Patents

Literature

75results about How to "Higher specific stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

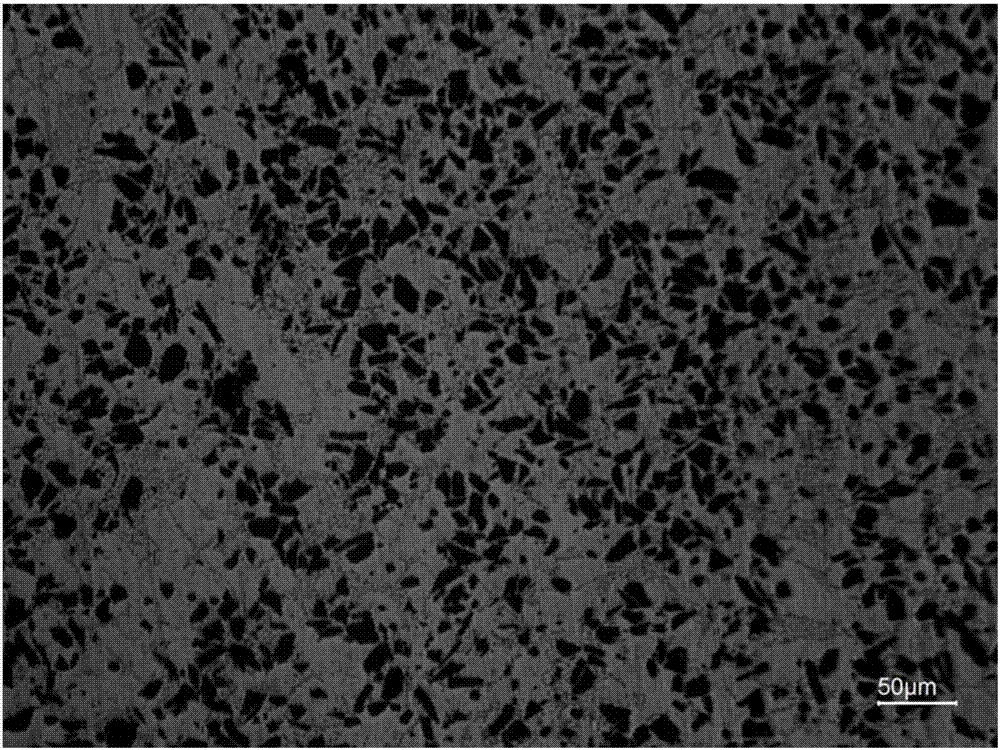

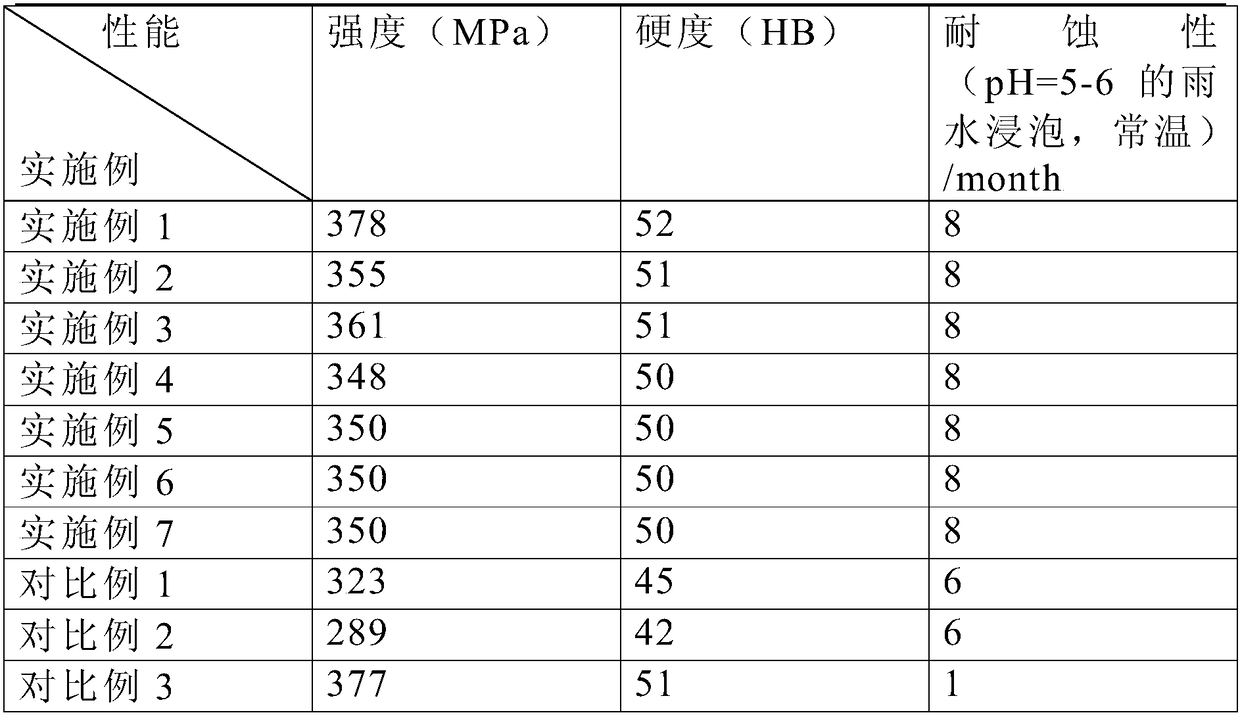

Preparation method for SiC particle reinforced aluminum-based composite material

InactiveCN103484707AGood physical propertiesImprove mechanical propertiesThermal insulationMetal mold

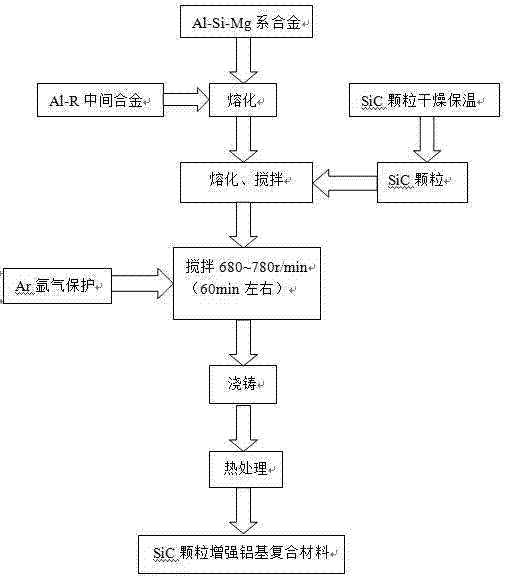

The invention provides a preparation method for SiC particle reinforced aluminum-based composite material. The preparation method comprises the steps as follows: step 1, the Al-Si-Mg alloy is placed into a homemade dry pot resistance furnace, after the Al-Si-Mg alloy is completely melted, 1-17 parts of intermediate alloy Al-R by weight, which is prepared in advance, is added into the melt, wherein the intermediate alloy is prepared in advance through a surface modification technology; step 2, the melt is stirred to enable rare-earth elements to be uniformly distributed into the melt; step 3, SiC is added into the melt; step 4, the melt is poured into a metal mould for formation; step 5, quenching is performed in water with the temperature of 50-60 DEG C; step 6, quenching is performed in water with the temperature of 70-80 DEG C; step 7, air cooling is performed after aging thermal insulation is performed for 6.5-7.5 h at the temperature of 165-175 DEG C. The thermal shock performance of the aluminum-based composite material can be greatly enhanced, the dimensional stability of the material is maintained when the material is used in temperature varying places, the service life of the material is prolonged, and the material has a broad market prospect when being applied to parts requiring weight reduction and excellent abrasion resistance.

Owner:TONGJI UNIV

High-strength and high-toughness blind hole foam aluminum and preparation method thereof

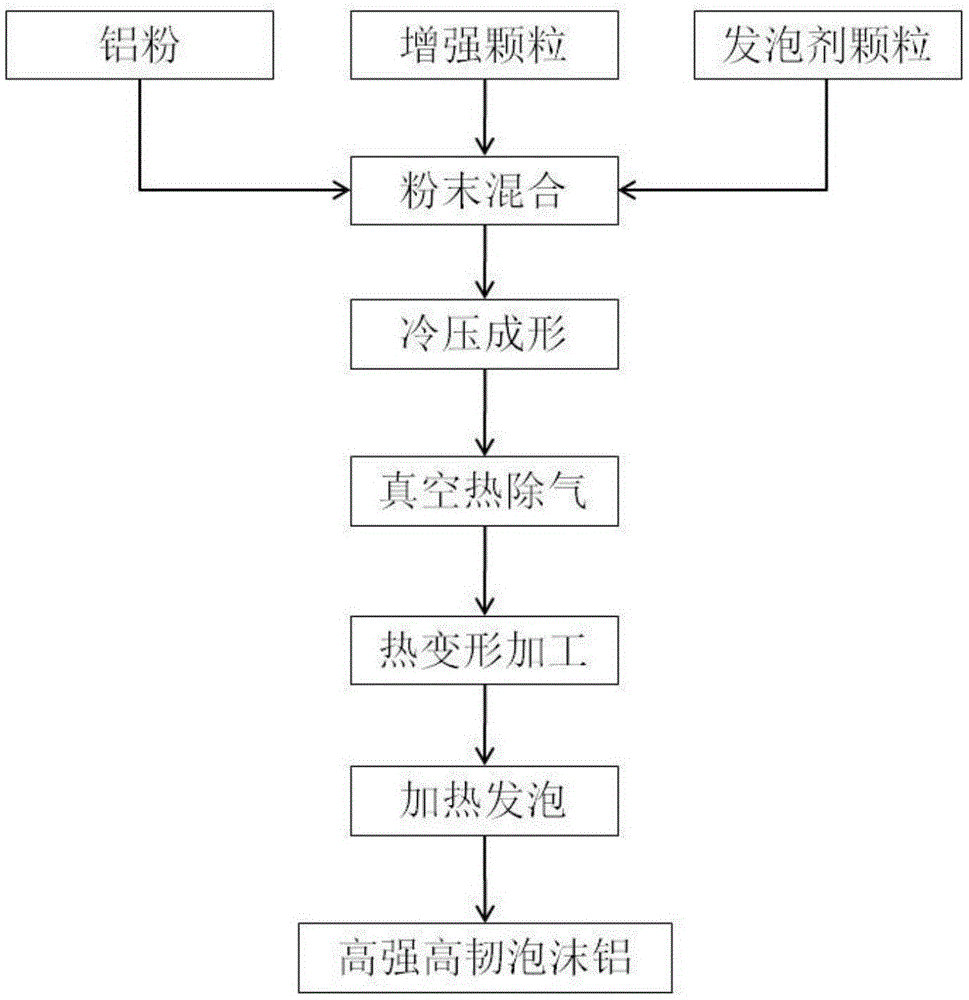

The invention relates to high-strength and high-toughness foam aluminum and a preparation method thereof. The density of the foam aluminum is 0.4-1 g / cm3; the average size of foam holes is 2-5 mm; the hole walls consist of aluminum basal bodies and reinforcing particles dispersed therein; and the reinforcing particles and the aluminum basal bodies form high-strength-bonded metallurgy interfaces. Firstly, aluminum basal body powder, the reinforcing particles and foaming agent particles are uniformly mixed and coldly pressed to prepare a rough blank; and the rough blank is thermally deformed to prepare a foamable prefabricated body after vacuum heat degassing, and is heated and foamed to prepare the foam aluminum. The product has the characteristics of high strength, high toughness and high energy absorption, and can be applied to light support structural parts or high-damping vibration reduction and energy absorption parts in the fields of vehicles, rail traffic and spaceflight war industry; and the preparation method is flexible, strong in designability, nearly suitable for preparation of all alloy system foam aluminum, can randomly add matched reinforcing particles according to the alloy performance, and can be used for customizing the foam aluminum with different mechanical performances to satisfy the demands in all fields.

Owner:有研金属复材技术有限公司

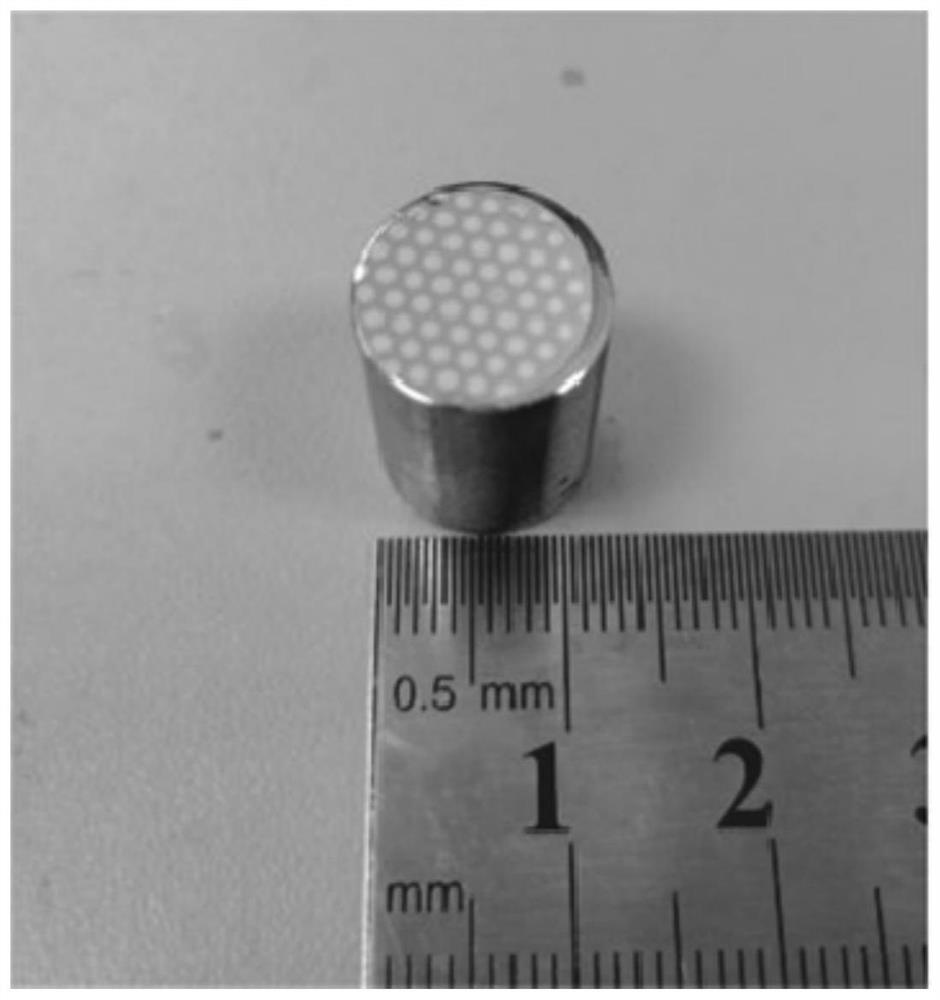

Nanometer silicon carbide particle reinforced aluminum matrix composite and preparation method thereof

The invention relates to the technical field of particle reinforced aluminum matrix composites and discloses a nanometer silicon carbide particle reinforced aluminum matrix composite and a preparation method thereof. The composite is prepared by uniformly distributing nanometer silicon carbide particles with the volume percentage of 6-16% into aluminum alloy with the volume percentage of 84-94%. The preparation method comprises the steps of firstly, proportioning, ball milling, premolding and carrying out hot pressing molding to prepare 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite; next, carrying out vacuum concentration on the 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite to evaporate parts of aluminum alloy matrixes; and finally, carrying out solid solution and aging treatment to prepare the nanometer silicon carbide particle reinforced aluminum matrix composite disclosed by the invention. Experiment data proves that the reinforced aluminum matrix composite with high nanometer silicon carbide particle content, prepared by using the preparation method not only has the functional properties of high heat conductivity, electrical conductivity, specific modulus, wear resistance and the like due to the high nanometer silicon carbide particle content, but also has strength as well as plasticity and toughness.

Owner:HENAN UNIV OF SCI & TECH

Double-steel pipe composite member filled with foamed aluminum

InactiveCN104772933AImprove energy dissipation and vibration damping performanceSimple structureLoad-supporting elementsMetal layered productsAbsorbed energyUltimate tensile strength

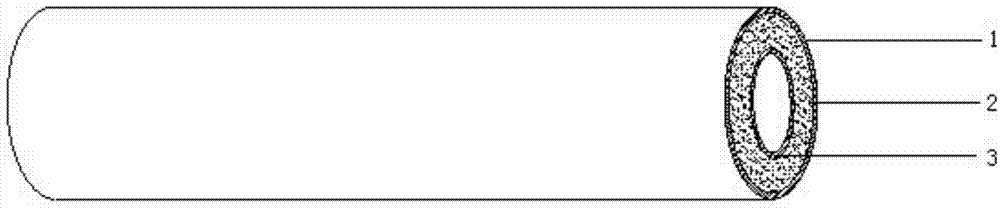

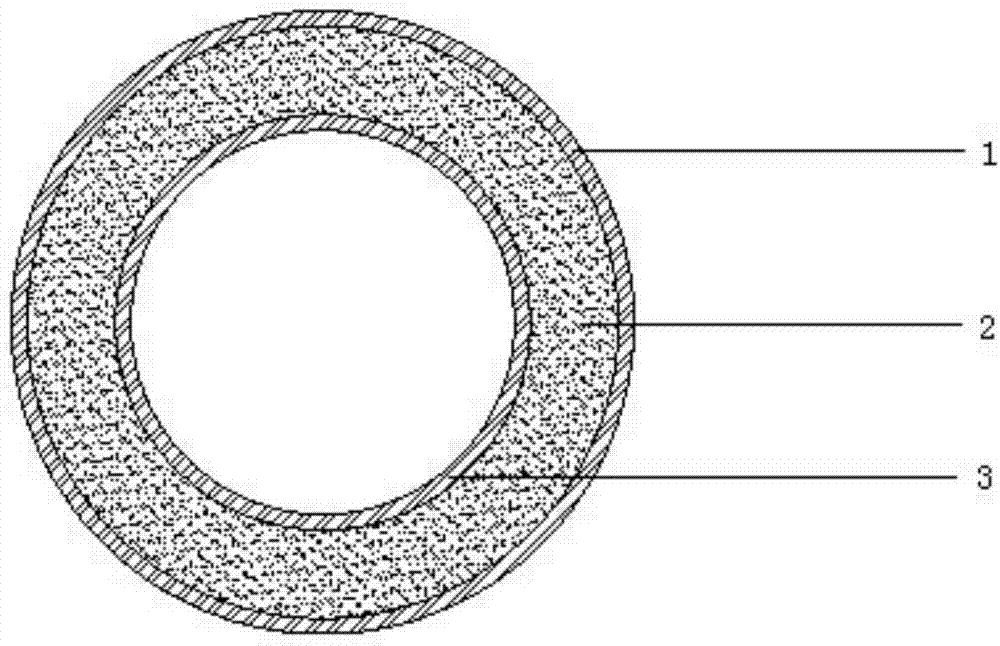

The invention discloses a double-steel pipe composite member filled with foamed aluminum. The composite member is of a cylindrical structure and comprises, from exterior layer to interior layer, an outer steel pipe (1), foamed aluminum (2) and an inner steel pipe (3), wherein the place between the outer steel pipe (1) and the inner steel pipe (3) is filled with the foamed aluminum (2), the center of the inner steel pipe (3) is filled with nothing, the wall thickness of the outer steel pipe (1) is no less than the wall thickness of the inner steel pipe (3), and the foamed aluminum (2) is of an open-pore or closed-pore structure which can be filled with a high-performance viscoelastic material. The outer and inner steel pipes provide peripheral constraint to the foamed aluminum and improve the strength of the foamed aluminum, and addition of the foamed aluminum compensates for the defects of low damping and poor energy-absorbing performance of a steel pipe member; the outer and inner steel pipes mainly bear axial acting force; and foamed aluminum between the outer and inner steel pipes is mainly used for absorbing energy and protect the structure during an earthquake, a strong breeze and violent vibration. The double-steel pipe composite member filled with the foamed aluminum is applicable to buildings and structures in a high-intensity zone, a high-performance structure and a high-rise building (such as a building of a thousand-meters scale).

