High-damping self-compaction concrete

A self-compacting concrete and high damping technology, applied in the field of concrete, can solve problems such as strength reduction, and achieve the effects of convenient operation, improved comfort and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

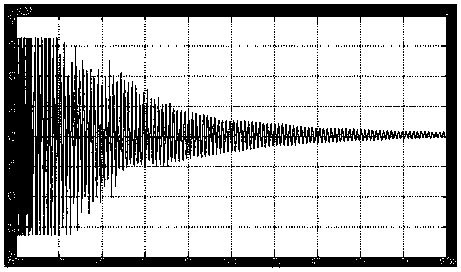

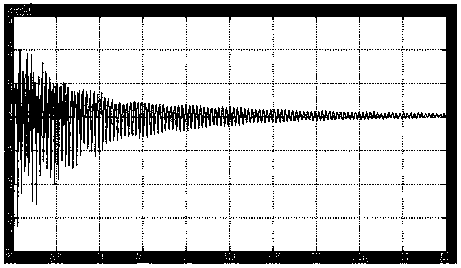

Image

Examples

Embodiment Construction

[0041] The following examples are intended to illustrate the present invention rather than to further limit the present invention.

[0042] A high-damping self-compacting concrete, composed of P.O42.5 ordinary Portland cement, composite reinforcing powder, anionic emulsified asphalt polymer, polycarboxylate high-efficiency water reducer, mixing water, composite deformation components, The fineness modulus is between 2.6 and 3.0, graded river sand in zone II, the particle size is between 5 and 20mm, limestone gravel, etc., the anionic emulsified asphalt polymer is 250C Engel viscosity is 6, and the solid content is 6. 60-61% anionic emulsified asphalt polymer, the composite reinforcing powder is composed of 4.2 parts of nanoclay, 0.2 parts of lignocellulose, 12.6 parts of ultrafine high-activity metakaolin with a fineness of 1600 mesh and 83 parts of Class I fly ash The composite deformation component is composed of 1.7 parts of polypropylene fiber, 1.8 parts of EPS particles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Dynamic modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com