Large-pore-diameter high-bulk-density continuous reforming catalyst, preparation thereof and applications of the catalyst

A technology for reforming catalysts and large pore diameters, applied in physical/chemical process catalysts, chemical instruments and methods, catalytic reforming of naphtha, etc., can solve the problem of uneven distribution of reaction products, uneven flow of catalysts, and increased oil and gas treatment capacity major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Get 1000 grams of pseudo-boehmite (produced by Sasol Company, , the total amount of aluminum oxide is 76m%) and 1.4 liters of deionized water, stirred and slurried at room temperature for 0.5 hours. Then add 60 ml (1:1 volume) of nitric acid, a predetermined amount of stannous chloride in hydrochloric acid solution, and acidify for 2 hours. Then drop the ball into the oil ammonia column, wherein the oil column is aviation kerosene, and the wet ball is solidified in the ammonia water column for 2 hours, then filtered, washed with deionized water three times, dried at 60°C for 6 hours, and dried at 120°C for 2 hours. Calcined at 500°C for 4 hours in a flowing air atmosphere. The properties of the prepared carrier No. 1 are shown in Table 1.

Embodiment 2

[0043] Dissolve 98 grams of aluminum nitrate nonahydrate in 200 milliliters of water, add 3.4 milliliters of stannous chloride hydrochloric acid solution (the solubility of tin is 12 mg / ml) after the dissolution is transparent, stir evenly and impregnate 200 grams of No. 1 carrier for 5 hours , under vacuum conditions, evaporate the impregnation solution at 60°C, dry at 120°C for 4 hours, and then bake at 450°C for 4 hours. Carrier No. 2 was prepared, and its physical properties are listed in Table 1.

Embodiment 3

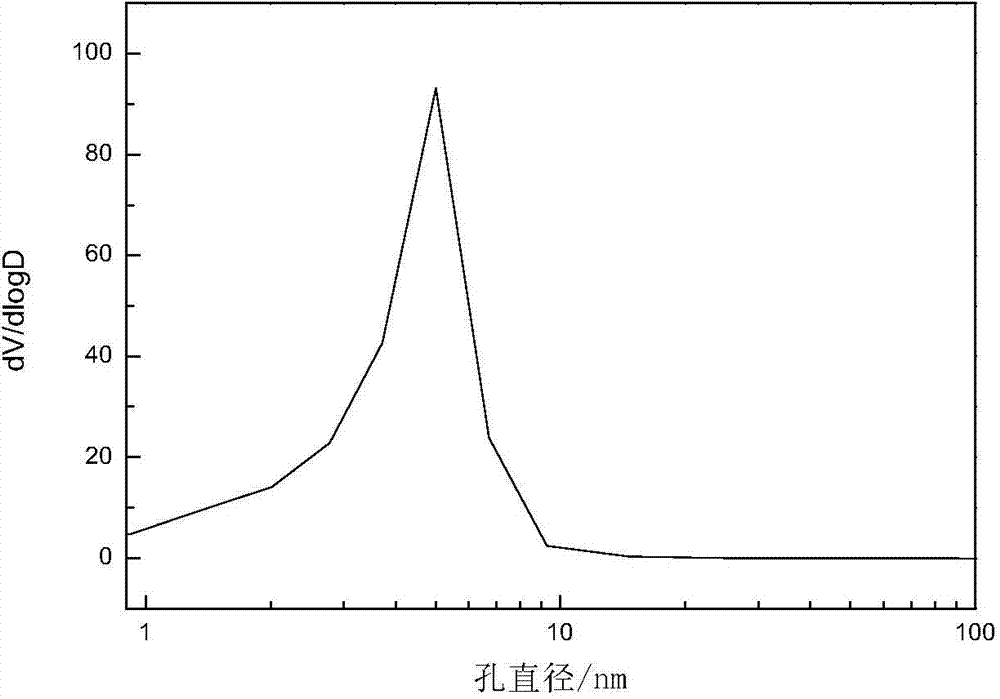

[0045] No. 3 carrier was prepared according to the method of Example 2, except that 180 grams of aluminum nitrate nonahydrate was dissolved in 300 milliliters of water, and after the dissolution was transparent, 6.4 milliliters of tin protochloride hydrochloric acid solution (tin solubility was 12 mg / ml) was added. The physical properties of No. 3 carrier are listed in Table 1, and its pore size distribution is as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com