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

Preparing method for SiC particle enhanced aluminum-base composite material

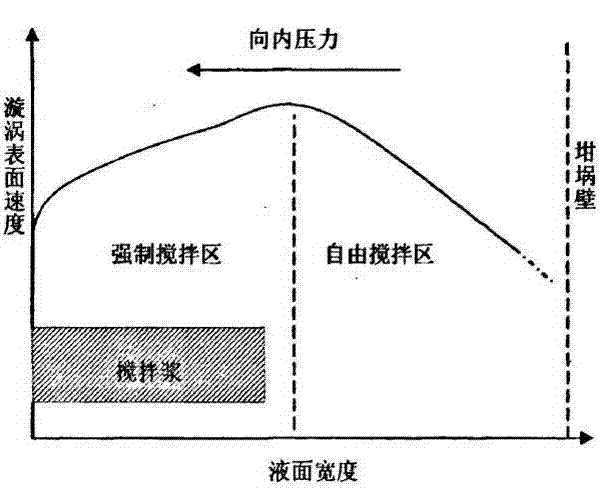

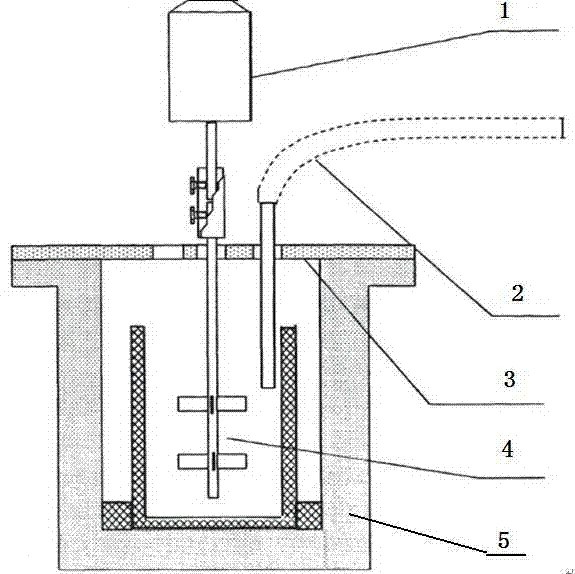

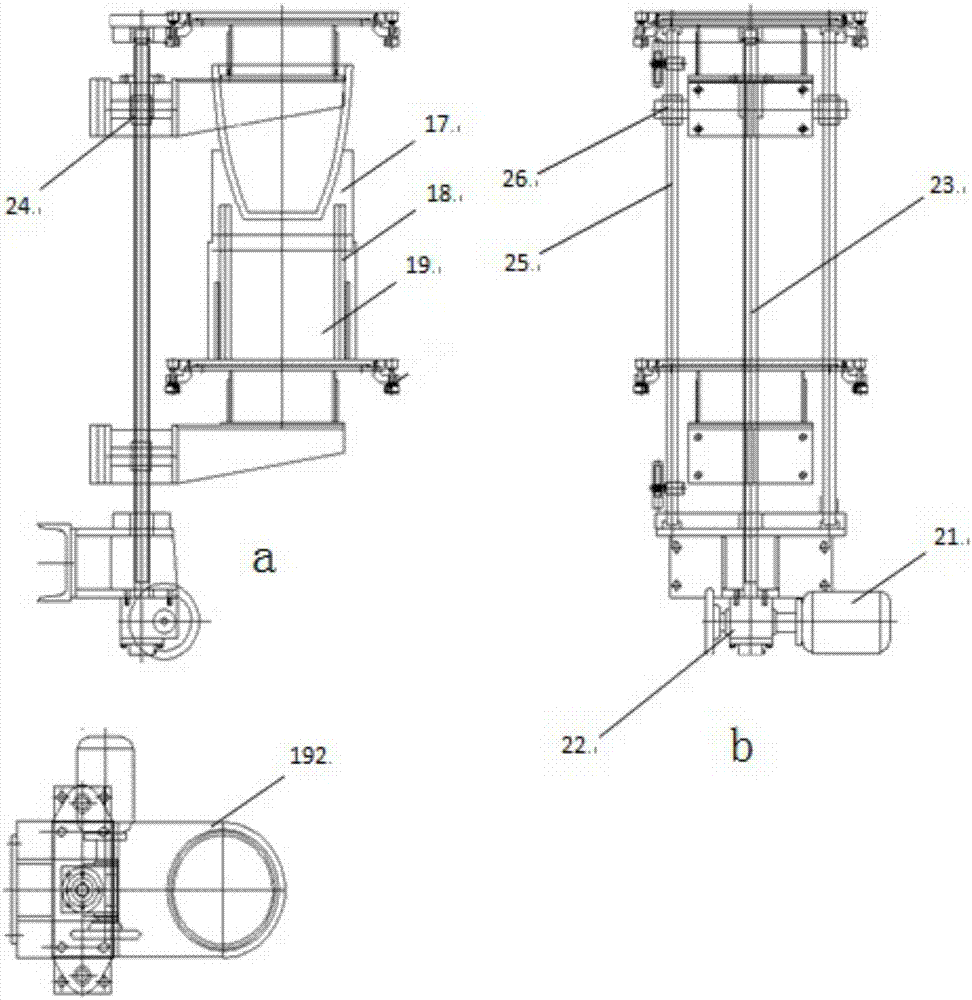

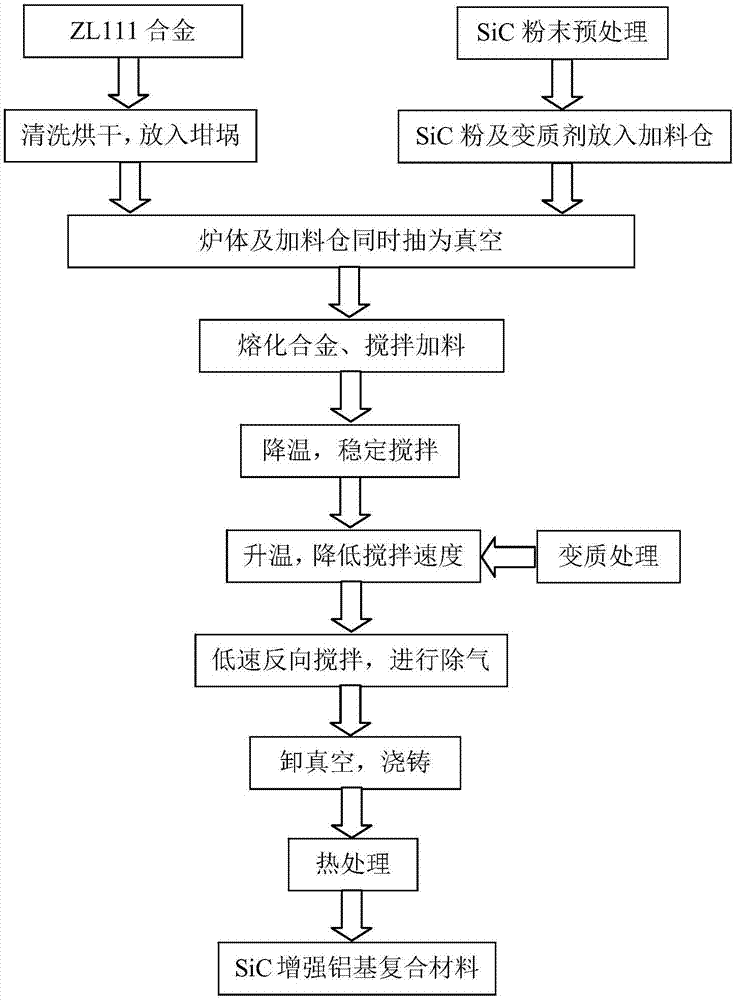

The invention aims at disclosing a specially-made vacuum smelting furnace and a preparing technology for a SiC particle enhanced aluminum-base composite material. A certain component proportion and a special smelting casting technology are adopted. The vacuum smelting furnace is adopted in the technology, overall closing and vacuum-state charging can be achieved, the inner temperature of melt can be measured in real time, the particles accurately fall into a melt vortex center with a certain speed and are evenly distributed in the melt under powerful stirring, the functions of deoxygenation and degassing can be effectively achieved on the composite material melt, and therefore the composite material uniform in component, low in porosity, high in mechanical performance and excellent in heat-conducting property can be produced through the technology. The crucible lifting type vacuum smelting furnace comprises a crucible composite device and lifting platform system, a stirring device and lifting platform system, a charging device, a vacuum system, a handheld lifting thermocouple, a sealing system and an electric control system.

Owner:SUZHOU WUCHUANG MATERIAL TECH DEV CO LTD

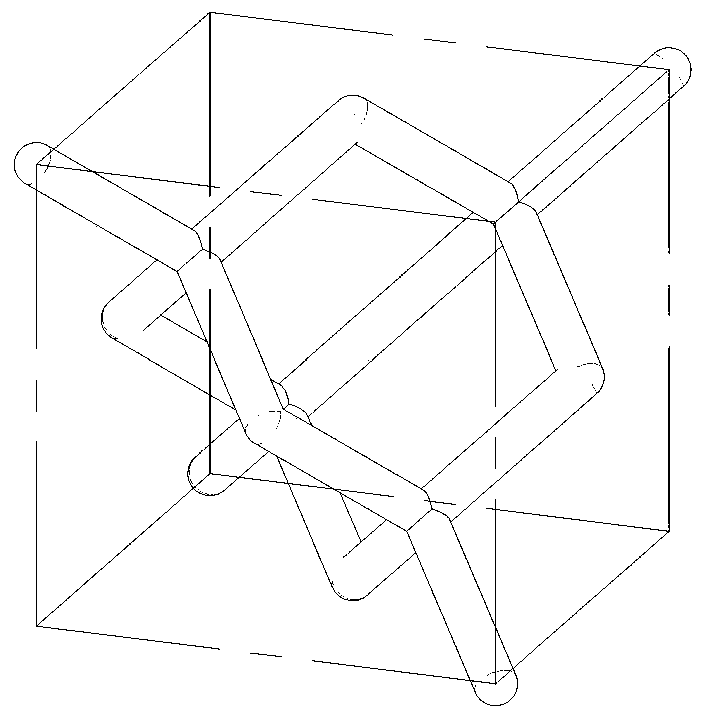

Self-driving repetitive locking releasing mechanism with honeycomb structure and four-dimensional printing preparation method and locking releasing method thereof

ActiveCN108945522AReduce shockSimple structureCollapsable antennas meansCosmonautic vehiclesSelf drivenSelf driving

The invention relates to a self-driving repetitive locking releasing mechanism with a honeycomb structure and a four-dimensional printing preparation method and a locking releasing method thereof to solve the problem of surrounding device damaging caused by huge impact and explosive debris or gas generated in exploding of mechanism releasing of traditional explosive bolts and the problem of high weight of the explosive bolts. A locking releasing mechanism is composed of a locking piece and a connecting piece. The locking piece is composed of a locking piece base and a deformation rod. The connecting piece is composed of a connecting rod and a connecting rod fixing block. Material of the main body of the deformation rod is a shape memory polymer. During application, shaping is firstly conducted, and the deformation rod after shaping is arranged at the connecting rod in a sleeving mode to achieve locking, and then the deformation deformation rod is driven to recover the shape to completereleasing. The locking releasing mechanism completes releasing during the shape recovery process, excessive impact force does not generated instantly; and the deformation rod reduces occupied space in the satellite launching process. The self-driving repetitive locking releasing mechanism is suitable for locking releasing of an antenna or a solar wing.

Owner:HARBIN INST OF TECH

Aluminum base carbon fiber graphite composite material and preparation method

The invention relates to an aluminum base composite material, in particular to an aluminum base carbon fiber graphite composite material and a preparation method. The method comprises the following steps of: firstly, adopting finely sorted, processed and checked graphite fluoride powder as raw materials for preparing spherical graphite particles through granulation and spheroidization; then, using a stainless steel plate as a cathode and pure aluminum as an anode, filling insert gas between the two electrodes, exerting voltage, soaking the spherical graphite particles by glucose amide containing 0.23 to 0.6 percent of boron, cleaning and baking the spherical graphite particles, placing the spherical graphite particles on a disc between the cathode and the anode, shaking the disc while exerting the voltage, and arranging latticed high-performance carbon fiber in a casting mold at the arrangement density determined according to the intensity requirement of the materials; filling the spherical graphite particles with the diameter between 1 and 5mm in the casting mold, finally, injecting aluminum liquid, applying pressure at the upper part of the mold so that the aluminum liquid can be filled between the spherical graphite particles, and obtaining products after cooling. The composite material is simple to prepare, and has the advantages of high product intensity, light weight, wear resistance, low raw material consumption and high production efficiency.

Owner:蔡乐勤

Node enhanced lattice structure

InactiveCN110043594AImprove mechanical propertiesImprove reliabilityElastic dampersShock absorbersMechanical propertyComputer science

The invention discloses a node enhanced lattice structure. The node enhanced lattice structure comprises a plurality of periodically repeatedly-arranged lattice single cells; the lattice single cellscomprise a plurality of spherical nodes which are distributed in a spatial manner and a rod body connected between the spherical nodes. According to the node enhanced lattice structure, spherical nodes are applied to an existing lattice structure, different rods are connected through rounded corners, so that smooth transition of the rod structure is realized, and the mechanical property of the lattice structure is improved.

Owner:CHONGQING UNIV

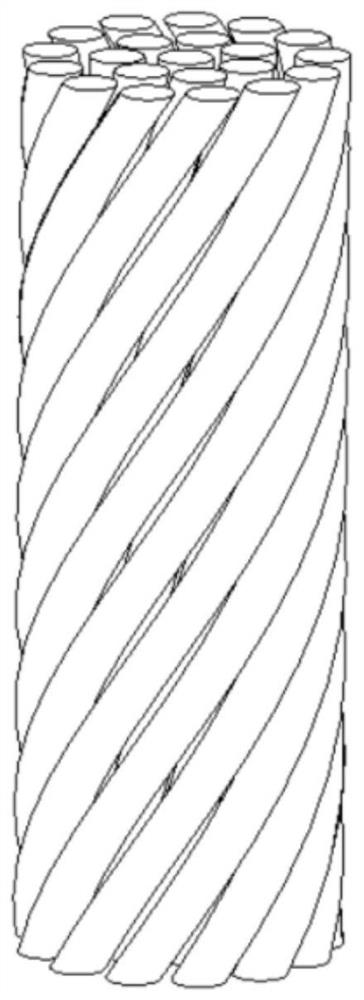

Three-dimensional braided carbon fiber reinforced metal-matrix composite and preparation method thereof

The invention relates to a three-dimensional braided carbon fiber reinforced metal-matrix composite and a preparation method of the three-dimensional braided carbon fiber reinforced metal-matrix composite. The preparation method comprises the following steps that firstly, pre-treatment is conducted on carbon fiber; secondly, carbon fiber bundles and fine metal wires are bound, so that metal wire-carbon fiber composite bodies are obtained, a three-dimensional framework reinforcing body is braided from the metal wire-carbon fiber composite bodies; thirdly, the braided three-dimensional fiber framework reinforcing body are soaked with silicon carbide particle dissolving slurry and potassium fluozirconate water solution; fourthly, the three-dimension fiber framework reinforcing body treated inthe third step is placed in matrix metal liquid and undergoes extrusion forming under ultrasonic vibration, and then the novel metal-matrix composite is obtained. According to the three-dimensional braided carbon fiber reinforced metal-matrix composite and the preparation method of the three-dimensional braided carbon fiber reinforced metal-matrix composite, a three-dimensional fiber framework isbraided from carbon fiber, net-shape manufacturing of the novel metal-matrix composite reinforced by the three-dimensional fiber framework reinforcing body and having excellent performance is achieved, the types and application range of the metal-matrix composite are expanded, and the three-dimensional braided carbon fiber reinforced metal-matrix composite certainly has broad application prospectin the aerospace field, the military project field and the civil field.

