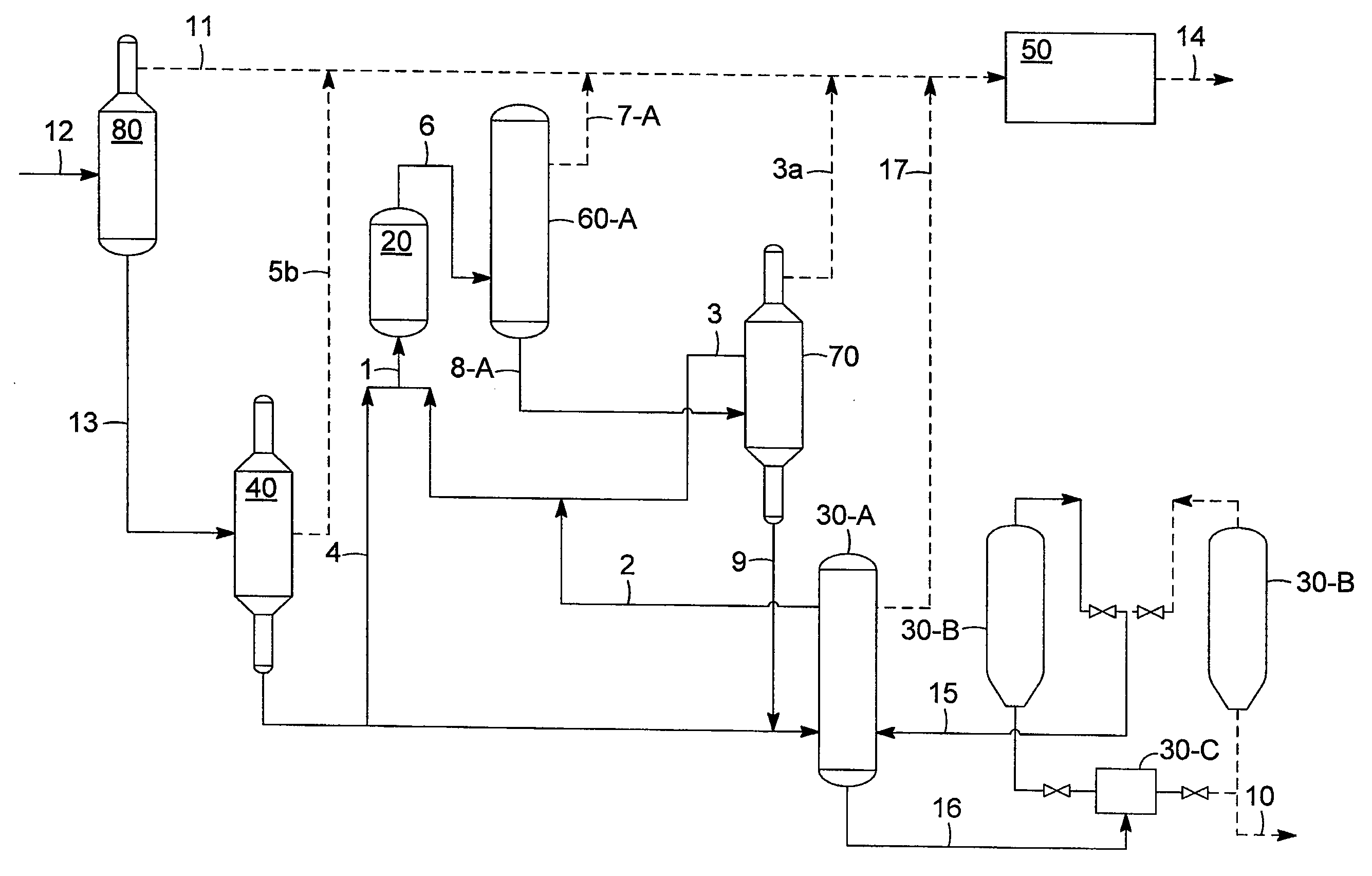

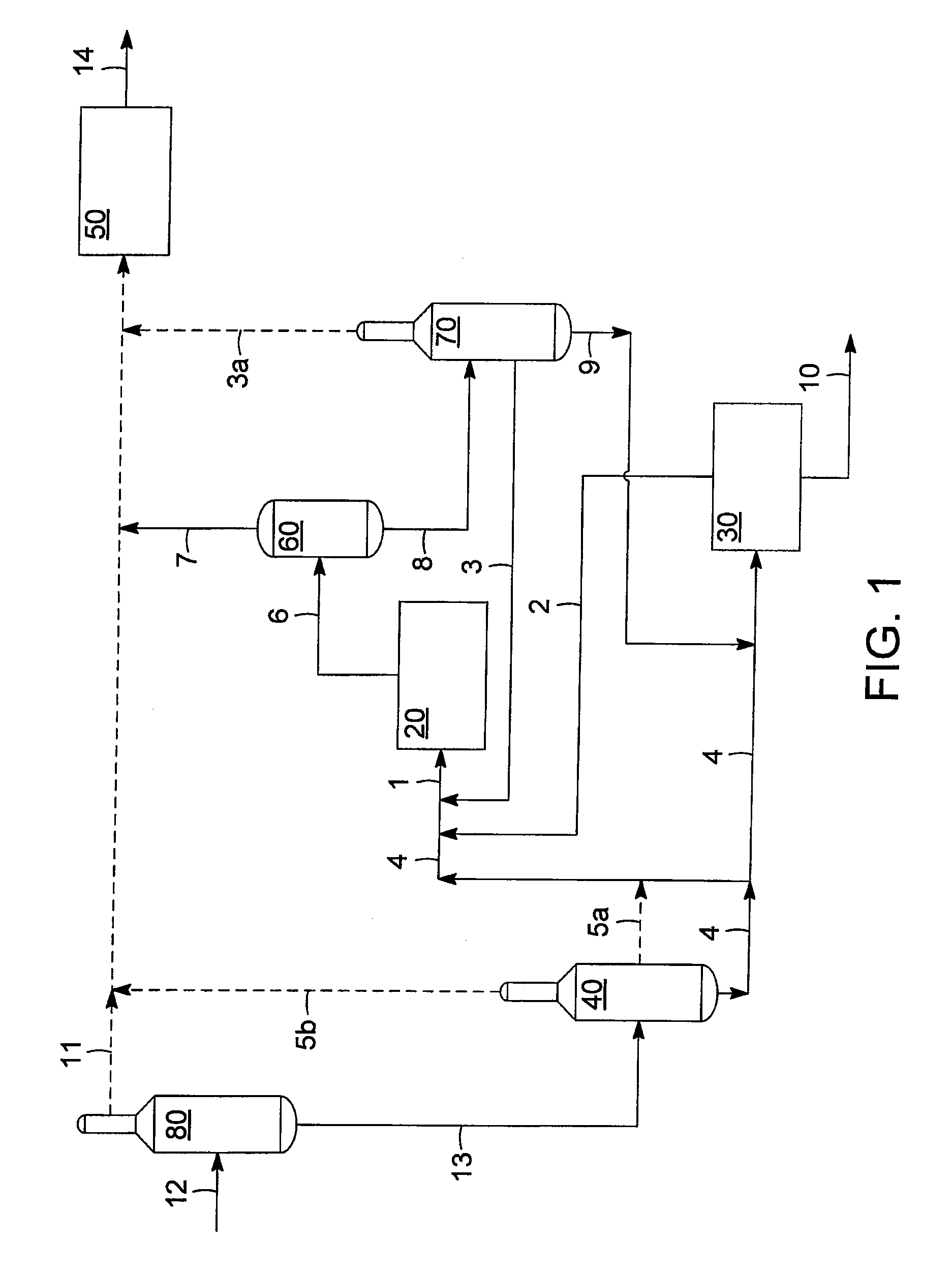

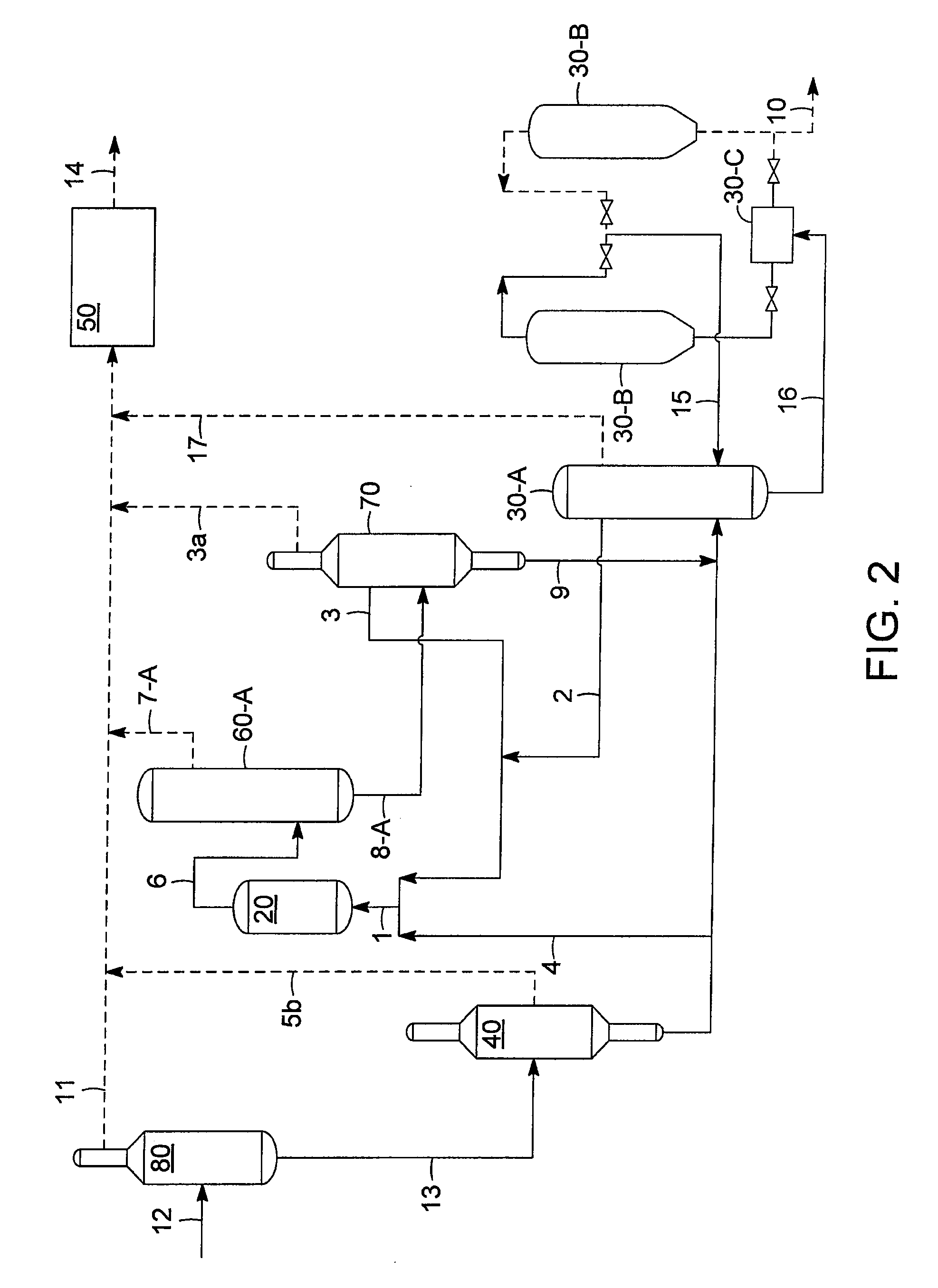

[0007]Aspects of the invention relate to the finding that slurry hydrocracking (SHC) can be effectively integrated with other refining processes such as coking, hydrotreating, and / or

crude oil fractionation to produce a high value distillate

stream while recycling unwanted gas oils, preferably to

extinction. SHC is generally known in the art for its ability to convert vacuum column residues to lighter products. However, it has now been surprisingly discovered that the use of coker gas oil (e.g.,

delayed coker VGO) as a heavy

hydrocarbon feedstock component or incremental feed to SHC can suppress

coke formation, in addition to being converted to more valuable

naphtha and distillate products, in the SHC reactor and provide other important benefits associated with the resulting SHC / coking integrated process.

