Preparation of MWCNTs reinforced zero-value nano iron/electrostatic spinning nano fiber felt

A zero-valent nano-iron and nano-fiber technology is applied in the directions of spinning solution preparation, fiber type, and fiber processing, which can solve the problems of increasing the mechanical strength of electrospinning polyacrylic acid nanofiber mats, and achieve improved mechanical strength and simple preparation method. , the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Take 10 mg of MWCNTs in a 1.5 mL centrifuge tube, add 1 mL of deionized water, and place it on an ultrasonic cleaner for 30 minutes to make the MWCNTs uniformly dispersed in the water for use.

[0052] Take 2.43261 g FeCl 3 ·6H 2 O, dissolved in deionized water, magnetically stirred to make it fully mixed evenly, and configured into transparent brown-yellow Fe with a concentration of 0.18mol / L 3+ Salt solution 50ml. Take 1.77801 grams of NaBH 4 , Dissolved in deionized water, stirred with a glass rod for several minutes to prepare 50ml of 0.94mol / L solution, and set aside.

[0053] Take 3 grams of polyvinyl alcohol (PVA) in a beaker, use deionized water as the solvent, place it on a magnetic stirrer and stir at 80°C for 3 hours to prepare an aqueous solution with a concentration of 10% by mass. use.

Embodiment 2

[0055] The uniformly dispersed MWCNTs in Example 1 were added to an aqueous solution of polyacrylic acid (PAA) with a concentration of 25% by mass, and ultrasonicated for 5 minutes to prepare a uniform PAA solution containing MWCNTs. Then add the PVA solution prepared in Example 1 to the PAA solution, and magnetically stir for 2 hours to prepare a 10 ml mixed solution with a total concentration of 10%, where the mass ratio of PAA to PVA is 1:1. Set the spinning process conditions as follows: the receiving distance is 25cm, the voltage is 16.6kV, and the flow rate is 0.5ml / h. The prepared nanofibers are finally deposited on the aluminum foil in the form of fiber mat. After the fiber mat is naturally dried in the air, it is stored in a desiccator.

