Patents

Literature

66results about How to "Avoid anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium-containing high-strength pipeline steel hot-rolled plate

InactiveCN1978695AImprove low temperature toughnessAvoid anisotropyHeat treatment process controlSheet steelChemical composition

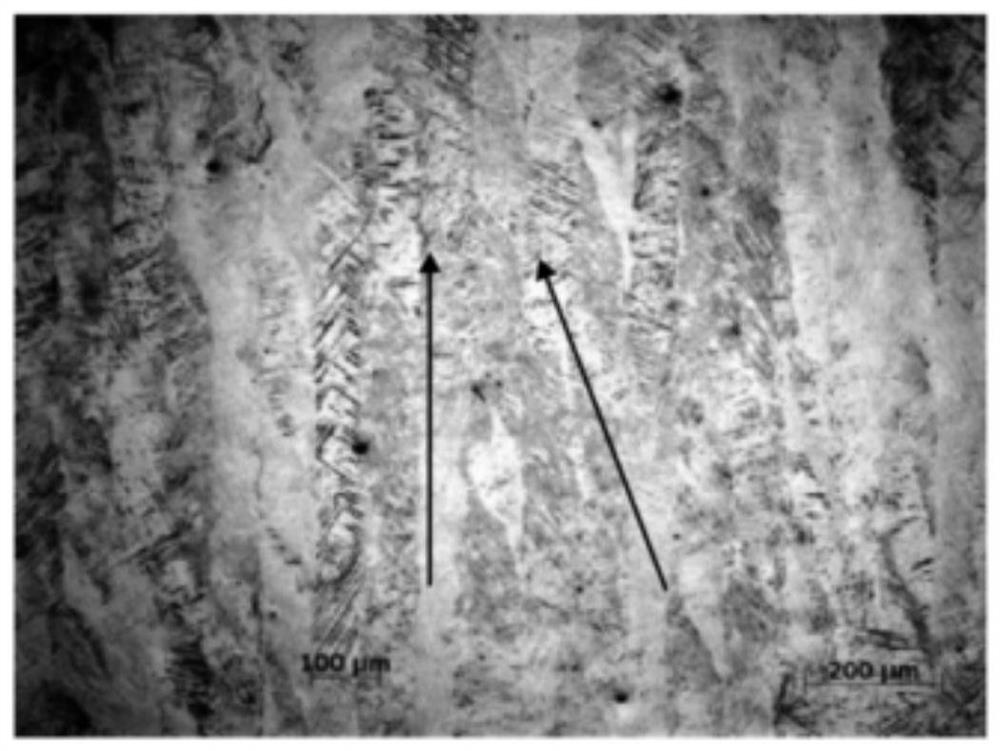

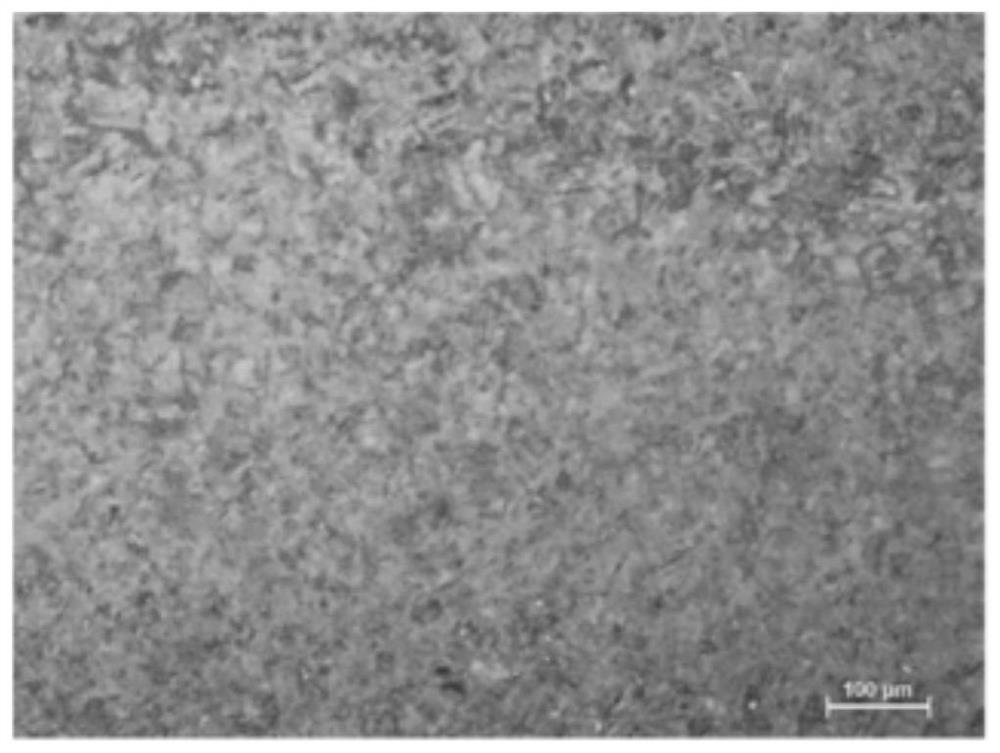

The invention discloses Cr bearing high strength pipeline steel hot rolling plate and producing method. Its components weight percentages are 0.30-0.60% Cr, 0.40-0.80% C, 0.10-0.35% Si, 1.80-2.20% Mn, 0.005-0.020% P, not more than 0.003% S, 0.04-0.10% Nb, 0.008-0.030% Ti, 0.15-0.60% Ni, 0.15-0.45% Mo, 0.15-0.30% Cu, the rest Fe and unavoidable impurity, contains 73-87% lower bainite, and the rest island martensite. The producing method includes the following steps: heating up to 1160-1220 degree centigrade; rough rolling at 1010-1150 degree centigrade; finish rolling at 830-950 degree centigrade; water cooling; final cooling at 300-450 degree centigrade; controlling cooling speed at 15-30 degree centigrade per second. The invention can gain the LB main complex phase organization which can make the pipeline steel hot rolling plate yield strength reach 690-825MPa, tensile strength reach 780-960MPa, -20 degree centigrade absorbed-in-fracture energy be not less than 200J, -15 degree centigrade DWTT shearing area be not less than 85%, solve steel anisotropy caused by two phase field rolling, release the demand of large rolling load for the two phase field rolling.

Owner:ANGANG STEEL CO LTD

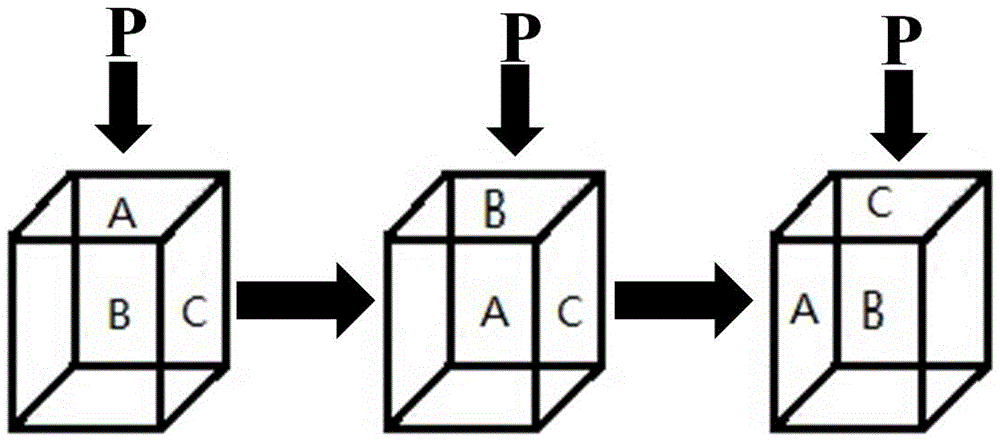

Fine-grain high-strength TiAl alloy including nano Y2O3 and preparation method thereof

ActiveCN106521238ASolve the problem of severe segregationIncrease profitMechanical heat treatmentYttrium

The invention discloses fine-grain high-strength TiAl alloy including nano Y2O3 and a preparation method thereof. In order to solve the problems that existing aluminum-yttrium intermediate alloy is added to cause Y-phase-rich uneven distribution, the dimensions differ greatly, and microscopic structure and mechanical property anisotropism is caused by an existing mechanical heat treatment technology, the method includes the specific steps that first, all the raw material components are weighed; second, an ingot casting is prepared by means of water-cooling copper crucible reaction kish smelting and fired mold precision casting; third, a blank is pretreated; and fourth, multi-directional forging is performed, and accordingly the fine-grain high-strength TiAl alloy can be obtained. The forging stock structure obtained through the method is uniform, crystal grains are small, and the excellent mechanical property can be achieved in three directions.

Owner:TAIYUAN UNIV OF TECH

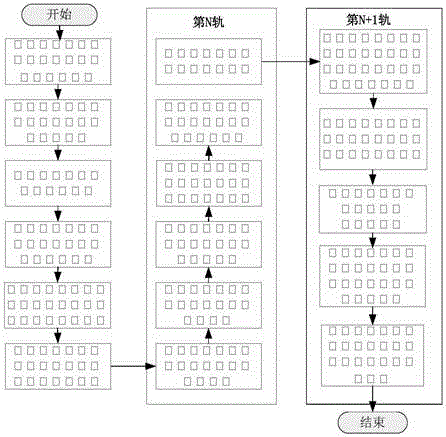

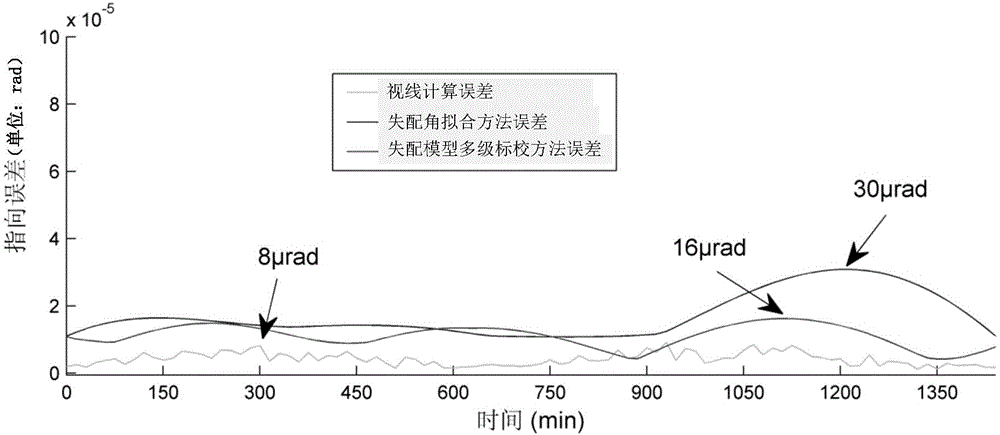

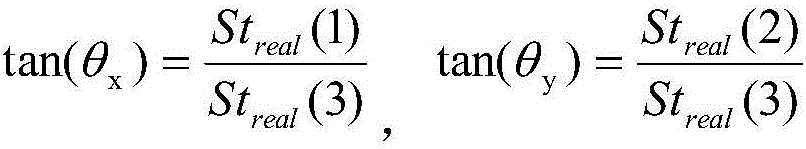

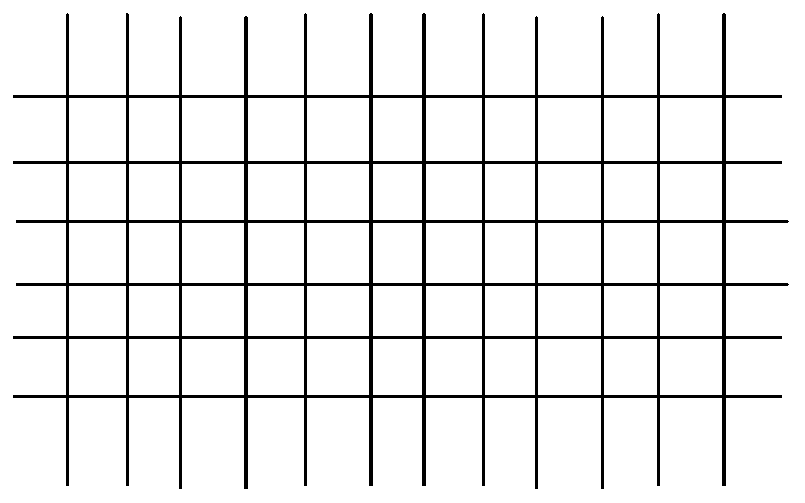

Equivalent mismatch model multistage calibration method used for increasing satellite image positioning accuracy

ActiveCN106767714AAvoid anisotropyReduce demandPicture taking arrangementsSatellite imageModel parameters

The invention discloses an equivalent mismatch model multistage calibration method used for increasing satellite image positioning accuracy. The equivalent mismatch model multistage calibration method comprises following steps: firstly, a space-borne scanning camera imaging positioning model containing equivalent mismatching angles is constructed; in orbit, fixed stars or terrestrial landmarks are observed via controlling camera intervals; equivalent mismatching angle parameter sets of space-borne cameras on star sensor attitude reference caused by thermal deformation on the stars of the same orbit at different times are calculated; mesh generation of the space-borne camera all view based on two-dimensional scanning rotating angles is carried out; in a one orbit cycle, imaging positioning model parameter reconstitution and high accuracy pointing error multi-stage fitting calibration are carried out so as to obtain stable thermal deformation change rule parameter sets used for high accuracy imaging positioning of a next orbit, and avoid imaging positioning problems of singular equivalent mismatching angle calculating caused by few and scattered, or concentrated camera in-orbit sparse or concentrated control points for observing fixed star or landmarks. The equivalent mismatch model multistage calibration method is capable of solving a technical problem, and realizing high accuracy positioning of triaxial stable scanning optical remote sensing satellite when the control points are few and scattered.

Owner:SHANGHAI SATELLITE ENG INST

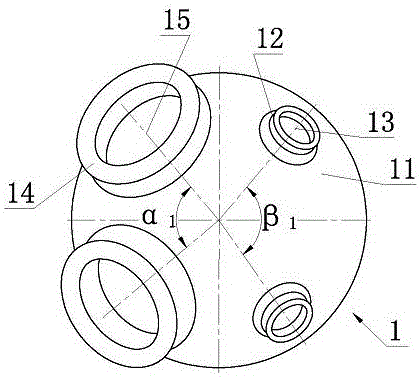

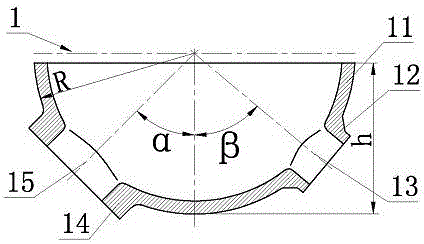

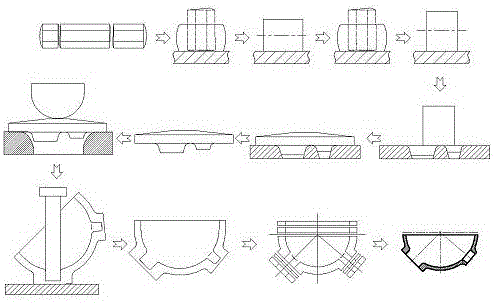

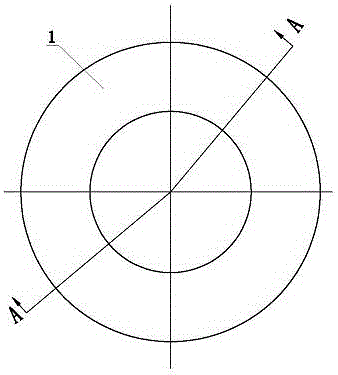

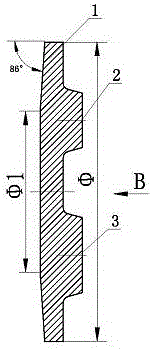

Pressure vessel integrated end socket for nuclear power, end socket plate blank of pressure vessel integrated end socket and forging method of pressure vessel integrated end socket

ActiveCN106051721AImprove mechanical propertiesImprove operational safetyMetal-working apparatusSteam boilersFiberPunching

The invention discloses a pressure vessel integrated end socket for nuclear power, an end socket plate blank of the pressure vessel integrated end socket and a forging method of the pressure vessel integrated end socket. According to the pressure vessel integrated end socket for nuclear power, a manhole base and a pipe hole base are arranged on an end socket body which is of a spherical crown structure; the manhole base and the pipe hole base are integrated with the end socket body in a forged mode; and the intersection point of the hole center line of a manhole and the hole center line of a pipe hole is located in the center of the sphere where the end socket body is located. A plate blank body of the end socket plate blank is of a circular plate structure, one surface of the plate blank body is provided with two manhole circular truncated cones and two pipe hole circular truncated cones, and the other surface of the plate blank body is a large-cone-angle circular truncated cone surface. The forging method comprises the following steps of steel ingot heating, forged blank blanking, forged blank upsetting and drawing, die forging formation, plate blank heat treatment, plate blank rough machining, end socket formation, end socket punching, forge piece heat treatment, machining of a forge piece, performance heat treatment and finished product machining. The integrated formation of the end socket of a vapor generator is achieved, the forge piece is uniform and compact in texture, the metal flow line is complete, and the fiber texture and the appearance of the forge piece tend to be more coincident.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

