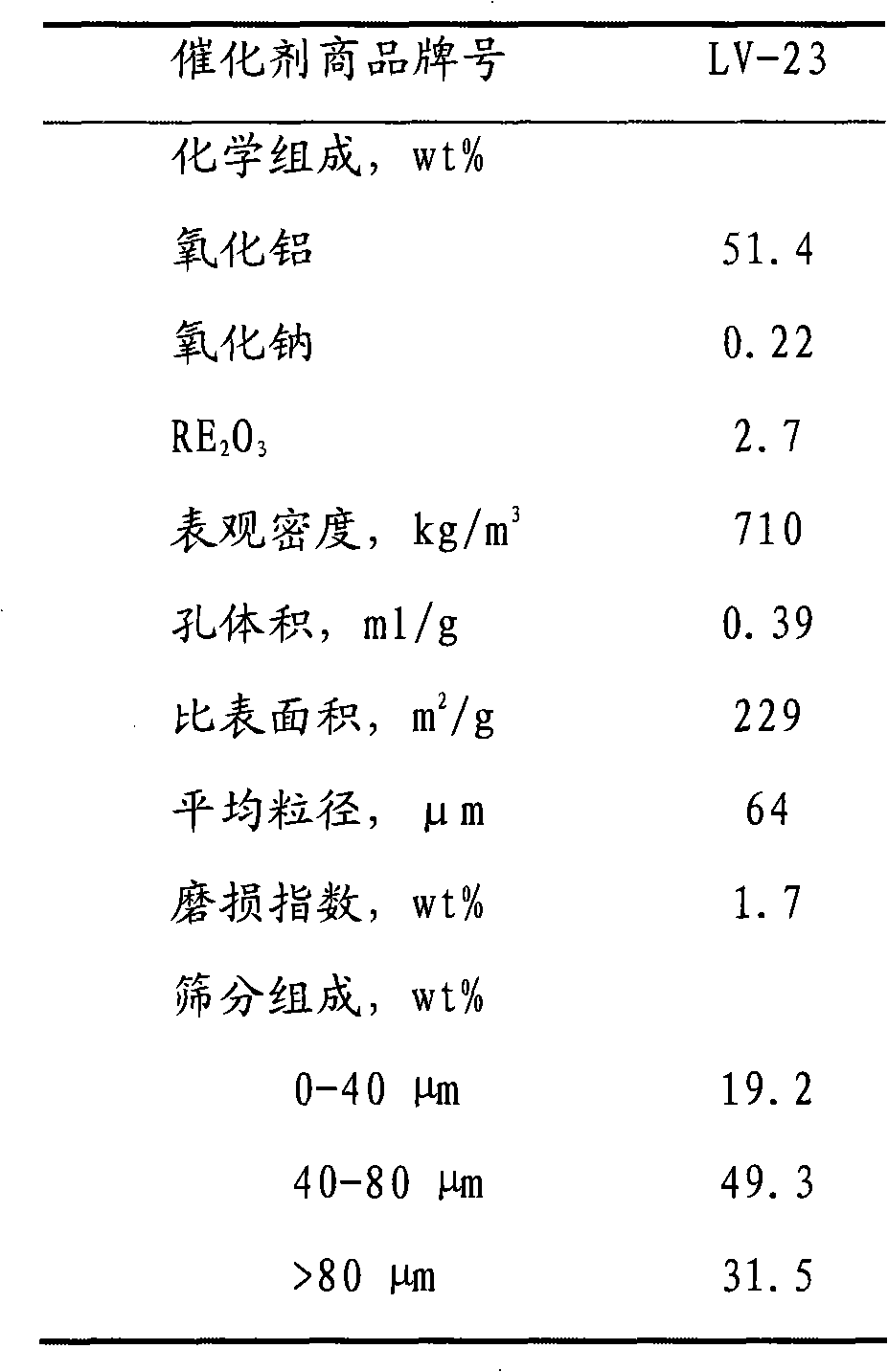

Gibbsite catalytic cracking catalyst

InactiveUS20130131419A1Reduce coke yieldCatalytic crackingMolecular sieve catalystsFaujasiteOrganic chemistry

A fluid catalytic cracking catalyst exhibiting reduced coke make comprises a zeolite cracking component in a matrix of gibbsite having a median particle size of not more than 0.4 microns and preferably not more than 0.3 microns. The zeolite cracking component will normally be a faujasite, with preference to zeolite Y in its various forms such as Y, HY, REY, REHY, USY, REUSY and secondary zeolite additives may be present, including ZSM-5.

Owner:EXXON RES & ENG CO

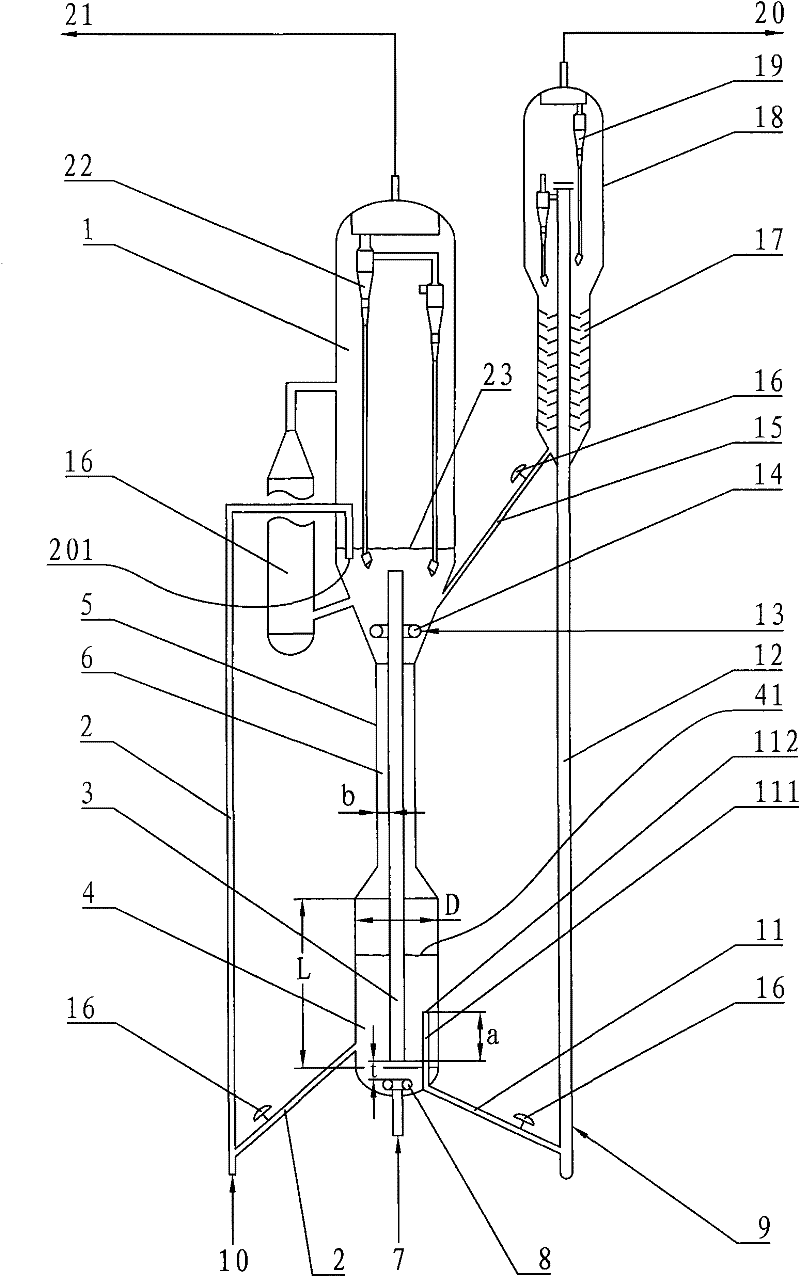

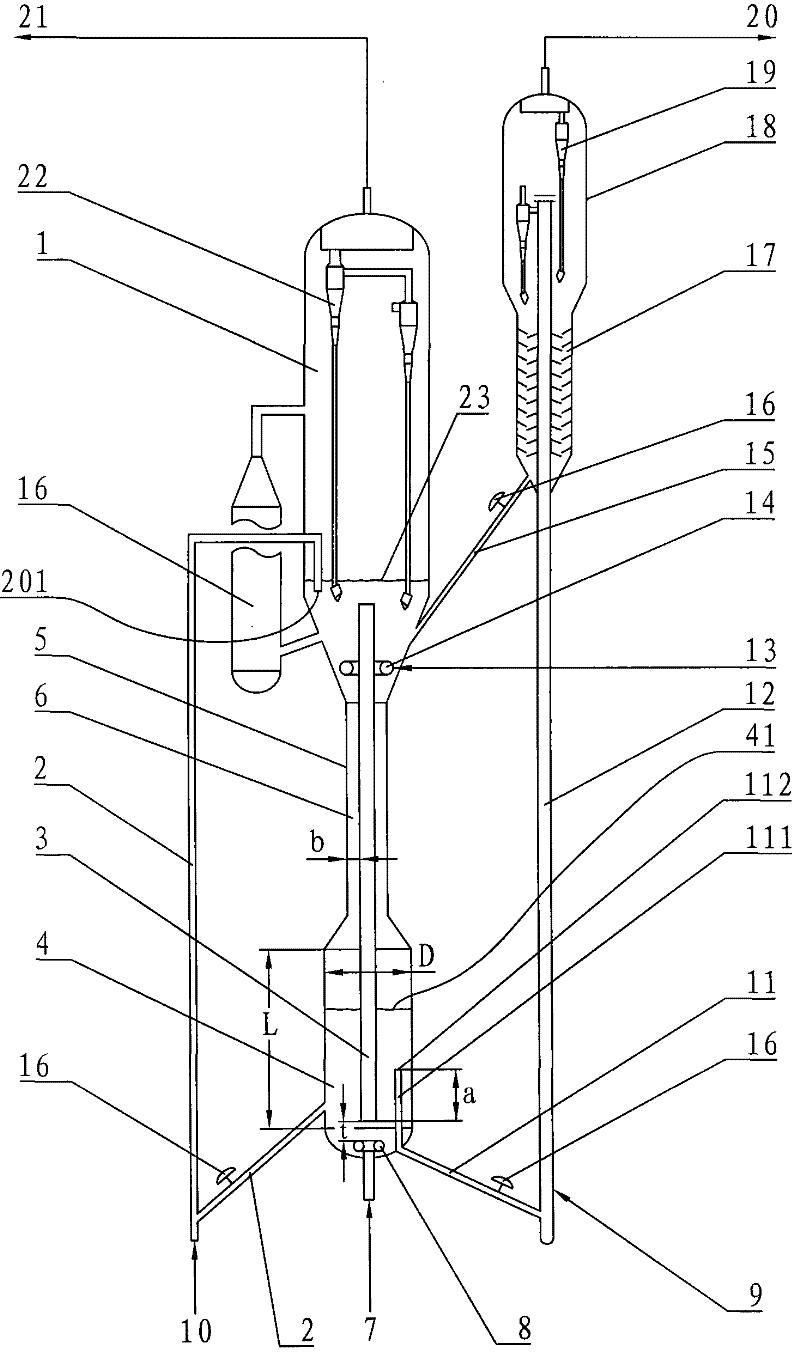

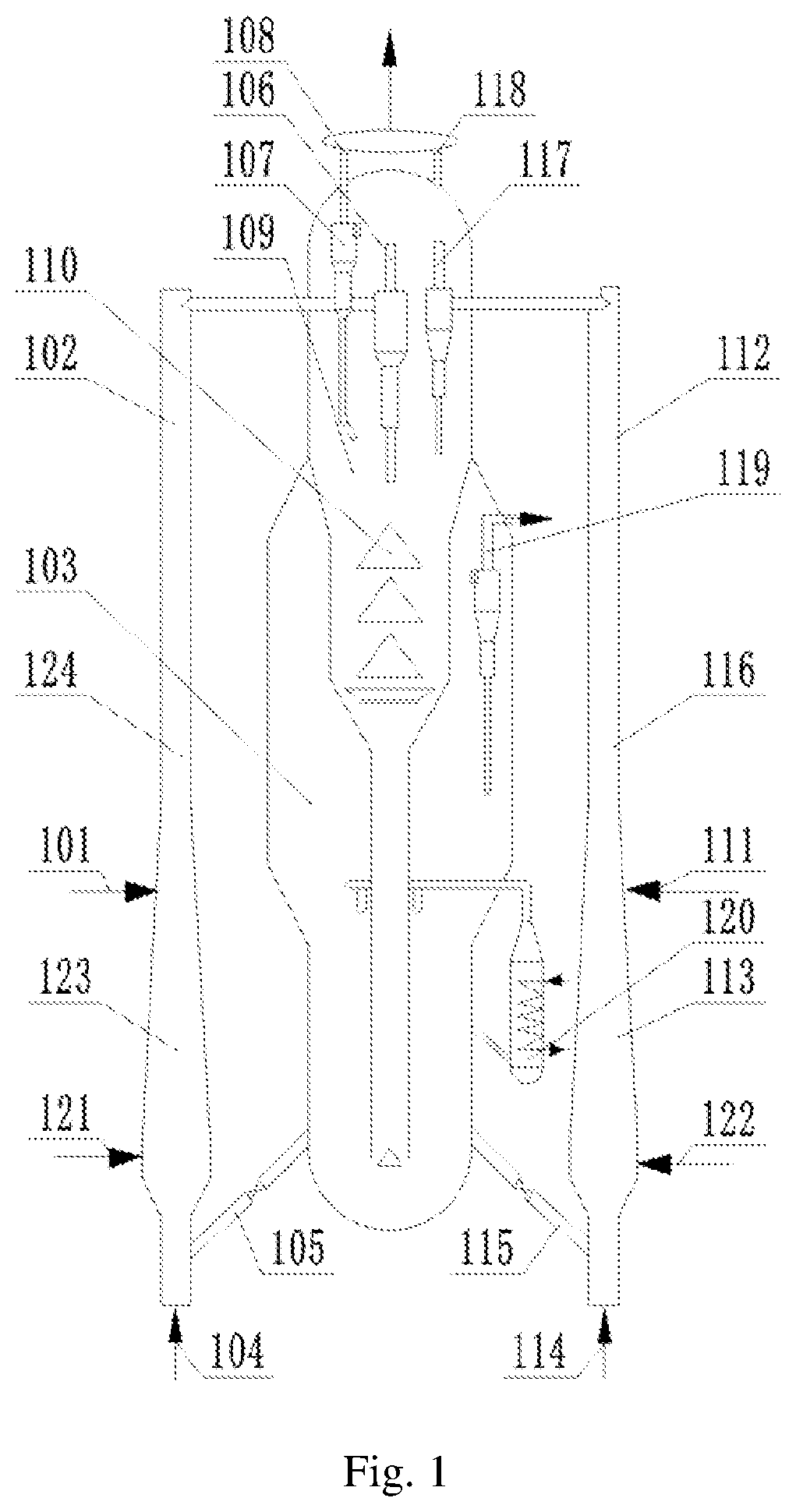

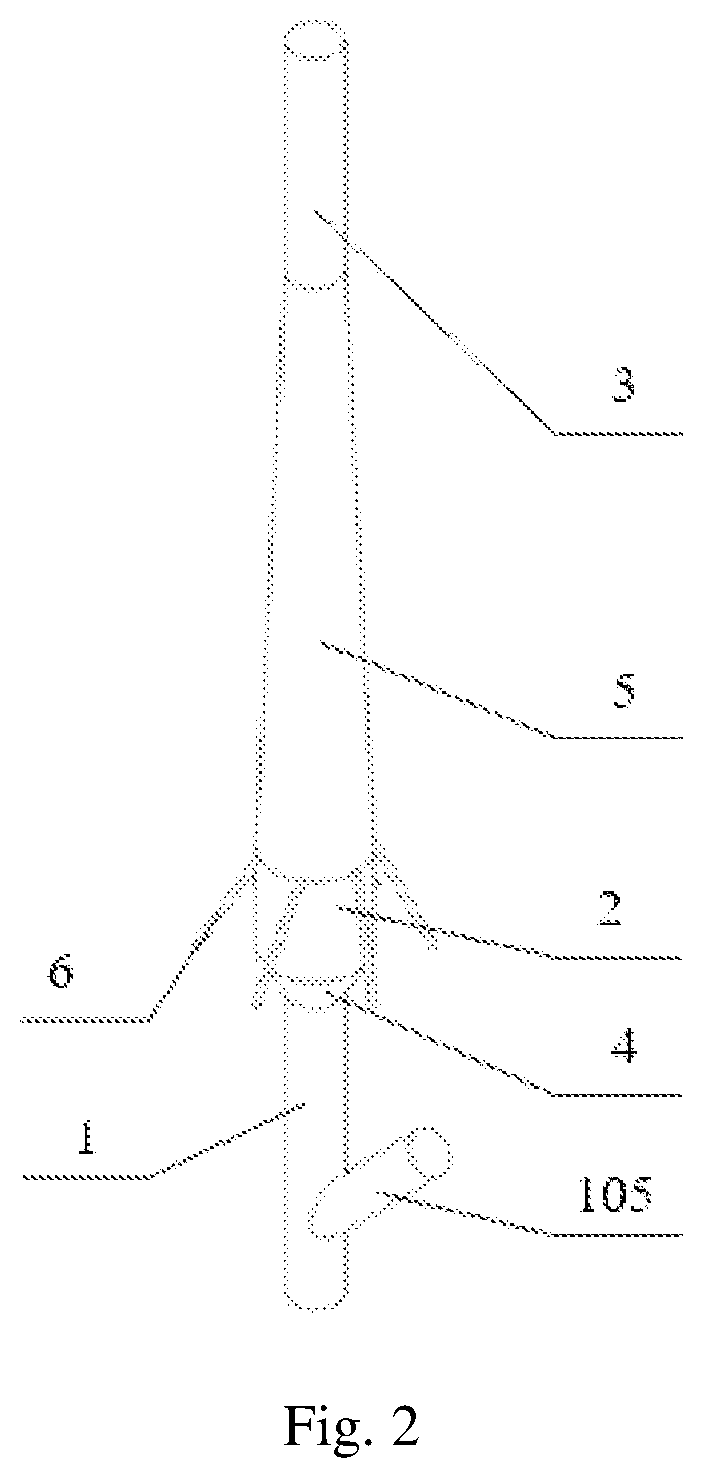

Device and method for reducing the temperature of catalytic cracking regenerated catalyst