Owner:尚辰(浙江绍兴)复合材料科技有限公司

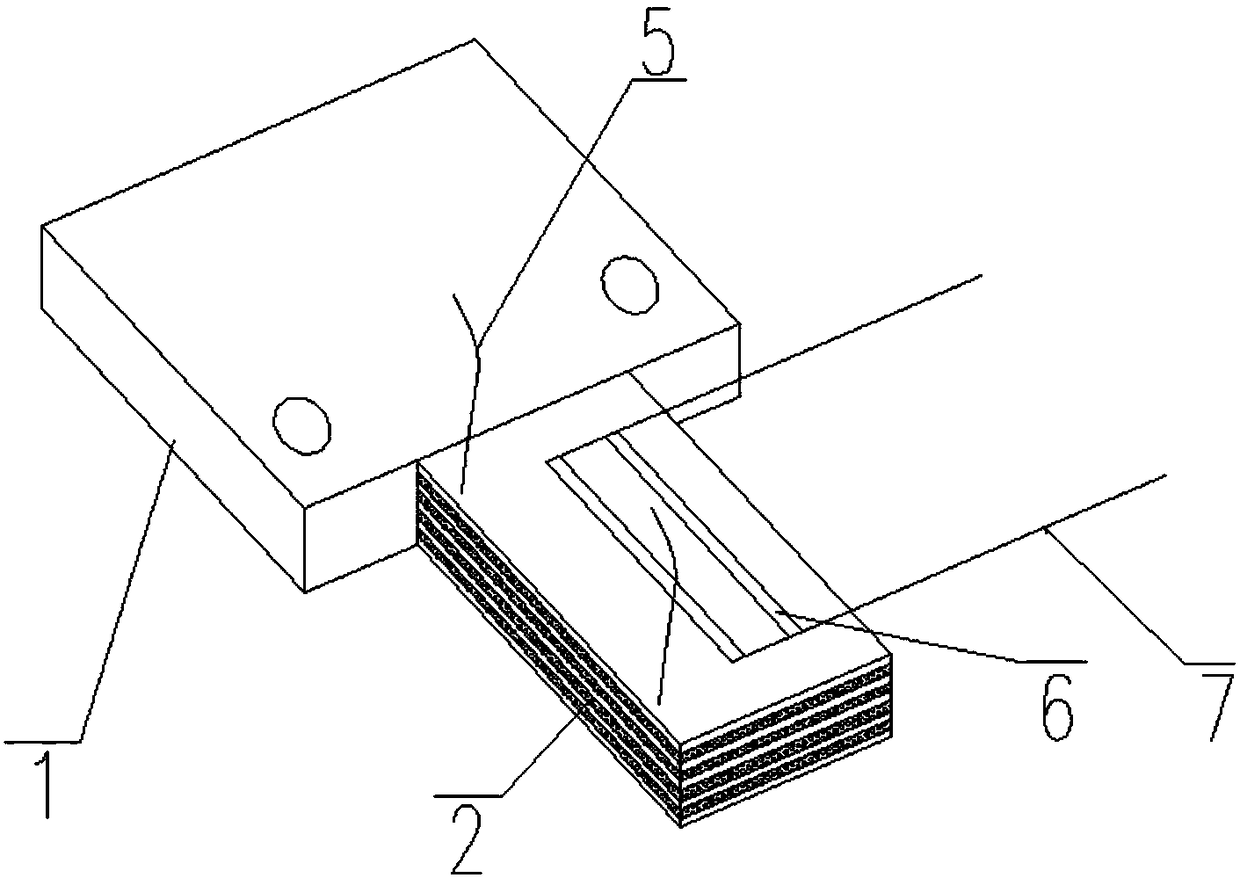

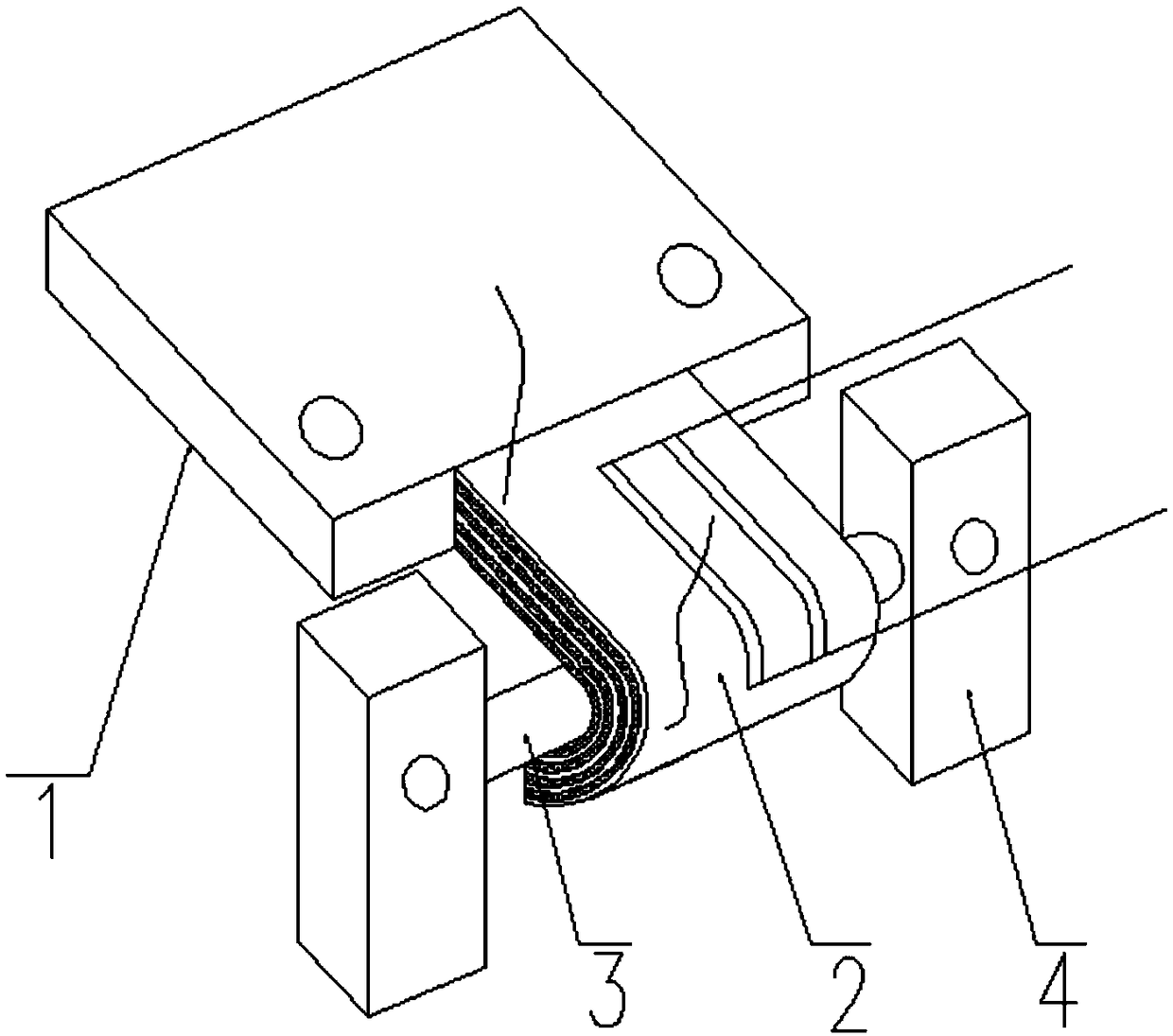

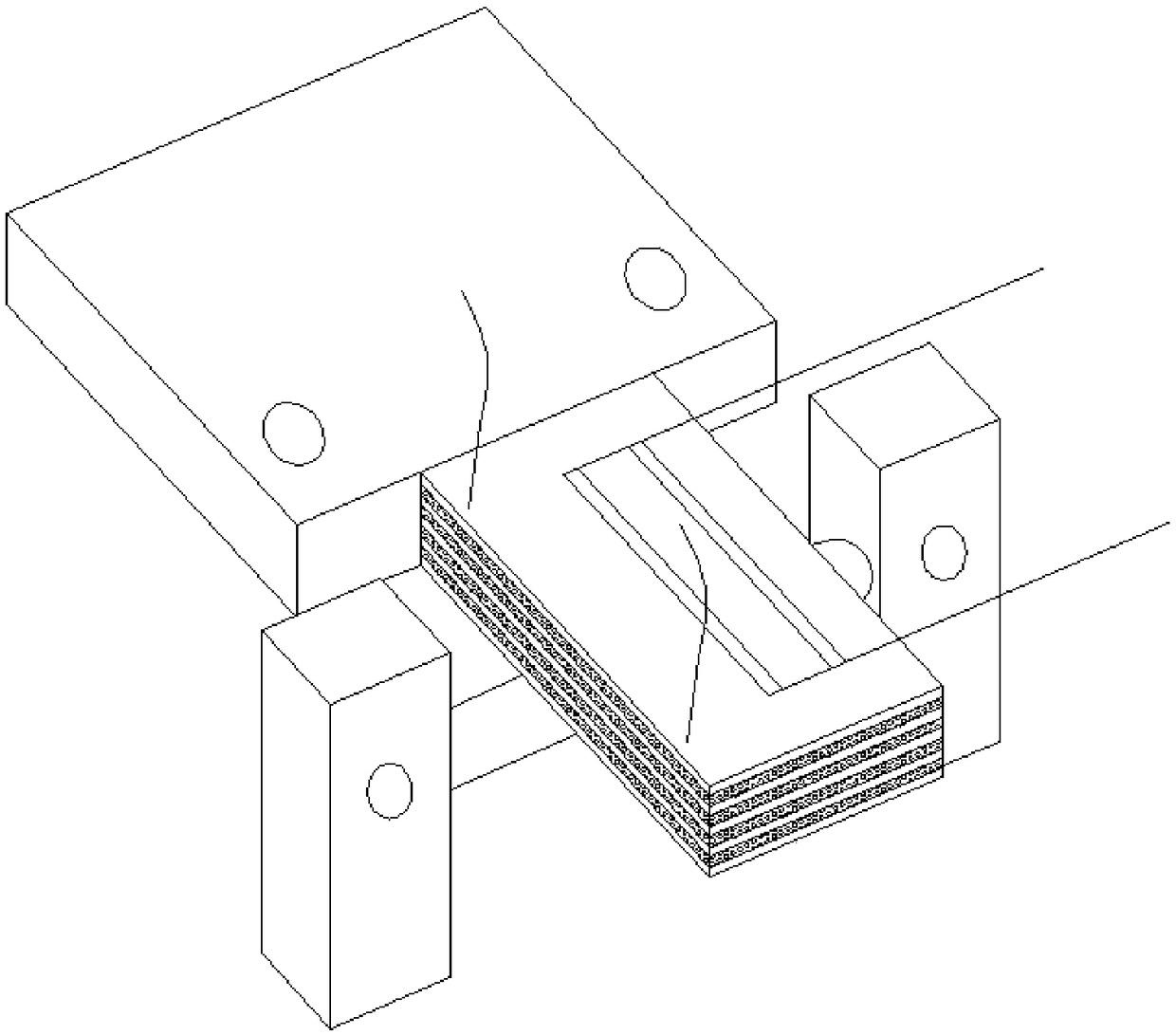

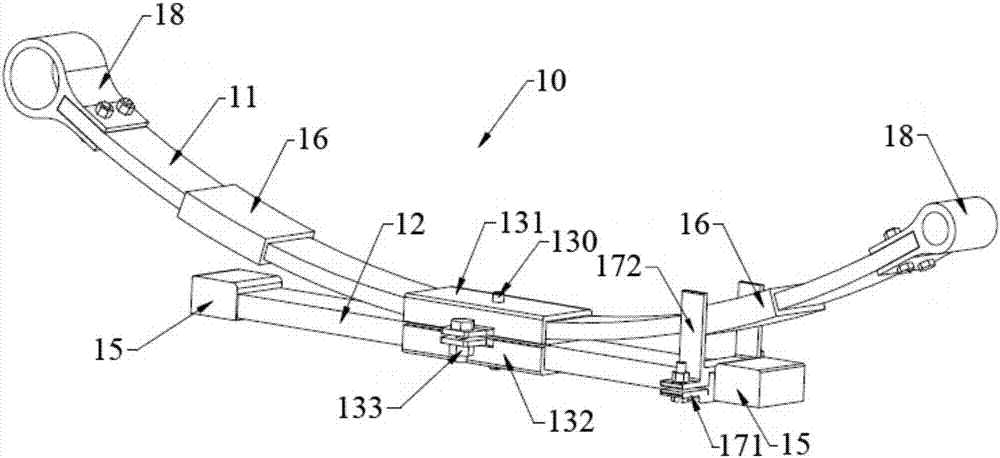

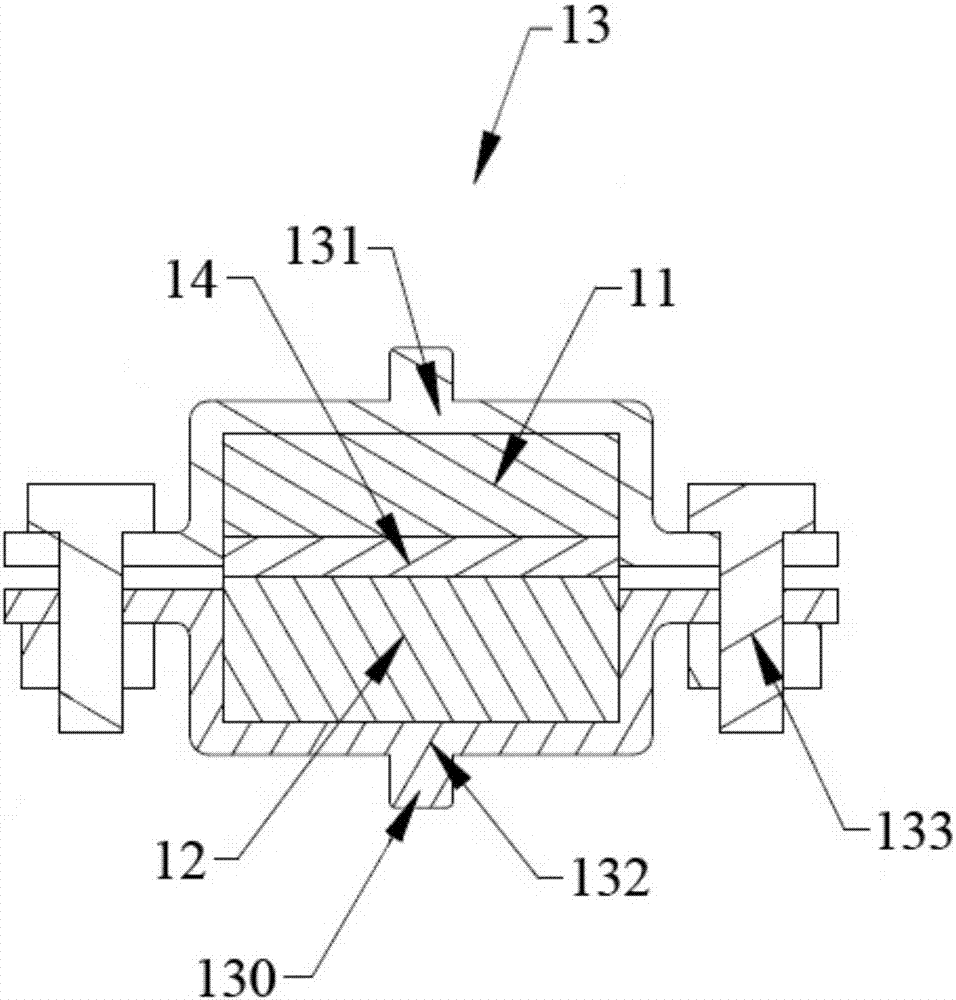

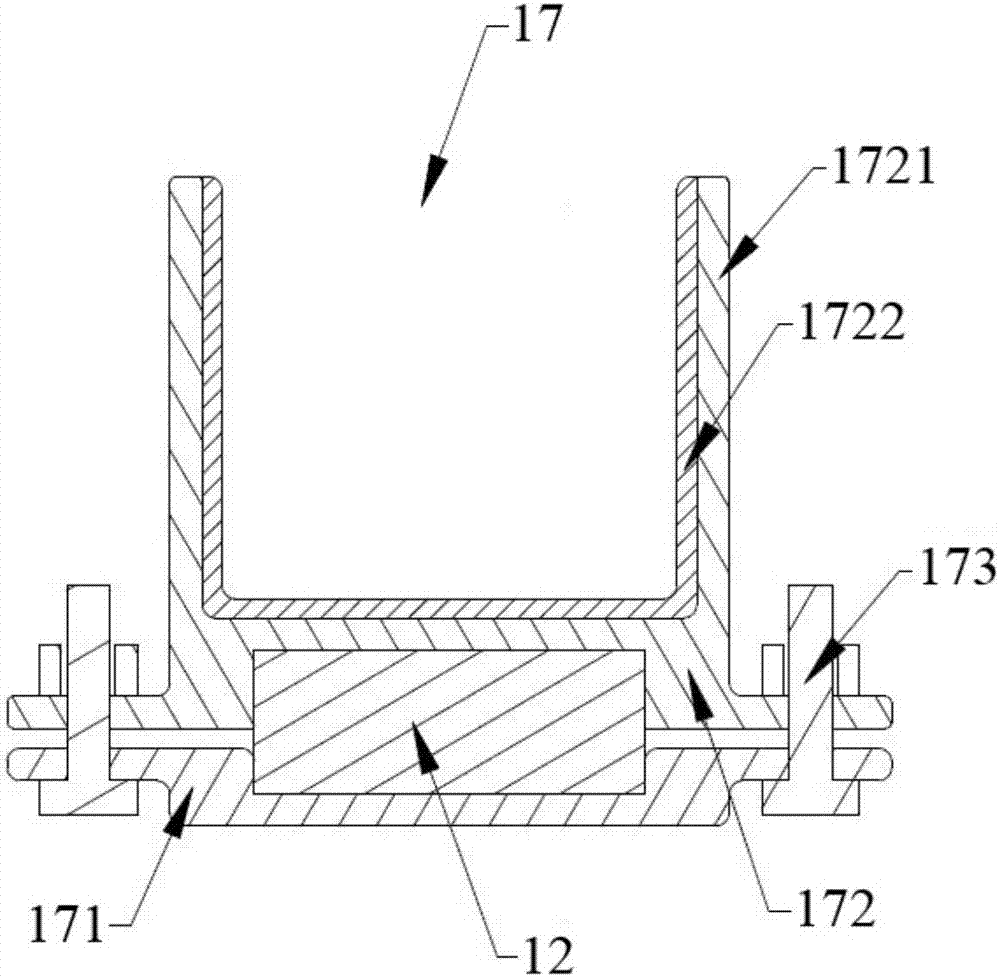

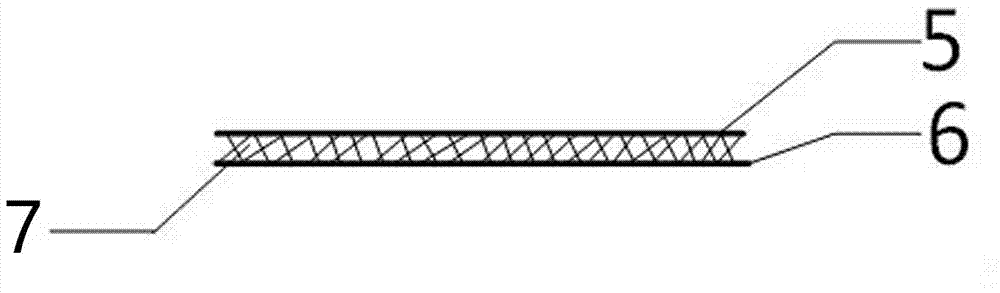

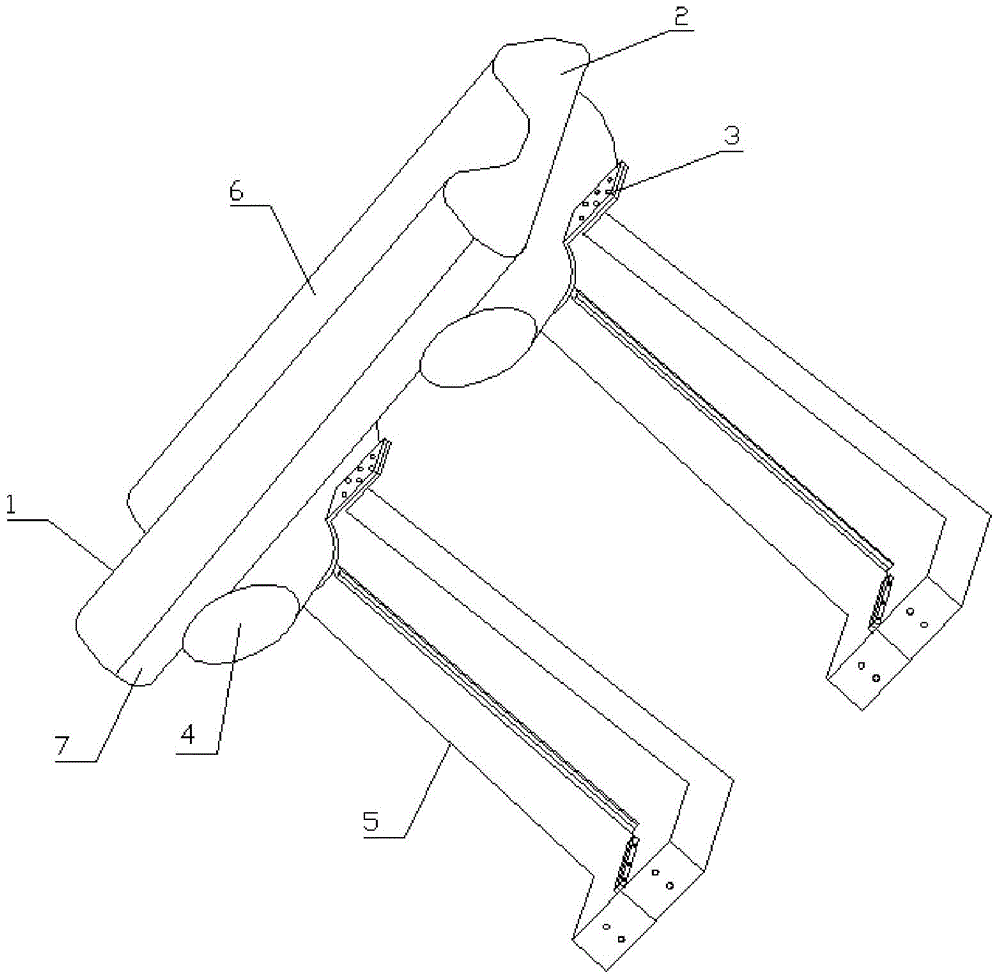

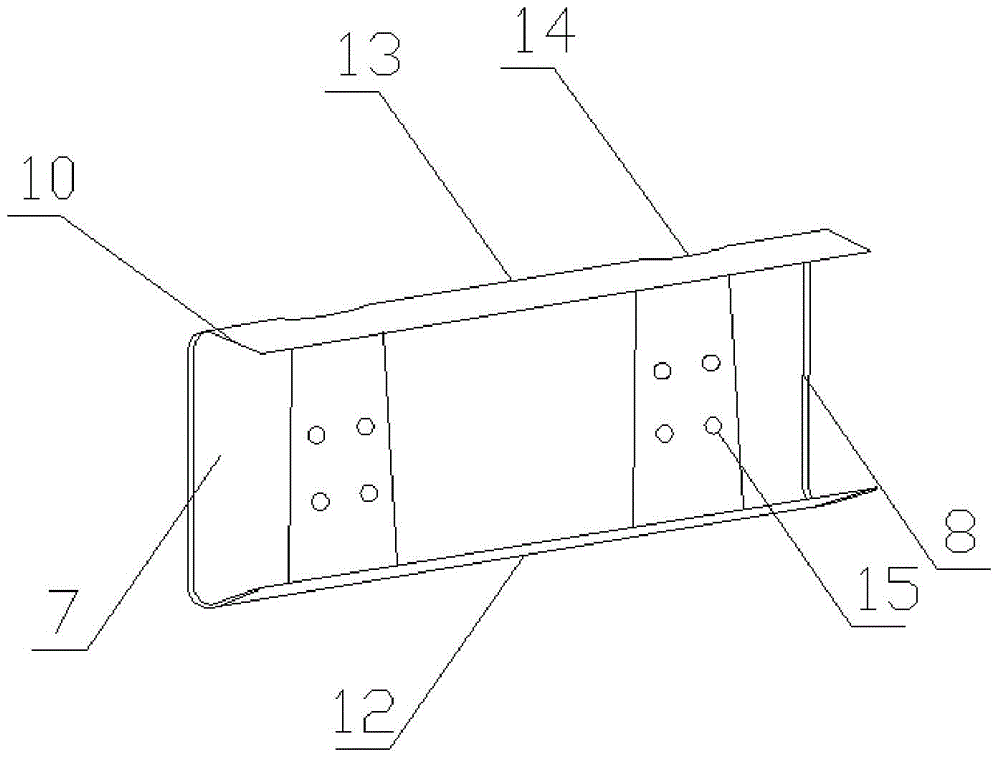

Plate-type spring assembly and vehicle hanging device

InactiveCN107215160ASolve the stiffness problemTroubleshoot changing technical issuesLeaf springsResilient suspensionsFiberEngineering

Provided is a plate-type spring assembly (10) for a vehicle hanging device. The assembly includes a first plate spring (11), a second plate spring (12) arranged on the bottom side of the first plate spring, and a connecting mechanism (13) used for connecting the first plate spring and the second plate spring, wherein gaps are set between the two ends of the second plate spring and the first plate spring, and the length of the second plate spring is smaller than that of the first plate spring. The invention also provides the vehicle hanging device. The vehicle hanging device includes a pair of lifting lugs (18) and the plate-type spring assembly (10), wherein the both ends of the first plate spring are fixedly connected to the lifting lugs respectively. Since the plate-type spring assembly and the vehicle hanging device adopt the combination of the first plate spring and the second plate spring, the stiffness of the plate-type spring assembly can change along with the load change of a vehicle, and therefore, the technical problem that the stiffness of existing plate-type springs can not change along with the load change is solved, so that the specific stiffness, specific strength and corrosion resistance of vehicle hanging are improved.

Owner:SHENZHEN KEJU NEW MATERIAL

Method for preparing carbon fiber composite material reflector and carbon fiber composite material reflector

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

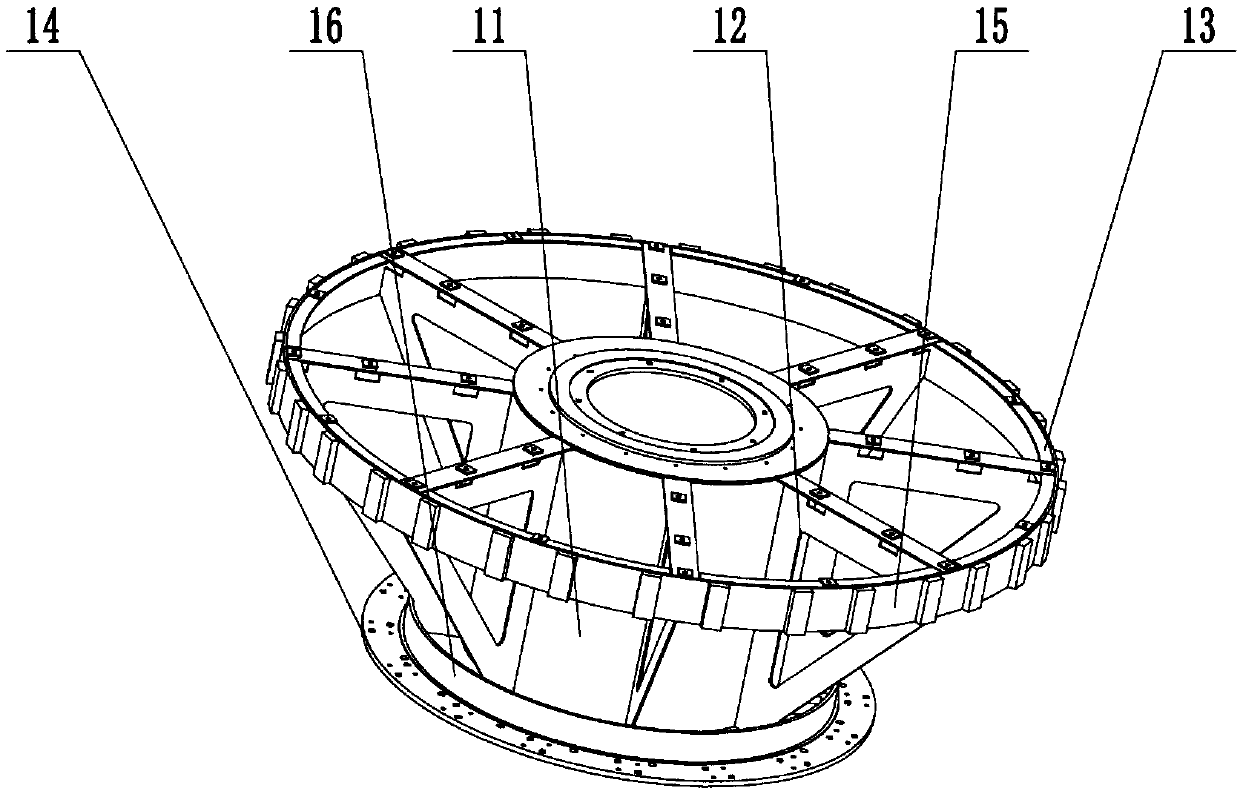

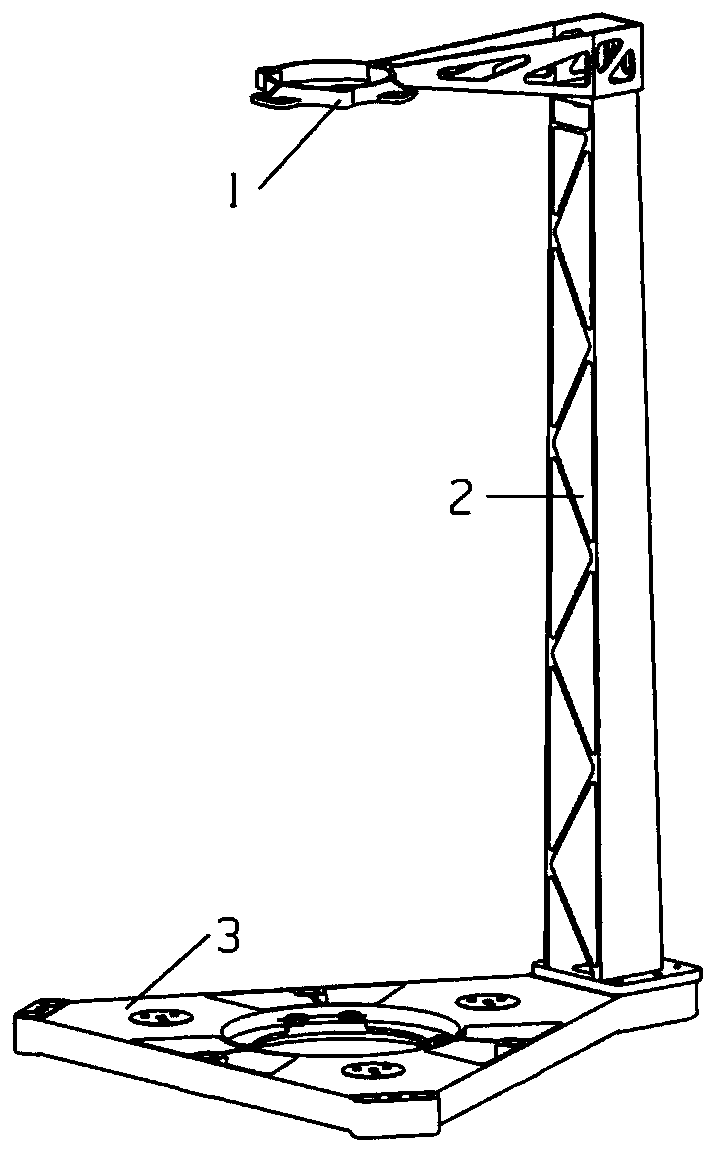

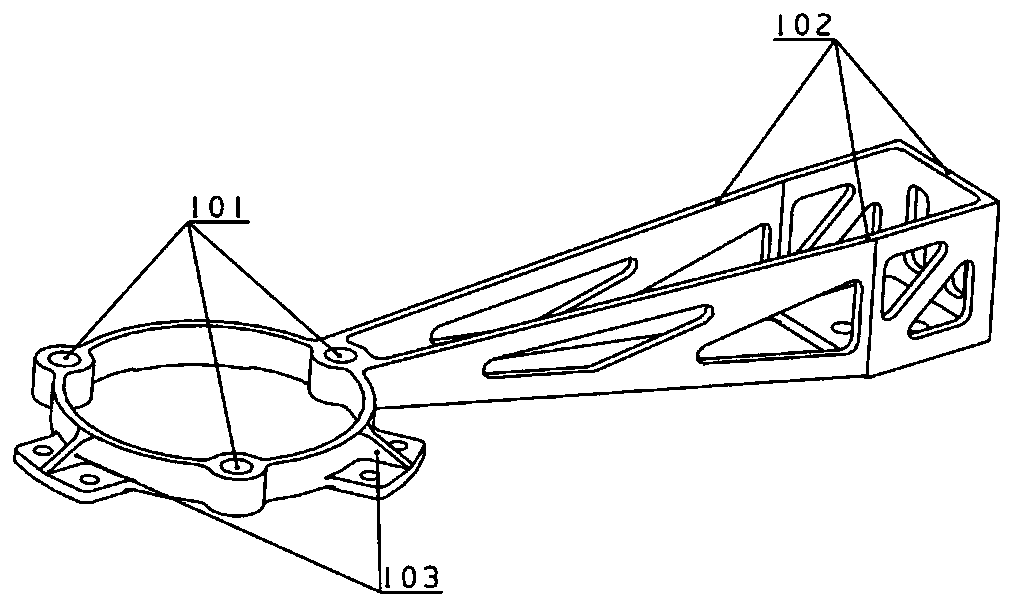

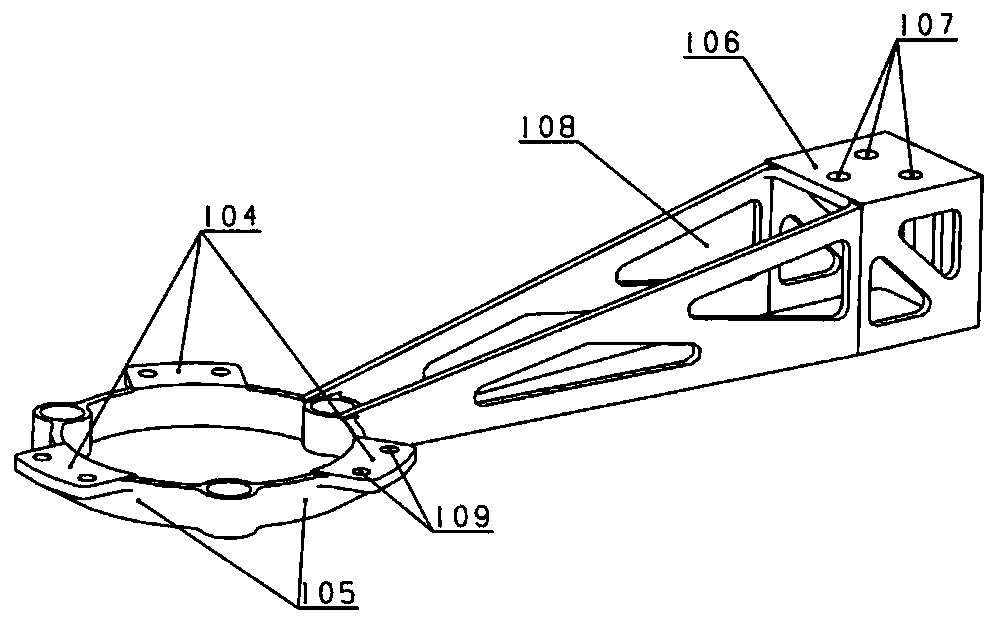

Light Ka-band reflecting-surface antenna and manufacturing method thereof

The invention discloses a light Ka-band reflecting-surface antenna and a manufacturing method thereof, and relates to the technical field of reflecting-surface antennas. The antenna comprises a trusssupport, a central reflecting surface, a main reflecting surface, a feeding source network support device, a feeding source network and an auxiliary reflecting body, wherein each main reflecting-surface surface unit comprises a honeycomb main body, a skin and six pairs of pre-buried pieces, adjacent two main reflecting surface units are connected by a top connection piece and a panel adjustment assembly, and the main reflecting surface and the truss support are connected by a root adjustment assembly and a pull rod assembly. Each main reflecting surface unit is independently connected with thetruss support, and radial, circumferential and normal adjustment of the gesture of the main reflecting surface is achieved by the semi-enclosed panel adjustment assembly; the reflecting surfaces areintegrally connected by the panel adjustment assembly and are directly connected with a panel pre-buried piece, and the welding matching process is omitted; and by the open truss support and the pullrod assembly, the design of an antenna back rack is greatly simplified. The antenna has the characteristics of light weight, good shape maintenance, high adjustment efficiency and the like.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Single rod type main bearing structure applicable to micro-nano remote sensing camera

