Patents

Literature

52results about How to "Reduce shape change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

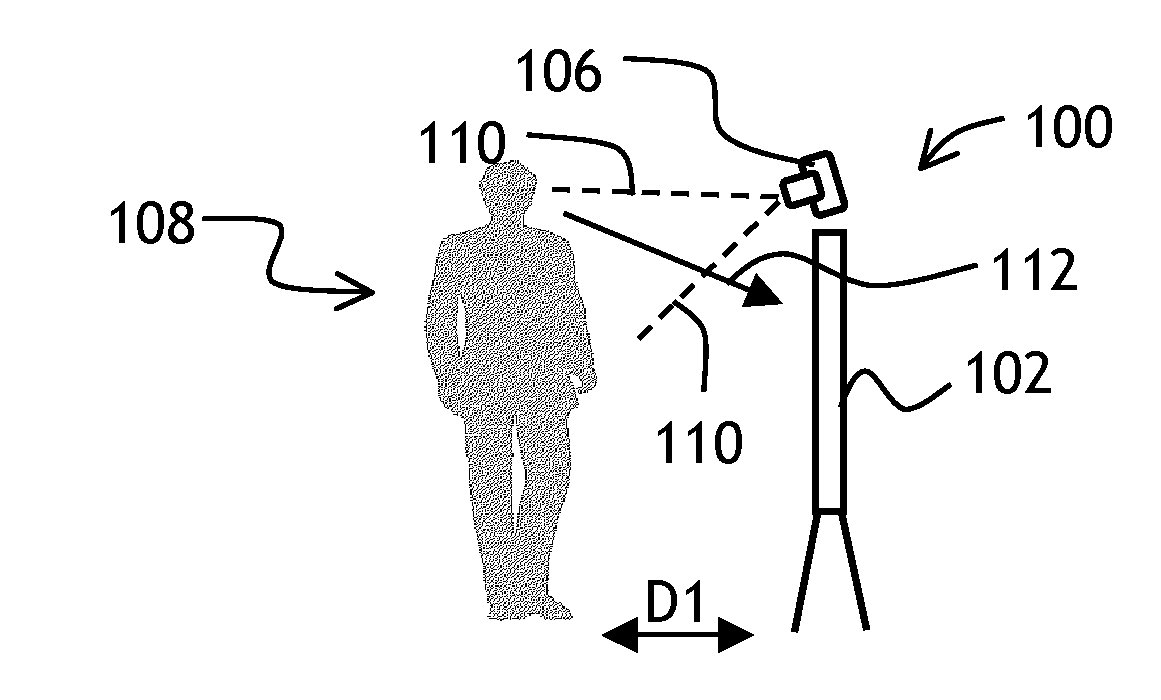

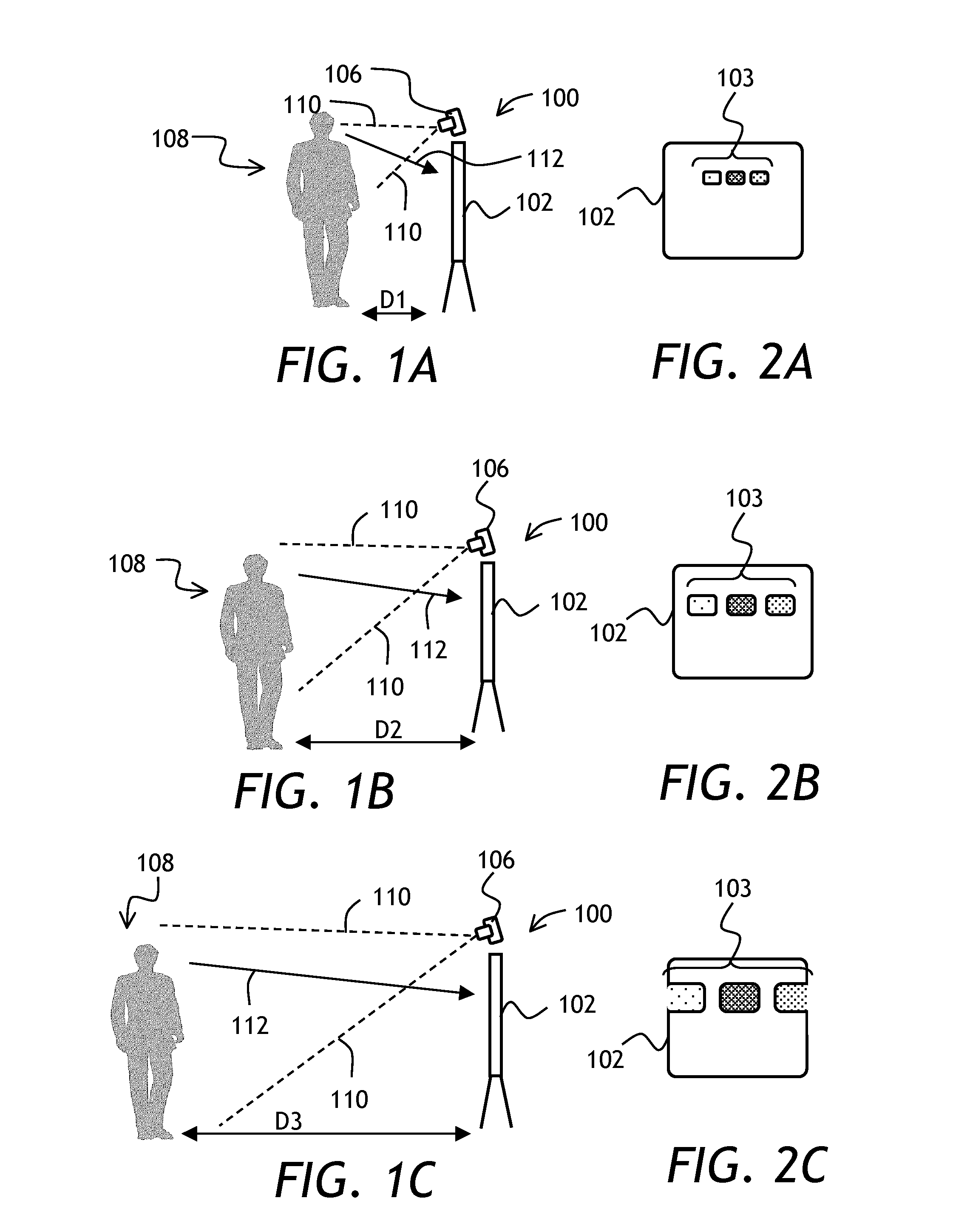

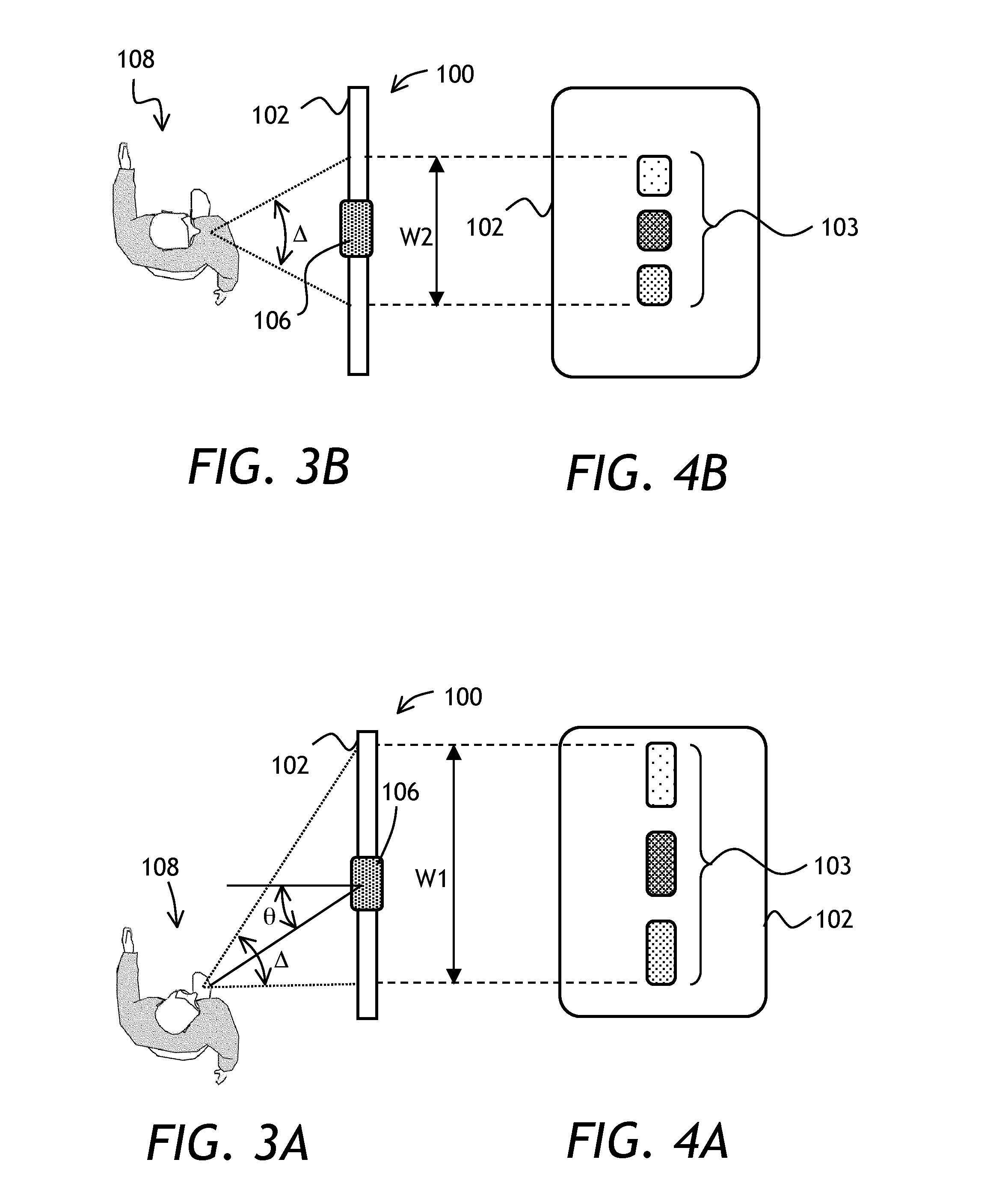

Graphical user interface adjusting to a change of user's disposition

ActiveUS20140118255A1Expand the scope of usersEasy to operateCharacter and pattern recognitionCathode-ray tube indicatorsGraphicsGraphical user interface

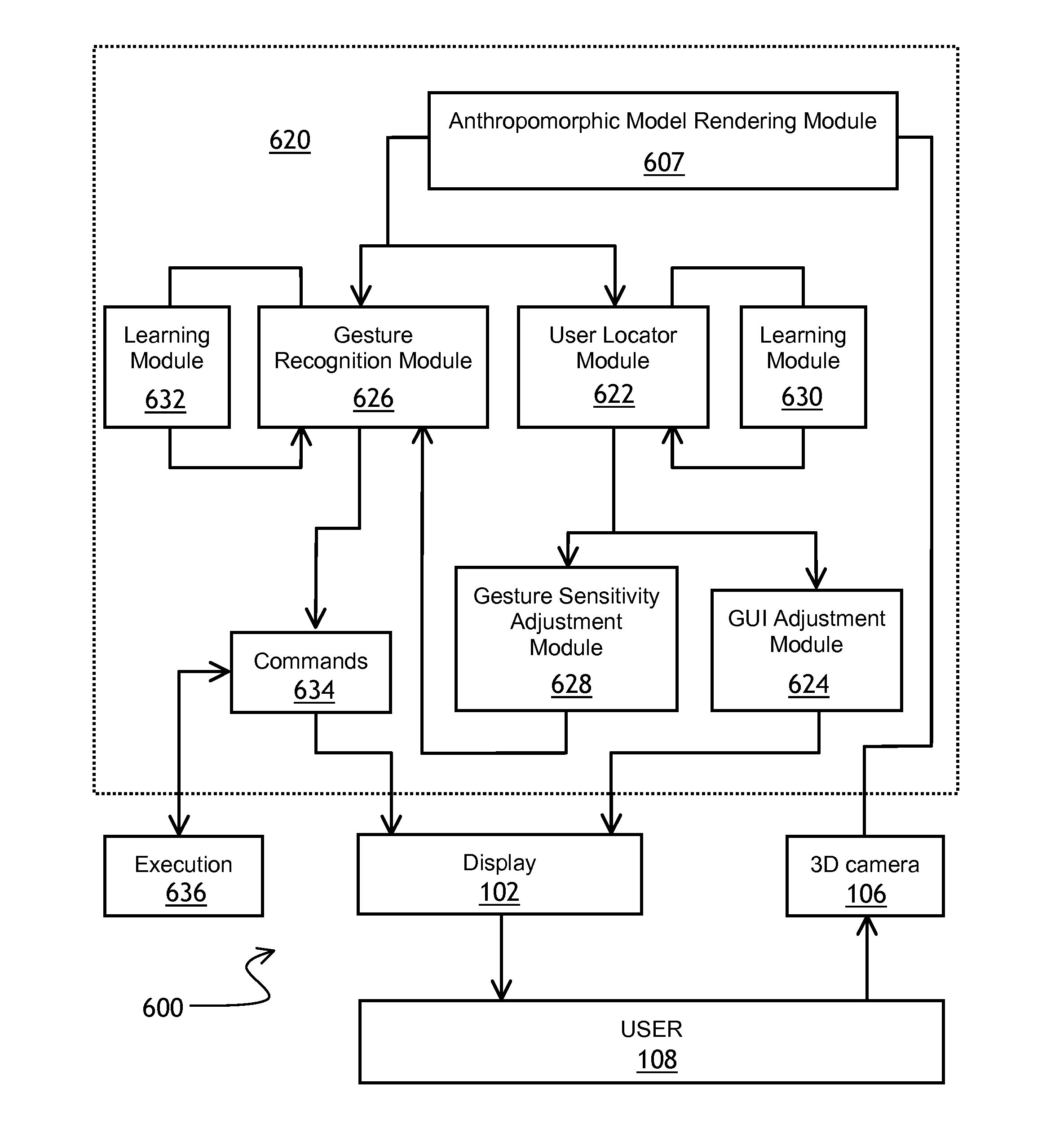

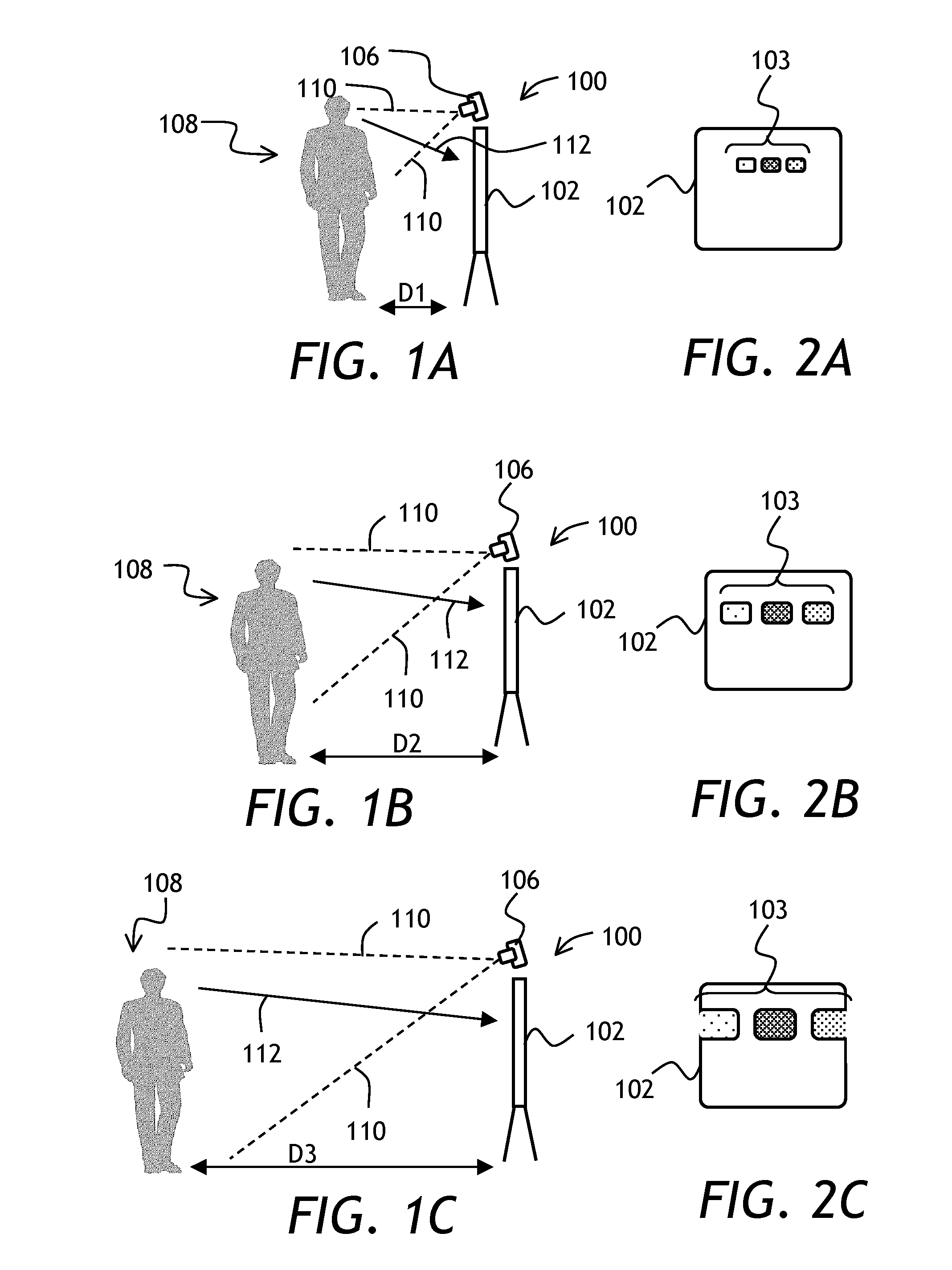

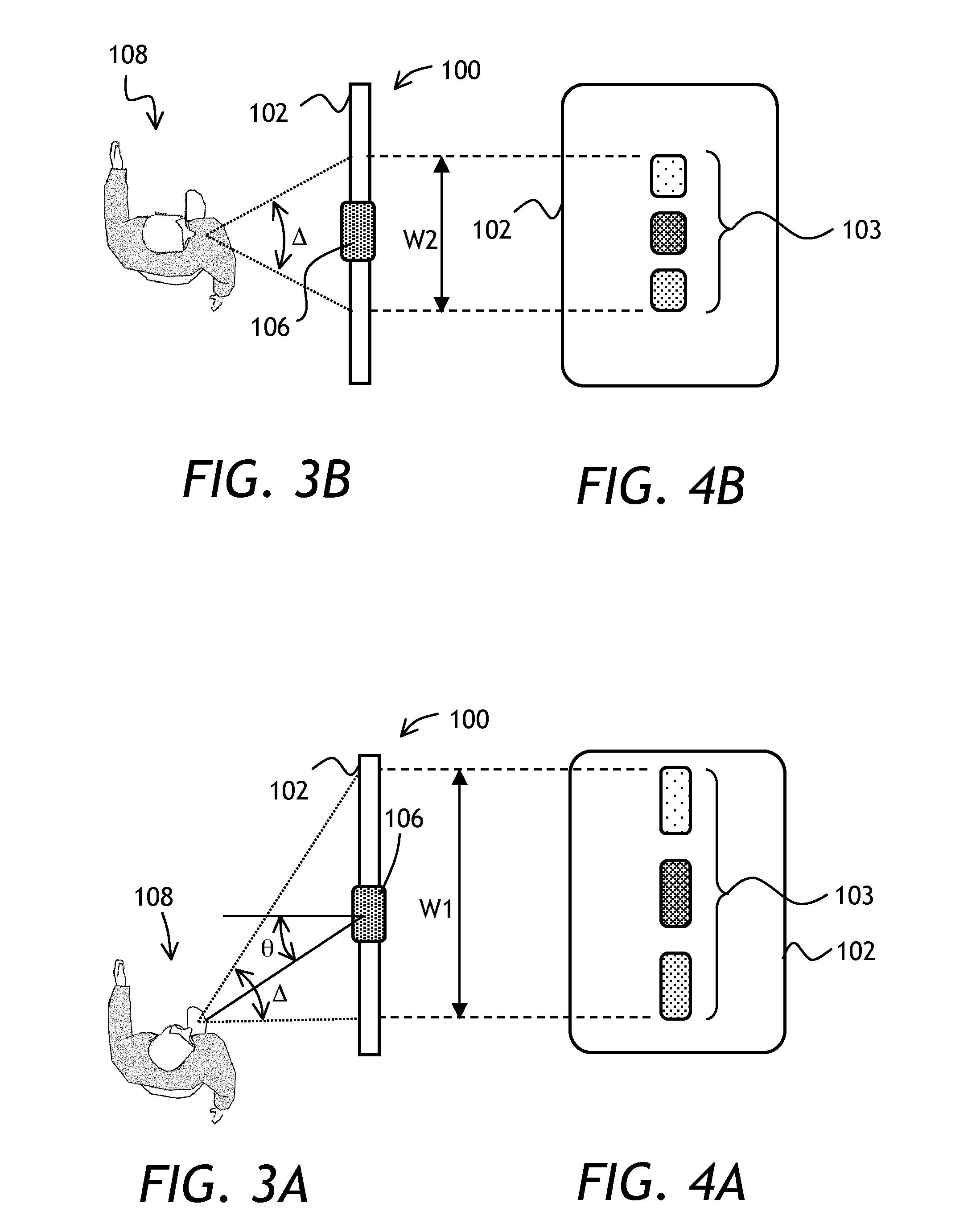

A user interface apparatus and a method for adjusting the apparatus are disclosed. A position and / or a viewing angle of the user is tracked, and graphical interface objects are adjusted to keep them visible at different user's distances and viewing angles. For example, as the user steps away from the display, the objects on the display can be proportionally enlarged to make them appear of the same size to the user. The sensitivity of a gesture recognition system to the user's movements and gestures can be also adjusted to facilitate manipulation of the objects by the user at different distances from the display of the graphical user interface.

Owner:LUMENTUM OPERATIONS LLC

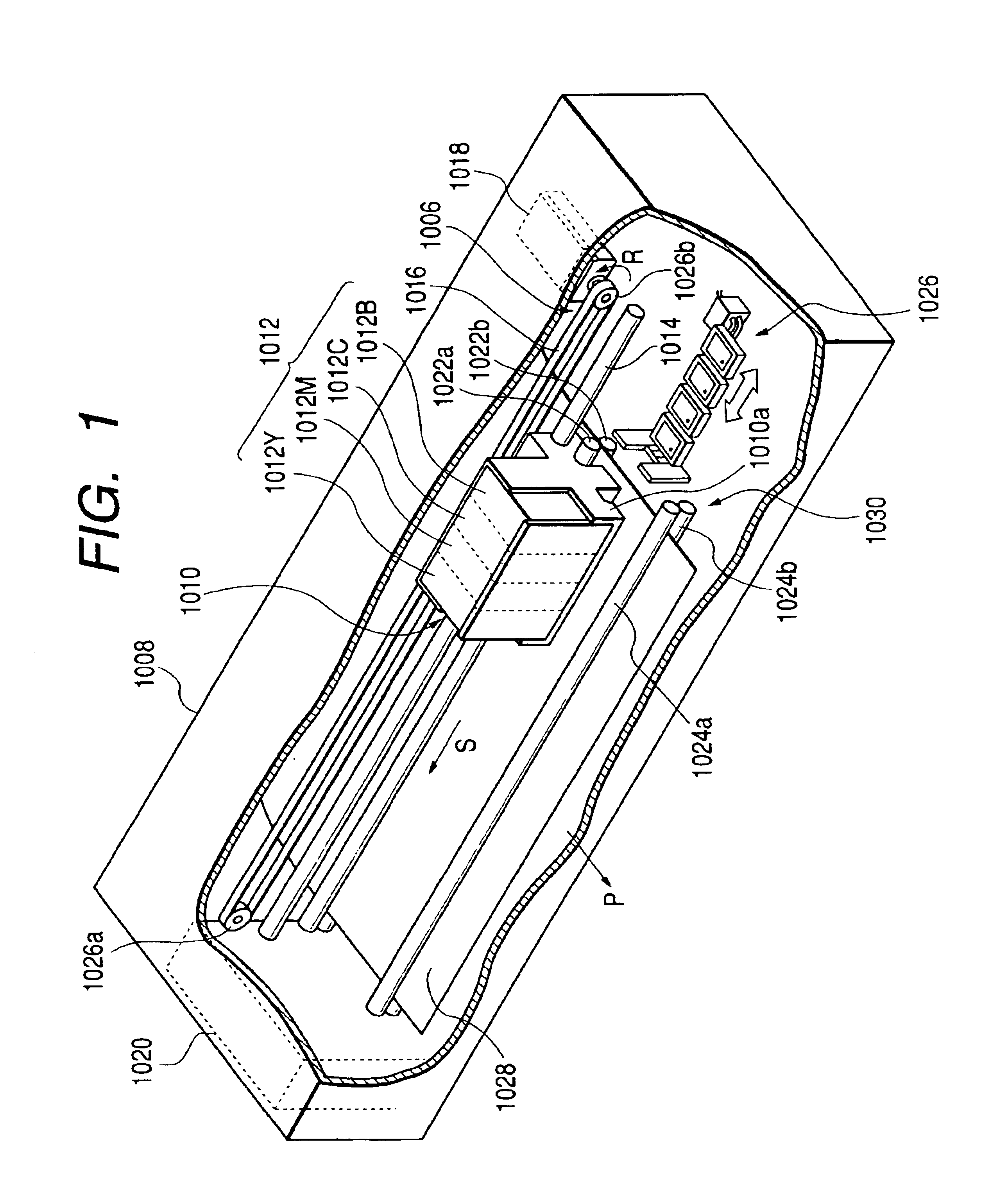

Anticurling agent, ink jet ink, method for ink jet recording and method for reducing curling

InactiveUS6966944B2Easy to operateReduce shape changeOrganic chemistryCurl-resistant paperShape changeImaging quality

The present invention provides an anti-curl agent containing an amide compound of specific structure and molecular weight, an ink jet ink containing the amide compound, a method for ink jet recording to form images by ejecting the ink, and a method for reducing curl of recording media using the ink. The anti-curl agent of the present invention can reduce shape changes of a printed paper with a lapse of time, i.e., the curl phenomenon, tending to occur in particular with a plain paper printed over the entire surface, without deteriorating image quality.

