Device and method for reducing the temperature of catalytic cracking regenerated catalyst

A catalytic cracking unit and regeneration catalyst technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of small application range, cracking performance inferior to regeneration catalyst, etc., achieve wide application range, reduce thermal cracking reaction, good cracking performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

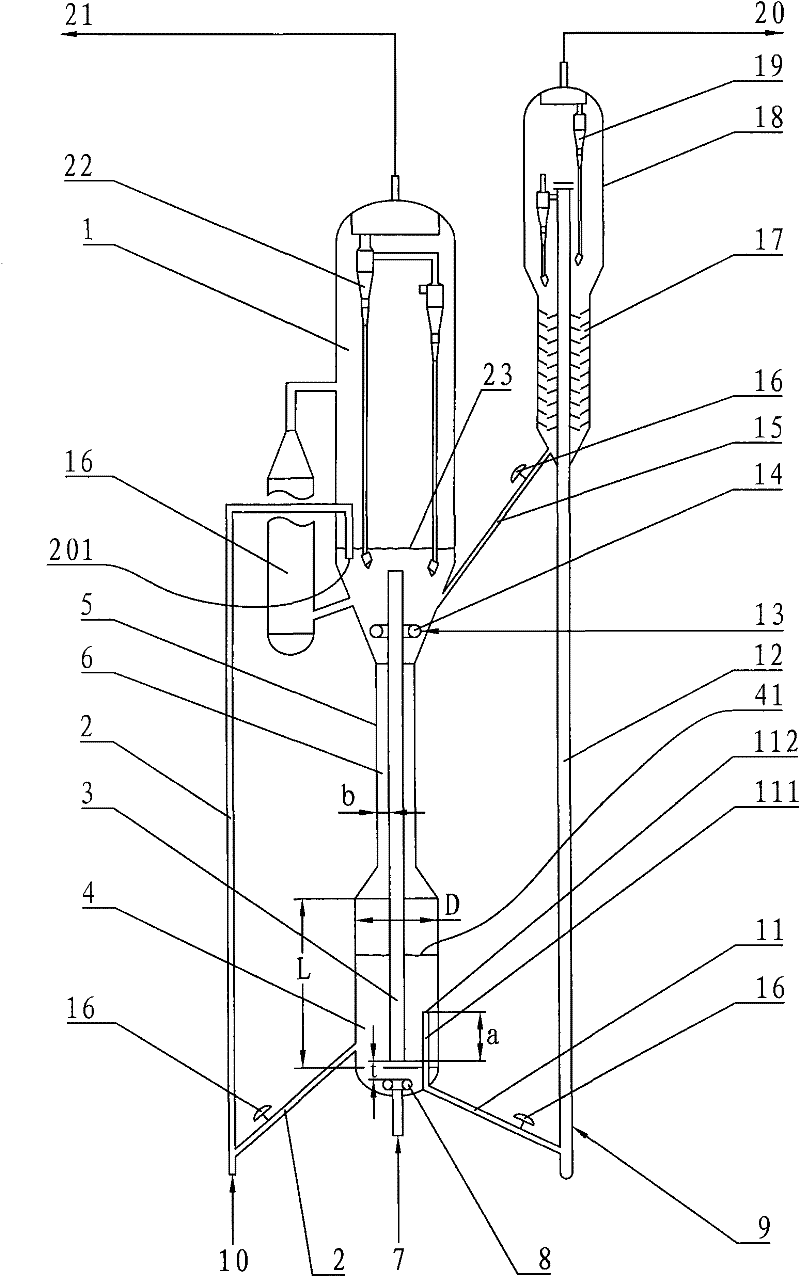

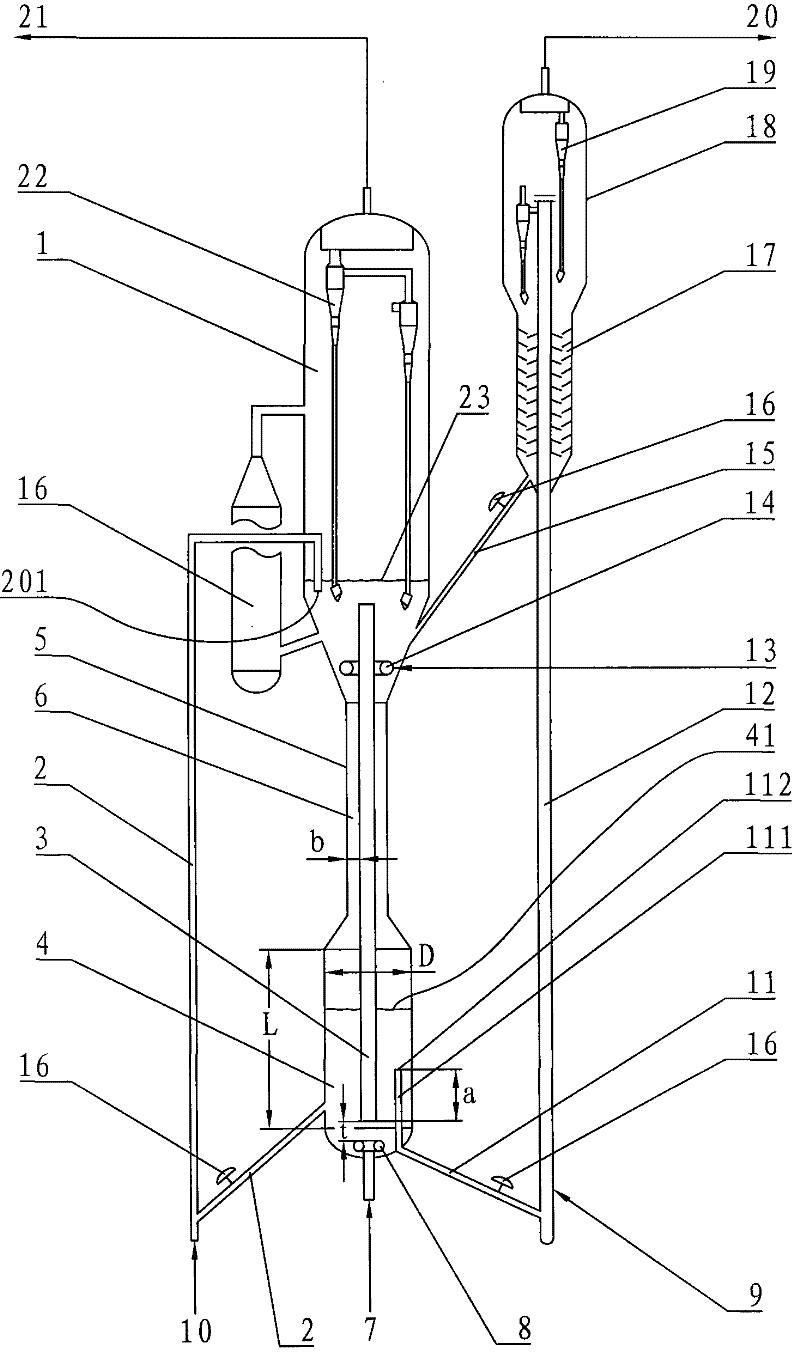

[0043] exist figure 1 The test is carried out on the catalytic cracking pilot plant with a single heavy oil riser reactor as shown. The pilot plant is equipped with the device for lowering the temperature of the catalytic cracking regenerated catalyst according to the present invention, but no regenerated catalyst circulation pipe is installed, and the regenerated catalyst cooled in the regenerated catalyst cooler is not circulated back to the regenerator through the regenerated catalyst circulation pipe.

[0044] The heavy oil riser reactor processes Daqing catalytic raw material, with a processing capacity of 30kg / d, and simulates full back refining operation; commercially available CC-20D catalytic cracking catalyst is used. The stripping medium in the stripping section of the settler is water vapor, and the stripping temperature is 500°C.

Embodiment 2