The invention discloses a single rod type main bearing structure applicable to a micro-nano remote sensing camera, relates to the technical field of space optical remote sensing, and solves the problems that the existing coaxial space camera main support structure is high in weight and large in shading ratio and process difficulty, an integrated formation structure is too high in production cost and long in processing period and the like. According to the single rod type main bearing structure applicable to the micro-nano remote sensing camera disclosed by the invention, a secondary mirror bracket and a support rod are in flanged connection; the support rod and a main backplate are in flanged connection; due to adoption of a split type structure, instead of an integrated structure, the processing difficulty of silicon carbide can be greatly reduced; the production period and the manufacturing cost are greatly reduced; the low-cost and short-period requirements of micro-nano load are satisfied; a countersunk bottom hole and an embedded part are pre-punched on a silicon carbide material; an epoxy resin adhering manner is adopted; and the problems that the process of directly processing a threaded hole in the silicon carbide material is high and damage is easily caused can be avoided. By means of the single rod type main bearing structure applicable to the micro-nano remote sensing camera disclosed by the invention, the structural precision and the stability are improved; the structural part number and the manufacturing process are simplified; and the processing period and theprocessing cost are shortened.

Owner:CHANGGUANG SATELLITE TECH CO LTD

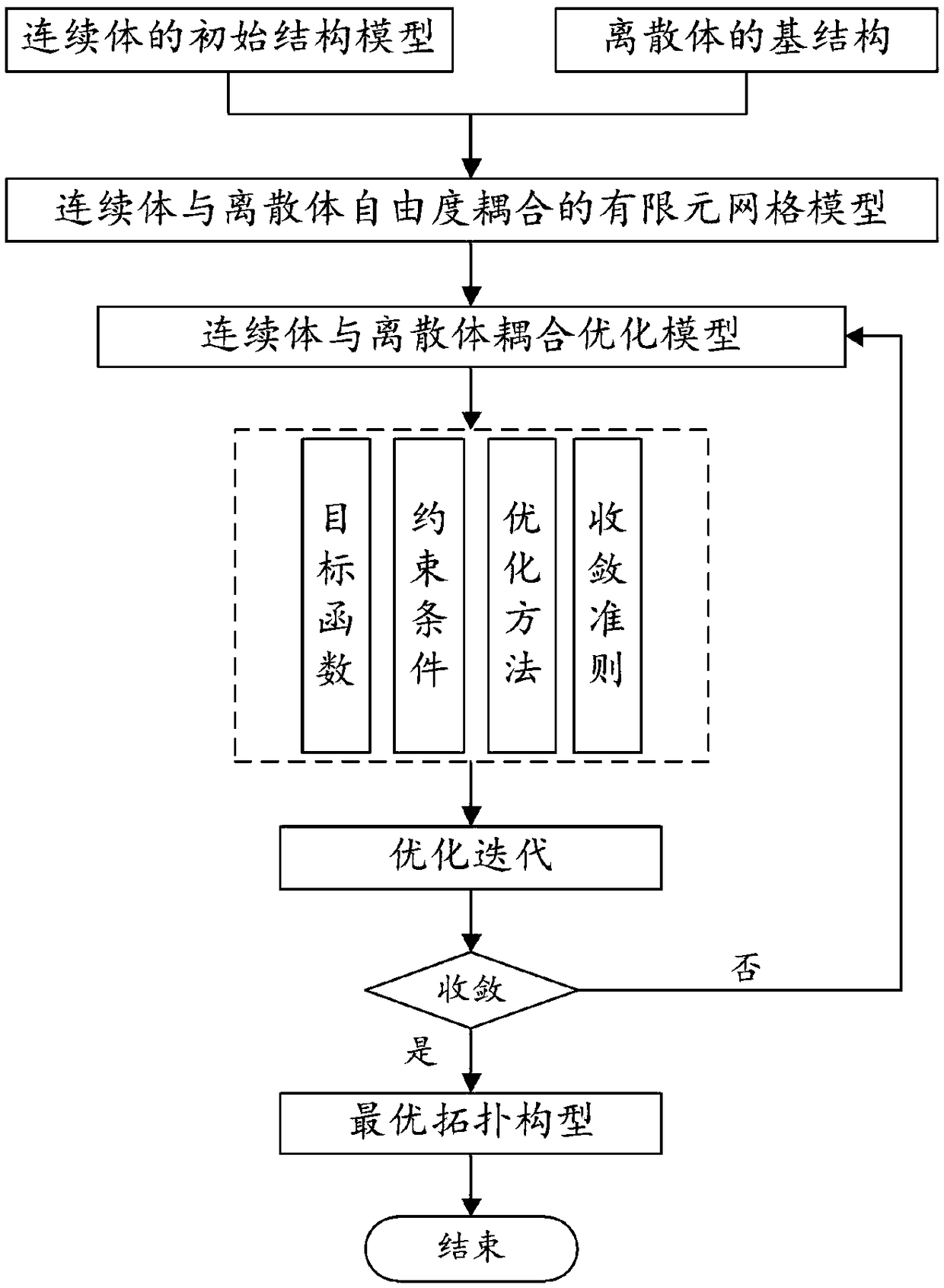

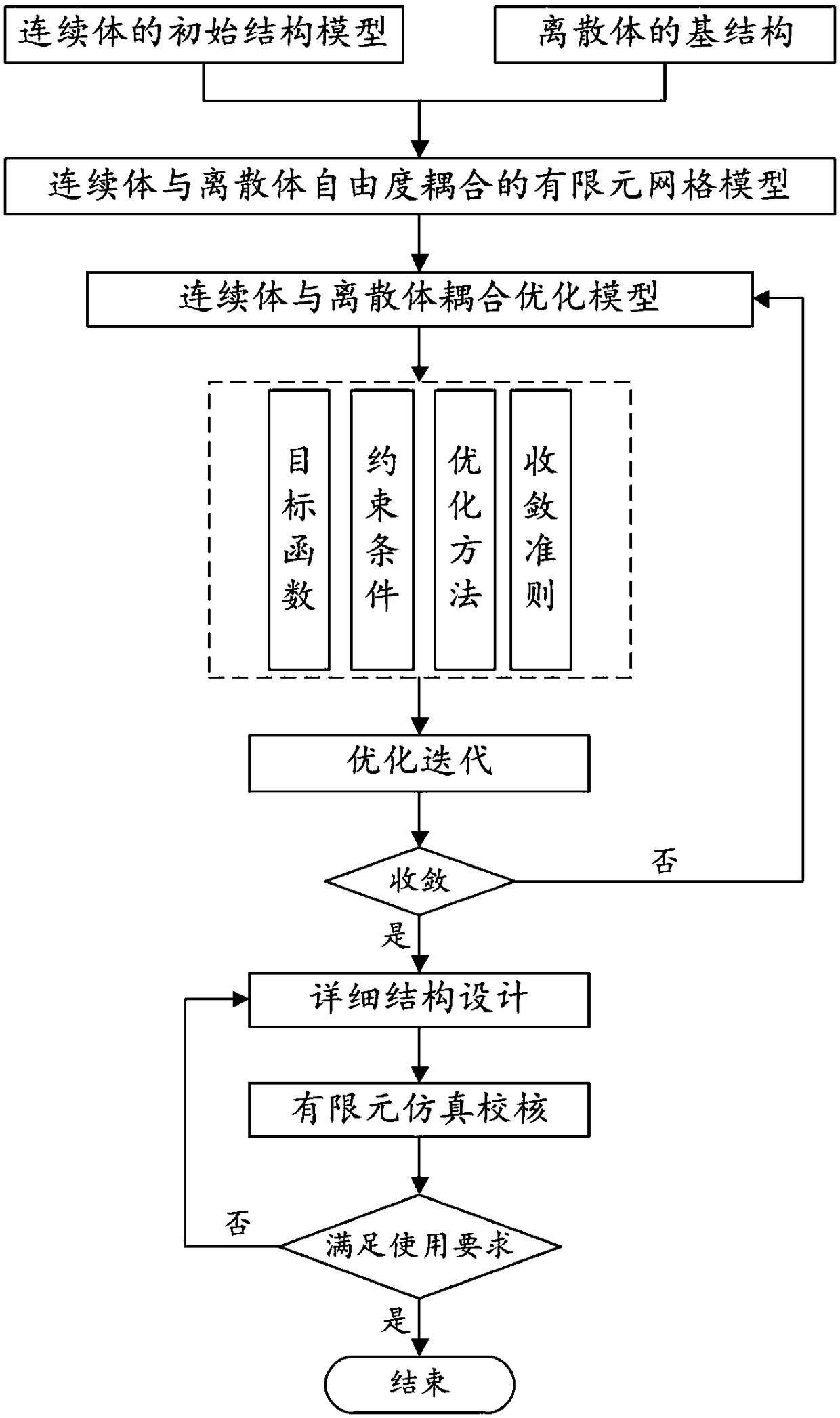

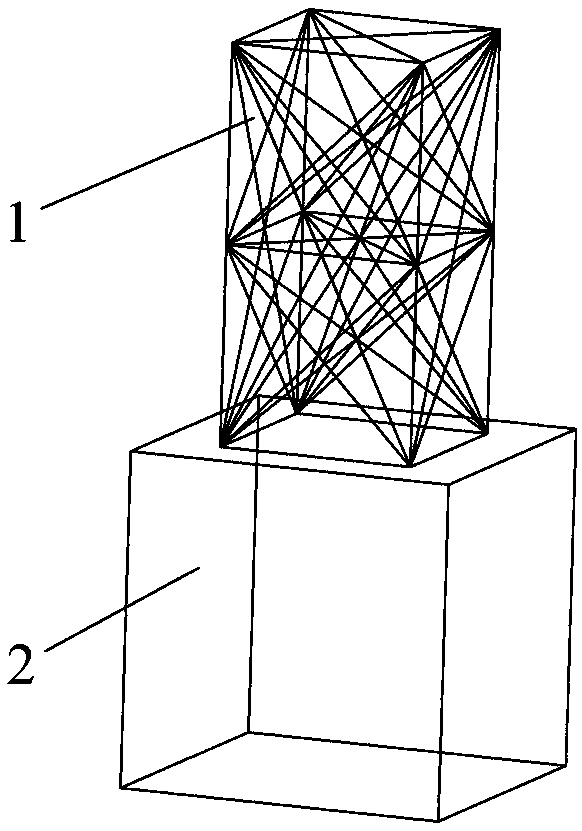

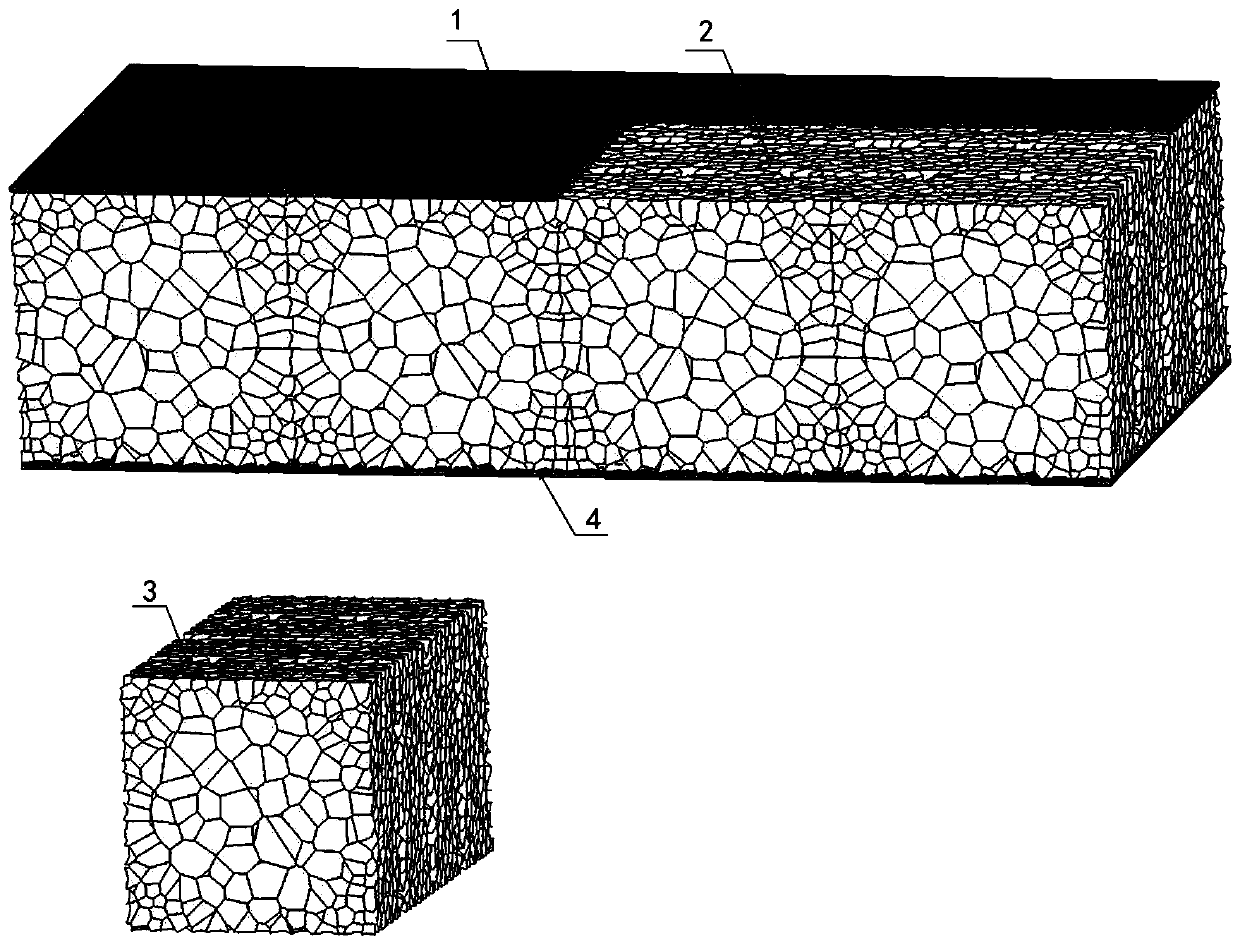

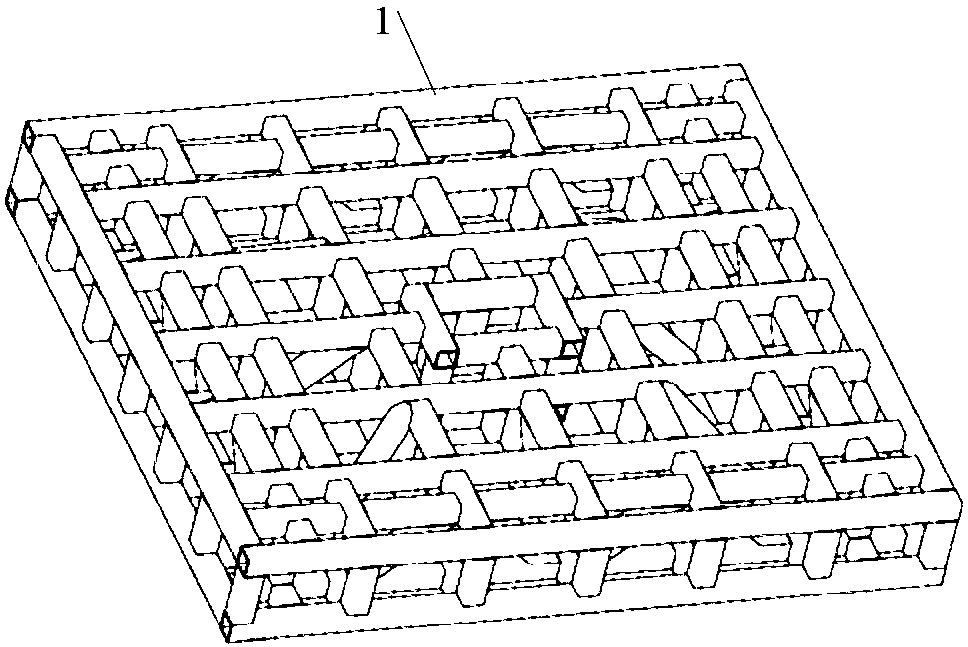

A continuum and discrete body coupling topology optimization method

ActiveCN109002668AAchieve lightweightHigher specific stiffnessDesign optimisation/simulationSpecial data processing applicationsEffective solutionTopology optimization

A continuum and discrete body coupling topology optimization method is provided. The invention solves the problem that the topology optimization method of the continuum or the discrete body alone in the prior art can not accurately obtain the optimal topology configuration of the continuum and the discrete body coupling structure form. At first, a finite element mesh model of coupling of degrees of freedom of a continuum and a discrete body is established, then a unified optimization model of a continuum and a discrete body is established, and the objective function, constraint condition, optimization method and convergence criterion are set in the optimization model. Finally, the optimal topology configuration of the continuum and discrete body is obtained by performing optimization solving based on the defined optimization model and displaying the topology optimization results. The invention can realize topology optimization of a continuum and discrete body coupling structure, improve specific stiffness of the continuum and discrete body coupling structure, realize lightweight of continuous and discrete body coupling structure on the premise of ensuring mechanical performance, and provide effective solution for conceptual design of continuous and discrete body coupling structure.

Owner:南通长光星辰光电技术有限公司

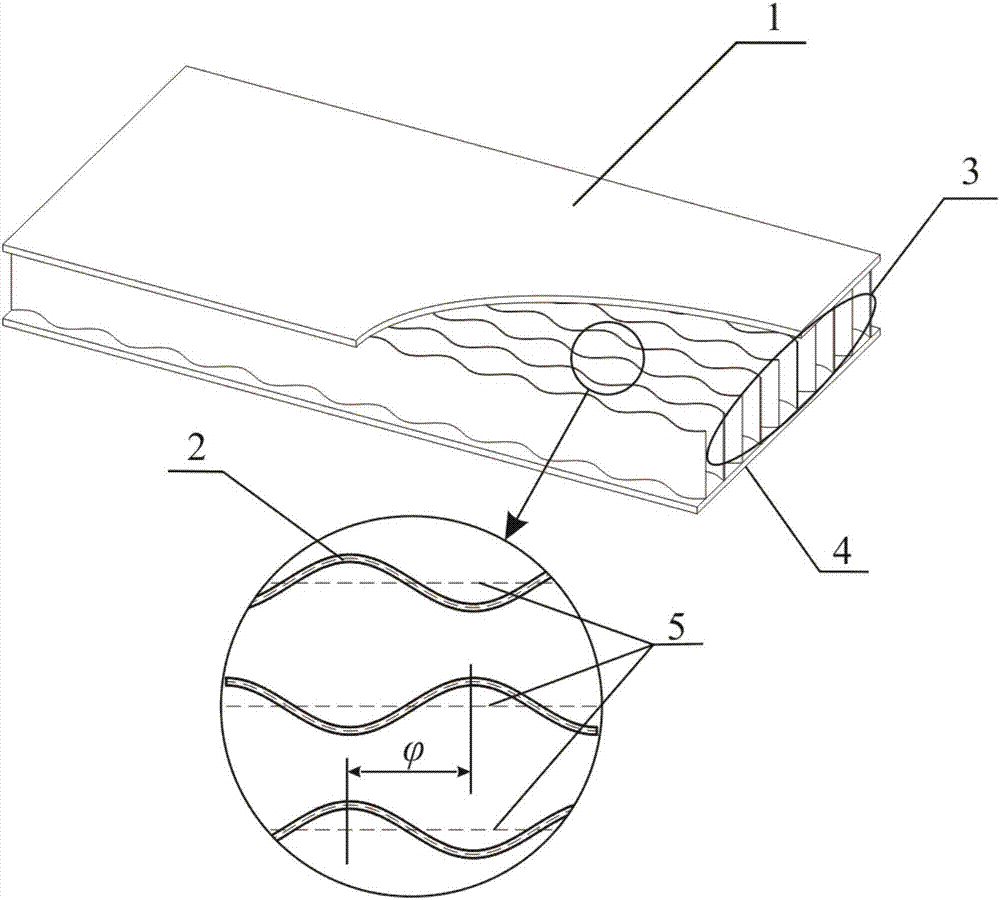

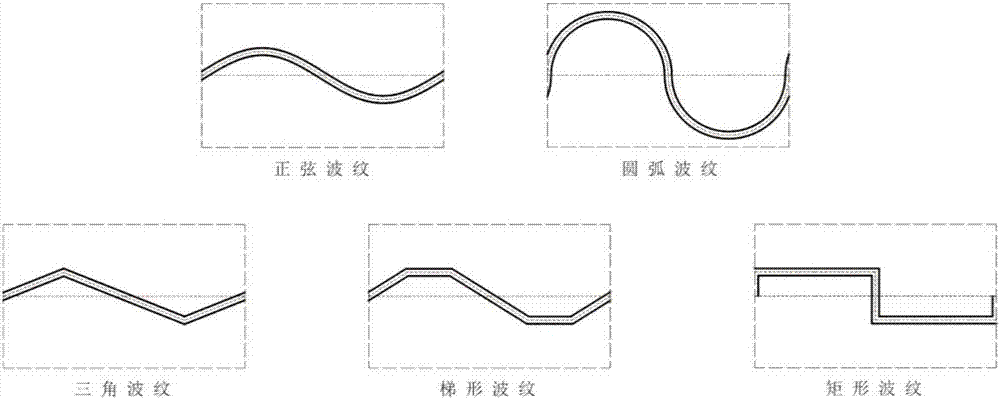

Core sandwich structure of corrugated channel and preparation method thereof

ActiveCN106891598AChange relative densityOptimal Flow Heat Transfer CoefficientLaminationLamination apparatusAviationActive cooling

The invention discloses a core sandwich structure of a corrugated channel and a preparation method thereof. The core sandwich structure of the corrugated channel is composed of an upper panel, a corrugated channel core and a lower panel. A two-dimensional lattice core sandwich structure which has the multifunctional characteristic is obtained by using the corrugated channel core to replace an I-type core. Compared with the I-type structure, the properties, such as specific strength and specific rigidity, of the structure are improved by 20% above, and the flowing coefficient of heat conduction of the structure in a channel which is mainly based on a transition flow is increased by 50% above, and the structure has a mechanical property similar to that of a honeycomb sandwich structure and has an excellent active cooling function. The structure disclosed by the invention has the characteristics of high specific strength, high specific rigidity and excellent heat conduction, and can be applied to the field of space flight and aviation, ships, automobiles, machinery and civil engineering, and in particular has a wide application prospect in a load-carrying construction with thermal management requirements.

