Composite soft magnetic material and preparation method thereof

A composite soft magnetic and mixture technology, applied in the fields of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of high production cost, complex process, low production efficiency, etc., and achieve high saturation magnetization and production process. Simple formula and high compression stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Spherical FeSi6.5wt% powder with a particle size of 30-100μm is used as a raw material, and 2wt% of low-melting glass powder is added as an insulating agent and an adhesive to mix evenly. The melting point of the glass powder is 400°C and the average particle size is 5μm. An additional 0.5 wt% zinc stearate was added as a release agent, and the powder was molded into a ring-shaped powder core with an outer diameter of 27 mm, an inner diameter of 15 mm, and a height of about 8 mm under a pressure of 1200 MPa. The FeSi powder core is placed in a vacuum furnace, and the finished powder core material is obtained after heat treatment at 450° C. for 1 hour.

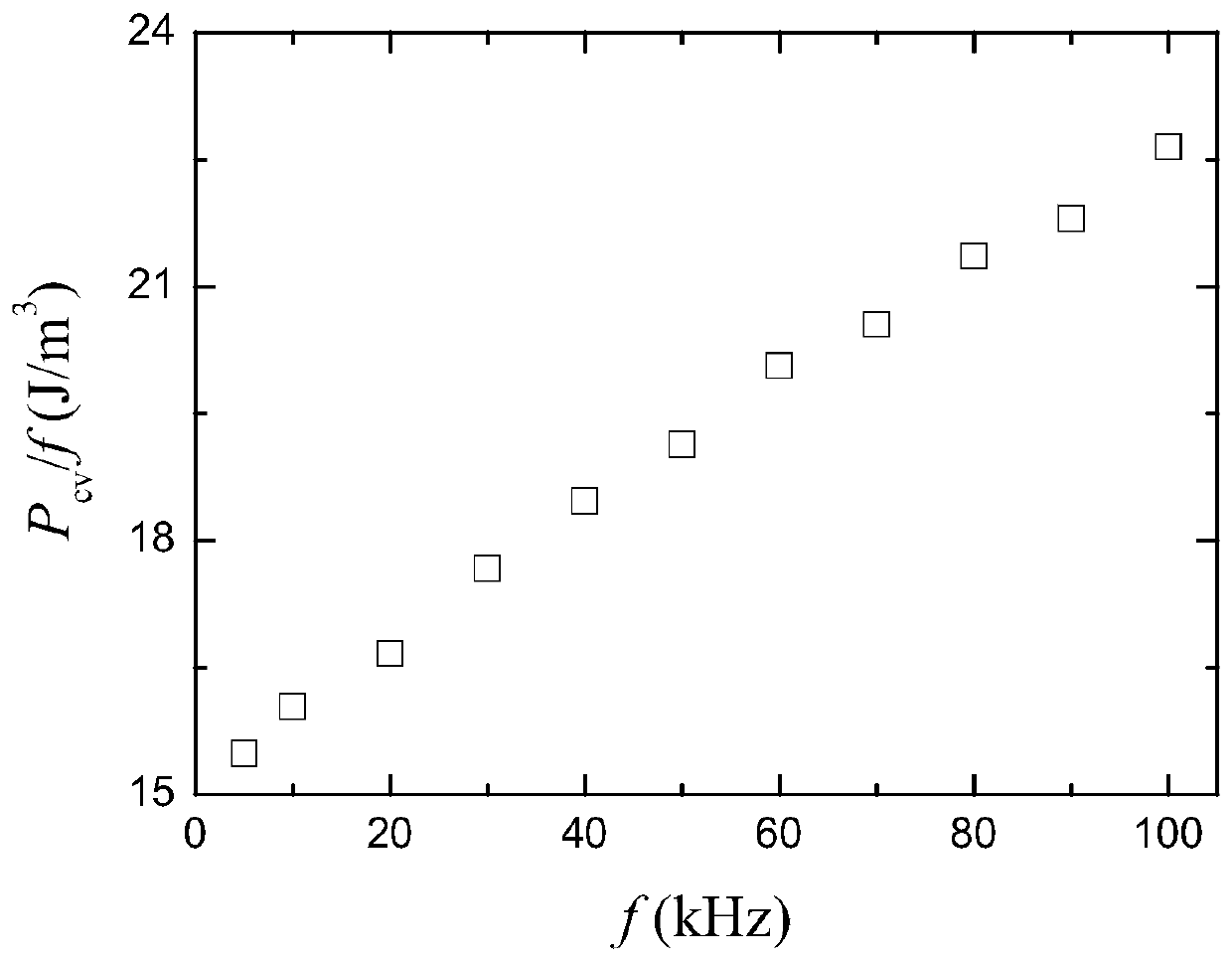

[0022] The magnetic measurement results show that the specific saturation magnetization of the material reaches 203emu / g, the initial permeability is 51, and the loss at 100kHz and 100mT is 2300kW / m 3 . figure 1 Shown is the relationship between power consumption and frequency in one cycle measured by the sample. It can...

Embodiment 2

[0024] Based on the commercial FeSiCr powder on the market, add 1wt% B 2 o 3 Mix well as insulating agent and adhesive. An additional 0.5 wt% zinc stearate was added as a release agent, and the powder was pressed into a ring-shaped powder core with a diameter of 20 mm, an inner diameter of 10 mm and a height of about 5 mm under a pressure of 500 MPa. The powder core is placed in a nitrogen-protected sintering furnace, and heat-treated at 500°C for 30 minutes to obtain a finished powder core material.

