Core sandwich structure of corrugated channel and preparation method thereof

A sandwich structure and corrugation technology, applied in the field of composite structural materials, can solve the problems of free flow obstruction of core fluid, inability to achieve active heat dissipation, buckling failure of core structure, etc., and achieve excellent thermal conductivity, high specific stiffness, and improved specific strength. and the effect of specific stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

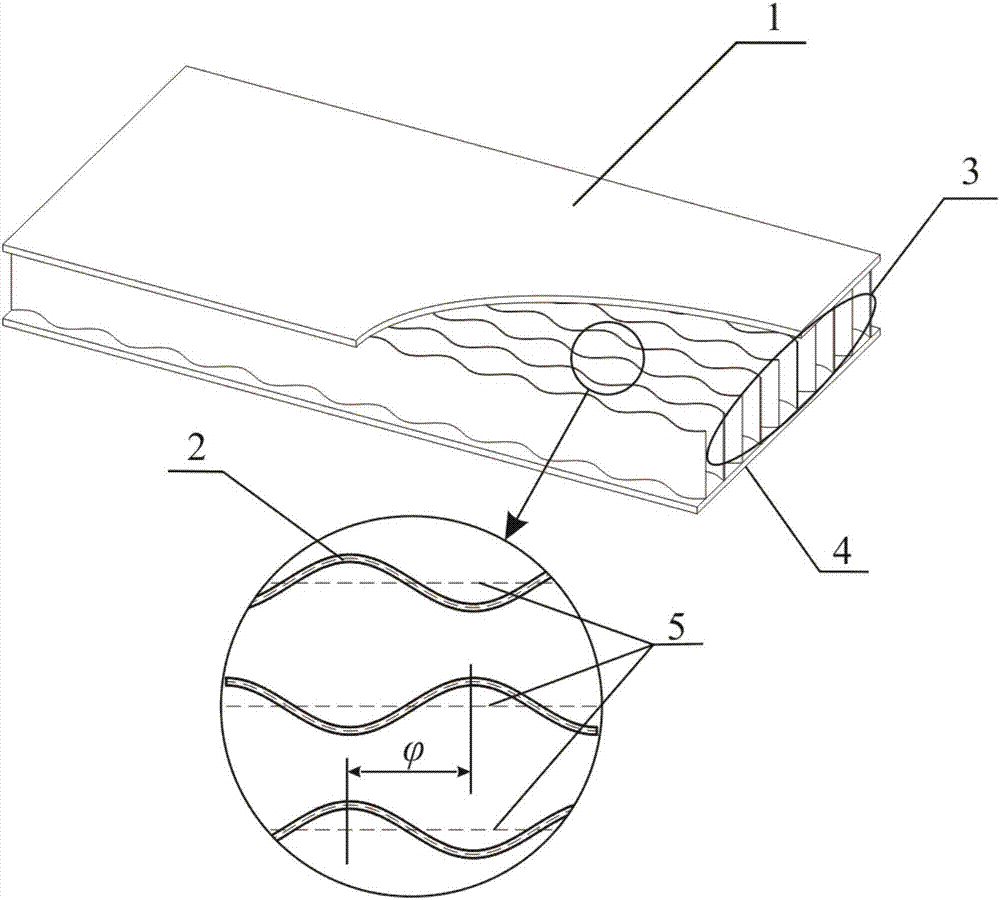

[0044] A method for preparing a corrugated channel core sandwich structure of the present invention comprises the following steps:

[0045] S1. Using stamping or rolling technology to make the flat sheet into a corrugated sheet;

[0046] S2, cutting the corrugated board into corrugated strips;

[0047] S3, cutting the flattened plate into an upper panel and a lower panel;

[0048] S4, after removing the oil and rust on the upper panel, the lower panel and the corrugated lath described in steps S2 and S3, put it into the drying machine to dry for subsequent use;

[0049] S5. Assemble the corrugated slats parallel to each other to form a corrugated channel core, and fix them for later use;

[0050] The phase difference of the corrugated slats 0° to 180°, and the equivalent neutral plane spacing of the corrugated slats is 10 to 100 times the thickness of the corrugated slats.

[0051] S6. Connect the corrugated channel core body described in step S5 with the upper panel and ...

Embodiment 1

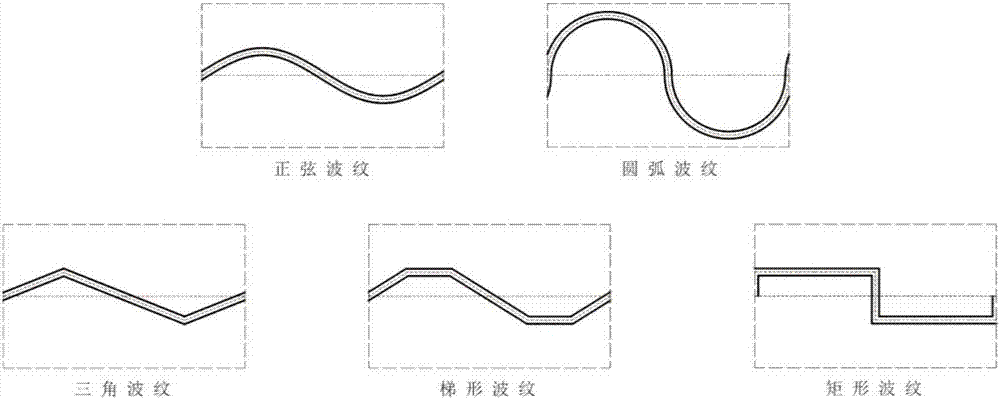

[0054] 1) First, the flattened titanium alloy plate is made into a sinusoidal corrugated plate by stamping technology;

[0055] 2) Then the corrugated board is cut into corrugated strips 2 as required by wire cutting technology;

[0056] 3) cutting the flattened titanium alloy plate into upper panel 1 and lower panel 4 of equal thickness by wire cutting technology;

[0057] 4) Clean the upper panel 1, the lower panel 4 and the corrugated slats 2 in an ultrasonic cleaning machine, and dry them in an oven at 40-50°C for later use;

[0058] 5) Assemble the corrugated slats 2 in parallel with each other according to the spacing of 10 times the thickness of the web plate and the phase difference of 90° to form the corrugated channel core 3, and fix it with tooling for standby;

[0059] 6) Evenly apply commercially available Ti-based brazing paste to the connecting position between the corrugated channel core 3 and the upper and lower panels 4, dry it in an oven at 80°C, then put it ...

Embodiment 2

[0062] 1) First, the flattened 1060 pure aluminum plate is made into a triangular corrugated plate by rolling technology;

[0063] 2) Then the corrugated board is cut into corrugated strips 2 as required by wire cutting technology;

[0064] 3) Cutting the flattened 1060 pure aluminum plate into upper panel 1 and lower panel 4 of equal thickness by wire cutting technology;

[0065] 4) Clean the upper panel 1, the lower panel 4 and the corrugated slats 2 with a metal cleaning agent to remove oil and rust, and put them in an oven at 40-50°C to dry for later use;

[0066] 5) Assemble the corrugated slats 2 in parallel with each other at a spacing of 20 times the thickness of the web plate and a phase difference of 180° to form a corrugated channel core 3, and fix it with tooling for standby;

[0067] 6) Evenly coat commercially available aluminum brazing paste on the connection position between the corrugated channel core 3 and the upper and lower panels 4, dry it in an oven at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com