Owner:湖南金康管业有限公司

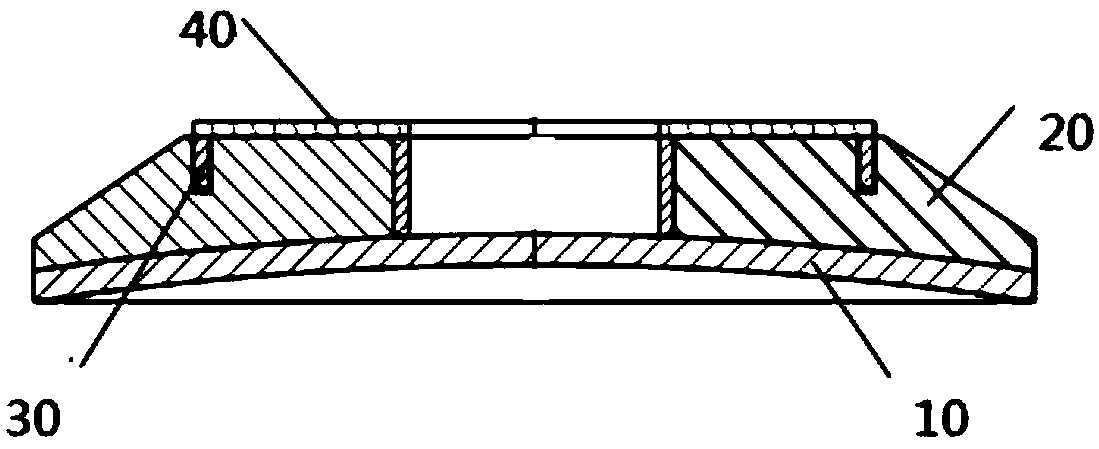

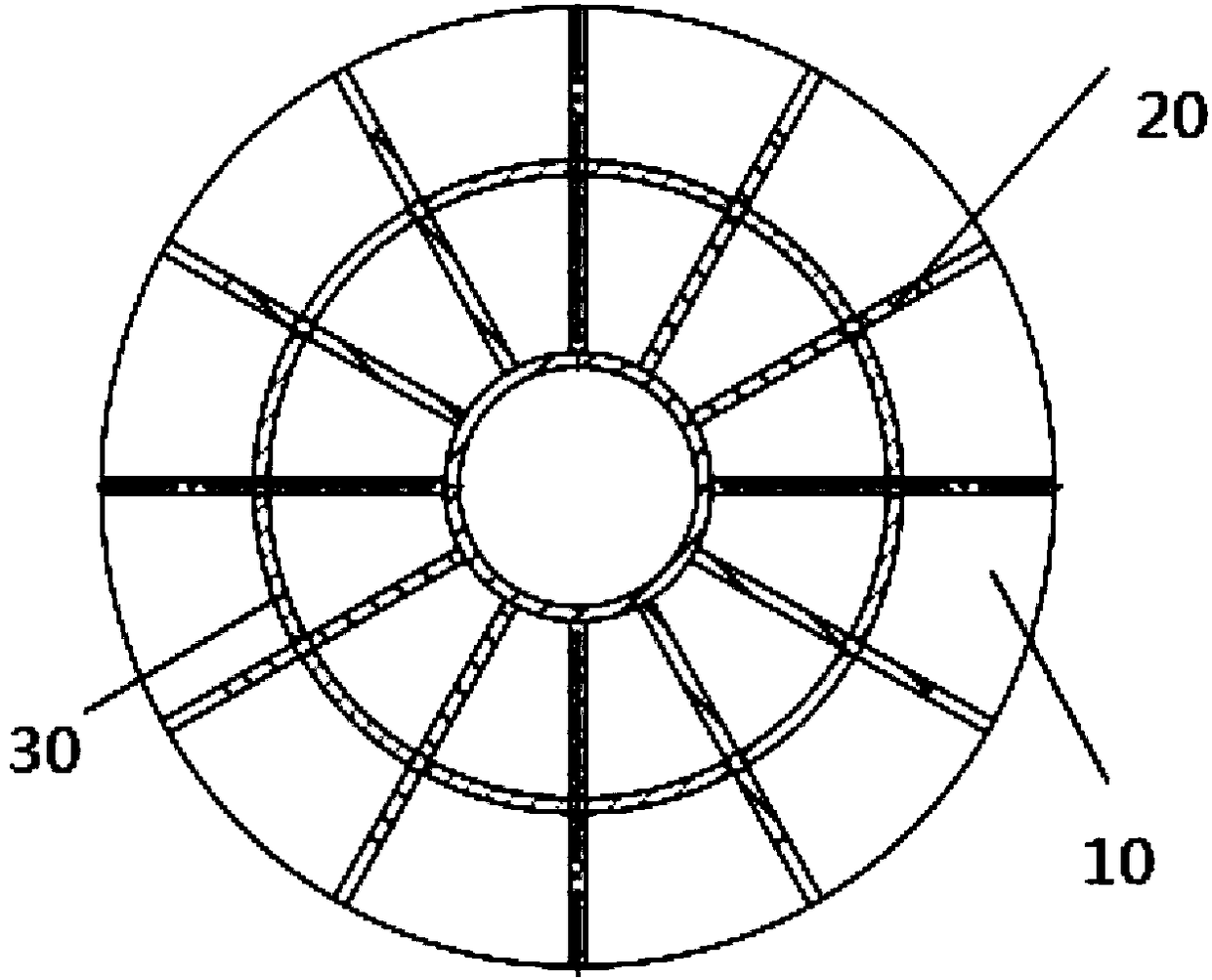

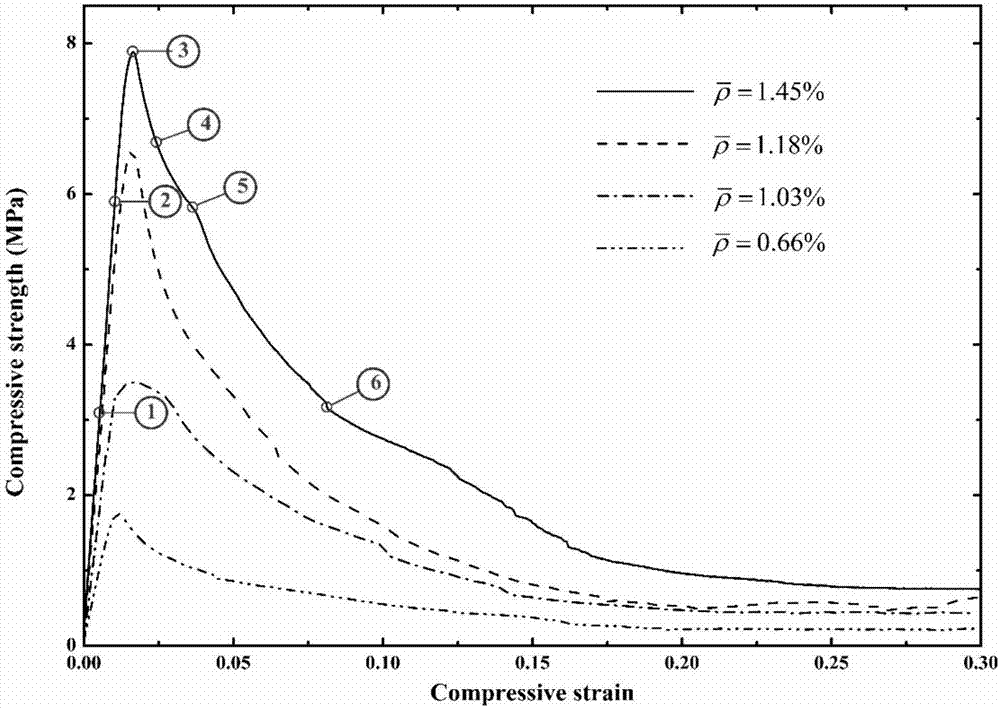

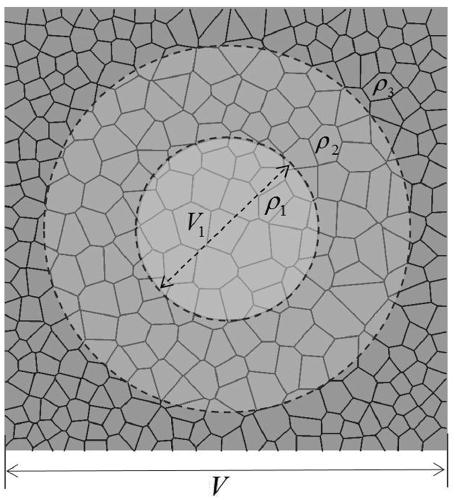

Radial negative gradient foamed aluminum sandwich panel and preparation method thereof

ActiveCN111196063AImprove performanceImprove stress resistanceSynthetic resin layered productsLaminationMetallic materialsElectromagnetic shielding

The invention belongs to the technical field of structural design of metal materials, and provides a radial negative gradient foamed aluminum sandwich panel. The aluminum sandwich panel is of a layered structure and sequentially comprises a lower plate layer, a radial negative gradient foamed aluminum core layer and an upper plate layer from bottom to top. The inner surfaces of the upper plate andthe lower plate are connected and fixed with the top and the bottom of the radial gradient foamed aluminum core layer by gluing or welding; the radial negative gradient foamed aluminum core layer isformed by sequentially arranging a plurality of radial negative gradient foamed aluminum unit cells in a plane, and the contact parts between the unit cells are welded or subjected to secondary foaming connection; the density of the negative gradient foamed aluminum unit cells starts from the center of a square and is gradually increased in the radius direction. The panel is reasonable in structure, excellent in performance, low in density, large in specific stiffness, high in specific strength, good in stability, impact resistance, electromagnetic shielding, excellent in damping characteristic, low in heat conductivity and electric conductivity, heat-insulating and sound-insulating, and has wide application prospects in the fields of engineering materials for chemical engineering, metallurgy, machinery, building civil engineering, high-speed automobiles, ships, packaging and transportation, aerospace, military protection and the like.

Owner:TAIYUAN UNIV OF TECH

High-specific-strength and high-specific-stiffness aluminum-lithium alloy thick-wall annular piece and preparation method thereof

ActiveCN114058912AThe density drop is not obviousImprove microstructureFoundry mouldsFoundry coresThick wallBoron nitride

The invention provides a high-specific-strength and high-specific-stiffness aluminum-lithium alloy thick-wall annular piece and a preparation method thereof, and belongs to the technical field of aluminum-lithium alloy new materials and manufacturing. The aluminum-lithium alloy thick-wall annular piece comprises the following chemical components: 0.8-2.8 wt% of Cu, 2.4-3.8 wt% of Li, 0.8-1.8 wt% of Mg, 0.5-1.5 wt% of Zn, 0.1-0.5 wt% of Er, 0.05-0.2 wt% of Zr, less than or equal to 0.08 wt% of Fe, less than or equal to 0.05 wt% of Si, and the balance of Al and inevitable impurities, wherein the total amount of the alloy elements is less than or equal to 8.5 wt%. The preparation method comprises the steps of alloy proportioning, boron nitride brushing, smelting, refining, centrifugal casting and heat treatment. According to the invention, the forming process of the aluminum alloy annular piece can be simplified, the internal structure is compact, and the specific strength and specific stiffness of the aluminum alloy annular part are remarkably improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

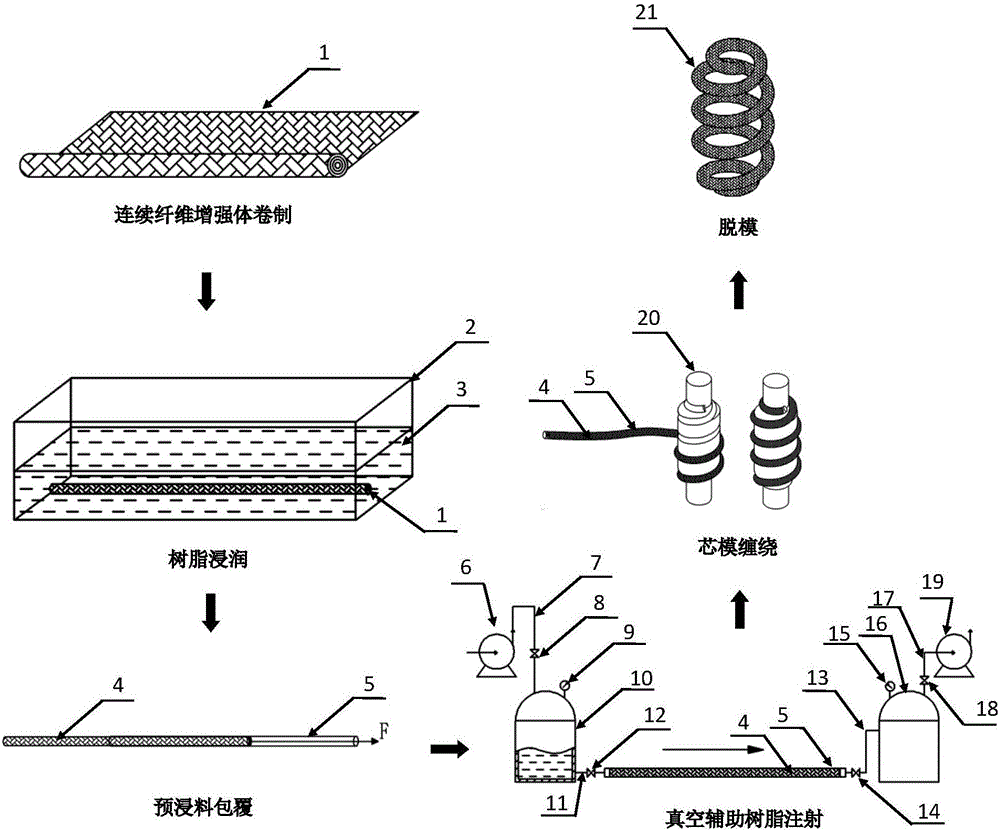

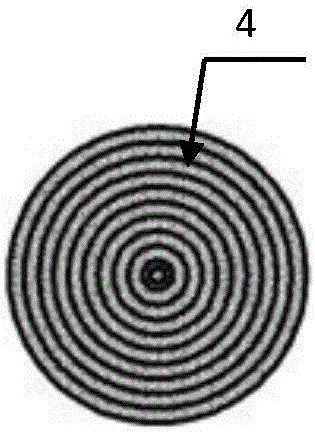

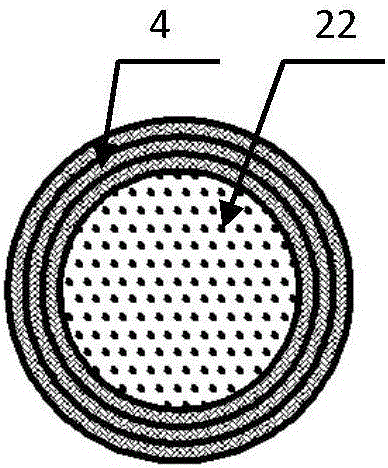

Spiral spring production method based on continuous fibers

InactiveCN106626340AImprove fatigue lifeIncrease the stiffness factorDomestic articlesCoatingsVacuum assistedCorrosion

The invention discloses a spiral spring production method based on continuous fibers and relates to a composite part forming technology. In the invention, the production of a spiral spring is realized based on continuous fiber reinforcement through the processes of resin wetting, prepreg coating, vacuum assisted resin injection, mandrel winding and demoulding. According to the experimental result, the produced spiral spring based on continuous fibers can be lightened by 40-60% in comparison with the traditional spiral spring, the fatigue life is prolonged by 80%, and the rigidity coefficient is improved by 1-2 times. Moreover, the spiral spring also has the advantages of relatively high specific strength and specific rigidity, good corrosion resistance, impact resistance and high-temperature property, good surface quality, simple forming technology, little pollution to a forming mould, and the like.

Owner:JILIN UNIV

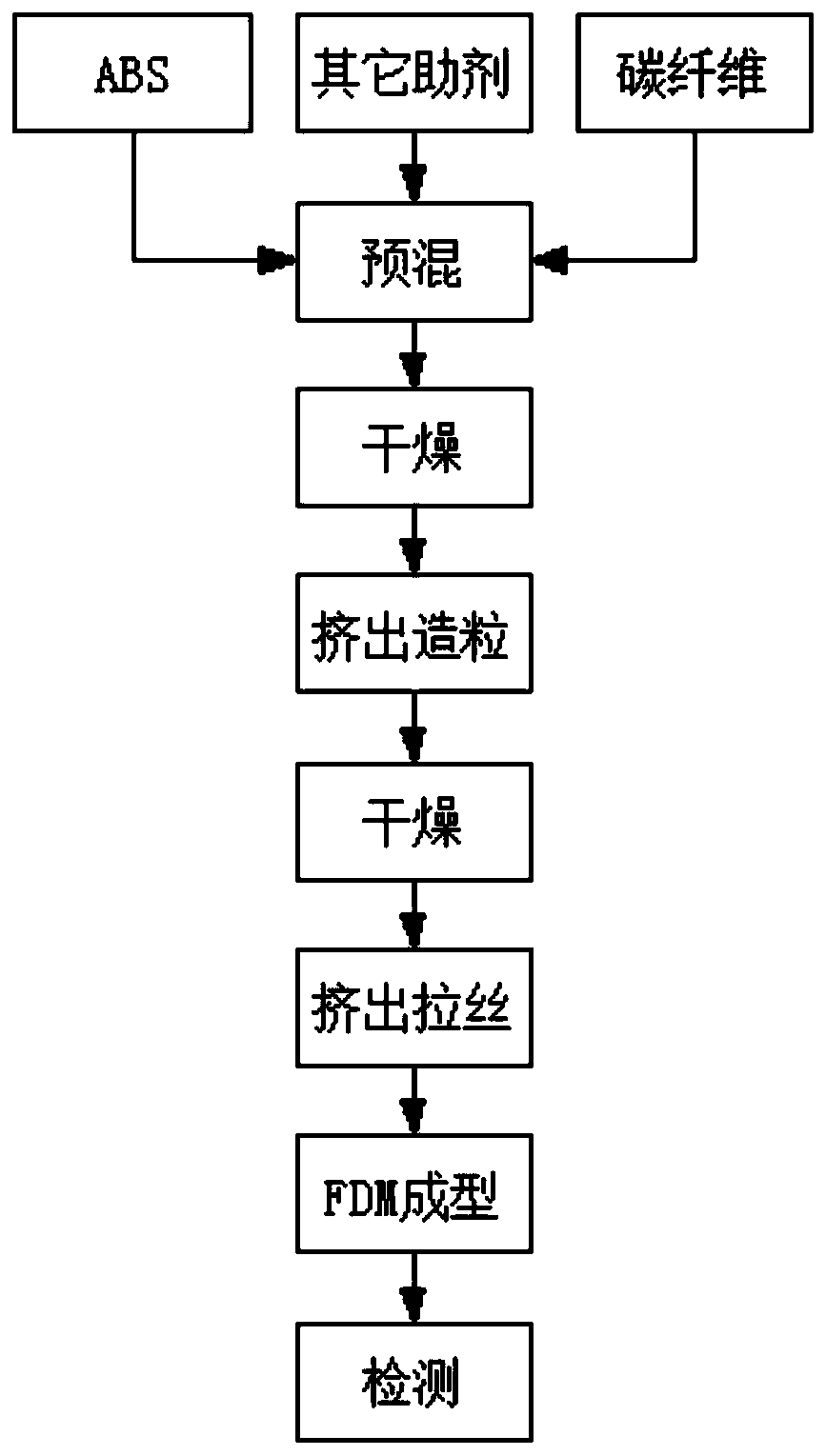

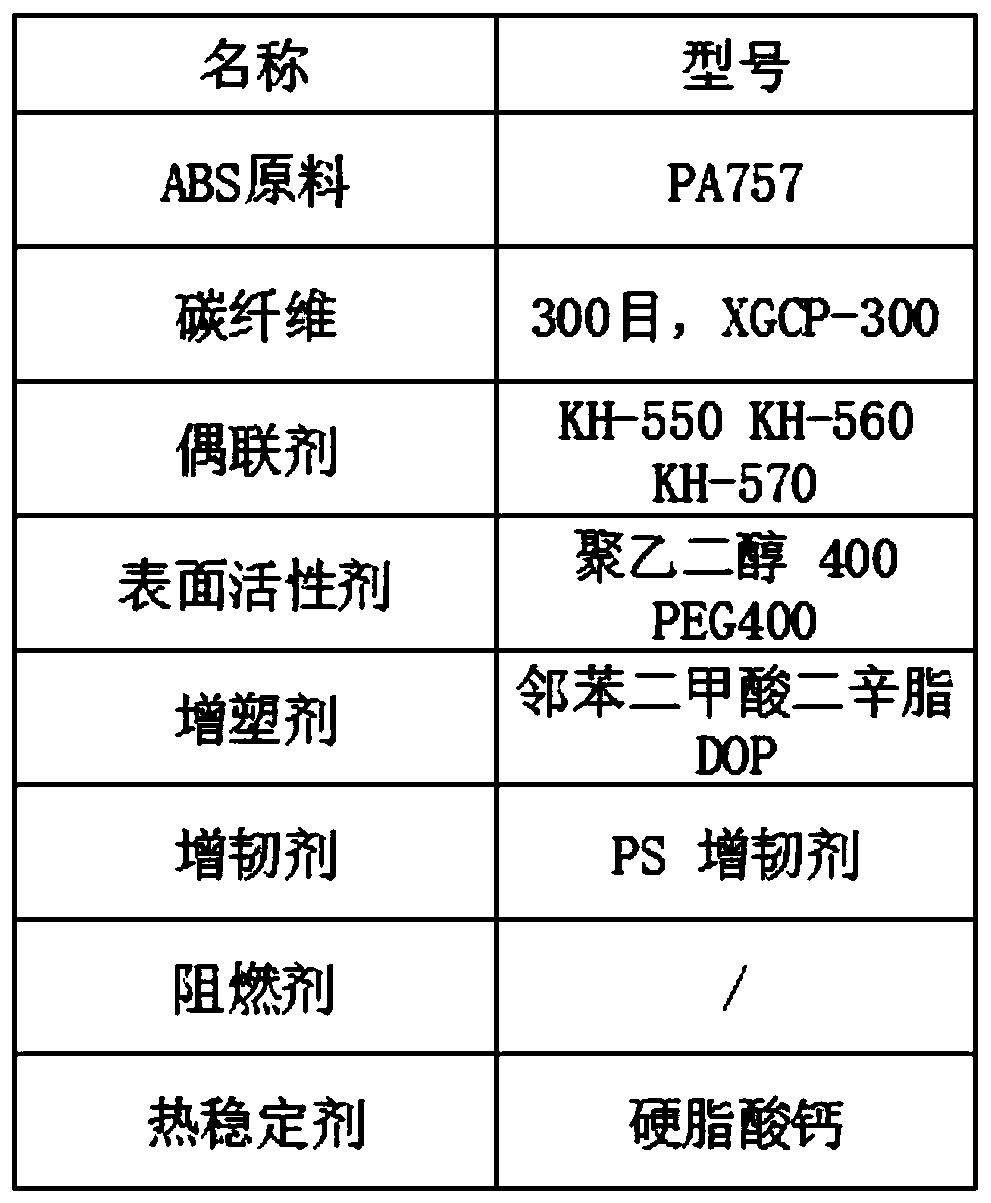

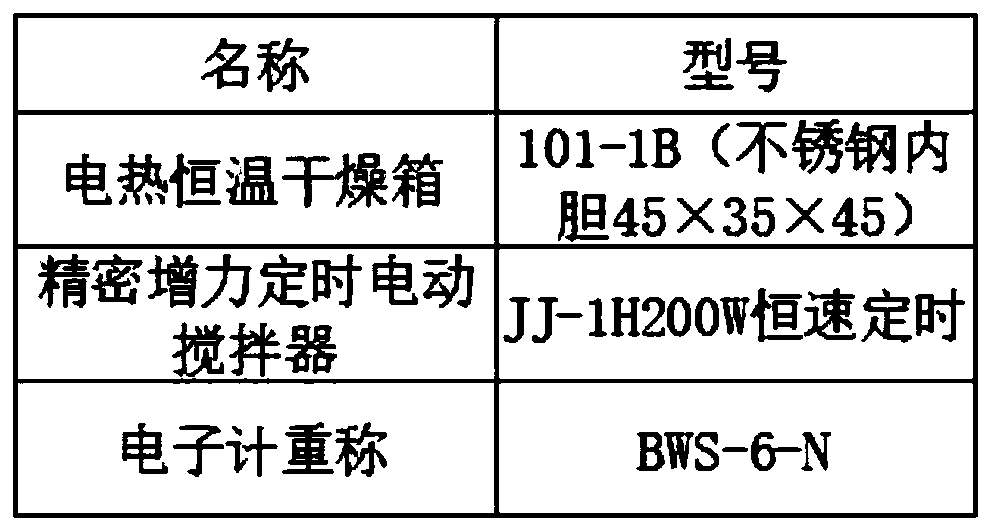

Production technology of ABS/carbon fiber composite material for FDM printing

InactiveCN110408163AImprove performanceHigh strengthAdditive manufacturing apparatusMaterials preparationFlexural strength