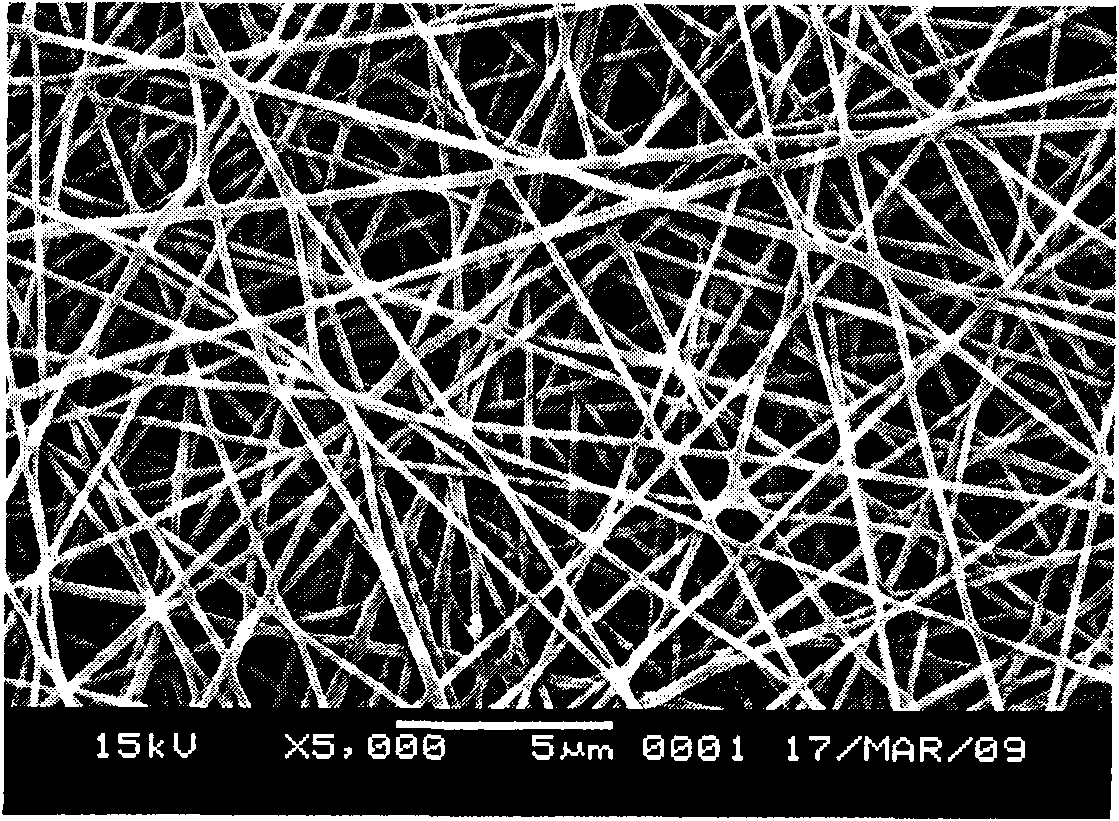

[0056] The SEM test results show that the diameter of the nanofibers is distributed in the range of 150-400nm, the average diameter is 240nm, the fiber surface is smooth, the thickness is uniform, and the formed fiber mat presents a go...