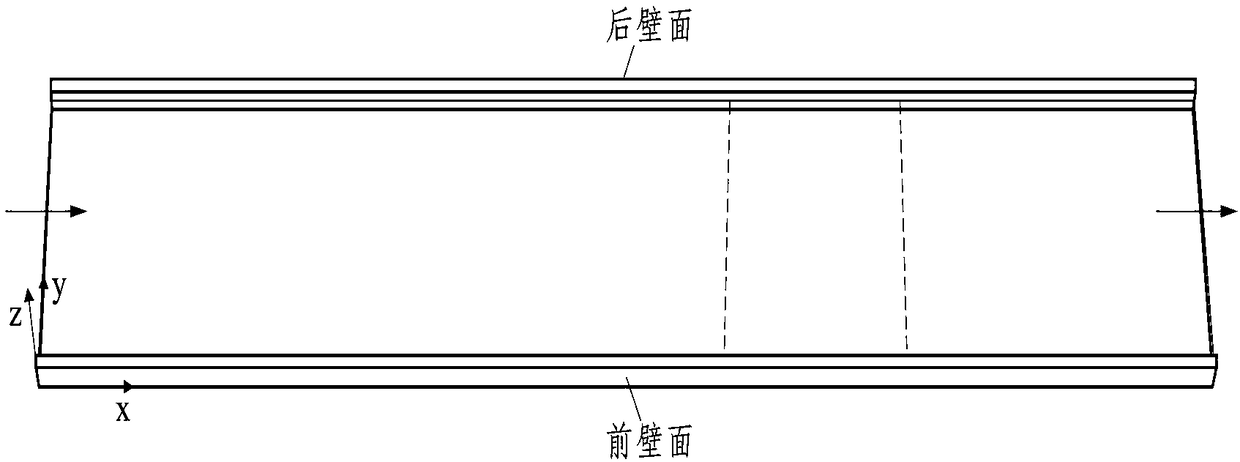

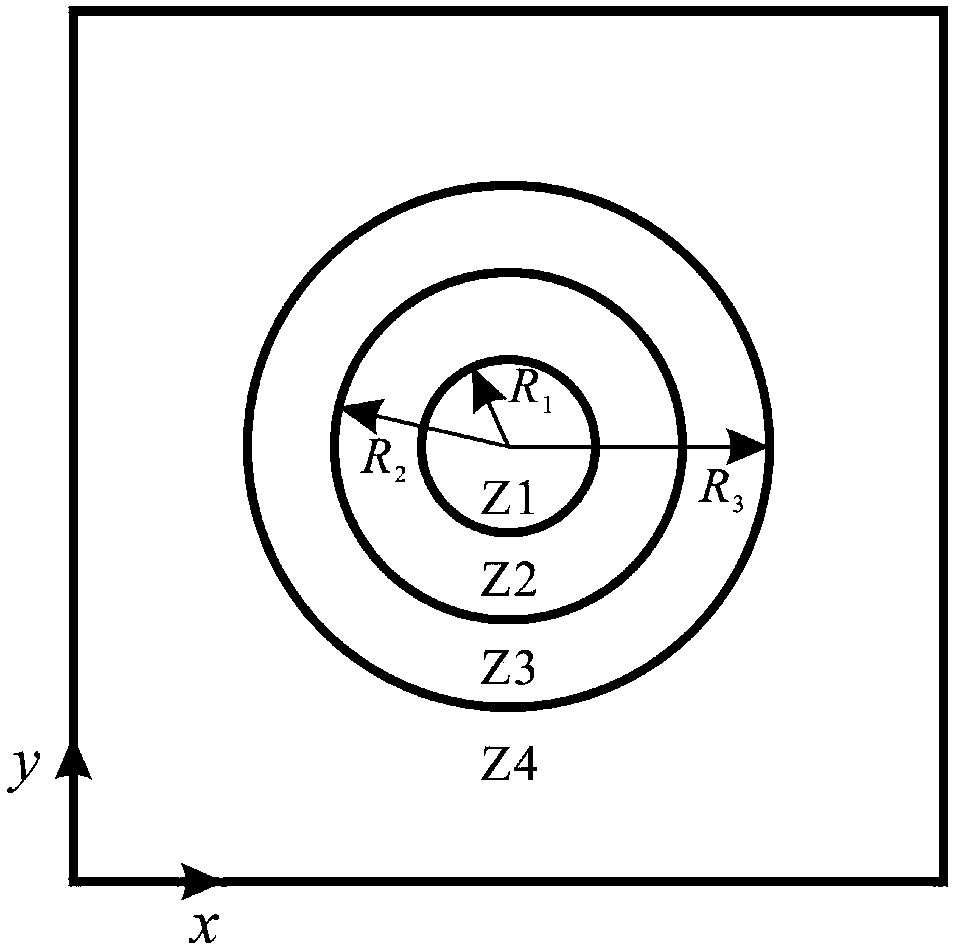

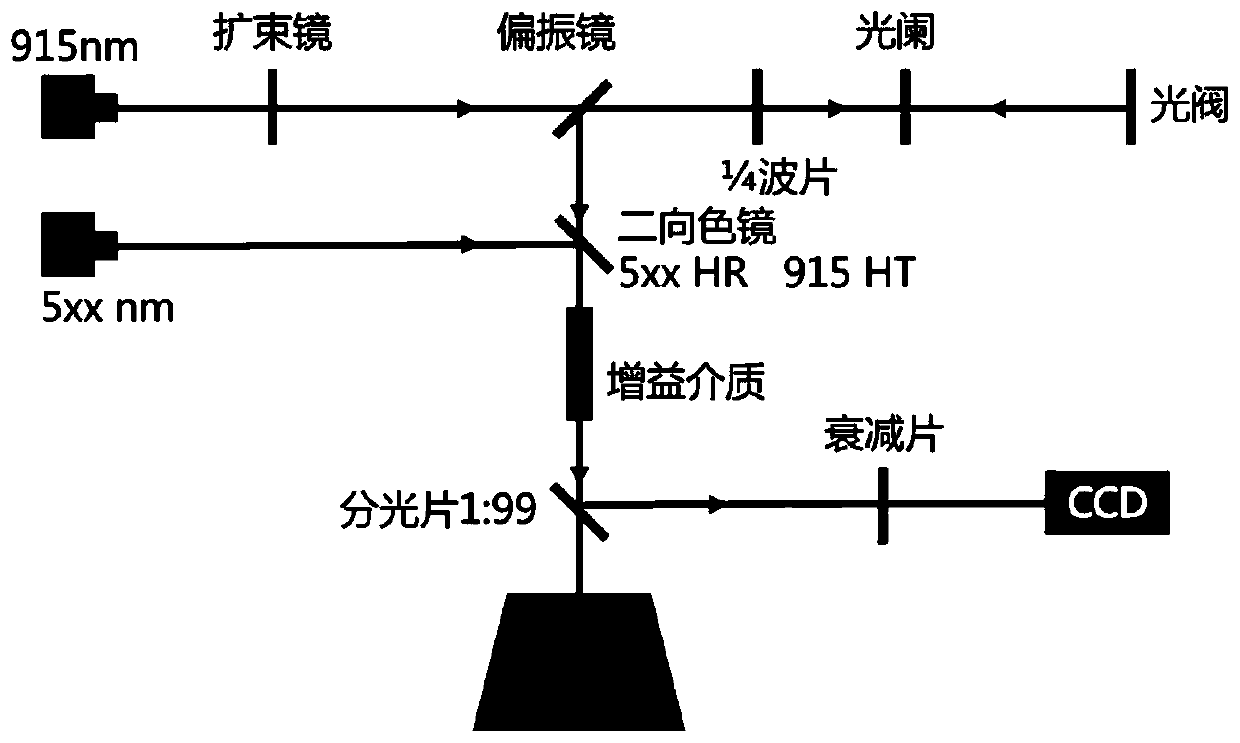

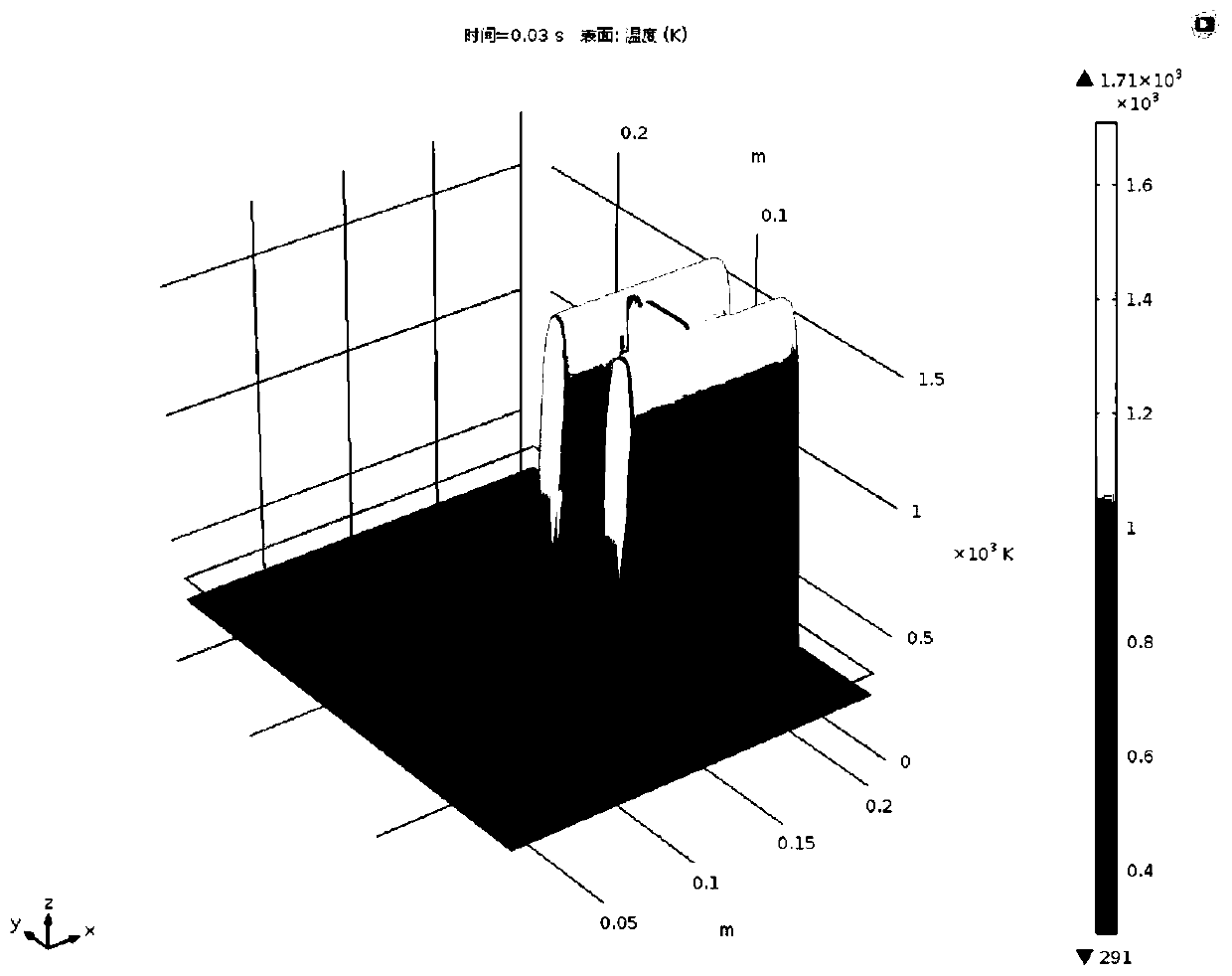

A two-dimensional convective thermal stealth cloak design method based on active control heat source

ActiveCN109033495AAchieve temperature distributionAvoid anisotropyGeometric CADSpecial data processing applicationsEngineeringObject function

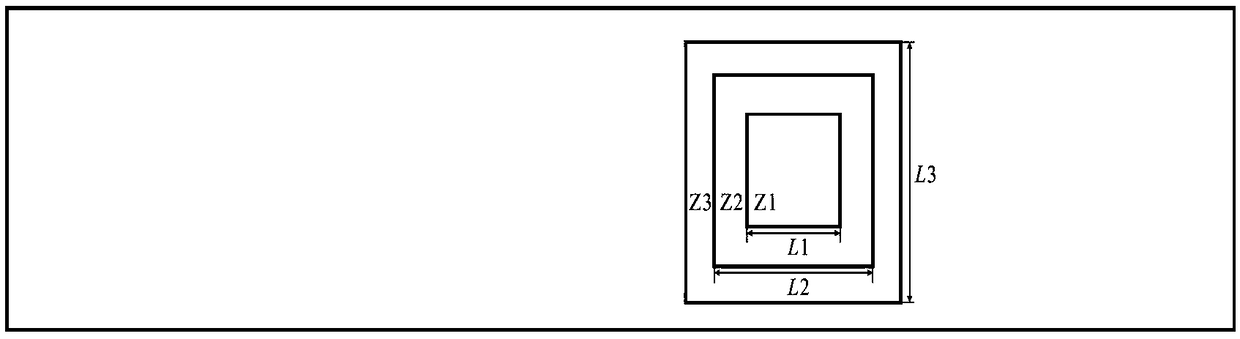

The invention relates to a two-dimensional convective heat stealth cloak design method based on active control heat source, comprising the following steps of: establishing a three-dimensional coordinate system x-y-z and determining that the region surrounded by the coordinate system is a design region. The velocity distribution and background temperature of the flow field are calculated. The direct problem, the adjoint problem, the derivative of the objective function, the conjugate coefficient, the iterative direction coefficient, the sensitivity problem, the iterative step length and the objective function of the heat source in Z2 and Z3 regions are solved respectively, and the heat source distribution is updated. The composite objective functions of Z2 and Z3 regions are calculated. According to the flow field velocity and the background temperature, the invention establishes a stealth cloak by applying a heat source at the bottom of the flow channel, and heats or cools the fluid flowing in a specific area, so as to realize the temperature distribution in the flow field that satisfies the function of the stealth cloak.

