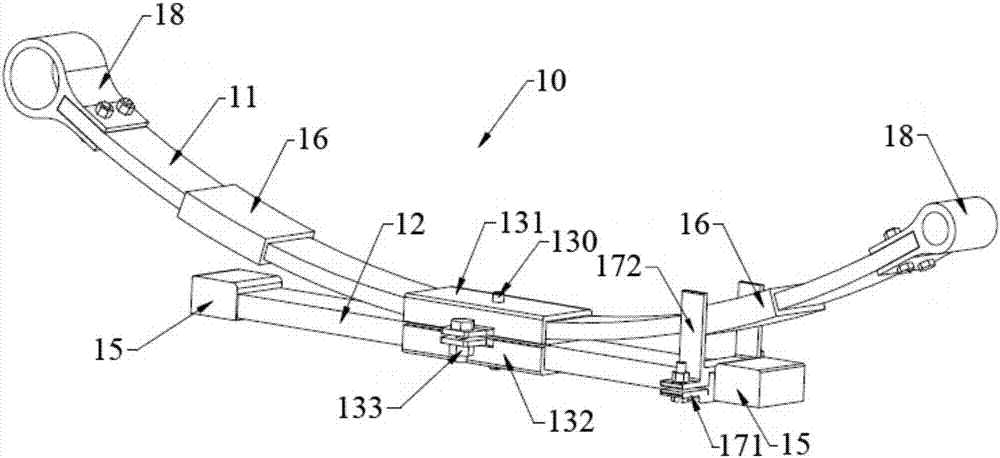

Plate-type spring assembly and vehicle hanging device

A technology of leaf springs and suspension devices, which is applied in the direction of springs, vehicle springs, elastic suspensions, etc., can solve the problems that leaf springs cannot meet the stiffness and changes, and achieve the effects of improving specific stiffness, prolonging service life, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