Embodiment 3

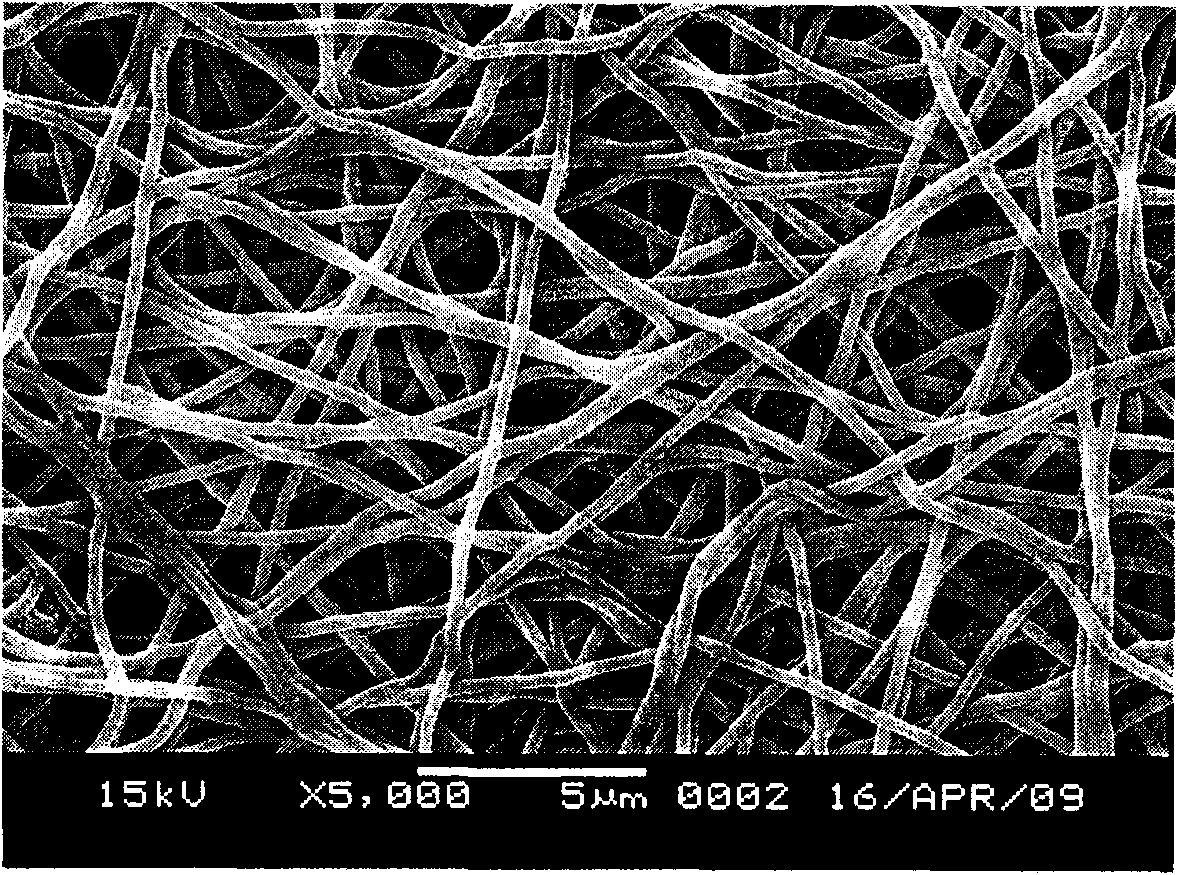

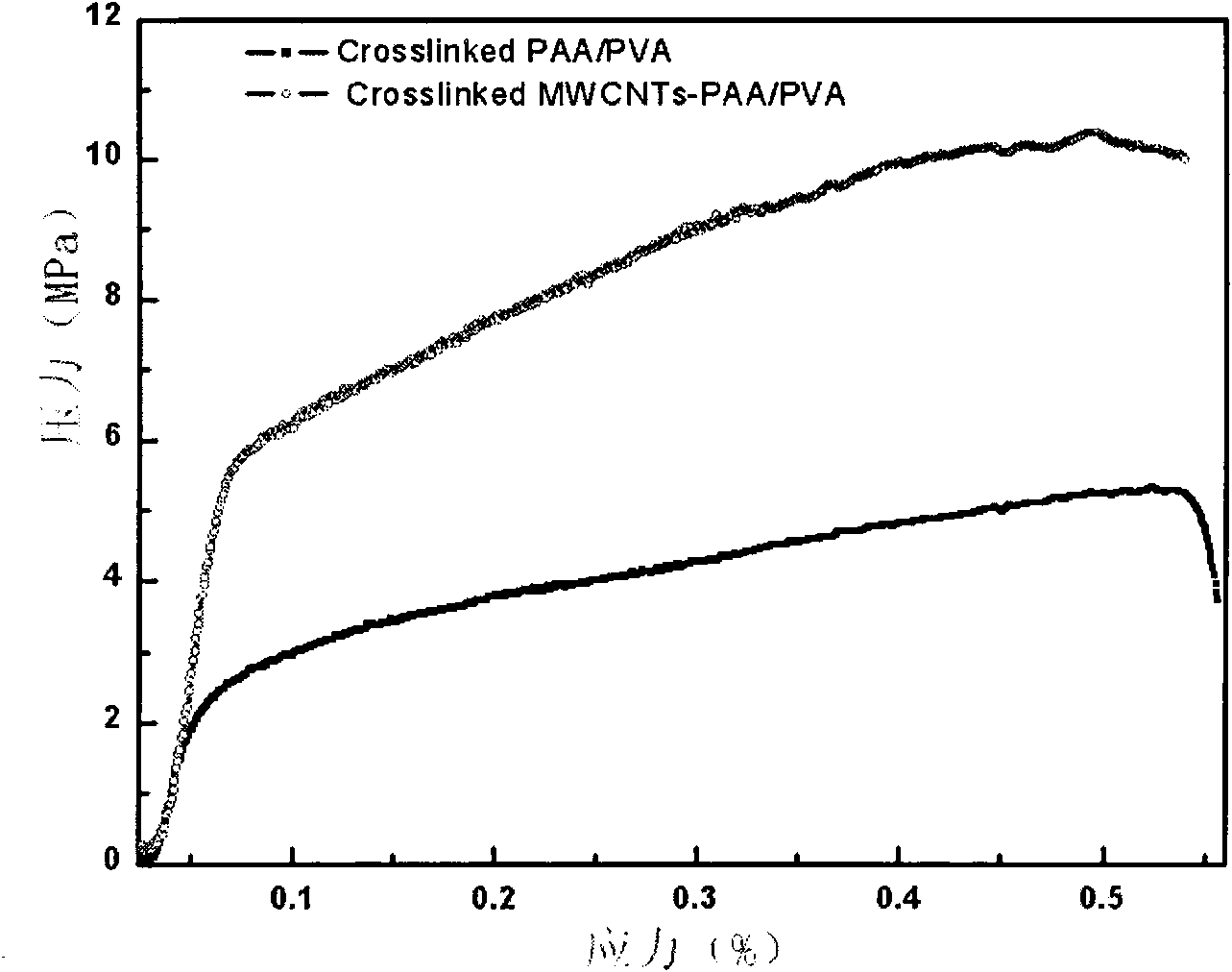

[0058] A certain amount of the fiber mat prepared in Example 2 was heat-treated at 140-150° C. for 30 min, and the sample was cross-linked. After the sample was cooled to room temperature, it was immersed in deionized water. Observing the water stability of the fiber mat, it can be seen that the fiber has good water stability and can maintain the shape of the fiber mat in water. The fiber mat that has not been heat-treated will dissolve immediately after being immersed in water. Take a certain mass of cross-linked MWCNTs-reinforced PAA / PVA fiber mat soaked in Fe with a concentration of 0.18 mol / L as configured in Example 1. 3+ In the salt solution, the quality of the fiber mat and the Fe taken 3+ The volume ratio of the salt solution is configured to be 1 mg / mL. After soaking in iron salt solution for 3 hours, take it out, and wash it in deionized water 3 times for 3 minutes each time. The fiber felt changes from white to brown. Drop NaBH with a concentration of 0.94mol / L 4 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com