Owner:CHINA PETROCHEMICAL CORP +1

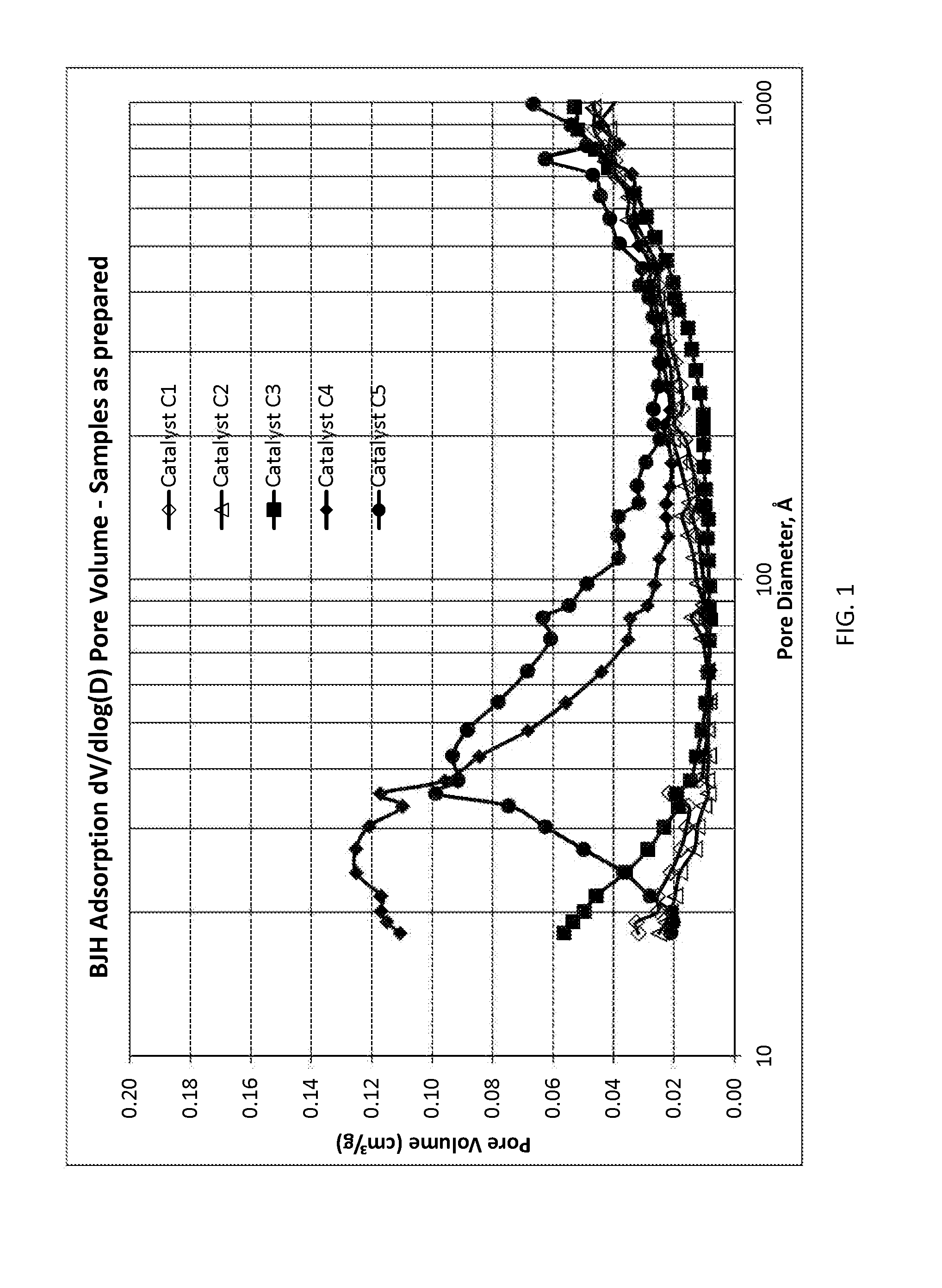

Hybrid silica and alumina as catalyst matrix and/or binder in biomass conversion catalysts and bio-oil upgrading

InactiveUS20140007493A1Long catalyst lifeIncrease resistanceProductsFatty acid chemical modificationCatalytic pyrolysisPorosity

The invention relates to catalyst compositions and components thereof for use in a catalytic process, and more particularly in a catalytic pyrolysis process or gasification of solid biomass material. In one aspect, a catalyst component is provided. The catalyst component includes a hybrid silica-alumina having a controlled Lewis acidity, and having a controlled porosity providing optimized accessibility for reactants.

Owner:INAERIS TECH

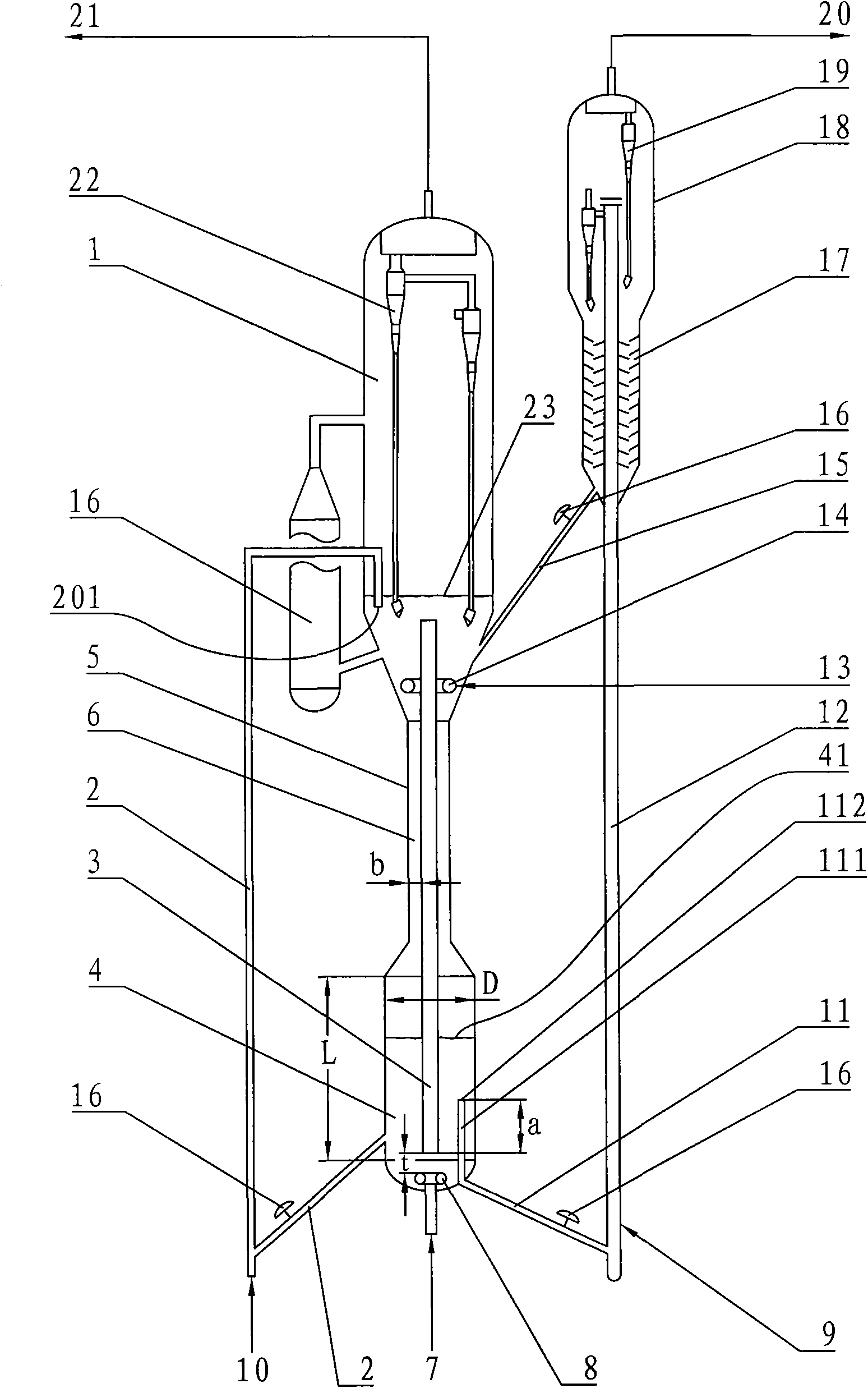

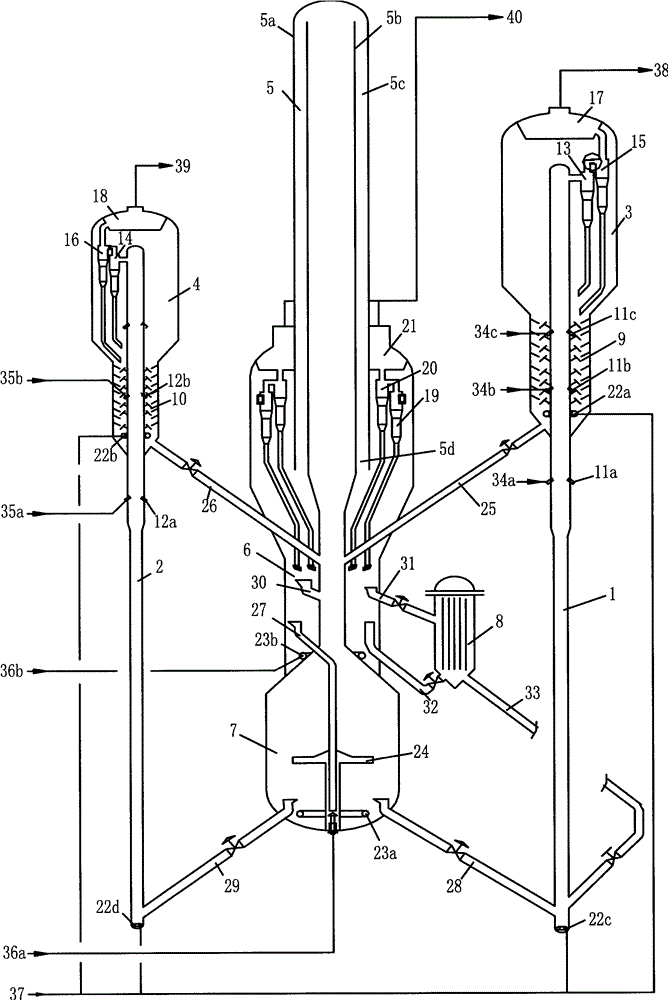

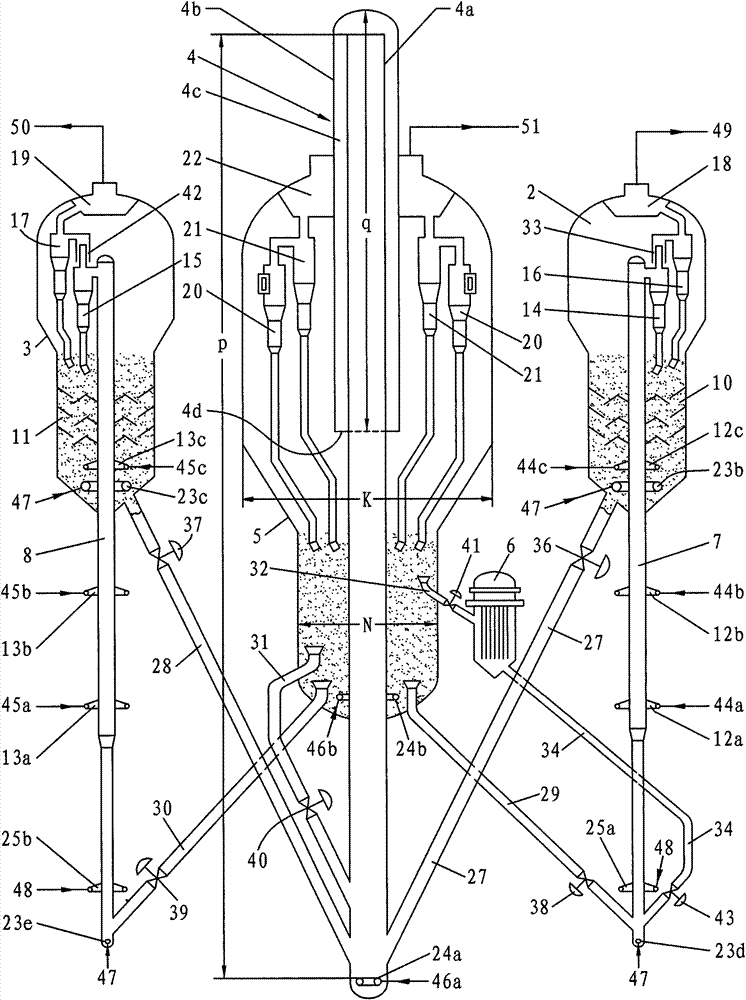

Device and method for reducing the temperature of catalytic cracking regenerated catalyst

ActiveCN101575534AWide range of applicationsReduce carbon contentCatalytic crackingPetrochemicalPetroleum

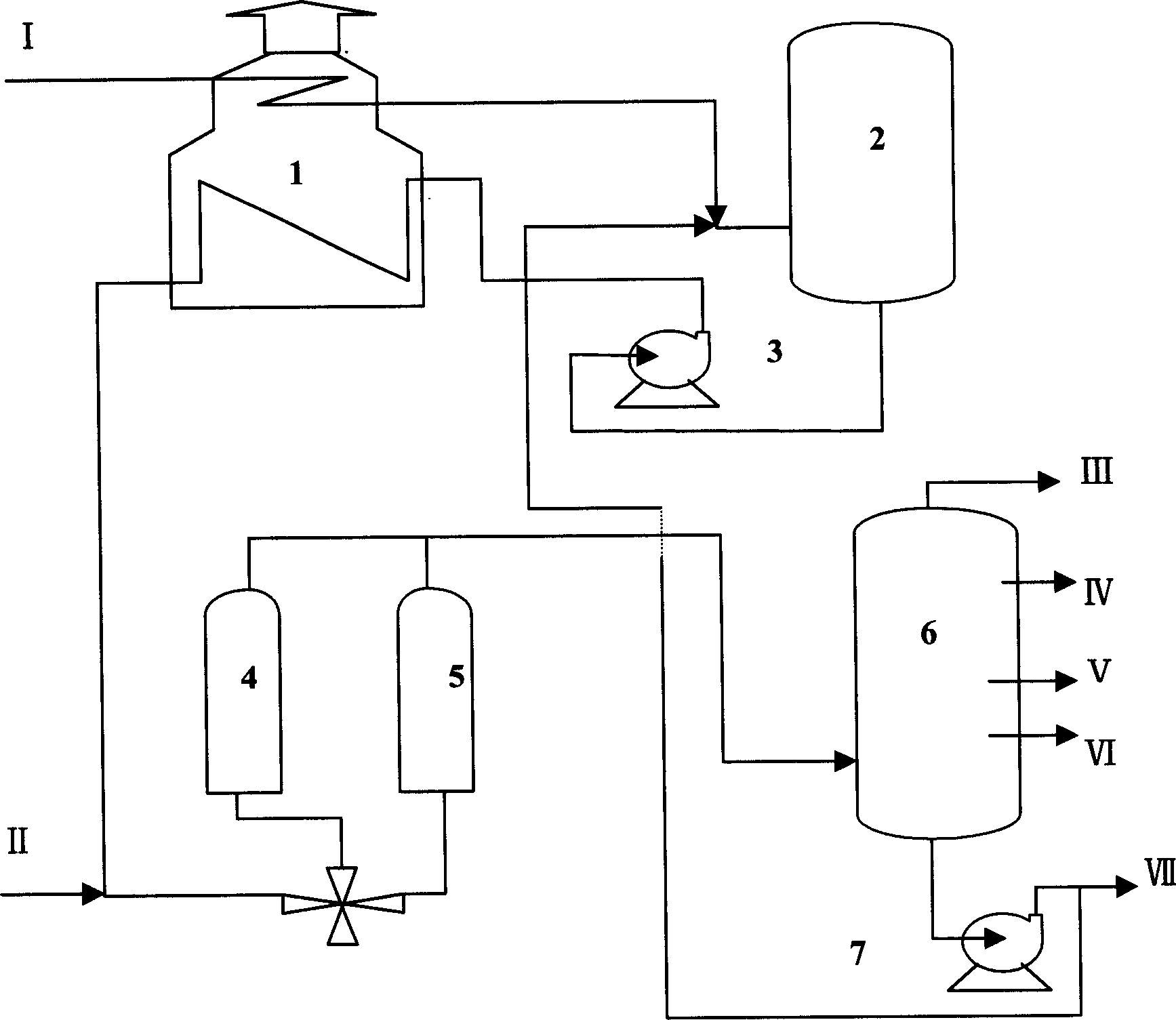

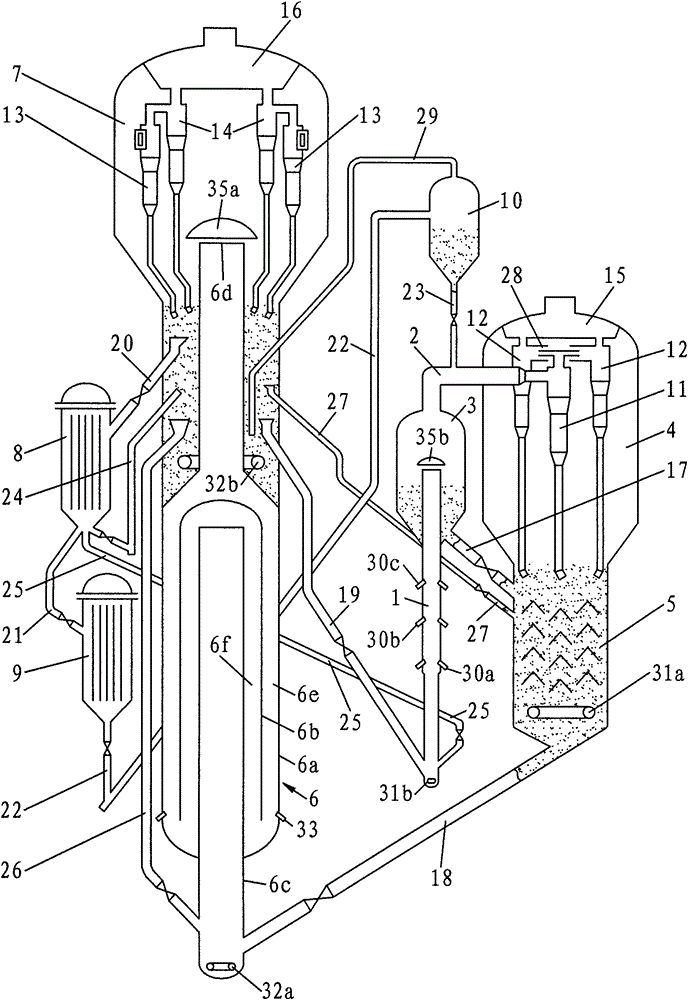

The invention discloses a device and a method for reducing the temperature of catalytic cracking regenerated catalyst in the field of petrochemical industry catalytic cracking and aims to solve the problems that the method for reducing the temperature of catalytic cracking regenerated catalyst has a small application range in the prior art, and the like. The device comprises a regenerated catalyst cooler (4) arranged below a regenerator (1) and the bottom head of the cooler is internally provided with a cooling main air distributor (8). A sleeve (5) is arranged between the top of a taper section of the regenerated catalyst cooler and the bottom of the regenerator and provided with a regenerated catalyst conveying pipe (3) internally, and an annular space (6) is formed between the sleeve and the conveying pipe. A regenerated inclined pipe (11) is arranged between the regenerated catalyst cooler and a heavy oil riser reactor (12) of a catalytic cracking device. The invention also discloses a method for reducing the temperature of catalytic cracking regenerated catalyst by adopting the device. The device and the method can be used for setting a catalytic cracking device of a single heavy oil riser reactor and a plurality of riser reactors.

