Fluid catalytic cracking device

A fluidized catalytic cracking and catalyst technology, applied in the field of fluidized catalytic cracking devices, can solve the problems of low activity, limited improvement range, and difficulty in realizing oil contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

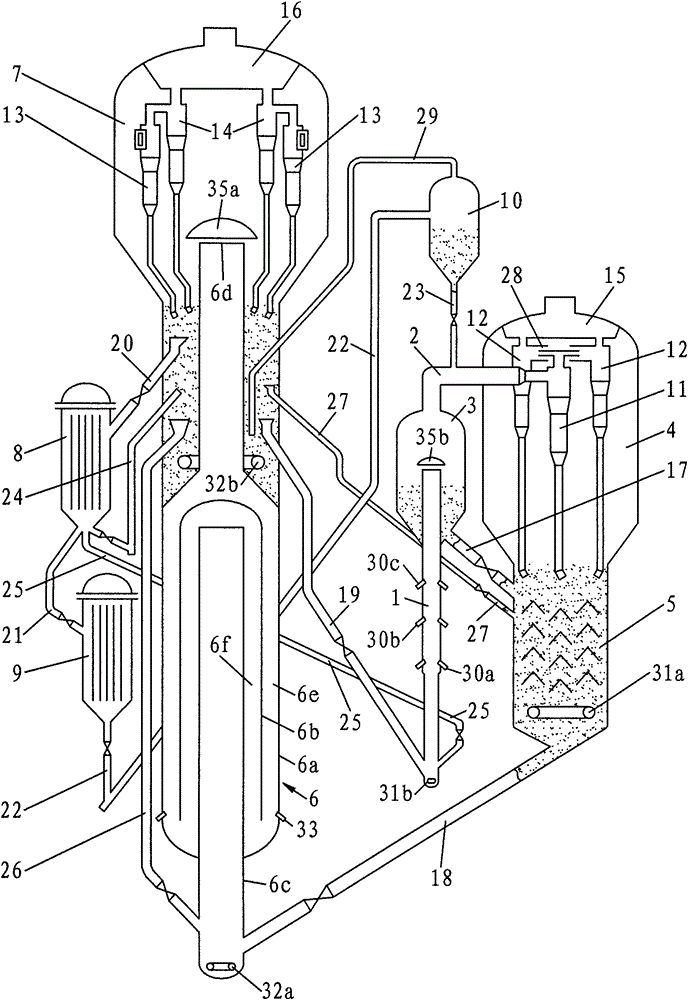

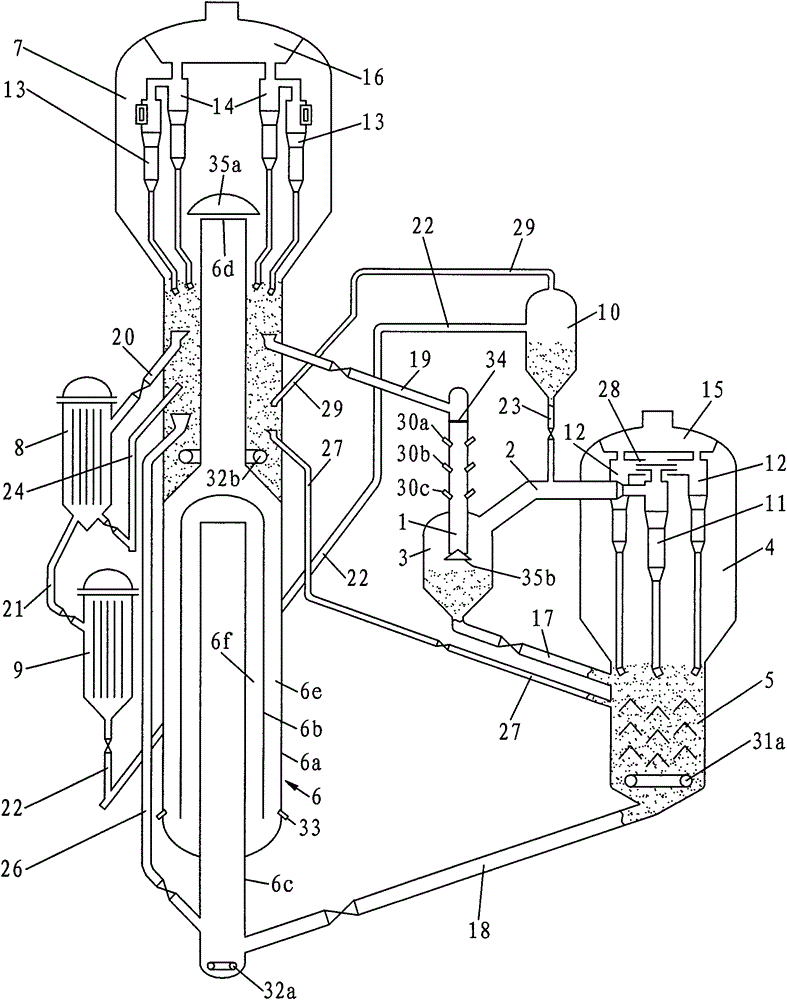

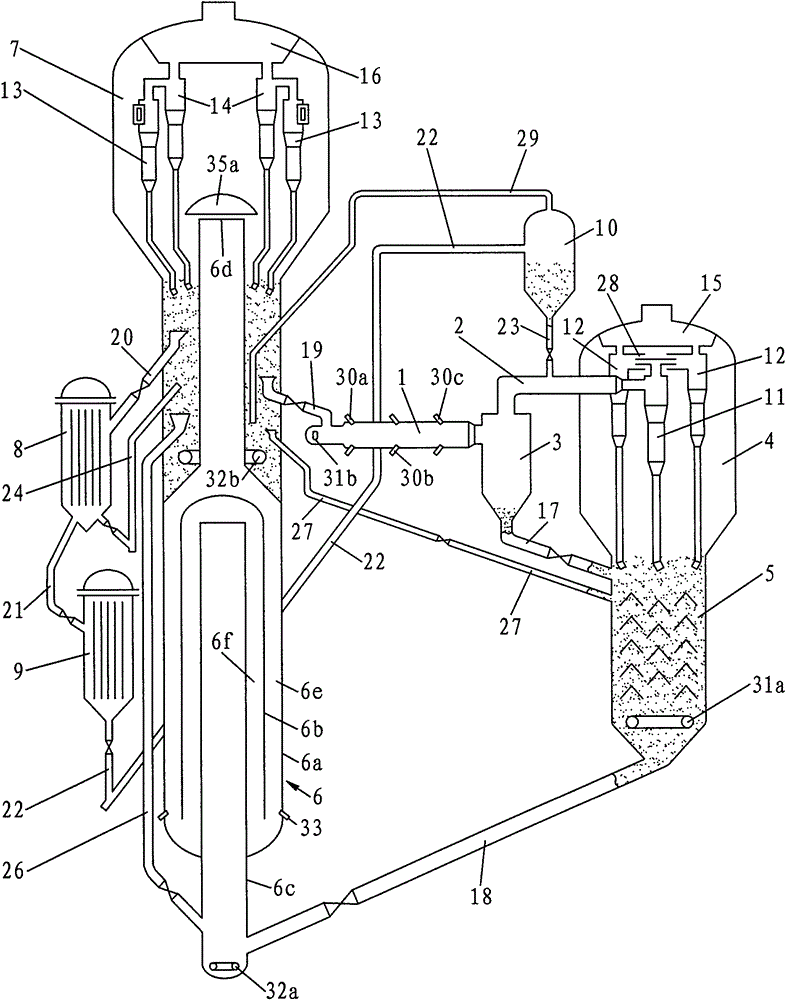

[0084] Embodiments similar to the present invention figure 1 The fluidized catalytic cracking pilot plant of the device shown is partly carried out according to the specific implementation method figure 1 The relevant description of the device shown is tested, the difference is that the first tubular reactor is equipped with two layers of heavy oil feed nozzles, and there is no regenerated catalyst delivery pipe between the dense phase section and the upper part of the stripping section of the turbulent bed regenerator. The design capacity of the first tubular reactor and the second tubular reactor is 60kg / d.

[0085] In the embodiment, the heavy oil raw material processed by the first tubular reactor is the same Daqing atmospheric residue as the comparative example, and the catalyst adopts the same CC-20D catalytic cracking industrial equilibrium catalyst as the comparative example. The feed refers to Daqing atmospheric residue and re-refined oil for the first tubular reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com