Owner:CANON KK

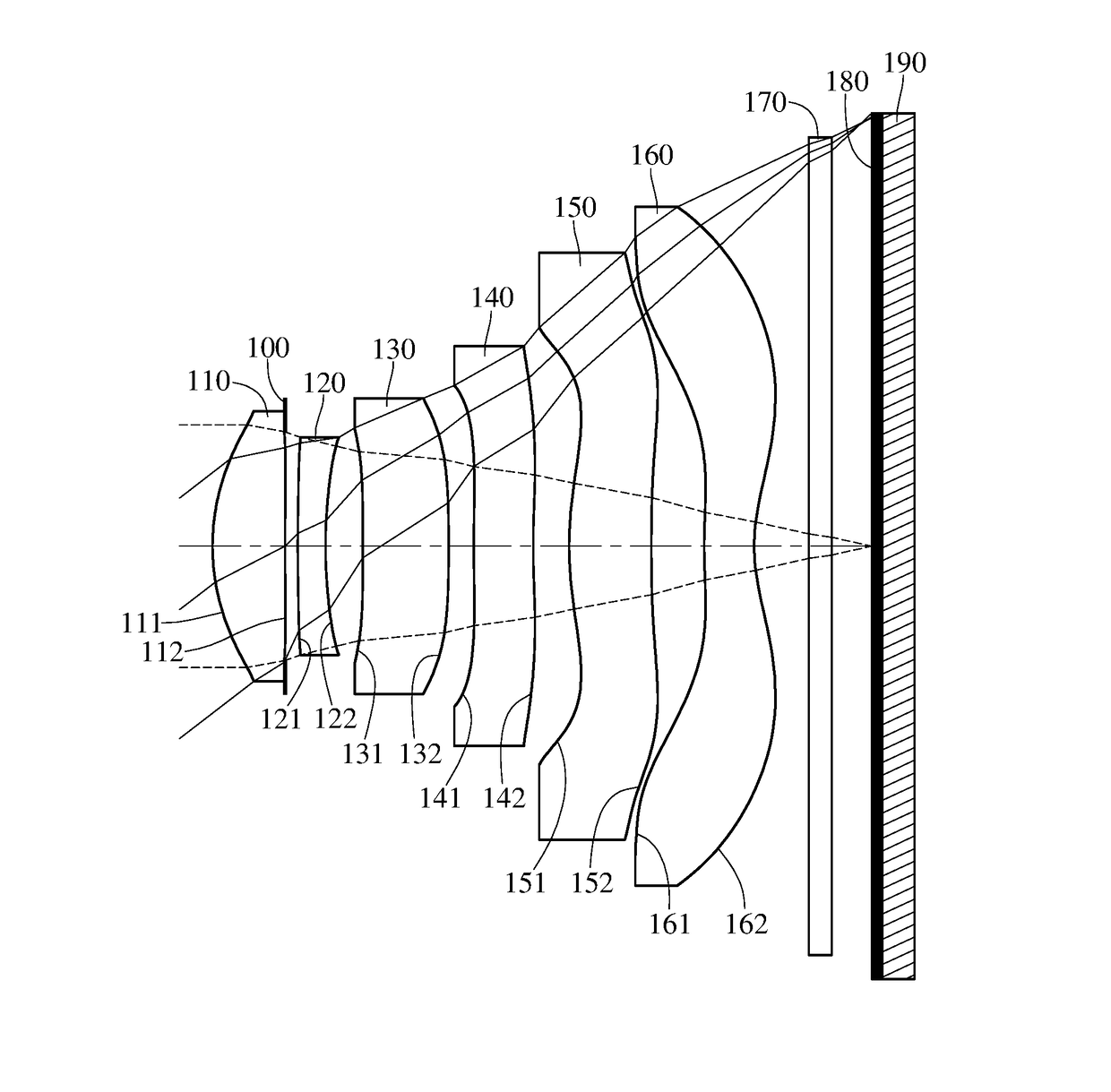

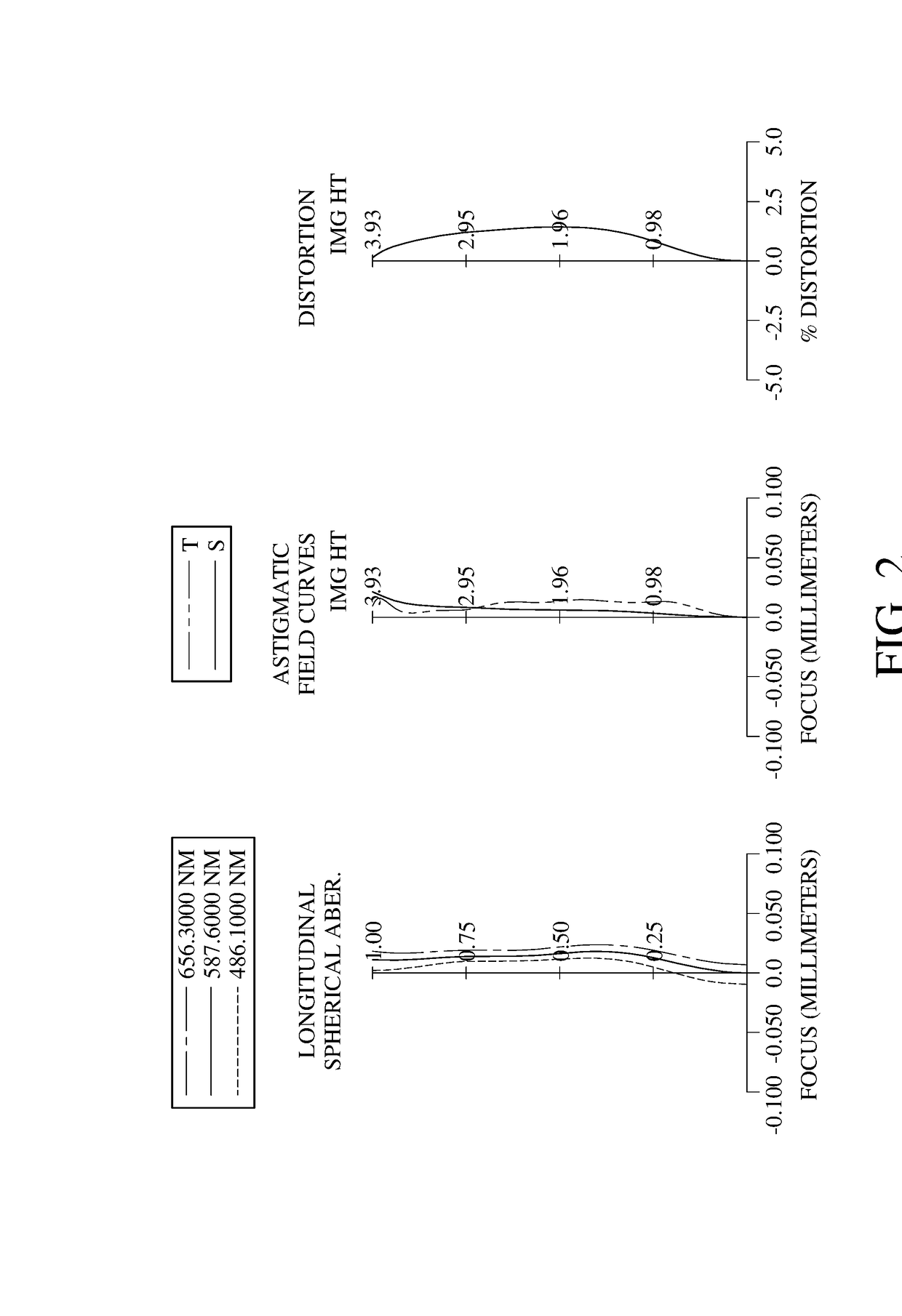

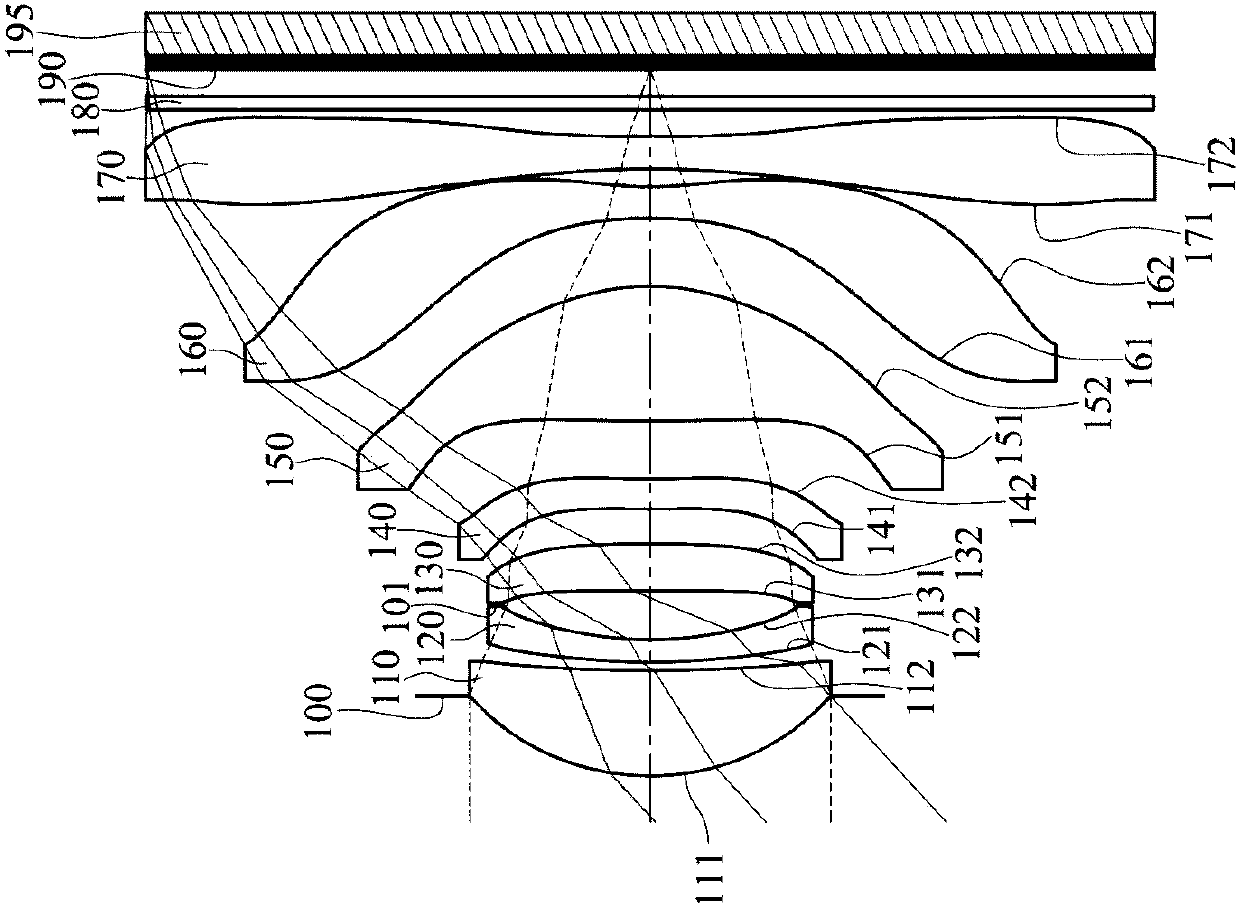

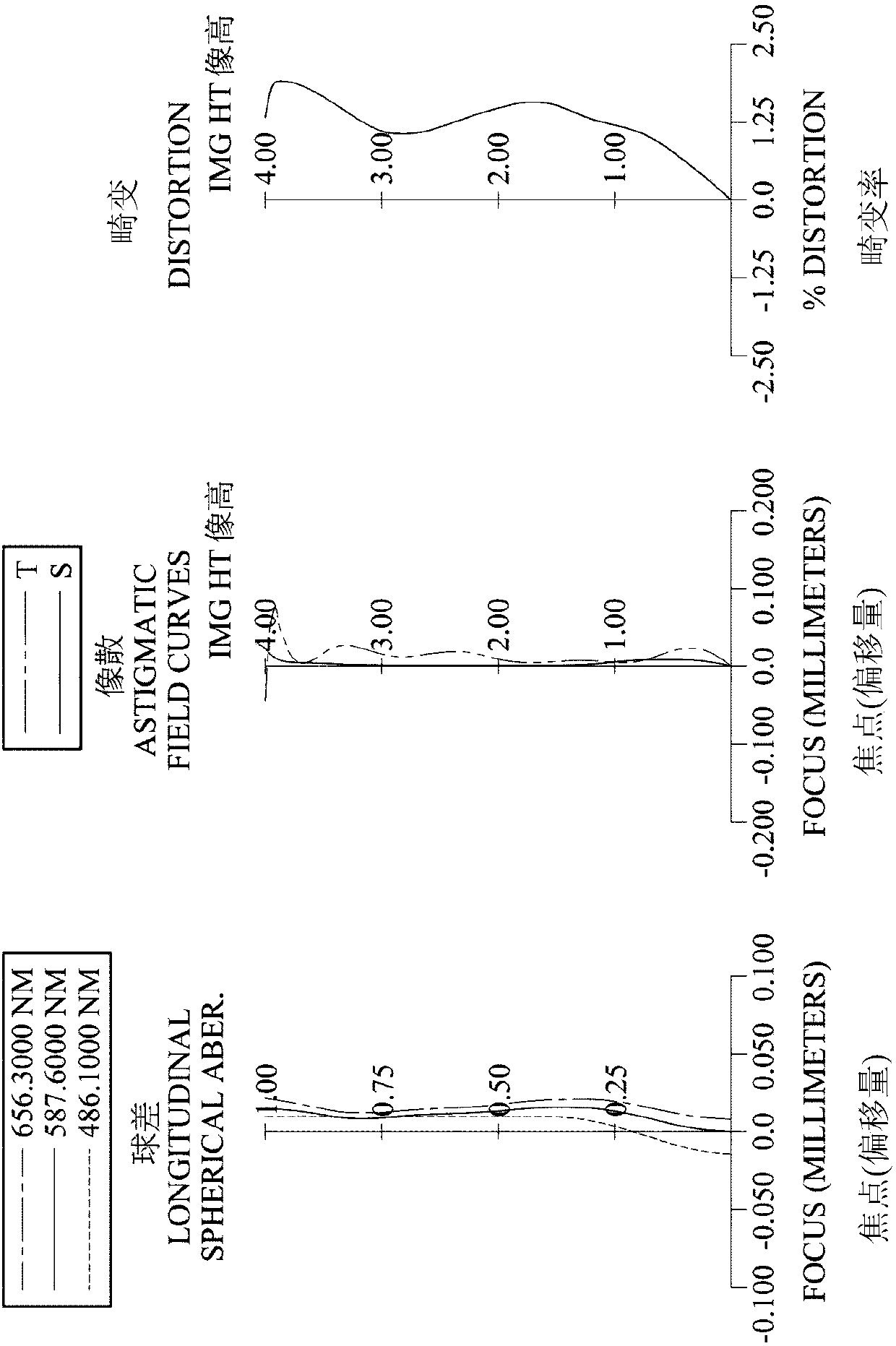

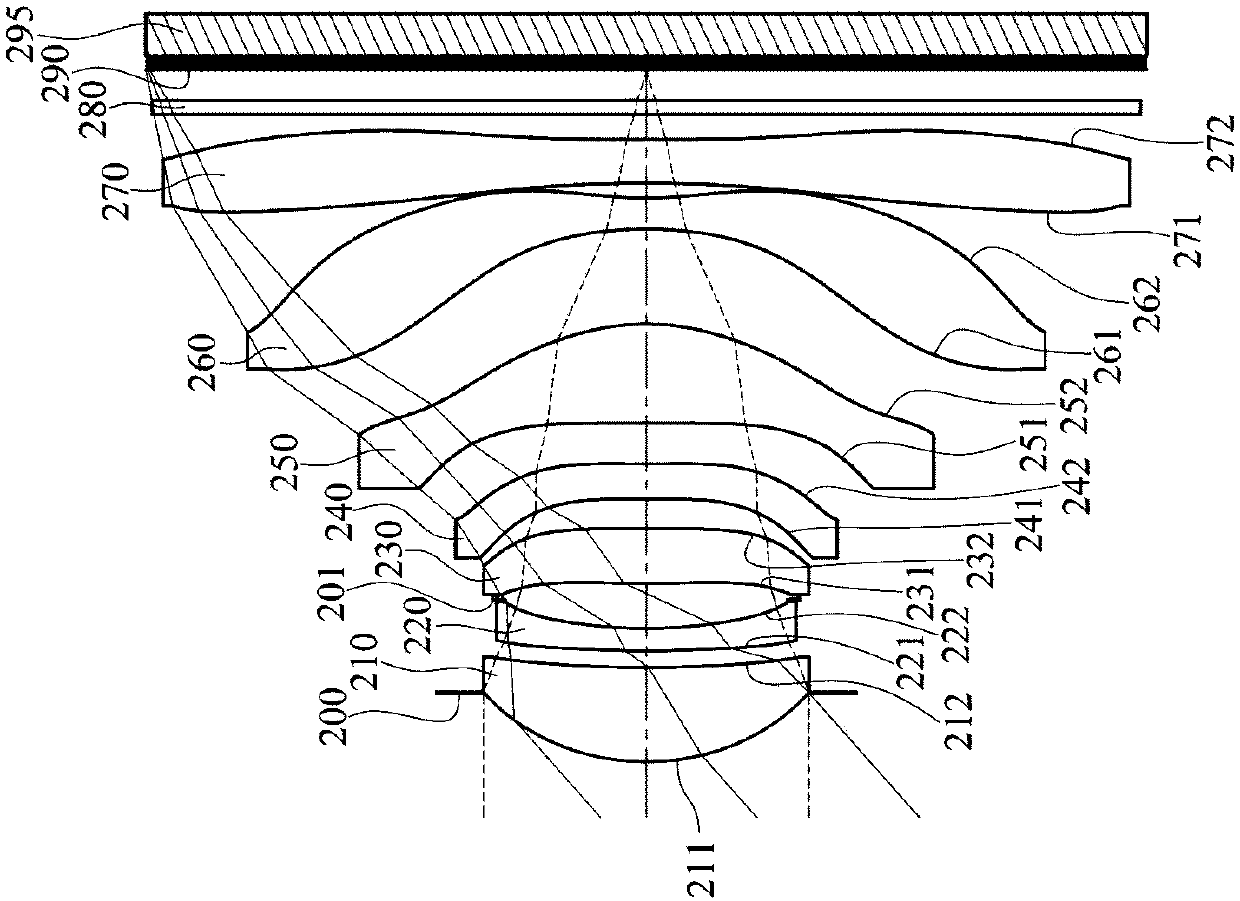

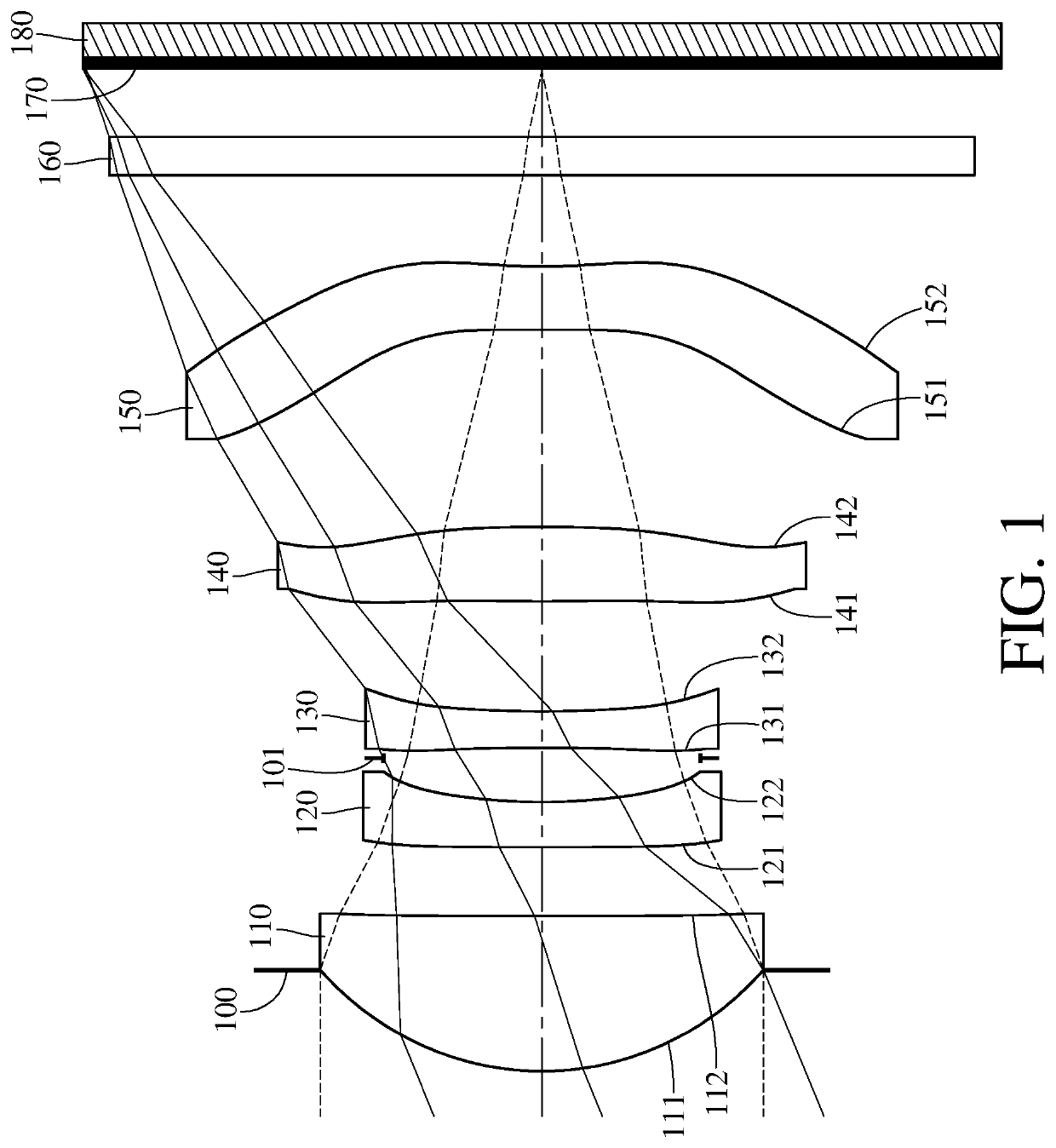

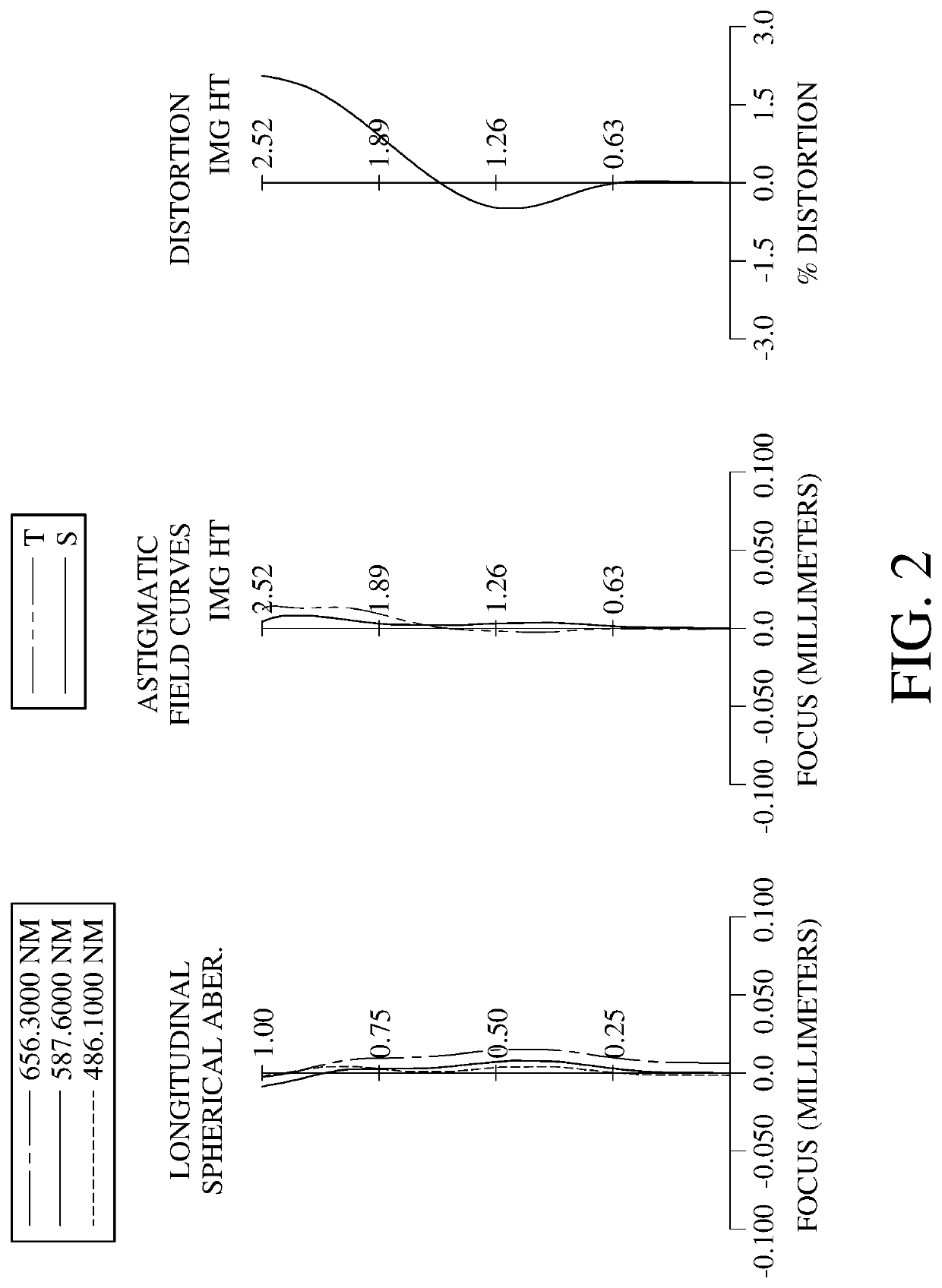

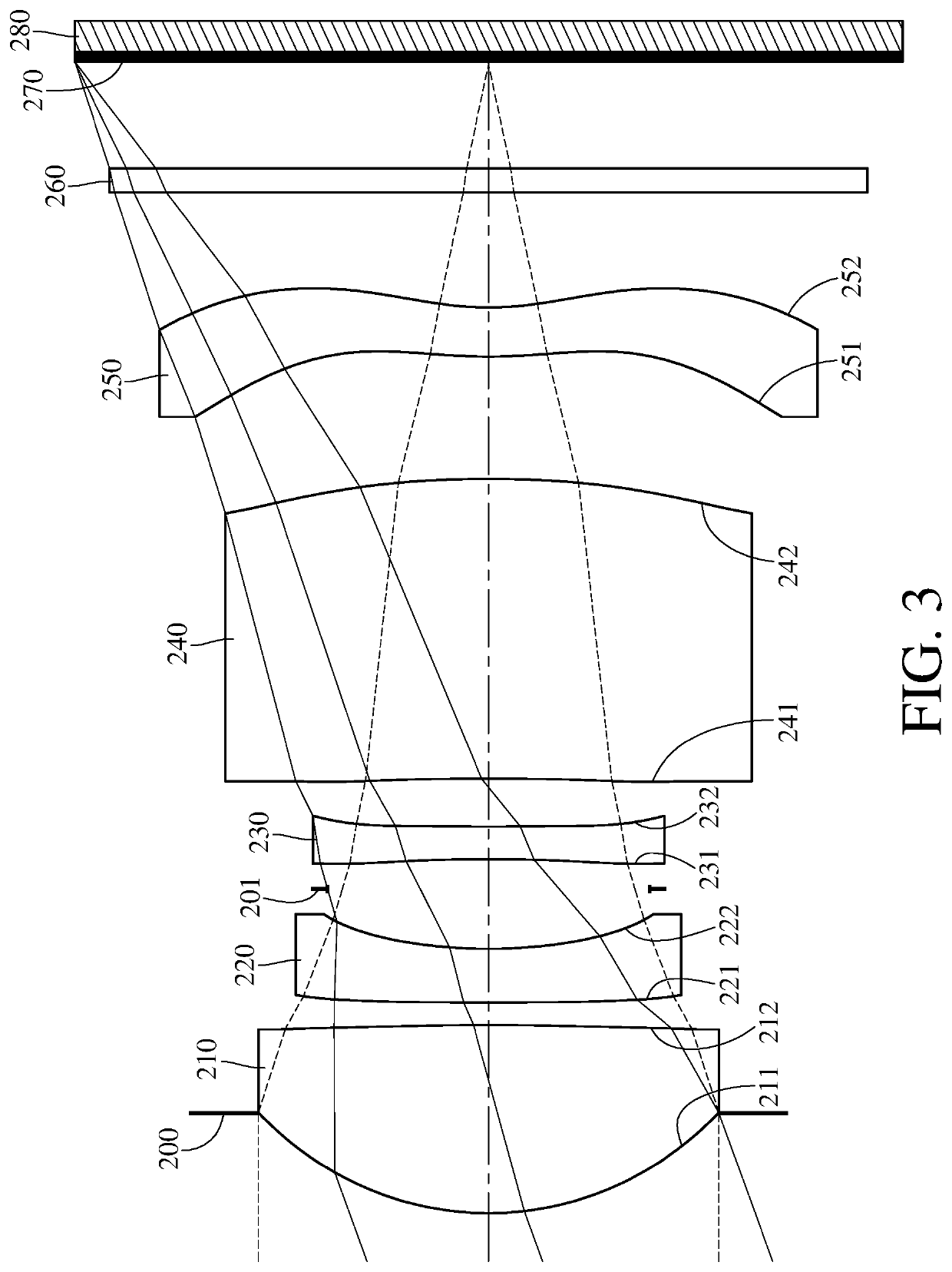

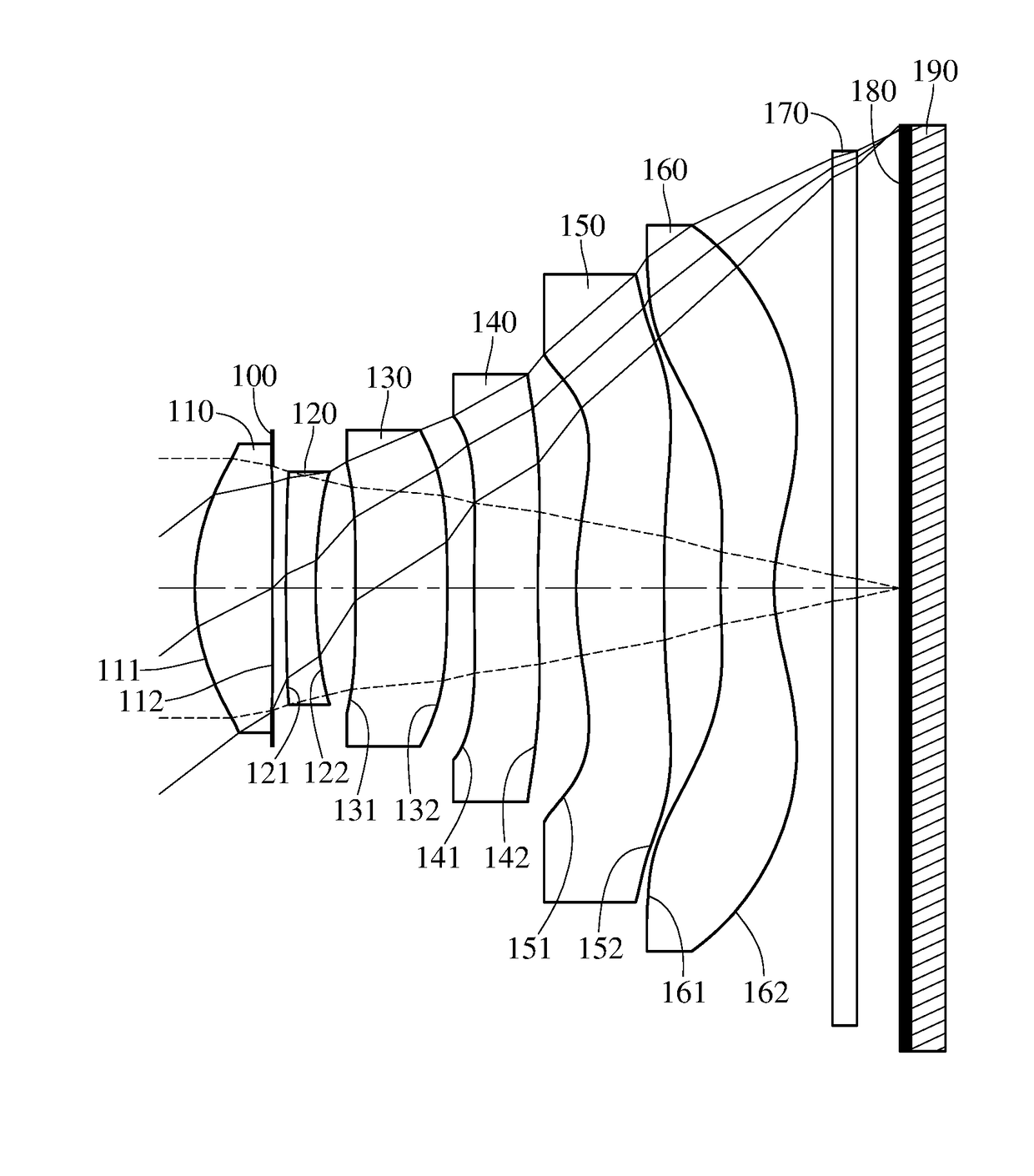

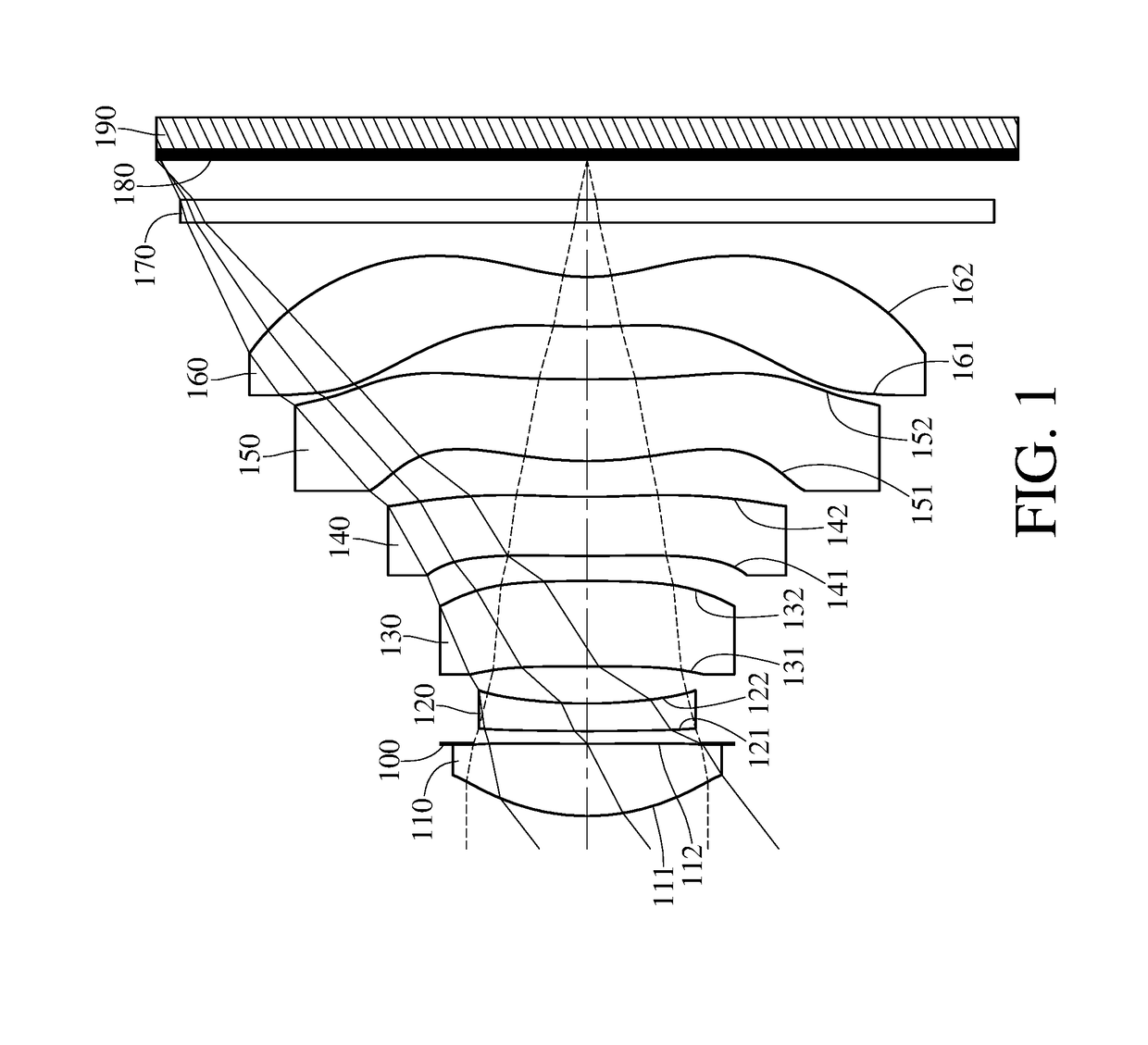

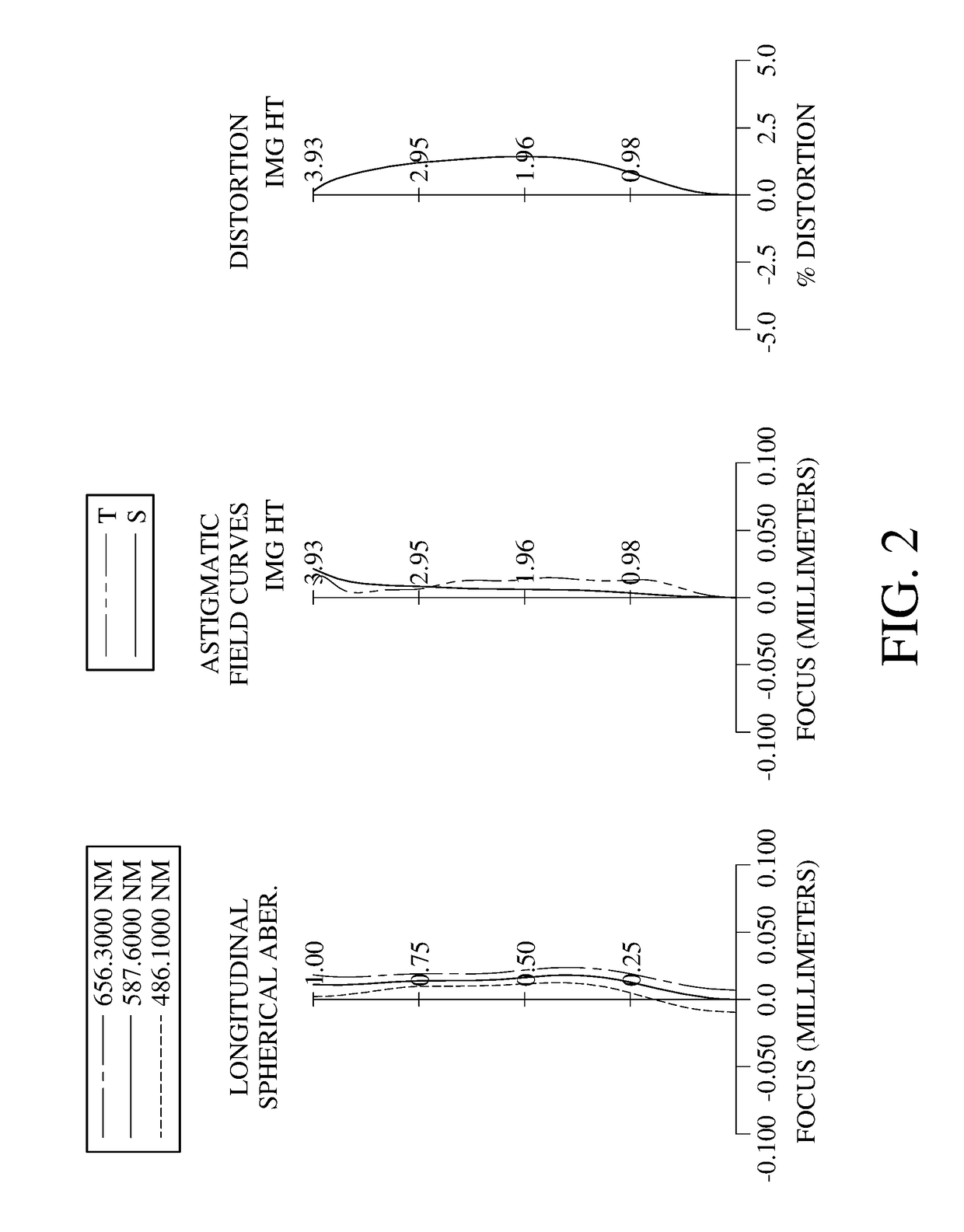

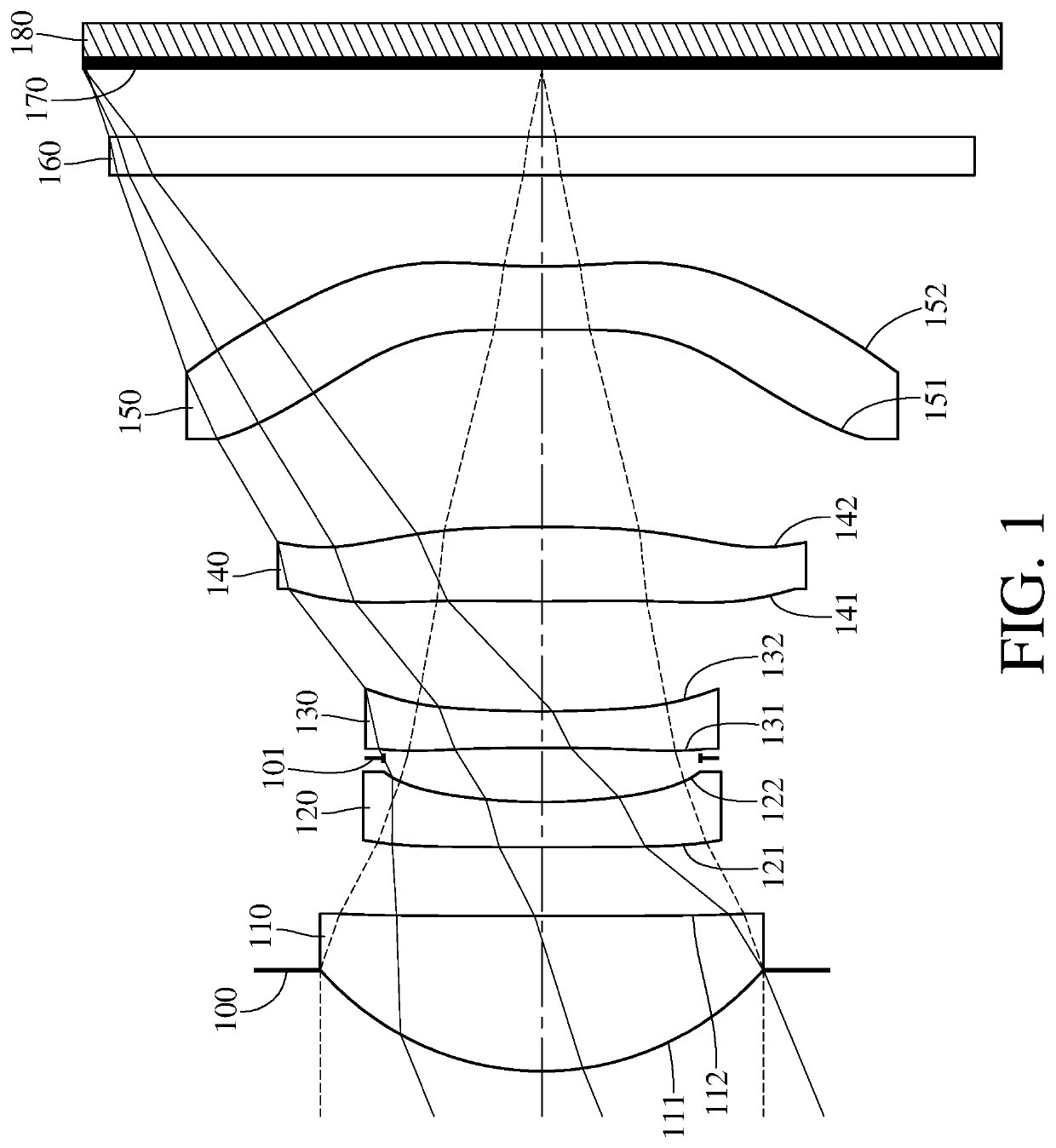

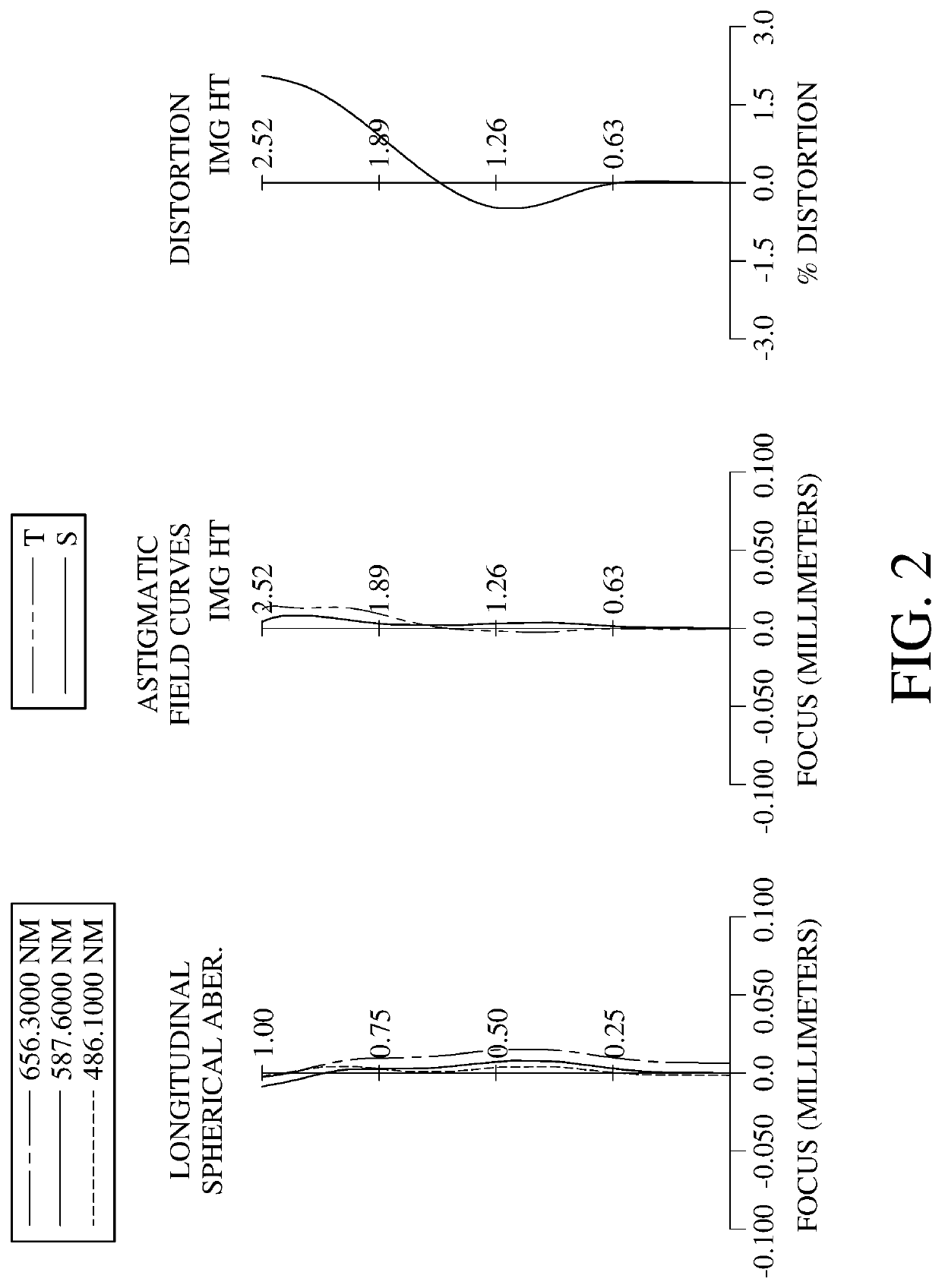

Optical imaging lens assembly, image capturing unit and electronic device

An optical imaging lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element with positive refractive power has an object-side surface being convex. The second lens element has negative refractive power. At least one of two surfaces of the fourth lens element has at least one inflection point, and the two surfaces thereof are aspheric. The fifth lens element has an object-side surface being convex and an image-side surface having at least one inflection point, and the two surfaces thereof are aspheric. The sixth lens element has an image-side surface being concave, wherein the image-side surface of the sixth lens element has at least one convex shape in off-axial region, and the two surfaces thereof are aspheric.