Owner:CHINA PETROCHEMICAL CORP +1

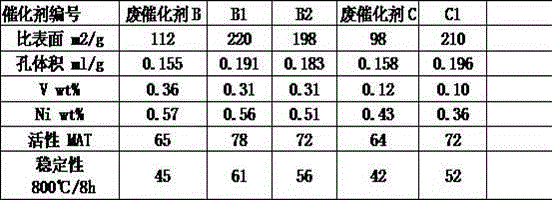

Revivification method for catalytic cracking waste catalyst

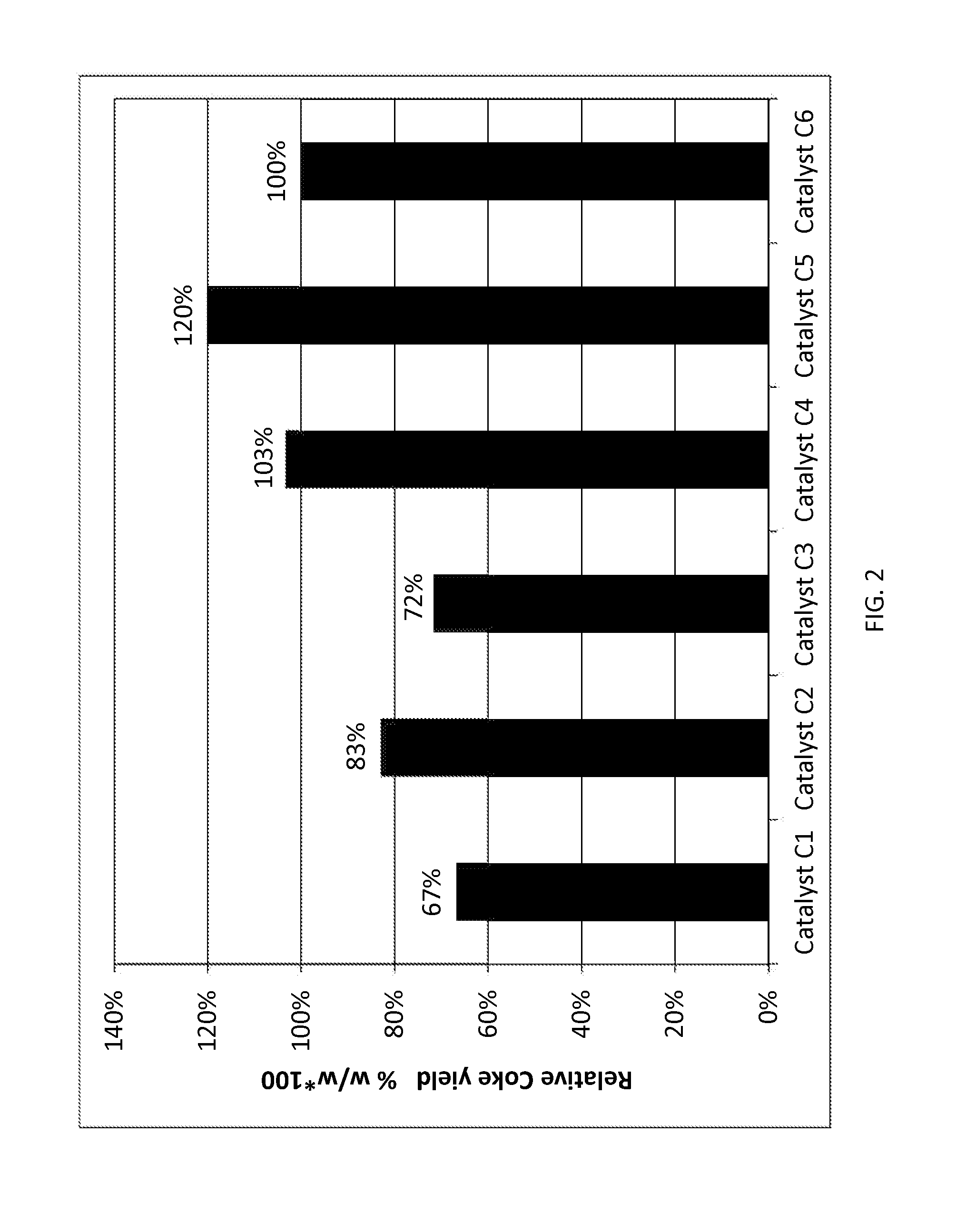

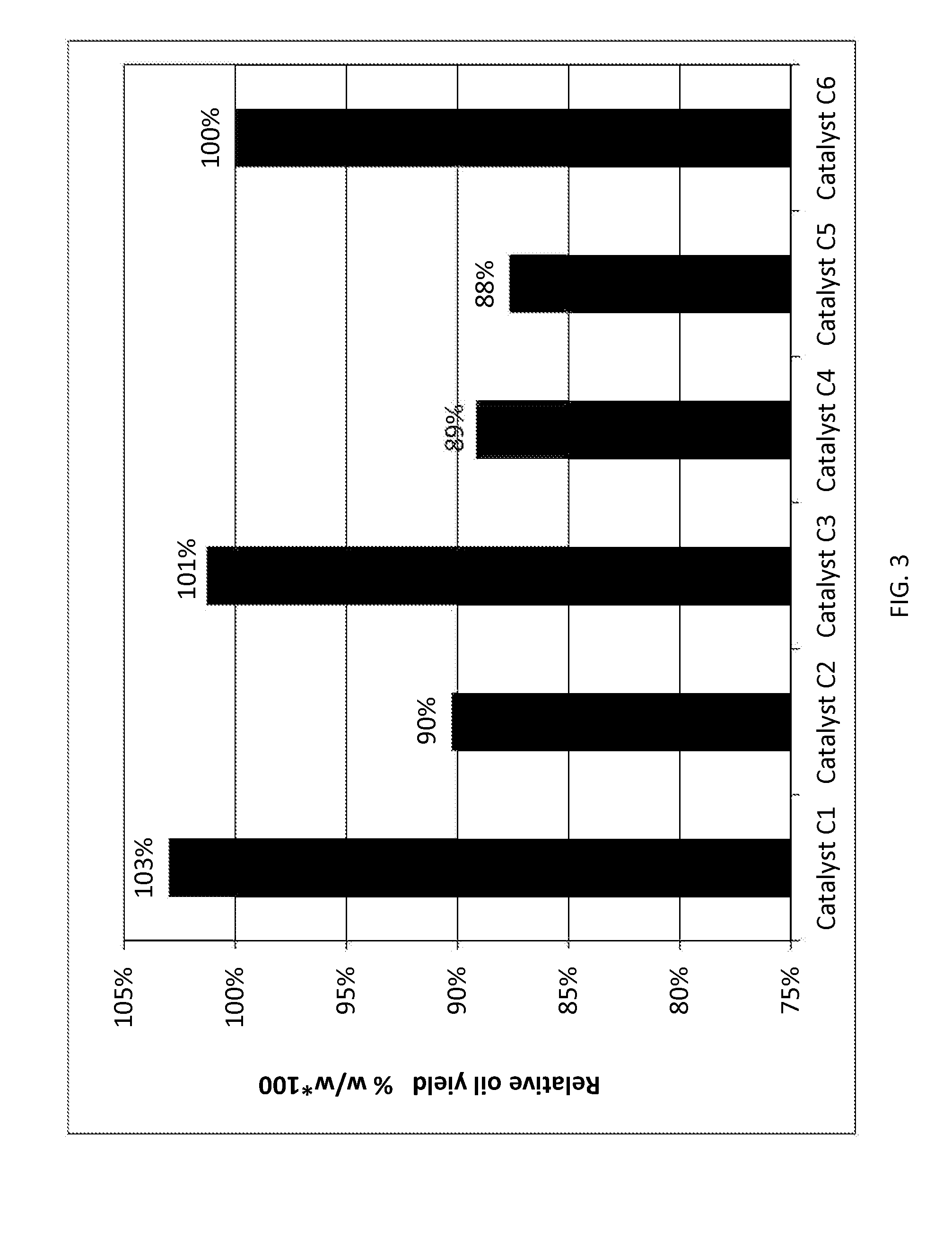

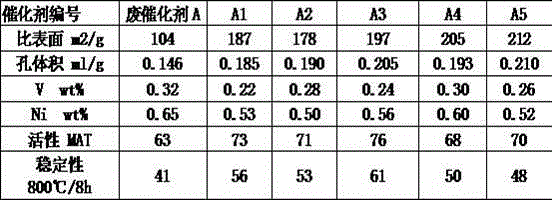

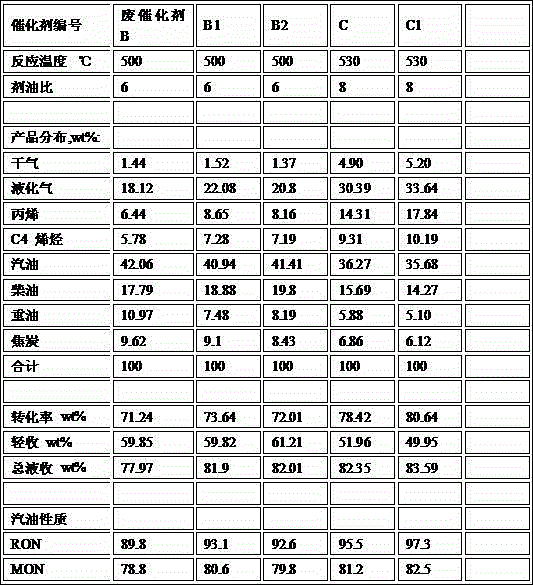

ActiveCN104815702AImprove liquid yieldReduce coke yieldCatalyst regeneration/reactivationPhosphoric acidChemistry

The invention relates to a revivification method for a catalytic cracking waste catalyst, which is characterized in that composite acid and ammonium salt are treated, and at least one of a supported rare earth treatment process and a phosphorus-containing acid treatment process is employed. a principle is characterized in that by improving a tunnel structure of the catalyst, composite acid is used for dredging the tunnel of the catalyst, a part of structure of molecular sieve is reconstructed through reaction and calcinations, acidity of the catalyst is adjusted by a rare earth compound-containing and / or phosphate-containing compound, so that waste catalyst performance can be recovered, the specific surface and activity of the recovered catalyst can be obviously increased, stability is obviously increased, good liquefied gas and low carbon olefin selectivity can be presented, green coke is reduced, liquid recovery is increased, gasoline RON is increased by 0.5-3 points, propylene and butylene yield can be respectively increased by more than 20-40% and 10-30%.

Owner:于向真

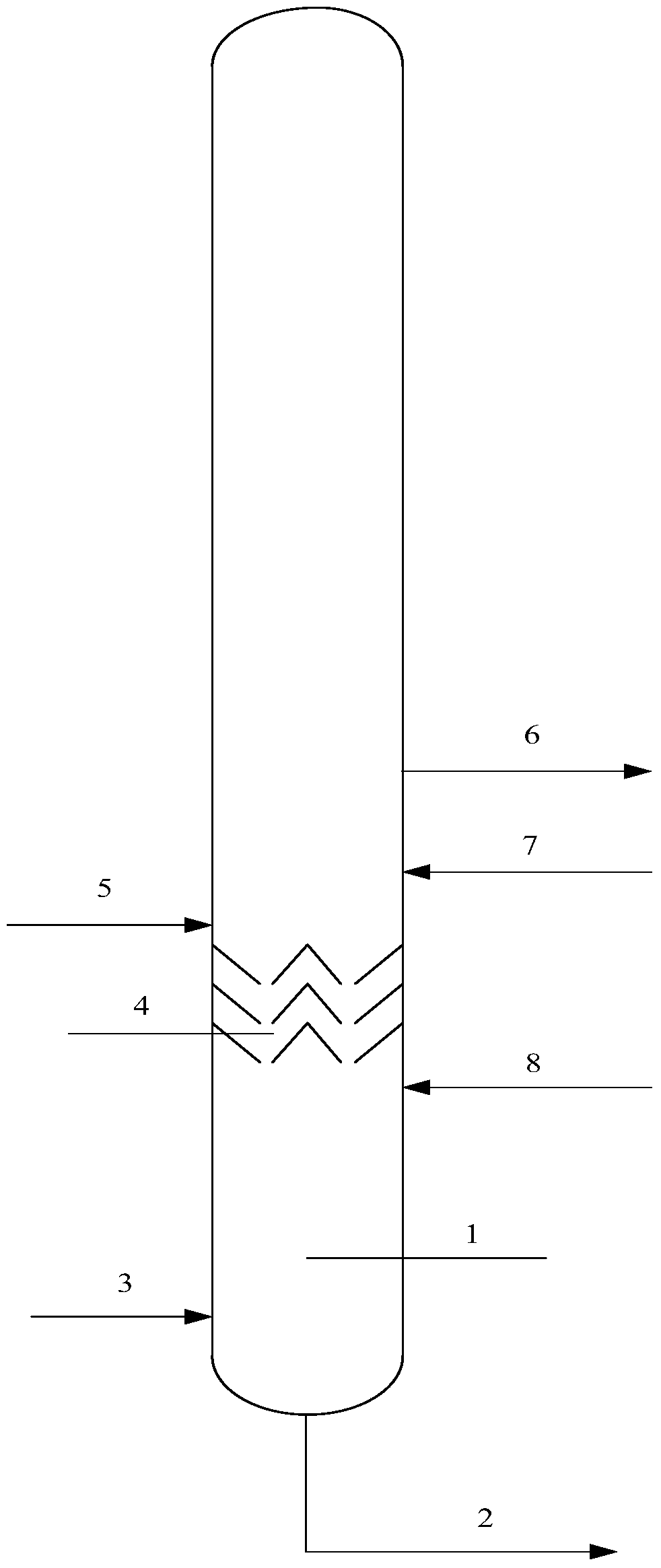

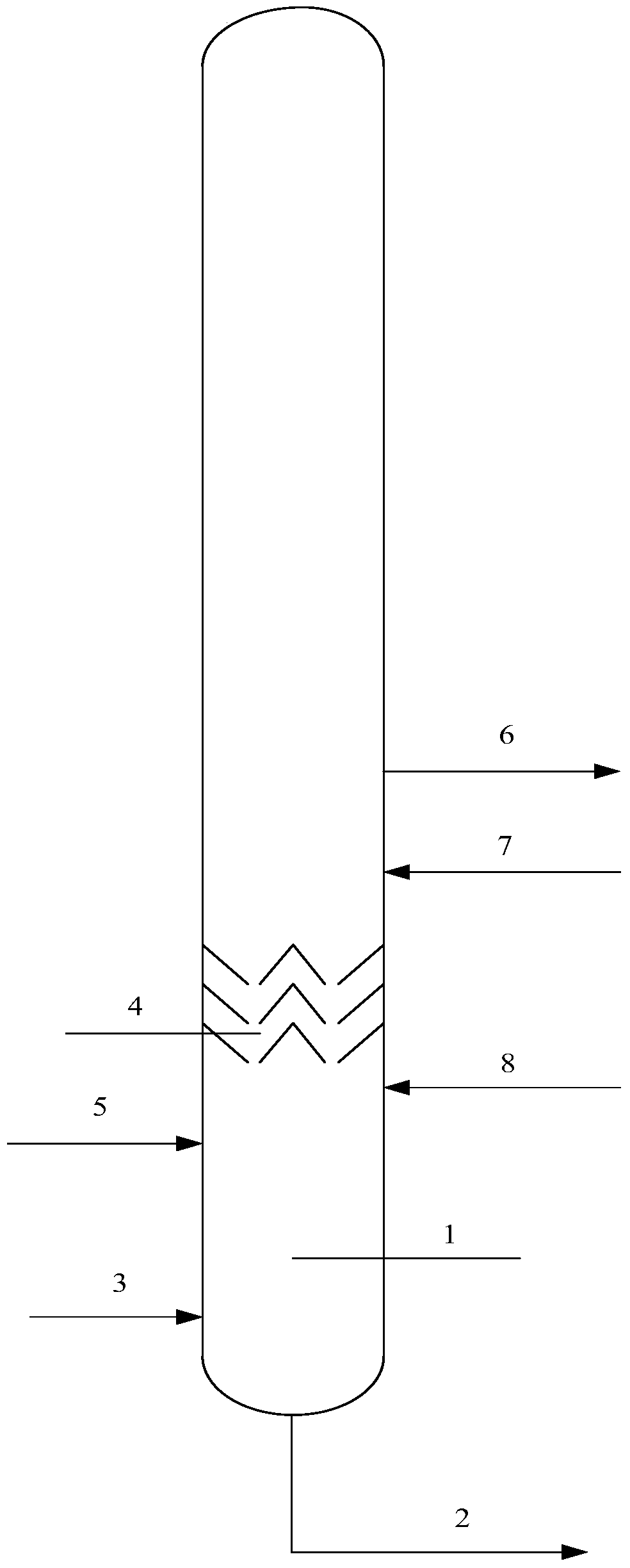

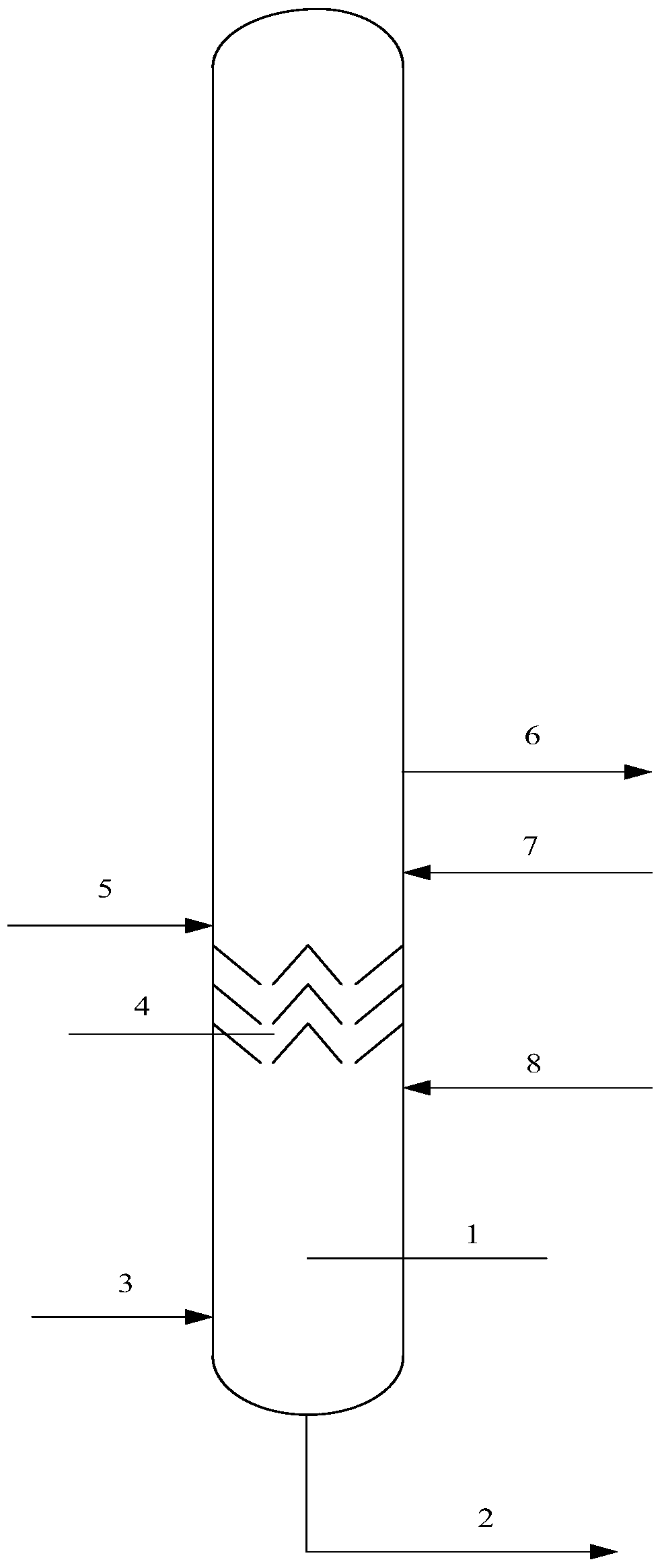

A method for controlling the bottom liquid level and reaction severity of fractionation tower

ActiveCN106924984BReduce coke yieldReduce yieldDistillation regulation/controlHydrocarbon distillationPhysical chemistryFractionating column

A method for controlling bottom liquid level and reaction severity of a fractionating column is characterized in that a collapsing plate of the fractionating column is positioned at the lower portion of the fractionating column, catalytic cracking raw oil medium that is subjected to heat exchange is introduced to a position on the sidewall of the fractionating column, near the collapsing plate vertical height, wherein a mass ratio of the catalytic cracking raw oil medium to the catalytic cracking reaction product of the fractionating column to 1:1000 to 0.5:1; the position on the sidewall of the fractionating column near the collapsing plate vertical height is on the sidewall of the fractionating column between the collapsing plate and a catalytic cracking reaction product inlet, or on the sidewall of the fractionating column between the collapsing plate and a recycle oil outlet. By using the method, the bottom liquid level and reaction severity of a fractionating column can be controlled, catalytic cracking coke yield is decreased effectively, and continuous production of equipment is achieved.

