Induction heating device and method for metal plate

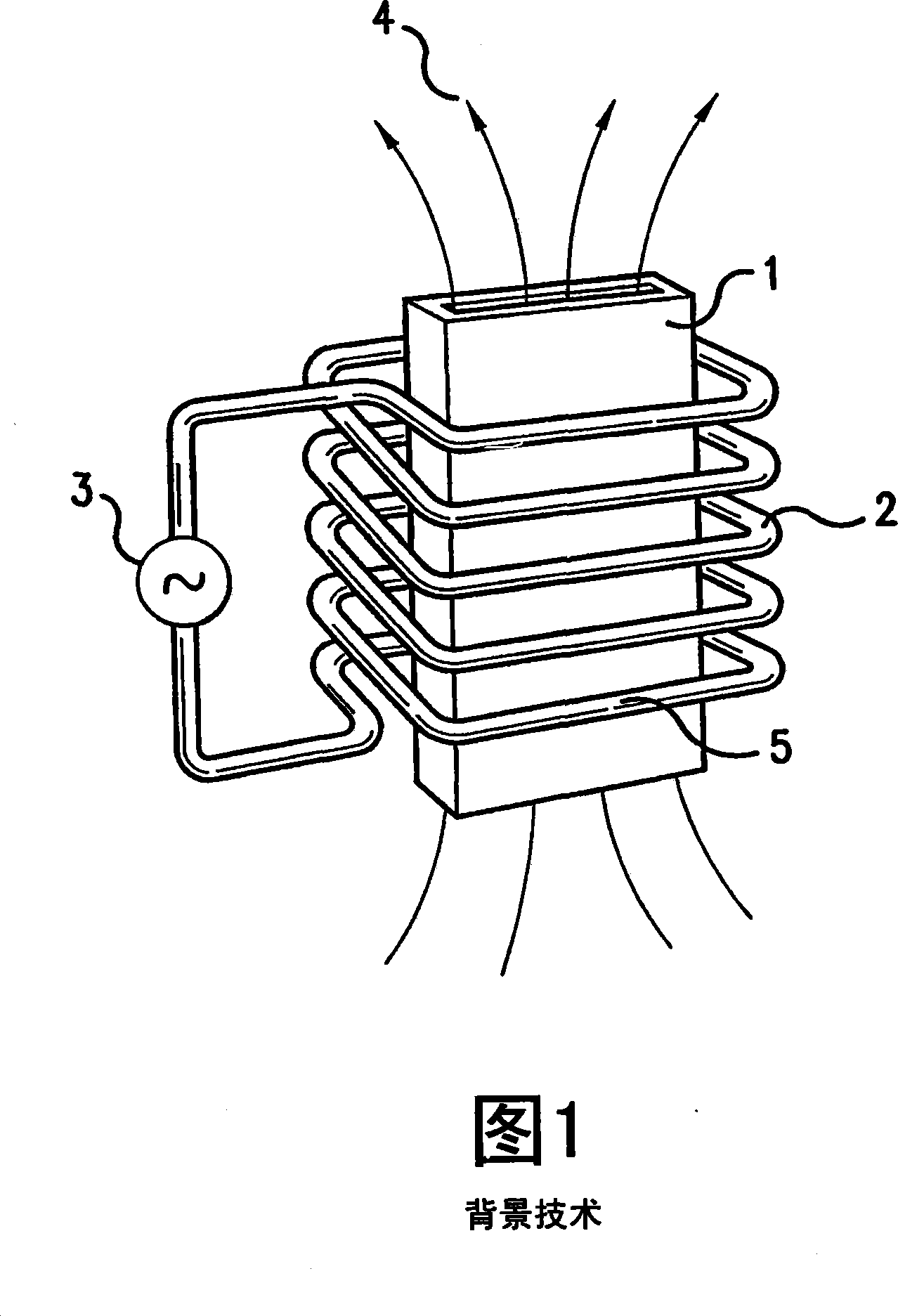

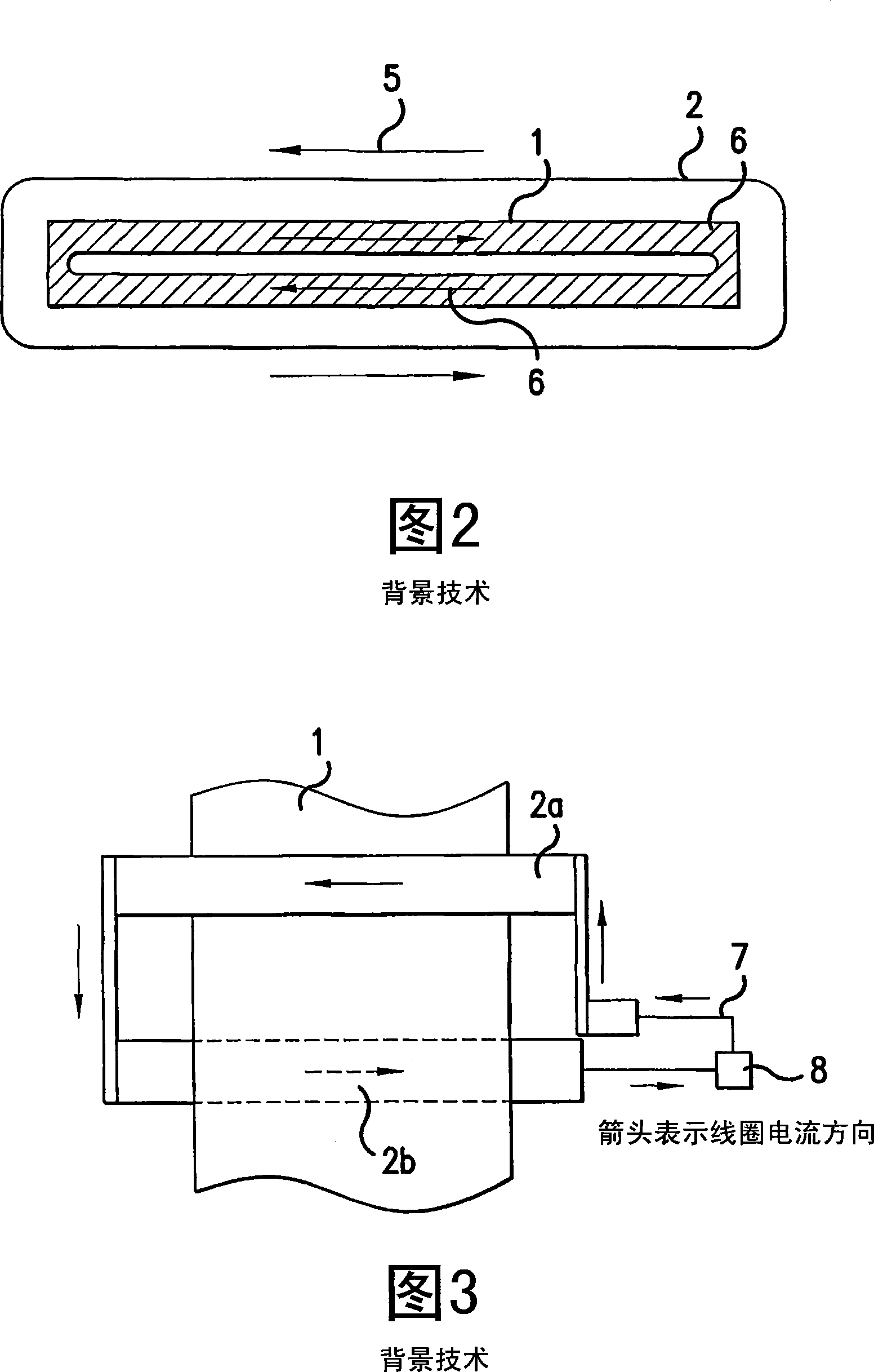

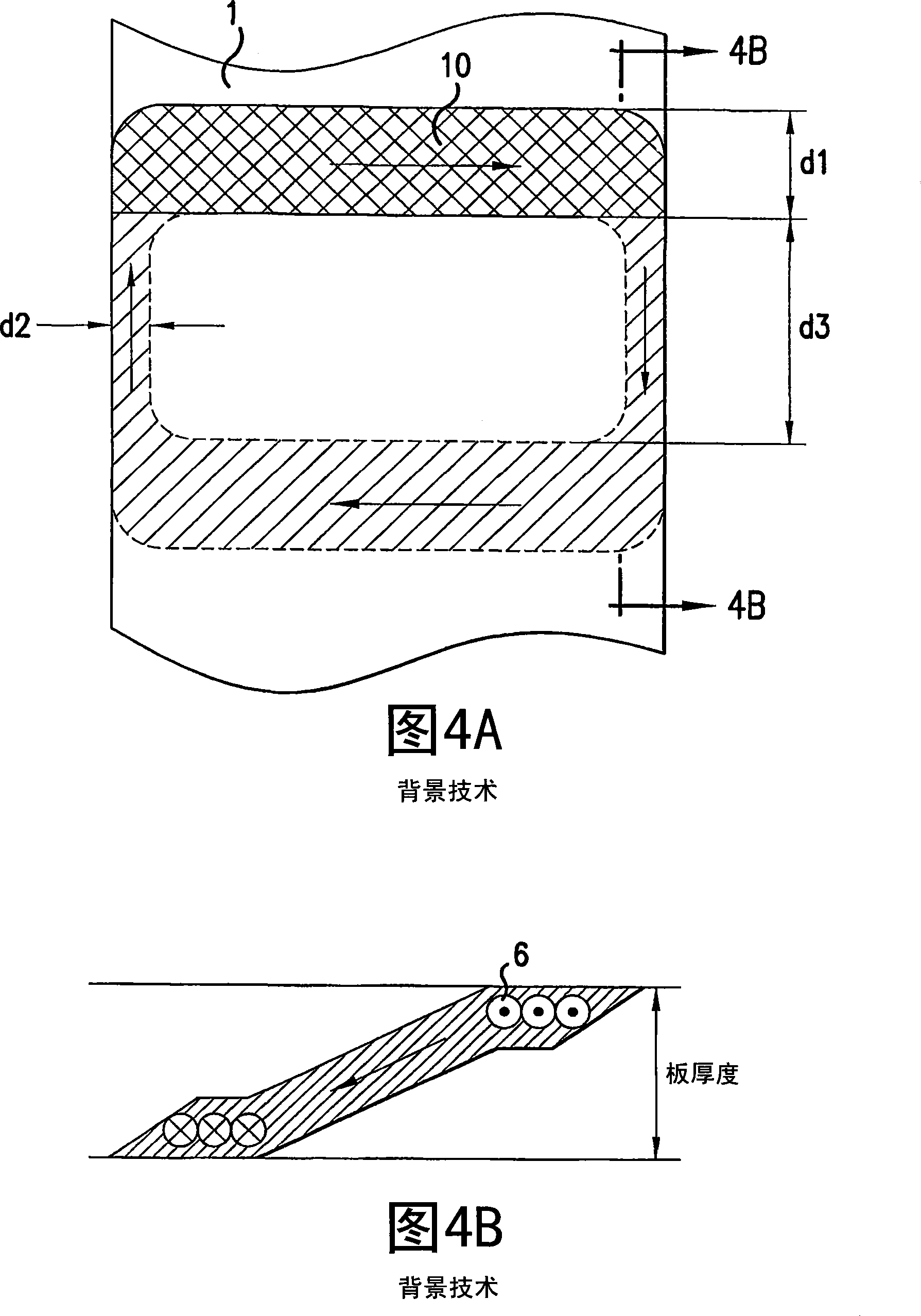

A technology of induction heating equipment and metal plates, applied in induction heating, electric heating devices, coil devices, etc., can solve problems such as uneven temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The invention will now be described with reference to the accompanying drawings. All figures show a single turn induction coil wrapped around a metal plate. However, the number of turns of the induction coil is not limited to a specific number in the present invention.

[0064] Fig. 6 is a schematic plan view of an example of the induction heating device of the present invention. FIG. 7 is a schematic cross-sectional view taken along line 7-7 of FIG. 6 . In the present invention, the induction coil located above the metal plate and another induction coil located below the metal plate are arranged to be spaced apart from each other along the longitudinal direction of the metal plate at least at one position in the transverse direction of the metal plate. The distance between the upper induction coil and the lower induction coil spaced apart from each other in the longitudinal direction is defined as the distance between the two projected images of the upper induction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com