Owner:LARGAN PRECISION

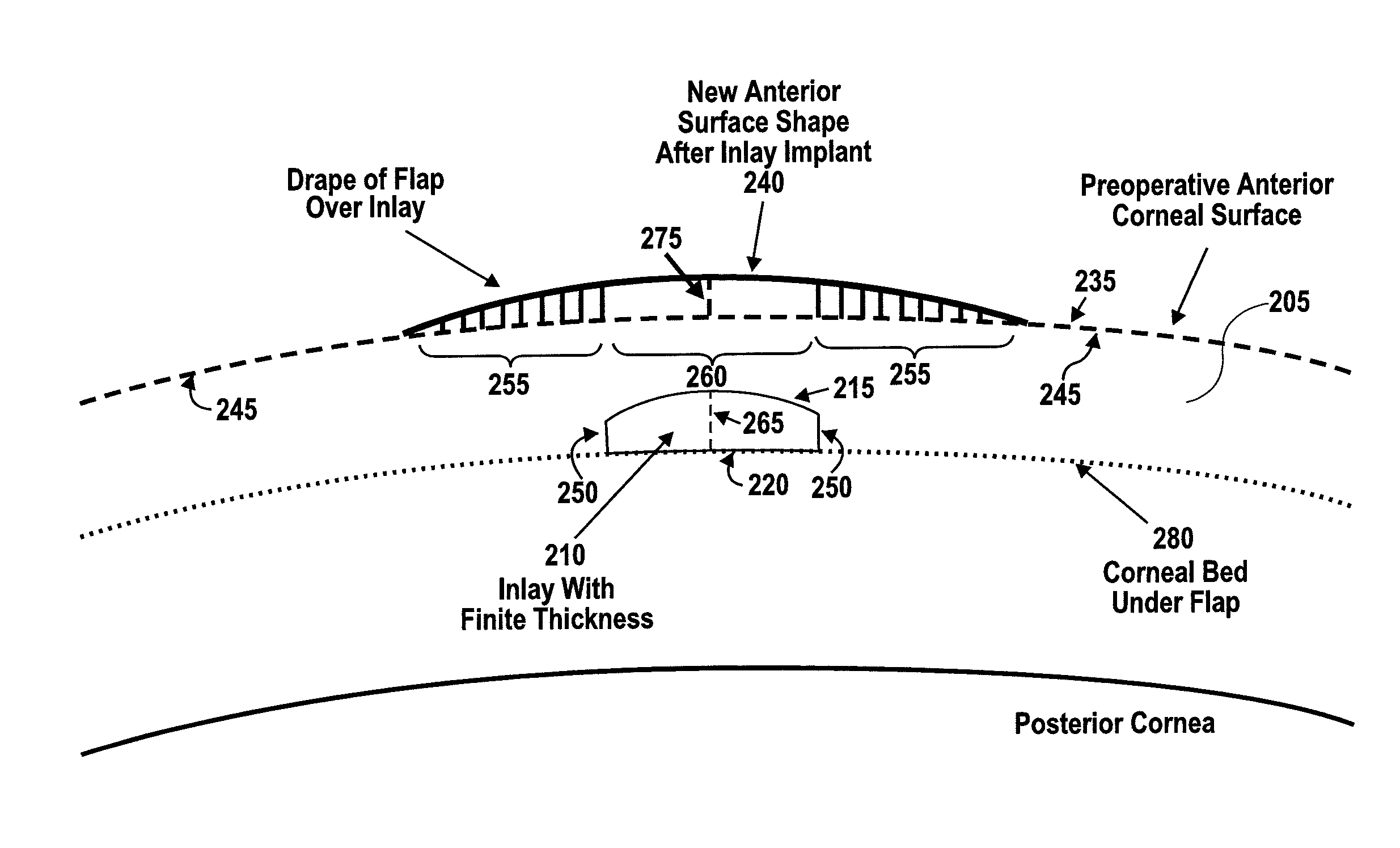

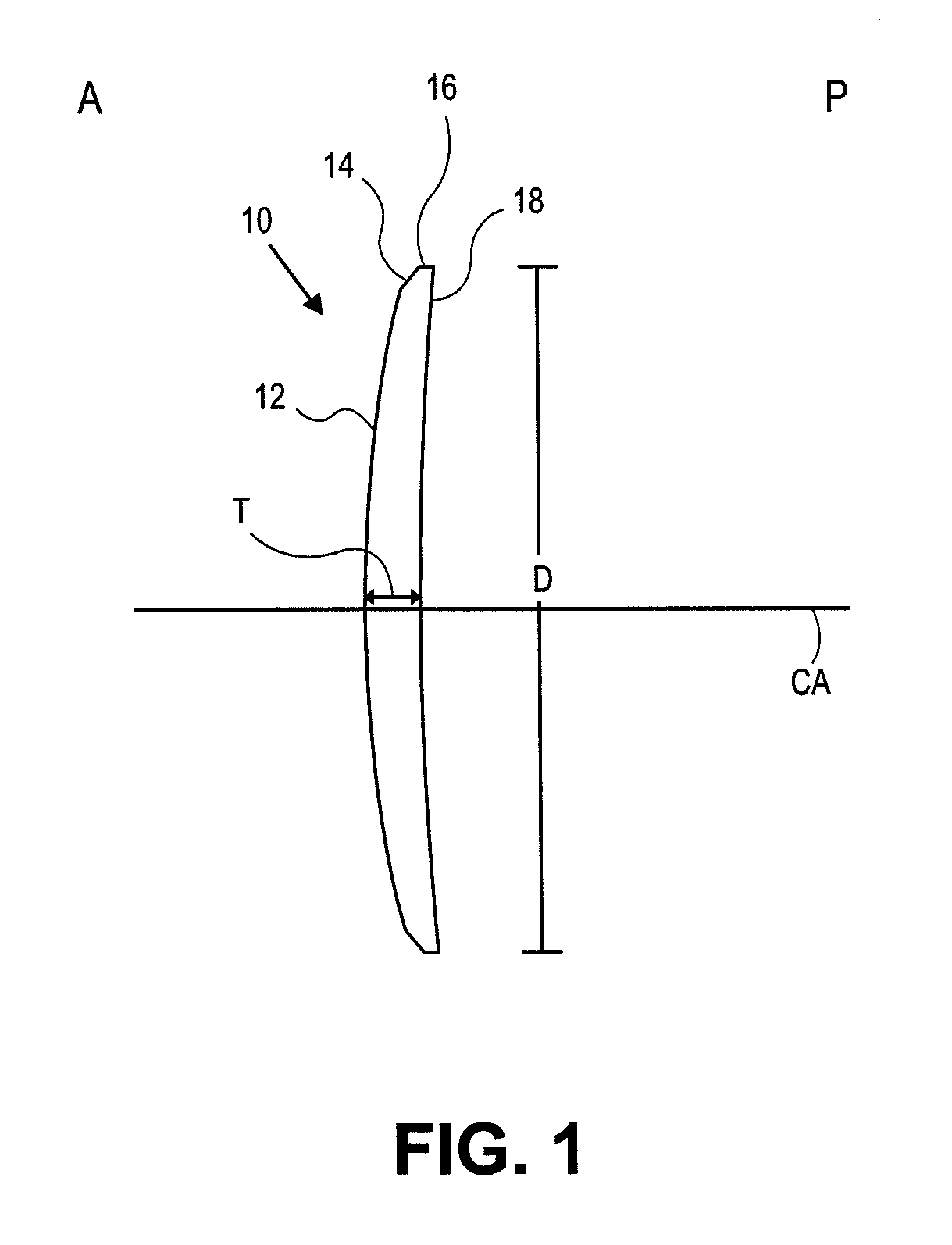

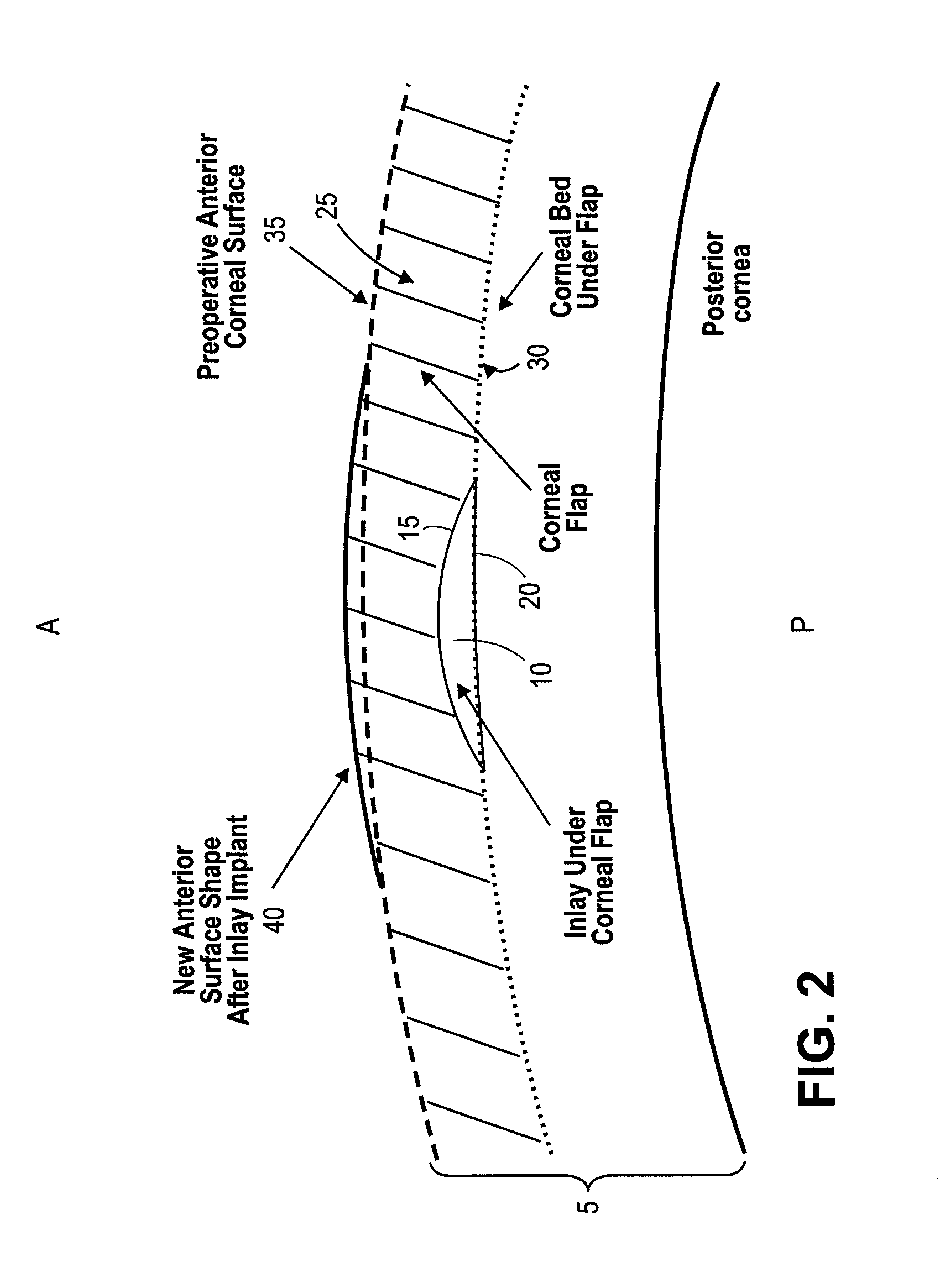

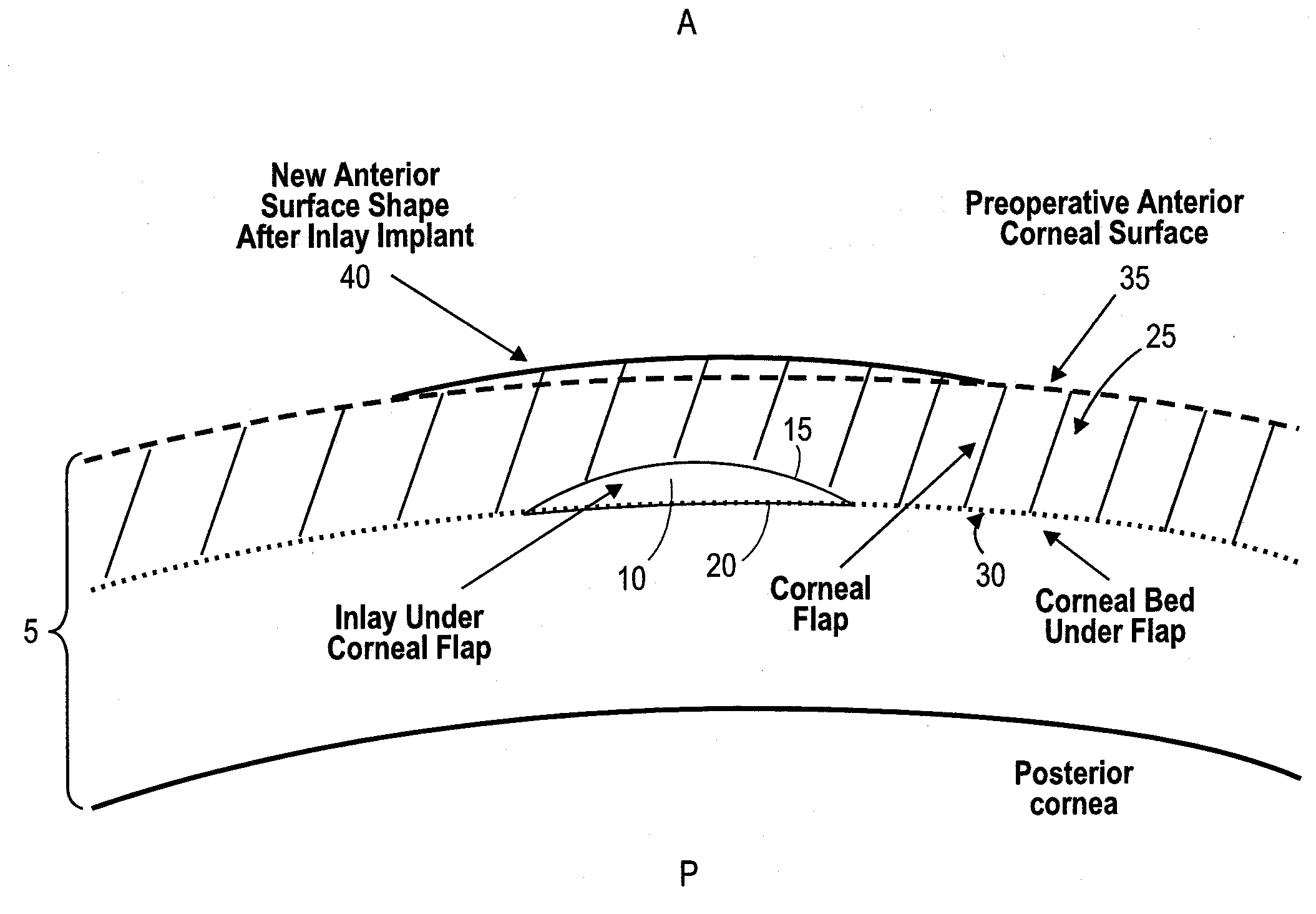

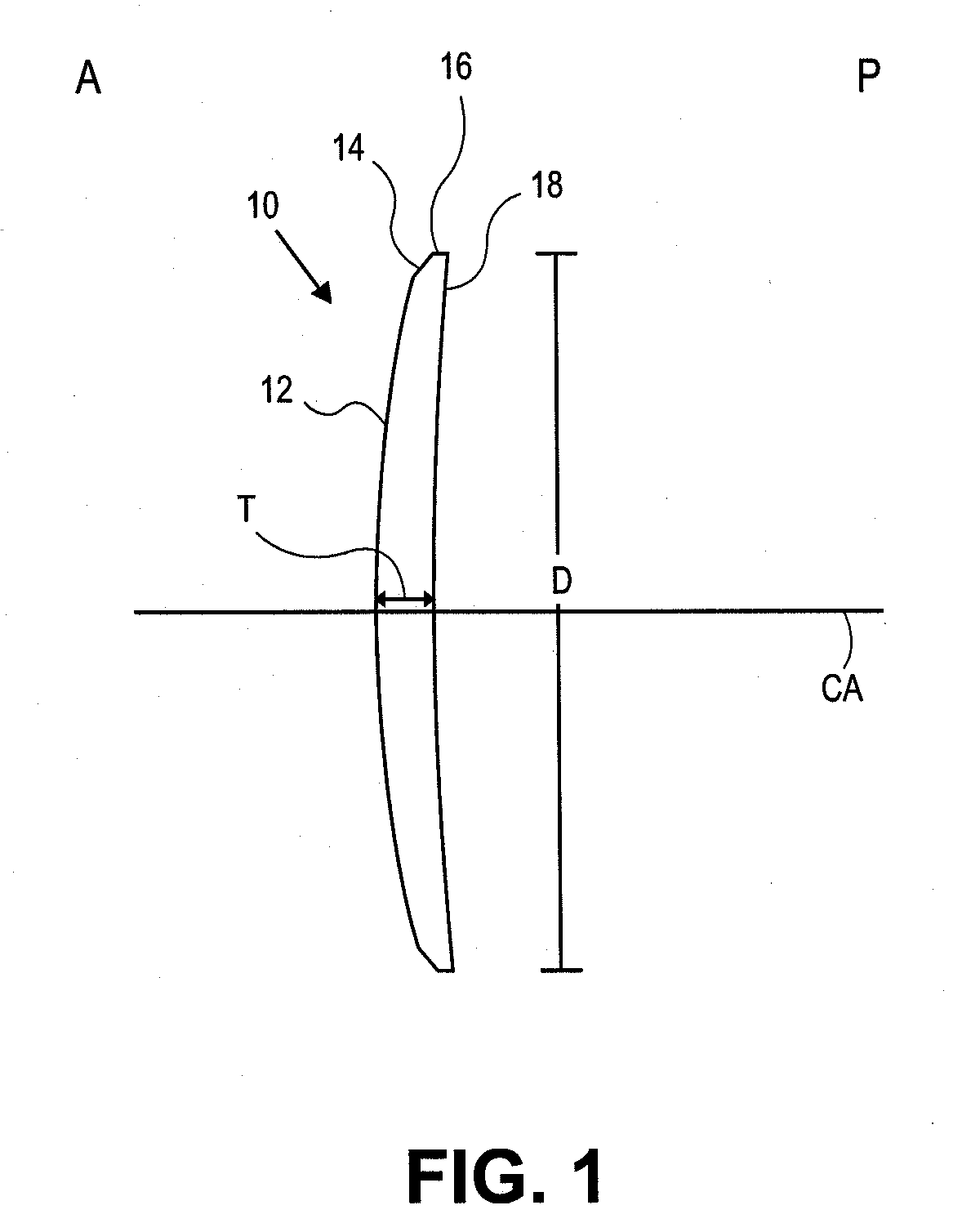

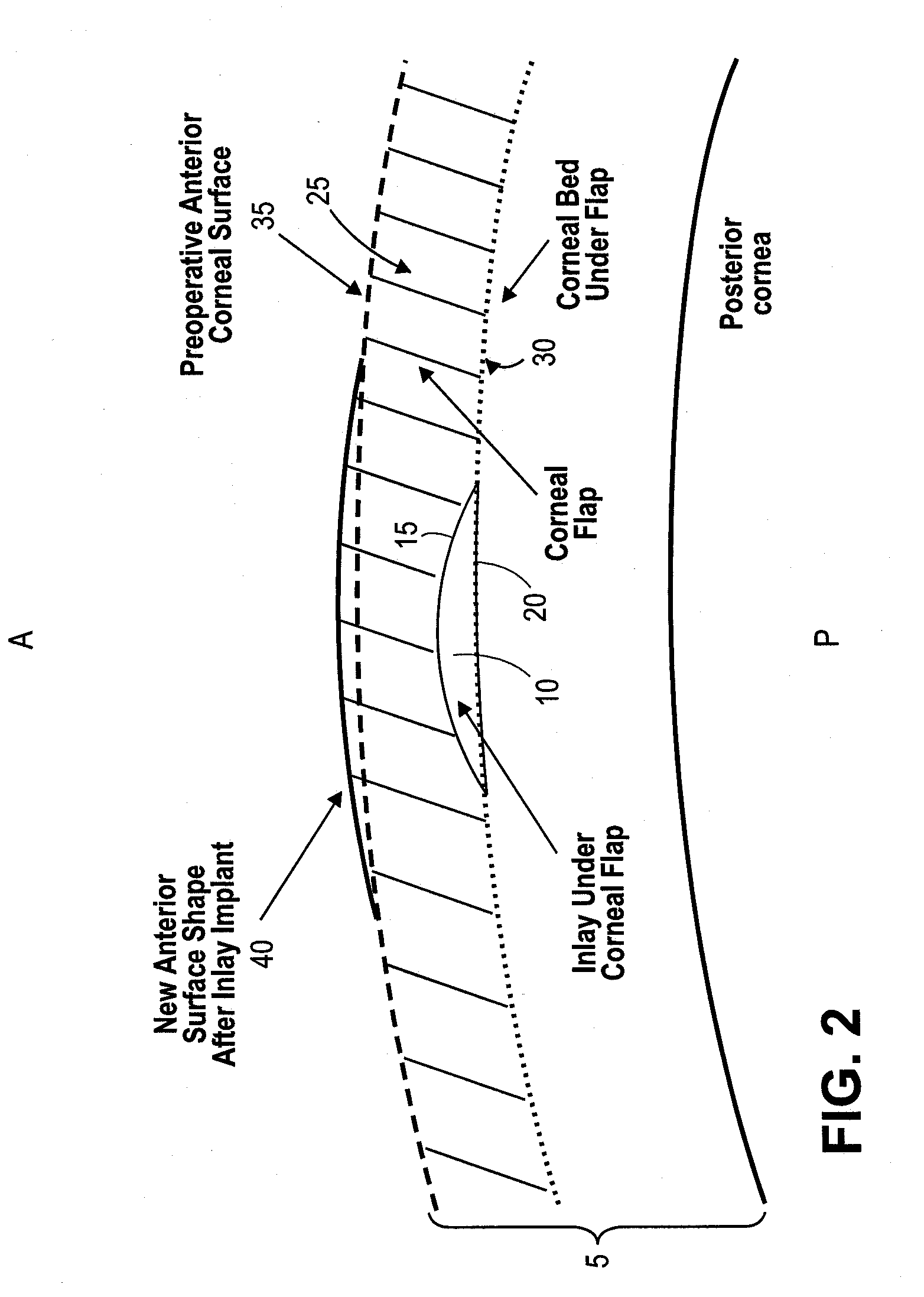

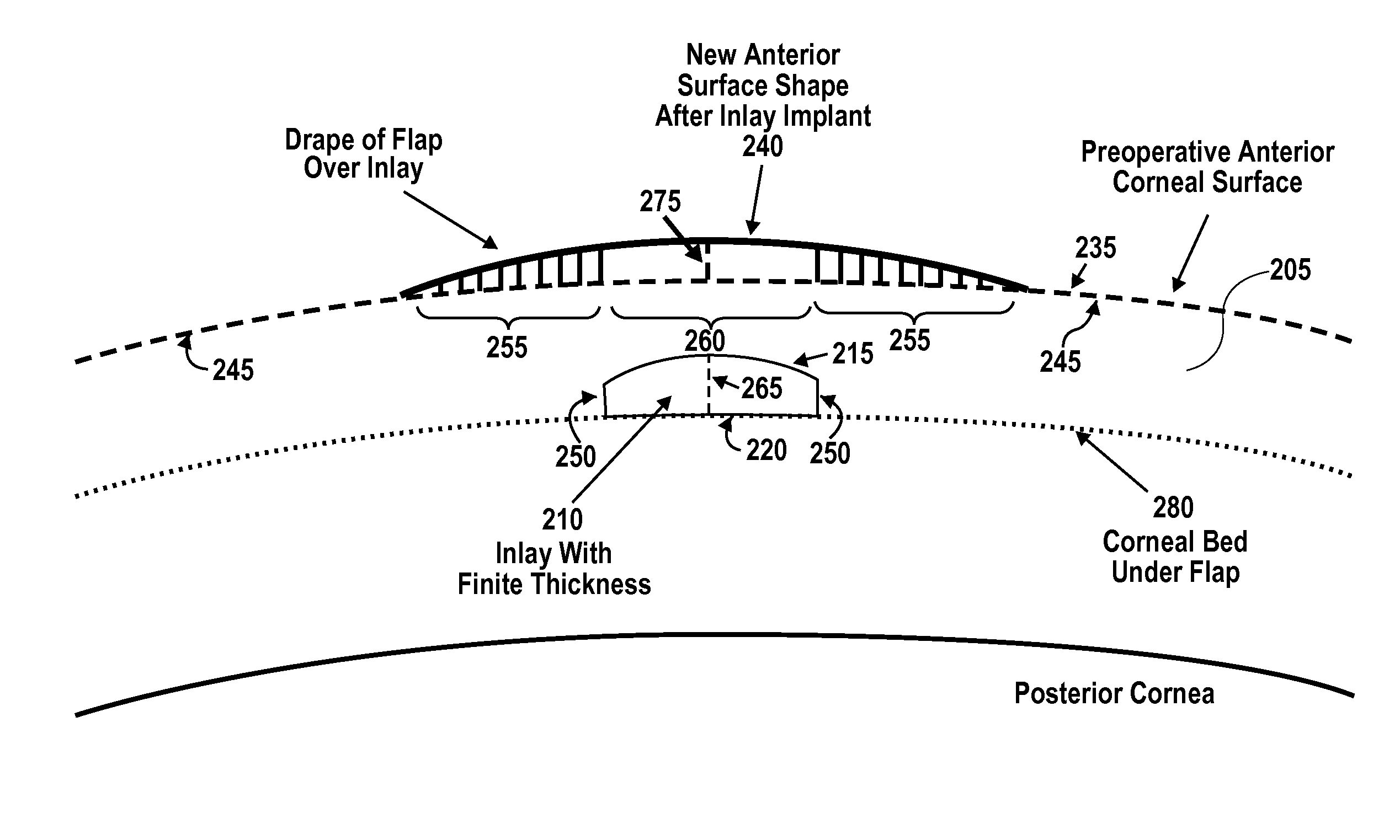

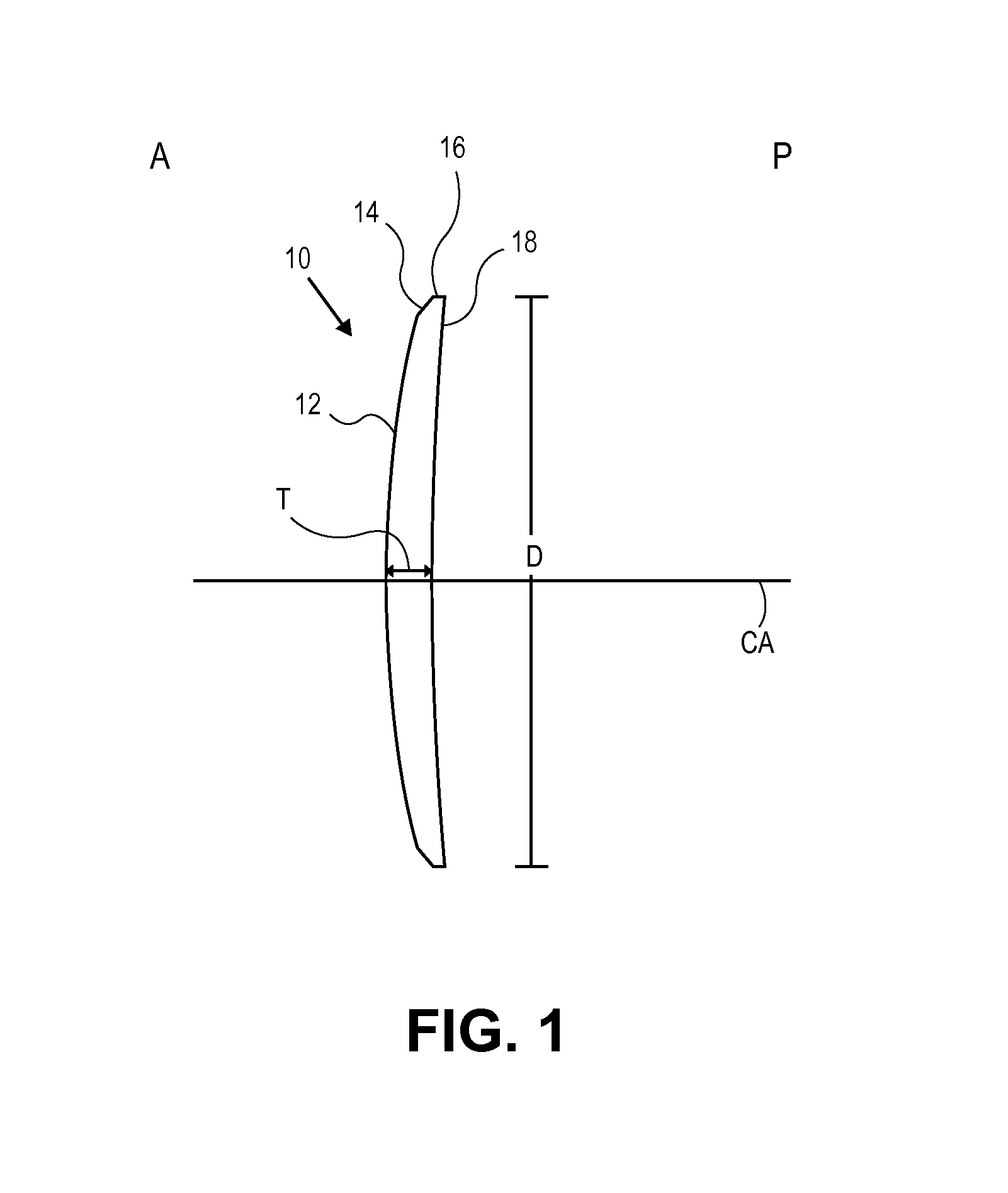

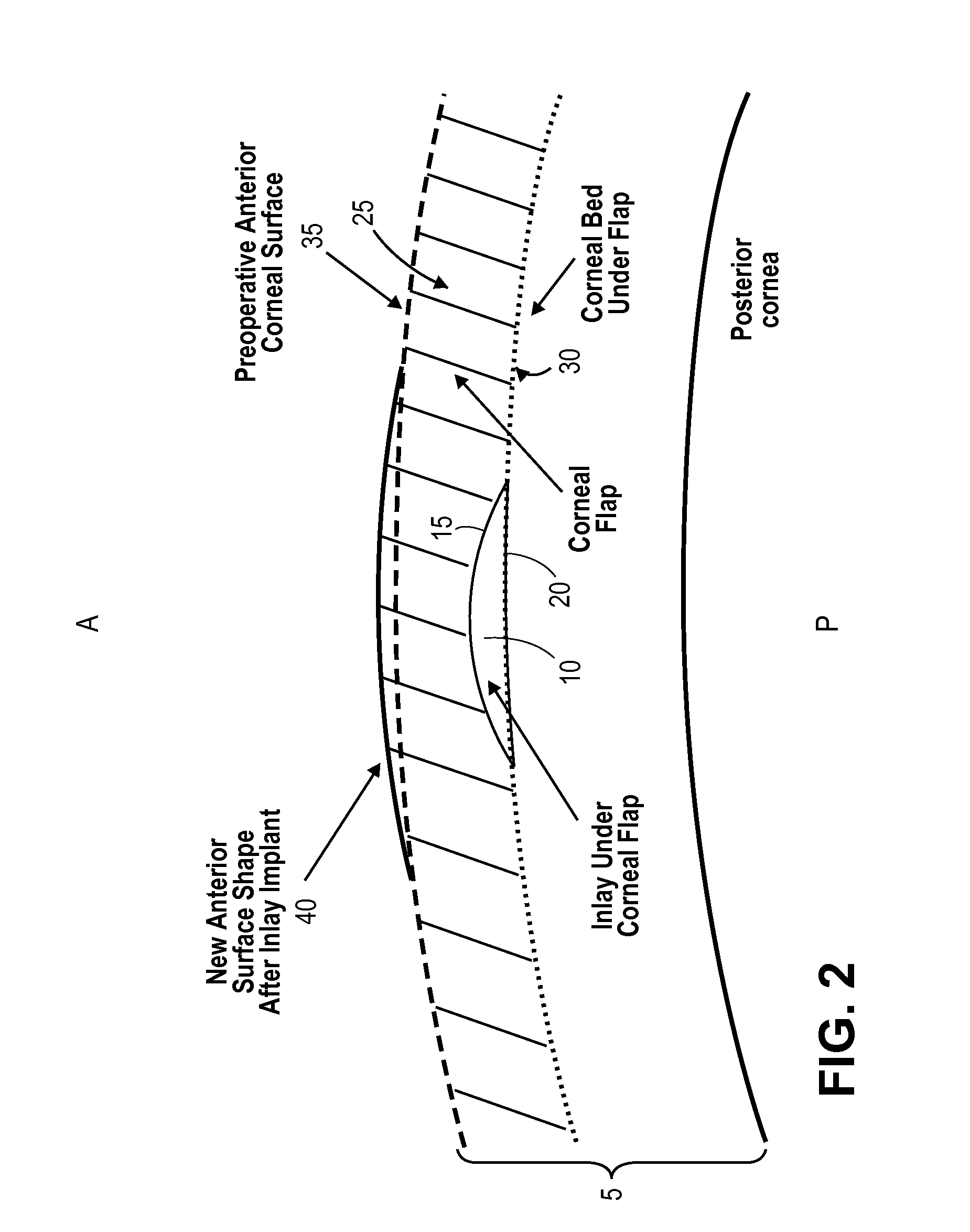

Corneal inlay design and methods of correcting vision

Methods of designing corneal implants, such as inlays, to compensate for a corneal response, such as epithelial remodeling of the epithelial layer, to the presence of the implant. Additionally, methods of performing alternative corneal vision correction procedures to compensate for an epithelial response to the procedure. Methods of compensating for a corneal response when performing a vision correction procedure to create a center near region of the cornea for near vision while providing distance vision peripheral to the central near zone.