Owner:PETROCHINA CO LTD

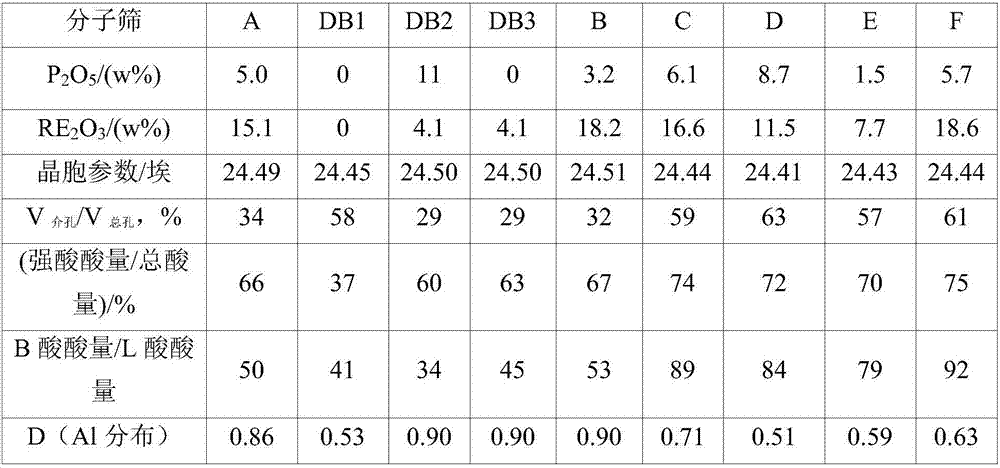

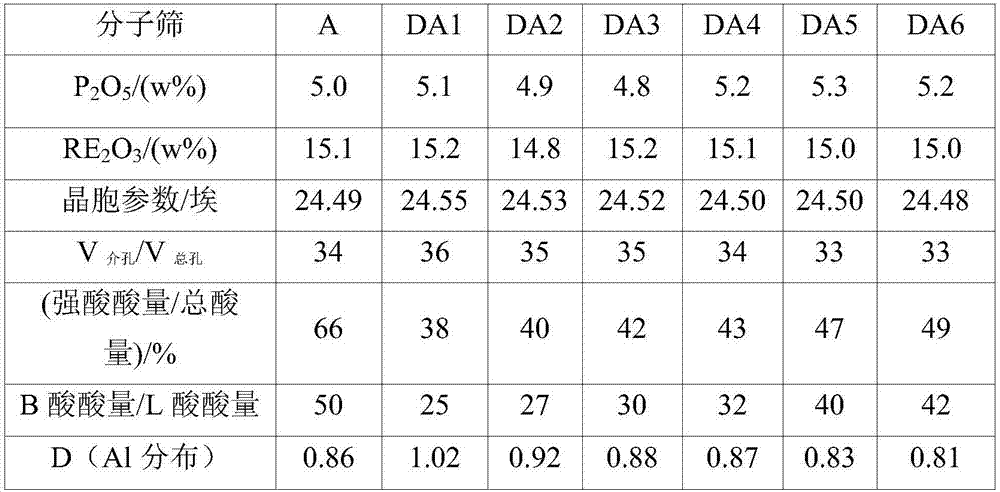

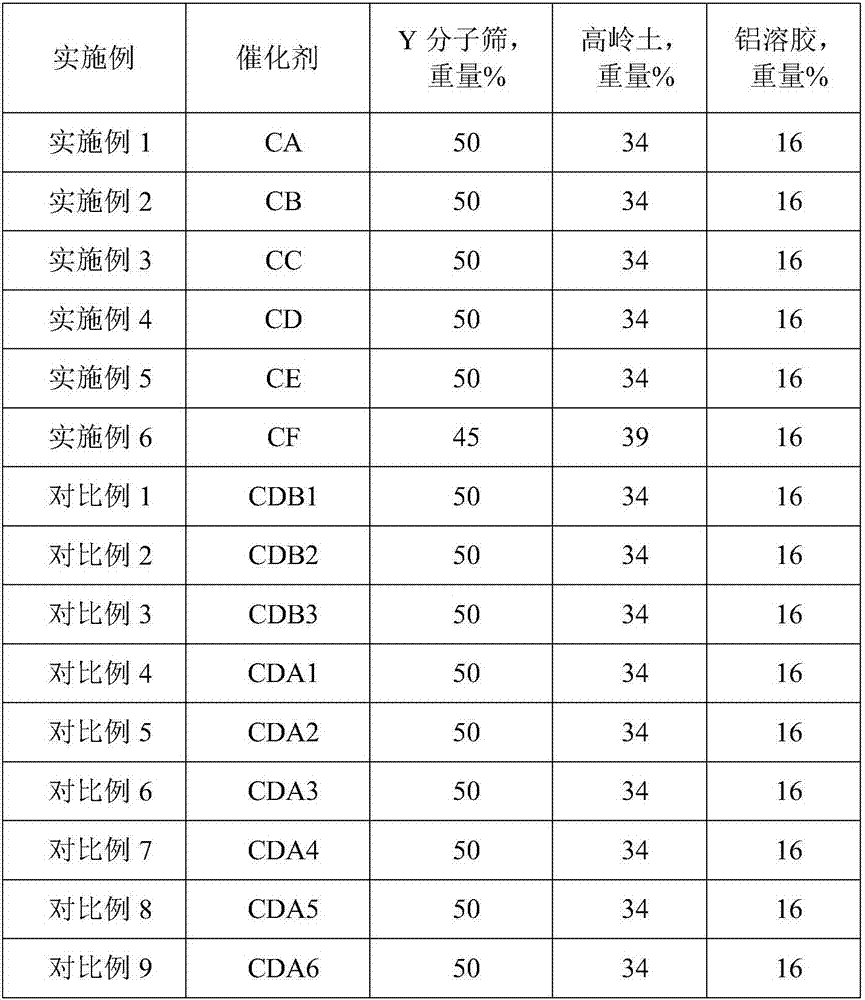

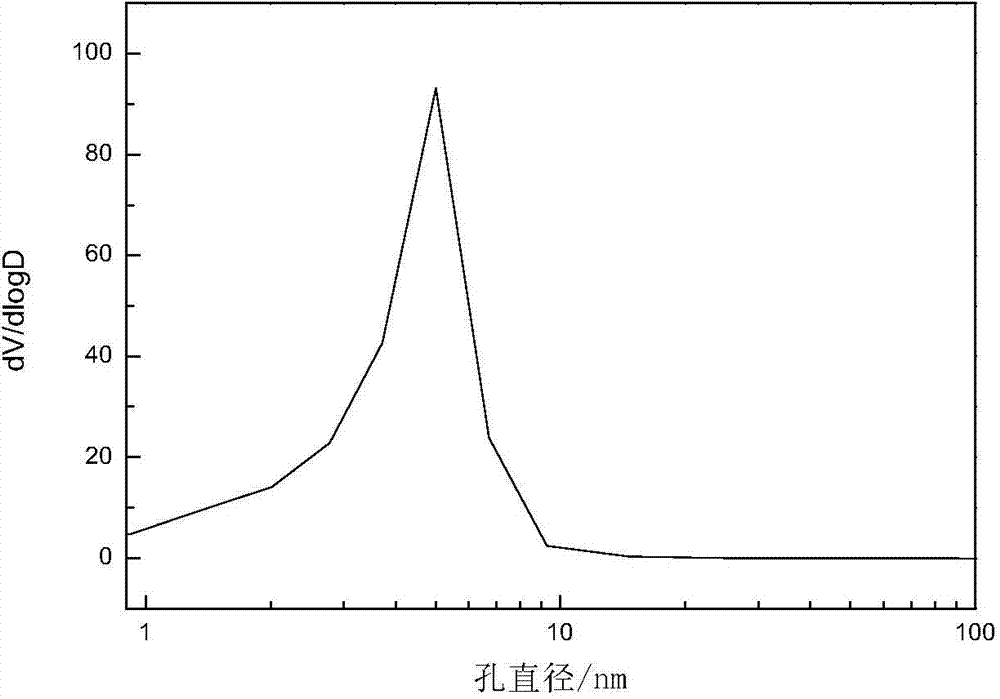

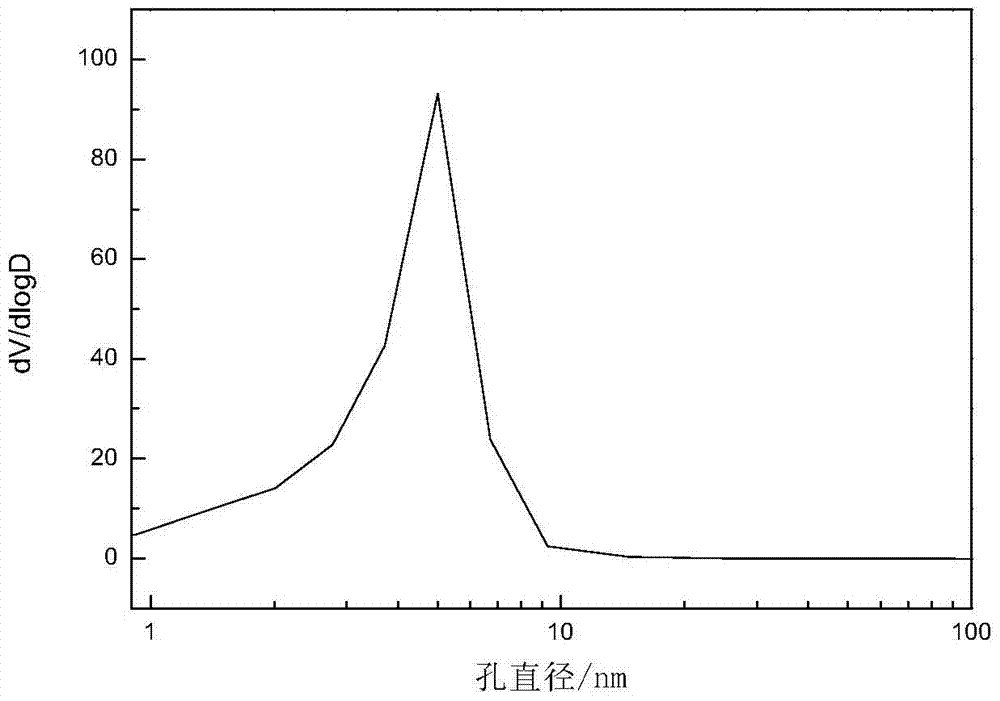

Catalytic cracking catalyst and preparation method thereof

ActiveCN107970974AStrong ability to convert heavy oilHigh gasoline yieldCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

The invention relates to a catalytic cracking catalyst and a preparation method thereof. The catalytic cracking catalyst comprises, 25 to 75 wt% of a Y molecular sieve containing phosphorus and rare earth, 10 to 30 wt% of an inorganic oxide binder and 15 to 65 wt% of natural mineral matters, wherein the Y molecular sieve containing phosphorus and rare earth has a cell parameter of 24.35 to 24.55 angstroms; the phosphorus content of the molecular sieve is 0.3 to 10.0 wt% in terms of P<2>O<5> and on the basis of the dry base weight of the molecular sieve; the rare earth content of the molecularsieve is 0.5 to 19 wt% in terms of RE<2>O<3> and on the basis of the dry base weight of the molecular sieve; the distribution parameter D of Al in the molecular sieve is no less than 0.4 and no more than 0.9; the mesopore volume of the molecular sieve accounts for 25 to 65% of total pore volume; the amount of strong acids in the molecular sieve accounts for 65 to 78% of total acid amount; and a ratio of the amount of the acid B to the amount of the acid L is 21 to 98. The catalytic cracking catalyst provided by the invention has the advantages of excellent heavy oil conversion capability, higher gasoline yield and lower coke yield when applied to catalytic cracking of heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

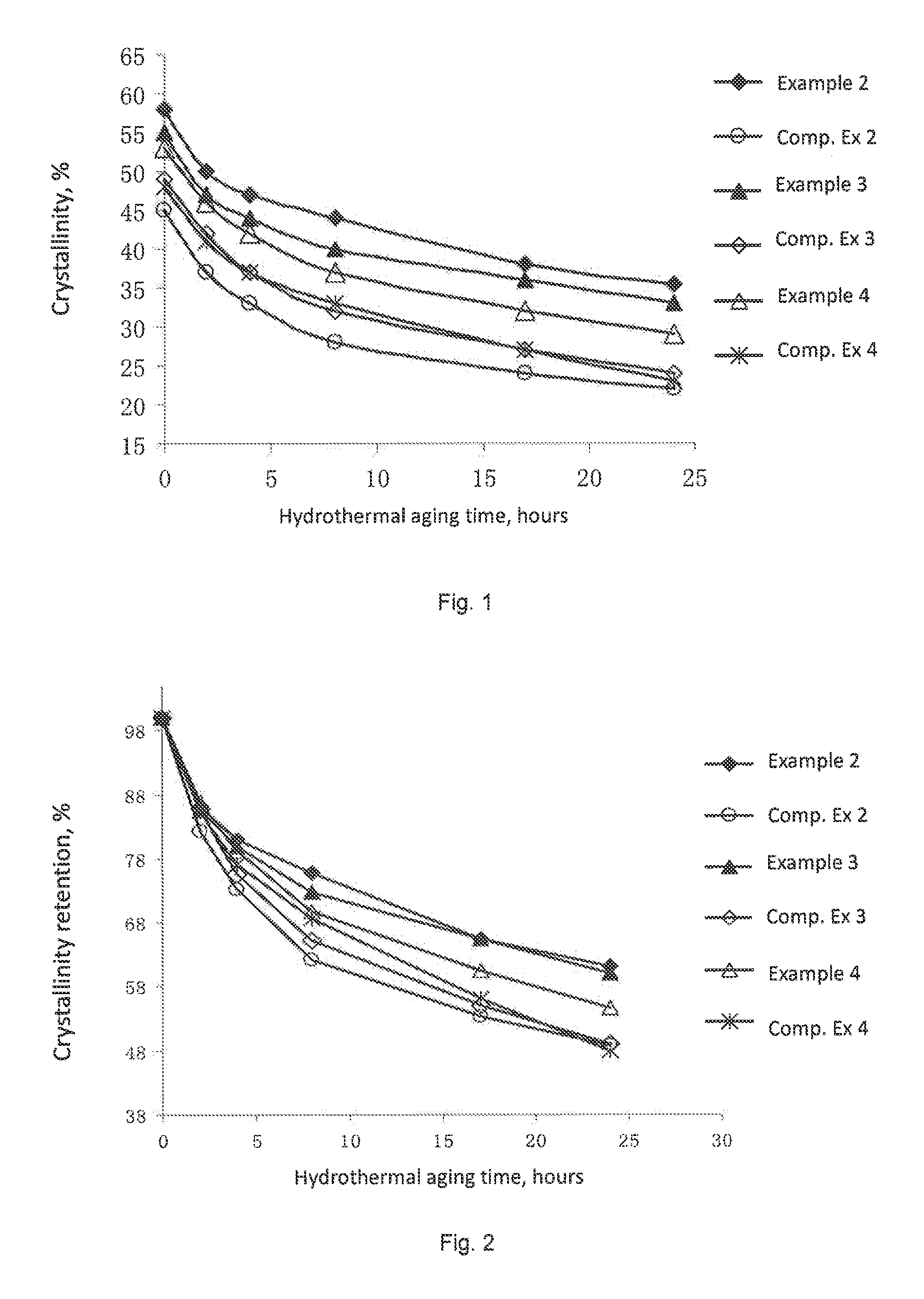

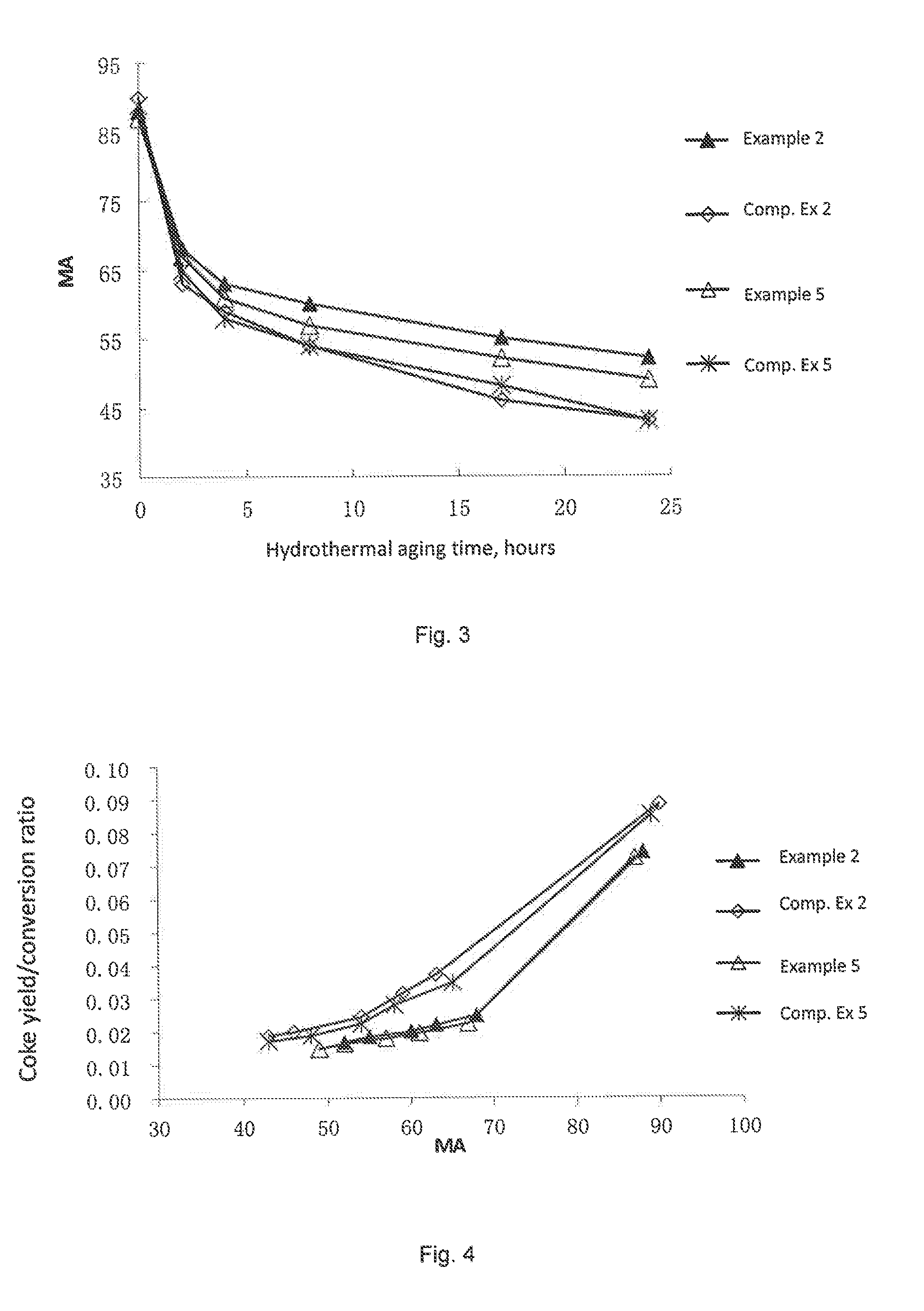

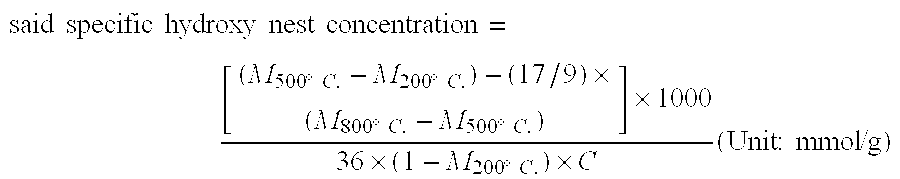

Modified y-type zeolite and preparation process and use thereof

ActiveUS20140299511A1Improve stabilityReduce coke yieldAluminium compoundsCatalytic crackingMolecular sieveSample Measure

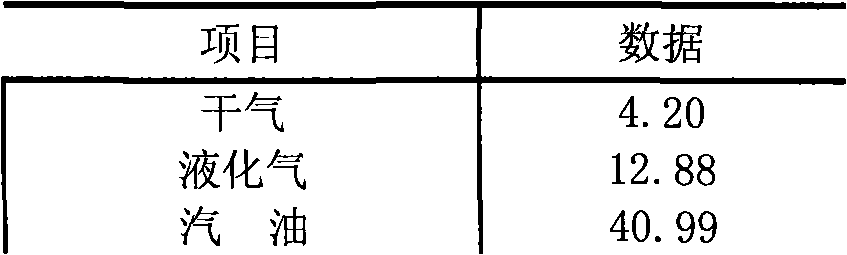

The present invention provides a modified Y-type molecular sieve, characterized by having a unit cell size of 2.420-2.440 nm; as percent by weight of the modified Y-type molecular sieve, a phosphorus content of 0.05-6%, a RE2O3 content of 0.03-10%, and an alumina content of less than 22%; and a specific hydroxyl nest concentration of less than 0.35 mmol / g and more than 0.05 mmol / g,saidspecifichydroxylnestconcentration=[(M500°C.-M200°C.)-(17 / 9)×(M800°C.-M500°C.)]×100036×(1-M200°C.)×C(Unit:mmol / g)wherein M200° C., M500° C. and M800° C. respectively represent the weight loss percents of a sample measured at 200° C., 500° C. and 800° C., and C is the crystallinity of the sample. The modified Y-type molecular sieve has few defect in the crystal lattice. The application of the zeolite in the catalytic cracking catalyst as active component can maintain a long period stable activity, effectively control the coke yield and increase the heavy oil utilization. The present invention also relates to the preparing method and the use of the modified Y-type molecular sieve.

