Pressure vessel integrated end socket for nuclear power, end socket plate blank of pressure vessel integrated end socket and forging method of pressure vessel integrated end socket

A technology for pressure vessels and heads, which is applied in the field of large structural parts for nuclear power equipment, can solve problems such as poor quality stability in stress areas, increased manufacturing costs, and complicated welding processes, and achieves improved longitudinal and transverse mechanical properties and improved operation. Enhanced safety and operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

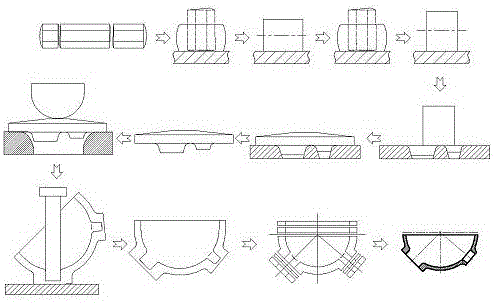

[0055] In this process step, an octagonal prism-shaped steel ingot is first selected, the material of the steel ingot is 508-3 steel, and the weight of the steel ingot is 38 tons. First, the steel ingot is heated in sections, and the steel ingot is put into the heating furnace for heating to improve the plasticity of the metal, make it easy to flow and form and obtain a good forged structure, and choose the appropriate heating temperature range to make the metal blank Forming in a state of good plasticity; since the steel ingot is a large block, in order to reduce the temperature stress caused by the temperature difference of the section, the steel ingot should be heated evenly. The present invention adopts the standard of segmental heating and temperature rise. First, the steel ingot is sent to the heating furnace to be heated to 580°C, and kept at this temperature for 3 hours. The second heating section is heated to 830°C at a heating rate of 55°C / h. Keep warm for 4 hours, a...

Embodiment 2

[0068] In this embodiment, the octagonal prism-shaped steel ingot is still selected, and the material of the steel ingot is still 508-3 steel, and the weight of the steel ingot is 50 tons. First, the steel ingot is heated in sections. First, the steel ingot is sent to the heating furnace to be heated to 620°C, and kept at this temperature for 3 hours. The second heating section is heated to 870°C at a heating rate of 60°C / h. At this temperature Keep warm for 4 hours, and the third heating section heats up to 1170°C at a heating rate of 82°C / h. When the temperature of the steel ingot is higher than 800°C, the steel ingot already has a certain degree of plasticity, so this heating section adopts a relatively fast heating rate. , the fourth section is also heated to 1240°C at a heating rate of 78°C / h, and the steel ingot is kept at this temperature for 1 hour to form a forged heating blank.

[0069] Cutting of forgings: Use the chopping knife as the upper anvil to cut the head an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com