Method for increasing burning speed of coal

A combustion speed, coal technology, applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve the problems of reducing the volume ratio of coal in the boiler, erosion, boiler carbonization, etc., to reduce the emission of harmful gases, increase the combustion speed, and accelerate oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

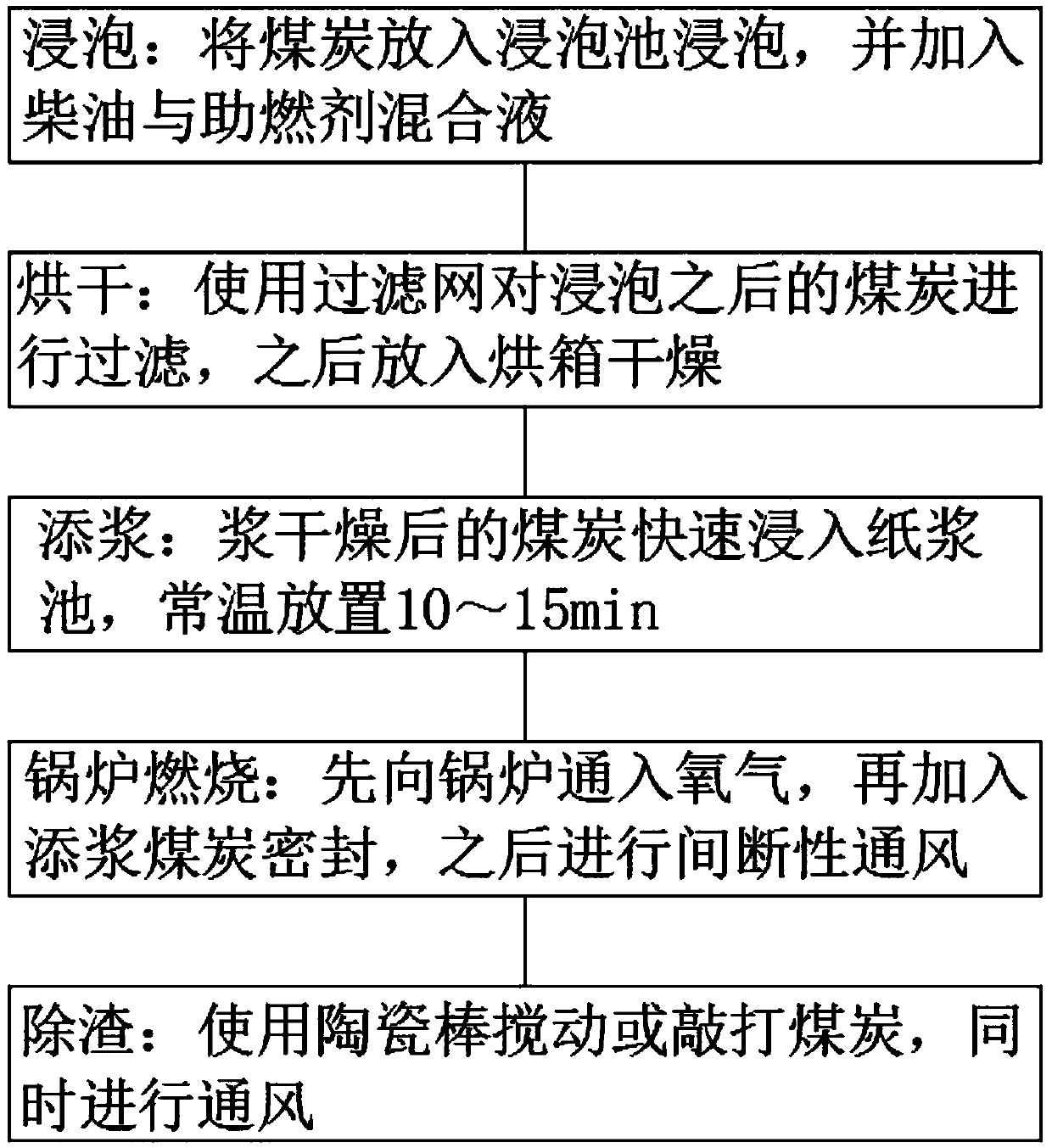

[0026] Such as figure 1 shown, including the following steps:

[0027] (1), Soaking: Put the coal into the immersion pool for 20 minutes, and add the mixture of diesel oil and combustion aid, the mixture of combustion aid consists of the following parts by weight: 7 parts of alkylphenol polyoxyethylene, 10 parts Dinitrotoluene, 15 parts of oxalic acid, 5 parts of acetylacetone, and 3 parts of penetration aid, the penetration aid consists of the following parts by weight: 50 parts of oxalic acid, 12 parts of ethyl ester, and 5 parts of glycerol;

[0028] (2), drying: use filter screen to filter the soaked coal, use 100 mesh filter screen to filter during filtration, then put into oven for drying, oven temperature is 45 ℃, and stop when drying until coal water content is 1.2%, Get puffed coal;

[0029] (3) Boiler combustion: first feed oxygen into the boiler, the oxygen feed rate is 2.5L / min, and the feed time is 8 minutes, then add slurrying coal to seal, the seal time is 5 m...

