Catalytic conversion method of hydrocarbon oil

A catalytic conversion method and hydrocarbon oil technology, applied in the direction of catalytic cracking, cracking, petroleum industry, etc., can solve the problems of increased coke yield and poor raw material atomization effect, so as to increase yield, reduce coke yield, reduce Effect of Dry Gas Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

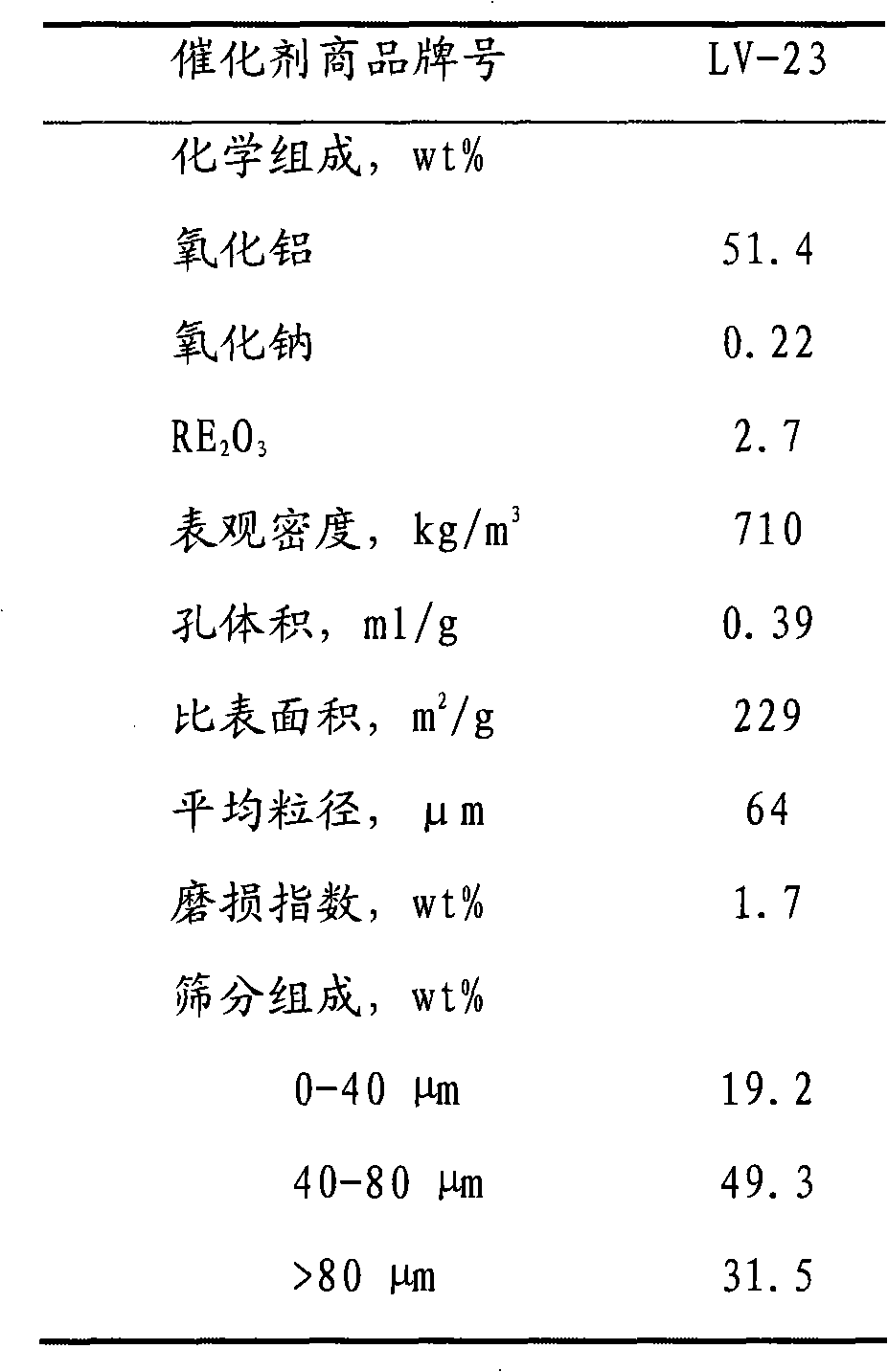

Embodiment 1

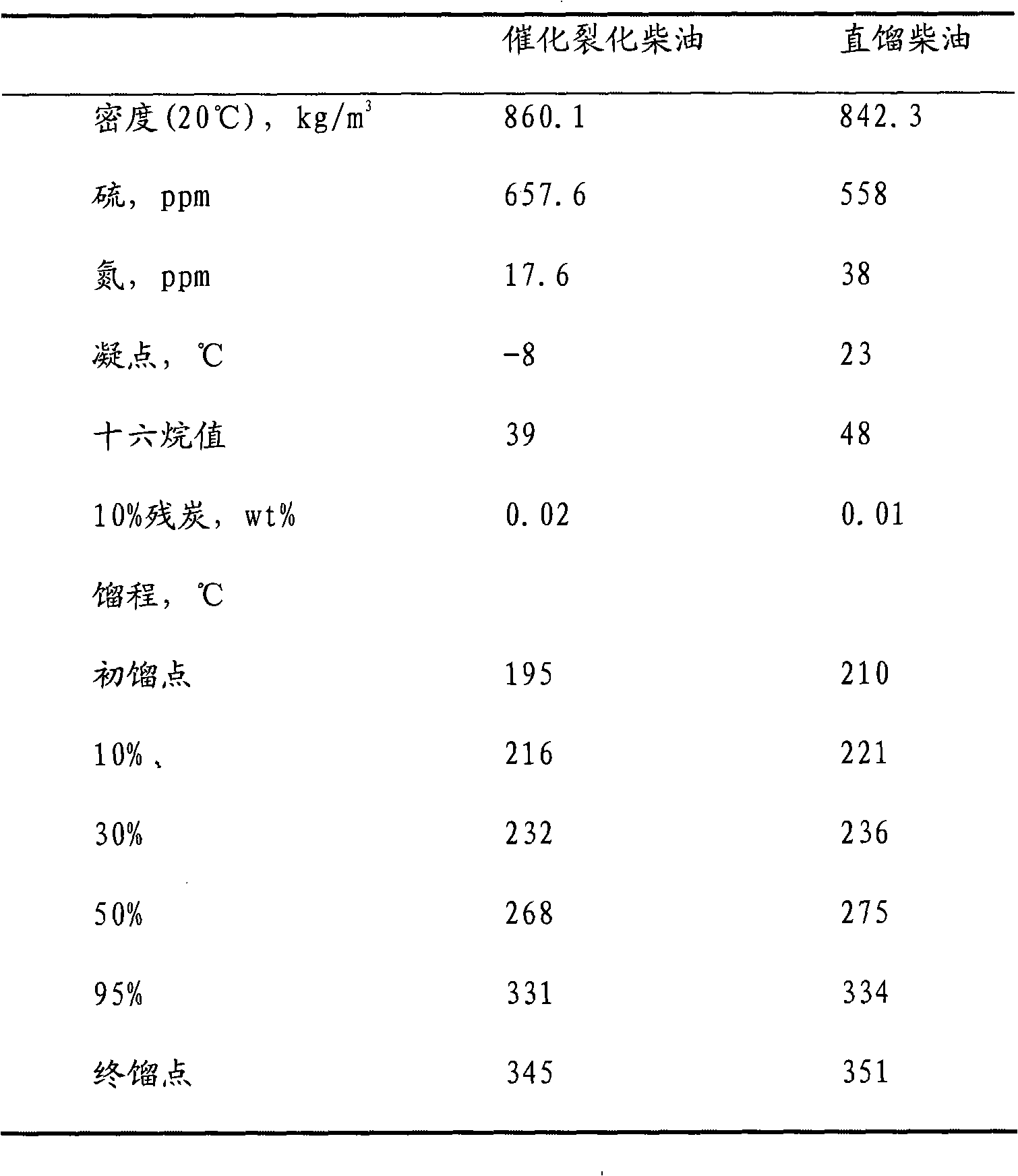

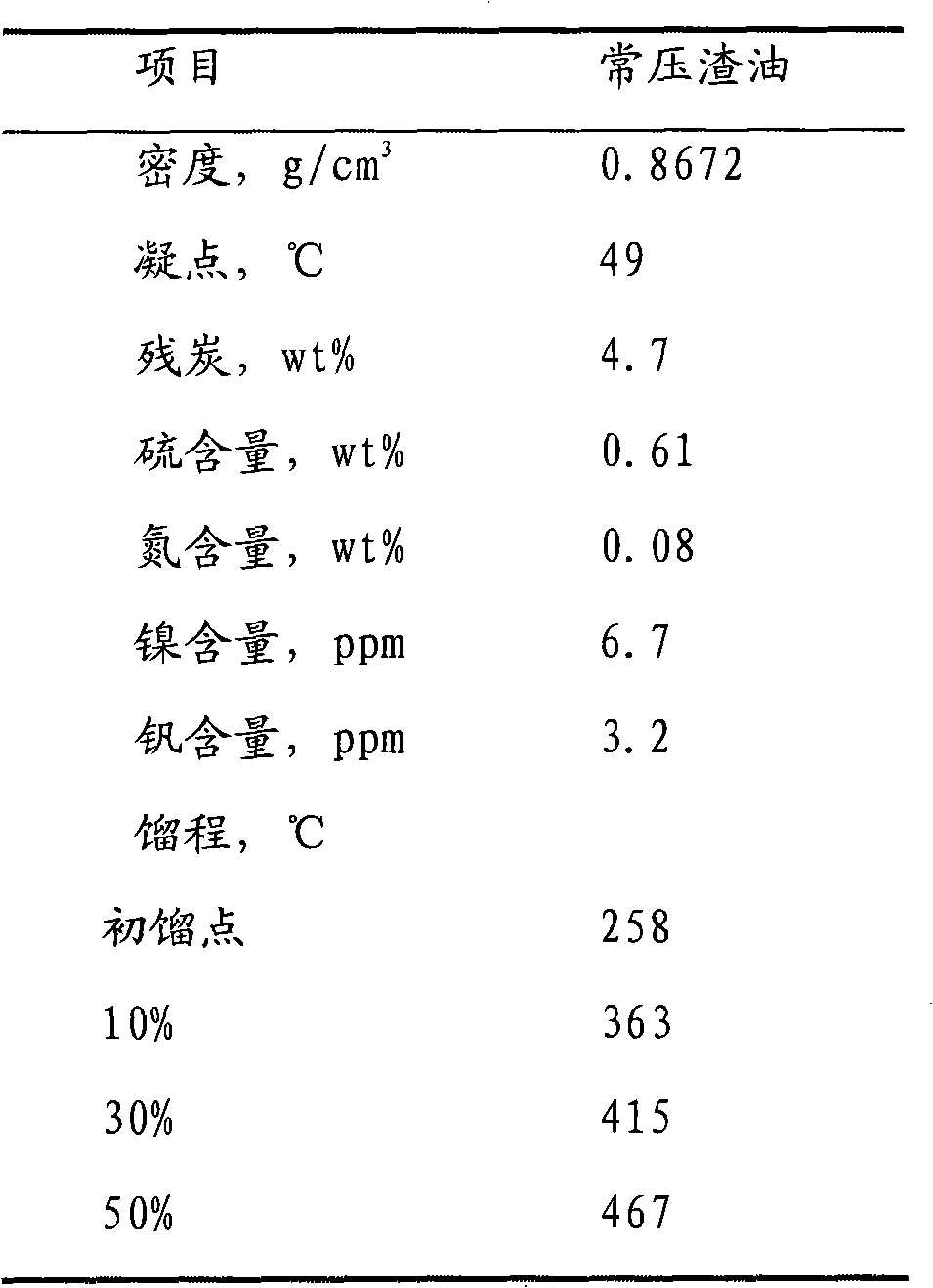

[0034]Load LV-23 into the reactor of the fixed fluidized bed reaction device, and the catalyst loading amount is 240g. The atmospheric residue raw material and catalytic cracking diesel oil are mixed in a ratio of 90:10, heated by a preheater, mixed with atomized steam, and then entered into a reactor, where they react with a