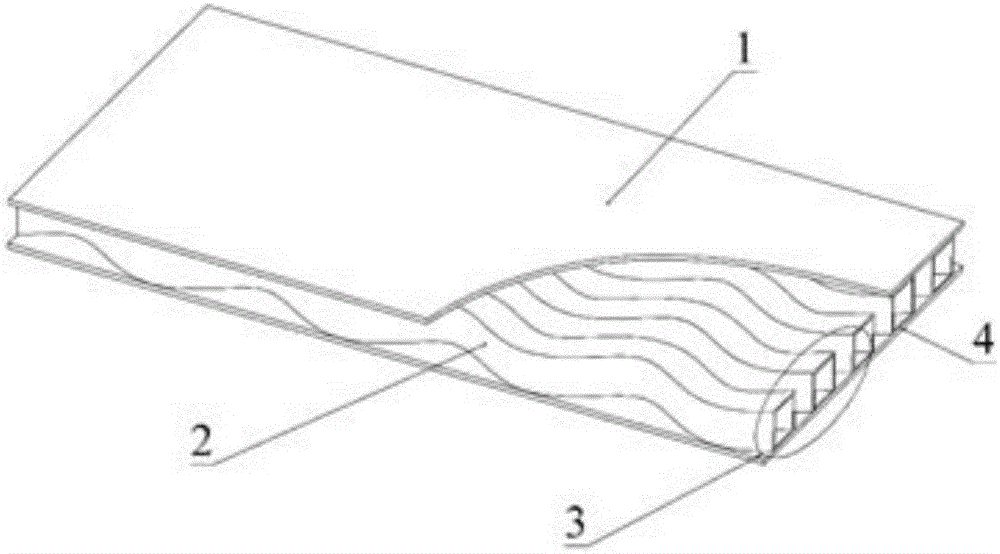

Sandwich structure of corrugated square tube core body and preparation method thereof

A sandwich structure and corrugated technology, applied in the corrugated square tube core sandwich structure and its preparation, in the field of composite materials with multifunctional properties, can solve the problems of low load-bearing performance and energy absorption efficiency, and achieve easy operation and wide application prospects , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention also discloses a method for preparing a sandwich structure of a corrugated square tube core body, which includes the following steps:

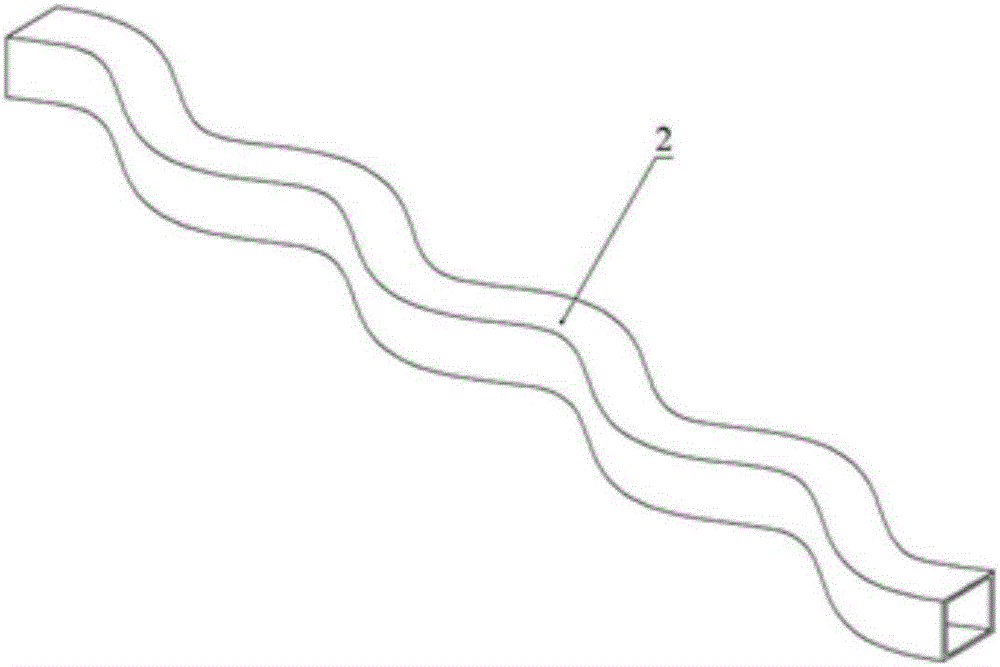

[0041] S1. Bending the rectangular tube according to the sinusoidal corrugation to make a corrugated square tube;

[0042] The section of the corrugated square tube is a square section or a rectangular section;

[0043] S2, cutting the flattened plate into an upper panel and a lower panel;

[0044] S3. Clean the upper panel, the lower panel and the corrugated square pipe, and put them into a dryer to dry for later use;

[0045] S4. Assembling a plurality of corrugated square tubes in parallel with each other into a corrugated square tube core body, and fixing them for later use;

[0046] The corrugated square tubes are assembled in parallel at 1 to 2 times the tube wall spacing to form a corrugated square tube core; the phase difference between adjacent corrugated square tubes is 0° to 180°;

[0047] S5, connecting the ...

Embodiment 1

[0050] 1) First use a pipe bender to make a 1060 aluminum alloy rectangular pipe into a sinusoidal corrugated square pipe according to the specified requirements;

[0051] 2) Cutting the flattened 1060 aluminum alloy plate into an upper panel and a lower panel by wire cutting technology;

[0052] 3) Clean the upper panel, lower panel and corrugated square pipe to remove oil and rust, and put them in the dryer to dry for later use;

[0053] 4) Assemble the corrugated square tube parallel to each other according to 1 times the tube wall spacing and 90° phase difference to form a corrugated square tube core body, and fix it with tooling for standby;

[0054] 5) Dry the commercially available aluminum brazing paste evenly at the junction of the corrugated square tube core body and the upper and lower panels in an oven at 40-50°C, then put it into a high-temperature brazing furnace for welding, and slowly cool to Take out the oven at room temperature to obtain the corrugated squar...

Embodiment 2

[0057] 1) First use the pipe bender to make the TC4 titanium alloy rectangular pipe into a semicircular corrugated square pipe according to the specified requirements;

[0058]2) The flattened TC4 titanium alloy plate is cut into an upper panel and a lower panel by wire cutting technology;

[0059] 3) Clean the upper panel, lower panel and corrugated square pipe to remove oil and rust, and put them in the dryer to dry for later use;

[0060] 4) Assemble the corrugated square tube parallel to each other according to 2 times the tube wall spacing and 180° phase difference to form a corrugated square tube core body, and fix it with tooling for standby;

[0061] 5) Apply Ag-based brazing paste evenly on the surface of the corrugated square tube core parallel to the upper panel and the lower panel, dry it in an oven at 80°C, then put it into a high-temperature brazing furnace for welding, and cool slowly after welding Take it out of the oven at room temperature to obtain a corruga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com