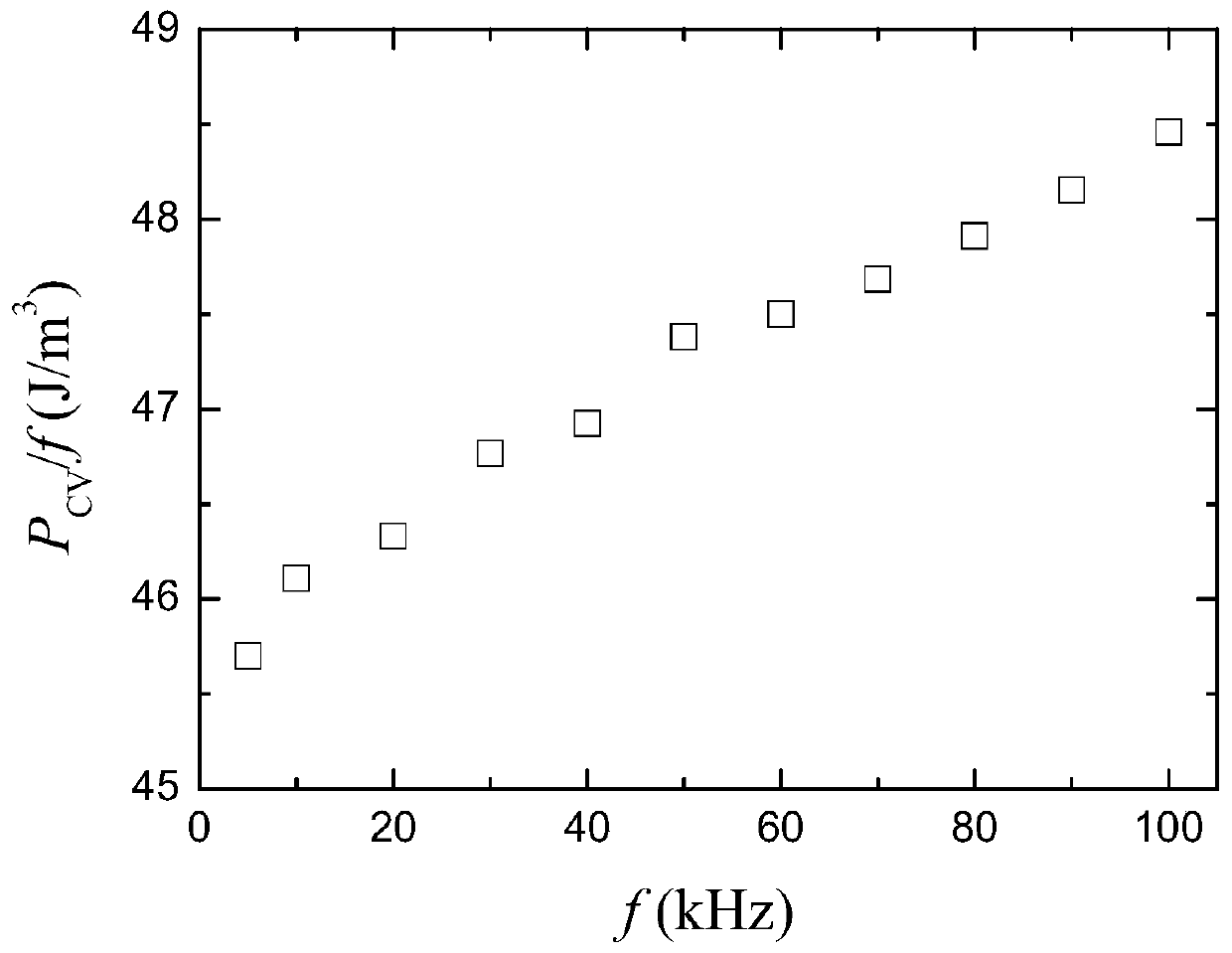

[0025] According to the magnetic test, the initial magnetic permeability of the powder core is 38, 100kHz, and the loss at 100mT is about 4800kW / m 3 . figure 2 The relationship between power consumption and frequency in one cycle measured by the sample is given. It can be seen from the figure that the lower slope shows that the FeSiCr powder core has relatively small eddy current loss, indicating that B 2 o 3 Played a good insulation effect. The total loss of powder core ...

Embodiment 3

[0027] Use the nanocrystalline powder of Antai Technology, add 3wt% B-Si-P-O glass powder as insulating agent and adhesive, and mix evenly. In addition, 0.5 wt% of zinc stearate was added as a release agent, and the mixed powder was pressed into a ring-shaped powder core with an outer diameter of 20 mm, an inner diameter of 10 mm, and a height of about 5 mm under a pressure of 700 MPa. Vacuum heat treatment at 600°C for 30 minutes. The nanocrystalline powder core material is obtained.

[0028] Magnetic measurements show that the magnetic permeability of the nanocrystalline powder core is 18, and the power consumption at 100kHz and 100mT is 2100kW / m 3 . The biggest advantage of nanocrystalline powder core is that it can be applied to MHz frequency band. However, due to the fine powder, there is a certain phenomenon of slag falling. Increasing the heat treatment temperature can improve the slag problem, but the magnetic properties will deteriorate rapidly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com