Owner:CHINA PETROCHEMICAL CORP +1

Method for reliving FCC dead catalyst

ActiveCN101219396BIncreased microreactivityHigh selectivityMolecular sieve catalystsOrganic acidGasoline

The invention relates to a method to rehabilitate waste FCC (fluid catalytic cracking) catalyst, pertaining to recovery and resource regeneration field of waste catalyst. The invention reconstructs the frameword of catalyst through the synergistic effects of inorganic acid and organic acid, to construct developed micropores-mesoporous compound pore-channel structure system during the reconstruction process, and eliminates or passivates heavy metal of the waste catalyst, so as to dramatically increase the specific surface area of the rehabilitated catalyst; the eliminating rate of heavy metal can reach 30 percent, the micro reactor activity can be improved by more than 10 percent, and the invention has comparatively higher selectivity of liquefied gas and gasoline and lower yield ratio of coke.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Catalyst containing a modified y-type zeolite and a preparaton process thereof

ActiveUS20140005032A1Improve stabilityDecreasing cokeCatalytic crackingMolecular sieve catalystsPtru catalystHydroxy group

The present invention discloses a catalytic cracking catalyst and a preparation process therefor. The catalytic cracking catalyst comprises a cracking active component, 10 wt %-70 wt % of a clay on the dry basis, and 10 wt %-40 wt % of an inorganic oxide binder (as oxide), relative to the weight of the catalytic cracking catalyst, wherein said cracking active component contains, relative to the weight of the catalytic cracking catalyst, 10 wt %-50 wt % of a modified Y-type zeolite on the dry basis and 0-40 wt % of other zeolite on the dry basis, wherein said modified Y-type zeolite is characterized by having a unit cell size of 2.420-2.440 nm; as percent by weight of the modified Y-type zeolite, a phosphorus content of 0.05-6%, a RE2O3 content of 0.03-10%, and an alumina content of less than 22%; and a specific hydroxy nest concentration of less than 0.35 mmol / g and more than 0.05 mmol / g.

Owner:CHINA PETROCHEMICAL CORP +1

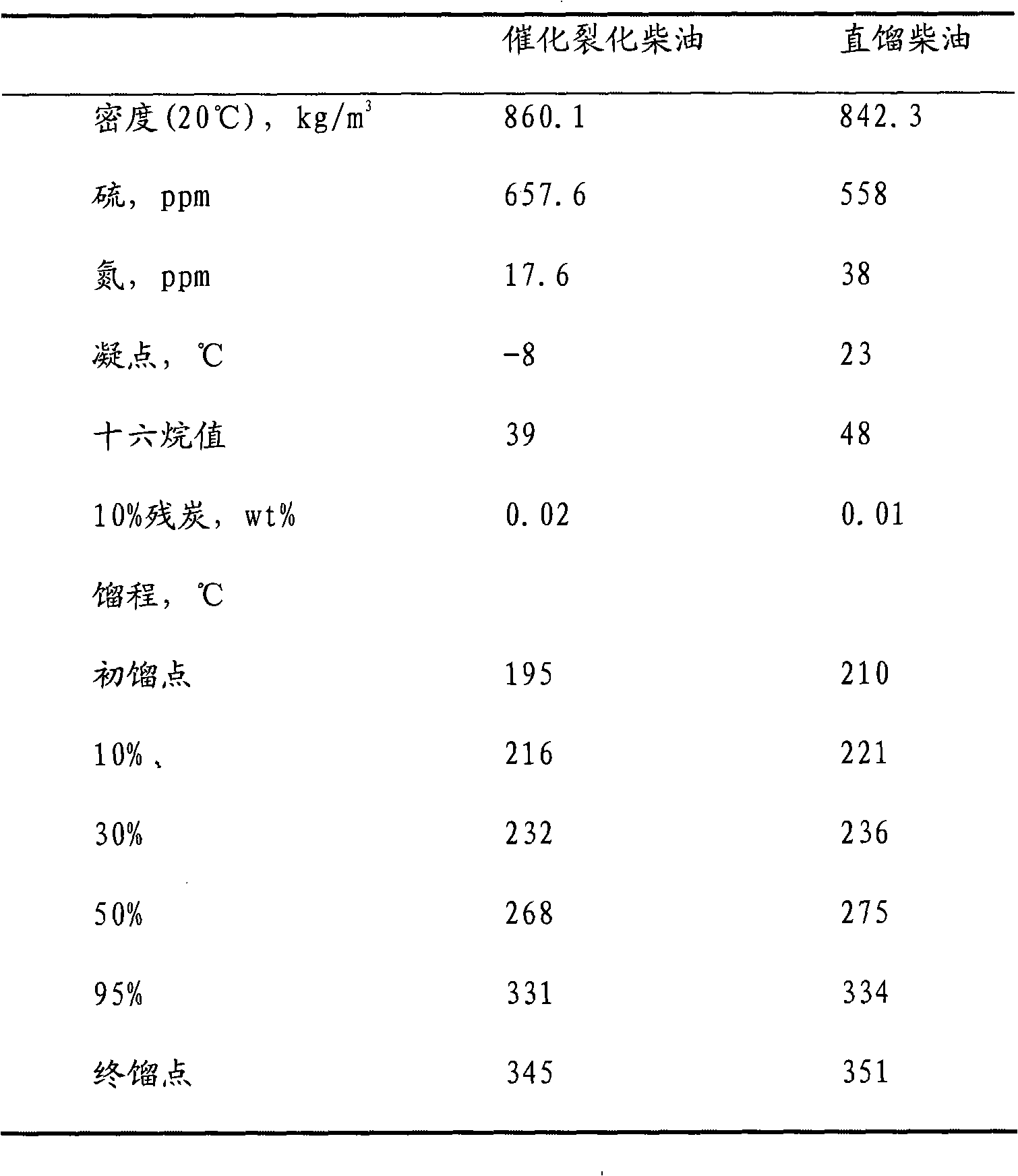

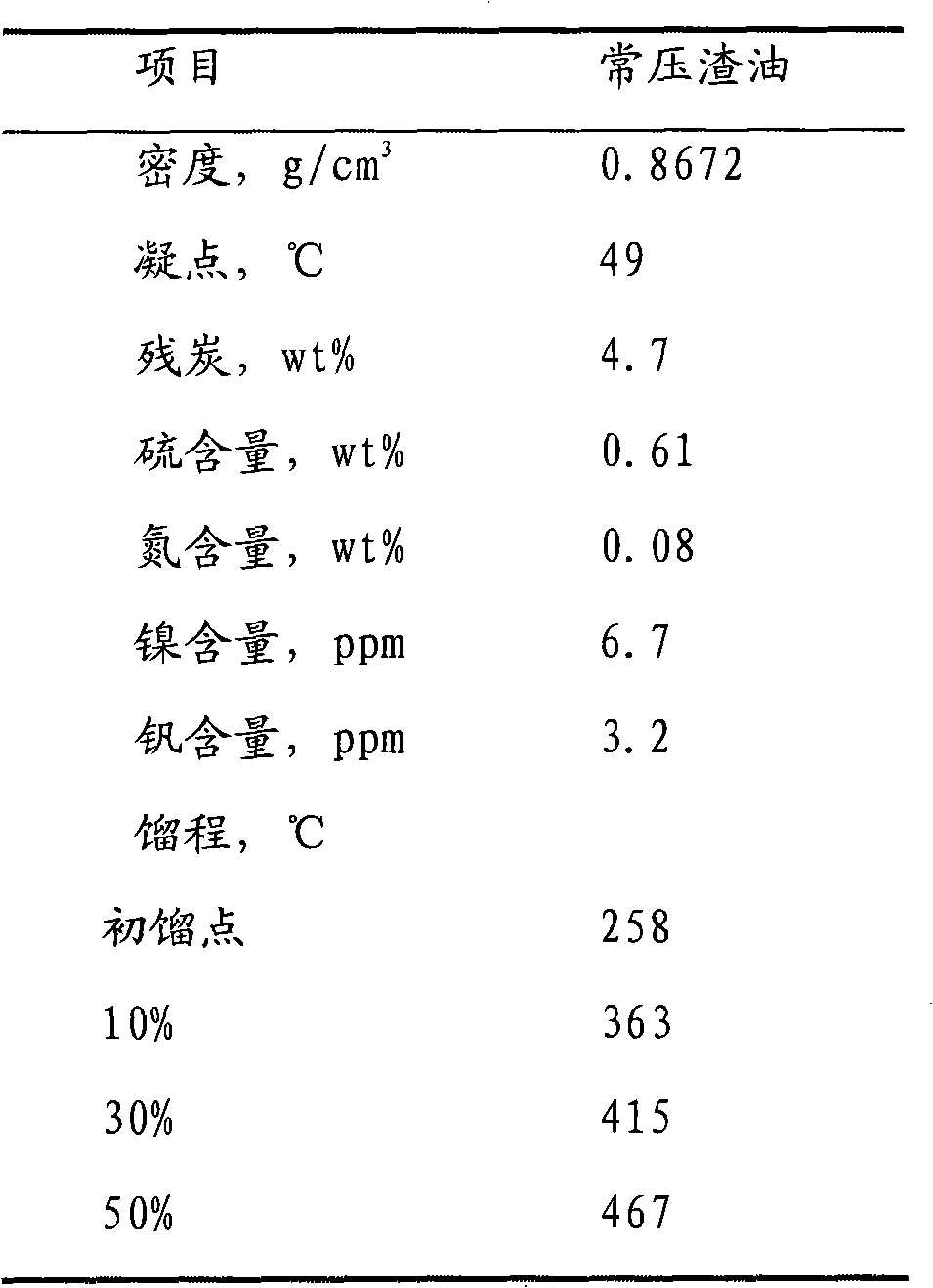

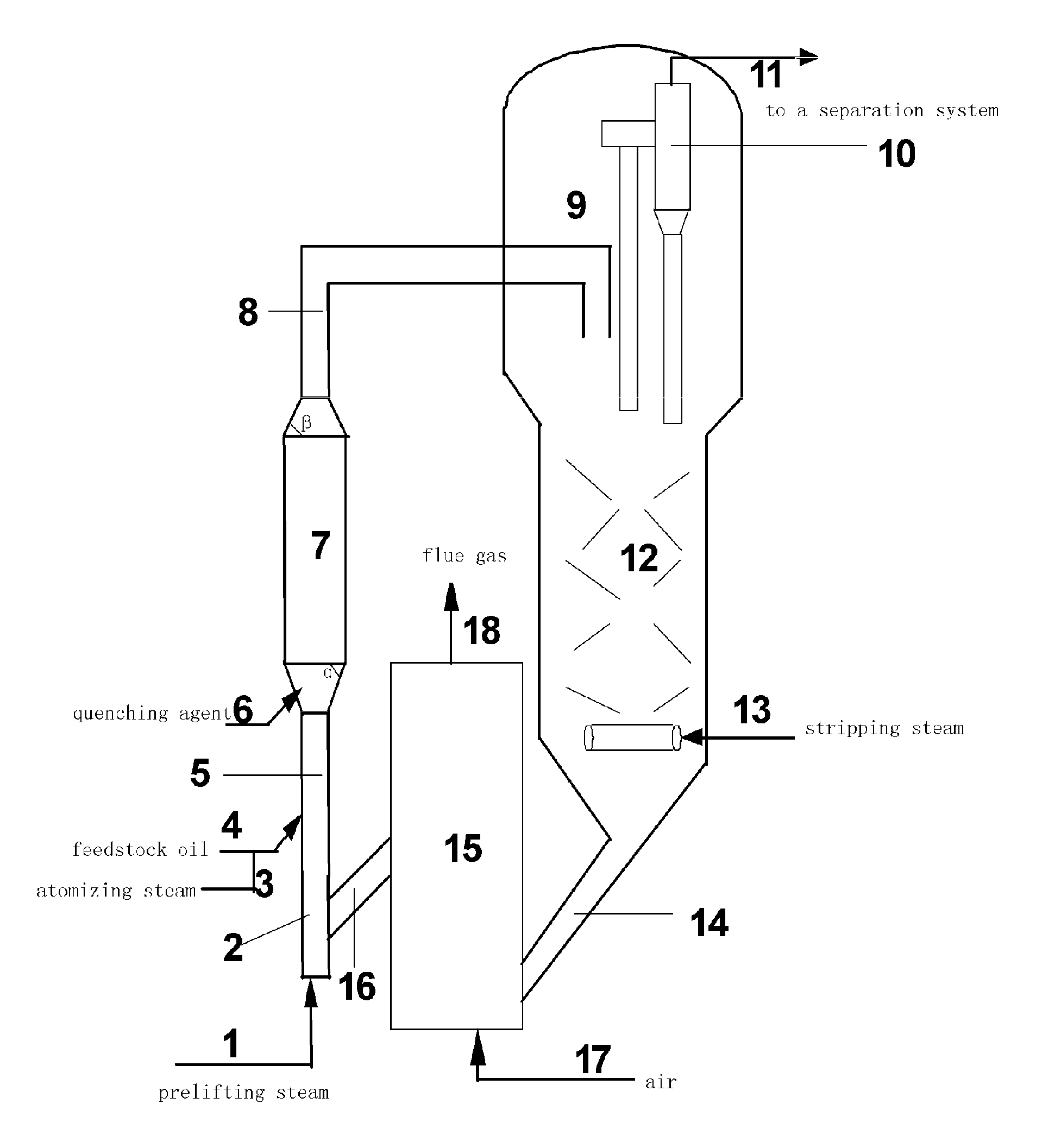

Catalytic conversion method of hydrocarbon oil

A catalytic conversion method of hydrocarbon oil comprises the following steps: leading the mixture of preheated light hydrocarbon oil and heavy hydrocarbon oil in a reactor from the bottom to contact a catalyst from a regenerator to carry out catalytic cracking reaction, the mixture and the catalyst flowing upward together, leading the reaction product and a spent catalyst with coke out of the reactor from an outlet on the upper part of the reactor, the reaction product and the spent catalyst entering into an oiling agent separation system, recycling the separated catalyst after stripping, burning and regenerating and the separated reaction oil and gas entering into a subsequent separation system to separate the product. The method provided by the invention can reduce the yield of the coke and increase the yields of the gasoline and the liquefied gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