The invention discloses a preparation technology of an ABS / carbon fiber composite material for FDM printing, and relates to the technical field of 3D printing technology treatment. The preparation technology of the ABS / carbon fiber composite material for FDM printing comprises the following steps: a, raw material preparation; b, drying and mixing; c, proportioning and mixing; and d, material preparation. A carbon fiber is a common material for enhancing the performances of a composite material, so the 3D printing composite material obtained by improving the materials of an ABS material with the carbon fiber has better strength and specific rigidity than the pure ABS material, the ABS / carbon fiber composite material has light weight, good fatigue resistance and good fracture resistance, andthe ABS / carbon fiber composite material is applied to a single-screw FDM wire extruder to extrude and print a wire in order to improve the bending strength, the compressive strength and the hardnessof the wire, enhance the mechanical properties, reduce the surface roughness of the wire and enhance the material properties.

Owner:NANTONG INST OF TECH

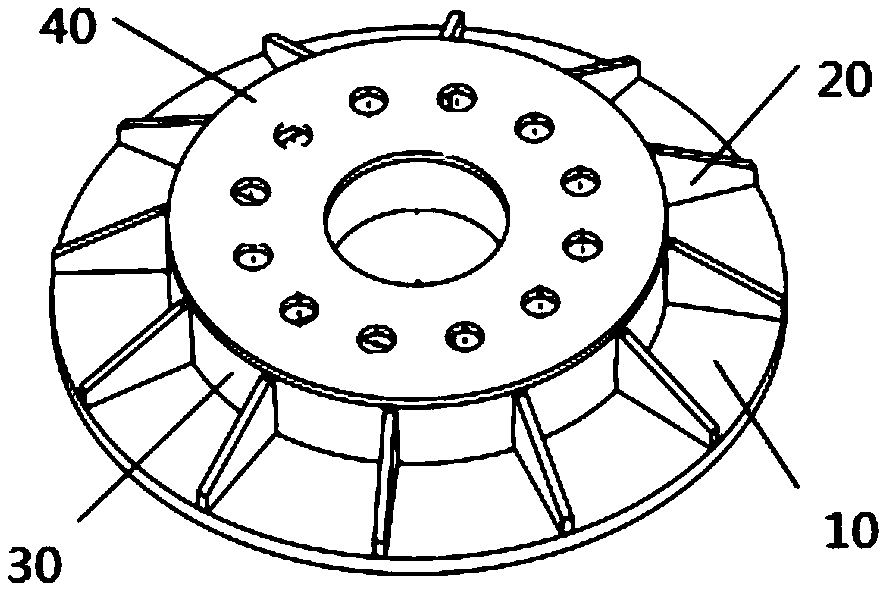

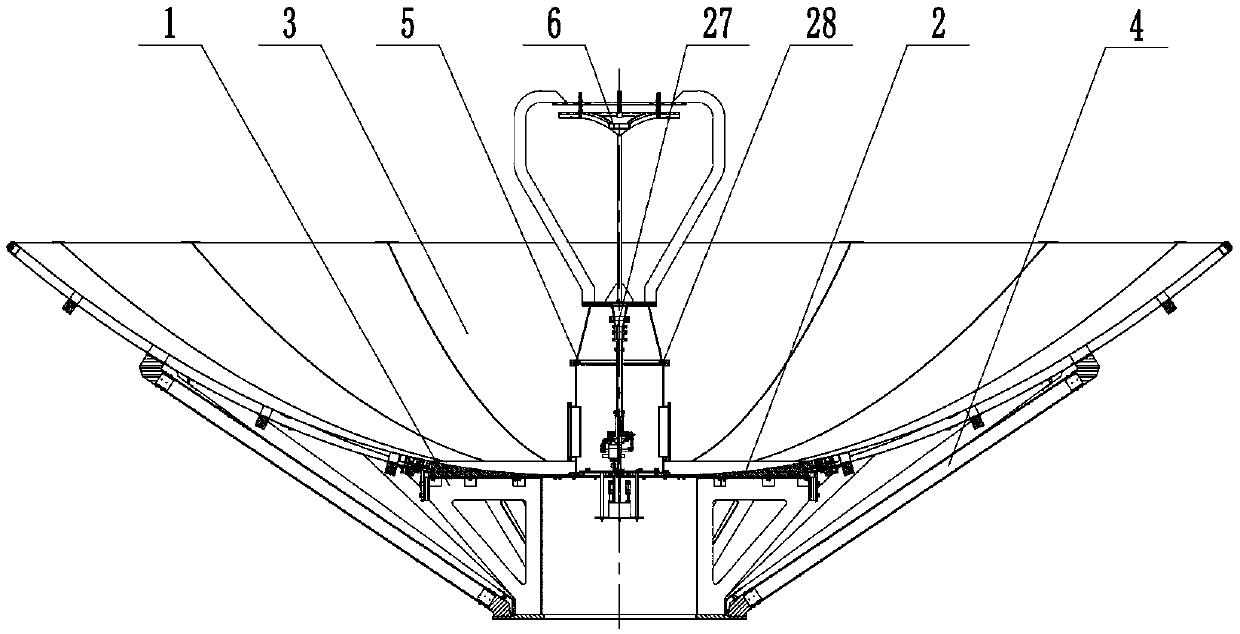

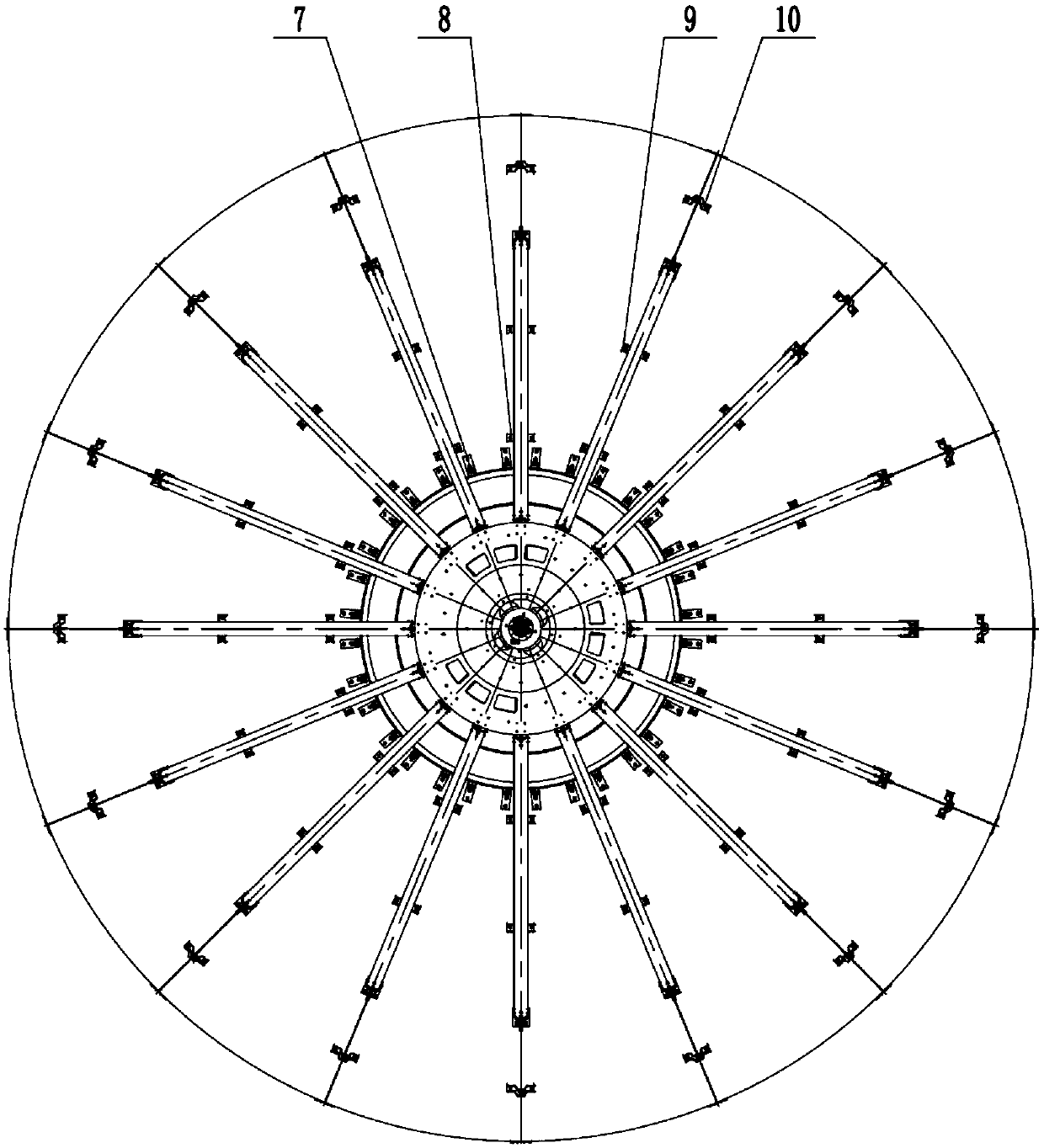

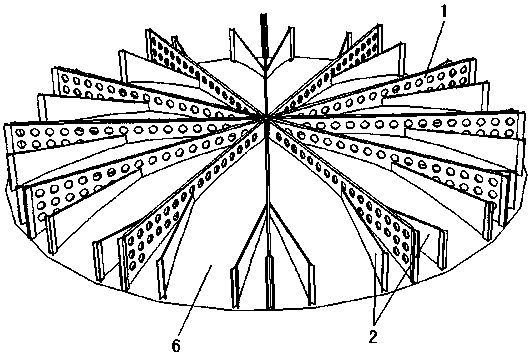

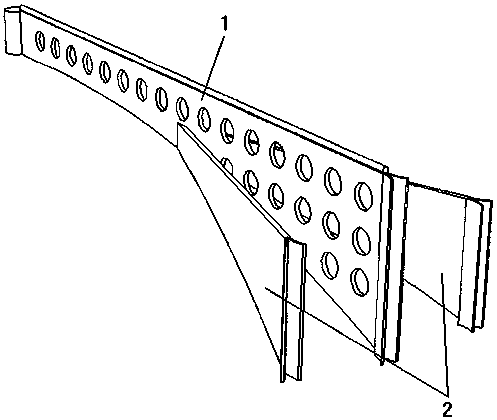

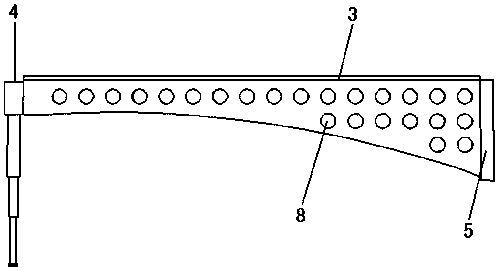

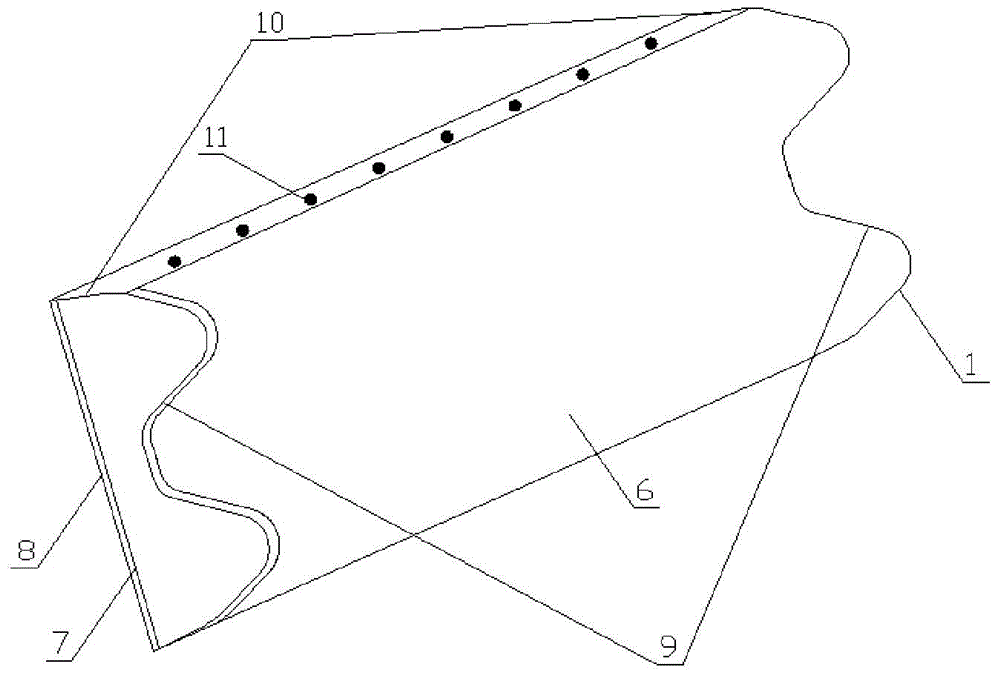

Expandable branching rib plate high-precision reflecting plane

ActiveCN107275795AIncreased out-of-plane bending stiffnessReduce local bucklingCollapsable antennas meansEngineeringParaboloid

The invention discloses an expandable branching rib plate high-precision reflecting plane, which comprises a center hub, main rib plates, auxiliary rib plates, positioning sheet-pressing springs, a paraboloid, a compressing belt, a waveguide rod and a feed source, and is characterized in that the upper side edge of each main rib plate is designed with dual straight pipes with an omega shape after being expanded, so that the out-plane bending rigidity is improved, and local buckling is substantially reduced. Each main rib plate is designed with the branched auxiliary rib plates, so that a defect of not satisfying an ideal paraboloid equation because of being away from a middle region is compensated, and the profile precision of a radial radiation rib plate antenna is improved. The lower side of the dual omega-shaped straight pipes is provided with the main rib plate with uniformly distributed circular holes, so that the structure mass can be effectively reduced, and the specific rigidity is improved. The positioning sheet-pressing springs drive expansion of the auxiliary rib plates and realize in-place expansion of the auxiliary rib plates at the same time.

Owner:HARBIN INST OF TECH

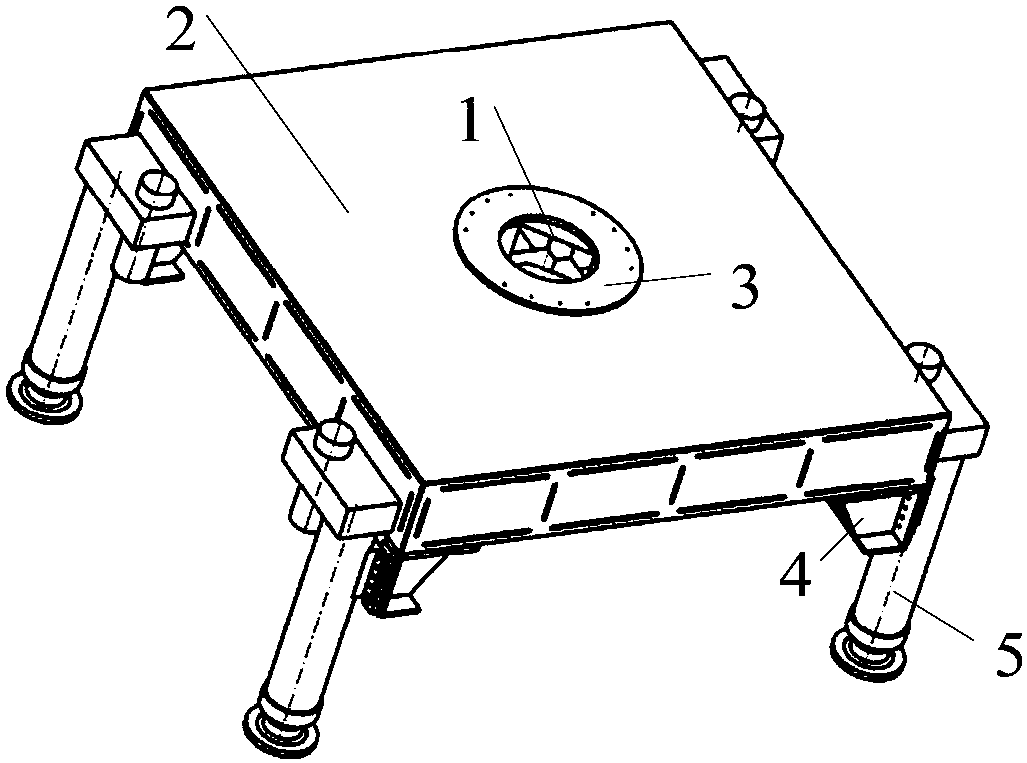

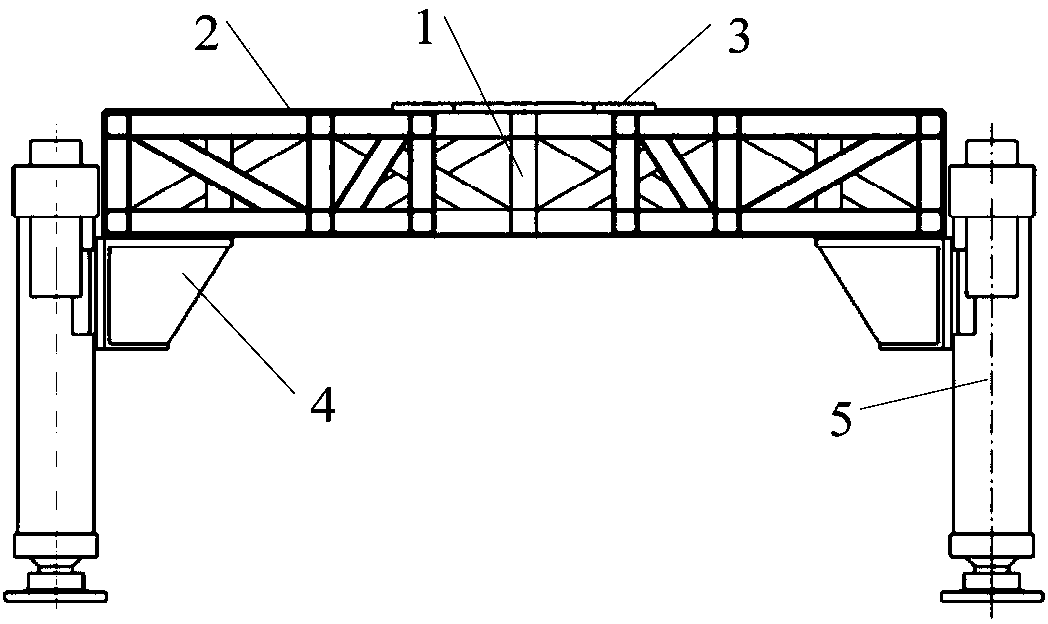

Vehicle-mounted theodolite supporting platform

ActiveCN108482263AImprove bearing efficiencyHigh specific stiffnessGeometric CADDesign optimisation/simulationEngineeringCable stayed

The invention discloses a vehicle-mounted theodolite supporting platform. The vehicle-mounted theodolite supporting platform comprises a platform supporting frame, a platform skin, a device installingboss, a platform supporting leg transferring member and a platform supporting leg assembly. The platform skin covers the platform supporting frame, the device installing boss is arranged on the platform supporting frame, the platform supporting frame is a rectangular frame welded by metal pipes, and cable-stayed rods are arranged in the rectangular frame according to the transfer path of force based on results of topological optimization. The platform supporting leg assembly is arranged below the four top corners of the platform supporting frame, and the platform supporting leg transferring member is arranged at the joint of the four top corners of the platform supporting frame and the platform supporting leg assembly. The vehicle-mounted theodolite supporting platform can guarantee the supporting stiffness of the vehicle-mounted platform and realizes the lightweight of the vehicle-mounted platform on the premise of fundamental vibrational frequency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