Owner:XI AN JIAOTONG UNIV

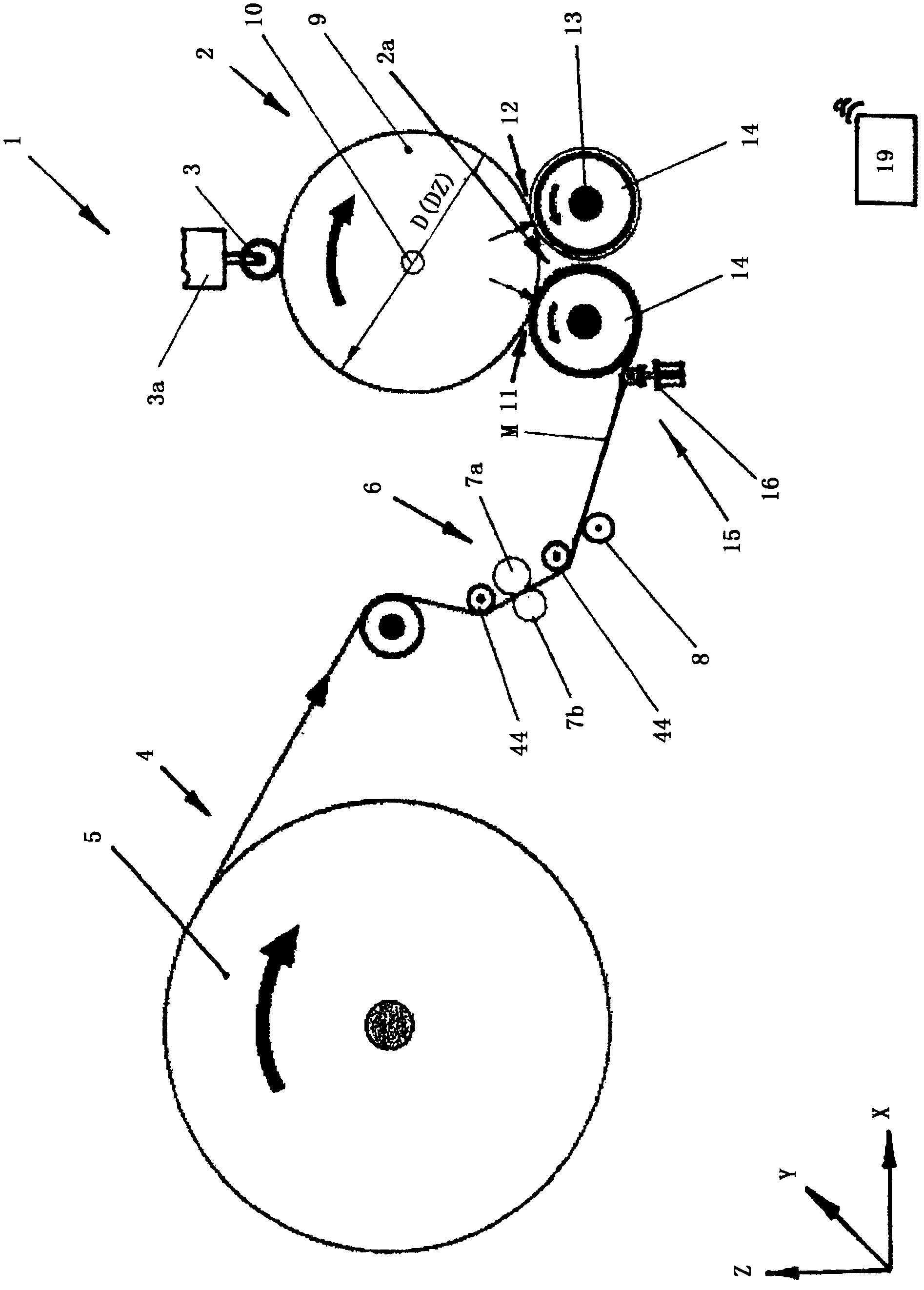

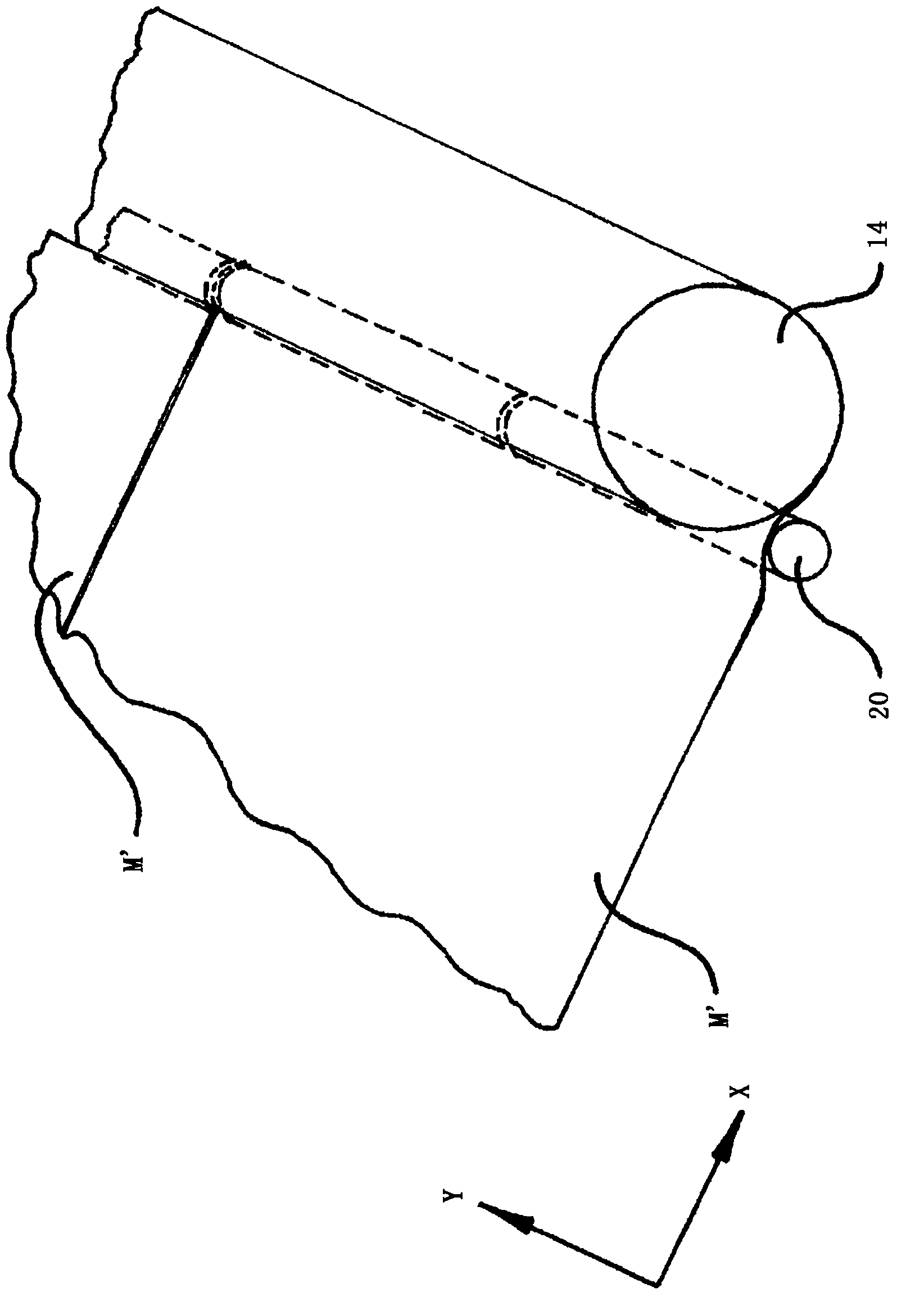

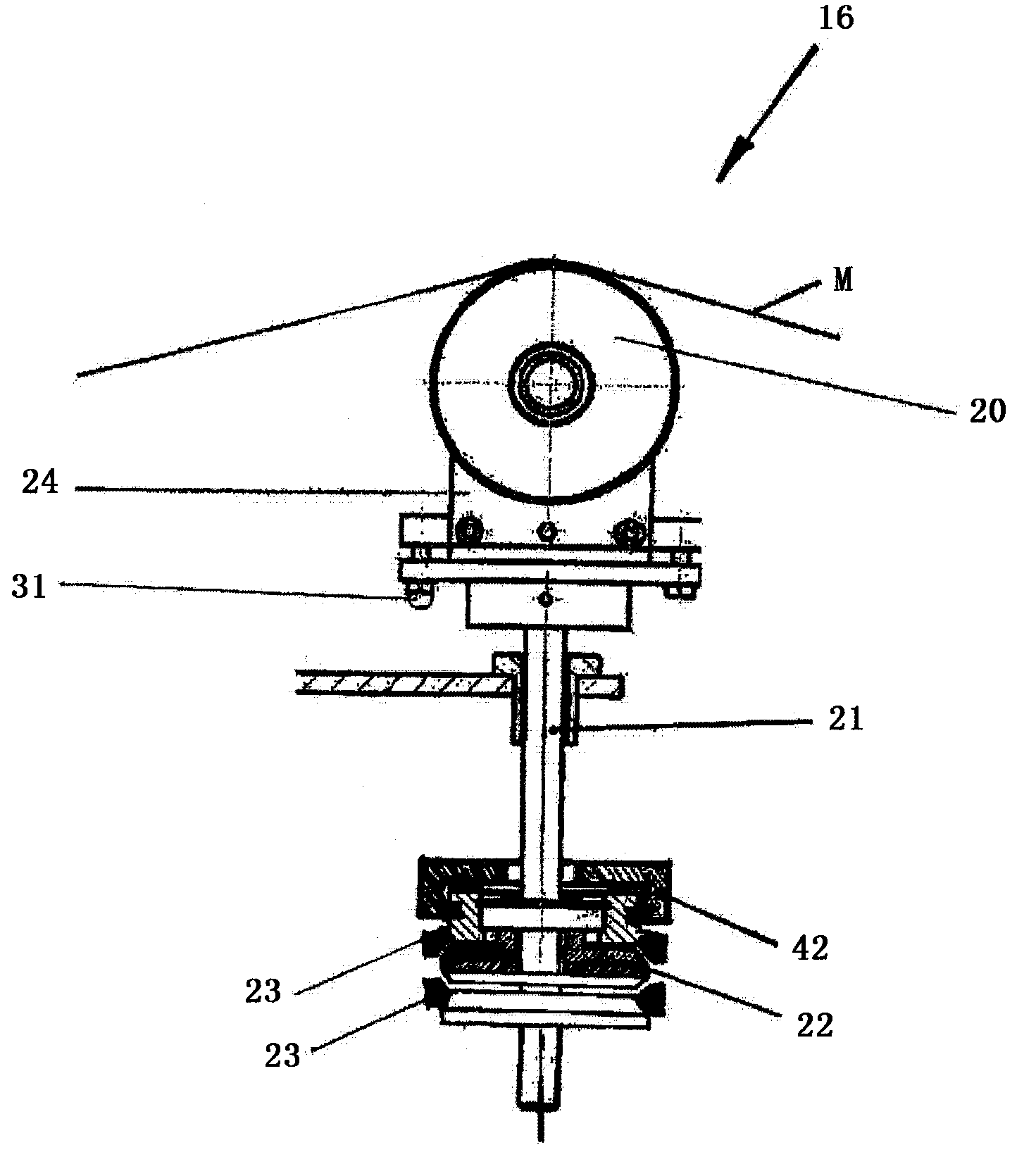

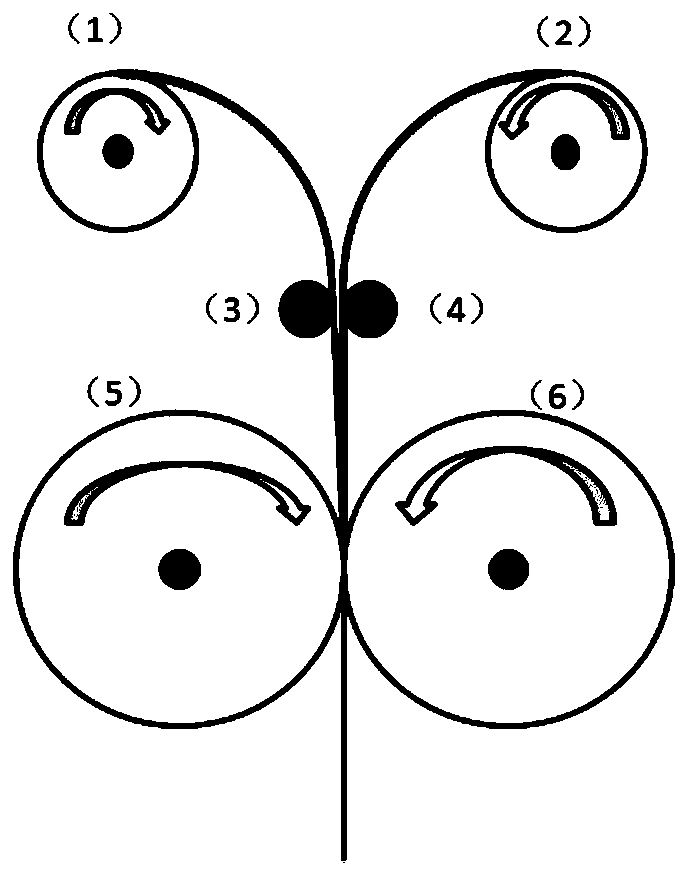

Method for wrapping a sheet of material and roll cutting device

The invention relates to a method for wrapping a sheet of material and a roll cutting device. According to the invention, According to the invention, a roll winding apparatus is used for winding a material web or paper card web onto a winding core, preferably winding onto a sleeve to form a reel. During a winding process, at least one roller presses against the reel. In order to improve the winding structure, especially stabilize the winding region, the roll winding apparatus comprises a winding hardness generator which does not contact with at least one reel.

Owner:VOITH PATENT GMBH

Two-dimensional thermal invisible cloak design method with internal heat source in hidden region

ActiveCN108959712ARealize stealth functionAvoid anisotropyDesign optimisation/simulationSpecial data processing applicationsCloakEngineering

The invention relates to a two-dimensional thermal invisible cloak design method with internal heat sources in a hidden region. The method comprises the steps of establishing a two-dimensional coordinate system x-y and determining the region encircled by the coordinate system as a design region; setting boundary conditions, and respectively solving a background temperature field of the design region when no internal heat source is in a region Z1 and a temperature distribution when the internal heat source is in the region Z1 according to the boundary conditions; respectively solving a direct problem, an adjoint problem of the heat sources in regions Z2 and Z3, a derivative of an objective function, a conjugated coefficient, an iterative direction coefficient, a sensitivity problem, an iterative step length and the objective function, and updating the distribution of the heat sources in the regions Z2 and Z3; and calculating a composite objective function of the regions Z2 and Z3. In the two-dimensional thermal invisible cloak design method with the internal heat sources in the hidden region, the heat sources are applied to the design region according to the internal heat sources and the background temperature field in the hidden region to establish an invisible cloak so as to implement an invisible function.

Owner:XI AN JIAOTONG UNIV

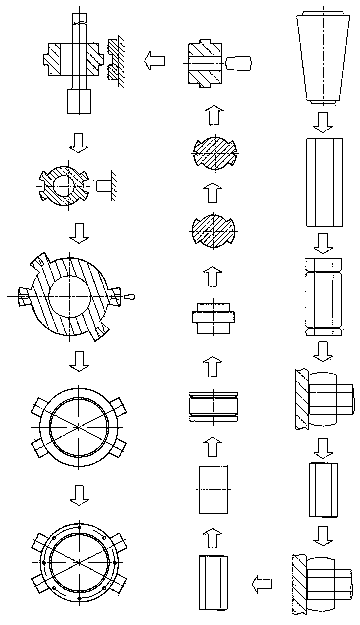

Integrated forging and forming method for reactor pressure vessel barrel flange adapter tube section

ActiveCN110090914AReduce potential riskWork stress homogenizationEngine componentsReactor pressure vesselIngot

The invention discloses an integrated forging and forming method for a reactor pressure vessel barrel flange adapter tube section. The integrated forging and forming method for the reactor pressure vessel barrel flange adapter tube section comprises the steps of (1) heating a steel ingot, and pressing the steel ingot to obtain an eight-edge prism steel billet; (2) blanking a forging billet: cutting a head part and a tail part of the eight-edge prism steel billet so as to obtain an eight-edge prism forging billet; (3) upsetting and drawing the forging billet: upsetting and drawing out the forging billet; (4) carrying out upsetting and rolling: upsetting and rolling the forging billet to obtain a short cylindrical forging billet; (5) carrying out marking and dividing in the circumferential direction: cutting two marking and dividing grooves at two ends of the short cylindrical forging billet; (6) carrying out rolling and necking: forming an adapter tube billet with a convex ring in the middle section; (7) carrying out marking and dividing in the axial direction: cutting four axial dividing grooves arranged along the axial direction; (8) circularly pressing a hemline; (9) marking anddividing a hemline boss: forming four sections of bosses on a hemline adapter tube billet; (10) punching a main hole; (11) carrying out chambering and forming; (12) carrying out shaping and chambering; (13) punching an adapter tube hole; (14) carrying out heat treatment after forging; (15) roughly machining the billet; (16) carrying out quenching; (17) carrying out hardening and tempering; and (18) processing a finished product. According to the method, integrated forming and forming is realized, the structure is uniform and dense, and a metal flow line is complete.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

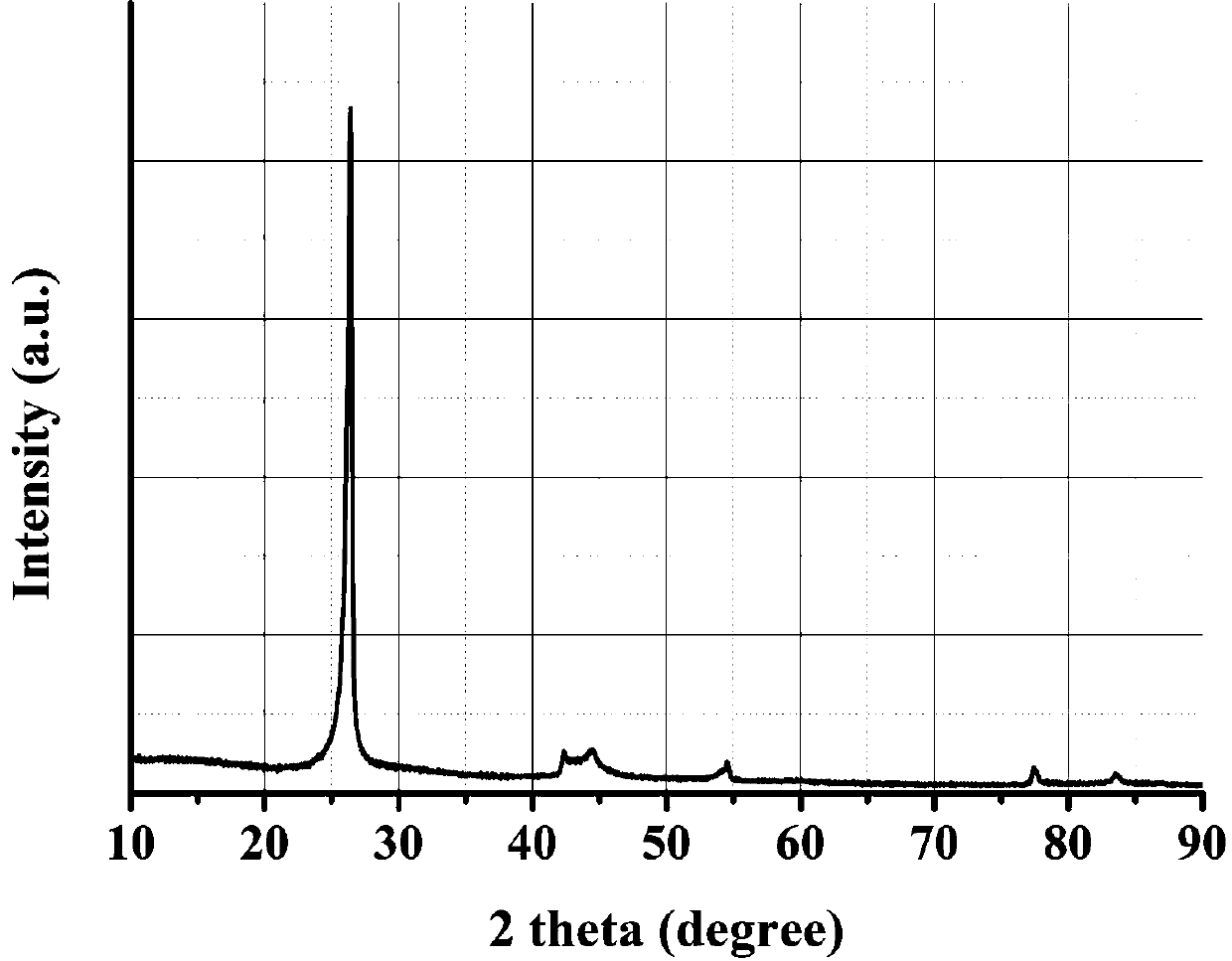

Preparation method of graphitized carbon negative electrode material

PendingCN106848258AIncrease electron densityImprove electronic conductivityCell electrodesGrapheneSucroseMetallurgy

The invention provides a preparation method of a graphitized carbon negative electrode material. The preparation method comprises the following steps: 1) calcining fatty acid in a nitrogen atmosphere at the temperature of 600-800 DEG C for 6-8h and cooling, so as to obtain amorphous carbon; 2) calcining the amorphous carbon in a nitrogen atmosphere at the temperature of 2,500-2,800 DEG C for 4-6h and cooling, so as to obtain graphitized carbon; 3) dispersing the graphitized carbon and a certain amount of nitrogenous polymers into anhydrous ethanol, uniformly mixing the mixture, atomizing to form balls and collecting precursors with a cyclone separator; 4) carbonizing the precursors in a nitrogen atmosphere at the temperature of 800-1,000 DEG C for 2-4h and cooling, so as to obtain porous graphitized carbon; 5) dispersing the porous graphitized carbon and a certain amount of sucrose into deionized water, uniformly mixing the mixture and performing air blast drying on the mixture at the temperature of 120-150 DEG C; carbonizing the mixture in a nitrogen atmosphere at the temperature of 800-1,000 DEG C for 2-3h and cooling, so as to obtain N-doped carbon-coated porous graphitized carbon.

Owner:OPTIMUM BATTERY CO LTD

Functional film prepared from functionalized organic powder, low-temperature damage-free manufacturing method and application

ActiveCN111004404AHigh strengthImprove toughnessOrganic-compounds/hydrides/coordination-complexes catalystsFinal product manufactureOrganic filmMicron scale

The invention provides a functional film prepared from functionalized organic powder, a low-temperature damage-free manufacturing method and application. The organic powder film material is composed of the functionalized organic powder and polytetrafluoroethylene (PTFE), polytetrafluoroethylene molecular chains are opened through preheated supersonic airflow, the functionalized organic powder is bonded, air in the powder is extruded to form a continuous cake shape, the powder forms a film through a low-temperature hot-pressing process, and then the film material with low porosity and uniform thickness is formed through a multi-layer film hot-pressing compounding process. According to the method, micron-sized organic films can be continuously prepared in a roll-to-roll mode, the physical and chemical properties of the organic powder can be brought into play to the maximum extent, and performance damage caused by high temperature or introduction of a solvent for film formation or anisotropy caused by recrystallization is prevented. No solvent is introduced in the manufacturing process, and the problems of environmental pollution, high energy consumption, uneven film material densityand the like caused in the solvent drying process are avoided.