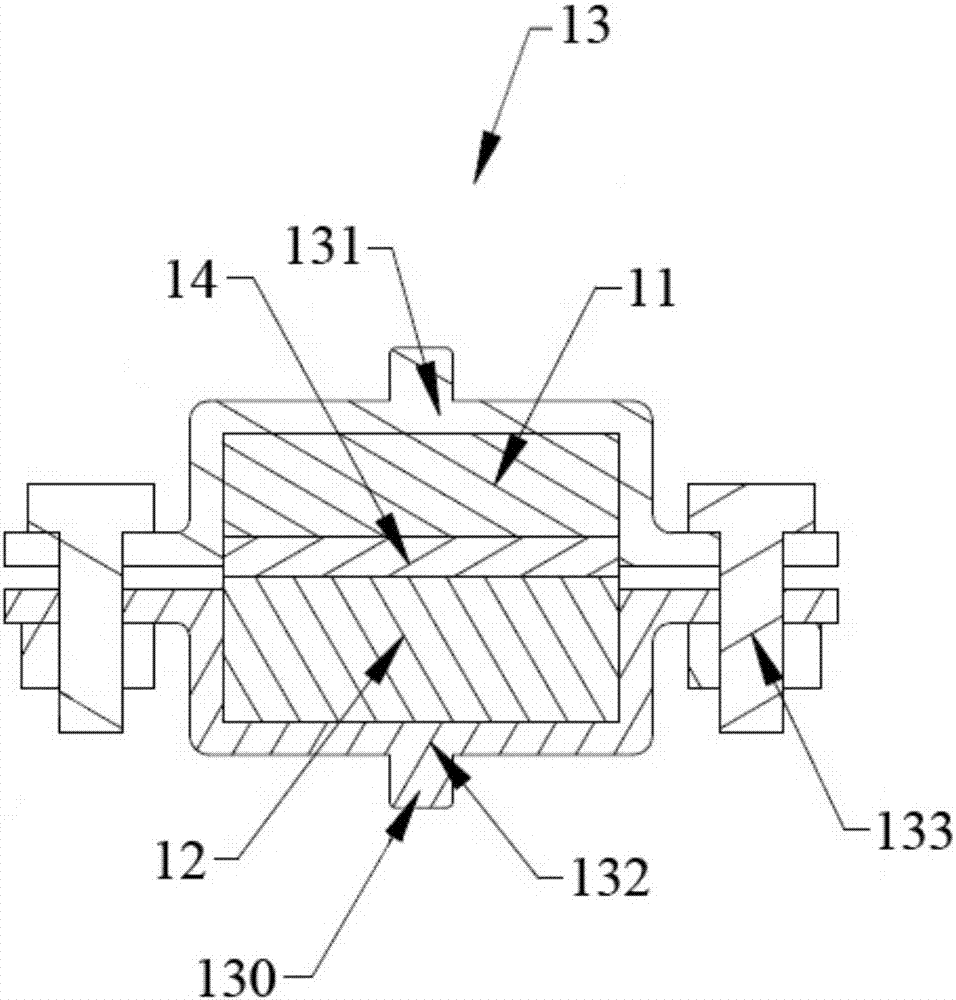

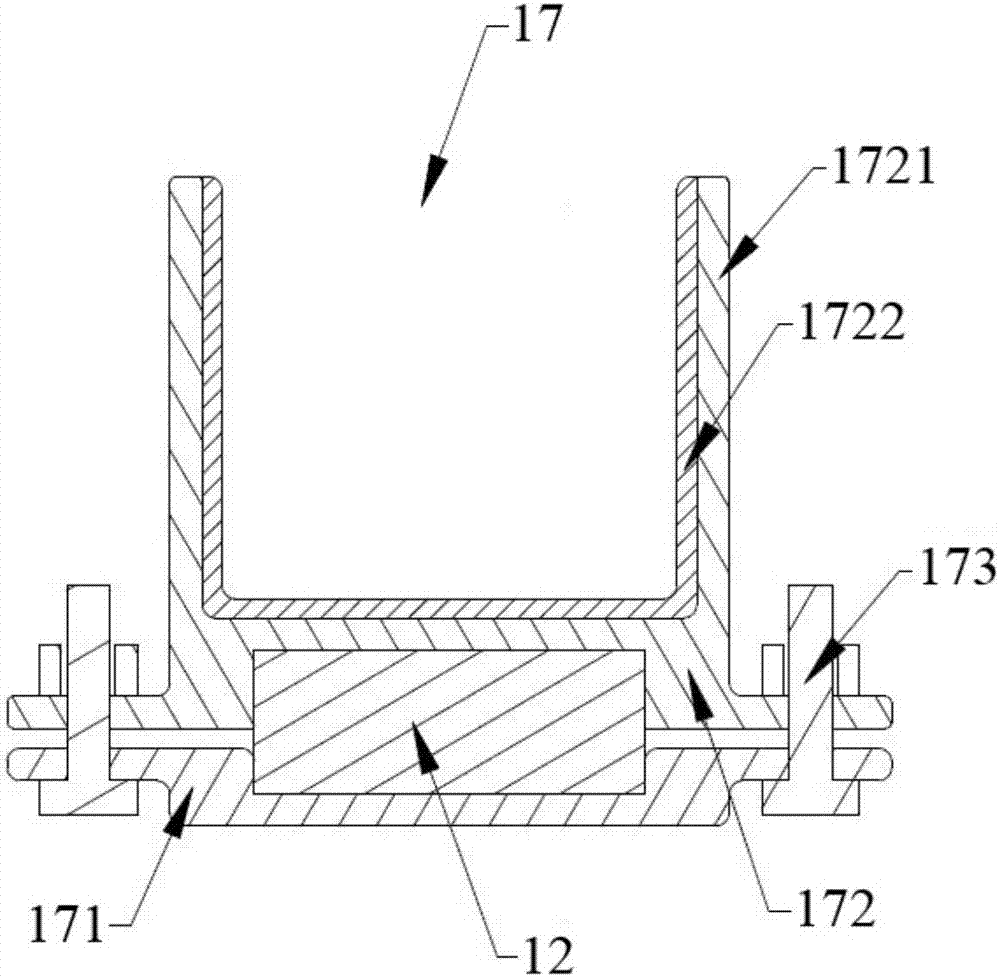

[0031] Further, see figure 2, as a specific embodiment of the leaf spring assembly provided by the present invention, the connecting mechanism 13 includes a first connecting piece 131, a second connecting piece 132 and a first fastener 133, wherein the first connecting piece 131 is arranged on the first The top side of the leaf spring 11 ; the second connecting piece 132 is disposed on the bottom side of the second leaf spring 12 ; and the first connecting piece 131 is fixedly connected to the second connecting piece 132 through the first fastener 133 . That is, the connecting mechanism 13 clamps the first leaf spring 11 and the second leaf spring 12 between the first connecting piece 131 and the second connecting piece 132 through the first fastener 133 . Here, the first fastener 133 can be a combination of bolts and nuts, or a combination of buckles and slots (not shown), of course, according to actual conditions and needs, in other embodiments of the present invention , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com