Three-dimensional braided carbon fiber reinforced metal-matrix composite and preparation method thereof

A composite material and three-dimensional weaving technology, which is applied in the field of carbon fiber reinforcement, can solve the problems of limiting the application and development of one-dimensional long fiber reinforced metal matrix composite materials, the difficulty of uniform arrangement and distribution of fiber filaments, and the insufficient transplantation of fiber high performance. Achieve the effect of facilitating large-scale mechanized production, high interlaminar shear strength and tensile strength, and broadening the type and application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

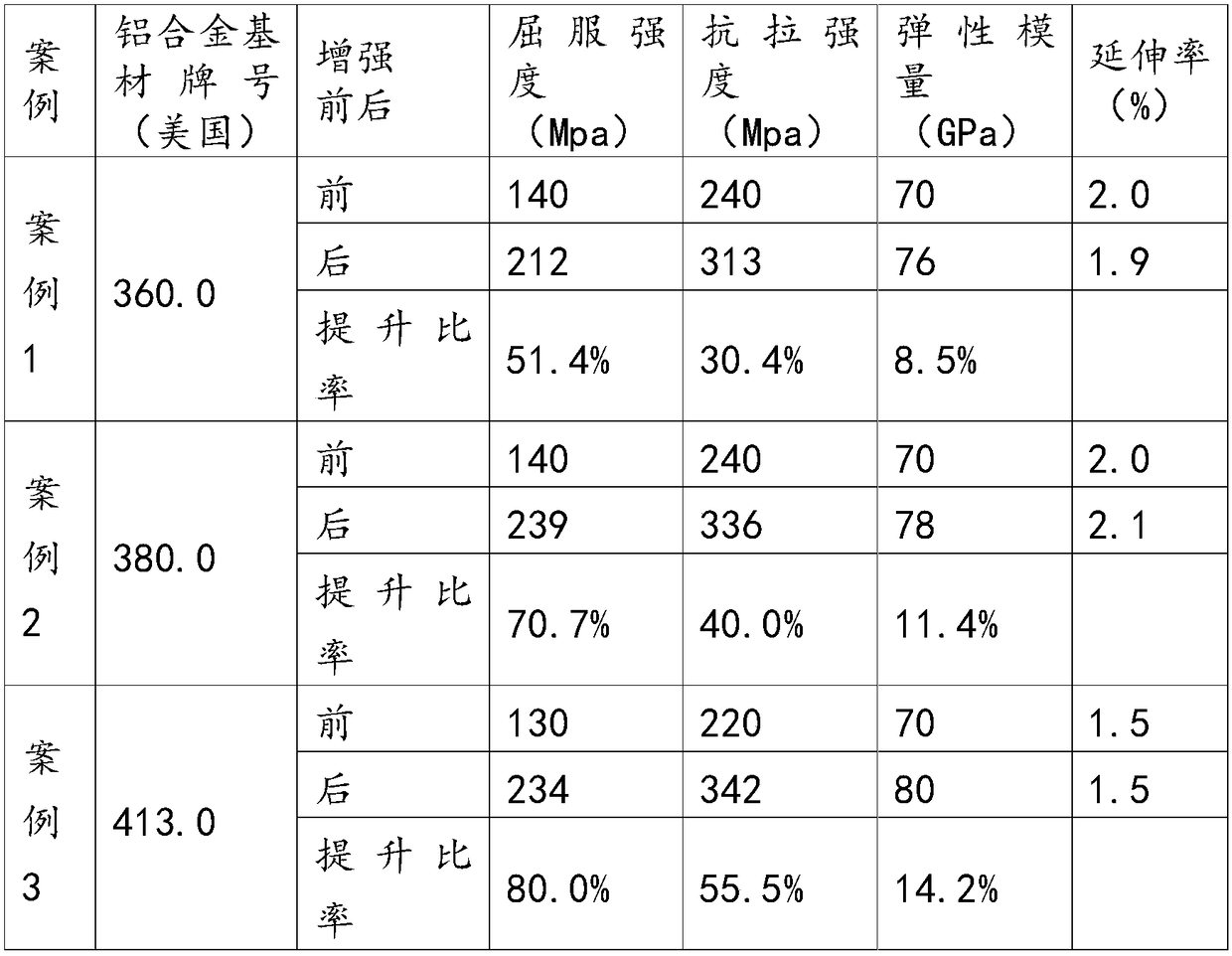

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0027] A three-dimensional braided carbon fiber reinforced metal matrix composite material and a preparation method thereof, comprising the following steps:

[0028] Step 1. Since carbon fibers are not monofilaments but fiber bundles, it is necessary to ensure that each monofilament is wetted, and at the same time ensure that the monofilaments of the fiber bundles in the composite material are properly dispersed, so carbon fibers need to be pretreated;

[0029] The concrete steps of described step 1 are:

[0030] Step 1.1, removing glue, roughening, sensitizing and activating the carbon fiber;

[0031] In step 1.2, the carbon fiber is subjected to vapor phase deposition coating SiC treatment, and dried after coating SiC.

[0032] Step 2. Since carbon fiber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com