Owner:东莞奥创能源科技有限公司

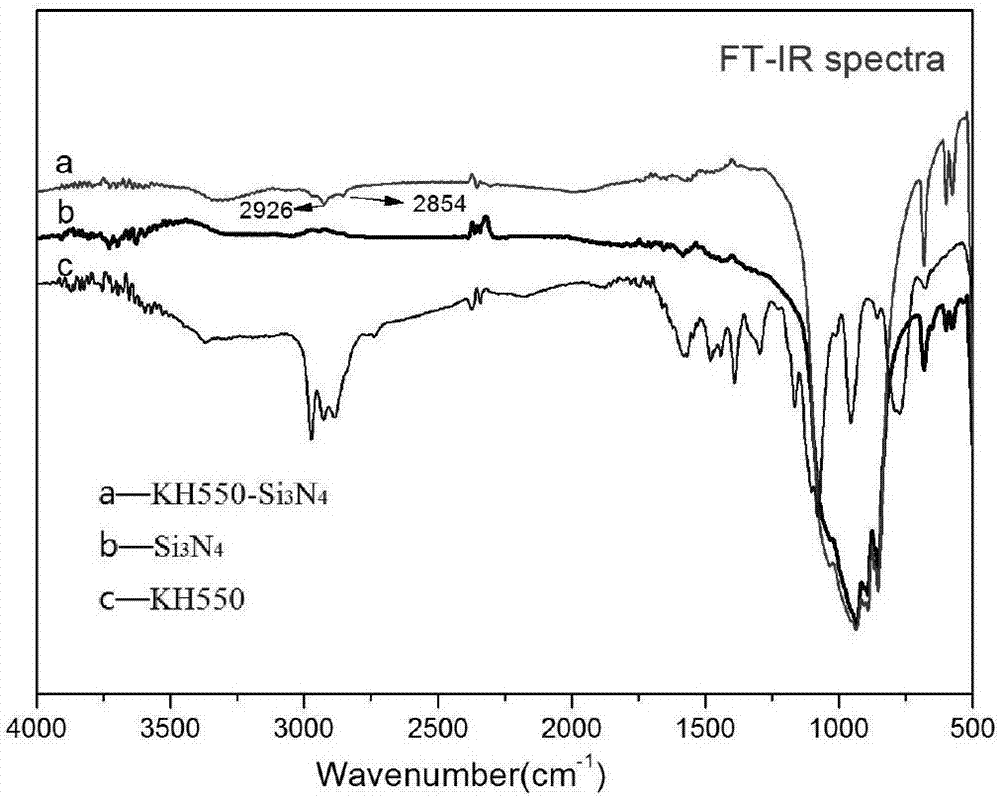

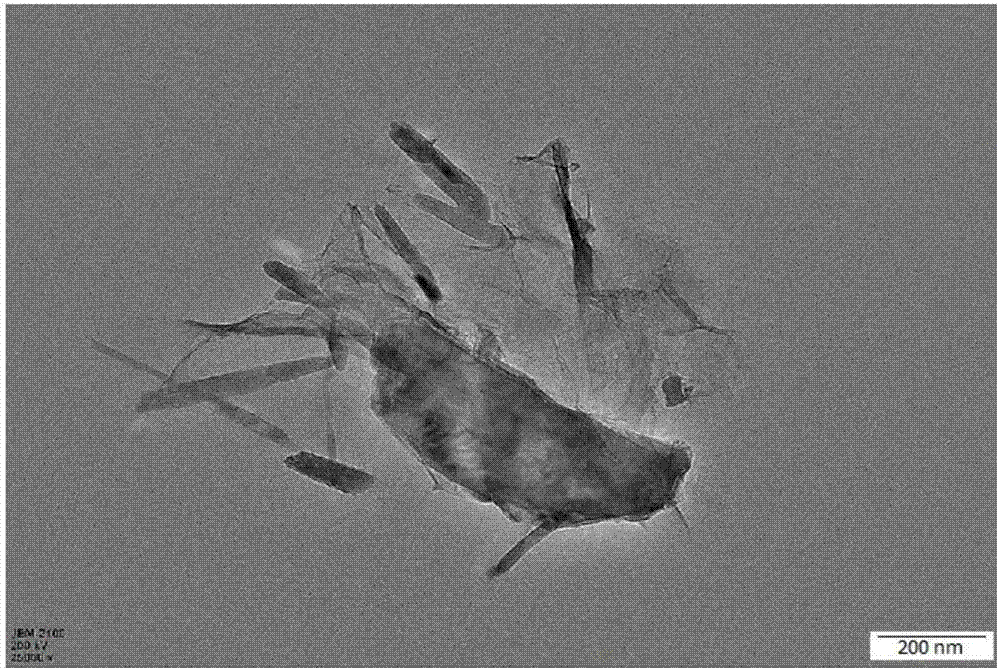

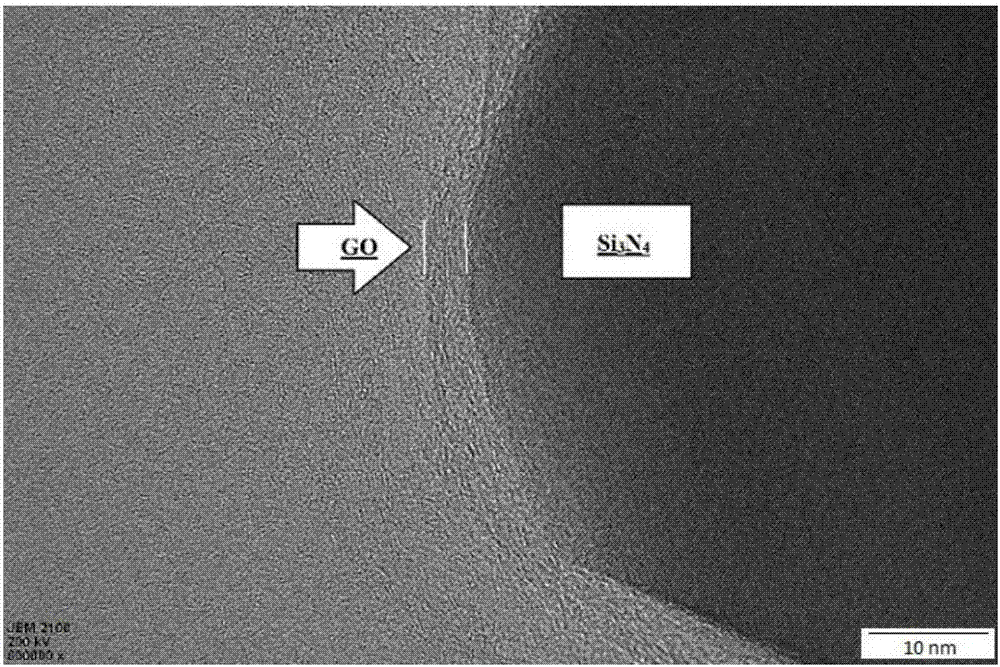

Method for preparing graphene oxide wrapped silicon nitride composite powder

The invention relates to a method for preparing graphene oxide wrapped silicon nitride composite powder. The method comprises the following steps: performing high-temperature surface oxidation on Si3N4 powder in hydrogen peroxide, putting a coupling agent hydrolysis solution into a surface oxidized Si3N4 suspension, and performing grafting modification treatment on the surface of Si3N4; and preparing a graphene oxide water dispersion, putting the Si3N4 suspension into the graphene oxide water dispersion, performing ultrasonic treatment, leaving to stand till wrapped particles completely settledown, removing supernate, and drying, thereby obtaining the graphene oxide wrapped silicon nitride composite powder. The graphene oxide wrapped silicon nitride composite powder prepared by using themethod is good in wrapping completeness, simple and convenient in process and high in efficiency. Application spaces of silicon nitride and graphene oxide are expanded, and after the graphene oxide wrapped silicon nitride composite powder is applied to a ceramic material, the mechanical properties of the ceramic material can be remarkably improved.

Owner:QILU UNIV OF TECH

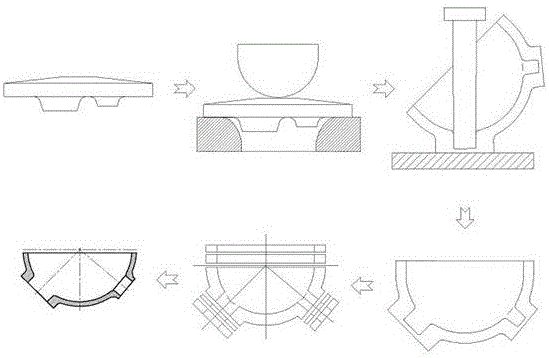

Integral seal punch molding method of nuclear power pressure container

The invention discloses an integral seal punch molding method of a nuclear power pressure container. The punch molding method comprises the following steps: roughening of a plate blank: the heated seal plate blank is machined; heating of the plate blank: the roughened seal plate blank is sent in a heating furnace for heating; molding of a seal: the seal plate blank is shifted to an annular mold with a center hole for punching to mold a semi-spherical seal blank; punching of the seal: a seal punching part with two man holes and two pipe holes is punched; heat treatment of the punched part: the punched part is discharged from a furnace for air cooling when being cooled to 180 DEG C along with the furnace after autoclaving; machining of the punched part: the heated seal punched part is machined as a seal rough finished product; performance heat treatment: the quenching treatment is performed firstly; and then, the thermal refining is performed; and the finished product is machined to a qualified seal finished product. The method realizes integral molding of a steam generator seal, and is uniform and compact in metal structure and complete in streamline.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

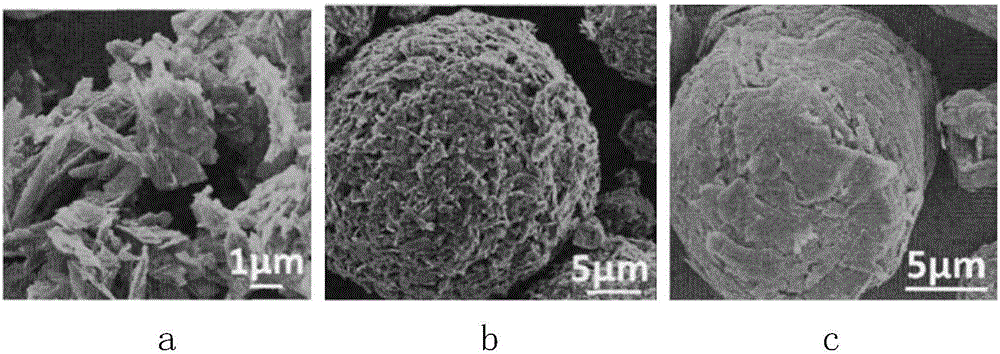

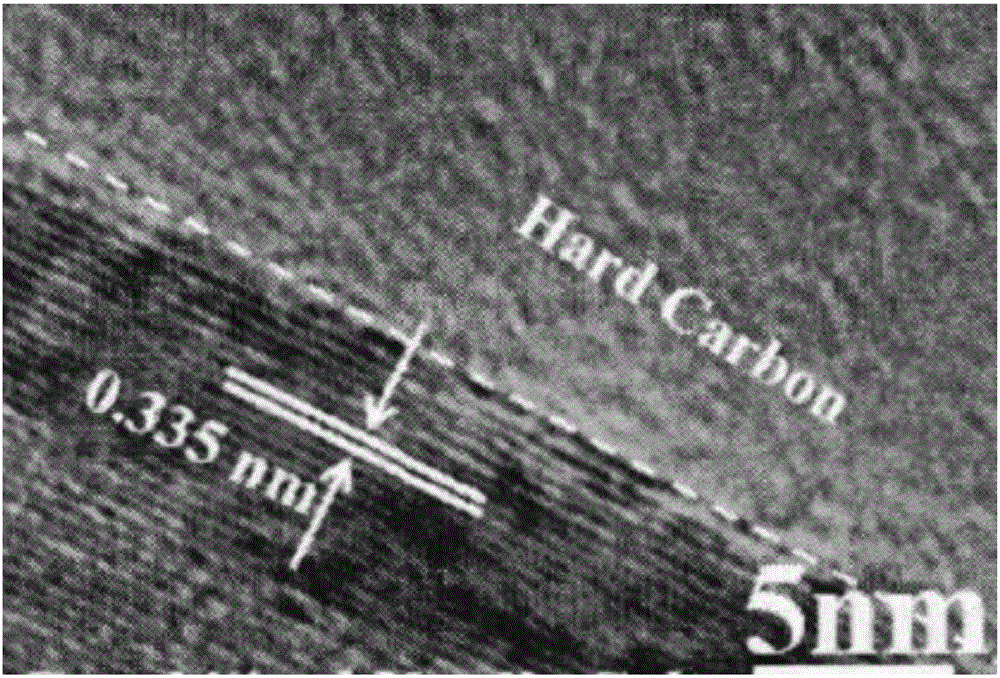

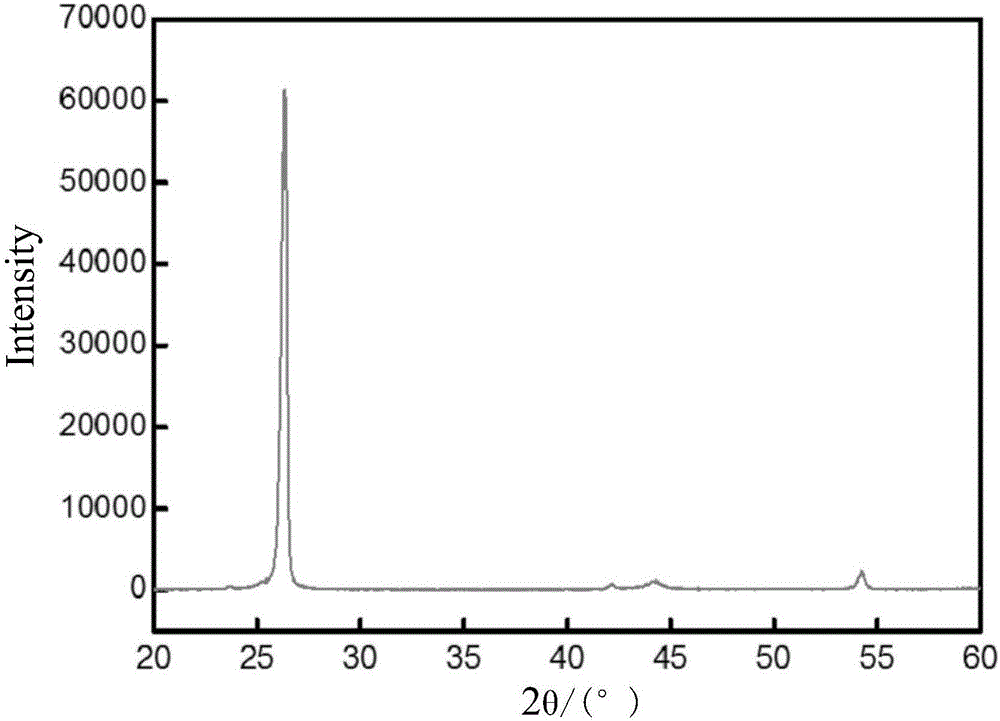

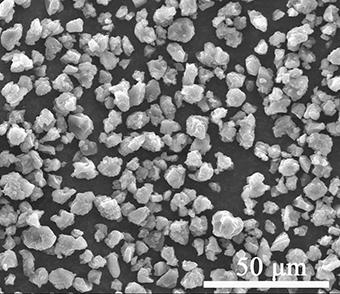

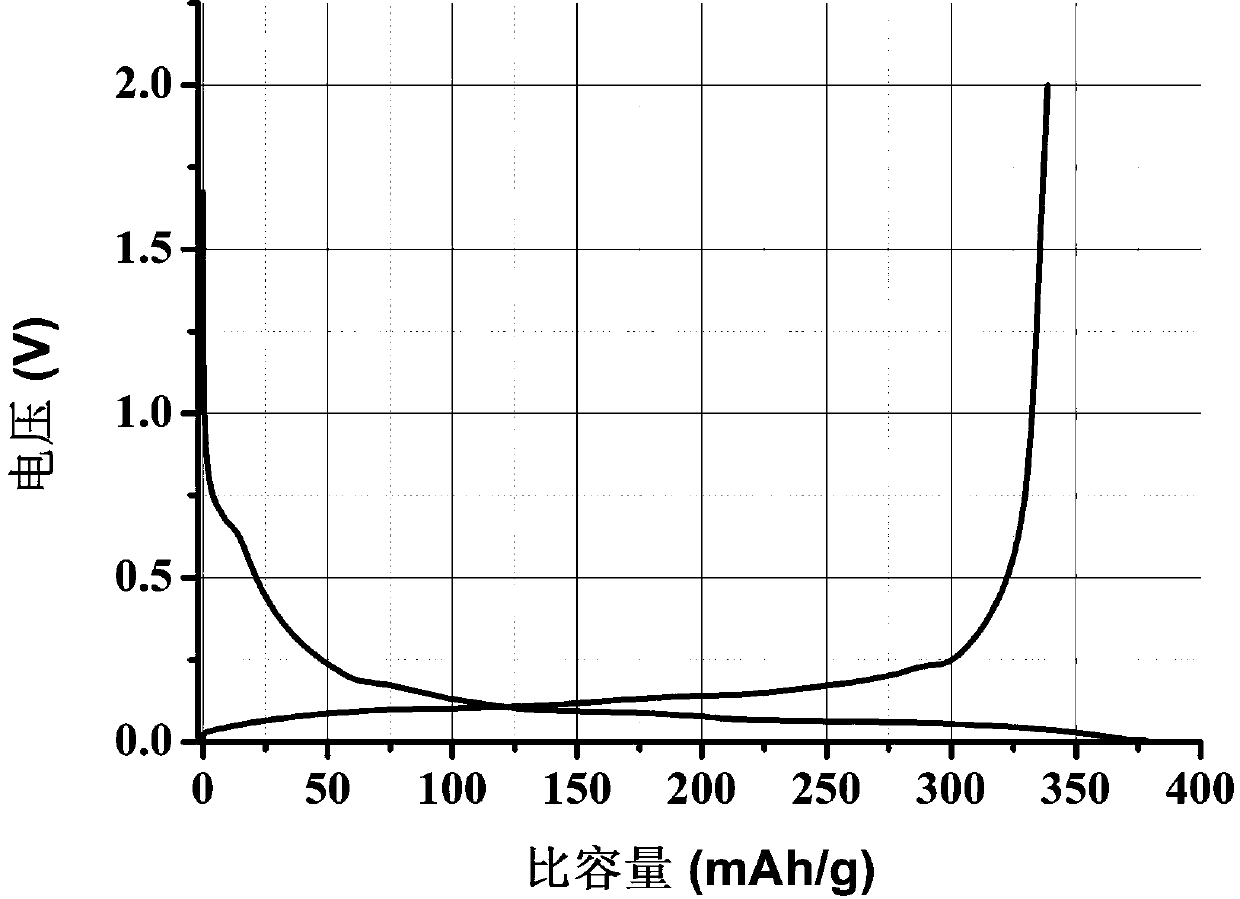

Hard carbon-like graphite cathode material for high-rate lithium ion battery and preparation method thereof

ActiveCN109626352AStable material structureAvoid anisotropySecondary cellsNegative electrodesChemistryPyrolysis

The invention relates to a hard carbon-like graphite cathode material for a high-rate lithium ion battery and a preparation method thereof. The preparation method comprises the following steps of S1,crushing a thermoplastic polymer to obtain polymer powders; S2, dispersing polymer powders in an aqueous solution containing an oxidizing agent and a surfactant for liquid-phase low-temperature oxidation reaction crosslinking, and then pyrolyzing to obtain an oxygen-rich carbon precursor; S3, crushing and graphitizing the oxygen-rich carbon precursor to obtain hard carbon-like graphitized carbon powders; S4, depolymerizing and screening the hard carbon-like graphitized carbon powders to obtain the hard carbon-like graphite cathode material. According to the preparation method, the thermoplastic polymer is used as a raw material, the isotropic oxygen-rich carbon precursor is obtained through liquid-phase low-temperature oxidation crosslinking and pyrolysis treatment, and then the hard carbon-like graphite negative electrode material with low orientation degree and large interlayer spacing is obtained through graphitization treatment, so that the charge-discharge rate performance of thematerial is improved; and when the material is used in the lithium ion battery, the charge-discharge rate can reach more than 15C.

Owner:SHANGHAI SHANSHAN TECH CO LTD

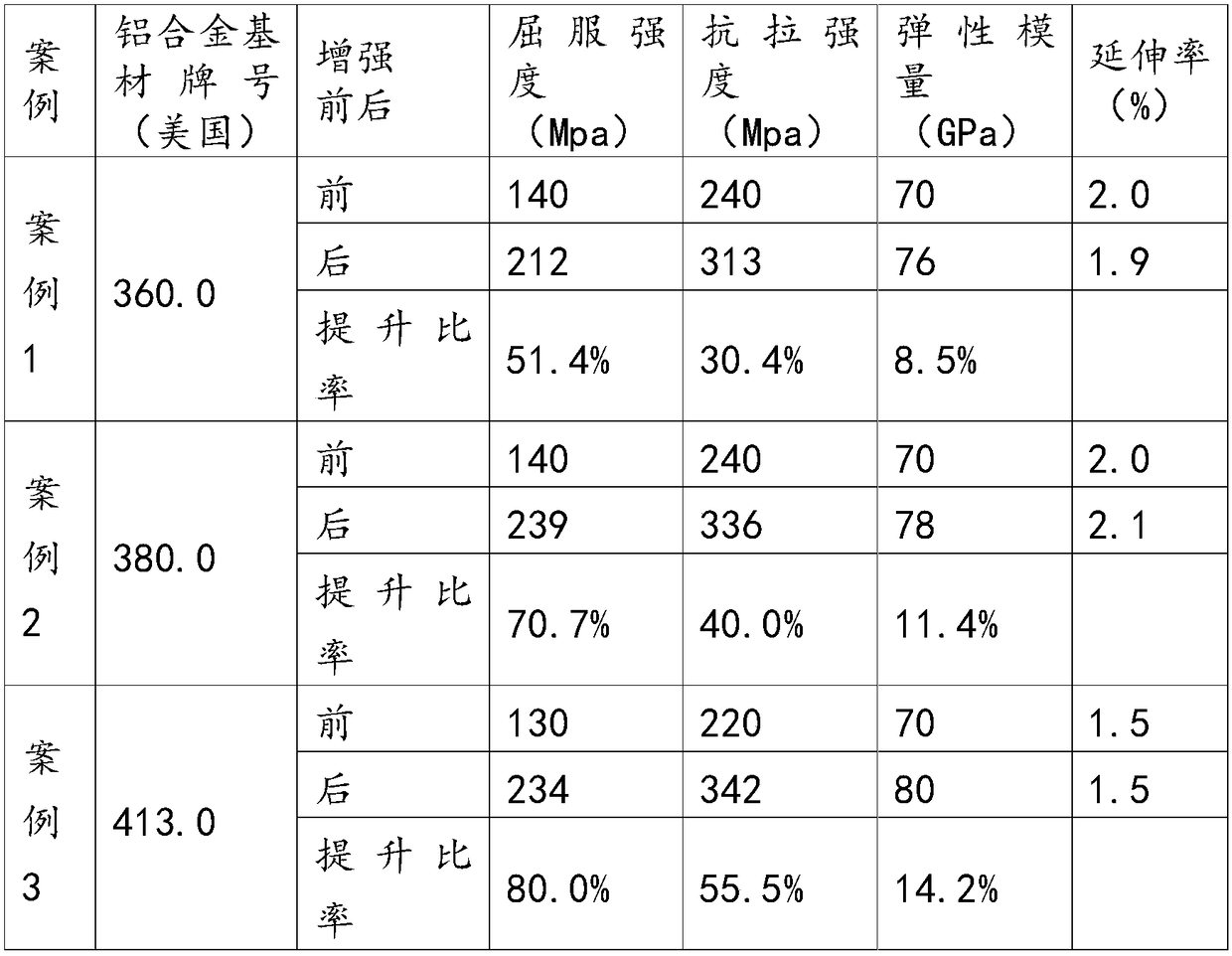

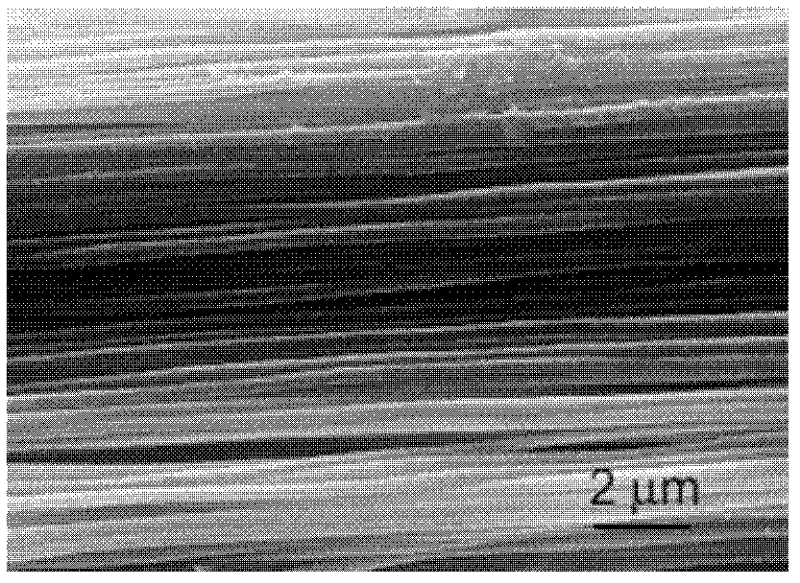

Three-dimensional braided carbon fiber reinforced metal-matrix composite and preparation method thereof

The invention relates to a three-dimensional braided carbon fiber reinforced metal-matrix composite and a preparation method of the three-dimensional braided carbon fiber reinforced metal-matrix composite. The preparation method comprises the following steps that firstly, pre-treatment is conducted on carbon fiber; secondly, carbon fiber bundles and fine metal wires are bound, so that metal wire-carbon fiber composite bodies are obtained, a three-dimensional framework reinforcing body is braided from the metal wire-carbon fiber composite bodies; thirdly, the braided three-dimensional fiber framework reinforcing body are soaked with silicon carbide particle dissolving slurry and potassium fluozirconate water solution; fourthly, the three-dimension fiber framework reinforcing body treated inthe third step is placed in matrix metal liquid and undergoes extrusion forming under ultrasonic vibration, and then the novel metal-matrix composite is obtained. According to the three-dimensional braided carbon fiber reinforced metal-matrix composite and the preparation method of the three-dimensional braided carbon fiber reinforced metal-matrix composite, a three-dimensional fiber framework isbraided from carbon fiber, net-shape manufacturing of the novel metal-matrix composite reinforced by the three-dimensional fiber framework reinforcing body and having excellent performance is achieved, the types and application range of the metal-matrix composite are expanded, and the three-dimensional braided carbon fiber reinforced metal-matrix composite certainly has broad application prospectin the aerospace field, the military project field and the civil field.

