A method for controlling the bottom liquid level and reaction severity of fractionation tower

A fractionation tower and severity technology, which is applied in the control field of the catalytic cracking process, can solve the problems of reducing the yield of the target product, increasing the solid content and density of the oil slurry at the bottom of the fractionation tower, and reducing the economic benefit of the device, so as to reduce the energy consumption. consumption and improve the efficiency of fractionation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

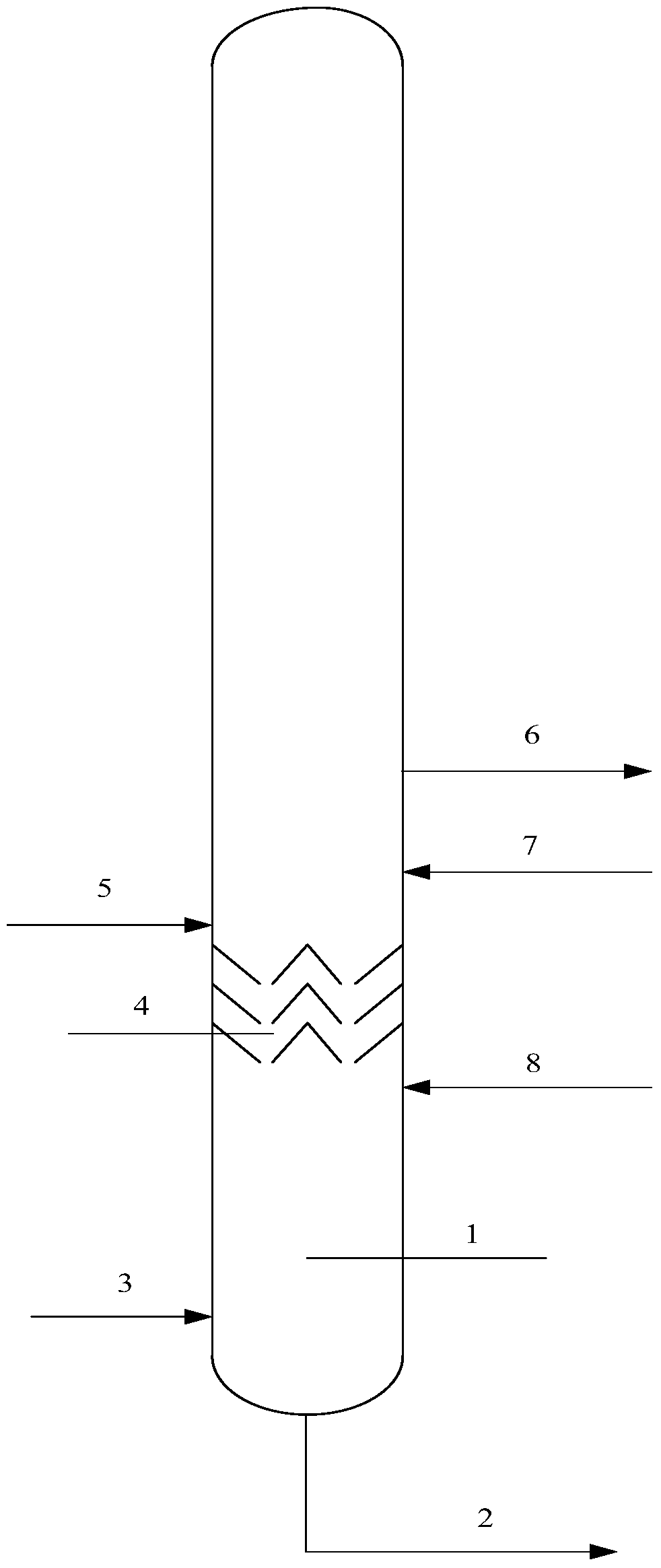

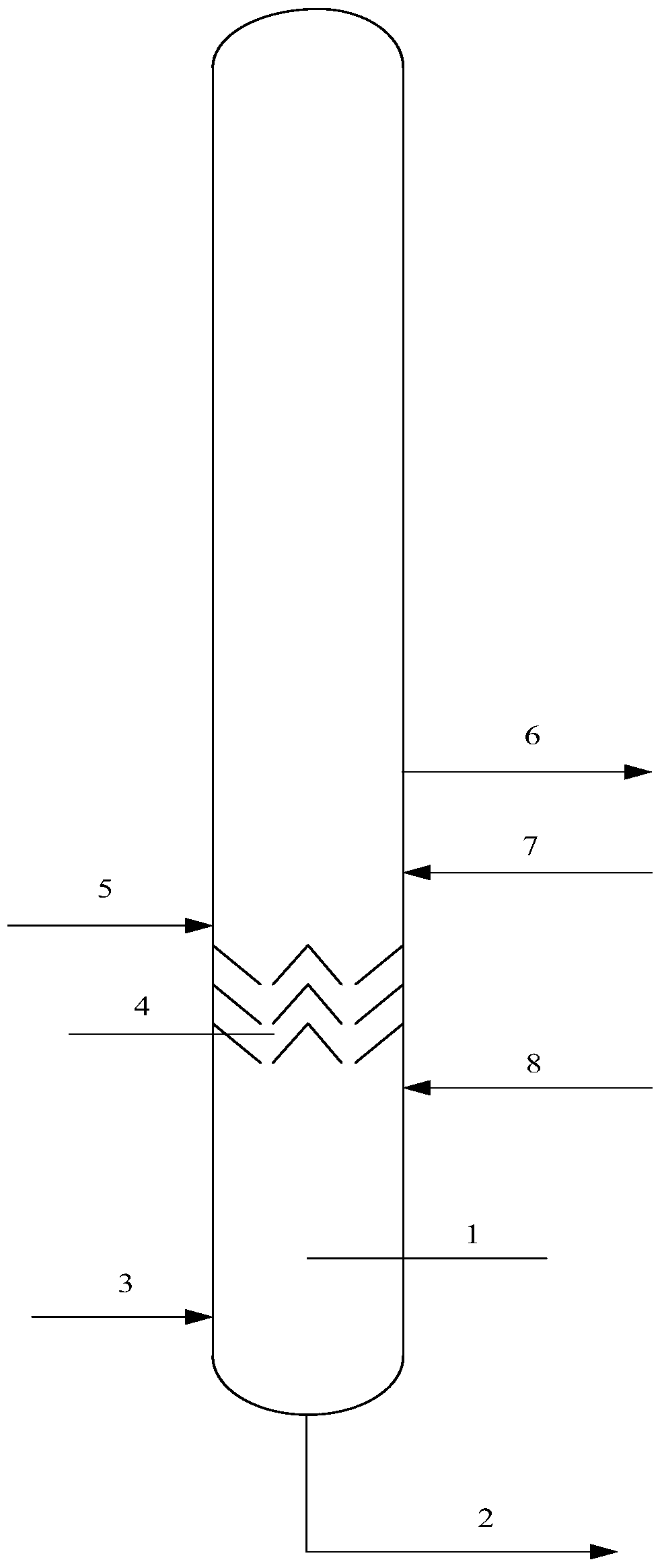

[0032] refer to figure 1 , 3 million catalysts were contacted and reacted with regenerated catalyst in Lanzhou 3 million tons / year catalytic cracking unit. The catalyst was HDO-70 fresh catalyst. Under the conditions of reaction temperature 500 ℃, agent-oil ratio 6, and reaction time 1.9s, after the reaction, enter The bottom of gas-solid sedimentation separator and fractionation tower 1; specific reaction conditions and results are shown in Table 2. The medium is vacuum wax oil, and the ratio of the flow rate of the raw oil medium into the fractionation tower to the mass of the reaction oil and gas is 1:20. The reaction conversion rate is 74.26%, and the oil slurry density is 1.01g / cm 3 , The liquid level at the bottom of the fractionation tower is 35.