Owner:RVO 2 0 INC D B A OPTICS MEDICAL

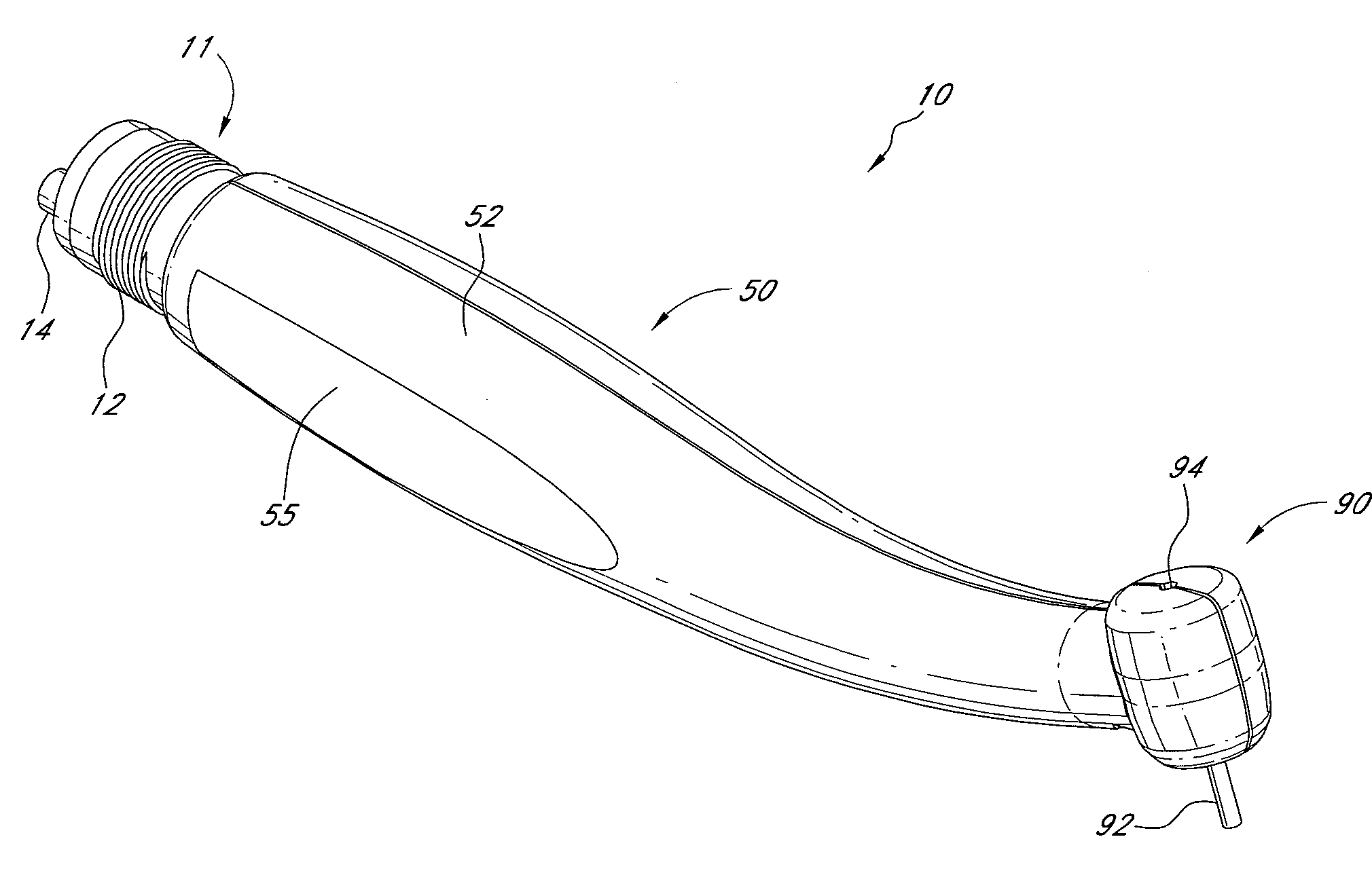

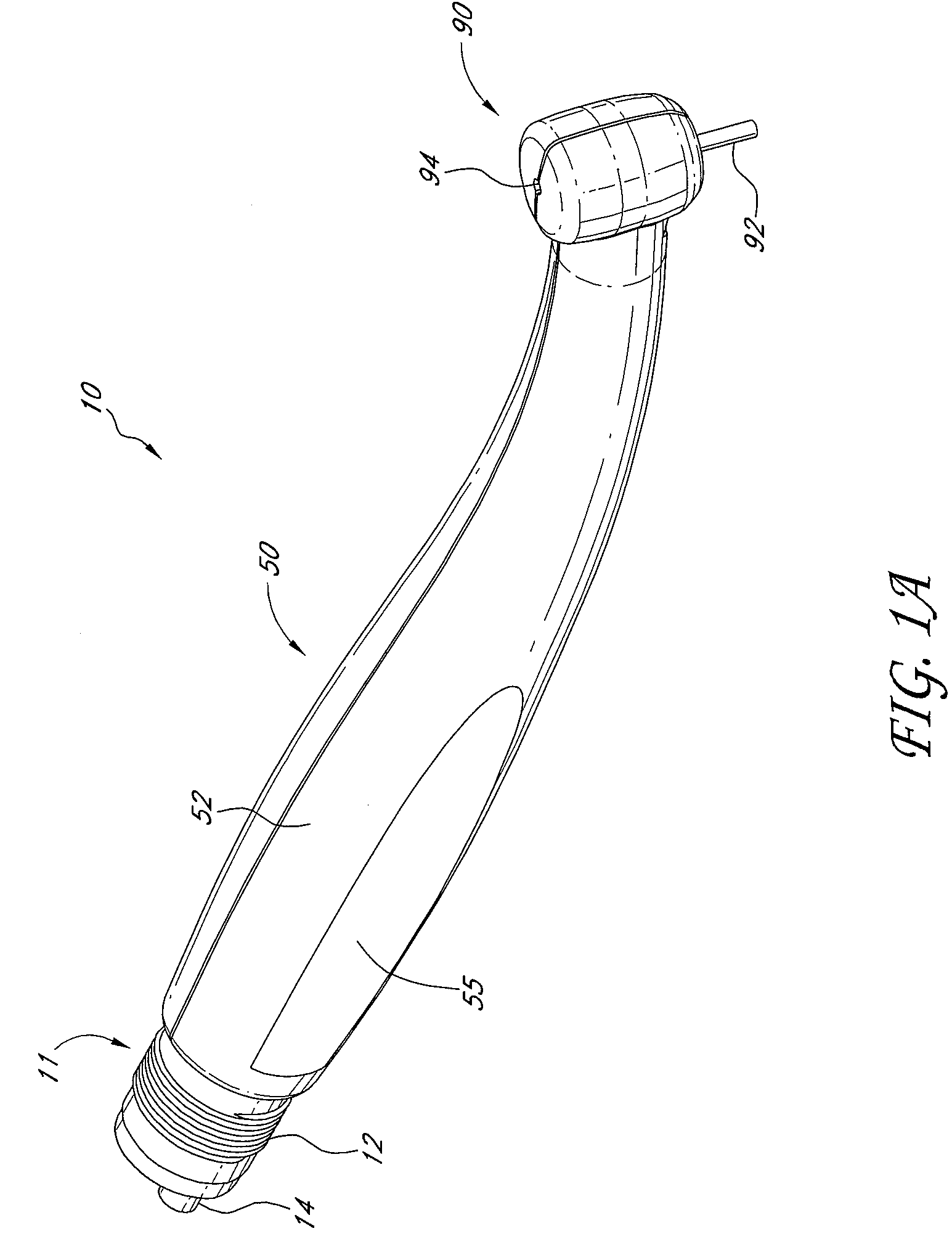

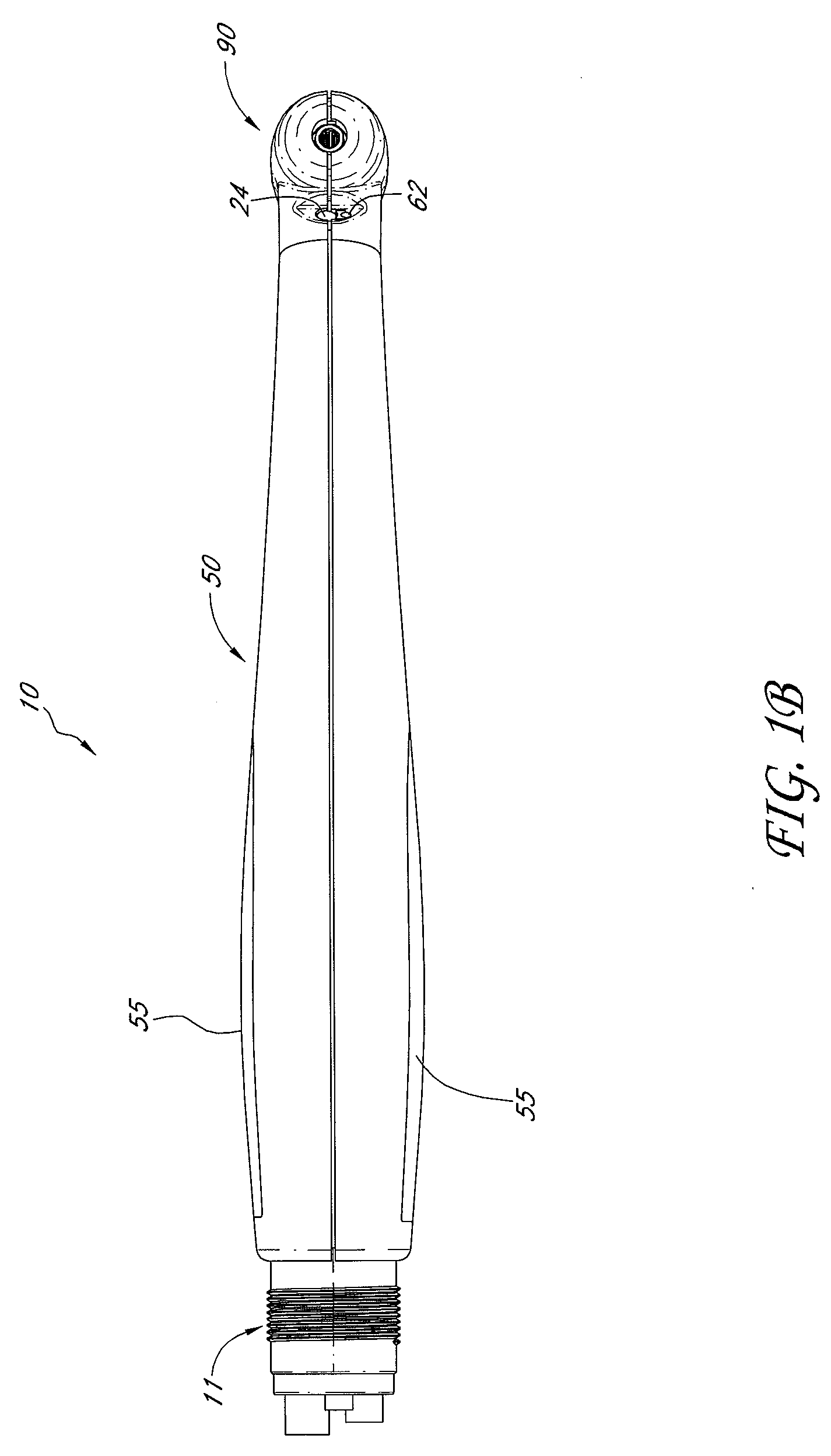

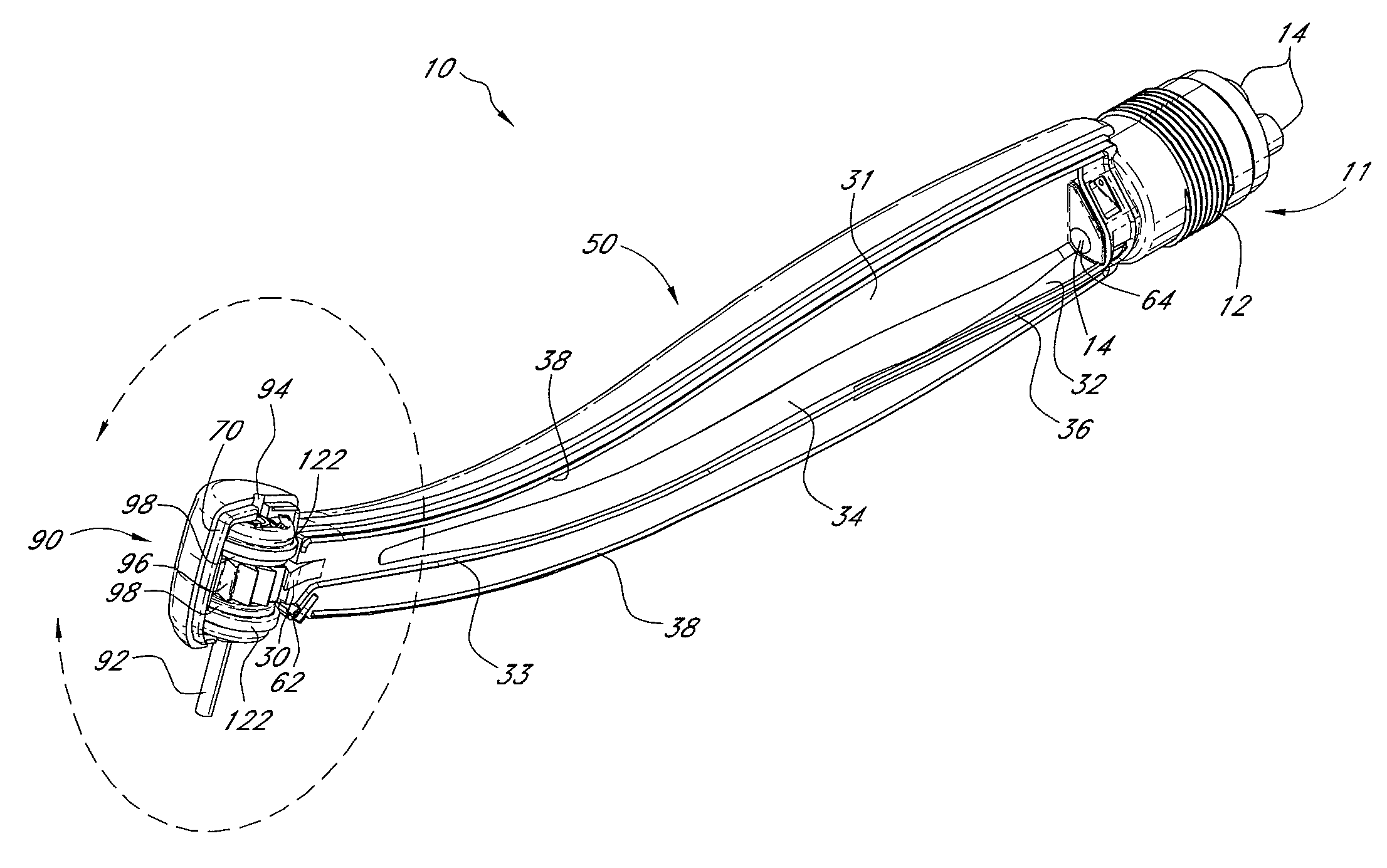

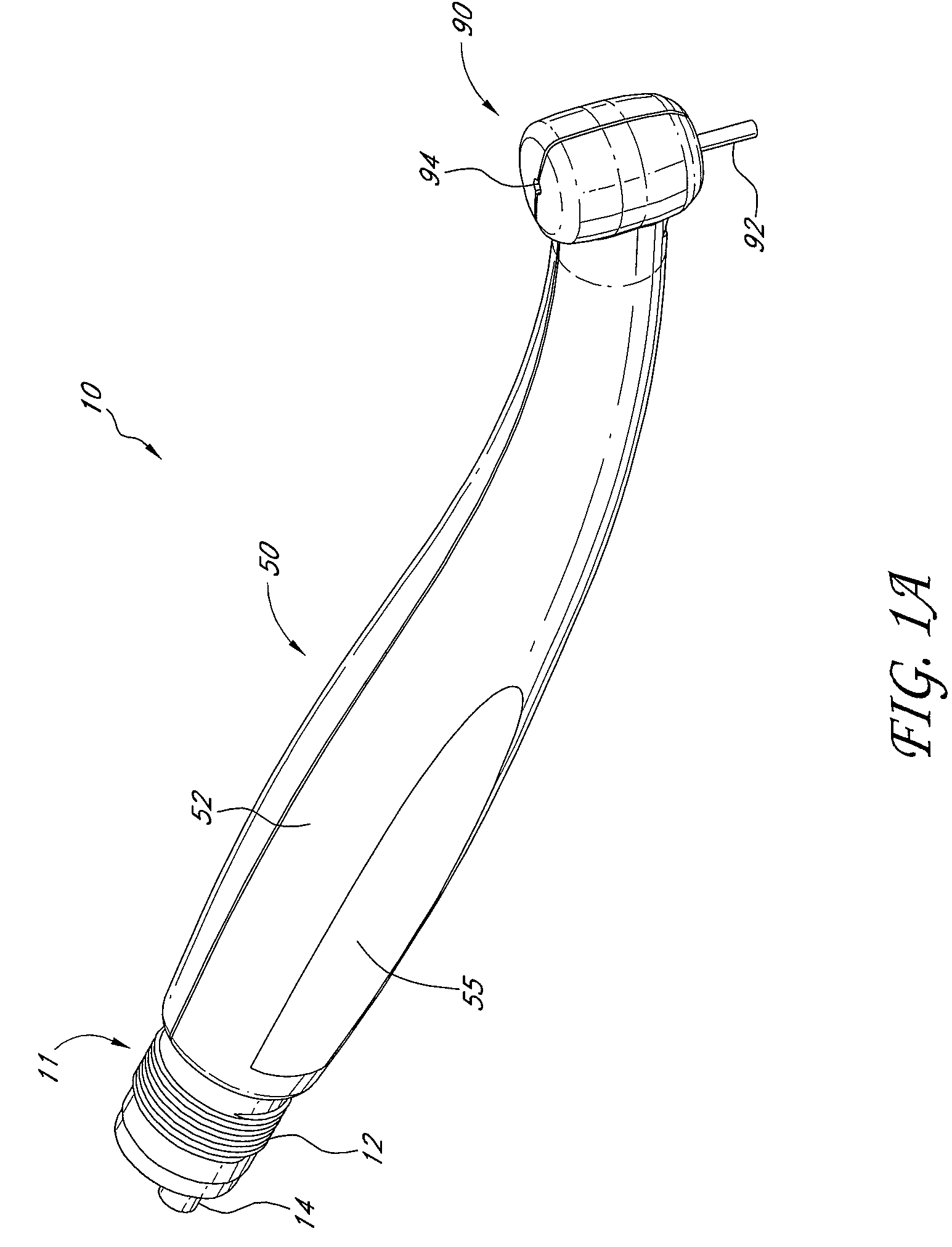

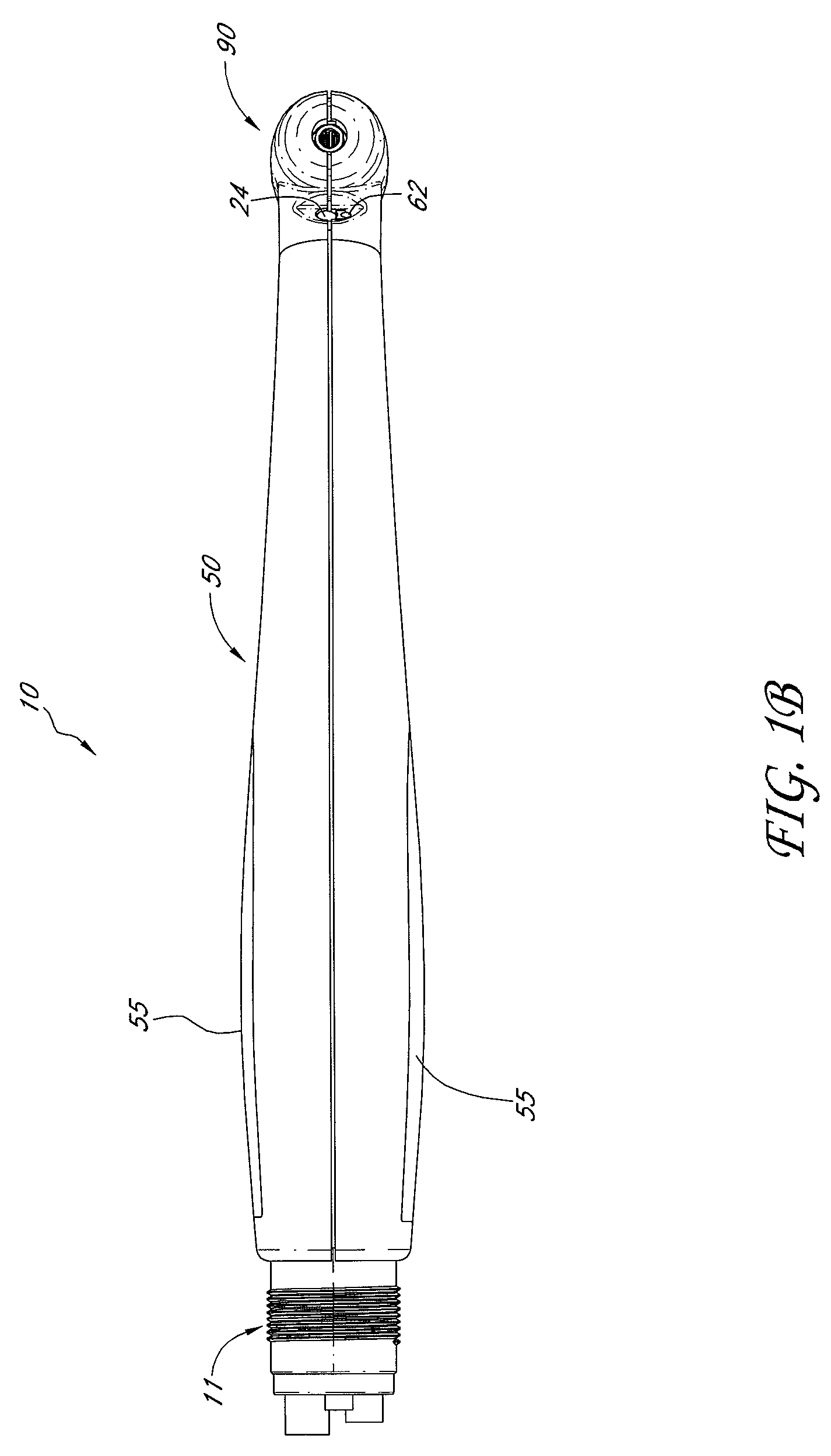

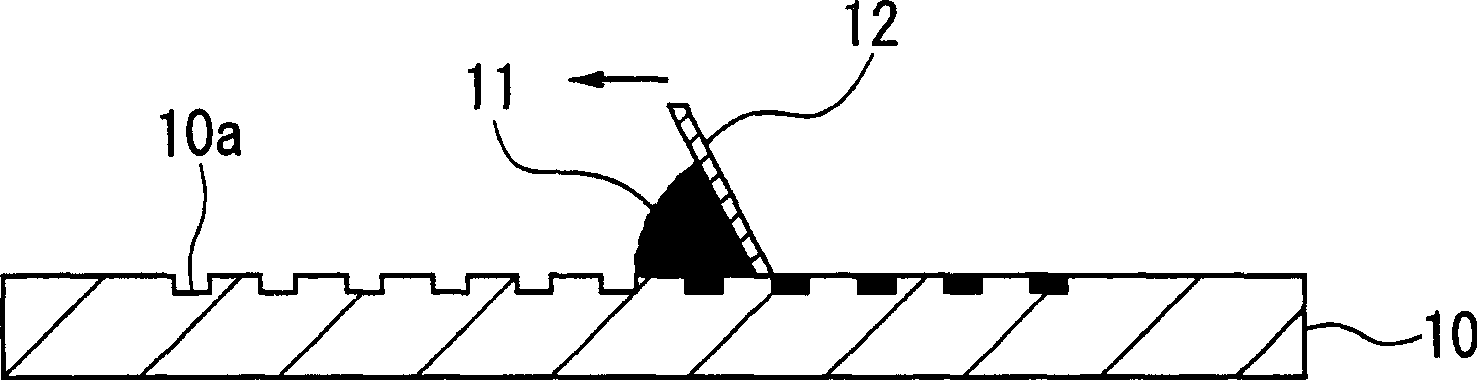

Disposable dental handpiece

A sterile, substantially maintenance free disposable dental handpiece is constructed from two shells and a center core, the center core having a flow deflector on one end. The shells are joined around the core with mating protrusions and / or tapered walls to form the body and head of the handpiece. A base is integrally-formed with the center core. The base has conduits that allow entry of light and pressurized air and / or water into the body. The head at the opposite end of the body from the base rotatably mounts an impeller assembly having an impeller shaft. The impeller shaft includes blades driven by the pressurized air. The blades can have cavities to reduce weight.

Owner:MURPHY DAVID +2

Corneal Inlay Design and Methods of Correcting Vision

ActiveUS20090198325A1Correct visionReduce shape changeLaser surgeryEye implantsCorneal inlayNear vision

Methods of designing corneal implants, such as inlays, to compensate for a corneal response, such as epithelial remodeling of the epithelial layer, to the presence of the implant. Additionally, methods of performing alternative corneal vision correction procedures to compensate for an epithelial response to the procedure. Methods of compensating for a corneal response when performing a vision correction procedure to create a center near region of the cornea for near vision while providing distance vision peripheral to the central near zone.

Owner:REVISION OPTICS

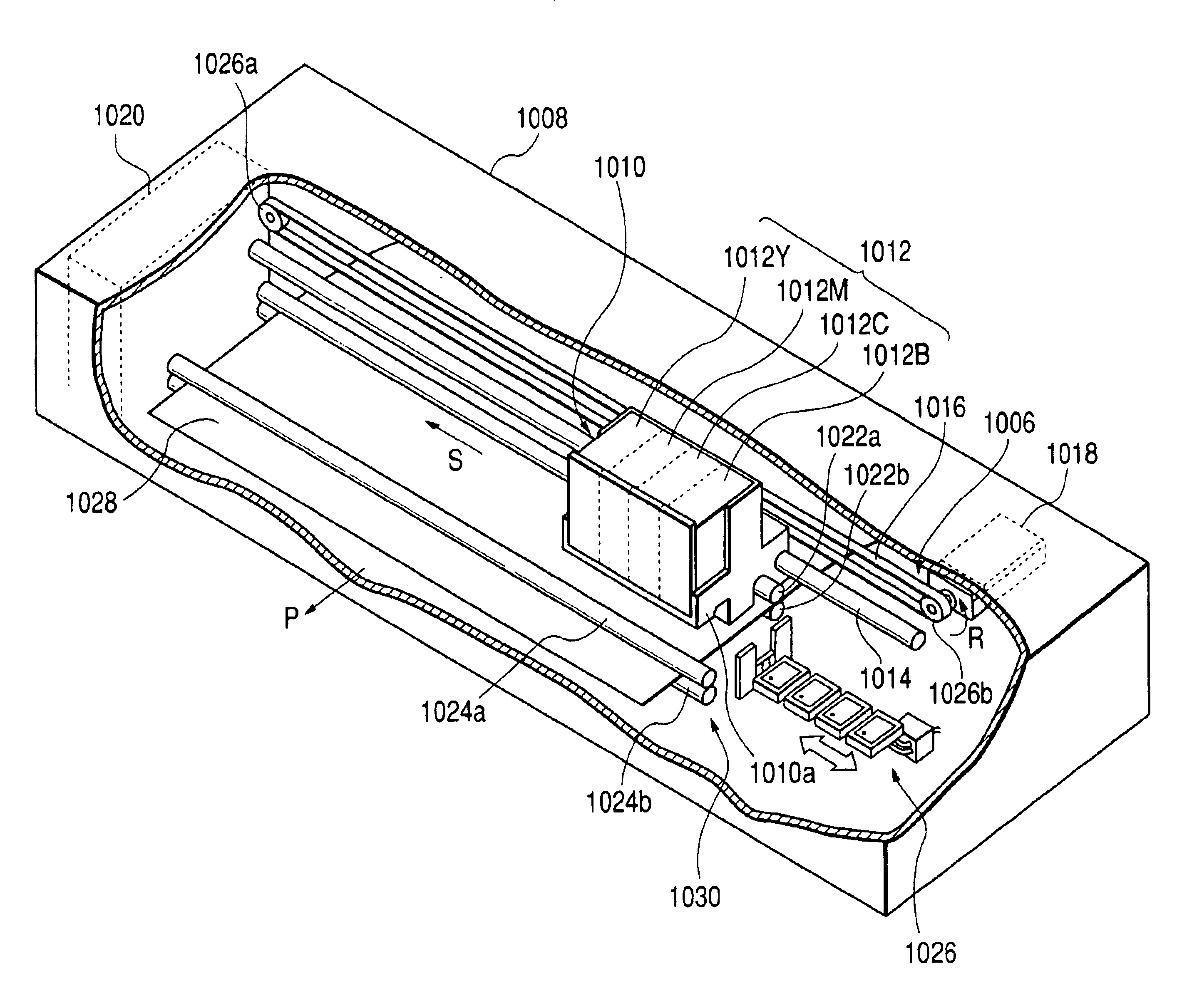

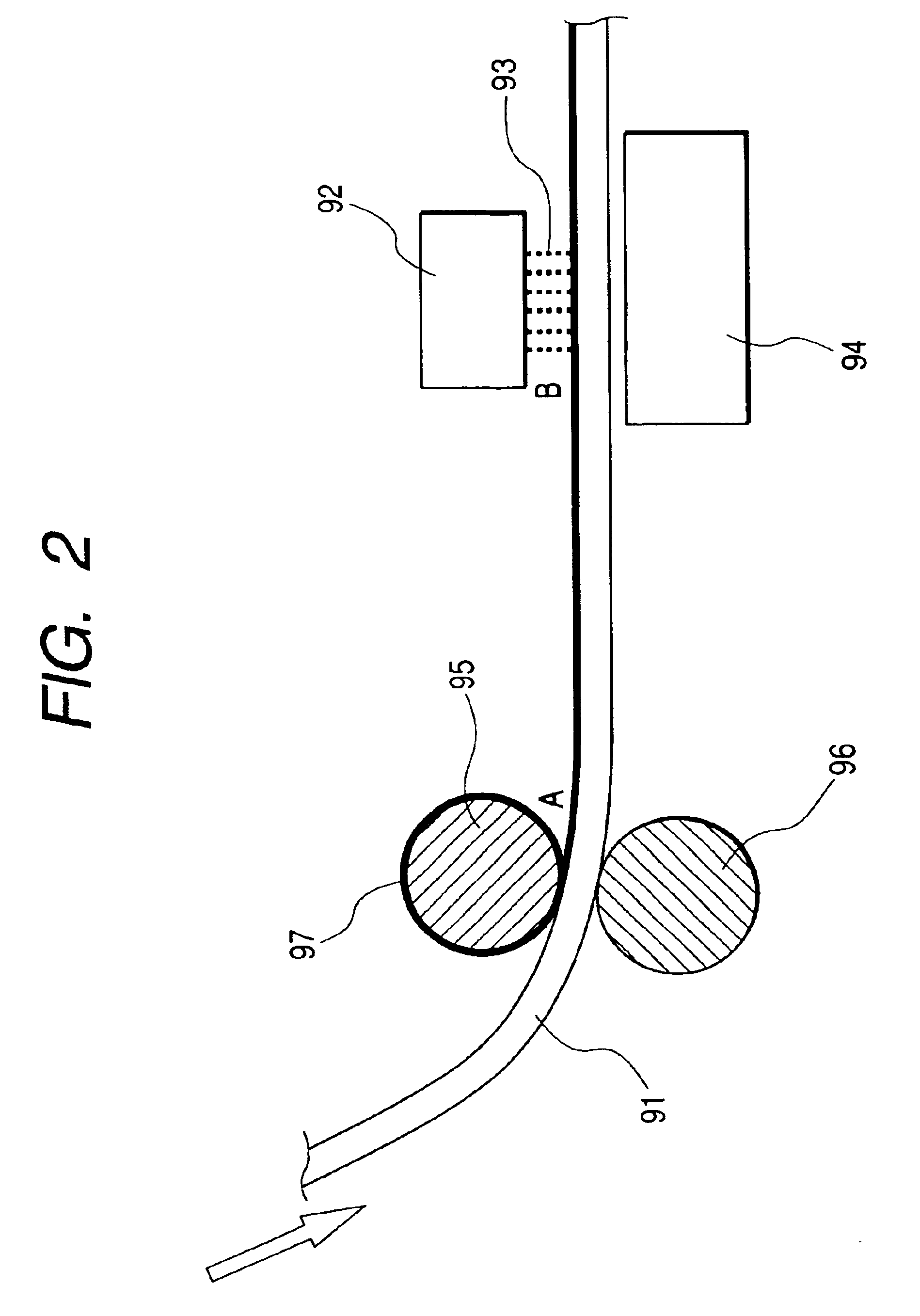

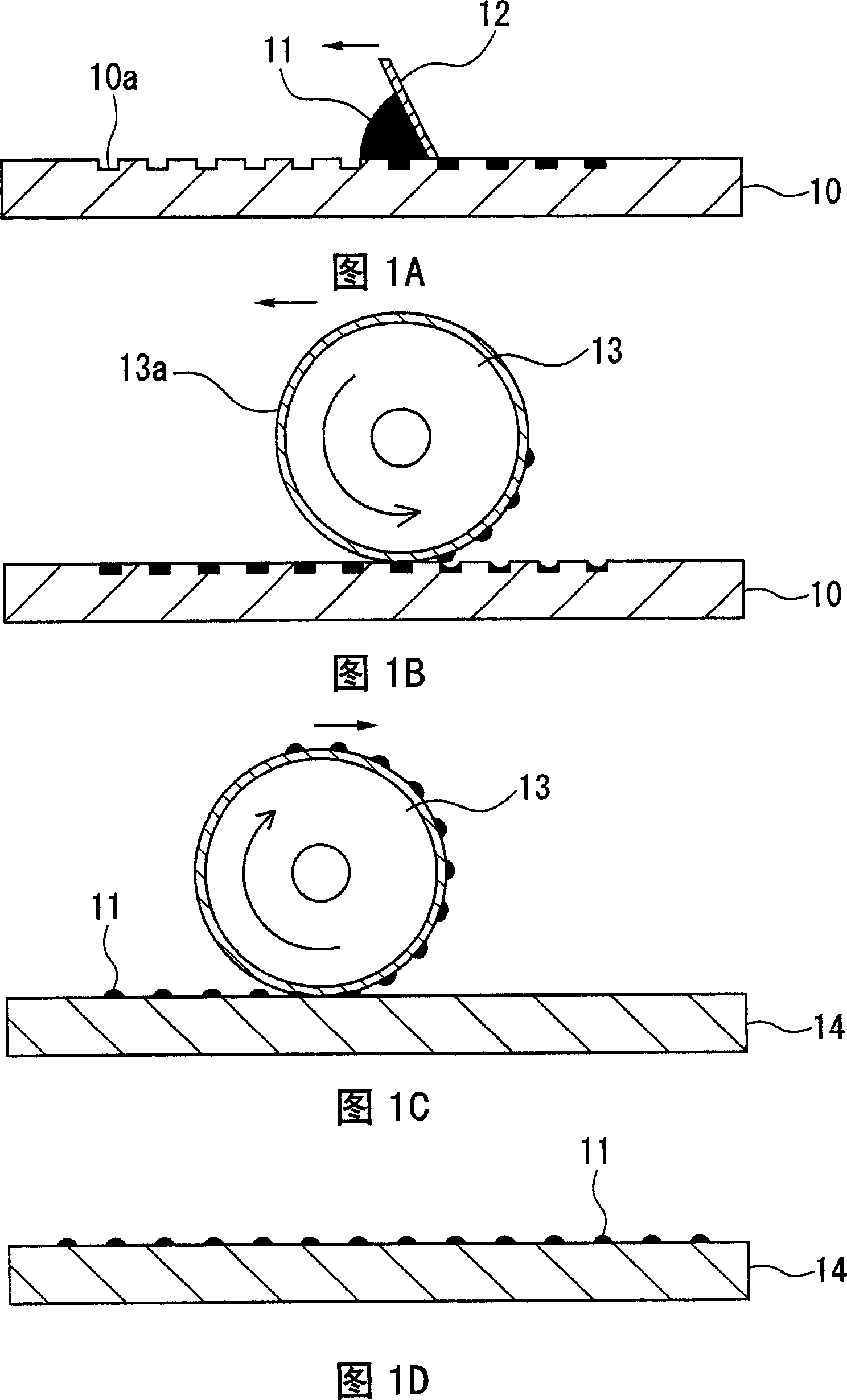

Printing oil ink and production method of coating film using the oil ink

The present invention provides a printing ink can reduce shape changes of printing pattern in consecutive printing using gravure offset printing. Said printing ink is used in gravure offset printing. In gravure offset printing, this ink is filled in printing plates with concave pattern, transfer filled ink to blankets for printing which have silicone rubber on surface, transfer ink from blankets to transferrer. Said printing ink at least includes powder component which comprise inorganic or organic powder, when including one or two kinds of rosin and solvent component which selected from group consist of acrylic resin and methyl acrylic resin, solvent component comprising more than one or two kinds of glycols solvent.

Owner:MITSUBISHI MATERIALS CORP

Corneal inlay design and methods of correcting vision

Methods of designing corneal implants, such as inlays, to compensate for a corneal response, such as epithelial remodeling of the epithelial layer, to the presence of the implant. Additionally, methods of performing alternative corneal vision correction procedures to compensate for an epithelial response to the procedure. Methods of compensating for a corneal response when performing a vision correction procedure to create a center near region of the cornea for near vision while providing distance vision peripheral to the central near zone.

Owner:REVISION OPTICS

Preparation method of food-grade calcium alginate

The invention discloses a preparation method of food-grade calcium alginate. The preparation method comprises the following steps: embathing brown alga, and adding sodium carbonate for digesting the brown alga to extract alginic acid; diluting and filtering the product; carrying out air air floatation separation; carrying out fine filtration; introducing chlorine gas for bleaching; adding calcium chloride solution to enable water-soluble sodium alginate to be converted into water-insoluble calcium alginate; washing; carrying out dehydration; drying; grinding. According to the preparation method, kieselguhr is added for fine filtration, so that harmful substances such as pigment, heavy metal and the like are removed; the produced calcium alginate meets the food grade requirements and is widely used in the industries such as medicines, food and daily use chemical.

Owner:江苏明月海洋生物科技有限公司

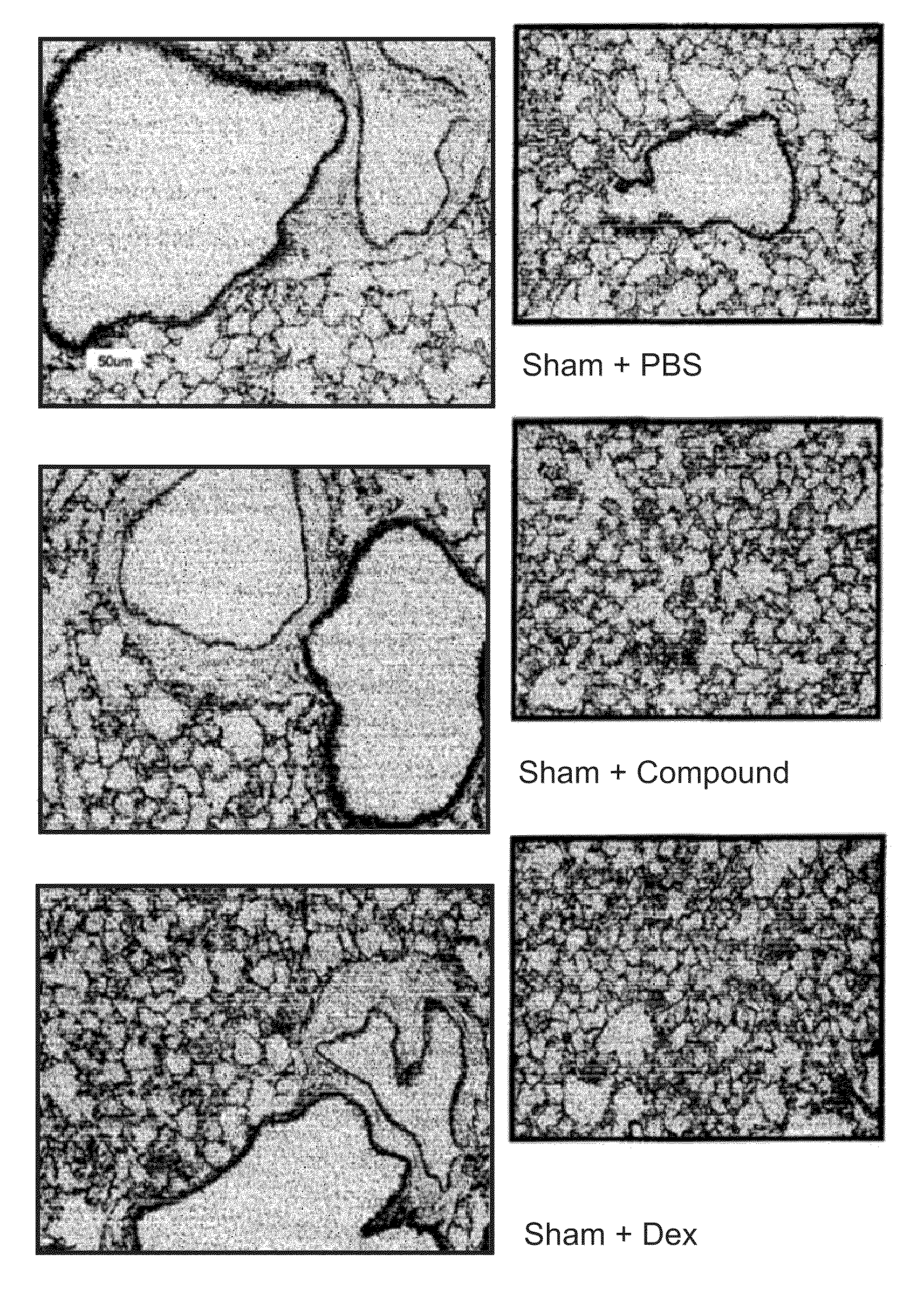

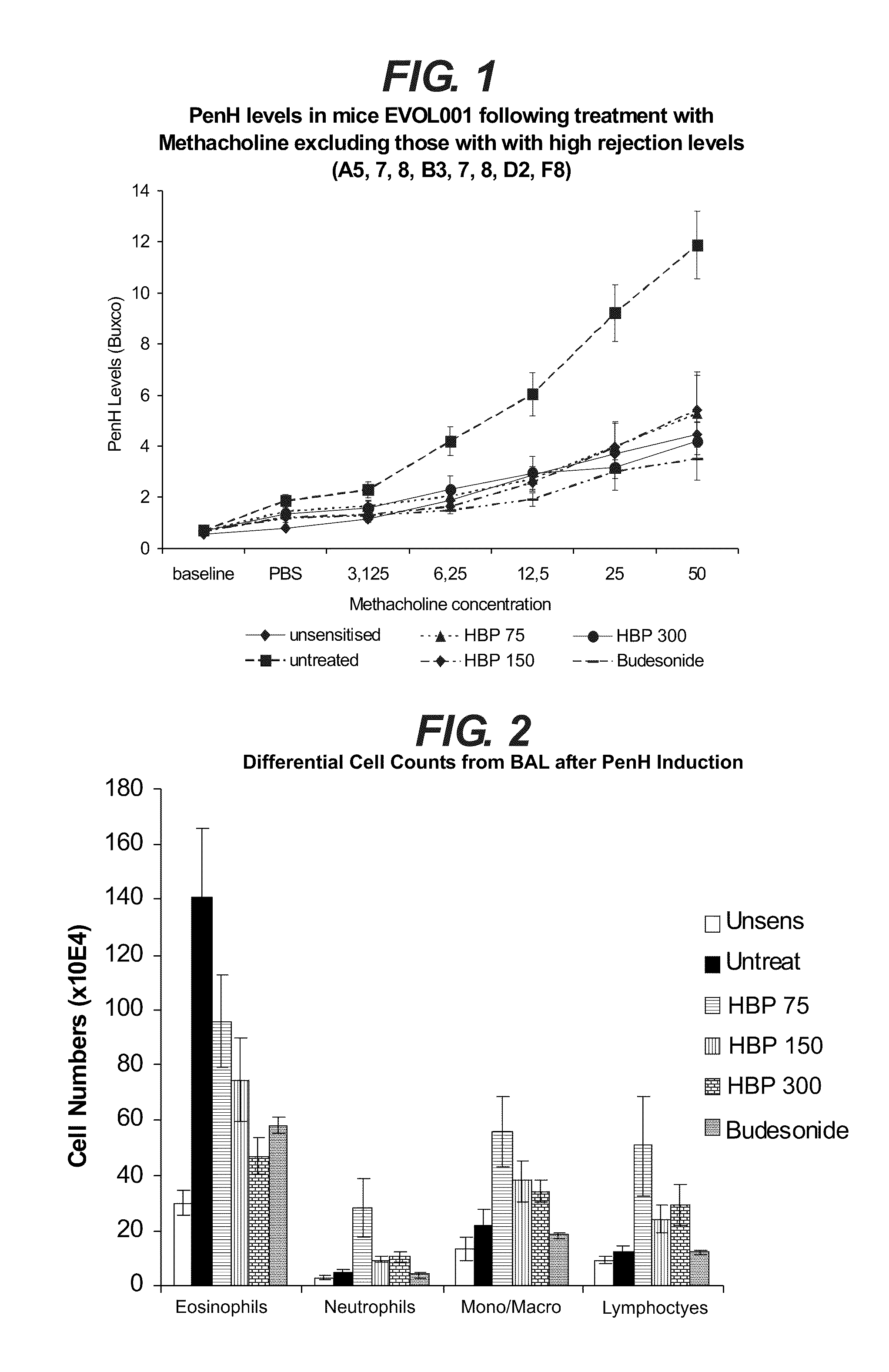

Histamine binding protein

InactiveUS20110152171A1Reduction TIMP-Improve the level ofSenses disorderPeptide/protein ingredientsHistamine bindingHistamine