Owner:尚辰(浙江绍兴)复合材料科技有限公司

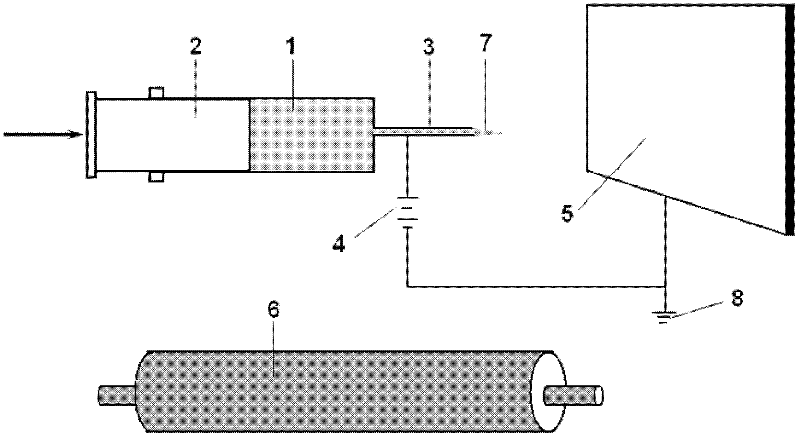

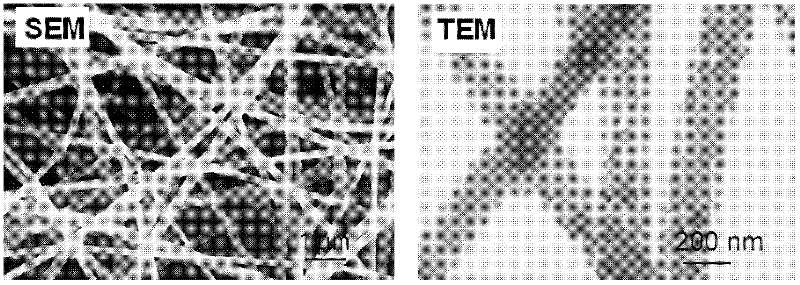

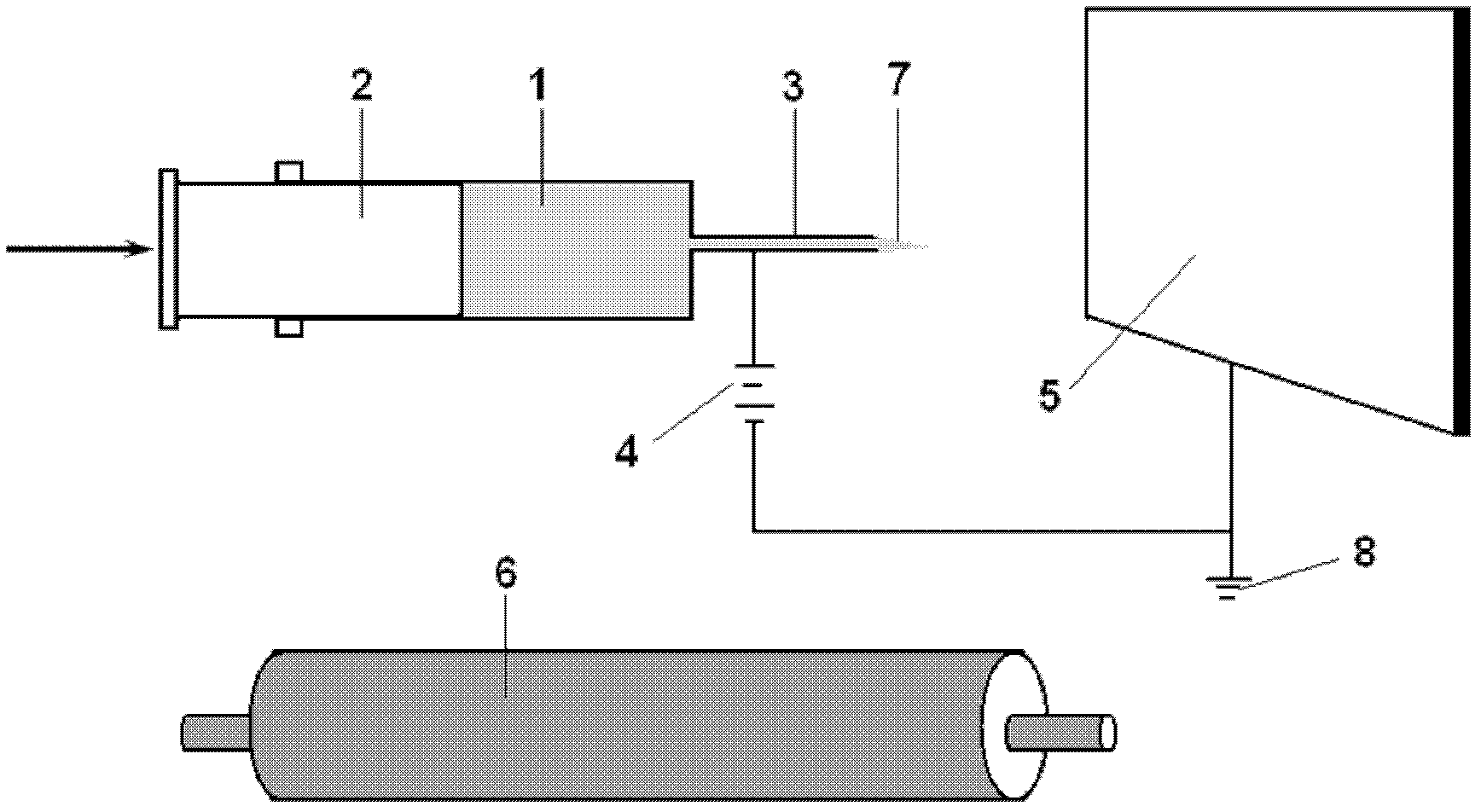

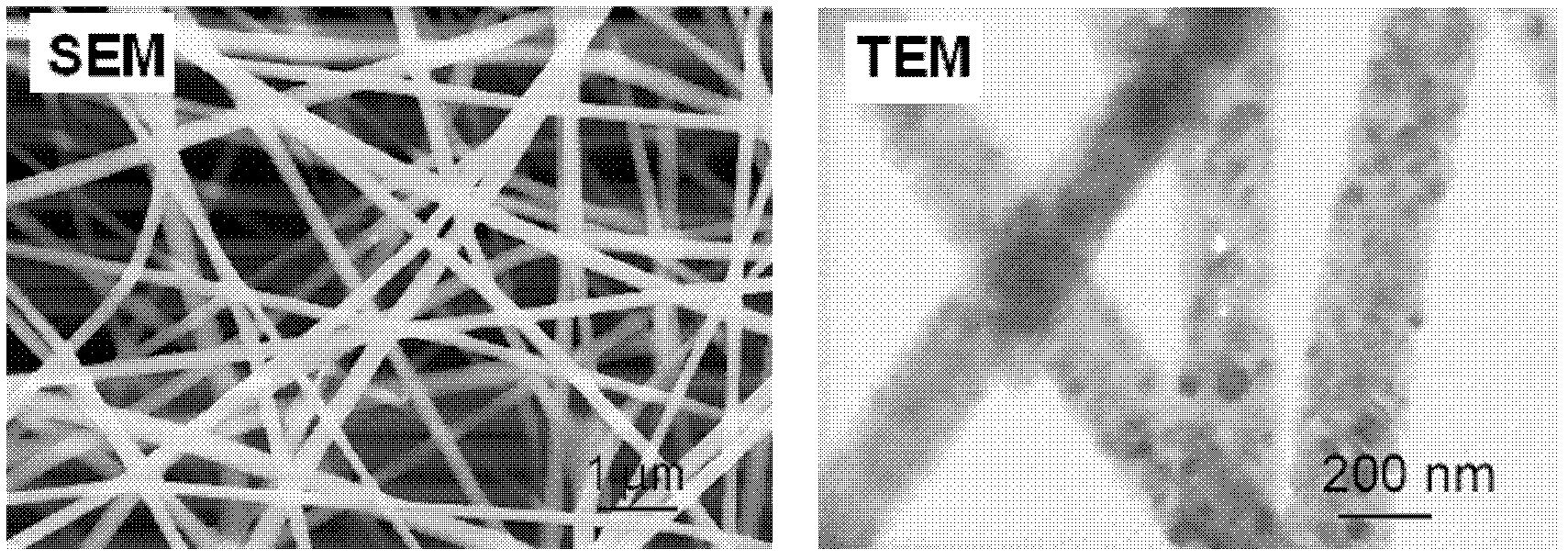

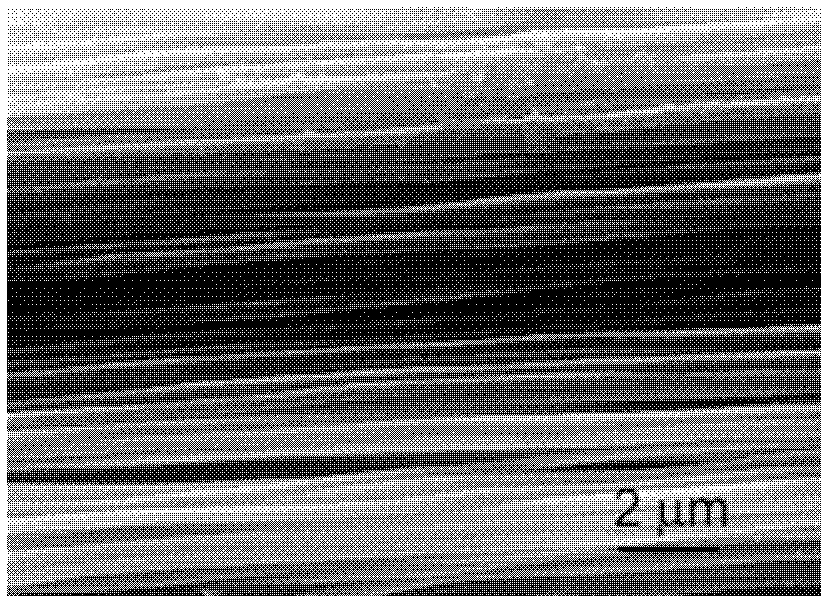

Calcium phosphate-collagen nanometer fiber compound nanometer artificial bone and preparation method thereof

InactiveCN102512709AImprove mechanical strengthGood bioactivity and biocompatibilityHeating/cooling textile fabricsNon-woven fabricsBiomechanical strengthCartilage

The invention discloses a calcium phosphate-collagen nanometer fiber compound nanometer artificial bone and a preparation method thereof. A calcium phosphate nanometer fiber film serves as a nanometer structural unit and combines with collagen to form the compound nanometer artificial bone; or a collagen nanometer fiber film serves the nanometer structural unit and combines with the calcium phosphate to form the compound nanometer artificial bone. The preparation method comprises the steps of preparing the calcium phosphate nanometer fiber film and collagen nanometer fiber film by using a static spinning device; and alternatively combining with collagen or calcium phosphate after taking the calcium phosphate nanometer fiber film or collagen nanometer fiber film as the nanometer structural unit to form the calcium phosphate-collagen nanometer fiber compound nanometer artificial bone. The compound nanometer artificial bone disclosed by the invention at least comprises one nanometer fiber in calcium phosphate or collagen, has biologic activity, biological compatibility and biomechanic intensity and can be used for repairing defects parts of weight bearing bones, including skulls, limb-stem bones, orofacial bones, vertebral columns and the like and serving as gradient materials to repair the connection parts of cartilages and bones.

Owner:SICHUAN UNIV

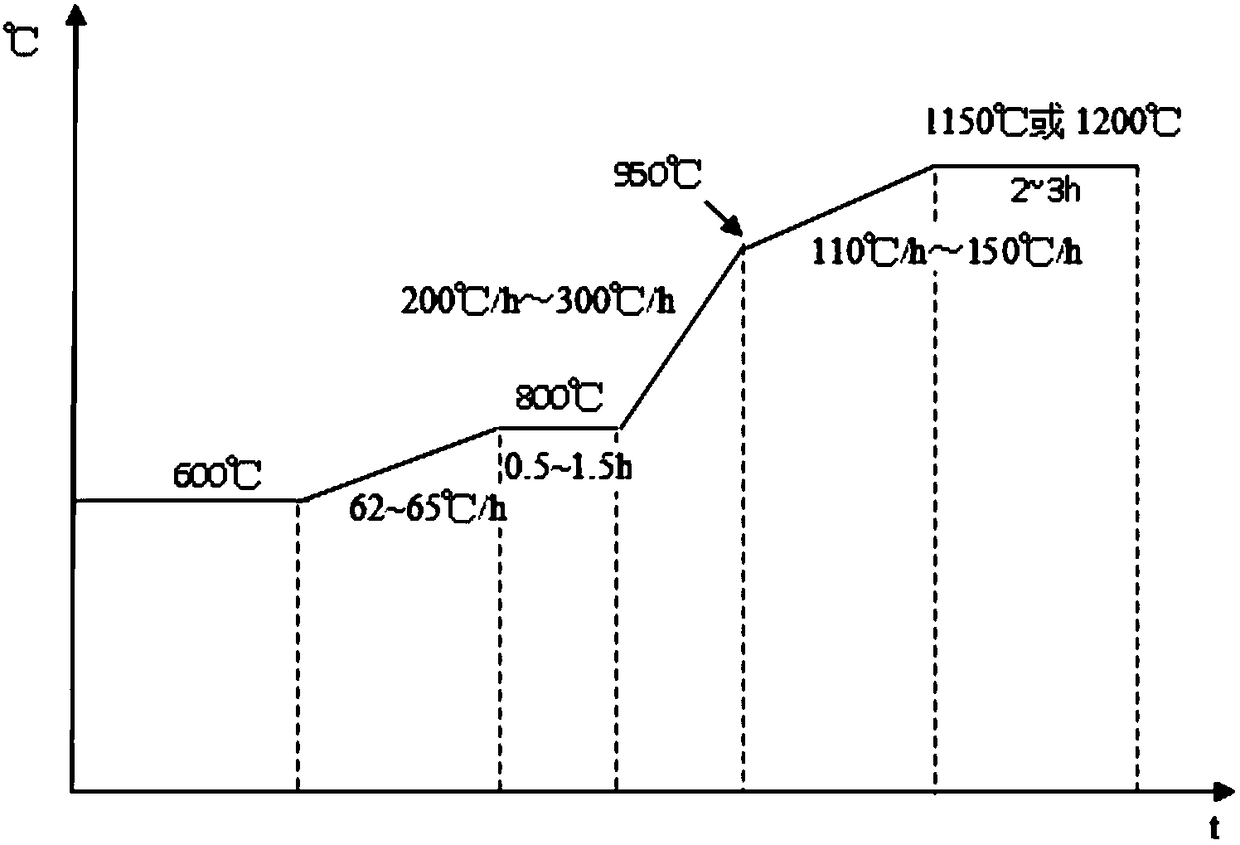

Cogging and forging method of 2507 super duplex stainless steel casting billet

ActiveCN108356189AImprove plasticityEliminate the effects ofMetal-working apparatusDouble phaseIngot

The invention relates to a cogging and forging method of a 2507 super duplex stainless steel casting billet, belongs to the technical field of hot processing of duplex stainless steel, and solves theproblem that a small steel ingot cracks during the cogging process. The cogging and forging method comprises the following steps: step 1, loading a furnace with 100 kg to 300 kg of the to-be-cast 2507super duplex stainless steel casting billet; step 2, heating the 2507 super duplex stainless steel casting billet by adopting a stepwise heating method; and step 3, carrying out cogging on the heated2507 super duplex stainless steel casting billet by adopting a two-heating-number forging method, wherein the two-heating-number forging method comprises the procedures of first-heating-number forging, in-furnace remelting for temperature equalization as well as second-heating-number forging, and both the finish forging temperature of the first-heating-number forging procedure and the finish forging temperature of the second-heating-number forging procedure are higher than or equal to 1050 DEG C. By adoption of the cogging and forging method provided by the invention, the 2507 super duplex stainless steel casting billet of which the billet surface quality is good can be obtained.