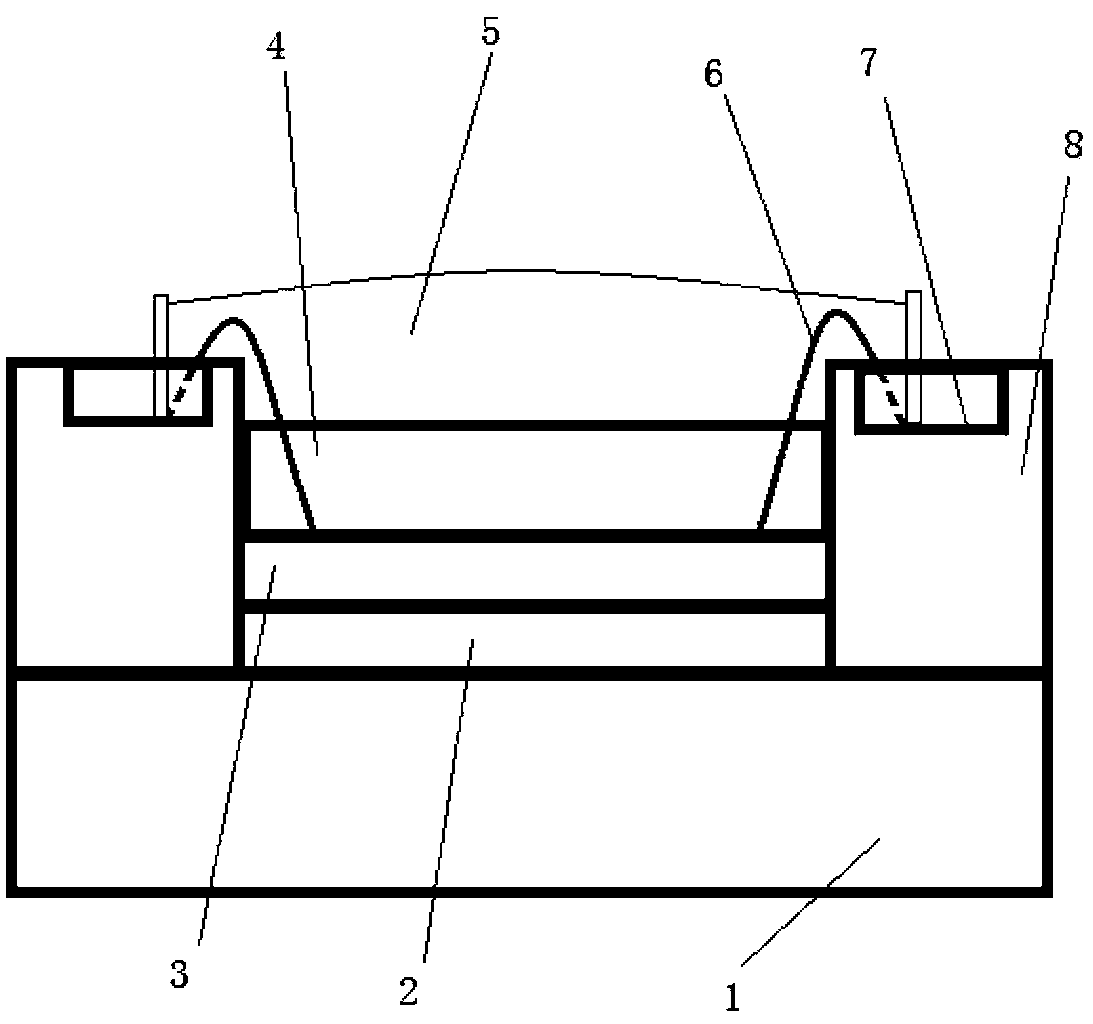

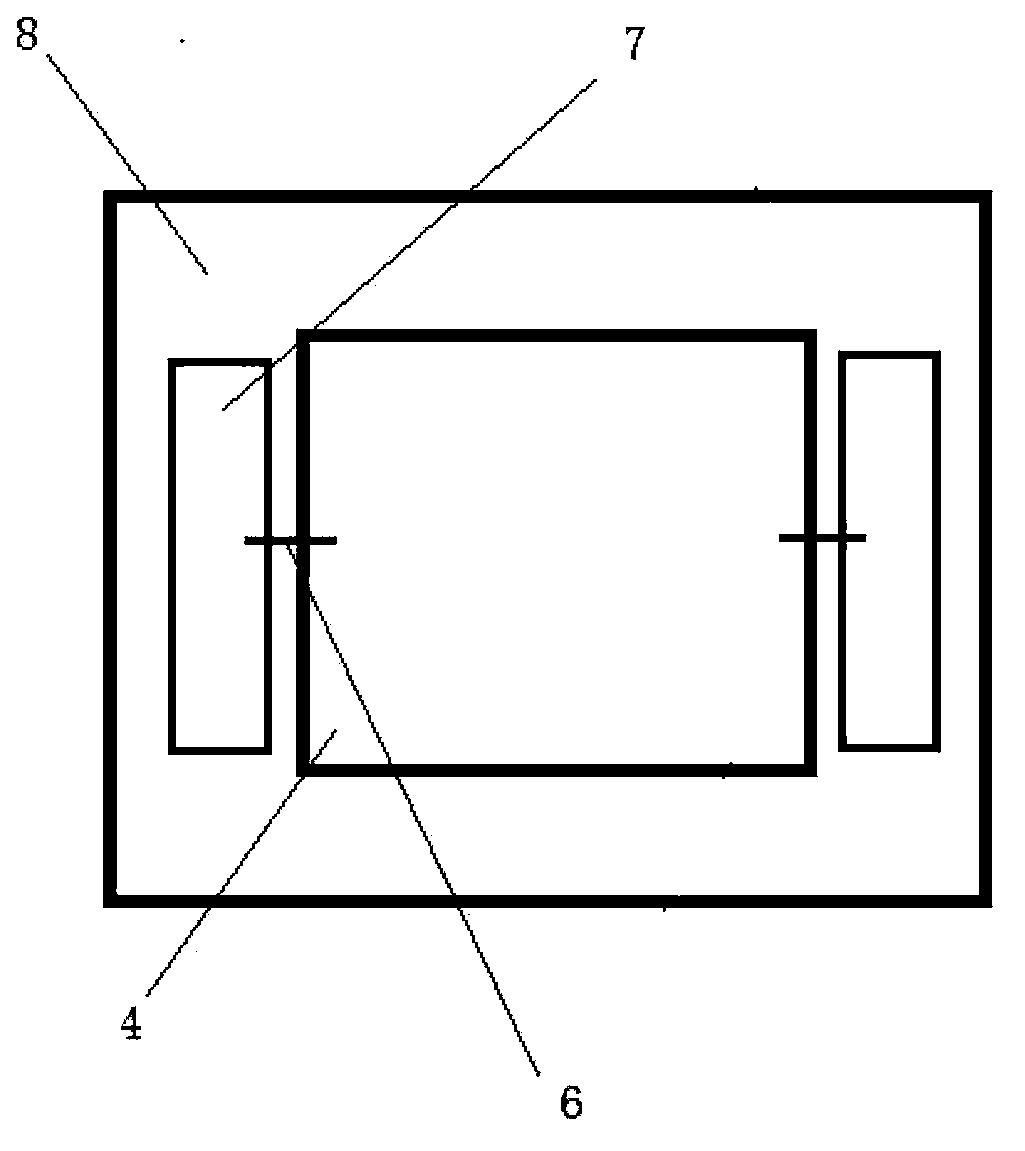

Light-emitting diode (LED) packaged with AlSiC composite substrate

The invention discloses an LED packaged with an AlSiC composite substrate. The LED comprises the AlSiC composite cooling substrate, an LED light source module, gold threads and an alumina ceramic frame, wherein the surface of the AlSiC composite cooling substrate is plated with a copper film and a silver film sequentially; the LED light source module is packaged on the AlSiC composite cooling substrate; the alumina ceramic frame is arranged on the outer side of the LED light source module and adheres to the LED light source module; two copper-film electrodes are plated on the alumina ceramic frame and connected with a positive pole and a negative pole of the LED light source module through the gold threads respectively. According to the LED, thermal expansion coefficients of the AlSiC composite substrate and an LED chip material are matched, so that an LED chip which is packaged on the substrate is not prone to falling, and the service life of the LED is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

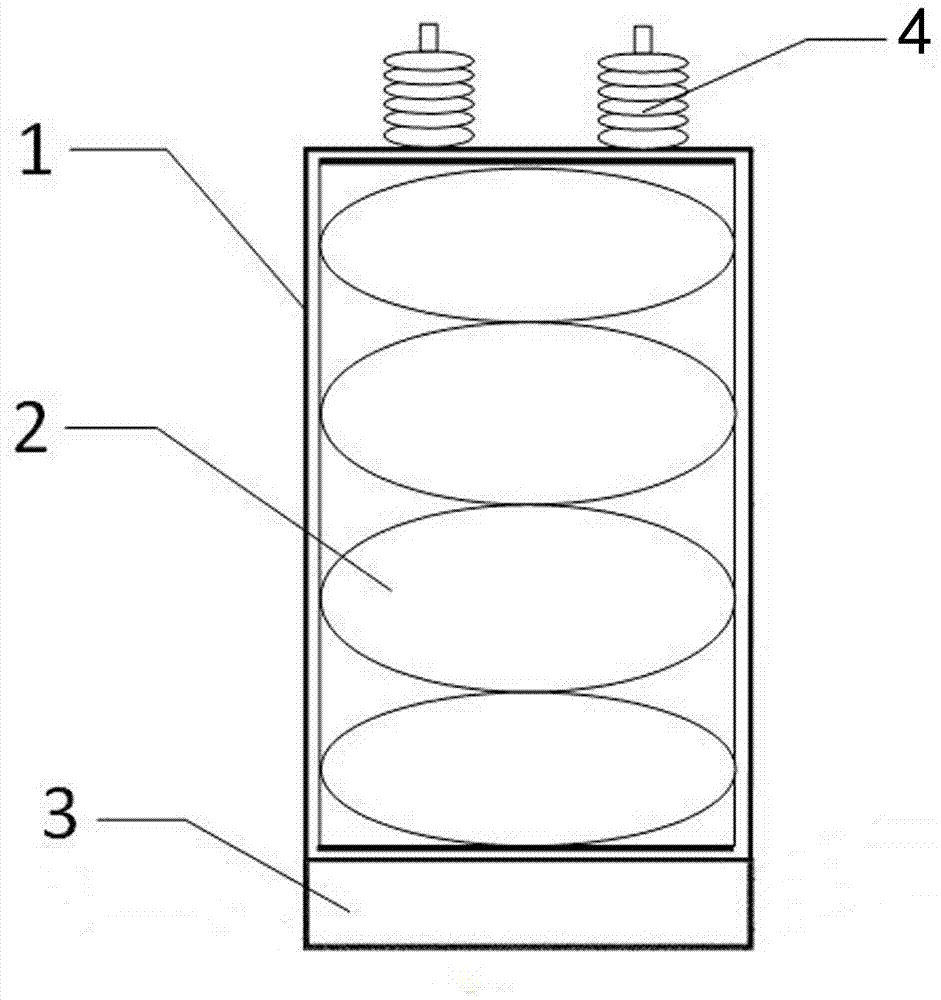

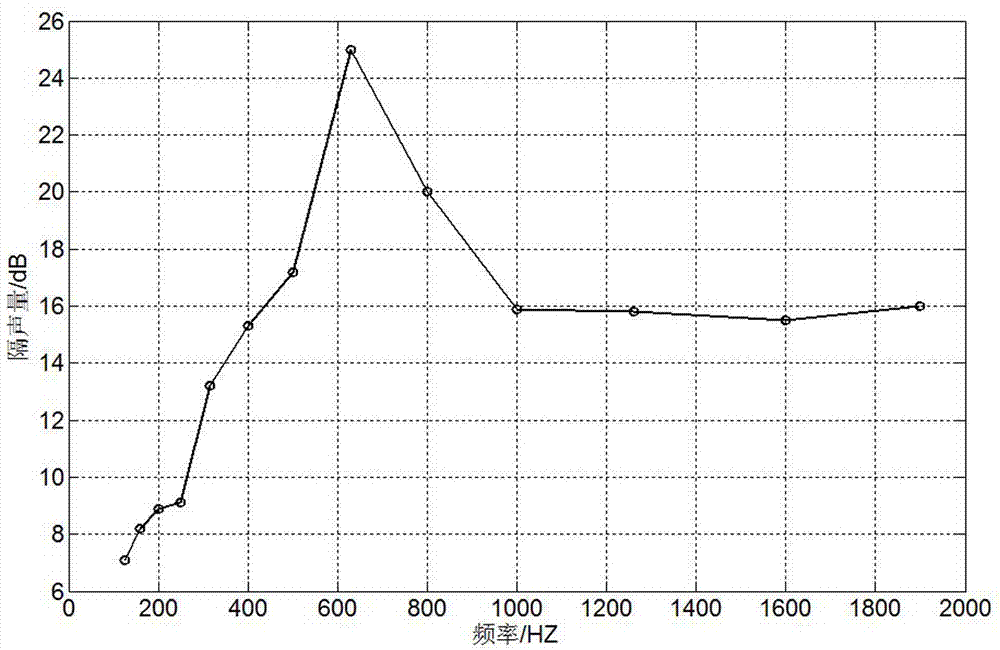

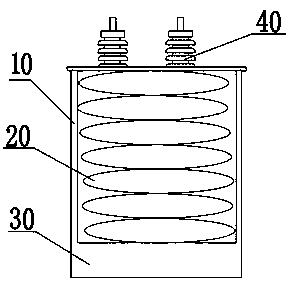

Low-noise power capacitor using damping steel plates

InactiveCN106910625ALow densityHigh specific strengthFixed capacitor housing/encapsulationLow noiseEngineering

The invention discloses a low-noise power capacitor using damping steel plates. The low-noise power capacitor comprises a capacitor shell, a core, a casing, and a sound insulation cavity. The casing is arranged on the top of the capacitor shell. The core is arranged inside the capacitor shell. The sound insulation cavity is arranged at the bottom of the capacitor shell. The sound insulation cavity is a closed cavity structure composed of inner and outer steel plates. A damping material is arranged between the outer steel plate and the inner steel plate to form a three-layer closed cavity structure. By making use of low density, sound insulation, noise reduction, vibration absorption, high strength, high specific rigidity and other advantages of the damping steel plates, vibration at the bottom of the power capacitor can be reduced. The closed cavity formed by welding the damping steel plates is used to insulate sound in the main contribution frequency band of noise, so that vibration at the bottom of the power capacitor is reduced, and actual engineering requirements are met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Airtight oil tank

ActiveCN108146232AImprove purification effectLarge specific surface areaPower plant fuel tanksUnderstructuresThermal conductivityCarbon nanotube

The invention discloses an airtight oil tank and belongs to the technical field of metal materials. The airtight oil tank comprises an oil tank body and a covering film on the surface of the oil tankbody. The oil tank body is composed of an aluminum alloy comprising the following components of, by mass, 0.2%-0.3% of Si, 0.05%-0.15% of Mn, 0.1%-0.3% of Cr, 0.2%-0.4% of Ni, 0.1%-0.3% of Mo, 0.05%-0.1% of Ti, 0.1%-0.5% of C and the balance Al and impurities. The Si element, the Ti element and the C element are added in the form of SiC and TiC so that the impurity content can be decreased effectively. The covering film on the surface of the oil tank body is made of carbon nanotubes or C60. The isomer of graphite has both of the inertia of the C element and the active property of a nano-scalematerial and is easily combined with the aluminum alloy, so that the specific strength, specific stiffness and the effects of low expansion, high thermal conductivity and the like of the aluminum alloy are improved; and through cooperation of a developed novel sand core, the situation that the sand core is easy to remove after integrated forming of the oil tank is facilitated.

Owner:SAIKESI HYDRAULIC TECH CO LTD

A kind of nano silicon carbide particle reinforced aluminum matrix composite material and preparation method thereof

The invention relates to the technical field of particle-reinforced aluminum-based composite materials, and discloses a nano-silicon carbide particle-reinforced aluminum-based composite material and a preparation method thereof. The composite material is composed of nano-silicon carbide particles with a volume fraction of 6-16% uniformly distributed in an aluminum alloy with a volume fraction of 84-94%. The preparation method is firstly through batching, ball milling, preforming and hot pressing Prepare 1-5% nano-silicon carbide particle-reinforced aluminum-based composite material, then vacuum concentrate and evaporate part of the aluminum alloy matrix, and finally undergo solid solution and aging treatment to obtain the reinforced aluminum-based composite material with nano-silicon carbide particle content of the present invention. Material. Experimental data proves that the reinforced aluminum matrix composite material with high nano-silicon carbide particle content prepared by the present invention not only has high thermal conductivity, electrical conductivity, specific modulus, wear resistance and other functional properties due to the high content of nano-silicon carbide particles, but also takes into account the strength and plastic toughness.

Owner:HENAN UNIV OF SCI & TECH

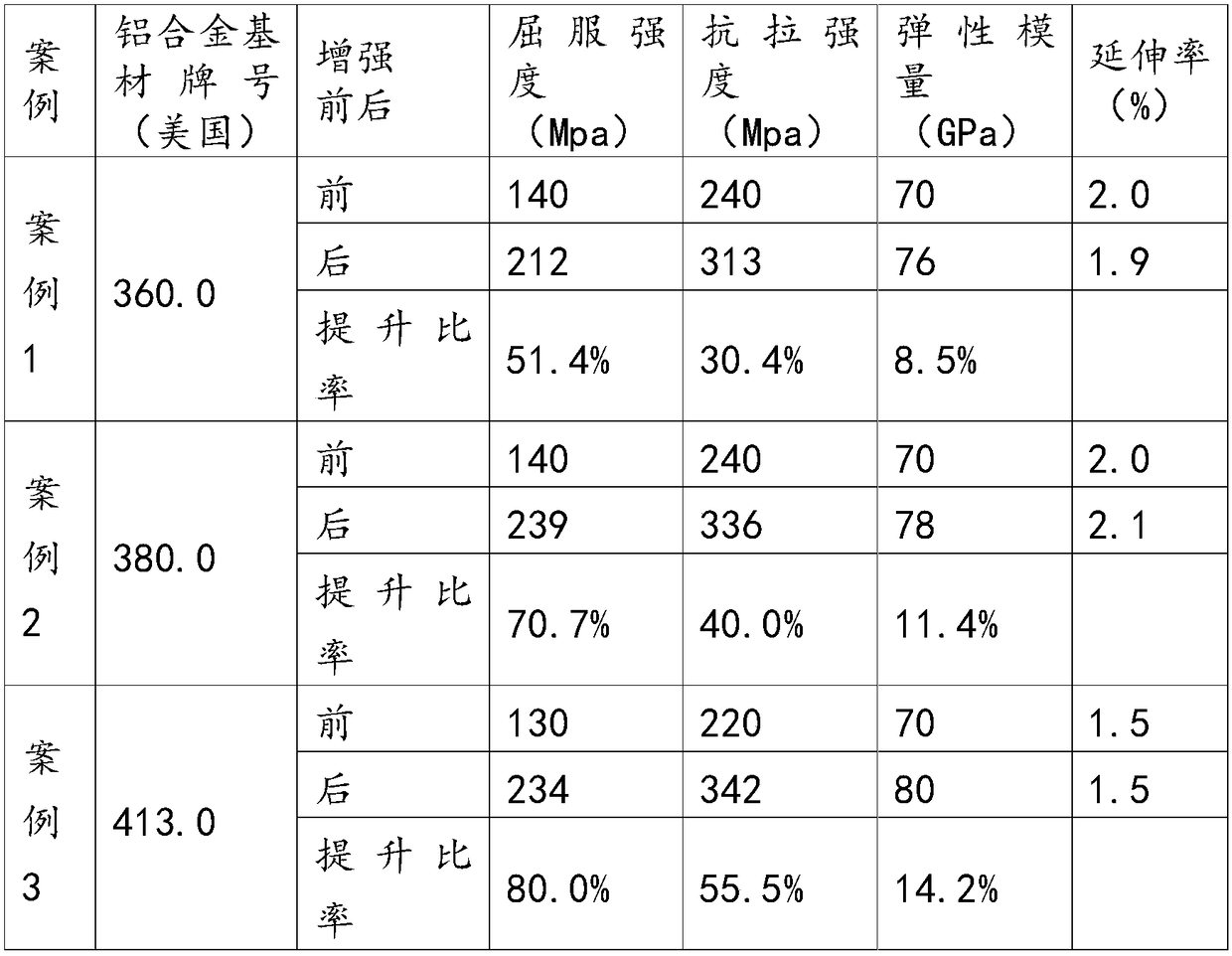

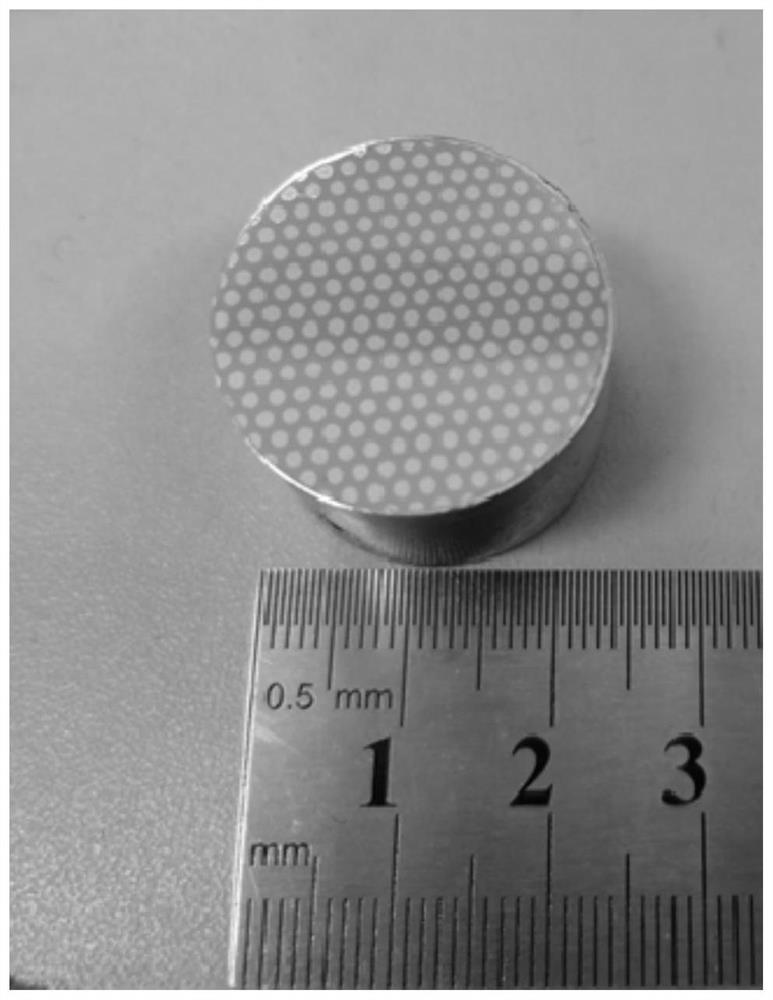

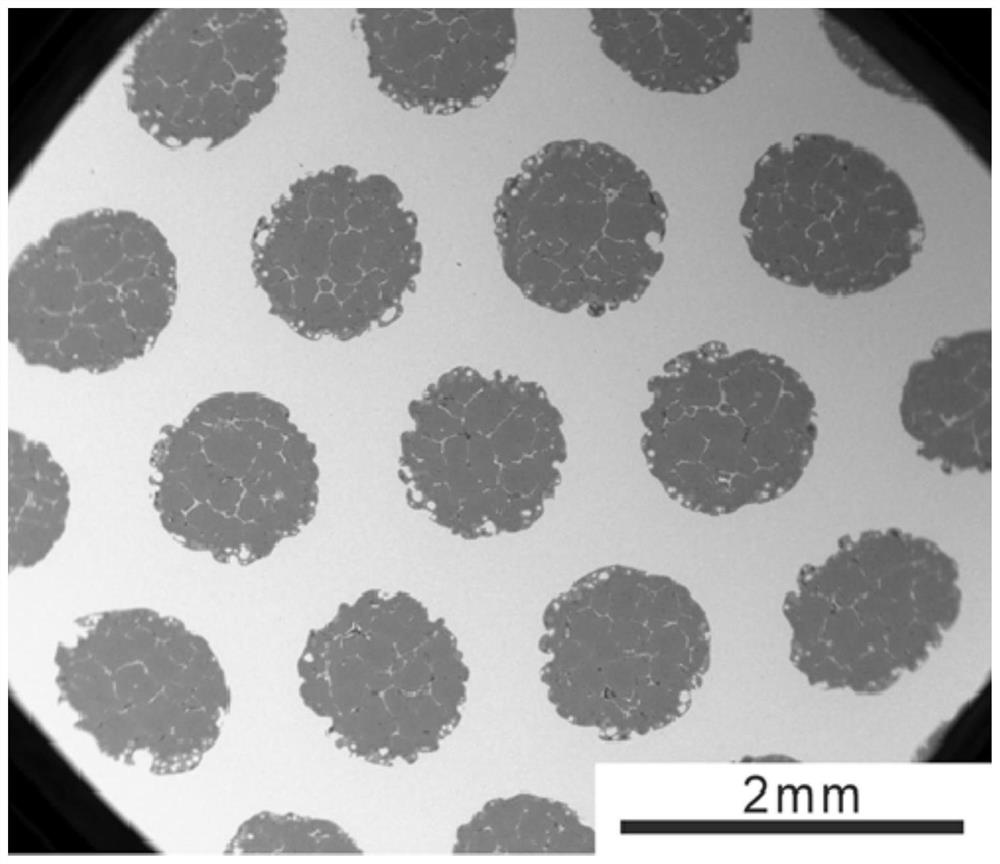

Titanium alloy dot matrix reinforced aluminum matrix composite and preparation method thereof

ActiveCN114807683AHigh strengthIncrease stiffnessAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingAluminium matrix

The invention discloses a titanium alloy lattice structure reinforced aluminum-based composite material and a preparation method thereof. The titanium alloy lattice structure reinforced aluminum matrix composite comprises a Ti-6Al-4V lattice reinforcement body and an aluminum matrix, and the Ti-6Al-4V lattice reinforcement body is of a two-dimensional circular or two-dimensional honeycomb structure. According to the method, a three-dimensional model of a lattice structure of a Ti-6Al-4V lattice reinforcement is designed, and Ti-6Al-4V metal powder is formed through selective laser melting; the method comprises the following steps: heating an aluminum matrix and a Ti-6Al-4V dot matrix reinforcement body to 700-850 DEG C in a vacuum environment, and infiltrating the aluminum matrix into a dot matrix structure of the Ti-6Al-4V dot matrix reinforcement body by utilizing inert gas pressurization; and cooling to obtain the titanium alloy lattice structure reinforced aluminum matrix composite material. The composite material prepared by the invention is accurate and controllable in structure, so that the performance can be effectively regulated and controlled, and the composite material has the excellent characteristics of high specific strength and high elastic modulus.