high-temperature catalyst, and the generated oil and gas are cooled by three stages Finally, the cracked gas and liquid products are collected separately. The spent catalyst with coke deposited on the surface is regenerated by passing excess air at high temperature, and the volume of flue gas and cracked gas and the weight of liquid products are measured. The experimental conditions are: oil intake 40g, oil intake time 120s, preheating temperature 220°C, reaction temperature 500°C, agent-oil ratio 6, space velocity 4h -1 , and the results are listed in Table 4.

Embodiment 2

[0036] Load LV-23 into the reactor of the fixed fluidized bed reaction device, and the catalyst loading amount is 240g. The raw material of atmospheric residual oil and straight-run diesel oil is mixed at a ratio of 80:20, heated by a preheater, mixed with atomized steam, and then entered into a reactor, where it reacts with a high-temperature catalyst, and the generated oil gas is cooled by three stages Finally, the cracked gas and liquid products are collected separately. The spent catalyst with coke deposited on the surface is regenerated by passing excess air at high temperature, and the volume of flue gas and cracked gas and the weight of liquid products are measured. The experimental conditions are: oil intake 40g, oil intake time 120s, preheating temperature 220°C, reaction temperature 500°C, agent-oil ratio 6, space velocity 4h -1 , and the results are listed in Table 4.

Embodiment 3

[0043] The test of Comparative Example 2 was repeated, except that the feedstock oil was a mixture of atmospheric residue and catalytic diesel oil, and the weight ratio of the two was 90:10. The results are listed in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com