Method for preparing graphene oxide wrapped silicon nitride composite powder

A technology of composite powder and graphene, which is applied in the field of graphene toughened and reinforced ceramic composite materials, can solve the problems of difficult batch production, complicated process, high equipment requirements, etc., and achieve the advantages of convenient industrial production, simple operation and less time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Graphene oxide coated silicon nitride (Si 3 N 4 @GO) preparation method of composite powder, the steps are as follows:

[0044] (1) Weigh the raw material Si with an average particle size of 100nm 3 N 4 Add 200 mL of 15% hydrogen peroxide solution to 2 g of powder, stir magnetically, raise the temperature to 70° C., and react for 15 min. Cool to room temperature, centrifuge, wash with distilled water 2 to 3 times, place in a drying oven at 200°C for 6 hours at high temperature, and obtain surface oxidized Si 3 N 4 Powder.

[0045] (2) Prepare 3-aminopropyltrimethoxysilane (KH540) silane coupling agent solution: the amount of silane coupling agent is 0.05g, dropwise into 50mL absolute ethanol:distilled water=1:1 volume ratio solution, Ultrasonic hydrolysis for 30min for later use.

[0046] (3) get the surface oxidized Si prepared by step (1) 3 N 4 2g of powder, placed in 200mL of absolute ethanol: distilled water = 1:1 volume ratio solution and ultrasonically st...

Embodiment 2

[0051] Graphene oxide coated silicon nitride (Si 3 N 4 @GO) preparation method of composite powder, the steps are as follows:

[0052] (1) Weigh the raw material Si with an average particle size of 200nm 3 N 4 Add 200 mL of 20% hydrogen peroxide solution to 2 g of powder, stir magnetically, raise the temperature to 80° C., and react for 20 min. Cool to room temperature, centrifuge, wash with distilled water 2 to 3 times, place in a drying oven at 220°C for 8 hours at high temperature, and obtain surface oxidized Si 3 N 4 Powder.

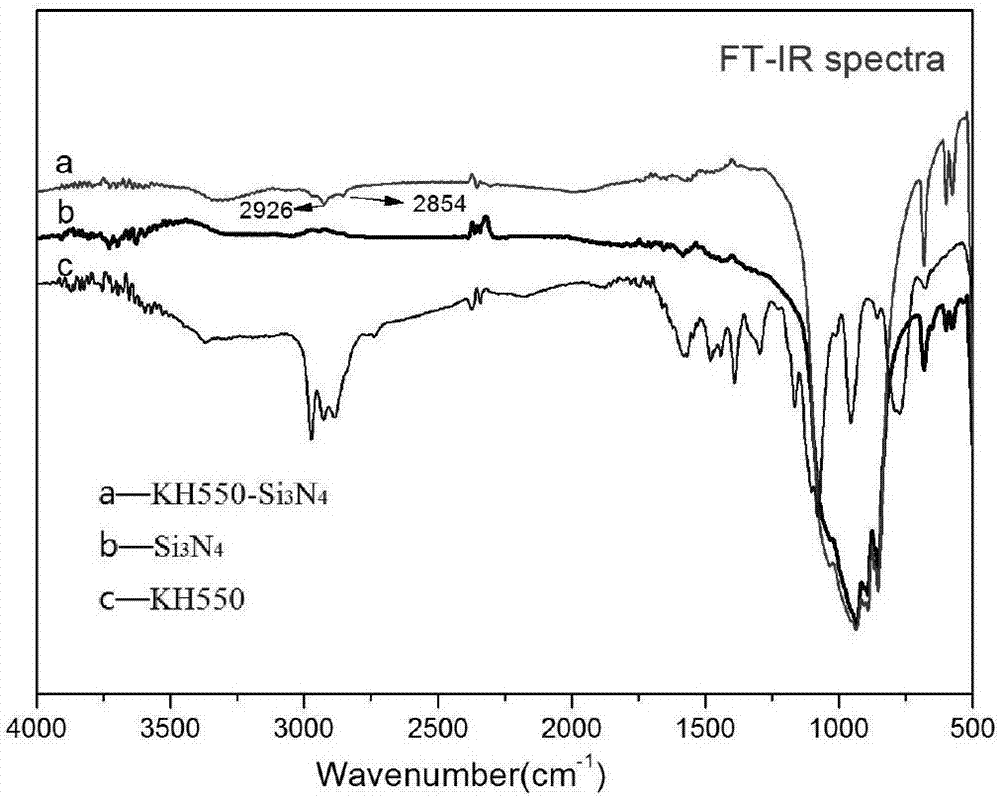

[0053] (2) Prepare 3-aminopropyltriethoxysilane (KH-550) silane coupling agent solution, the amount of silane coupling agent is 0.1g, drop into 80mL absolute ethanol:distilled water=1:1 volume ratio solution, ultrasonically hydrolyzed for 40 min for later use.

[0054] (3) get the surface oxidized Si prepared by step (1) 3 N 4 2g of powder, placed in 200mL of absolute ethanol: distilled water = 1:1 volume ratio of the solution ultrasonically s...

Embodiment 3

[0059] Graphene oxide coated silicon nitride (Si 3 N 4 @GO) preparation method of composite powder, the steps are as follows:

[0060] (1) Weigh the raw material Si with an average particle size of 200nm 3 N 4 Add 200mL of 30% hydrogen peroxide solution to 2g of powder, stir magnetically, raise the temperature to 90°C, and react for 30min. Cool to room temperature, centrifuge, wash with distilled water 2 to 3 times, and place in a drying oven at 250°C for 10 hours to obtain surface oxidized Si 3 N 4 Powder.

[0061] (2) Prepare N-2 (aminoethyl) 3-aminopropyltriethoxysilane (KH910) silane coupling agent solution, the amount of silane coupling agent is 0.2g, drop into 100mL absolute ethanol: distilled water = In a solution with a volume ratio of 1:1, ultrasonically hydrolyze for 50 minutes for later use.

[0062] (3) get the surface oxidized Si prepared by step (1) 3 N 4 Powder 2g, placed in 300mL of absolute ethanol: distilled water = 1:1 volume ratio of the solution u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com