Calcium phosphate-collagen nanometer fiber compound nanometer artificial bone and preparation method thereof

A nanofiber, nanofiber membrane technology, applied in spinning solution preparation, medical science, heating/cooling fabric, etc., can solve the problems of single chemical composition of nanofibers, limitation of mechanical properties, less than 20% of artificial bone market, etc. Achieve good biological activity, biocompatibility, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation of embodiment 1 disordered calcium phosphate nanofiber film

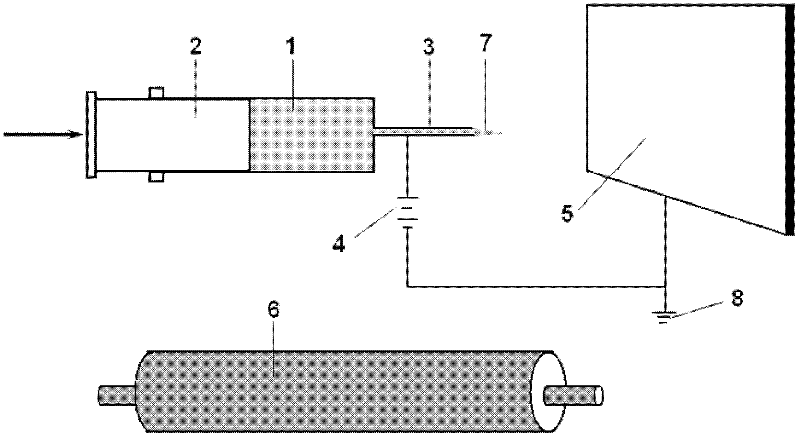

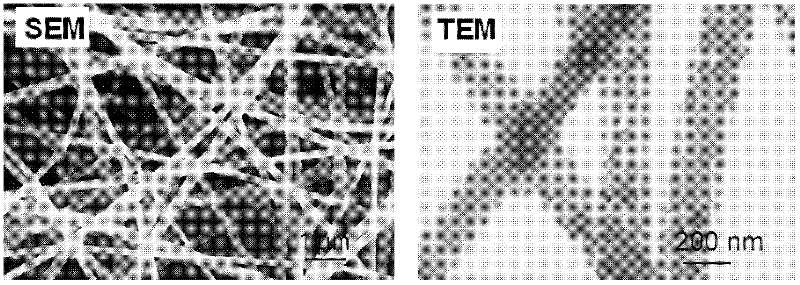

[0061] 5 g Ca(NO 3 ) 2 4H 2 O and 2 g (NH 4 ) 2 HPO 4 Add 100 ml of ethanol and water in a mixed solvent with a ratio of 4:1 to form a solution, add hydrochloric acid to adjust the pH to 3, and stir for 24 hours; add 3 grams of polyvinylpyrrolidone with a weight average molecular weight of 1,300,000 to the above solution Continue stirring for 1 hour to obtain a hydroxyapatite precursor electrospinning solution; transfer the electrospinning solution to the electrospinning container 1 carrying the spinning solution in the special equipment for electrospinning with a piston type input pump 2 , the electrospinning solution at the spinning port 3 is subjected to the action of a high-voltage electric field to form a liquid electrospinning jet 7, which is continuously refined in the electric field, and at the same time, the solvent in the jet volatilizes rapidly, and finally on the flat receivin...

Embodiment 2

[0062] Example 2 Preparation of Axial Array Calcium Phosphate Nanofiber Membrane

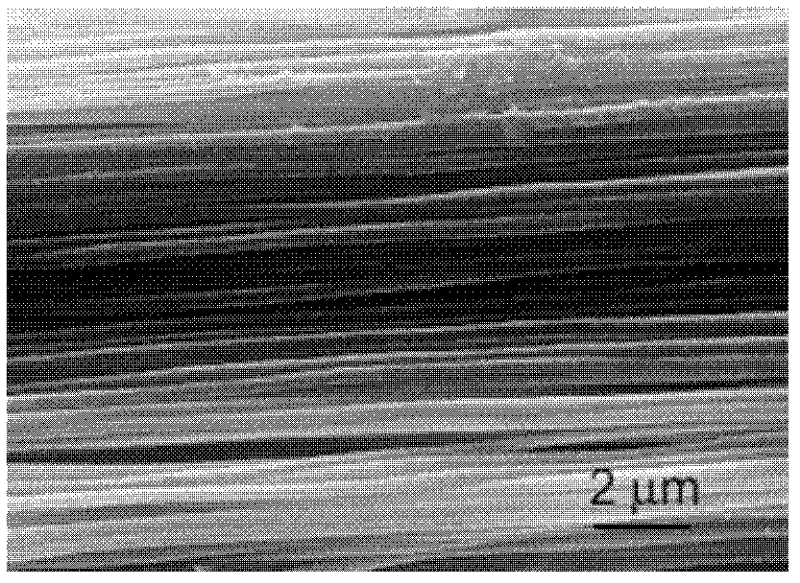

[0063] This example adopts the axial receiving drum 6 in the special equipment to receive the electrospinning nanofiber (at this moment, the flat receiving electrode plate 5 is changed into the axial receiving drum 6 and gets final product), and the rotating drum speed is 2000 rev / min. The collected axial array electrospun fibers were put into a box-type resistance furnace and roasted at a high temperature of 1000°C for 6 hours to remove organic components. The other preparation conditions were the same as in Example 1, and an axial array of hydroxyapatite nanofiber membranes was obtained as a result. , with an average diameter of 260 nm, such as image 3 shown.

Embodiment 3

[0064] Preparation of Example 3 Disordered Calcium Phosphate Nanofiber Membrane

[0065] Using Ca(NO 3 ) 2 4H 2 O:(NH 4 ) 2 HPO 4 ) molar ratio was 1.5, and other preparation conditions were the same as in Example 1 to obtain a tricalcium phosphate nanofibrous membrane with an average diameter of 350 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com