Owner:VARLEIGH IMMUNO PHARMA VIP

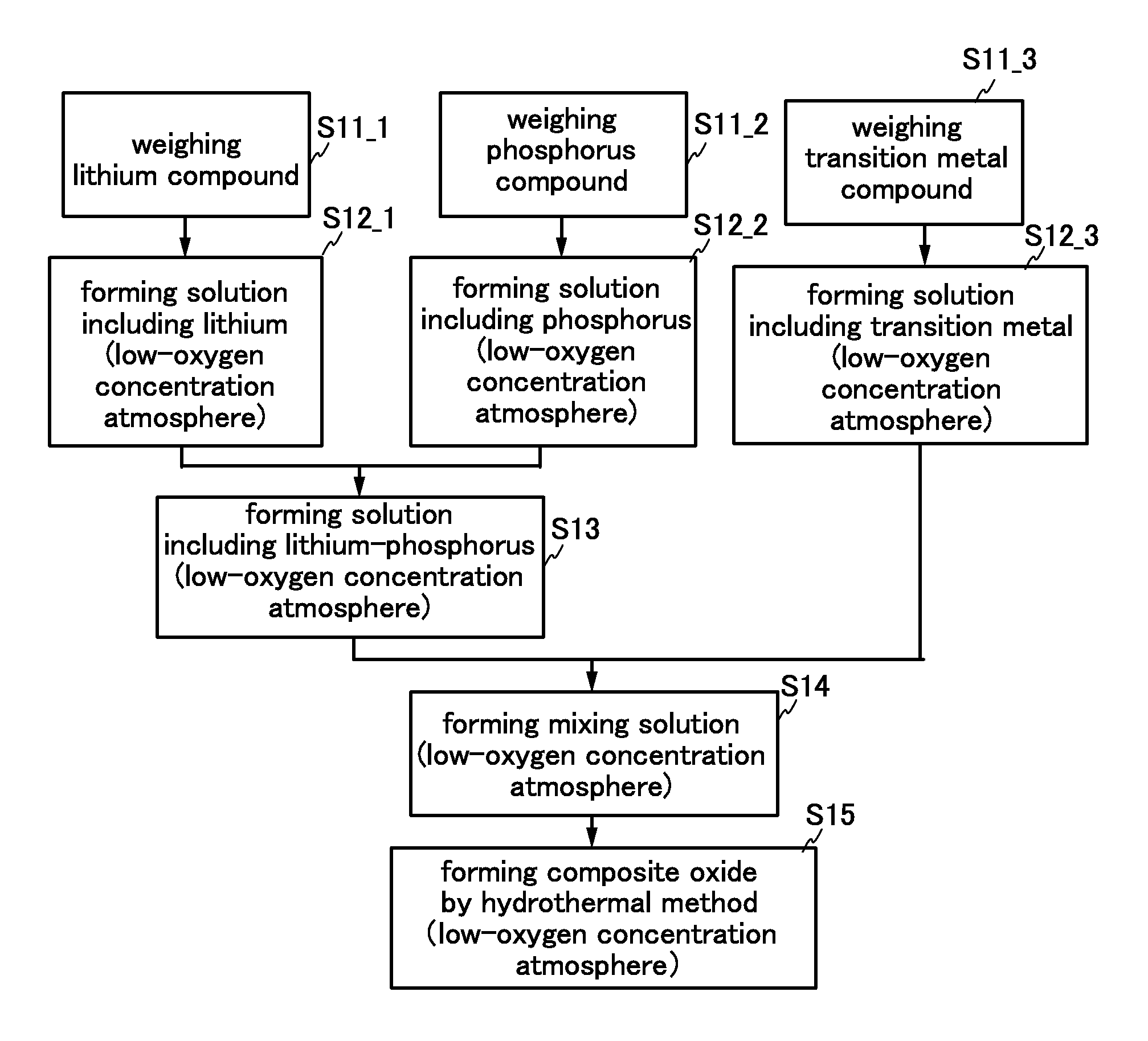

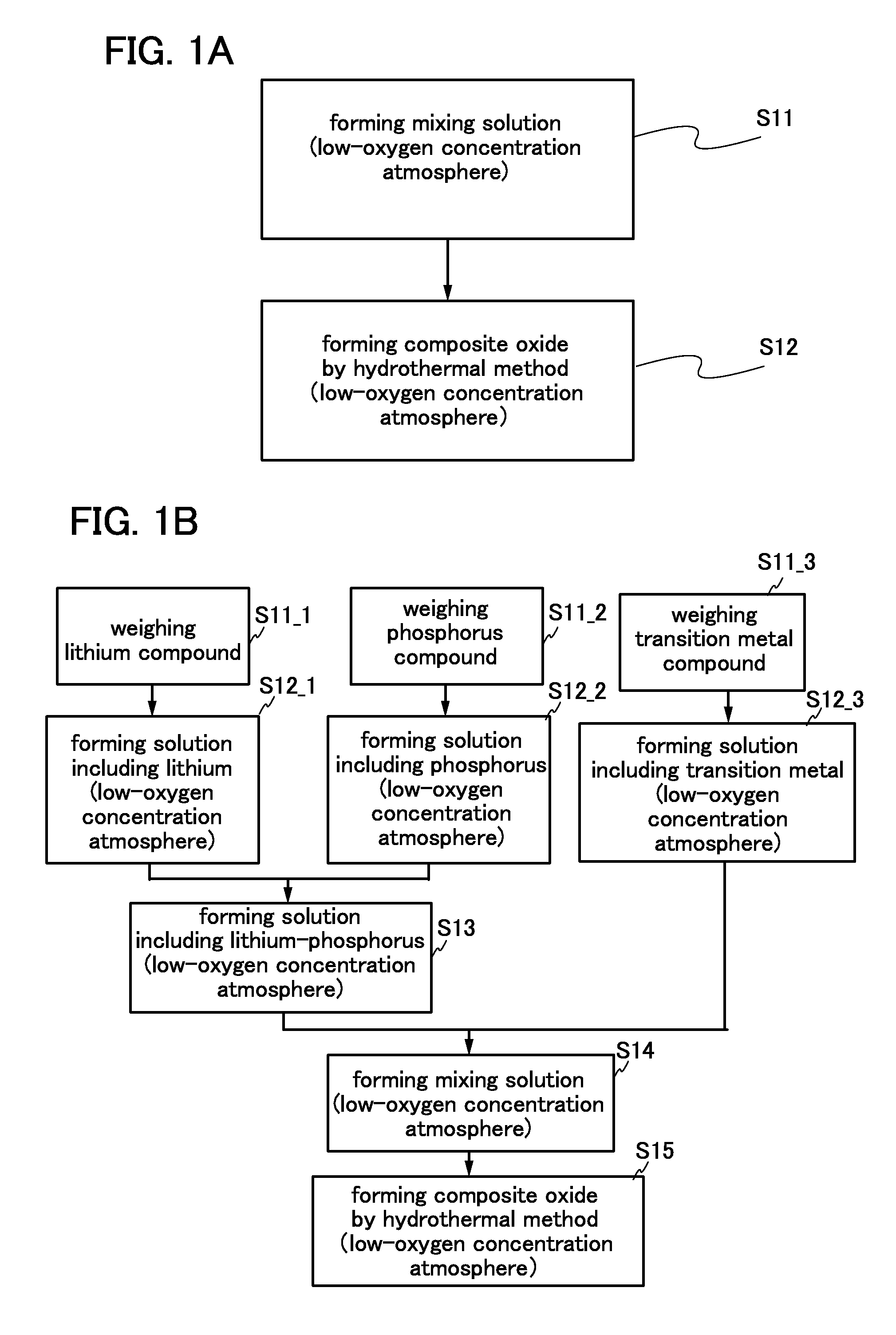

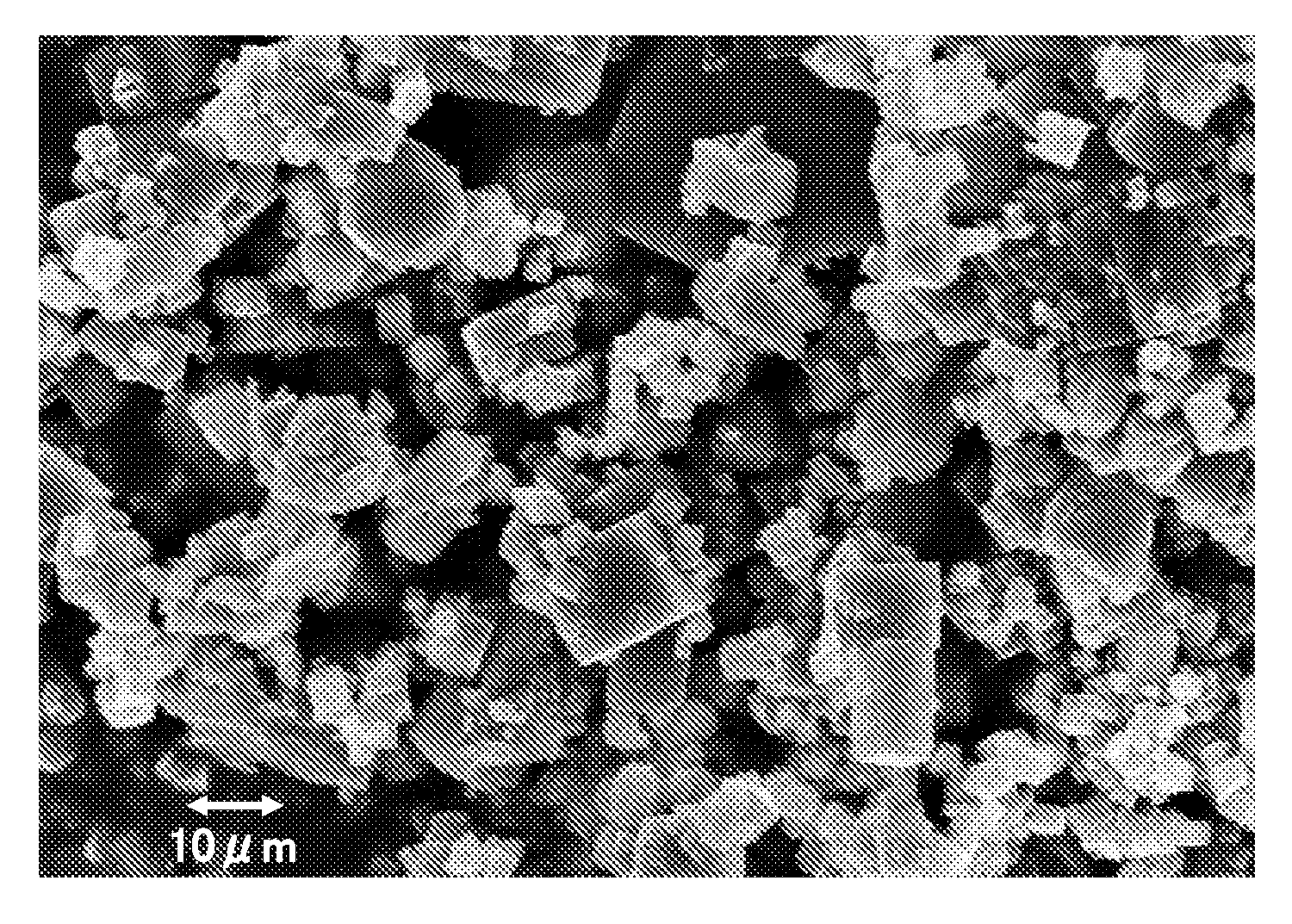

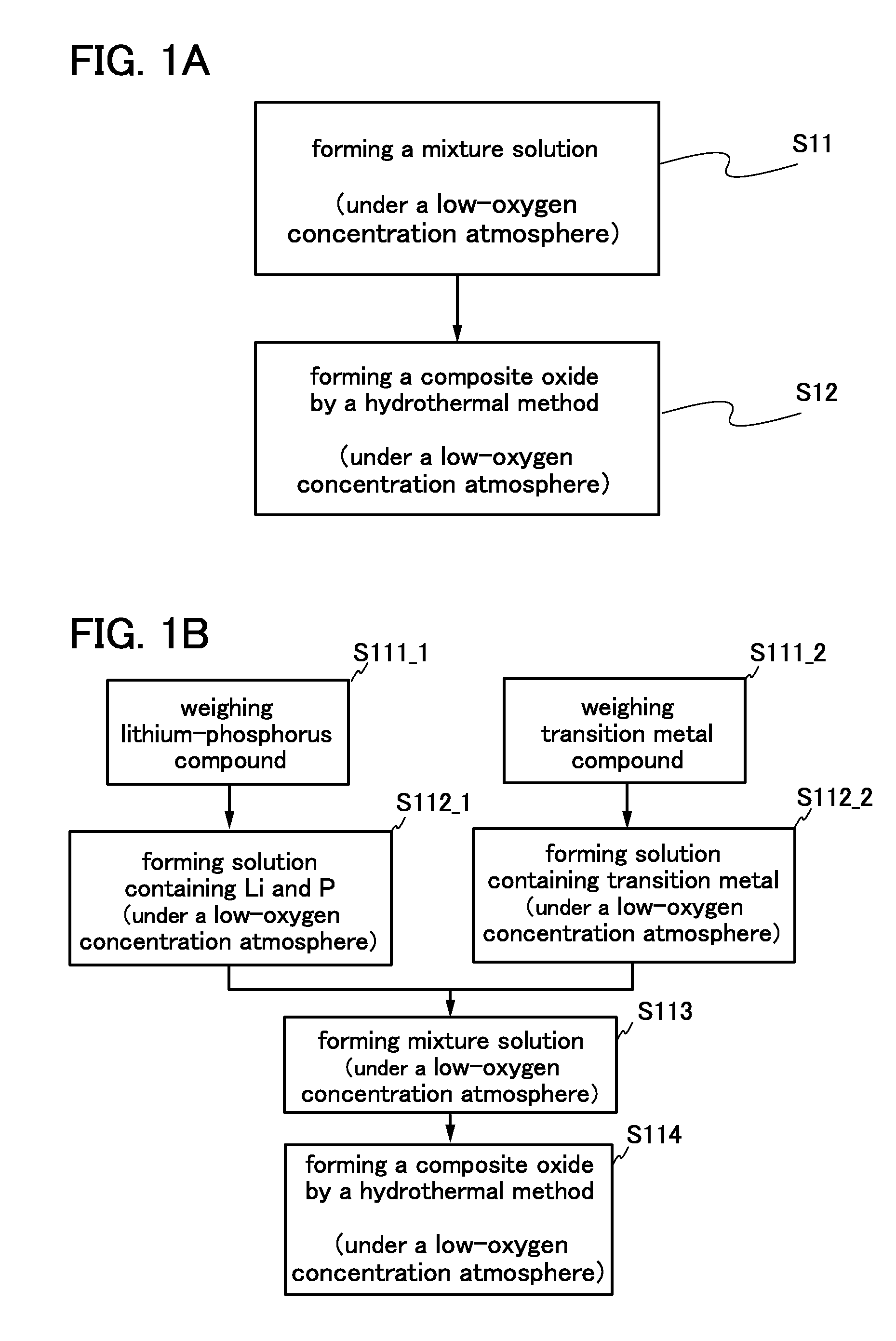

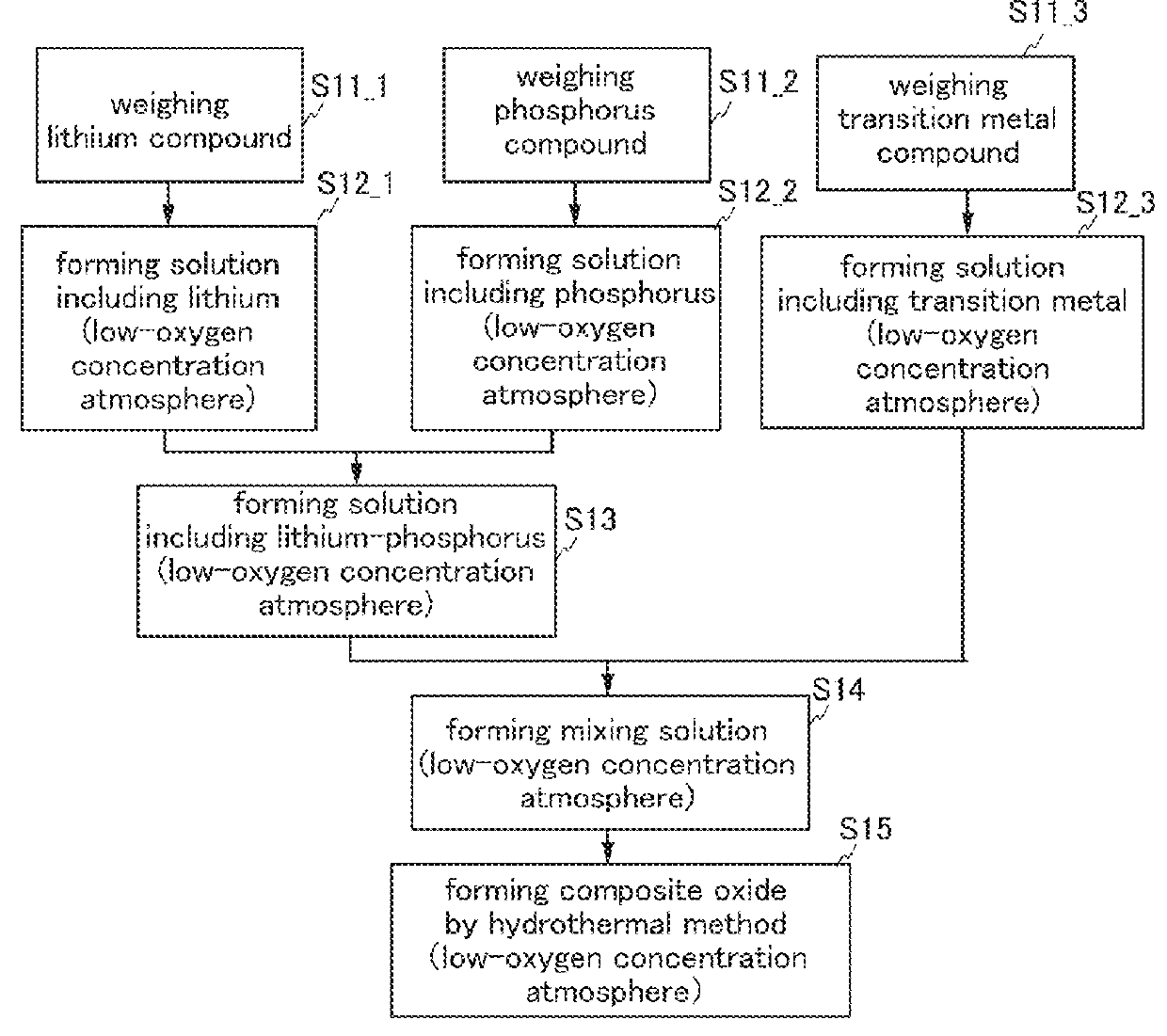

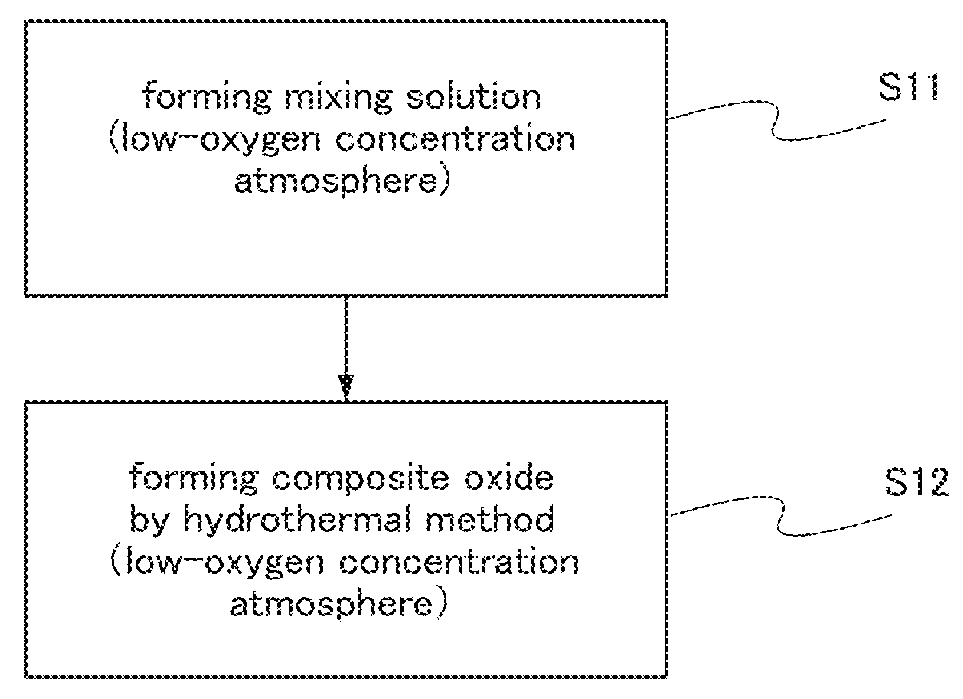

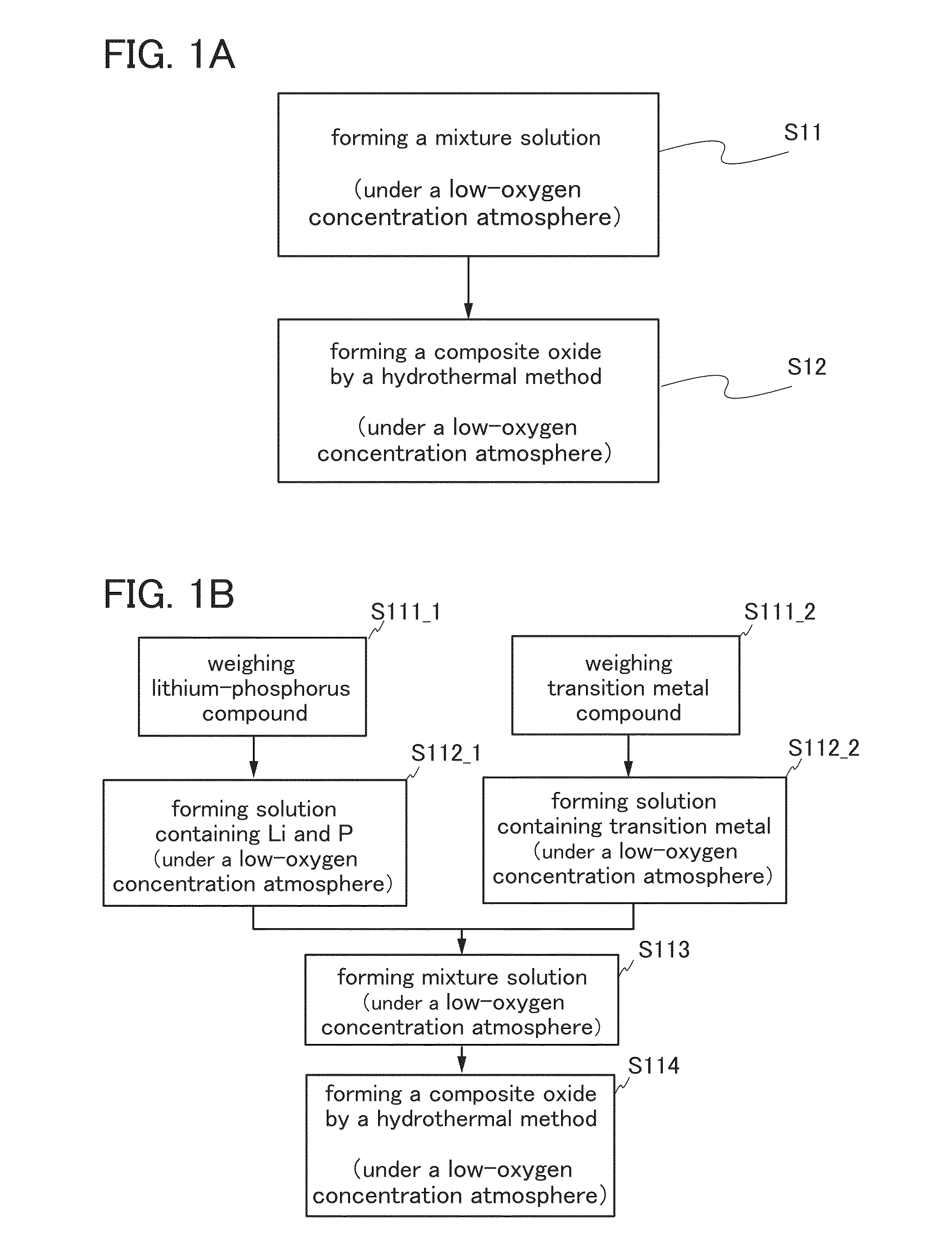

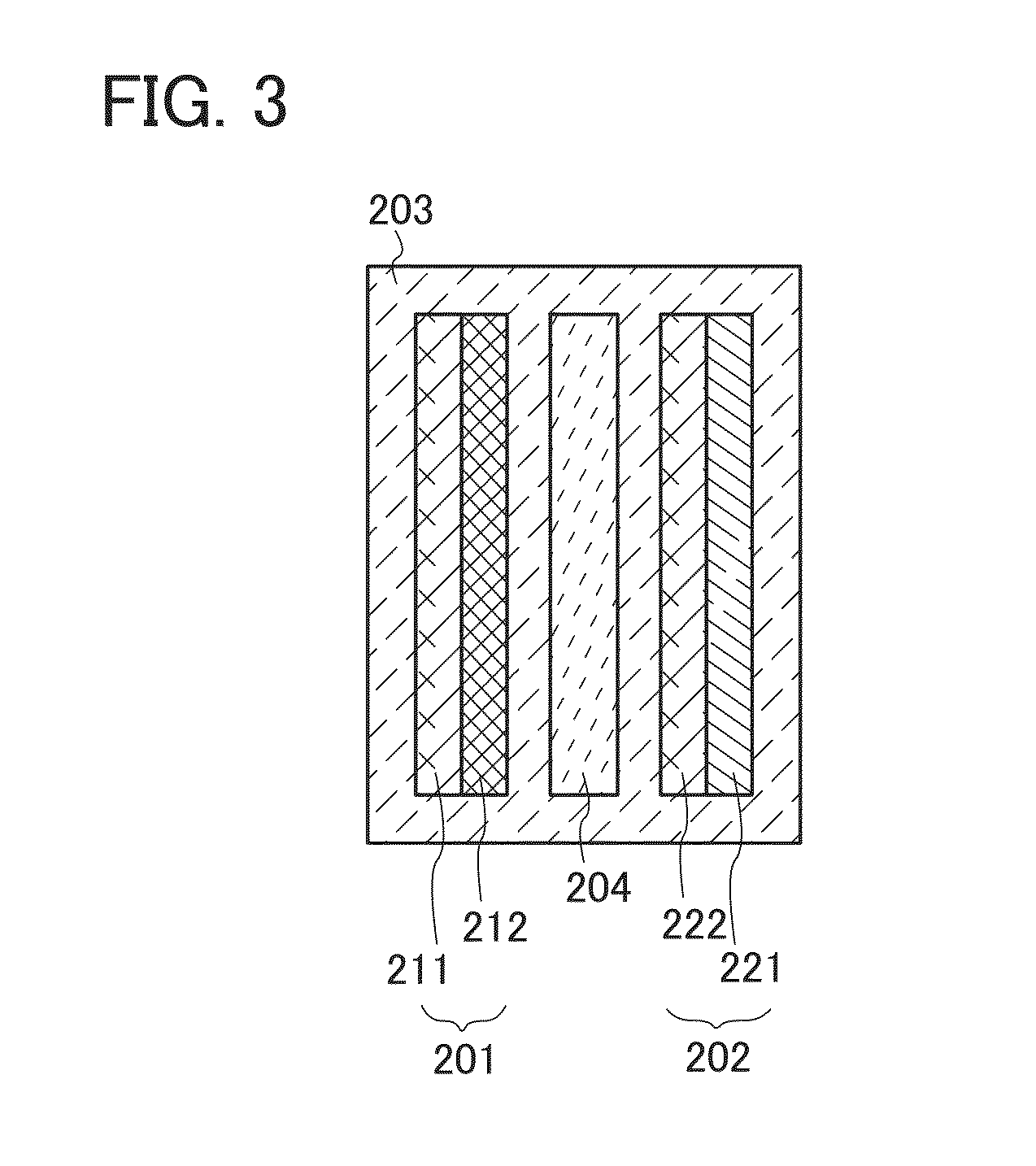

Manufacturing method of composite oxide and manufacturing method of power storage device

ActiveUS20130047915A1Reduce the differenceReduced characteristicsPolycrystalline material growthFrom normal temperature solutionsEngineeringOxygen

An object is to reduce variation in shape of crystals that are to be formed. Solutions containing respective raw materials are made in an environment where an oxygen concentration is lower than that in air, the solutions containing the respective raw materials are mixed in an environment where an oxygen concentration is lower than that in air to form a mixture solution, and with use of the mixture solution, a composite oxide is formed by a hydrothermal method.

Owner:SEMICON ENERGY LAB CO LTD

Graphical user interface adjusting to a change of user's disposition

ActiveUS8890812B2Expand the scope of usersEasy to operateCharacter and pattern recognitionCathode-ray tube indicatorsGraphicsGraphical user interface

A user interface apparatus and a method for adjusting the apparatus are disclosed. A position and / or a viewing angle of the user is tracked, and graphical interface objects are adjusted to keep them visible at different user's distances and viewing angles. For example, as the user steps away from the display, the objects on the display can be proportionally enlarged to make them appear of the same size to the user. The sensitivity of a gesture recognition system to the user's movements and gestures can be also adjusted to facilitate manipulation of the objects by the user at different distances from the display of the graphical user interface.

Owner:LUMENTUM OPERATIONS LLC

Manufacturing method of composite oxide and manufacturing method of power storage device

ActiveUS20130047422A1Reduce variationReduced characteristicsPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesEngineeringOxygen

An object is to reduce variation in shape of crystals that are to be manufactured. Raw materials are each weighed, solutions containing the respective raw materials are formed in an environment where an oxygen concentration is lower than that in air, the solutions containing the respective raw materials are mixed in an environment where an oxygen concentration is lower than that in air to form a mixture solution, and with use of the mixture solution, a composite oxide is formed by a hydrothermal method.