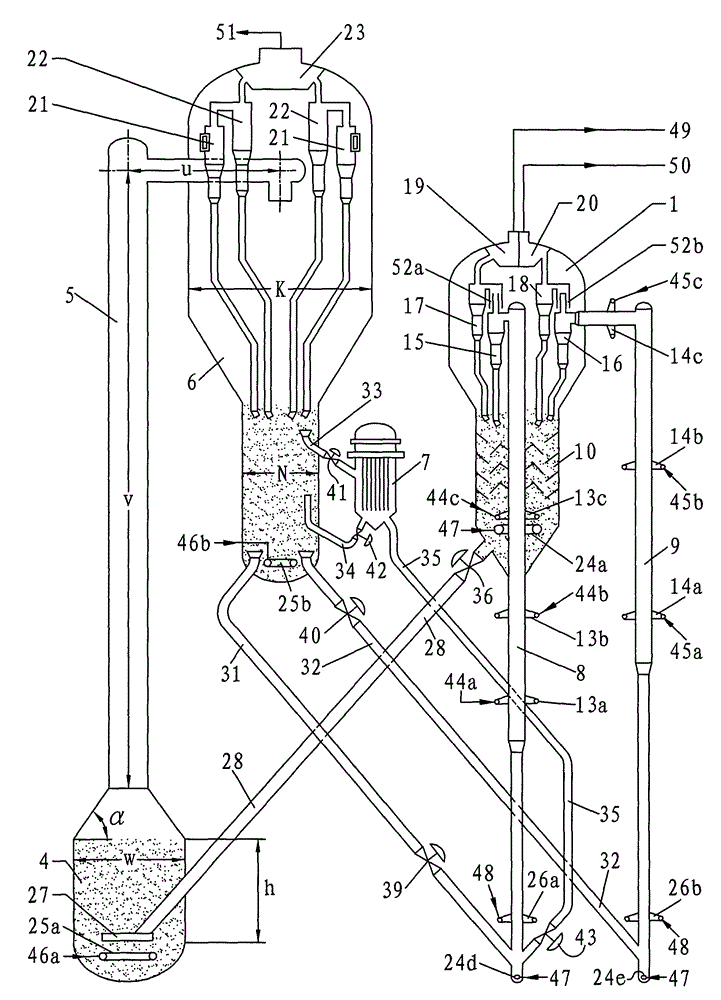

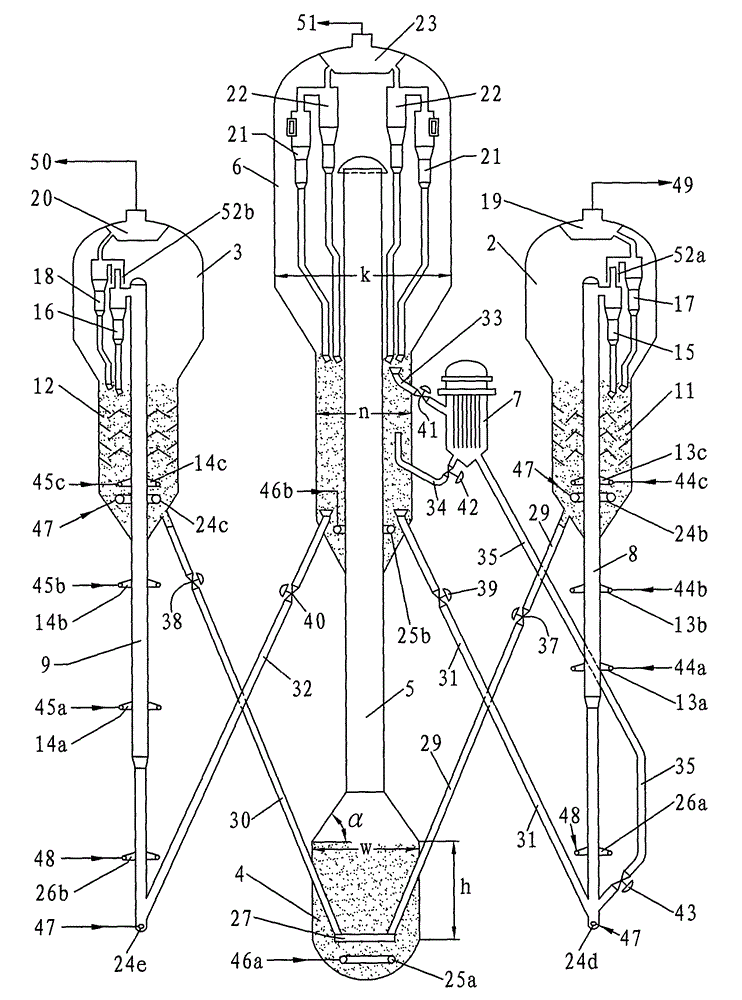

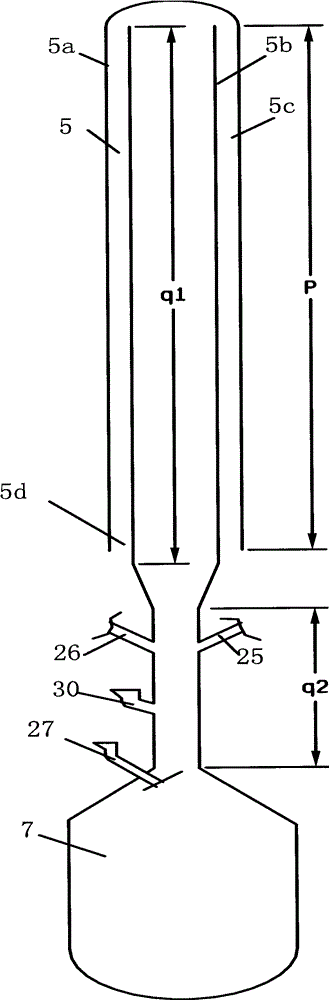

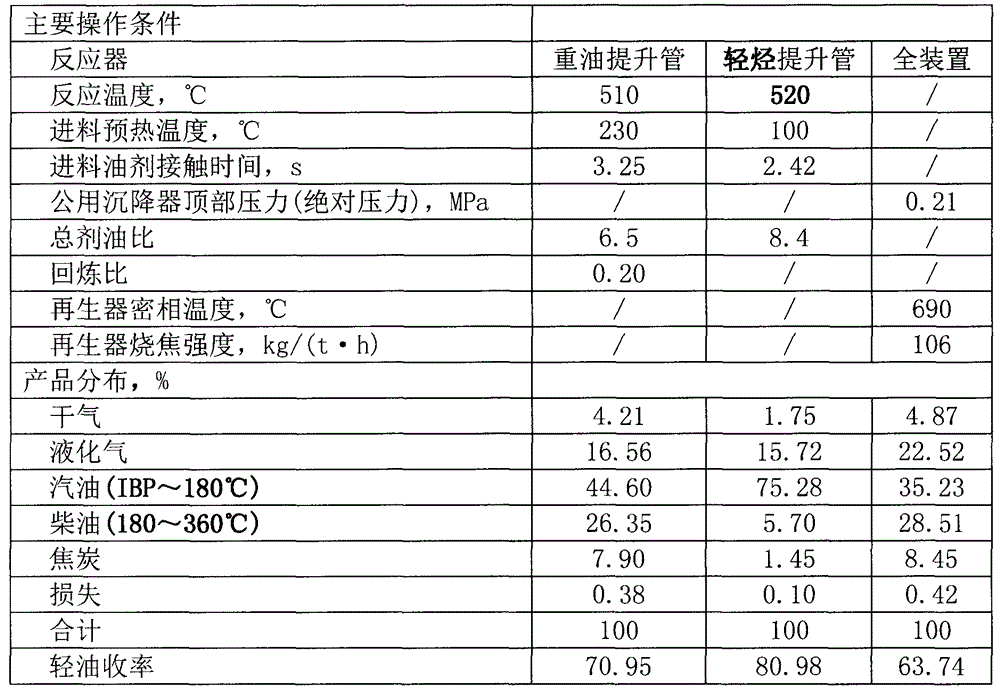

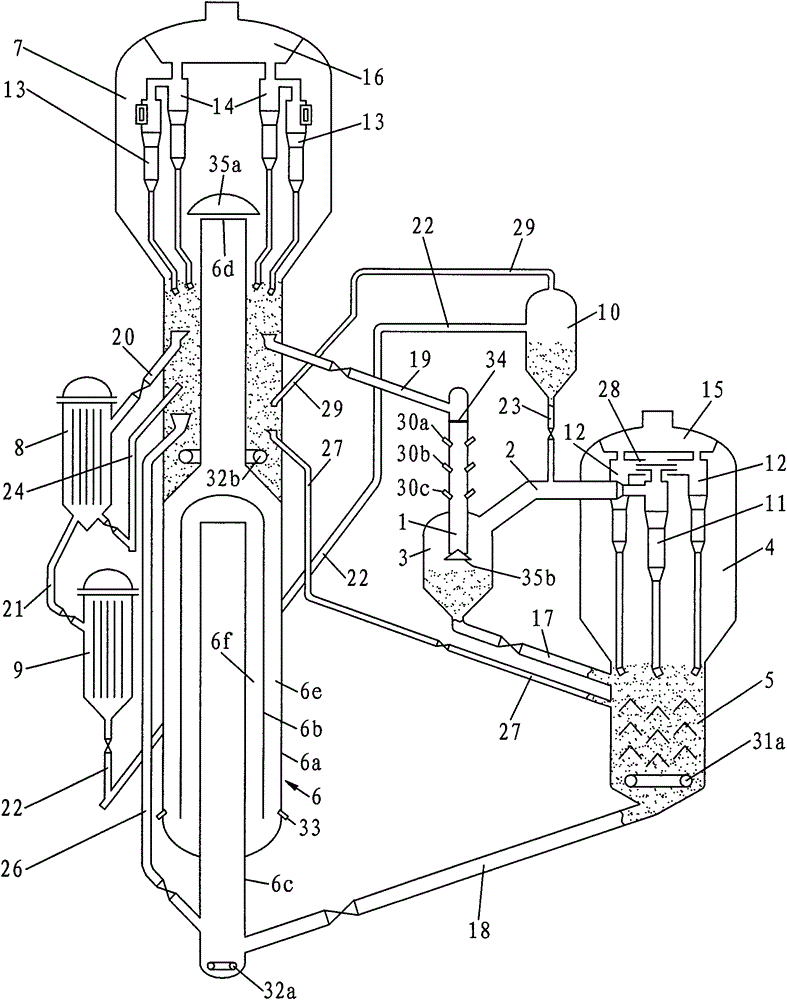

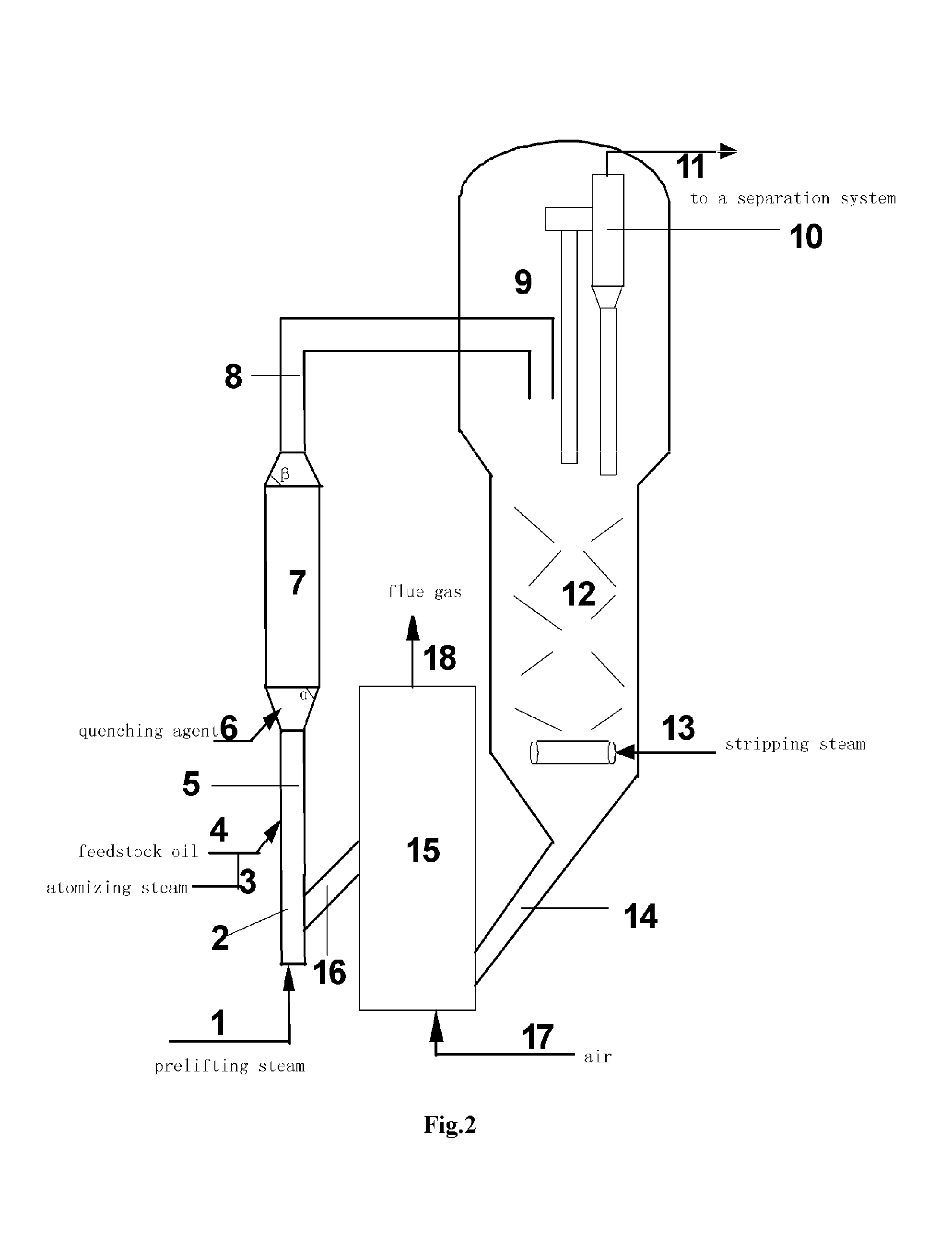

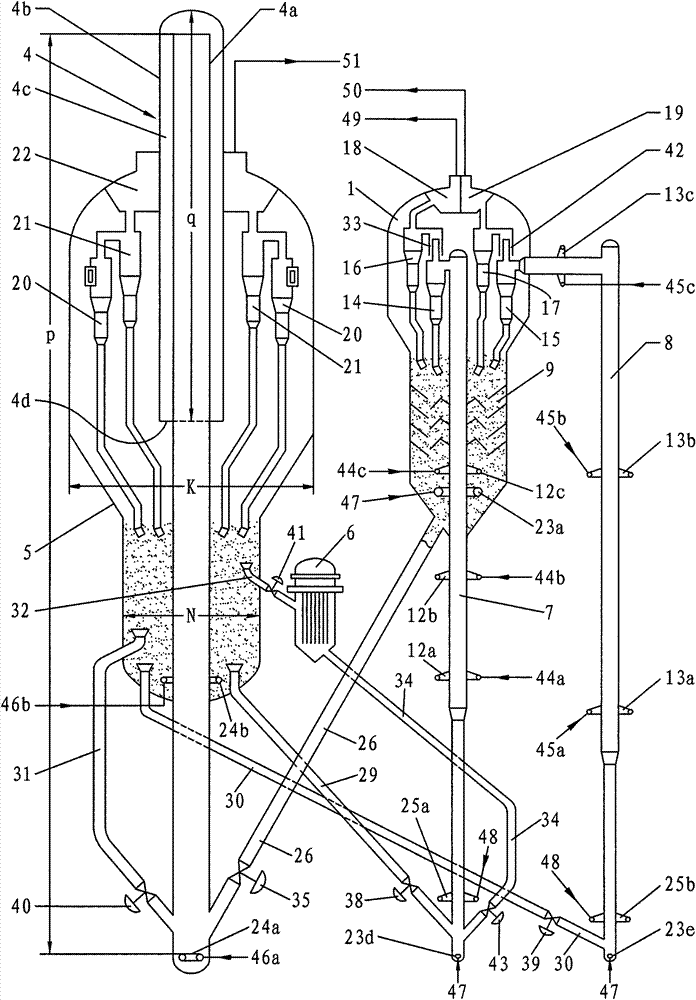

Catalytic cracking method and device employing double lift pipes

ActiveCN104419457ALower dense phase temperatureRaise the inlet temperatureCatalytic crackingHydrocarbon oils treatmentCatalytic reformingContact time

The invention discloses a catalytic cracking method and device employing double lift pipes in the petrochemical industry. The method comprises the following steps: carrying out heavy oil fluid catalytic cracking and light dydrocarbon catalytic reforming by adopting two lift pipes respectively, wherein the heavy oil catalytic cracking oil agent contact time is 0.2-1.5 seconds; carrying out gas-solid separation on two material flows by virtue of special cyclone separators; feeding a spent catalyst into a first turbulent bed regenerator after steam stripping, and contacting main air of the first turbulent bed regenerator in a down-flow manner, so as to burn off 40%-50% of generated coke; lifting a first section of semi-regenerated catalyst by smoke which is generated by the first turbulent bed regenerator to enter a tubular regenerator, and contacting the smoke which is generated by the first turbulent bed regenerator in a down-flow manner, so as to burn off 40%-50% of generated coke; feeding a second section of semi-regenerated catalyst into a second turbulent bed regenerator, and contacting main air of the second turbulent bed regenerator in a countercurrent manner, so as to burn off the residual generated coke; and returning the regenerated catalyst to the two lift pipes to recycle. The invention discloses a catalytic cracking device employing double lift pipes for achieving the method.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Delayed coking process

ActiveUS20150152334A1Reduce coke yieldGas may accumulateThermal non-catalytic crackingSolid waste disposalCelluloseJatropha

The present invention provides a delayed coking process comprising a step of subjecting a mixed feed comprises residual heavy hydrocarbon feedstock and bio oil obtained from fast pyrolysis of lignocellulosic biomass of one or more of Jatropha, Cashew nut, Karanjia and Neem to a delayed coking process and a system for the delayed coking process.

Owner:INDIAN OIL CORPORATION

Ultra-stable rare earth y-type molecular sieve and preparation method therefor

ActiveUS20150151284A1Improve activity stabilityReduce coke yieldAluminium compoundsCatalytic crackingMolecular sieveActive component

The present invention provides an ultra-stable rare earth type Y molecular sieve and the preparation method thereof, which method is carried out by subjecting a NaY molecular sieve as the raw material to a rare earth exchange and a dispersing pre-exchange, then to an ultra-stabilization calcination treatment. The molecular sieve comprises 1 to 20% by weight of rare earth oxide, not more than 1.2% by weight of sodium oxide, has a crystallinity of 51 to 69%, and a lattice parameter of 2.451 nm to 2.469 nm. In contrast to the prior art, in the molecular sieve prepared by this method, rare earth ions are located in sodalite cages, which is demonstrated by the fact that no rare earth ion is lost during the reverse exchange process. Moreover, the molecular sieve prepared by such a method has a molecular particle size D(v,0.5) of not more than 3.0 μm and a D(v,0.9) of not more than 20 μm. Cracking catalysts using the molecular sieve as an active component is characterized by a high heavy-oil-conversion capacity and a high yield of valuable target products.

