A two-dimensional convective thermal stealth cloak design method based on active control heat source

A design method and convective heat technology, applied in the fields of fluid mechanics and heat transfer, can solve the problems of thermal invisibility cloaks and difficult functions in the field of thermal convection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

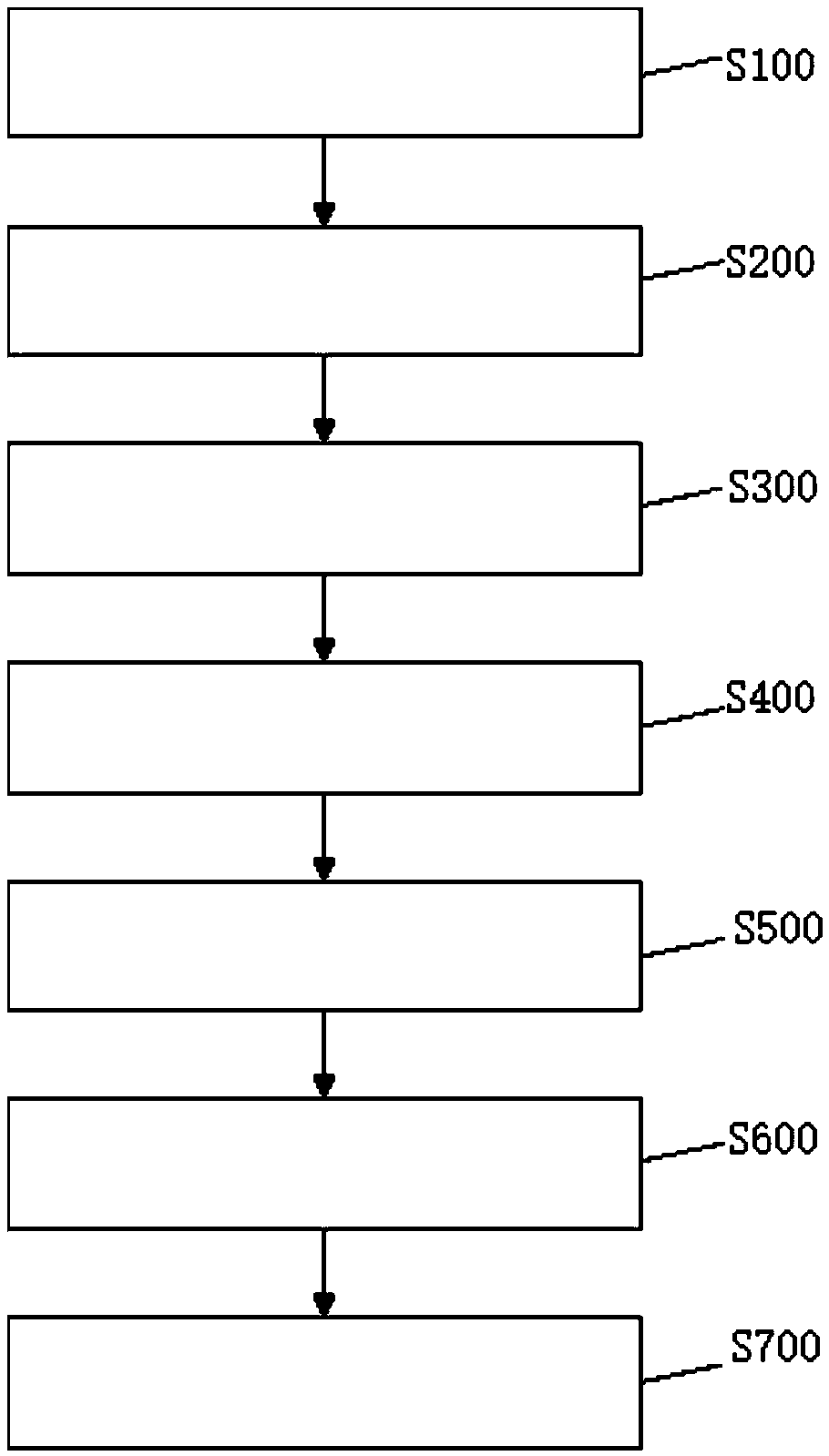

[0093] combine first Figure 1-Figure 5 , the technical solution of the embodiment of the present invention is described as follows:

[0094] Such as figure 1 As shown, the embodiment of the present invention provides a two-dimensional convective thermal cloak design method based on active regulation and control of heat sources, including:

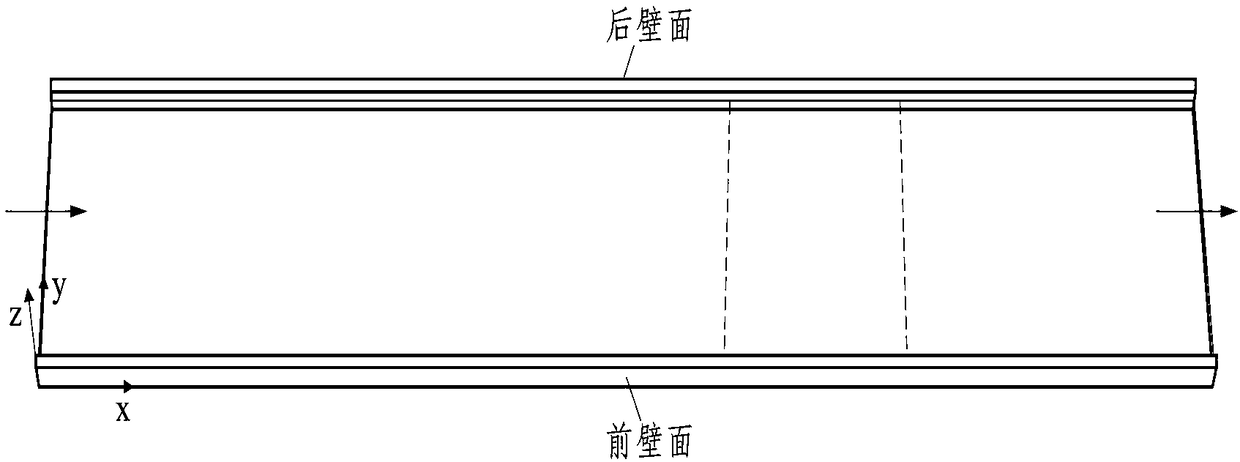

[0095] Step S100: Establish a three-dimensional coordinate system x-y-z, the fluid flows in from the left side of the flow channel, and flows out from the right side in the direction of the arrow, such as figure 2 shown. Set the inlet flow rate as u, set the front and rear walls of the flow channel as constant wall temperature, and set the wall temperature as T 1 and T 2 .

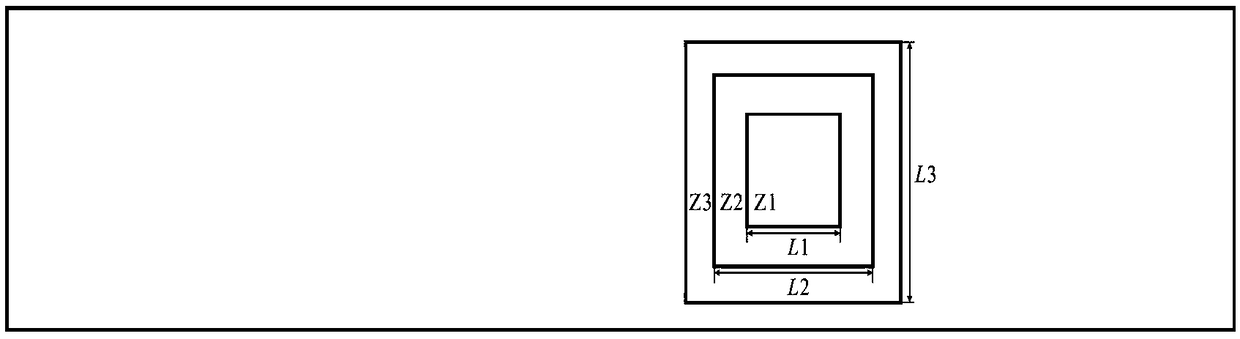

[0096] In this embodiment, the heat source is arranged on the plane of the runner z=0, and the distribution of the heat source is divided into regions, such as image 3 As shown, Z2 and Z3 are heat source areas, and Z1 and other areas are not treated. Set the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com