Owner:CENT IRON & STEEL RES INST +1

Low-cost and high-performance titanium alloy short process forging process

The invention provides a low-cost and high-performance titanium alloy short process forging process. The process includes the following steps that first, ingot casting is heated to be 1150 DEG C to 1200 DEG C, one heating number forging is conducted, and a forging stock is obtained after cogging; second, the blank obtained in the first step is heated to be 1000 DEG C to 1050 DEG C, and one heatingnumber reversing forging is conducted to obtain a forging stock; third, the blank obtained in the second step is heated to be 1000 DEG C to 1050 DEG C, and one heating number reversing forging is conducted to obtain a forging stock; and fourth, the forging stock in the third step is heated to be 30 DEG C to 50 DEG C below the beta phase transformation point temperature, and 1-3 heating number forging is conducted to obtain a forging stock with uniform structure properties. According to the low-cost and high-performance titanium alloy short process forging process, the technical problems of titanium alloy structure homogenization and fine crystallization through less forging heating numbers are successfully solved, the cost is lowered, and at the same time, the performance index of a titanium alloy is ensured.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

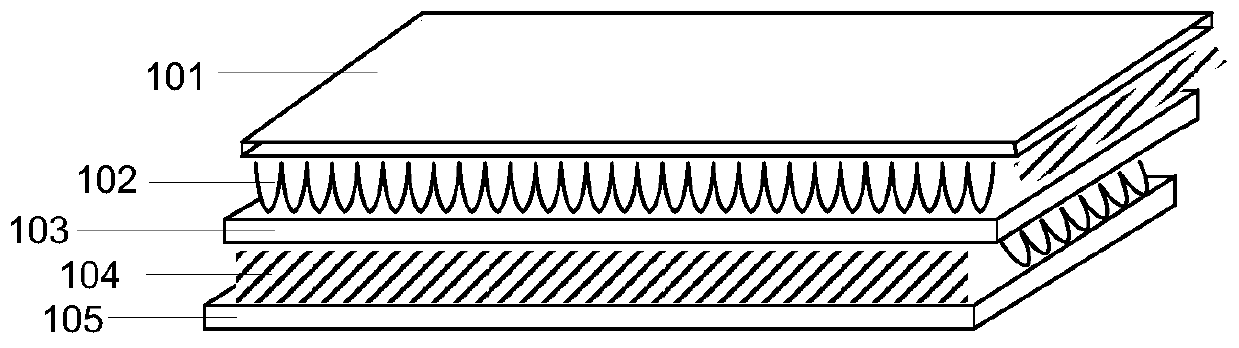

Aluminum alloy composite plate

InactiveCN109733019AReduce dosageReduce manufacturing costMetal layered productsAlloy compositeComposite plate

The invention relates to the technical field of aluminum alloy and discloses an aluminum alloy composite plate. The aluminum alloy composite plate comprises a first aluminum alloy layer, an aluminum core layer and a second aluminum layer in sequential lamination, wherein the aluminum core layer is an aluminum / aluminum alloy plate with a plurality of grooves. The joint of a core material in a groove structure and a surface material is a plane, and the combination area is larger than that of point-line combination, high combination force and less proneness to stripping are realized, anisotropismis prevented, and high strength and quality stability are realized. The structure with the grooves is easy to shape and can be bent along any directions to form the grooves, and low aluminum materialconsumption, light weight, thinness and low manufacturing cost are realized.

Owner:缪彬彬

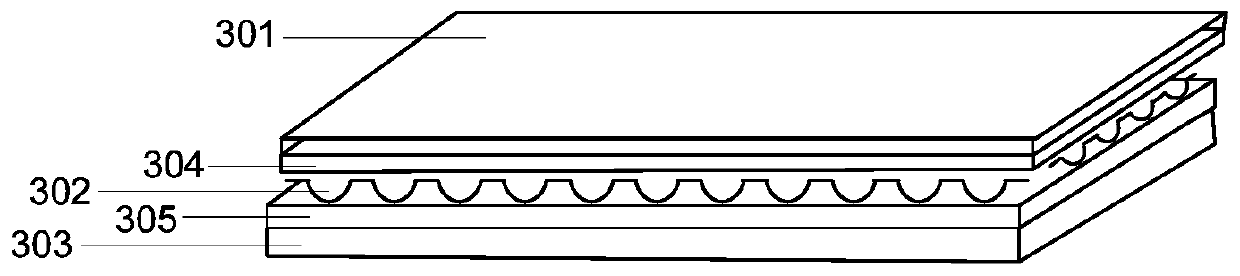

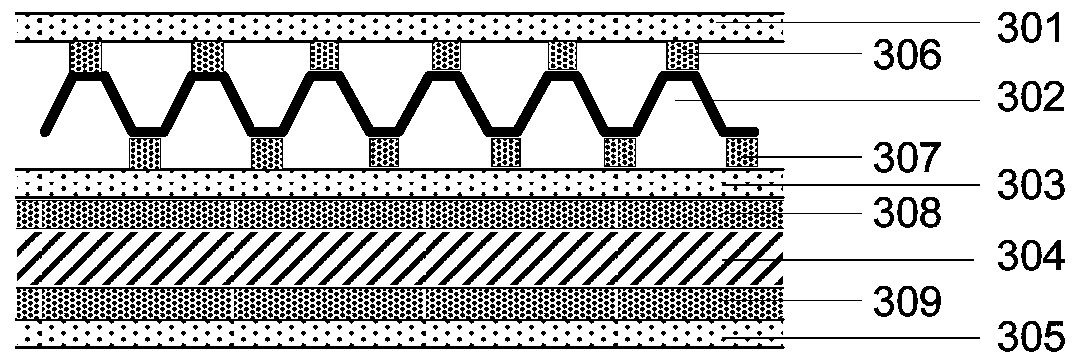

Aluminum alloy corrugated board

InactiveCN109693431AReinforcing performance strengthAvoid anisotropyMetal layered productsSurface plateAluminium alloy

The invention discloses an aluminum alloy corrugated board, and relates to the technical field of aluminum alloys. The aluminum alloy corrugated board comprises a first aluminum alloy layer, a first corrugated core layer, a second aluminum alloy layer, a second corrugated core layer and a third aluminum alloy layer which are sequentially laminated, wherein the first corrugated core layer and the second corrugated core layer are arranged in an interlaced manner. The above design mode can enhance the performance strength of the corrugated board, prevent anisotropy and reduce the probability of peeling of a core and a board.

Owner:缪彬彬

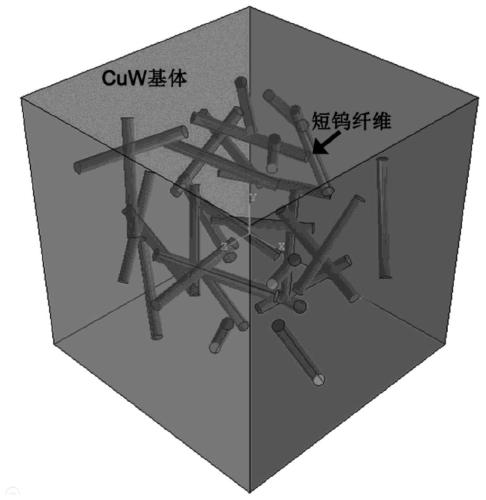

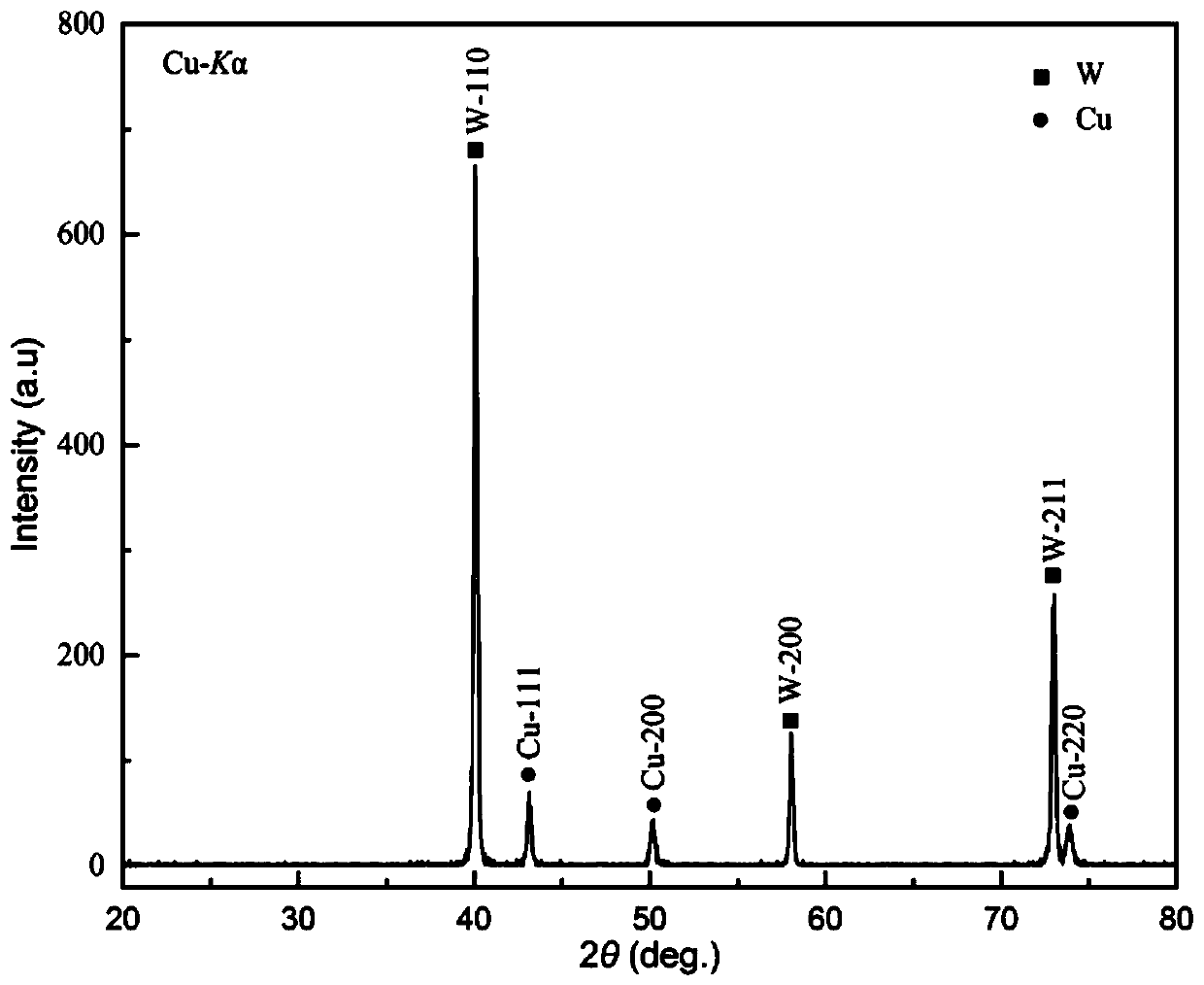

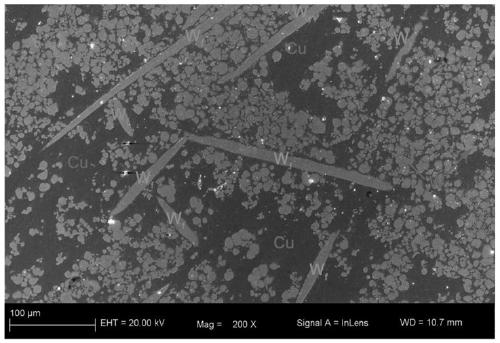

Randomly-distributed short tungsten fiber reinforced CuW composite and preparation method thereof

The invention discloses a randomly-distributed short tungsten fiber reinforced CuW composite. The randomly-distributed short tungsten fiber reinforced CuW composite is prepared from following raw materials in percent by mass including: 9.5%-30% of Cu powder, 60%-90% of W powder and 0.5%-15% of short tungsten fibers, wherein the sum of the mass percents of the components is 100%. The mechanical performance such as stretching, compression and frictional wear of the composite is remarkably improved. The invention further provides a preparation method of the composite. The preparation method specifically includes the steps that 1, 9.5%-30% of Cu powder, 60%-90% of W powder and 0.5%-15% of short tungsten fibers are weighed according to the mass percents, wherein the sum of the mass percents ofthe components is 100%; 2, the components are mixed; 3, a composite blank is prepared; 4, the composite blank is subjected to hot-pressed sintering; and 5, the composite blank obtained after hot-pressed sintering in S4 is subjected to copper infiltration. By means of the method, the comprehensive mechanical performance of the composite can be remarkably improved.

Owner:XIAN UNIV OF TECH

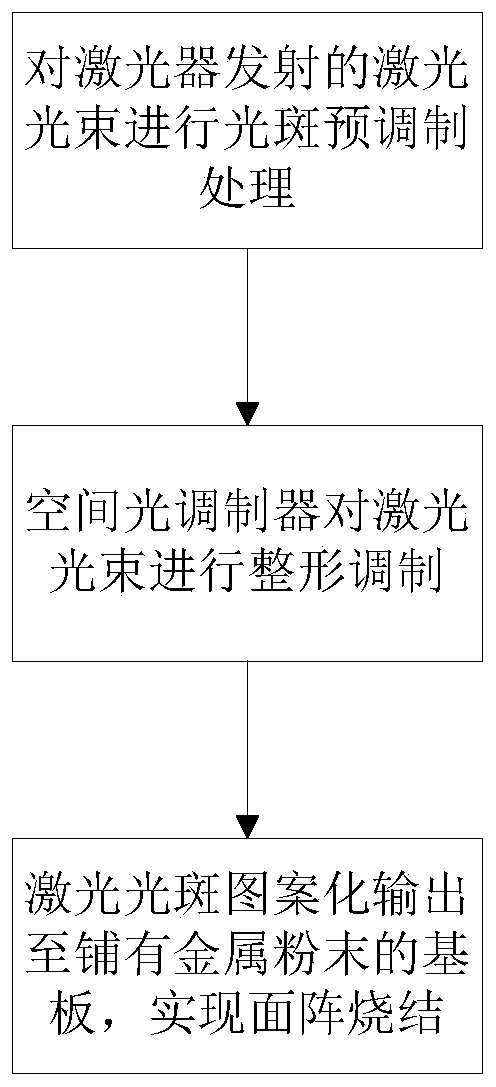

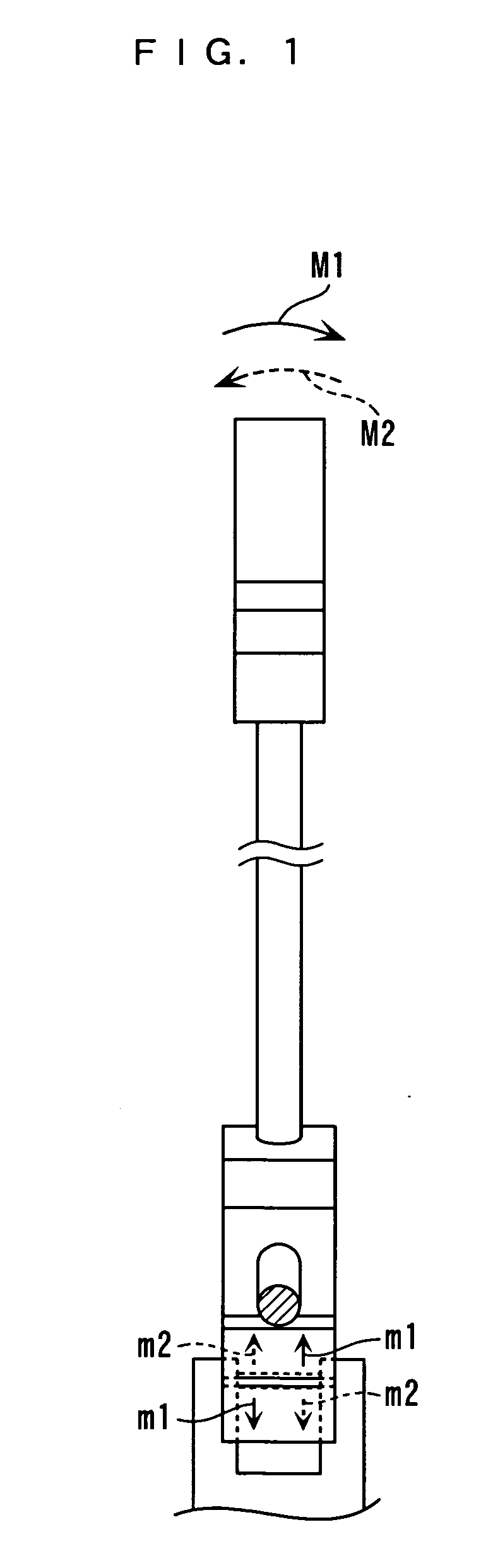

Metal selective melting forming method based on laser spot patterning output

ActiveCN110842198AAvoid anisotropyImprove molding qualityAdditive manufacturing apparatusIncreasing energy efficiencySpatial light modulatorControl system

The invention discloses a metal selective melting forming method based on laser spot patterning output. The method comprises the steps that firstly, laser beams are subjected to spot pre-modulation, and obtained initial seed light is incident into a spatial light modulator to be processed; secondly, a preprocessed metal model slice is input into a control system of the spatial light modulator, thecontrol system drives the spatial light modulator, and the incident initial seed light is modulated into spot patterning seed light in the shape corresponding to the metal model slice to be output; and thirdly, the spot patterning seed light output by the spatial light modulator is subjected to power amplification, the amplified light beams are projected to a base plate paved with metal powder, and metal powder area array sintering is achieved by adjusting the power density of laser projected to the base plate. According to the metal selective melting forming method, anisotropy on a metal workpiece slice layer due to the fact that path planning is too regular is avoided to the maximum degree, and accordingly the forming quality is improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