Embodiment 2

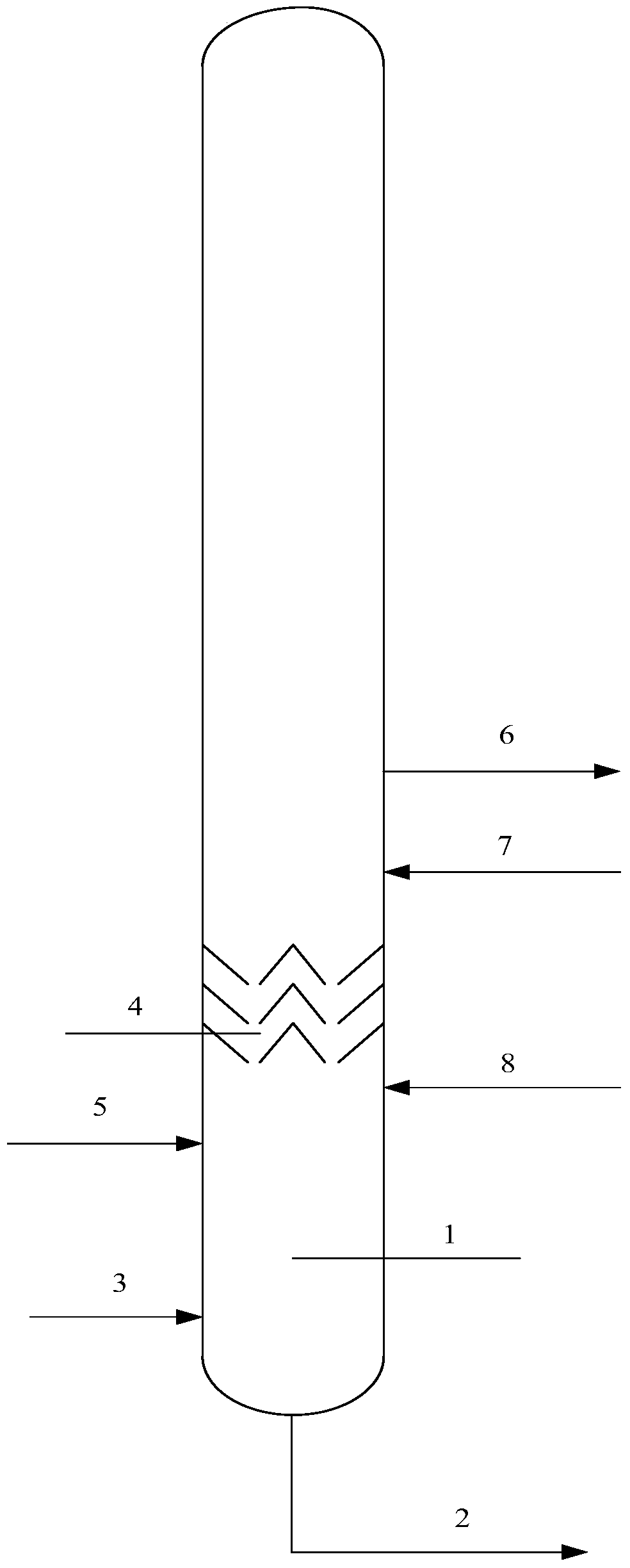

[0034] refer to figure 2 , 3 million catalysts were contacted and reacted with the regenerated catalyst in the 2.6 million tons / year MIP catalytic cracking unit in Hohhot. The catalyst was HDC-200 fresh catalyst. Under the condition of the second reaction zone time 3.5s, after the reaction, enter the gas-solid sedimentation separator and the bottom of the fractionation tower 1; the specific reaction conditions and results are shown in Table 2. The medium is 3 million catalysts, and the mass ratio of the flow rate of the medium entering the fractionation tower to the reaction oil gas 2 is 1:5. The reaction conversion rate is 72.87%, and the oil slurry density is 1.08g / cm 3 , The liquid level at the bottom of the fractionation tower is 38.

Embodiment 3

[0036] refer to figure 2 , 3 million catalysts were contacted and reacted with the regenerated catalyst in the 2.6 million tons / year MIP catalytic cracking unit in Hohhot. The catalyst was HDC-200 fresh catalyst. Under the condition of the second reaction zone time 3.5s, after the reaction, enter the gas-solid sedimentation separator and the bottom of the fractionation tower 1; the specific reaction conditions and results are shown in Table 2. The medium is 3 million catalysts, and the mass ratio of the flow rate of the medium entering the fractionation tower to the reaction oil gas 2 is 1:13. The reaction conversion rate is 69.17%, and the oil slurry density is 1.05g / cm 3 , The liquid level at the bottom of the fractionation tower is 42.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com