[0047] The operating conditions of the regenerator, the regenerated catalyst cooler and the heavy oil riser reactor, as well as the product distribution of the heavy oil riser reactor and some properties of the gasoline produced are shown in Table 4. The test device used in embodiment 2, heavy oil riser reactor feed, processing capacity, simulated full back refining operation mode and the catalytic cracking catalyst used, and the stripping medium and stripping temperature of the stripping section of the settler, and the implementation Example 1 is the same.

Embodiment 3

[0049] The operating conditions of the regenerator, the regenerated catalyst cooler and the heavy oil riser reactor, as well as the product distribution of the heavy oil riser reactor and some properties of the gasoline produced are shown in Table 5. The test device used in embodiment 3, heavy oil riser reactor feed, processing capacity, simulated full back refining operation mode and the catalytic cracking catalyst used, and the stripping medium and stripping temperature of the stripping section of the settler, and the implementation Example 1 is the same.

[0050] Table 1 Heavy Oil Riser Reactor Feed Properties (Comparative Examples, Examples 1-3)

[0051] Heavy Oil Riser Reactor Feed

Daqing Catalytic Raw Materials

Density (20℃), kg / m3

906.2

Charcoal residue, w%

4.0

Family composition, w%

saturated hydrocarbon

62.5

Aromatics

25.4

Colloid + asphaltenes

12.1

Sulfur content, μg / g

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com