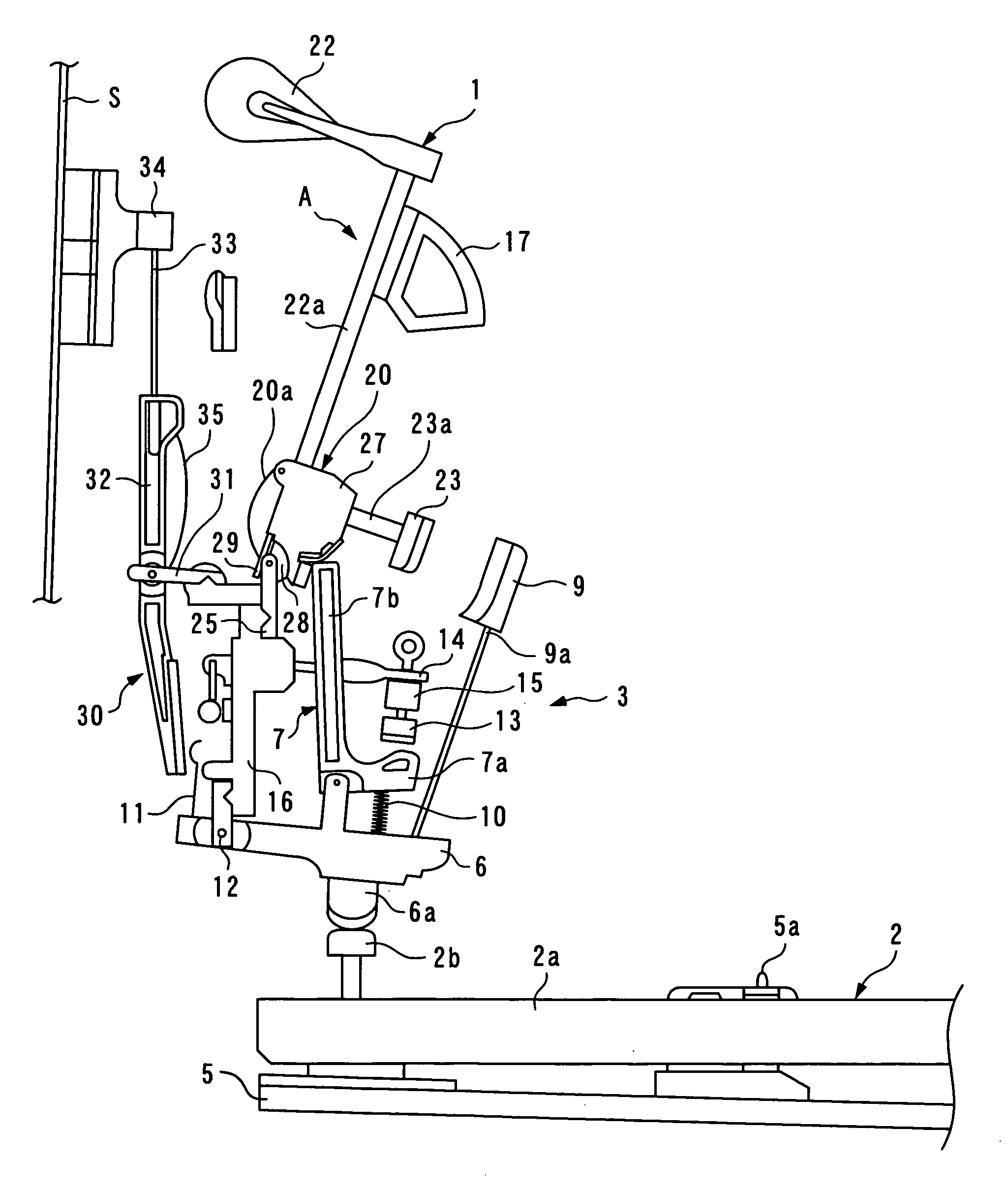

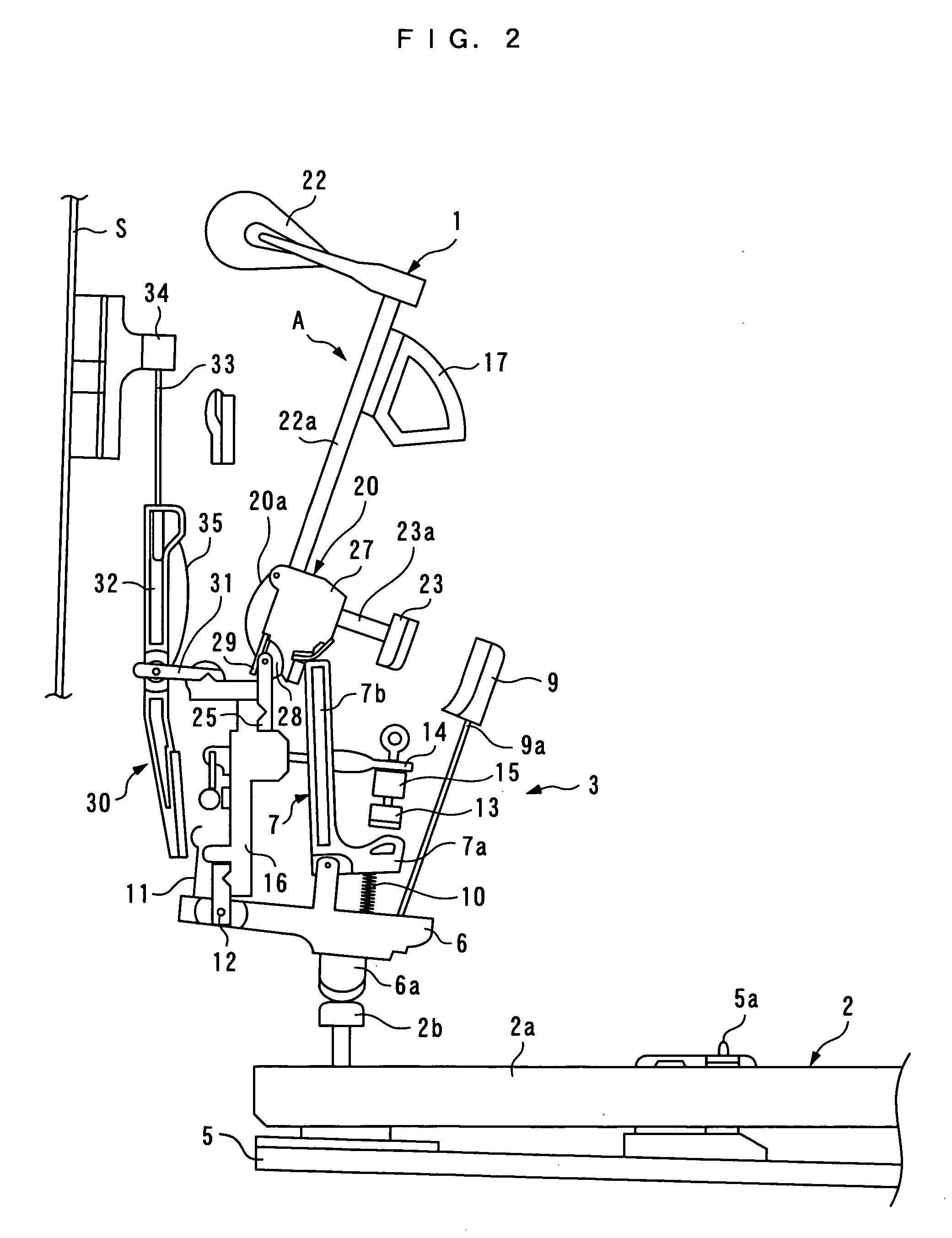

Bat for upright piano

A bat for an upright piano is provided for ensuring stable swinging movements of a hammer to generate a proper piano sound even if a hammer assembly has the centroid which is laterally asymmetric about a center pin. The bat for an upright piano is supported by the center pin having a circular cross section and arranged horizontally in a bat flange, in order to swing a hammer to cause the same to strike a string. The bat comprises a bat body integrally formed with the hammer, and having a linear pin holding groove in a back surface thereof, and a metal plate having a linear pin retaining groove in one side thereof, and attached to a back surface of the bat body such that the pin retaining groove extends in parallel with the pin holding groove, wherein the bat is pivotally supported by the center pin while the center pin is in engagement with the pin holding groove and the pin retaining groove, and the center pin is sandwiched between the bat body and the metal plate.

Owner:KAWAI MUSICAL INSTR MFG CO

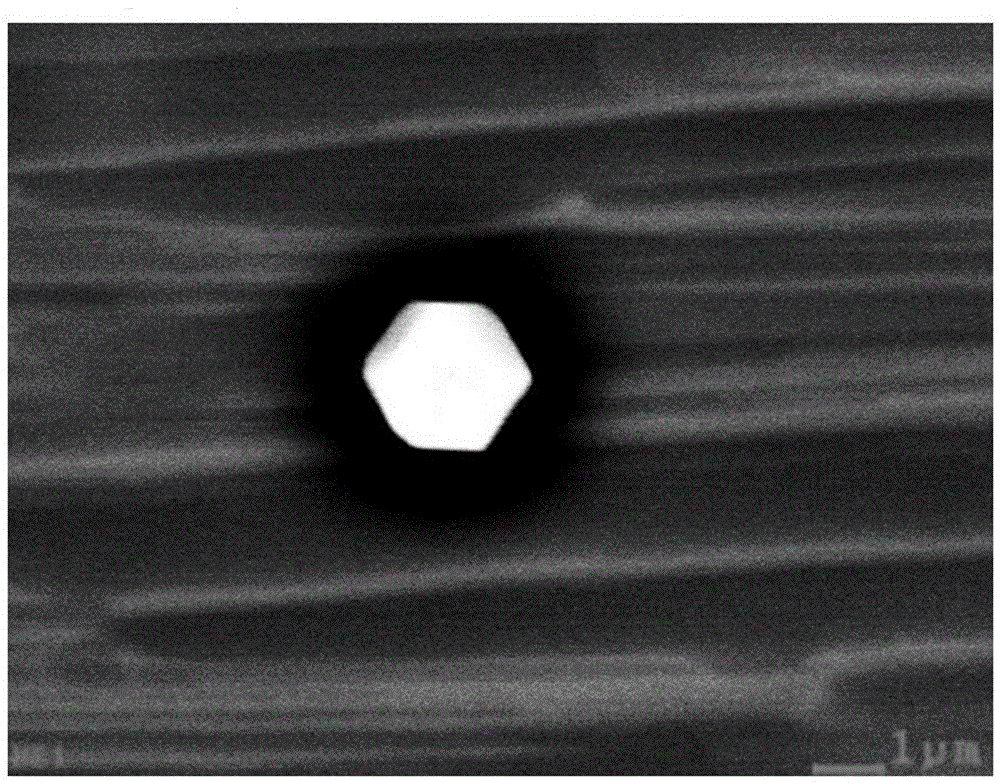

Boron nitride based ceramic material as well as preparation method and application thereof

ActiveCN107573079ALower sintering temperatureReduce manufacturing costBoron nitrideMechanical property

The invention relates to a boron nitride based ceramic material as well as a preparation method and application thereof. The boron nitride based ceramic material is prepared from boron nitride, electric-melting zirconium oxide, silicon carbide and an additive. The method comprises the following steps: 1, weighing raw materials; 2, preparing composite powder; 3, preparing boron nitride composite powder; 4, preparing a boron nitride based ceramic material prefabricated blank; 5, preparing the boron nitride based ceramic material. The invention further relates to the application of the boron nitride based ceramic material serving as a boron nitride based ceramic side sealing plate material for thin strip continuous casting. By adopting the boron nitride based ceramic material provided by theinvention, the technical problem that a boron nitride based complex phase ceramic material has high sintering temperature and a sintering auxiliary agent has a low melting point so that the service performance is reduced is solved; the density of the prepared boron nitride based ceramic material can reach 97 percent or more; the boron nitride based ceramic material has excellent integrated mechanical properties and the bending strength value can reach 420MPa, so that the boron nitride based ceramic material is very suitable for being used as the boron nitride based ceramic side sealing plate material for the thin strip continuous casting.

Owner:HARBIN INST OF TECH

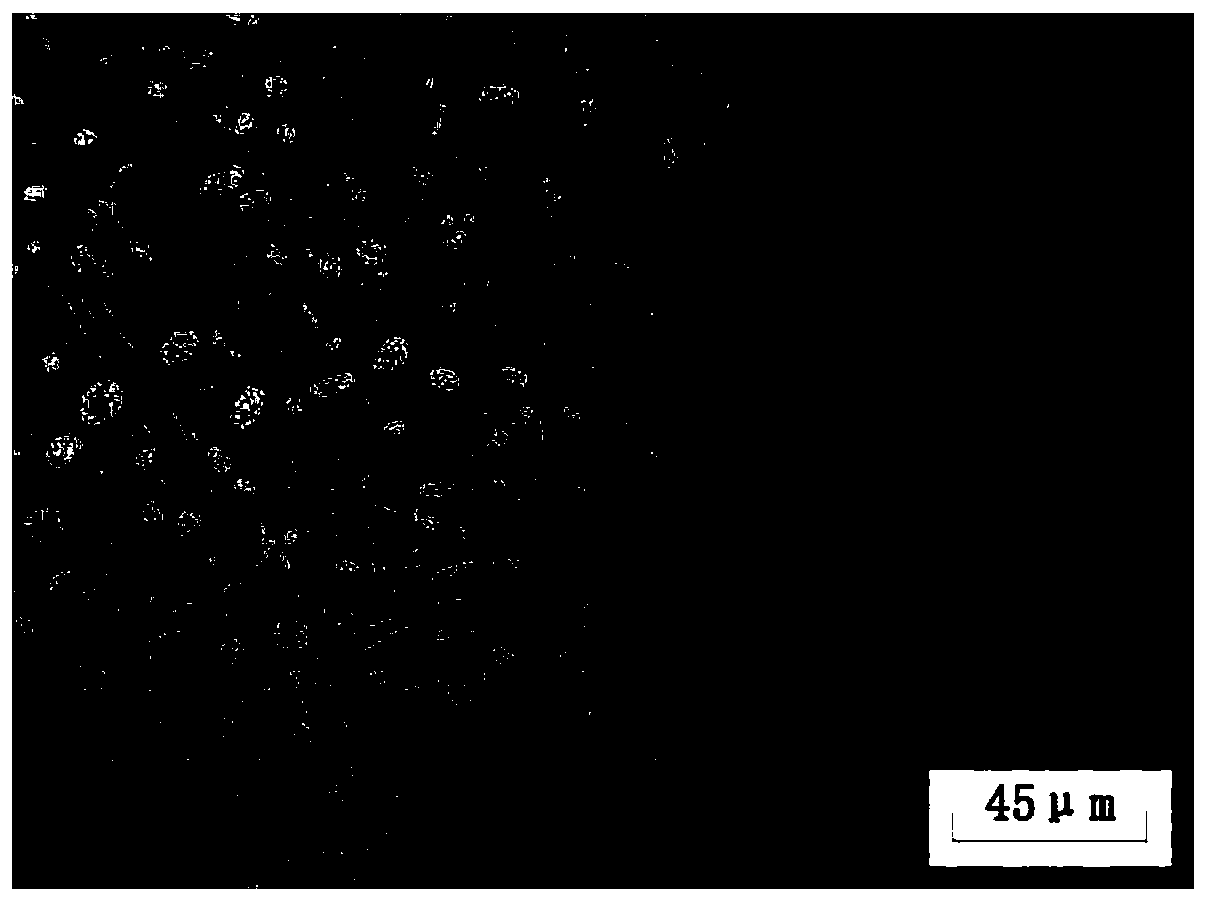

Titanium alloy powder with endogenous nano composite ceramic particles and preparation method and application thereof

PendingCN112251646AIncrease equiaxed crystal ratioHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyComposite ceramicTitanium

The invention is suitable for the technical field of additive manufacturing materials, and provides titanium alloy powder with endogenous nano composite ceramic particles and a preparation method andapplication thereof. The preparation method comprises the following steps that a titanium-based mother alloy is placed in a vacuum environment to be smelted, and a molten alloy is obtained; an aluminum-based intermediate alloy containing nano TiC and nano TiB2 is added into the molten alloy, homogenization treatment is carried out, and then casting molding is carried out to obtain a casting blank;and the casting blank is made into powder through a plasma rotating electrode atomization method or a gas atomization method, screening is conducted, and the nano TiC and nano TiB2 reinforced titanium alloy powder is obtained. According to the preparation method, by adding the nano TiC and the nano TiB2, the isometric crystal proportion of the titanium alloy powder through additive manufacturingparts can be remarkably increased, columnar crystals are reduced, and the structure uniformity after additive manufacturing is greatly improved, so that the anisotropy phenomenon can be avoided, the crack forming tendency is relieved, and the strength and plasticity of additive manufacturing metal products are improved.

Owner:JILIN UNIV

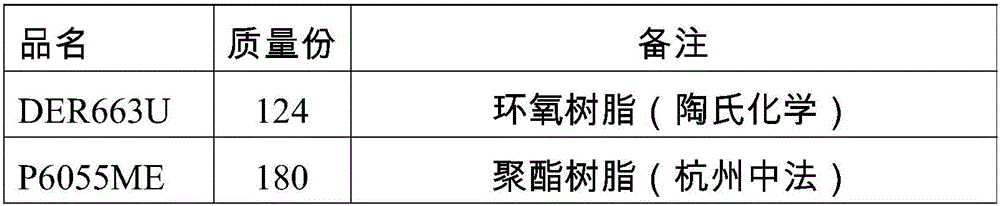

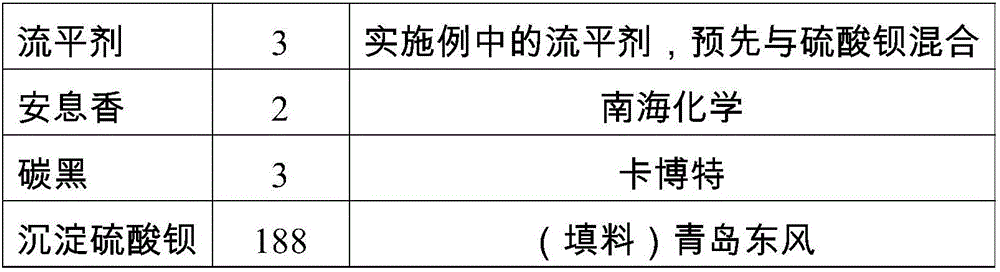

Powder coating leveling agent and preparation method and application thereof

The invention provides a powder coating leveling agent and a preparation method thereof. The powder coating leveling agent is made by copolymerizing 5-40% by weight of a vegetable oil, 40-95% by weight of alkyl acrylate monomer, 0-20% by weight of alkyl methacrylate monomer by conventional dropwise polymerization; this vegetable oil is one of or a mixture of more than one of soybean oil, palm oil, rapeseed oil and castor oil, the alkyl acrylate monomer includes linear, branched or cyclic aliphatic monohydric alcohol ester with 2-22 carbon atoms, the alkyl methacrylate monomer includes linear, branched or cyclic aliphatic monohydric alcohol ester with 1-12 carbon atoms. The powder coating leveling agent of the invention has the advantages of greenness, low cost, high hydrophobicity, good leveling performance, heat resistance, acid and alkali resistance, good waterproof performance and the like, the preparation method is simple, and the powder coating leveling agent is applicable to powder coatings or solvent coatings.

Owner:NINGBO SOUTH SEA CHEM

Calcium phosphate-collagen nanometer fiber compound nanometer artificial bone and preparation method thereof

InactiveCN102512709BImprove biological activityGood biocompatibilityHeating/cooling textile fabricsNon-woven fabricsFiberGradient material

Owner:SICHUAN UNIV

High-toughness wear-resistant flux-cored wire

InactiveCN107262964AStrong deoxygenation abilityAvoid infringementWelding/cutting media/materialsSoldering mediaWear resistantRare earth

The invention discloses a high-toughness wear-resistant flux-cored wire which consists of a flux core and stainless steel skin covering the flux core. The flux core comprises the following raw materials: graphite powder, silicon powder, magnesium powder, nickel powder, titanium powder, titanium dioxide powder, titanium boride powder, iron oxide powder, zirconium oxide powder, aluminum-strontium alloy powder, electrolytic manganese powder, ferromolybdenum powder, ferroniobium powder, ferrovanadium powder, rare earth ferroalloy powder, carbonate, metal fluoride, and the balance reduced iron powder and unavoidable impurities. The high-toughness wear-resistant flux-cored wire has the advantages that splashes are small, smoke is little, the forming is good, deslagging is easy, deposited metal is compact in structure, no pores or flaws appear, the high-toughness wear-resistant flux-cored wire is combined with parent metal well and is stable in performance, the deposited metal has good wear resistance, corrosion resistance and high toughness, and the high-toughness wear-resistant flux-cored wire has good economic benefits.