Embodiment 2

[0032] Such as figure 1 shown, including the following steps:

[0033] (1), Soaking: Put the coal into the immersion pool for 20 minutes, and add the mixture of diesel oil and combustion aid, the mixture of combustion aid consists of the following parts by weight: 7 parts of alkylphenol polyoxyethylene, 10 parts Dinitrotoluene, 15 parts of oxalic acid, 5 parts of acetylacetone, and 3 parts of penetration aid, the penetration aid consists of the following parts by weight: 50 parts of oxalic acid, 12 parts of ethyl ester, and 5 parts of glycerol;

[0034] (2), drying: use filter screen to filter the soaked coal, use 100 mesh filter screen to filter during filtration, then put into oven for drying, oven temperature is 45 ℃, and stop when drying until coal water content is 1.2%, Get puffed coal;

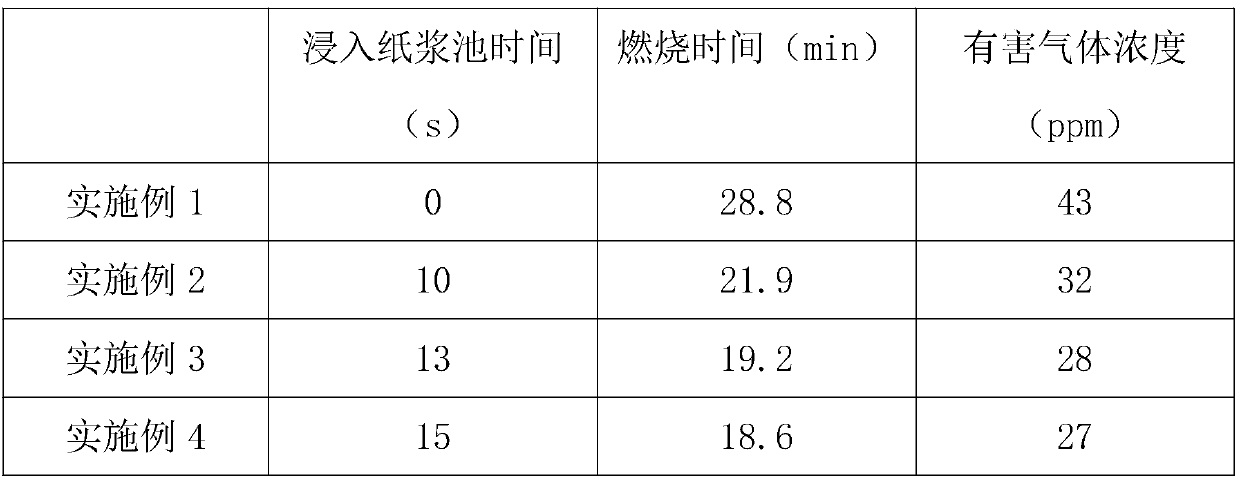

[0035] (3), slurrying: the coal after slurry drying is immersed in the pulp pool quickly, and placed at room temperature for 10 minutes to obtain the slurrying coal, and the time for i...

Embodiment 3

[0039] Such as figure 1 shown, including the following steps:

[0040] (1), Soaking: Put the coal into the immersion pool for 20 minutes, and add the mixture of diesel oil and combustion aid, the mixture of combustion aid consists of the following parts by weight: 7 parts of alkylphenol polyoxyethylene, 10 parts Dinitrotoluene, 15 parts of oxalic acid, 5 parts of acetylacetone, and 3 parts of penetration aid, the penetration aid consists of the following parts by weight: 50 parts of oxalic acid, 12 parts of ethyl ester, and 5 parts of glycerol;

[0041] (2), drying: use filter screen to filter the soaked coal, use 100 mesh filter screen to filter during filtration, then put into oven for drying, oven temperature is 45 ℃, and stop when drying until coal water content is 1.2%, Get puffed coal;

[0042] (3), slurrying: the coal after slurry drying is immersed in the pulp pool quickly, and placed at room temperature for 10 minutes to obtain the slurrying coal, and the time for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com