Owner:SEMICON ENERGY LAB CO LTD

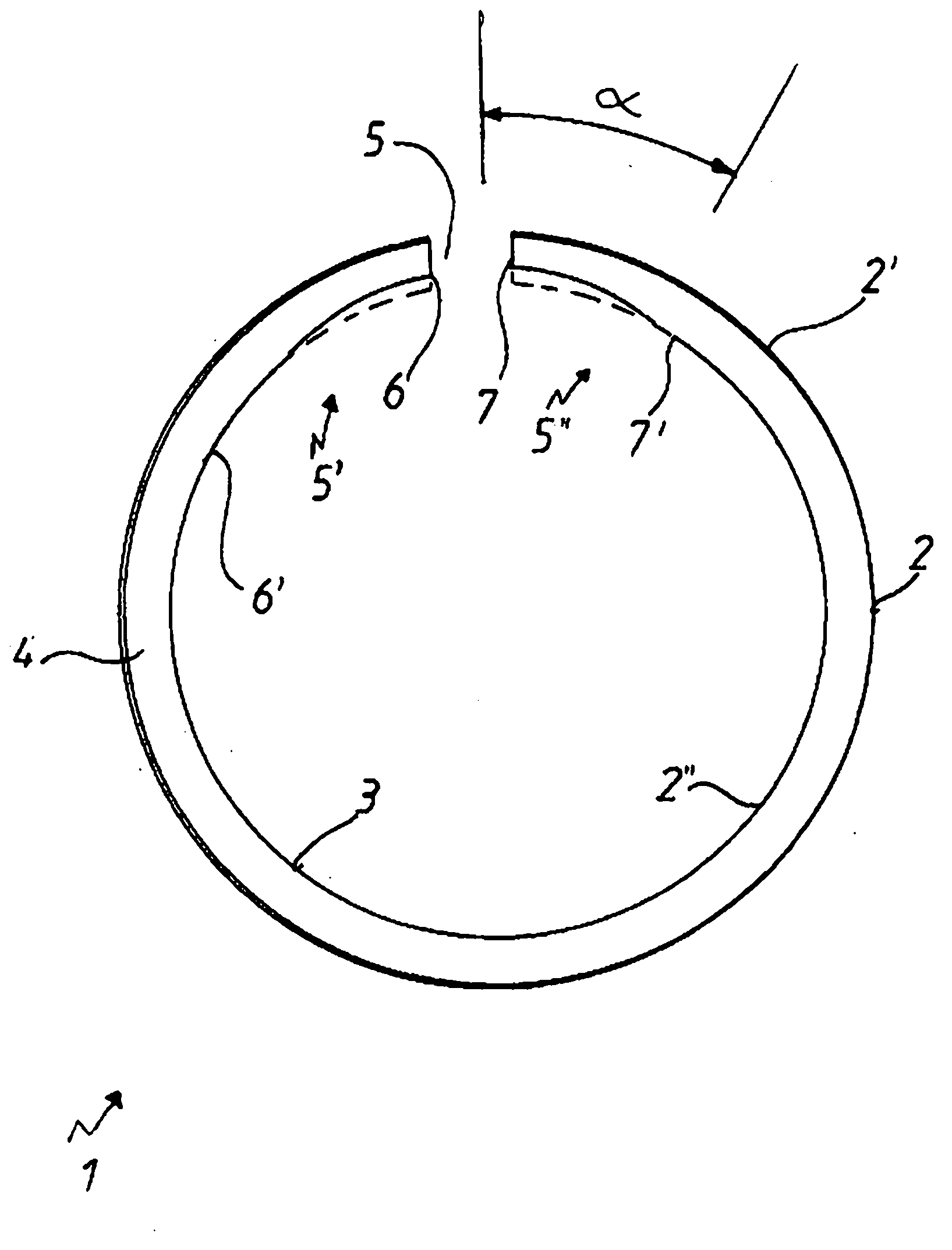

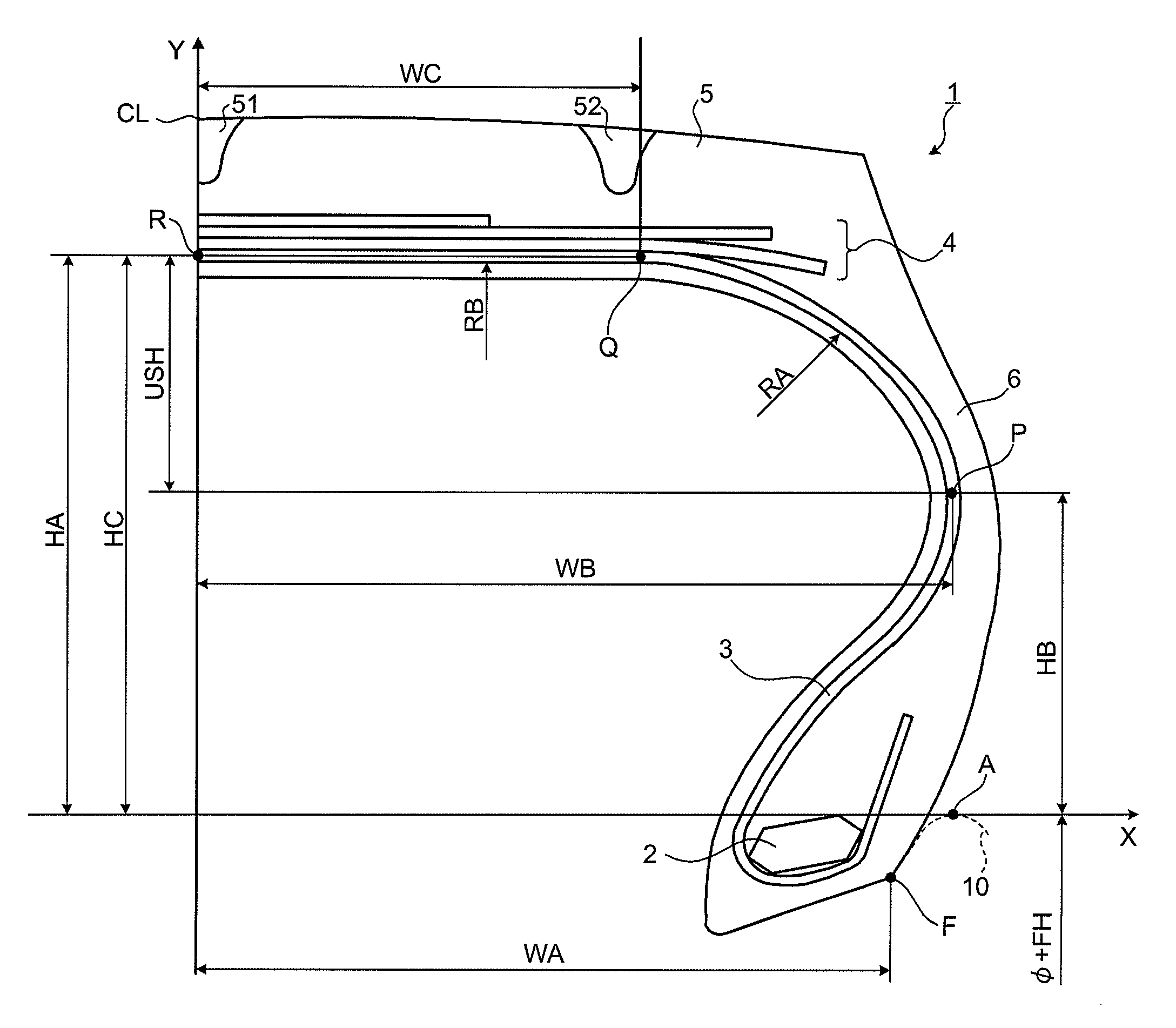

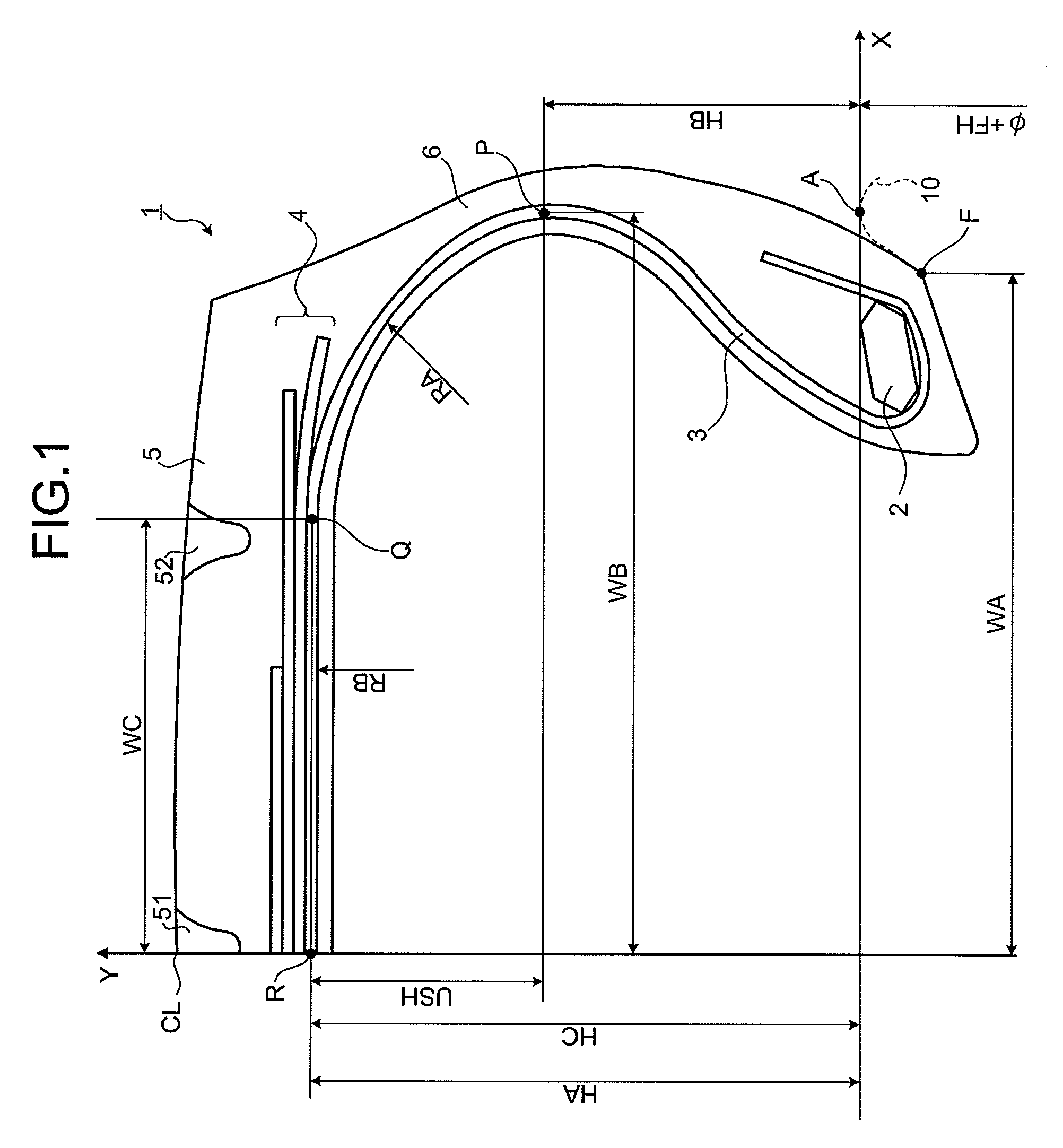

Method for producing a piston ring

ActiveCN103154583AReduce plane moment of inertiaReduce radial pressurePiston ringsMachines/enginesButt jointMaterial removal

The invention relates to a method for producing a piston ring (1) provided with a butt joint (5), in that an annular metal main body is provided with at least one hard layer (2') at least in the area of the outer circumferential surface (2) of said main body, wherein after this coating the inner circumferential surface (3) of the piston ring is at least partially subjected to a wall-thickness-reducing material removal process.

Owner:FEDERAL MOGUL BURSCHEID

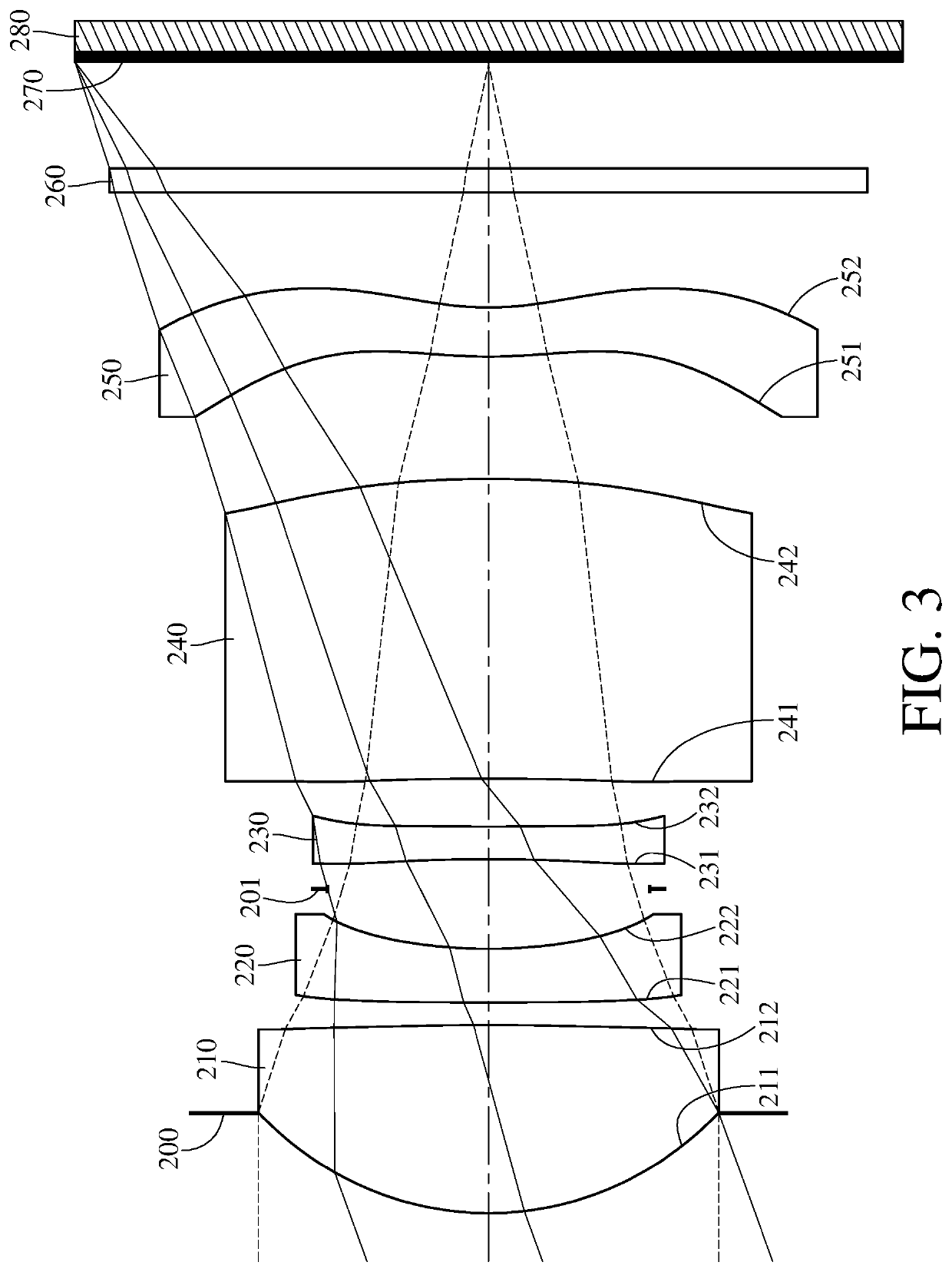

Photographing optical lens system, image capturing unit and electronic device

A photographing optical lens system includes seven lens elements which are, in order from an object side to an image side: a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element and a seventh lens element. Each of the seven lens elements has an object-side surface facing toward the object side and an image-side surface facing toward the image side. The object-side surface of the first lens element is convex in a paraxial region thereof. The seventh lens element has negative refractive power. The object-side surface of the seventh lens element is concave in a paraxial region thereof. At least one of all lens surfaces of the seven lens elements is aspheric and has at least one inflection point. When specific conditions are met, the photographing optical lens can meet the requirements of miniaturization and large aperture at the same time. The invention also provides an image capturing unit with the photographing optical lens and electronic device with the image capturing unit.

Owner:LARGAN PRECISION

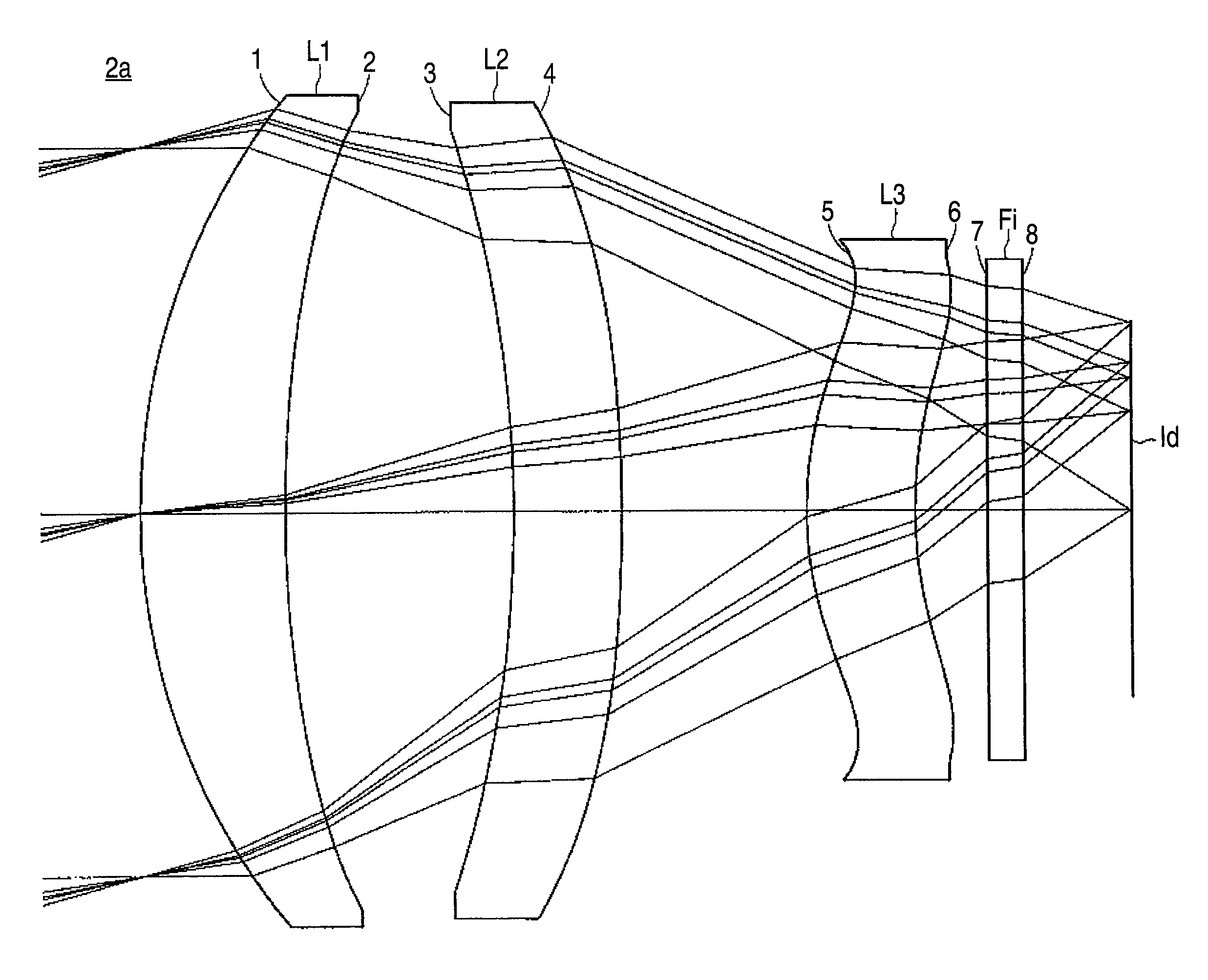

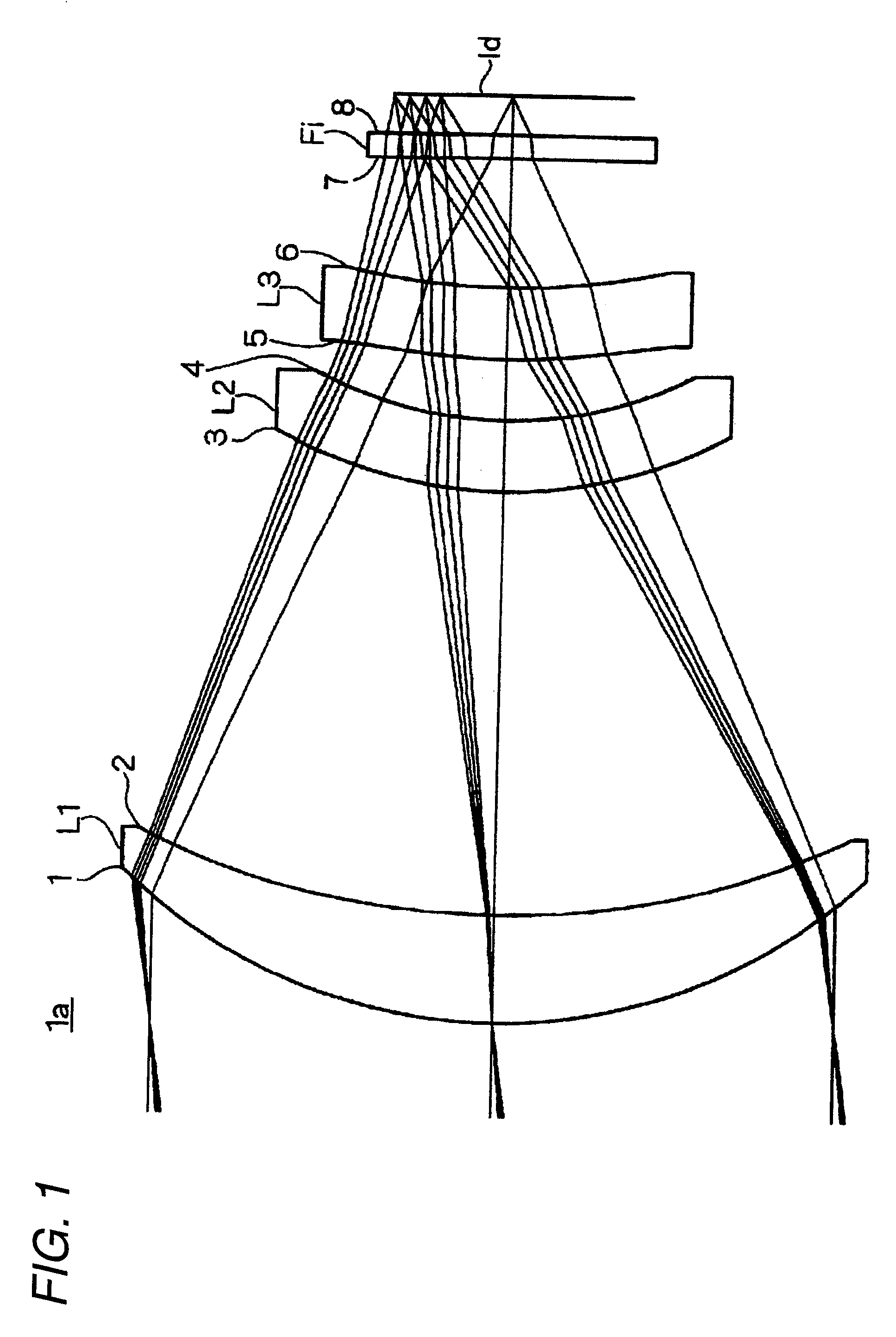

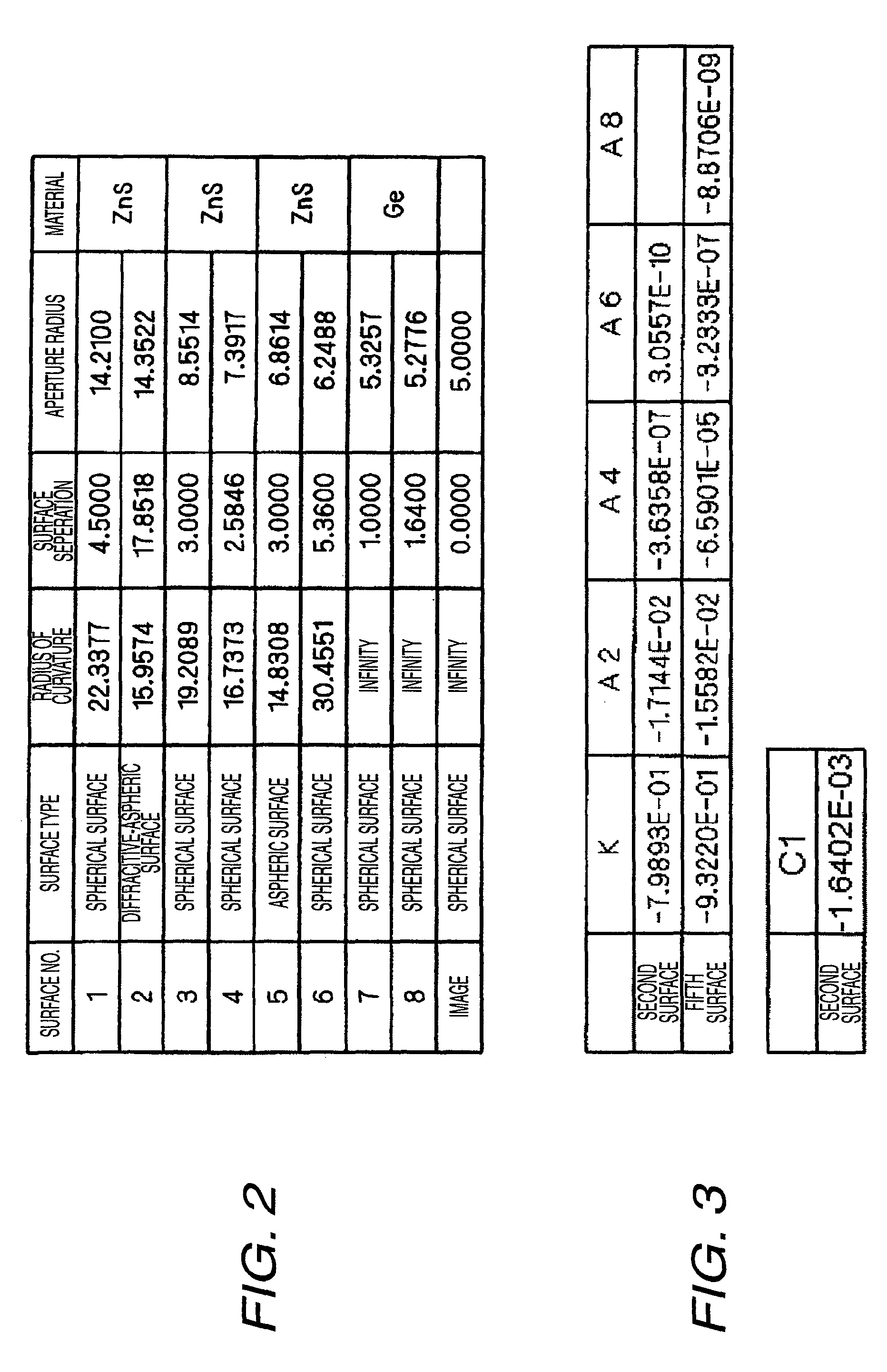

Infrared lens, infrared camera, and night vision

InactiveUS7911688B2Reduce light lossImprove imaging effectMaterial analysis by optical meansNon-linear opticsNight visionZinc sulfide

An infrared lens 1a includes first to third lenses L1 to L3 which are made of zinc sulfide and arranged in this order from an object side. Each of the first to third lenses L1 to L3 is configured as a positive meniscus lens of which convex surface is opposed to the object. The lenses L1 to L3 are formed by heat-press molding raw powder of zinc sulfide using a lens-shaped mold. In addition, a concave surface (the surface opposed to the image side) of the first lens L1 is formed as a diffractive surface.

Owner:SUMITOMO ELECTRIC IND LTD

Manufacturing method of composite oxide and manufacturing method of power storage device

ActiveUS9249524B2Reduced characteristicsReduce total powerPolycrystalline material growthFrom normal temperature solutionsEngineeringOxygen

An object is to reduce variation in shape of crystals that are to be formed. Solutions containing respective raw materials are made in an environment where an oxygen concentration is lower than that in air, the solutions containing the respective raw materials are mixed in an environment where an oxygen concentration is lower than that in air to form a mixture solution, and with use of the mixture solution, a composite oxide is formed by a hydrothermal method.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of composite oxide and manufacturing method of power storage device

ActiveUS9118077B2Reduced characteristicsReduce total powerCell electrodesPhosphorus compoundsEngineeringOxygen

An object is to reduce variation in shape of crystals that are to be manufactured. Raw materials are each weighed, solutions containing the respective raw materials are formed in an environment where an oxygen concentration is lower than that in air, the solutions containing the respective raw materials are mixed in an environment where an oxygen concentration is lower than that in air to form a mixture solution, and with use of the mixture solution, a composite oxide is formed by a hydrothermal method.

Owner:SEMICON ENERGY LAB CO LTD

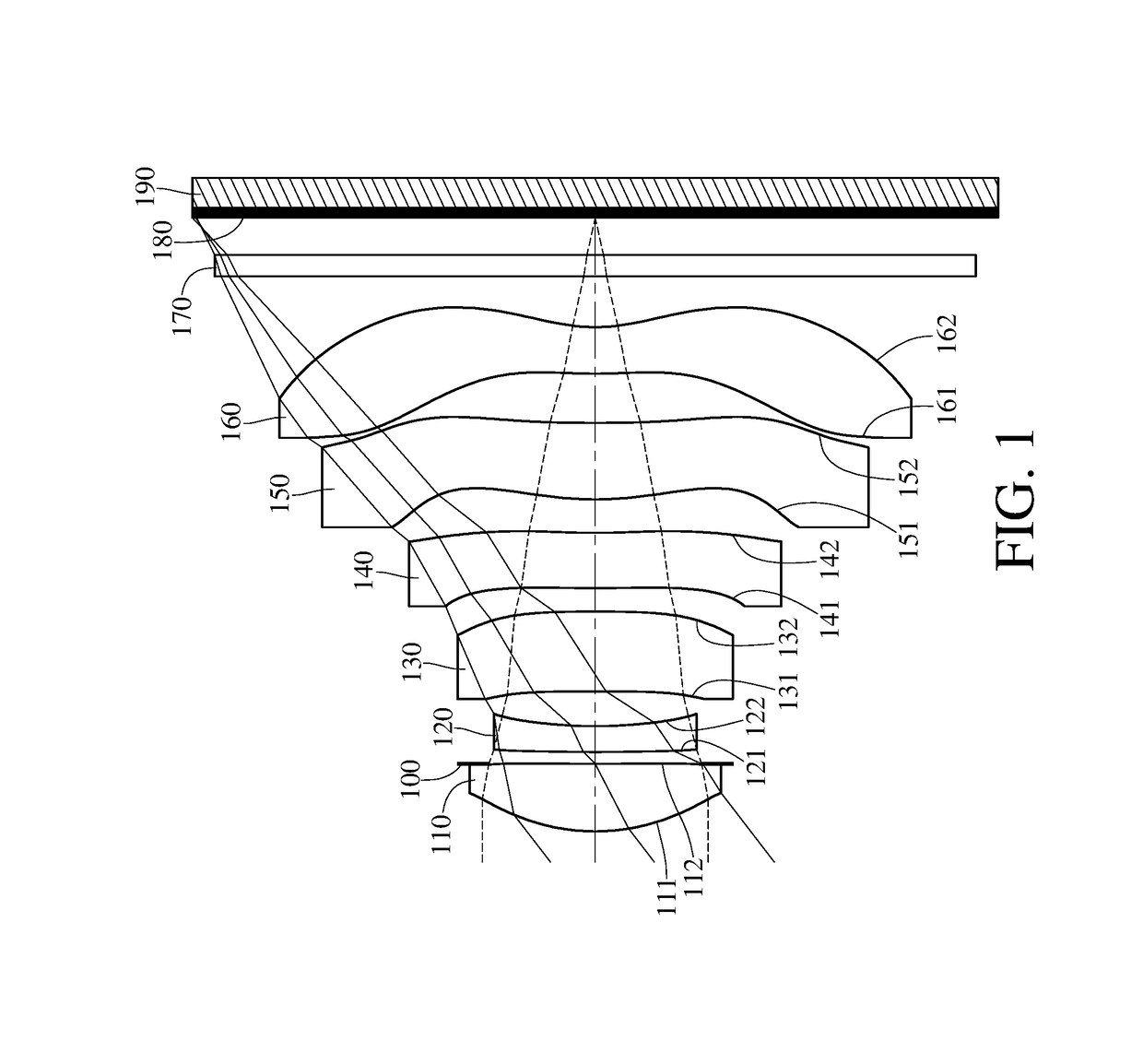

Optical imaging lens assembly, image capturing unit and electronic device

ActiveUS20190346661A1Optimize space utilizationReduce shape changeOptical elementsCamera lensElectronic equipment

An optical imaging lens assembly includes five lens elements, which are, in order from an object side to an image side: a first lens element, a second lens element, a third lens element, a fourth lens element and a fifth lens element. The first lens element with positive refractive power has an object-side surface being convex in a paraxial region thereof. The third lens element has negative refractive power. The fifth lens element has negative refractive power.