Owner:SOUTH CHINA UNIV OF TECH

Low-noise power capacitor based on damping steel plate

InactiveCN109585165AReduce noiseReduce vibrationFixed capacitor housing/encapsulationSound producing devicesLow noiseEngineering

The invention discloses a low-noise power capacitor based on a damping steel plate. The low-noise power capacitor comprises a capacitor shell, a capacitor core, a sound insulation cavity and a terminal sheath, wherein the capacitor core is arranged inside the capacitor shell; the sound insulation cavity is of a closed cavity structure formed by combining an inner layer steel plate and an outer layer steel plate; the sound insulation cavity is arranged in the bottom of the capacitor shell; the closed cavity structure is fixed to the bottom of the capacitor through welding; a damping material isarranged between the outer layer steel plate and the inner layer steel plate, and a three-layer closed cavity structure is formed; the terminal sheath is arranged at the top of the capacitor shell. According to the low-noise power capacitor, the damping steel plate which has the advantages of low density, sound insulation and noise reduction, vibration absorption, high specific strength, high specific rigidity and the like are utilized, so that the vibration of the bottom of the power capacitor can be reduced; and the closed cavity formed by welding the damping steel plate is used for carrying out sound insulation on the main noise contribution frequency band, so that the noise of the bottom of the power capacitor is reduced, and the practical requirements of engineering are met.

Owner:毛运蓉

Anti-collision buffer energy-absorbing device for side of truck

The invention discloses an anti-collision buffer energy-absorbing device for a side of a truck. The anti-collision buffer energy-absorbing device comprises a wave type energy-absorbing retainer plate, two energy-absorbing supporting filling barrels, tapered prism energy-absorbing supports and fixing plates. The wave type energy-absorbing retainer plate is far away from the outer side of a truck frame. The energy-absorbing supporting filling barrels act functions of fixing and connection in the middle and can absorb energy. The whole device is connected to the truck frame through the tapered prism energy-absorbing supports. The energy-absorbing supporting filling barrels are connected with the tapered prism energy-absorbing supports through the fixing plates. With the anti-collision buffer energy-absorbing device, when a small vehicle crashes into the side of the truck, more huge energy from the crash can be absorbed, initial peak stress of the crash of the small vehicle is decreased, the small vehicle is prevented from crashing into the bottom of the truck, and crash injuries of passengers in the small vehicle are reduced.

Owner:HUAQIAO UNIVERSITY

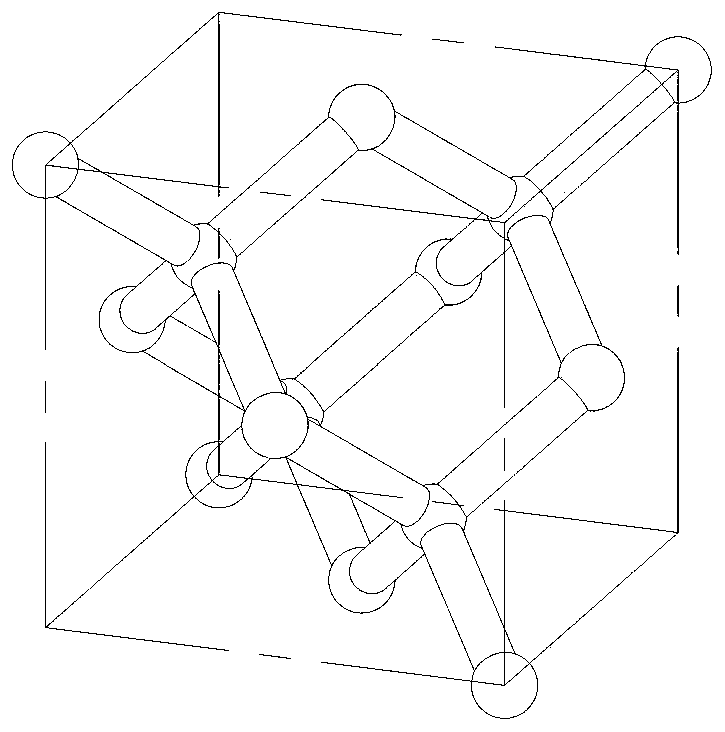

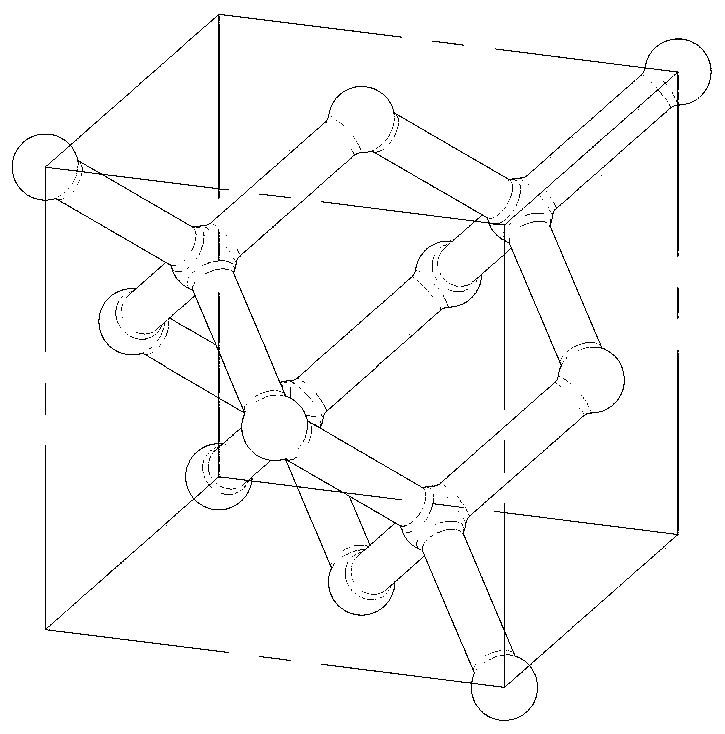

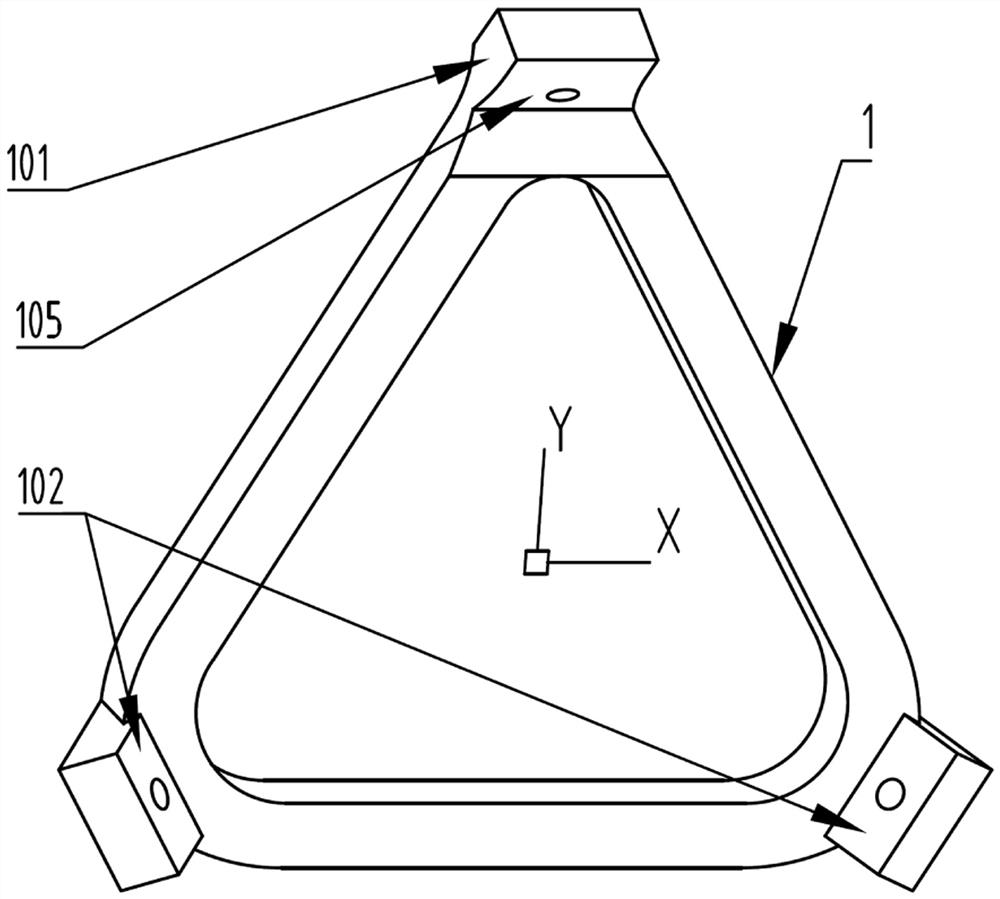

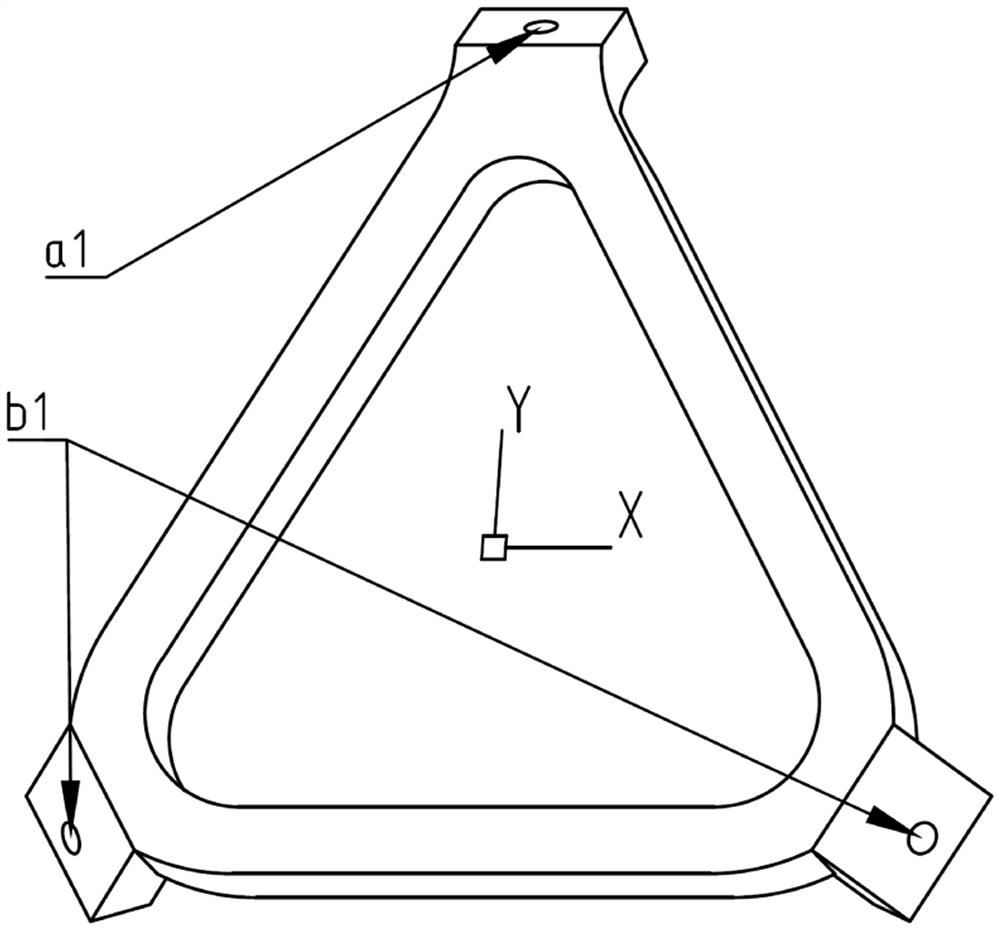

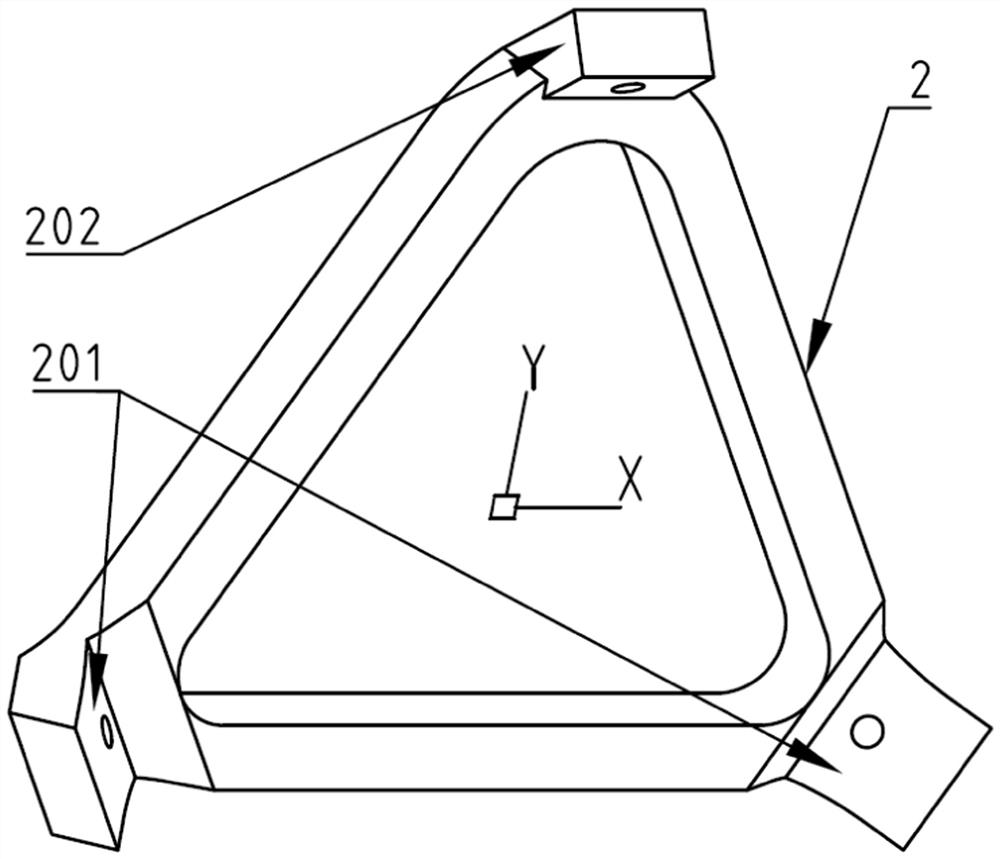

Assembled periodic octahedral truss lattice structure

ActiveCN114439873AImprove production efficiencyImproved Process LimitsElongated constructional elementsSpringsOctahedronEngineering

The invention discloses an assembled periodic octahedral truss lattice structure which is formed by connecting a plurality of octahedral truss lattice unit cells capable of being assembled, and each octahedral truss lattice unit cell capable of being assembled is composed of two I-type connecting blocks and two II-type connecting blocks. The four connecting blocks are mechanically connected through the bolt sets to form an octahedron, the six matching hole sets of the octahedron structure are internally connected and fixed through the short bolt sets to form octahedron truss lattice unit cells, and the different octahedron truss lattice unit cells are connected through the long bolt sets to form the periodic octahedron truss lattice structure. The lattice unit cell is decomposed into four parts, the octahedral truss lattice unit cell and the periodic octahedral truss lattice structure are assembled in a mechanical connection mode, limitation of machining equipment and technology can be avoided, and preparation of the periodic octahedral truss lattice structure controllable in size and rich in configuration is achieved on the premise of low cost.

Owner:CHINA THREE GORGES UNIV

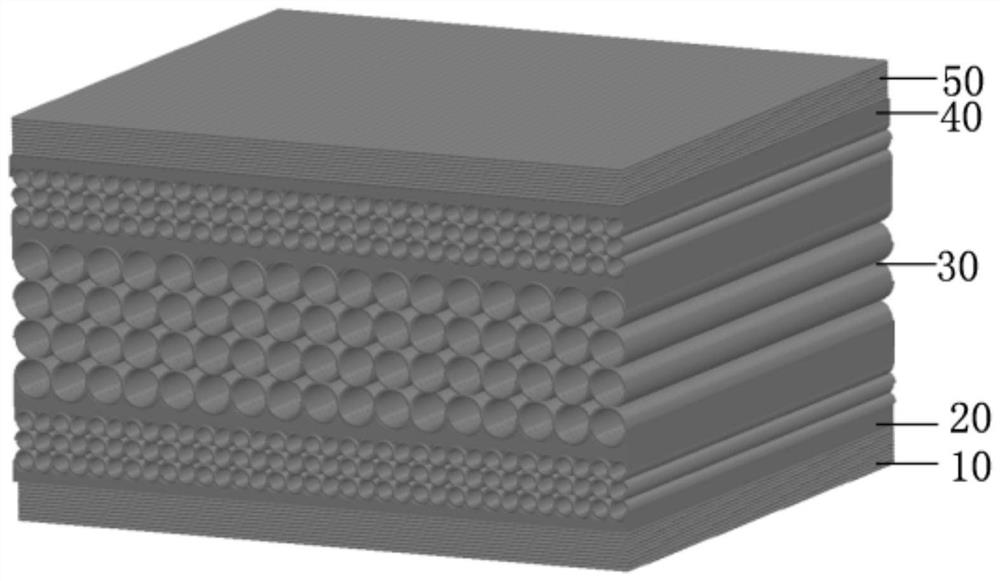

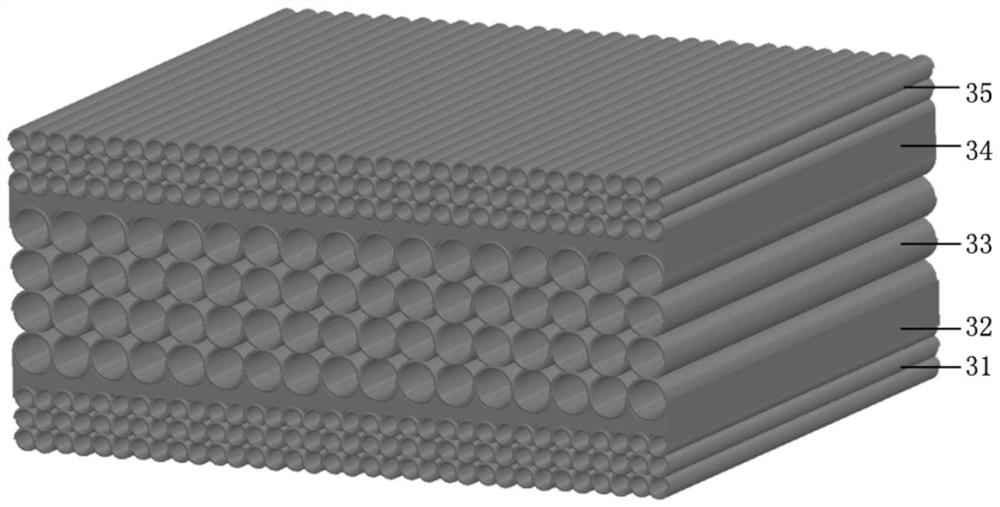

Light anti-bending and anti-torsion bionic composite material and preparation method thereof

ActiveCN112721341AImprove bending and torsional performanceEnhanced interlayer anti-peeling abilitySynthetic resin layered productsLaminationFiberCeramic materials

The invention discloses a light anti-bending and anti-torsion bionic composite material and a preparation method thereof. The composite material comprises a bottom layer, a lower partition plate layer, a hollow structure middle layer, an upper partition plate layer and an outer layer which are sequentially arranged in a stacked mode from bottom to top; the hollow structure middle layer comprises a first-stage dense hole structure, a loose hole upper-layer structure, a first-stage loose hole structure, a loose hole lower-layer structure and a second-stage dense hole structure which are sequentially stacked from bottom to top; and the first-level compact pore structure, the first-level loose pore structure and the second-level compact pore structure are each composed of a woven fiber resin layer, and each woven fiber resin layer is formed by alternately winding weft-wise fibers and warp-wise fibers on a core film. The middle layer of the hollow structure is arranged in the mode that the outside is dense and the inside is sparse, the weight of the material can be reduced, the specific rigidity of the material can be improved, when the material is bent, the upper surface of the middle layer of the hollow structure bears tensile stress, the lower surface of the middle layer of the hollow structure bears tensile pressure, and the bending resistance and toughness of the material are improved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com