Owner:天长市通联焊业有限公司

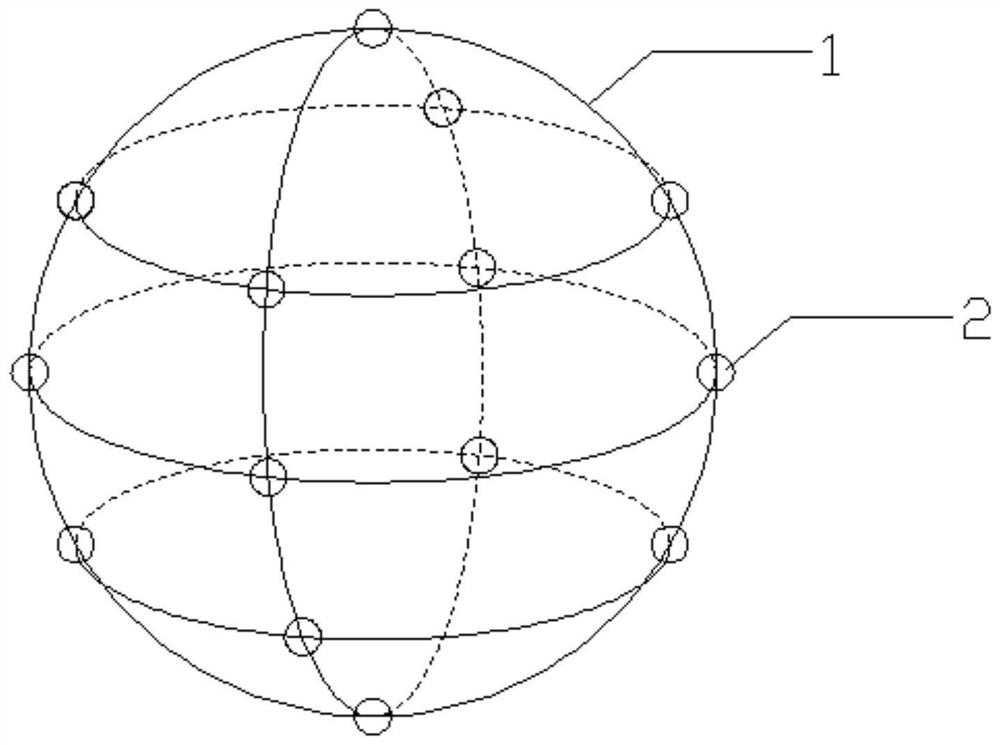

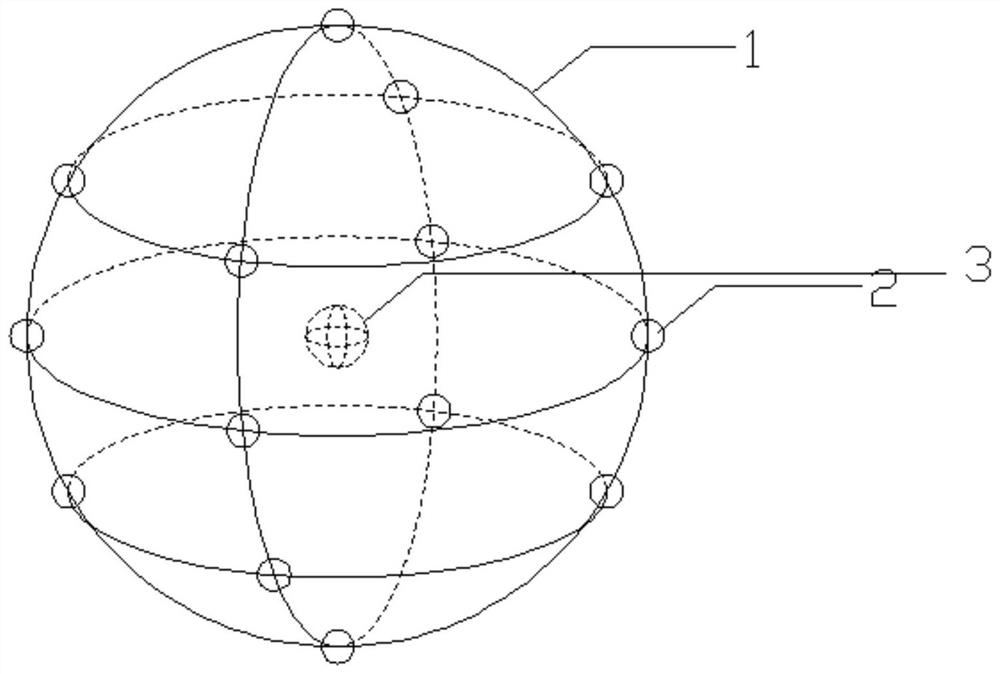

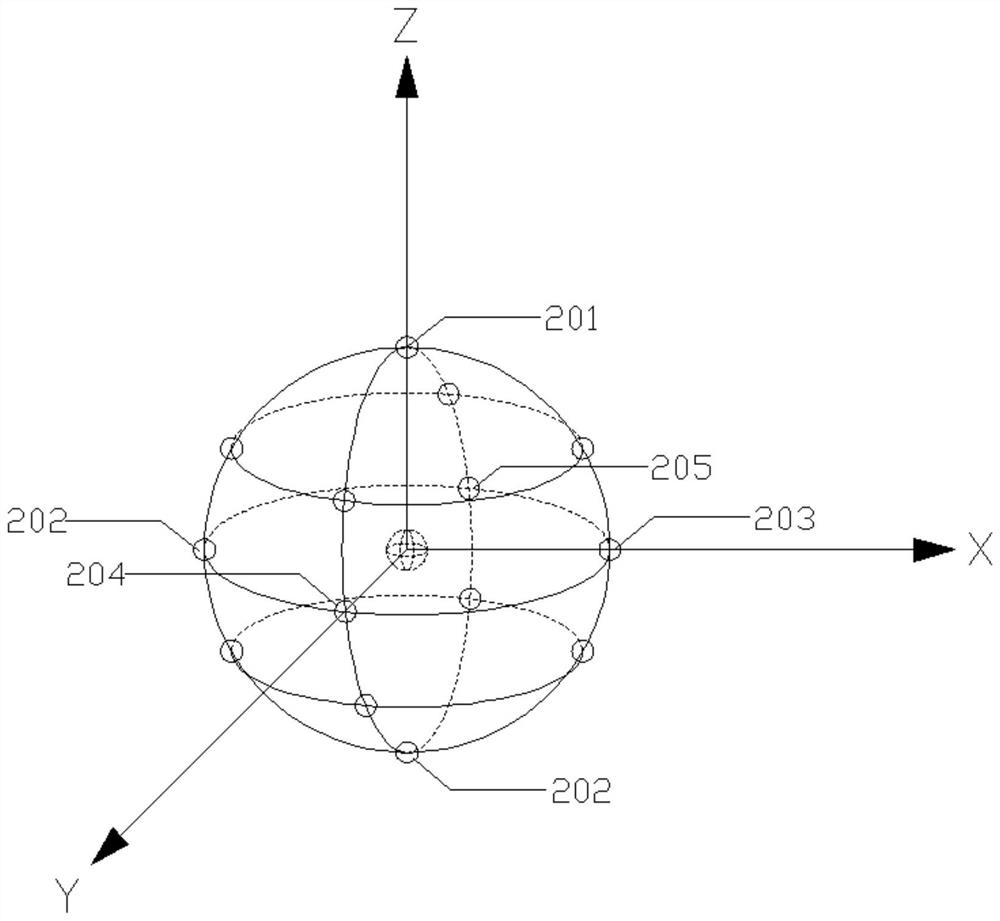

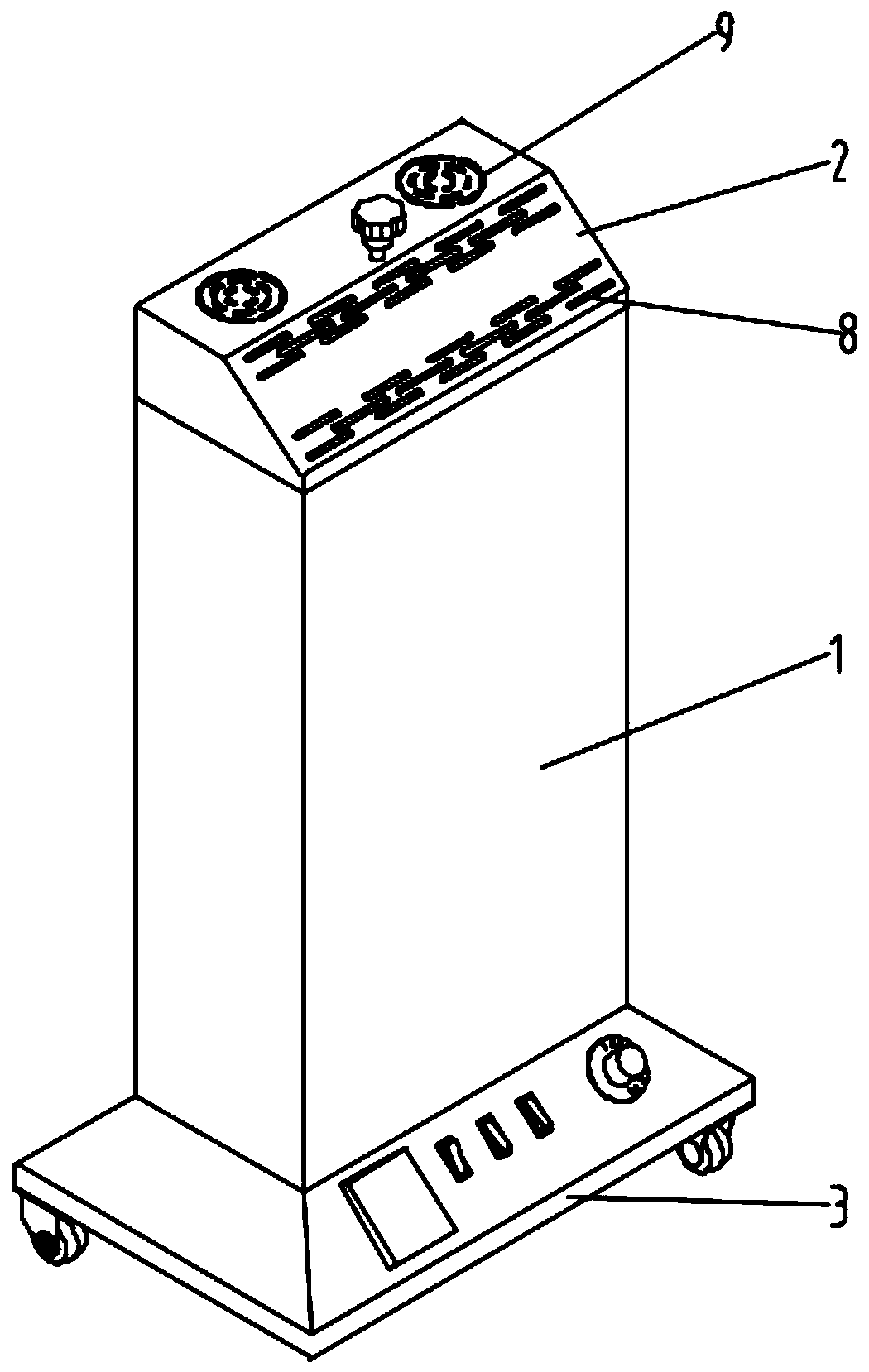

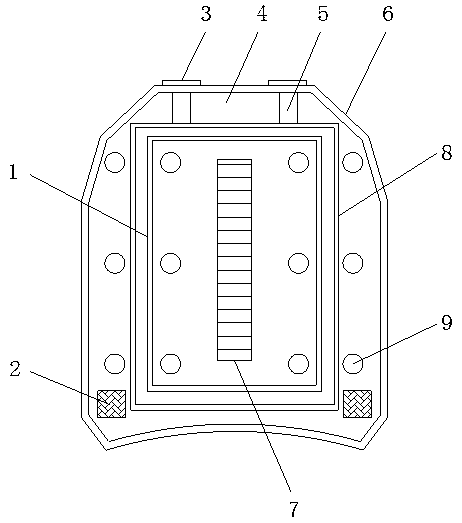

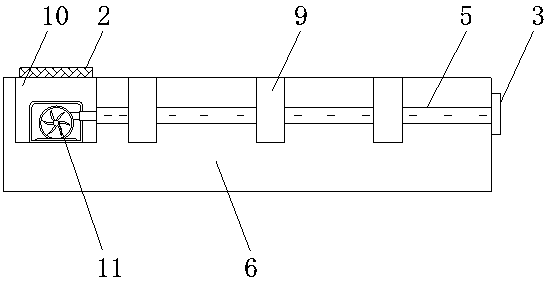

Underground water level monitoring device suitable for various aquifer conditions

PendingCN114660674AGuaranteed typicalityHigh precisionProspecting/detection of underground waterGyroscopeWater flow

The invention discloses an underground water level monitoring device suitable for various aquifer conditions, which comprises a spherical shell, 14 symmetrically distributed monitoring sensors are arranged on the spherical surface of the spherical shell, a gyroscope is arranged at the sphere center position of the spherical shell, a data processing module is arranged on one side of the bottom in the spherical shell, and a data processing module is arranged on the other side of the spherical shell. A signal output interface is arranged on one side of the top in the spherical shell, and a plurality of supports are arranged between the outer surface of the gyroscope and the inner surface of the spherical shell. By adopting the sphere structure, the influence of the water flow effect can be reduced, and the measurement value of each monitoring sensor can be ensured to have typicality, so that the underground water level measurement precision is greatly improved; by means of the built-in monitoring sensor and the gyroscope, water flow information such as pressure and flow velocity can be adopted in real time, high-precision pressure and flow velocity measurement and calculation are achieved in combination with a space coordinate system constructed by the data processing module, and therefore the problems that underground water level measurement is high in difficulty and low in precision and efficiency are effectively solved.

Owner:HEBEI UNIV OF ENG

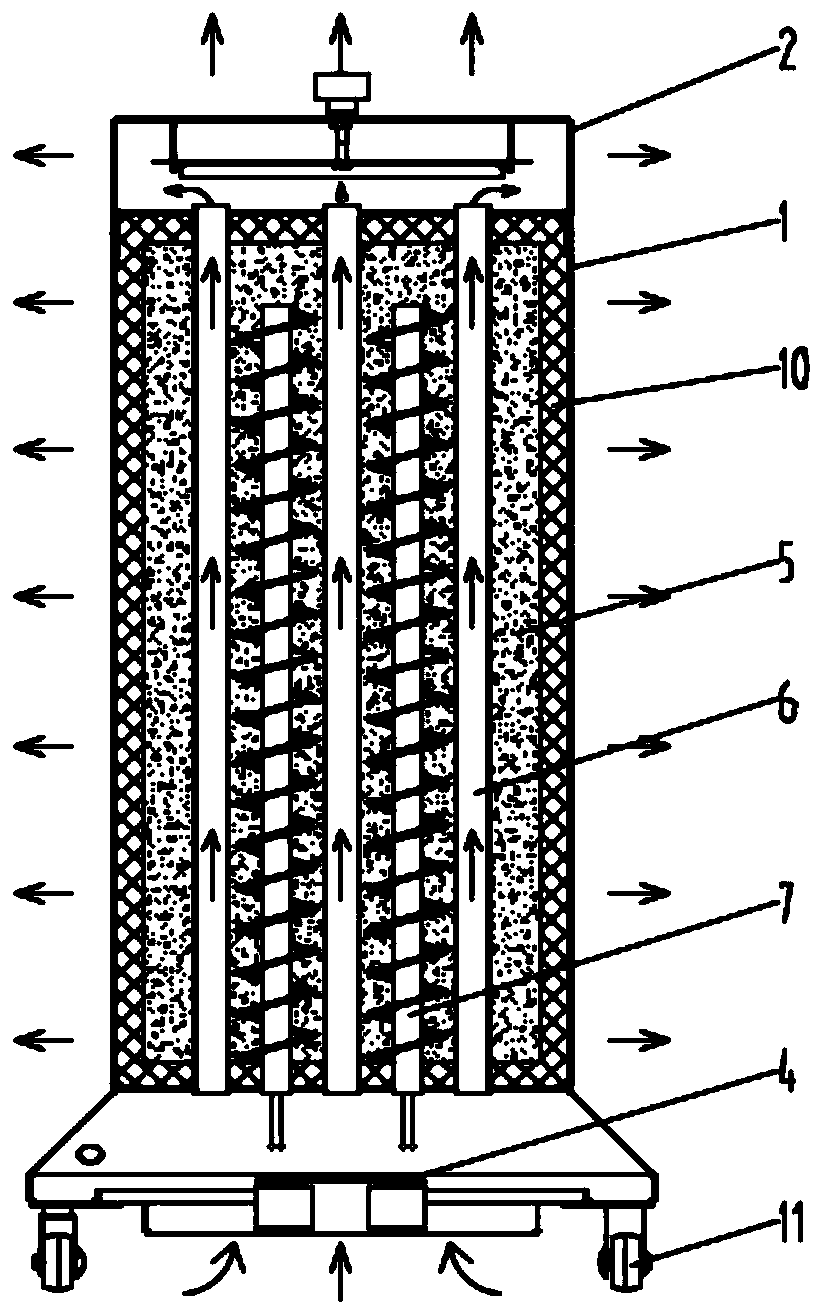

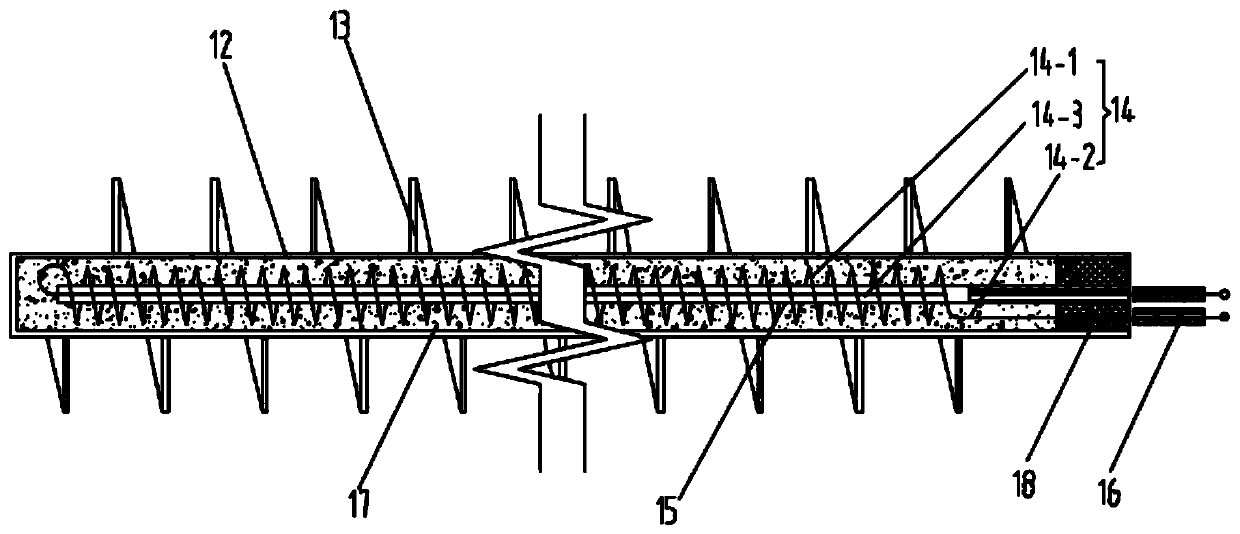

Heat accumulating type electric heater with heat accumulator formed by casting

PendingCN110017525APrevent oxidationExtended service lifeLighting and heating apparatusElectric heating systemElectricityGrating

The invention discloses a heat accumulating type electric heater with a heat accumulator formed by casting. The electric heater comprises a outer shell body, wherein a grating cover is arranged abovethe outer shell body, a skirt base is arranged below the outer shell body, at least one fan is arranged at the bottom of the skirt base; the heat accumulator is arranged in the outer shell body, the heat accumulator is a cast-formed solid heat accumulating material, a plurality of air flow channels are uniformly arranged in the heat accumulator at intervals, the lower ends of the air flow channelscommunicate with the interior of the skirt base, the upper ends of the airflow channels communicate with the interior of the grating cover, and an electric heater is arranged between every two adjacent airflow channels. According to the heat accumulating type electric heater, the heat accumulator, the electric heater and the heat preservation layer are in a totally-closed structure and are isolated from outside air, so that metal oxidation can be prevented, the service life of related components is prolonged, the closed structure becomes a thermodynamic closed system, the heat exchange is carried out with the outside, no matter and mass exchange exists, zero emission of the system is achieved, the environment-friendly effect is achieved, the water and the water vapor or the particles cannot be immersed, and a relatively high safety protection grade is achieved.

Owner:河北秦暖新能源科技有限公司

Carbon fiber engine cover for automobile

PendingCN108454708AImprove axial strengthHigh modulusSuperstructure subunitsPropulsion coolingCarbon fibersAgricultural engineering

The invention discloses a carbon fiber engine cover for an automobile. The carbon fiber engine cover comprises an engine cover body. The upper and lower portions inside the engine cover body are provided with a thermal insulating layer and a waterproof layer respectively, a carbon fiber layer is arranged in the center inside the engine cover body, the engine cover body comprises an outer installing plate, a sound insulating plate and an inner installing plate, the outer installing plate and the inner installing plate are arranged at the front and rear ends of the engine cover body respectively, the sound insulating plate is arranged between the outer installing plate and the inner installing plate, lightening holes are formed in the two sides of the front surfaces of the outer installing plate and the inner installing plate at equal intervals, electronic refrigeration pieces are electrically connected to the middle of the surface of the inner installing plate, and the bottoms of the two sides of the surface of the outer installing plate are fixedly connected with fans through formed installing grooves. By arranging the carbon fiber layer, the sound insulating plate, the waterprooflayer, the fans, a wind direction flow guiding groove, the electronic refrigeration pieces and the lightening holes, the carbon fiber engine cover has the advantages of prolonging the service life andachieving sound insulation, waterproofness, exhaust, heat dissipation and low weight.

Owner:HENAN DONGHAI COMPOUND MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com