Owner:PETROCHINA CO LTD

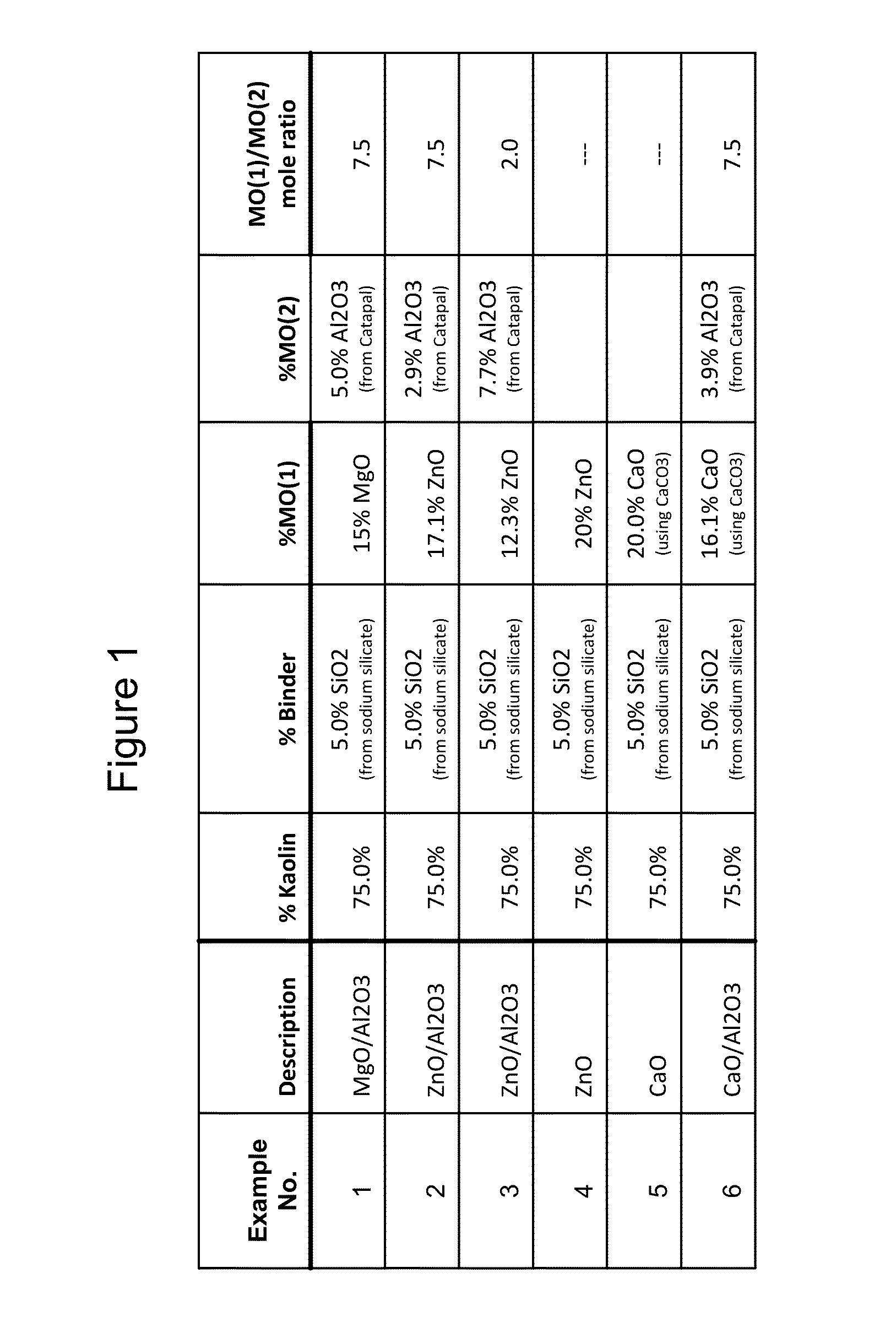

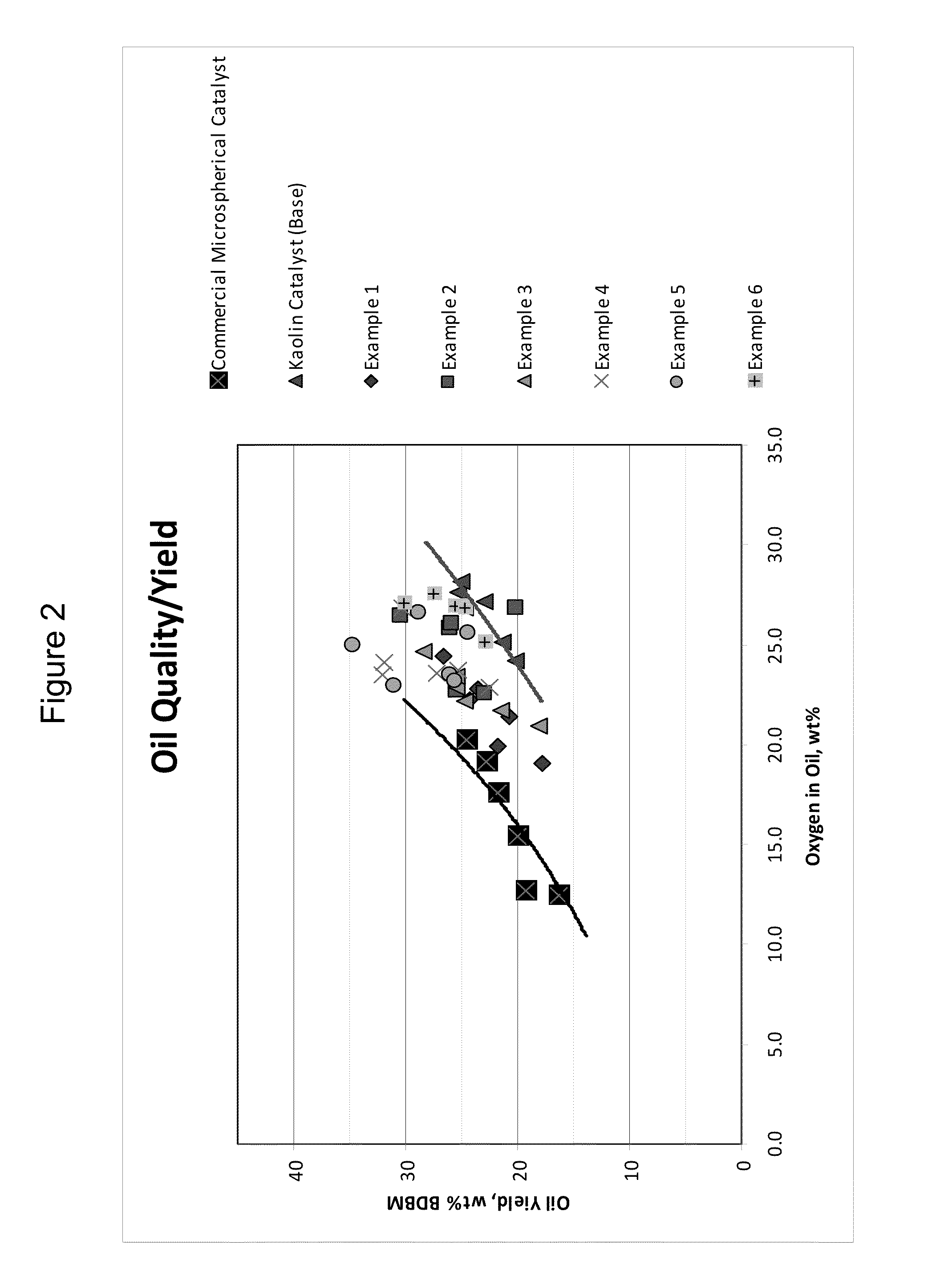

Phyllosilicate-Based Compositions and Methods of Making the Same for Catalytic Pyrolysis of Biomass

ActiveUS20130012376A1Reduce coke yieldImproved bio-oil yieldMolecular sieve catalystsBiofuelsCatalytic pyrolysisMicrosphere

A process for producing catalyst for biomass catalytic cracking is disclosed herein. The process includes modifying a phyllosilicate to produce a modified phyllosilicate having an improved yield of a pyrolysis reaction. The modification of the phyllosilicate includes leaching the clay with an acid or basic solution to form a leached clay preparation, calcining the leached clay and contacting the treated clay with a suspension comprising metal ions for ion-exchange. The modified clay catalyst can then be mixed with inorganic materials such as zeolites and dried to form fluidizable microspheres.

Owner:MARD INC

Supported hierarchical-pore HZSM-5 catalyst

ActiveCN108114739AIncrease olefin yieldReduce coke yieldMolecular sieve catalystsBiofuelsIon exchangeChemistry

The invention discloses a supported hierarchical-pore HZSM-5 catalyst. The catalyst is prepared by the following steps: depositing active metal on carbon nano particles by an atomic layer deposition method, putting the carbon nano particles into a precursor solution prepared from an aluminum source, a silicon source, an organic template agent and water, carrying out a hydrothermal reaction, and carrying out ion exchange with a NH4Cl solution, so as to obtain the supported hierarchical-pore HZSM-5 catalyst. The supported hierarchical-pore HZSM-5 is synthesized with the combination of the atomiclayer deposition technology, and the active metal is positioned in the pore canals of a molecular sieve, so that the active metal is introduced, and meanwhile mesoporous is also introduced. Differentfrom the common impregnation method, the preparation method provided by the invention reduces the metal supported on the surface of the molecular sieve, and thereby reduces the acidity influence on the surface of the molecular sieve. Meanwhile, when the catalyst provided by the invention is applied to the catalytic pyrolysis reaction of cellulose, the yield rates of aromatic hydrocarbons and olefins are greatly improved compared with the yield rates of aromatic hydrocarbons and olefins by using a conventional molecular sieve, and the coke yield rate is greatly reduced compared with the coke yield rate by using the conventional molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of improving catalytic cracking product distribution

InactiveCN1429881AHigh yieldReduce coke yieldCatalytic crackingProcess engineeringProduct distribution

Owner:CHINA PETROLEUM & CHEM CORP

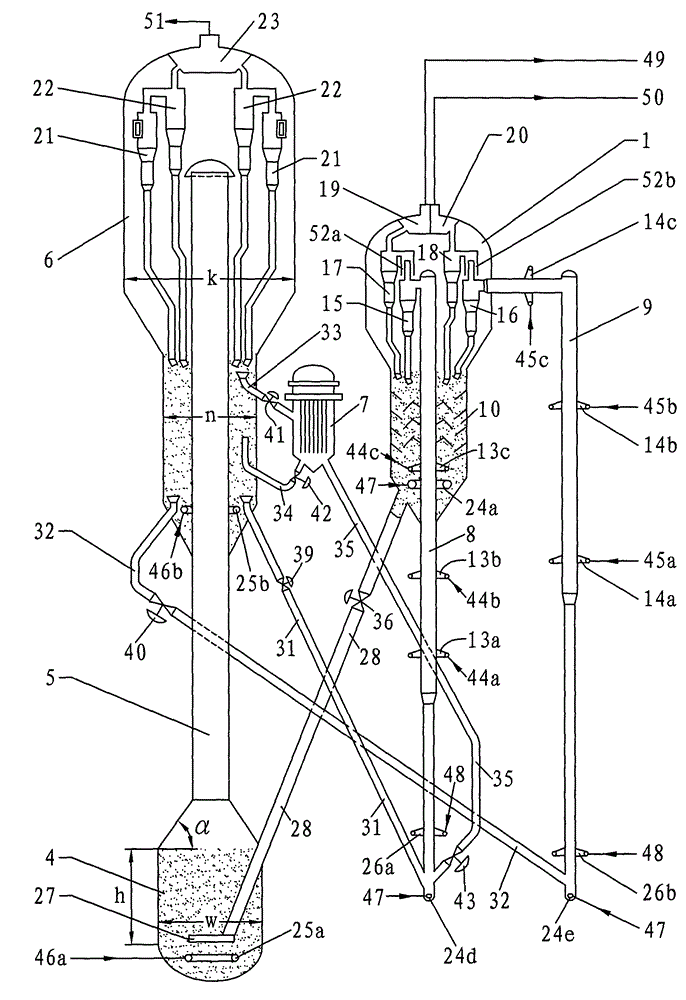

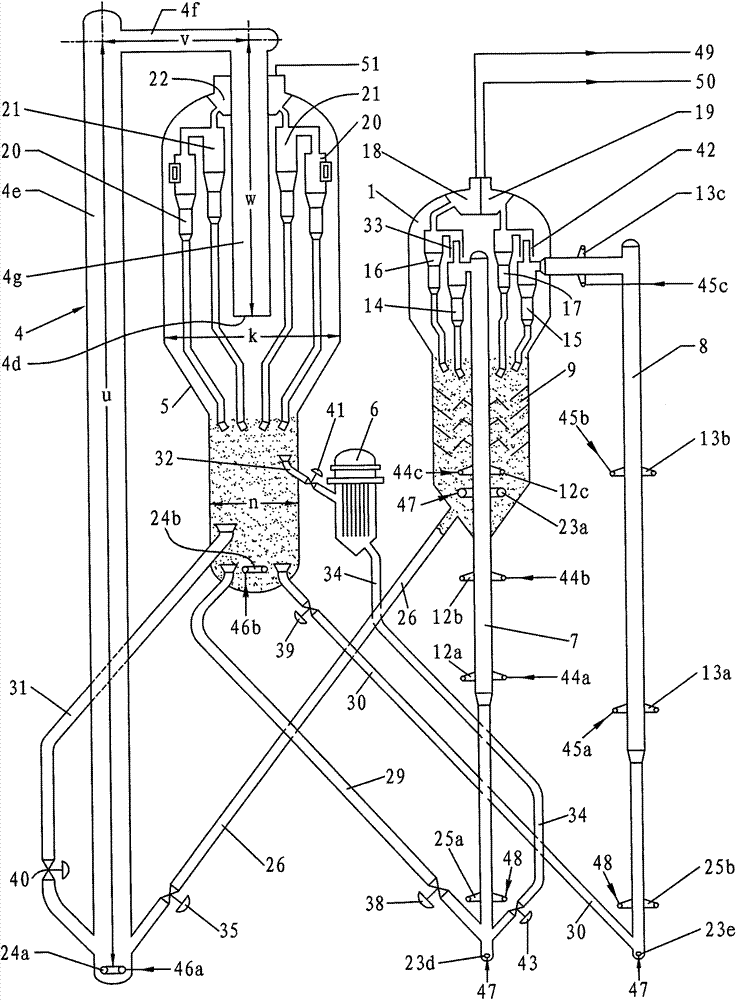

Double-lifted pipe catalytic cracking device and method thereof

ActiveCN105885941AReduce contact timeImprove distributionTreatment with plural parallel stages onlyChemical/physical processesContact timeFuel oil

The invention discloses a double-lifted pipe catalytic cracking device. The double-lifted pipe catalytic cracking device mainly comprises a heavy oil lifting pipe, a light hydrocarbon lifting pipe, a settlement device, regenerators and a catalyst cooler. The regenerators comprise a baffle plate regenerator and a turbulent bed regenerator, the baffle plate regenerator, the turbulent bed regenerator, and the catalyst cooler are coaxially arranged from top to down, the baffle plate regenerator is composed of an outer tube and an inner tube; a top of a circle bench-type cylindrical shell of the catalyst cooler is taken as a main wind outlet of the catalyst cooler for connecting with the bottom of a prevulcanization segment of the inner tube of the baffle plate regenerator; the bottom of the settlement device is communicated to a spent catalyst of the baffle plate regenerator, and the bottom of the catalyst cooler is respectively communicated to the bottom of the heavy oil lifting pipe and the light hydrocarbon lifting pipe through pipelines. By adopting the device disclosed by the invention, various heavy oil feed stocks and light hydrocarbon feed stocks are processed, a relatively short oiling agent contact time can be achieved, and the product quality is improved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

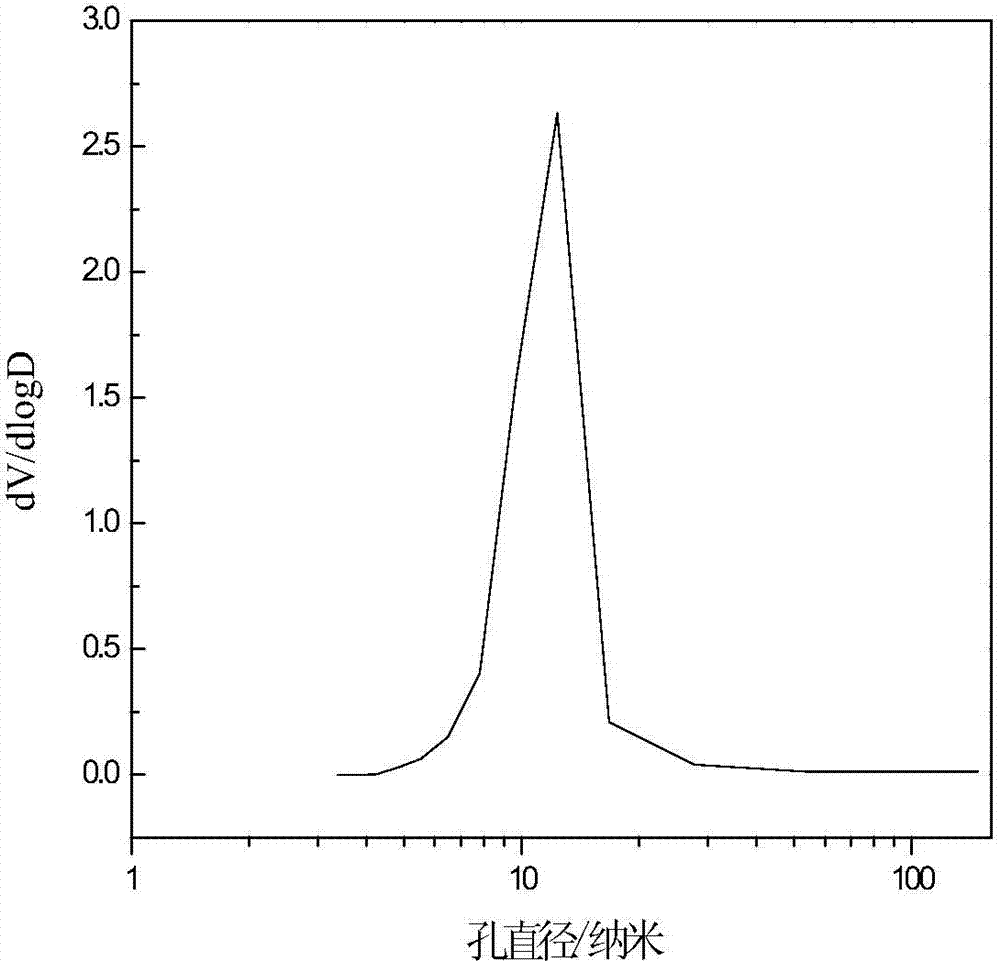

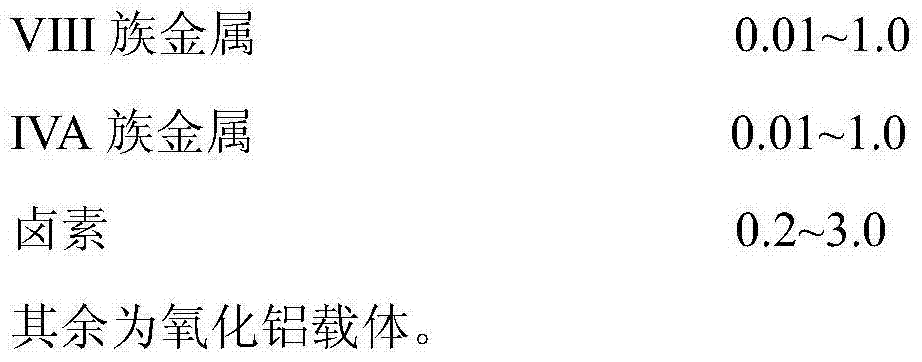

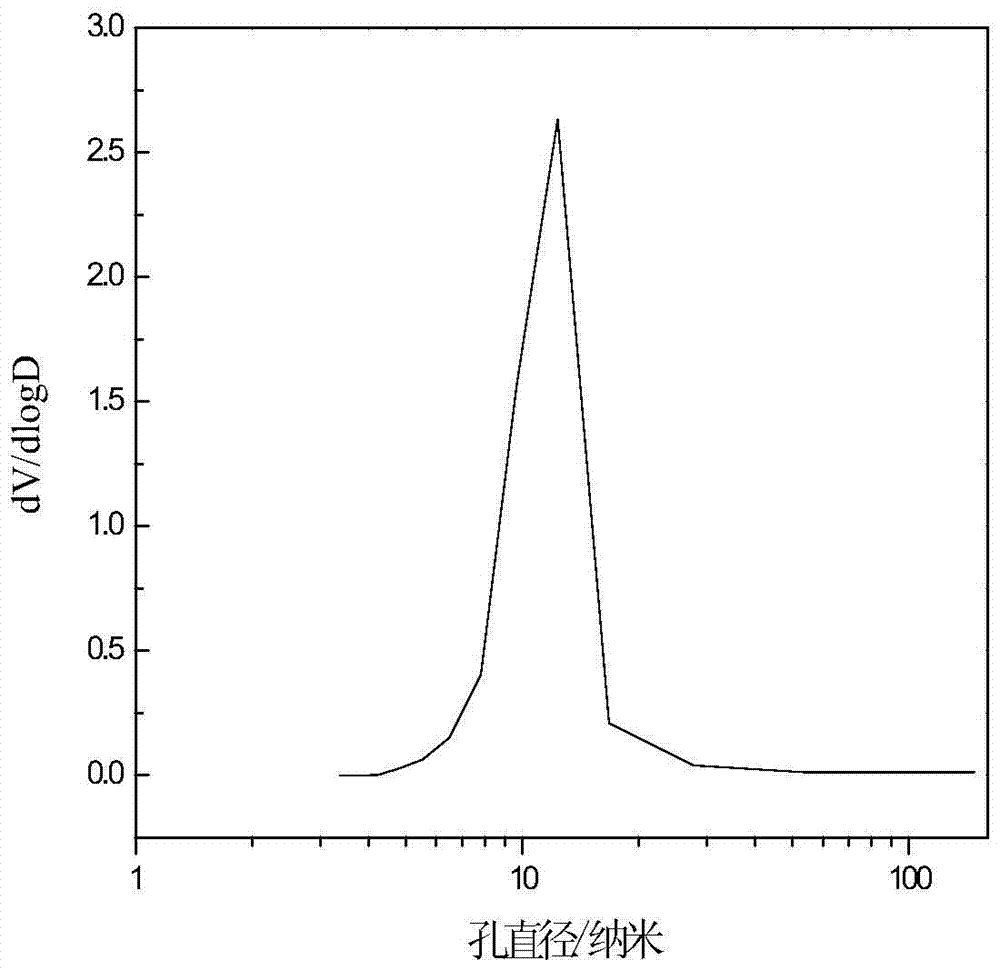

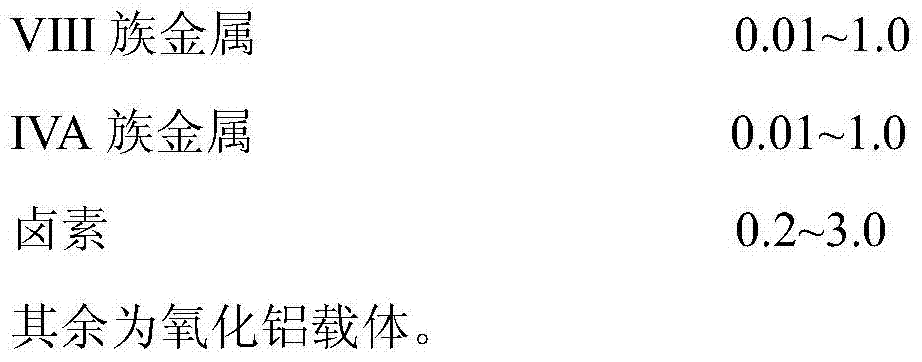

Large-pore-diameter high-bulk-density continuous reforming catalyst, preparation thereof and applications of the catalyst

ActiveCN104511291AHigh activityHigh Xylene YieldPhysical/chemical process catalystsCatalytic naphtha reformingHalogenLarge pore

The invention relates to a large-pore-diameter high-bulk-density continuous reforming catalyst, preparation thereof and applications of the catalyst. The catalyst comprises following components by mass, based on elements, 0.01-1.0% of a VIII-group metal, 0.01-1.0% of an IVA-group metal, and 0.2-3.0% of a halogen, wherein the VIII-group metal is platinum, the IVA-group metal is germanium or tin, the bulk density of the catalyst is 0.58-0.90 g / mL, the most probable pore diameter is 8-20 nm, and the specific surface area is 170-210 m<2> / g. The catalyst is applied in a continuous reforming process, and is high in activity, high in xylene yield and low in coke yield.