[0008]In a representative integrated process, low-quality coker gas oil is utilized in combination with recycled SHC gas oil, recovered from downstream fractionation / separation of the SHC

effluent, in the overall heavy

hydrocarbon feedstock to SHC. While portions of this feedstock also generally include conventional components such as vacuum column resid, the presence of coker gas oil improves the SHC reactor

effluent quality, particularly with respect to a reduced coke yield as well as an increased

naphtha and distillate yield, as discussed above. Moreover, coker gas oil is (1) often readily available in large quantities, particularly in the case of refineries

processing heavy crude oils, and (2) difficult to further

upgrade using FCC, hydrocracking, or hydrotreating due to the high levels of contaminants that poison (deactivate) catalysts used in these processes. However, it has now been determined that coker gas oil is an attractive incremental feedstock (e.g., in combination with a vacuum column residue) which is efficiently cracked using SHC to yield lighter and more valuable net distillate and optionally

naphtha products. Moreover, the integration of SHC with coking (e.g., delayed coking or fluidized coking) offers the further

advantage, according to some embodiments, of passing the

pitch byproduct of SHC to the coker inlet, together with

atmospheric column or vacuum column resids that are conventionally processed in coking operations. The

processing of SHC pitch in the coker thus allows for conversion / upgrading of this byproduct to higher value hydrocarbons and

solid coke. Whether or not the SHC pitch is processed in the coker, the reduced yield of gas oil end products, such as hydrocarbons boiling the VGO range, in the integrated SHC / coking process, diminishes the need for the separate hydrotreating and / or hydrocracking of such products.

[0009]According to one representative embodiment, an integrated SHC / coking process is combined with hydrotreating of the SHC distillate. As a result of the low (or non-existent) net yield of gas oil products such as VGO, due to recycling of these heavy-boiling fractions back to the SHC

reaction zone, the hydrotreated distillate has a sufficiently high

API gravity (e.g., at least about 20°), making it attractive for blending into a

synthetic crude oil that is transported via a pipeline. Thus, the hydrotreated distillate, or even the SHC distillate without hydrotreating, may be obtained as a high quality

transportation fuel blending component with only a minor amount or essentially no hydrocarbons boiling at a temperature representative of gas oils (e.g., greater than about 343° C. (650° F.)).

[0010]The SHC process may also be integrated with an existing

refinery hydrotreating process, conventionally used for

sulfur- and

nitrogen-containing compound removal from distillates, by hydrotreating a recovered SHC distillate product in conjunction with a straight-run distillate obtained from crude oil fractionation and / or other refinery distillate streams. This integration may advantageously reduce overall capital costs of the complex. As discussed above, the integration of SHC with existing coking, optionally hydrotreating, and optionally other conventional refinery operations has the potential to provide significant benefits in terms of improved processing efficiency and product yields, reduction or

elimination of low-value

refractory byproducts, and / or the associated

capital cost reduction. According to a specific embodiment of the invention, a crude oil vacuum column bottoms residue

stream provides a part of the heavy hydrocarbon feedstock to an SHC reactor, and is combined at the inlet of the SHC reactor with coker gas oil (e.g., coker VGO). Other portions of the residue from the vacuum column or other fractions from this column, may also be processed in the coker itself. In another embodiment, a coker gas oil or a portion of this refinery gas oil component provides, optionally together with a straight-run gas oil (e.g., straight-run VGO), a portion of the heavy hydrocarbon feedstock processed using SHC, and SHC pitch that is separated from the SHC effluent by fractionation may be in turn passed to the coker (e.g.,

delayed coker or fluidized coker) for upgrading.

Login to View More

Login to View More  Login to View More

Login to View More