Owner:PETROCHINA CO LTD

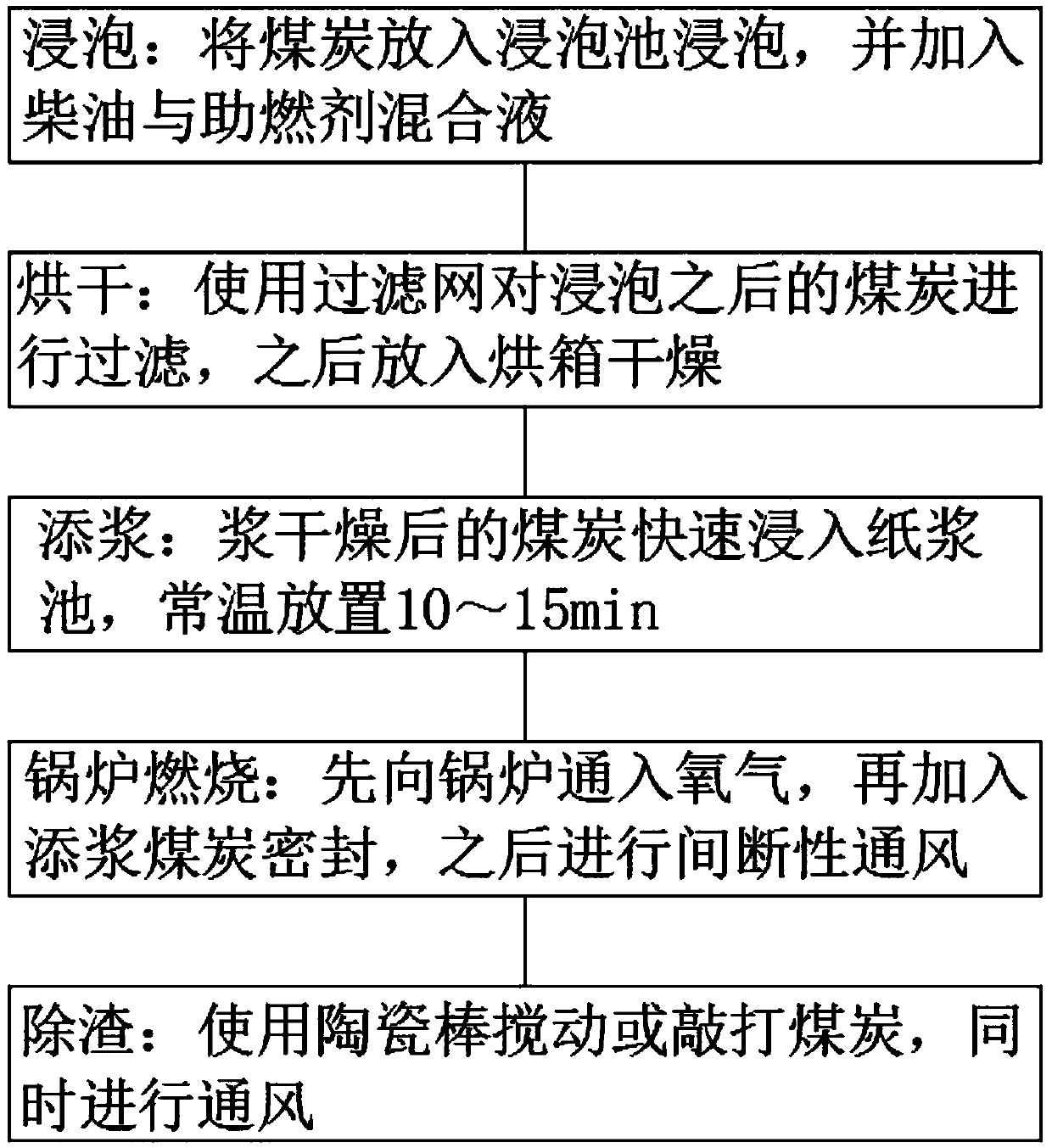

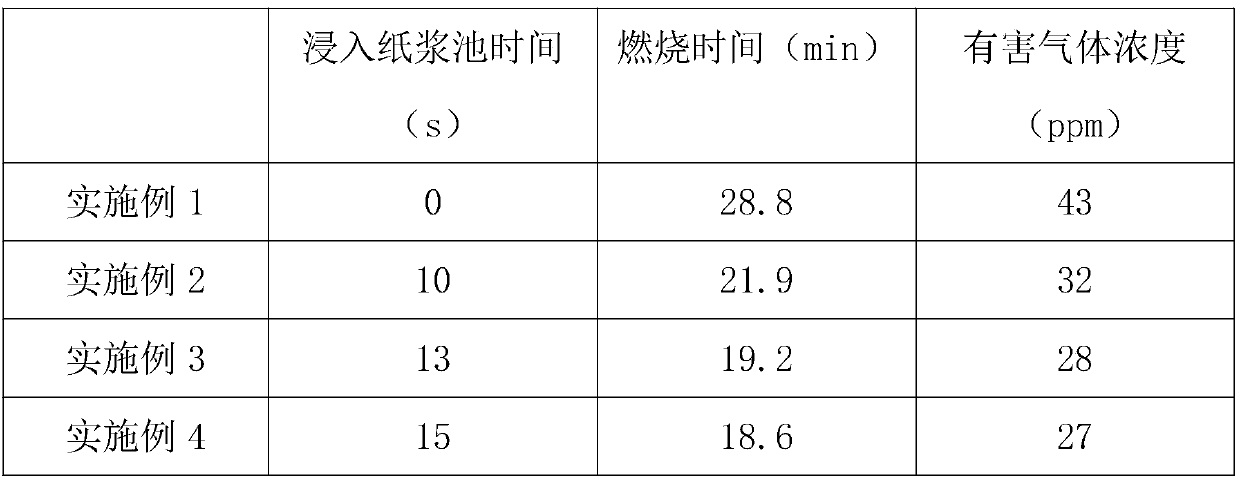

Method for increasing burning speed of coal

InactiveCN109609239ARealize comprehensive applicationWhen the boost occursSolid fuelsCombustionAlkylphenol

The invention discloses a method for increasing the burning speed of coal, comprising the following steps: immersing: immersing coal in a soaking pool for immersing for 20 min, and adding diesel oil and a combustion improver mixed liquid, wherein the combustion improver mixed liquid consists of, in parts by weight, 7 parts of alkylphenol polyoxyethylene. According to the method for improving the burning speed of coal, firstly heat stability and heat conduction are combined mutually during coal combustion, the coke yield is reduced when coal resources are used for coking, and the heat generation duration is improved during coal combustion; and secondly, when burning of coal, heating of the coal can be speeded up, the temperature can quickly enter a burning point of coal, further the burningspeed of coal is improved, at the same time emission of harmful gases is reduced when coal is burned at a low temperature, carbon ash on the surface of coal can be removed to enable internal coal tobe in contact with external air for accelerating oxidation of coal and further improving the combustion of coal, and thus better use prospects are brought.

Owner:亿利洁能科技(颍上)有限公司

Solid base catalyst and preparation method thereof

ActiveCN113509925AHigh proportion of mesoporesUnobstructed channelCatalyst carriersCatalytic crackingPolycyclic aromatic hydrocarbonPtru catalyst

The invention discloses a solid base catalyst and a preparation method thereof. The solid base catalyst is composed of an active component, an auxiliary agent, a molding auxiliary agent and a solid base catalyst carrier. The solid base catalyst carrier is a highly mesoporous catalytic carrier, and the solid base catalyst carrier is subjected to pore channel thickening treatment, transition metal doping and surface modification treatment, so that the hydrothermal stability of the catalyst is improved, parts of polar centers are eliminated, the adsorption capacity of the catalyst on polycyclic aromatic hydrocarbon and non-hydrocarbon impurities in heavy oil is reduced, and the service life of the catalyst is prolonged. The invention also provides a preparation method of the solid base catalyst, and microsphere, strip and spherical catalysts are prepared and used for fluidized bed catalytic cracking, fixed bed, moving bed and other reaction processes. When the solid base catalyst is used for treating heavy oil with the residual carbon content larger than 10 wt% and in the residual oil catalytic cracking process, the coke yield is smaller than 10 wt%, and the selectivity of low-carbon olefin in liquefied gas is larger than 80%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Process for delayed coking of whole crude oil

ActiveUS9023193B2Reduce coke yieldImprove coke qualityThermal non-catalytic crackingCatalytic crackingNaphthaFractionating column

Owner:SAUDI ARABIAN OIL CO

Fluid catalytic cracking device

ActiveCN105885938AHigh char strengthLarge heat capacityTreatment with plural serial stages onlyGasolinePetrochemical

The invention discloses a fluid catalytic cracking device in a petrochemical industry. The device mainly comprises a first tubular reactor with reaction section length of 5-15m, a second tubular reactor with reaction section length of 5-10m, a sedimentation device, a gas-solid separator, a regenerator composed of a baffle pipe-type separator and a turbulent bed separator, a first-grade regenerated catalyst cooler, a second-grade regenerated catalyst cooler, a low-temperature regenerated catalyst tank and pipes connected to corresponding devices. The baffle pipe-type separator mainly comprises a housing, an outer pipe and an inner pipe. The housing comprises a housing pipe, a transition section and an outlet pipe connected in series from top to bottom. Circular passages are formed between the housing pipe and the outer pipe and between the outer pipe and the inner pipe. The separator wall at the bottom of the inner pipe is provided with a regenerated catalyst inlet and an inlet of a catalyst to be regenerated. The separator wall at the bottom of the housing pipe is provided with a main air inlet pipe. The device can be used for heavy oil catalytic cracking and gasoline catalytic modification.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

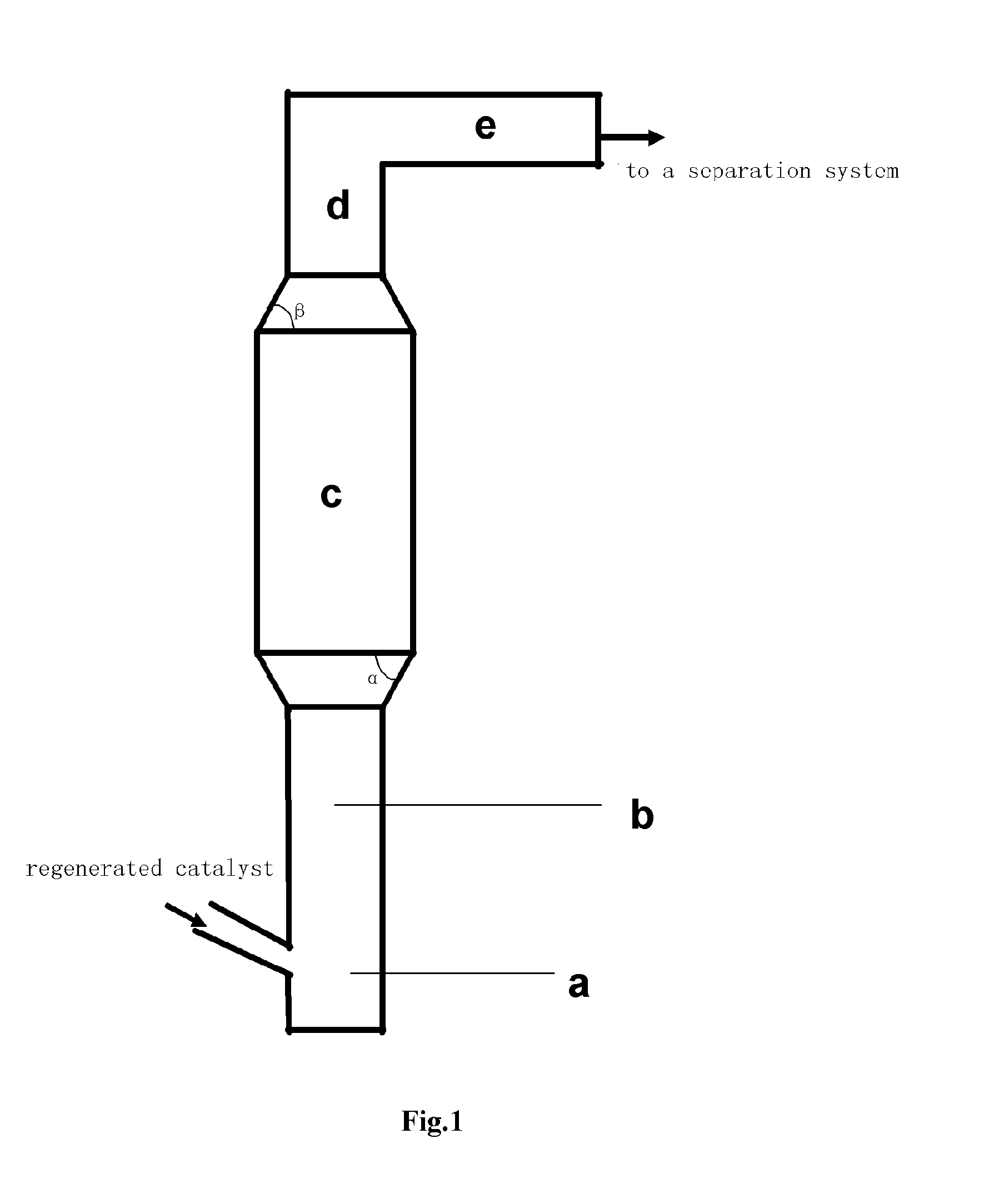

Catalytic conversion method for improving product distribution

ActiveUS20130211167A1Improve product distributionIncreasing isobutene contentCatalytic crackingHydrocarbonsPtru catalystCracking reaction

The present invention relates to a catalytic conversion process for improving the product distribution, characterized in that a feedstock oil of good quality is contacted with a hot regenerated catalyst having a lower activity in a reactor to carry out a cracking reaction, the reaction product is separated from the spent catalyst to be regenerated, then the reaction product is fed into a separation system, and the spent catalyst to be regenerated is stripped, regenerated and recycled in the process. The isobutene content in the liquefied petroleum gas (LPG) produced by the process is increased by a factor of more than 30%, and the olefin content in the gasoline composition may be increased to more than 30 wt. %. The product distribution is optimized, and the yields of dry gas and coke are decreased, so as to sufficiently utilize the petroleum resources.

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

Continuous Reforming Catalyst with Large Pore and High Bulk Density and Its Preparation and Application

ActiveCN104511291BHigh activityHigh Xylene YieldPhysical/chemical process catalystsCatalytic naphtha reformingPlatinumAs element

Owner:PETROCHINA CO LTD

Method for producing chemicals from crude oil by double-tube parallel multi-zone catalytic conversion

ActiveUS11434437B1Inhibit productionLight contentTreatment with plural serial cracking stages onlyCatalytic crackingCatalytic transformationPtru catalyst

A method for producing chemicals from crude oil by double-tube parallel multi-zone catalytic conversion is provided. The method may include the following steps: feeding the crude oil directly or separating the crude oil into light and heavy components by flash evaporation or distillation after desalination and dehydration; strengthening the contact and reaction between oil gas and catalyst by using two parallel reaction tubes with novel structure, controlling the reaction by zones, carrying out optimal combination on feeding modes according to different properties of reaction materials, controlling suitable reaction conditions for different materials, and increasing the production of light olefins and aromatics.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

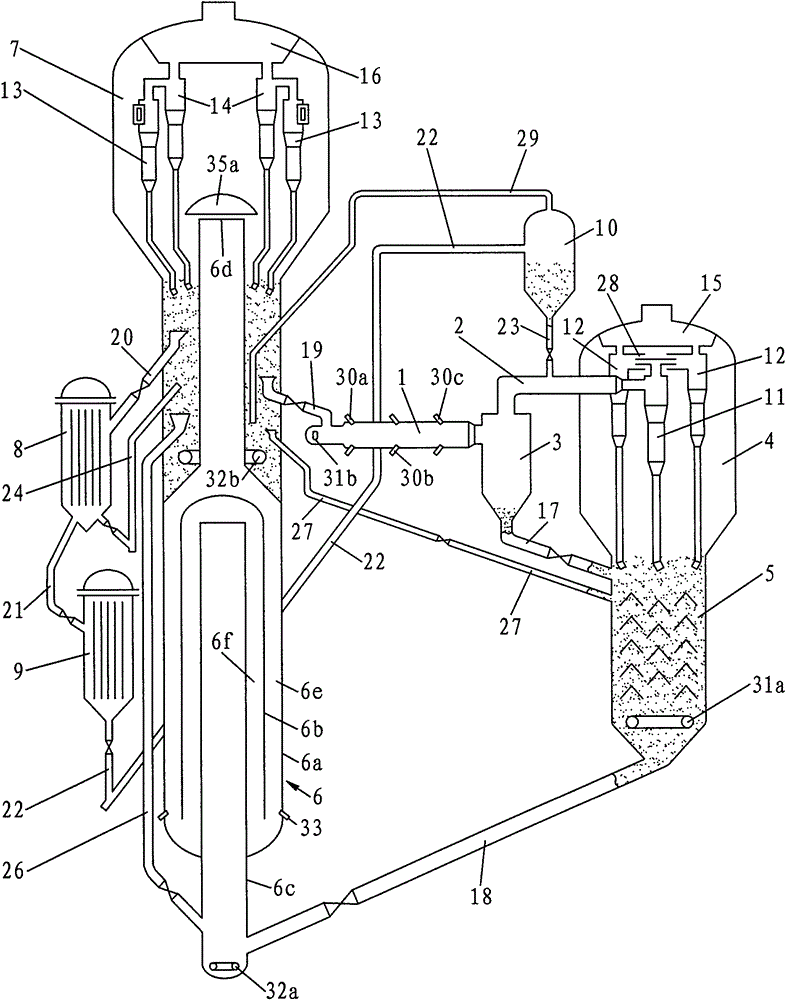

Double-riser catalytic cracking method and device

ActiveCN104513673AReduce contact timeImprove distributionHydrocarbon oils treatmentCycloneChemical industry

The invention discloses a double-riser catalytic cracking method and device in petroleum chemical industry. The catalytic cracking method is as follows: respectively performing heavy oil catalytic cracking reaction and light hydrocarbon catalytic modification reaction by use of double risers, wherein the heavy oil catalytic cracking oil agent contact time is 0.2-1.5e; respectively performing gas-solid separation on two reaction material flows by use of respective special cyclone separators; respectively entering two reaction oil and gas flows into respective special fractionating towers for fractional distillation; after steam stripping of a spent catalyst, entering the spent catalyst into a baffle tubular regenerator, after mixing with a uncooled cycle regenerated catalyst, burning off more than 90% of generated coke by main air co-current contact with the baffle tubular regenerator, entering a semi regenerated catalyst into a turbulent bed regenerator, burning off the rest generated coke by main air countercurrent contact with the turbulent bed regenerator, and returning the regenerated catalyst into the risers for recycling use. The invention discloses a double-riser catalytic cracking device for realizing the catalytic cracking method. The double-riser catalytic cracking method and device can be used for heavy oil catalytic cracking and light hydrocarbon catalytic modification.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com