Owner:LARGAN PRECISION

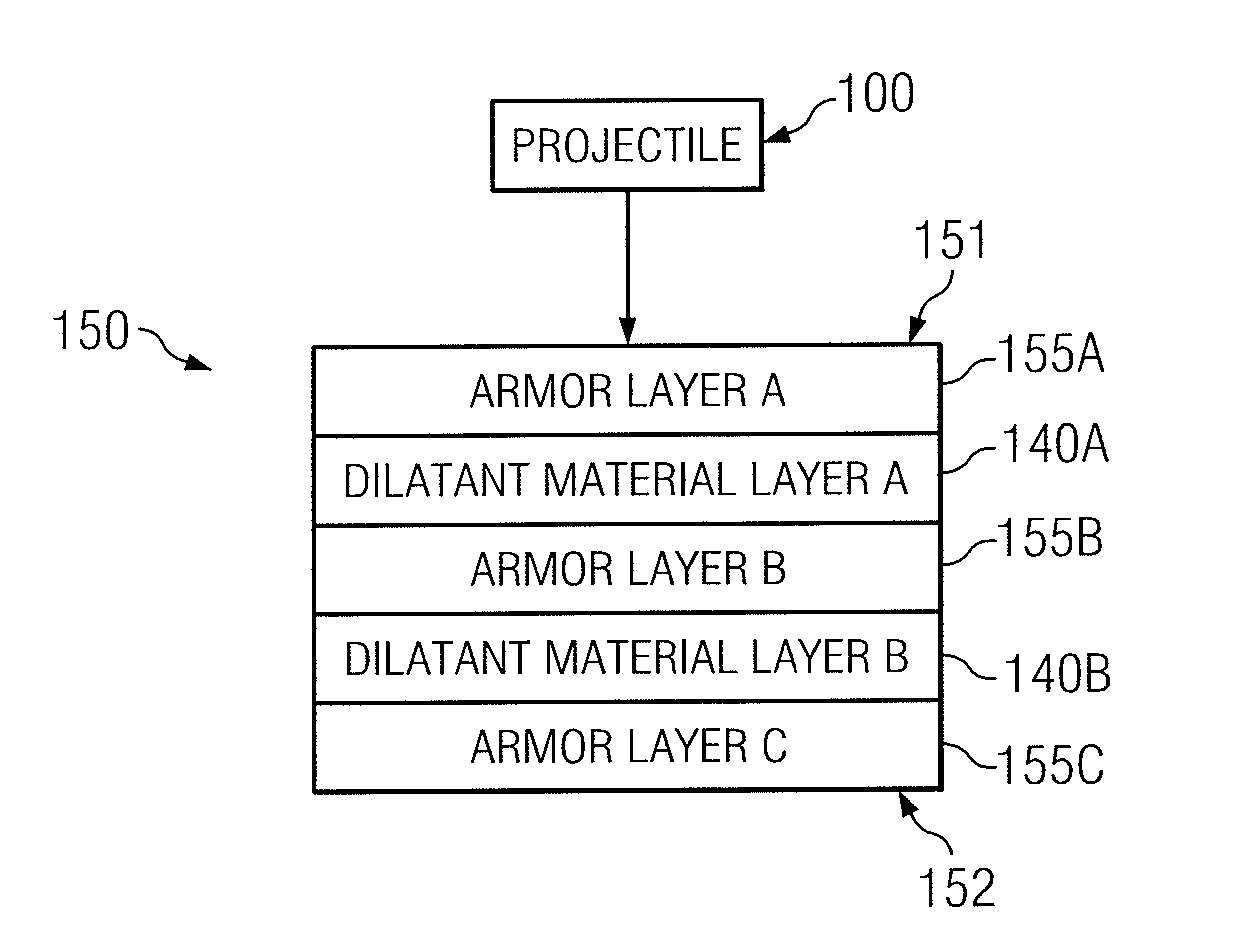

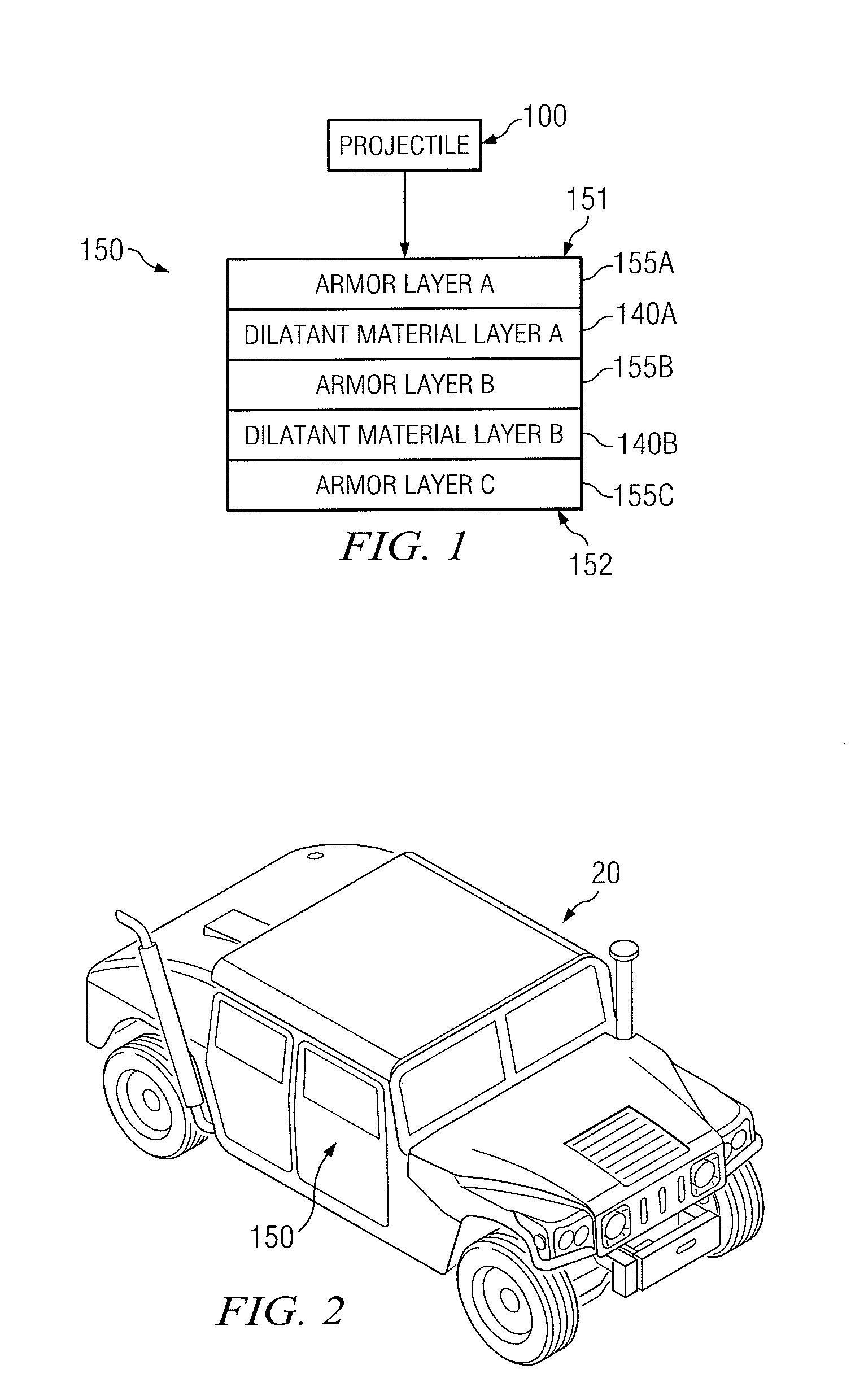

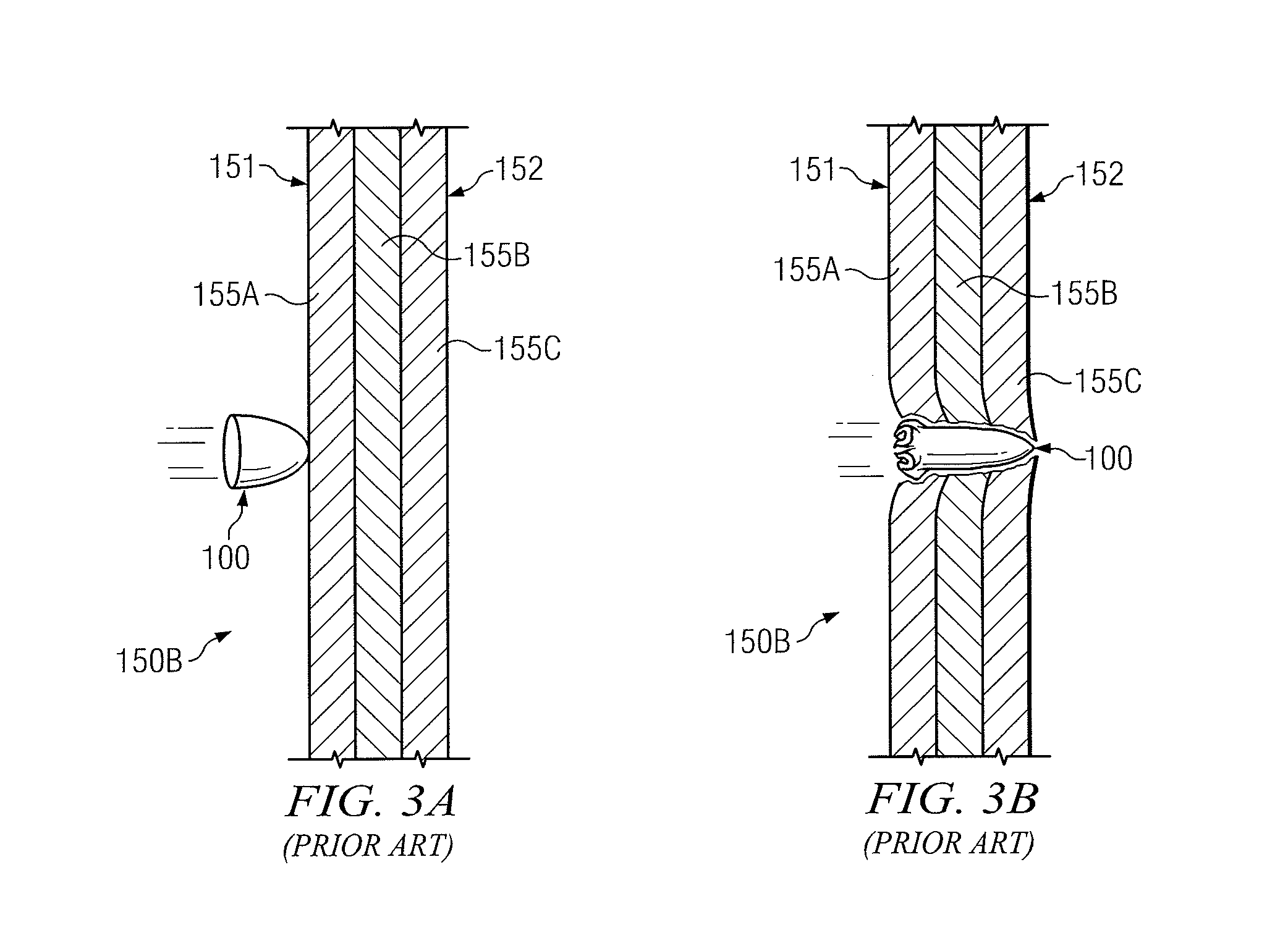

Armor System Comprising Dilatant Material To Improve Armor Protection

InactiveUS20120186431A1Slow down particleExtended impact timeArmoured vehiclesArmour platesEngineering

Owner:RAYTHEON CO

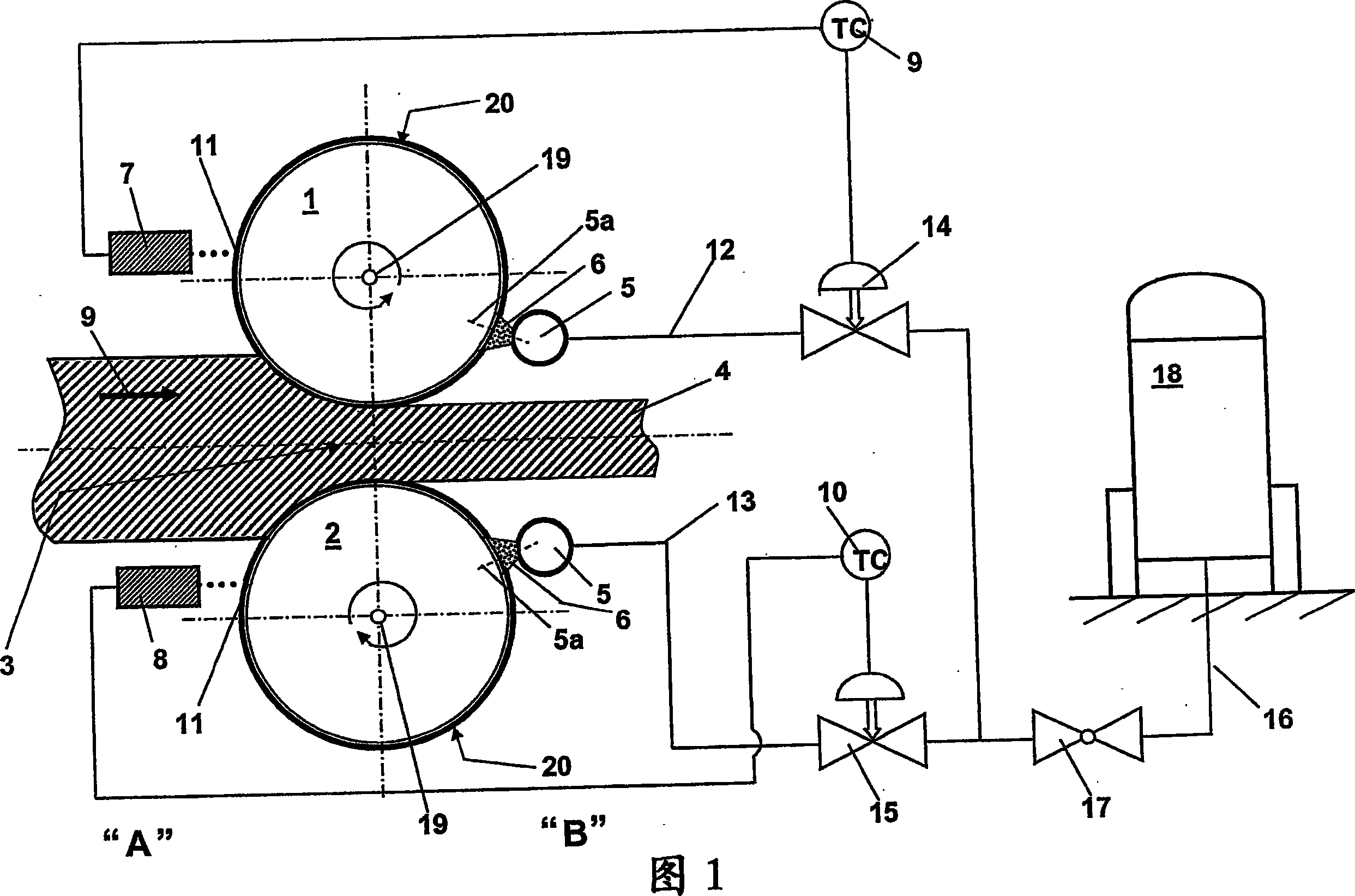

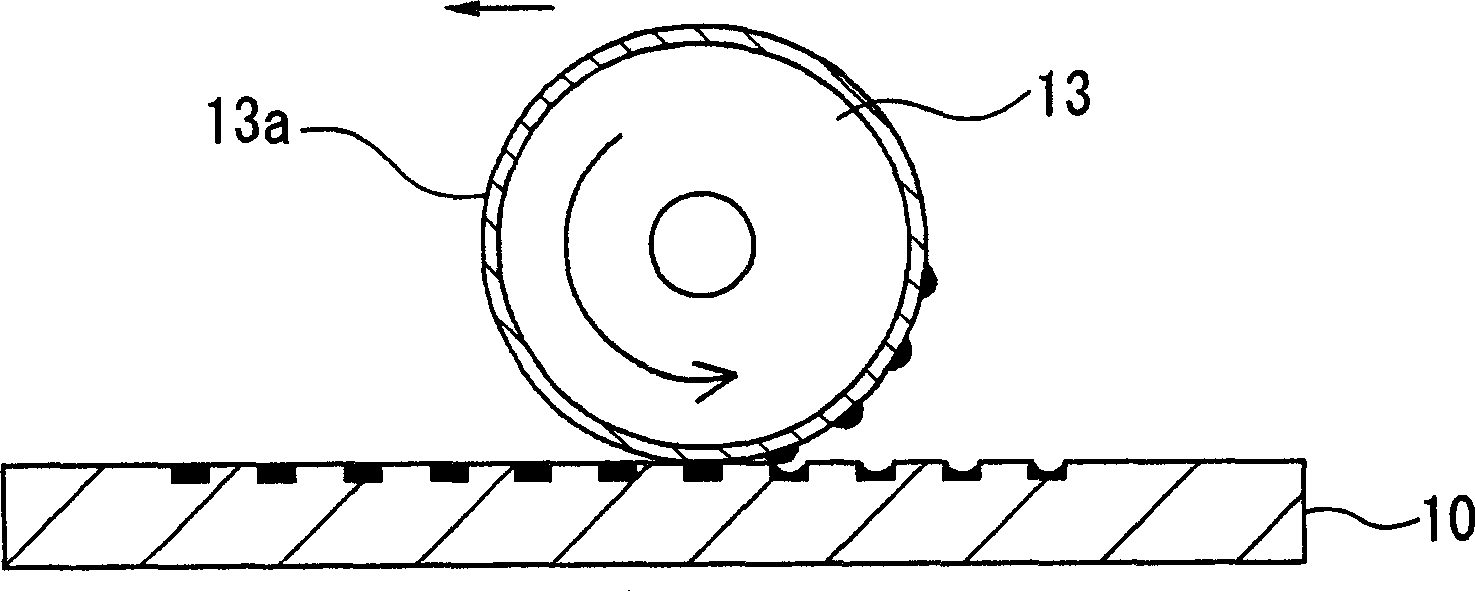

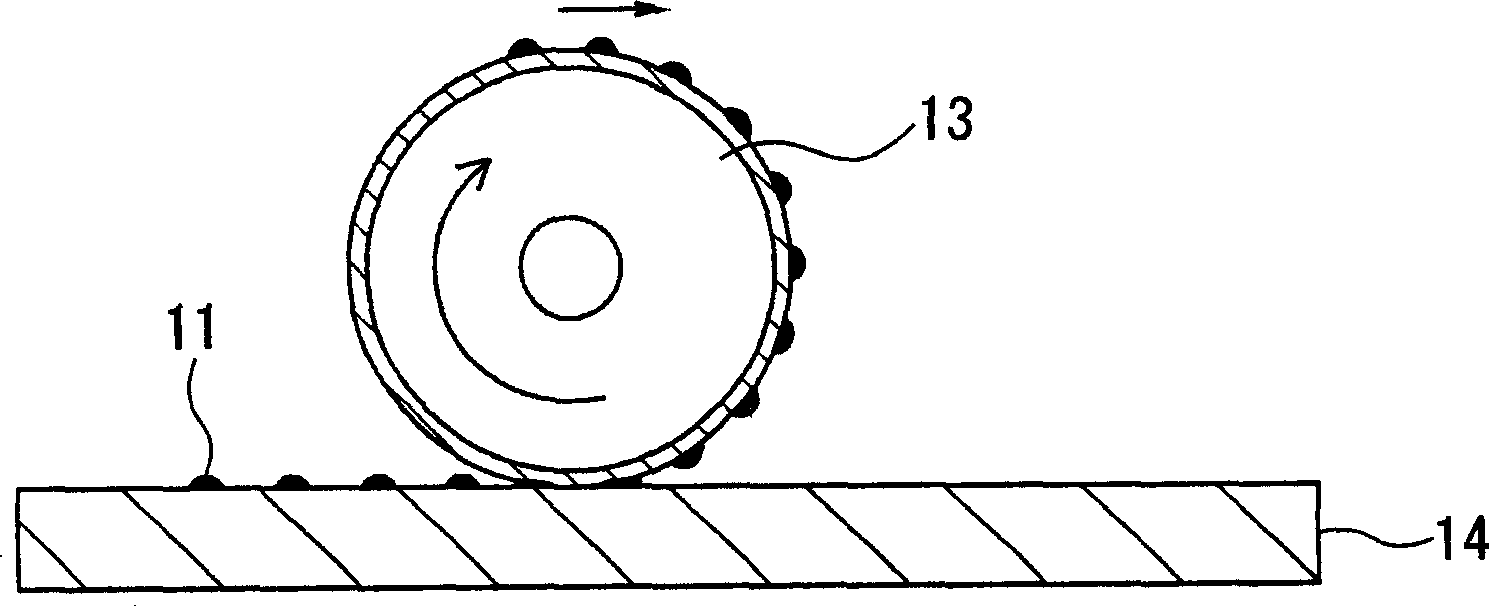

Method for the cold rolling of metallic rolled stock

InactiveCN101102856AImprove utilization efficiencyCool evenlyMeasuring devicesRollsCorrosionProduct gas

The invention is based on a known method for the cold rolling of metallic rolled stock (4) , which for plastic deformation enters a roll gap (3) formed between oppositely rotating rolls (1, 2) on a run-in side and leaves the roll gap on a run-out side, deformation heat that is produced being removed by supplying an industrial gas which is at a lower temperature than the rolled stock. In order on this basis to provide a cold rolling method with which, on the one hand, corrosion of the surfaces of the rolled stock and the surfaces of the rolls in the region of the roll .gap is effectively prevented and with which, on the other hand, condensation of moisture on the rolls and a reduction of the oxygen content of the ambient air of relevance to health as a result of the supply of large amounts of inert gas are avoided, it is proposed according to the invention that a measured value for the surface temperature of at least one of the rolls is determined, and that the supply of industrial gas is set on the basis of the measured value.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

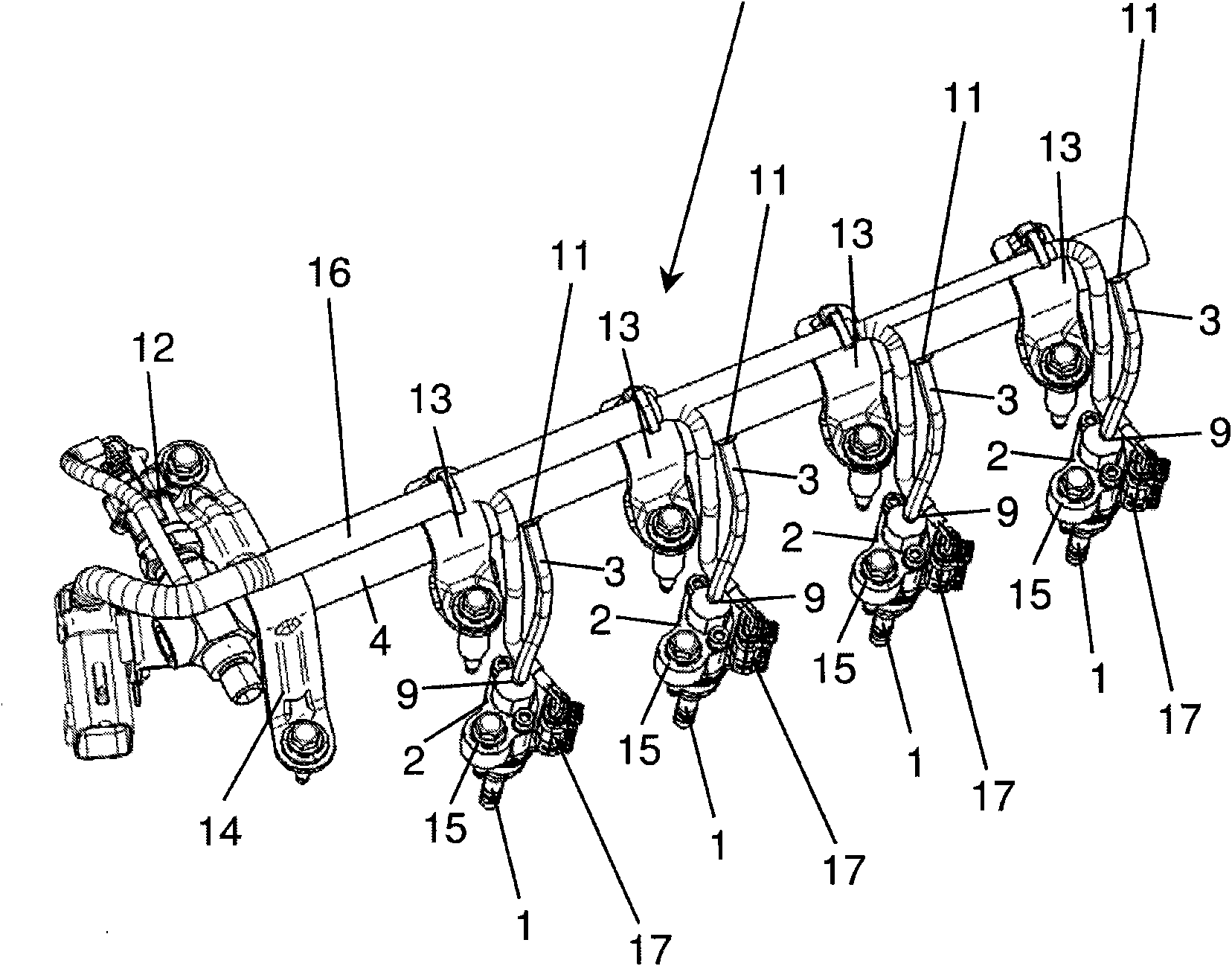

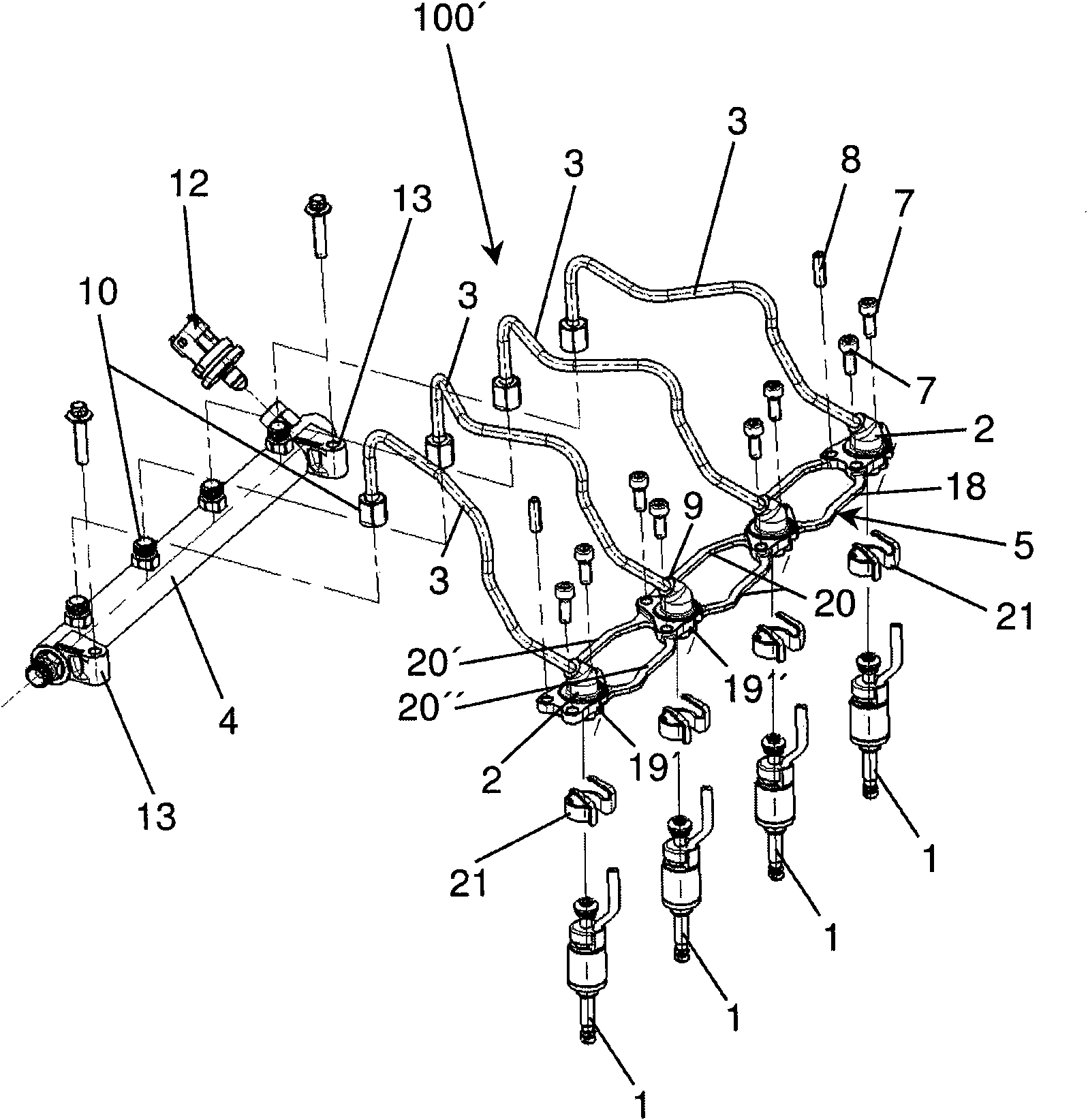

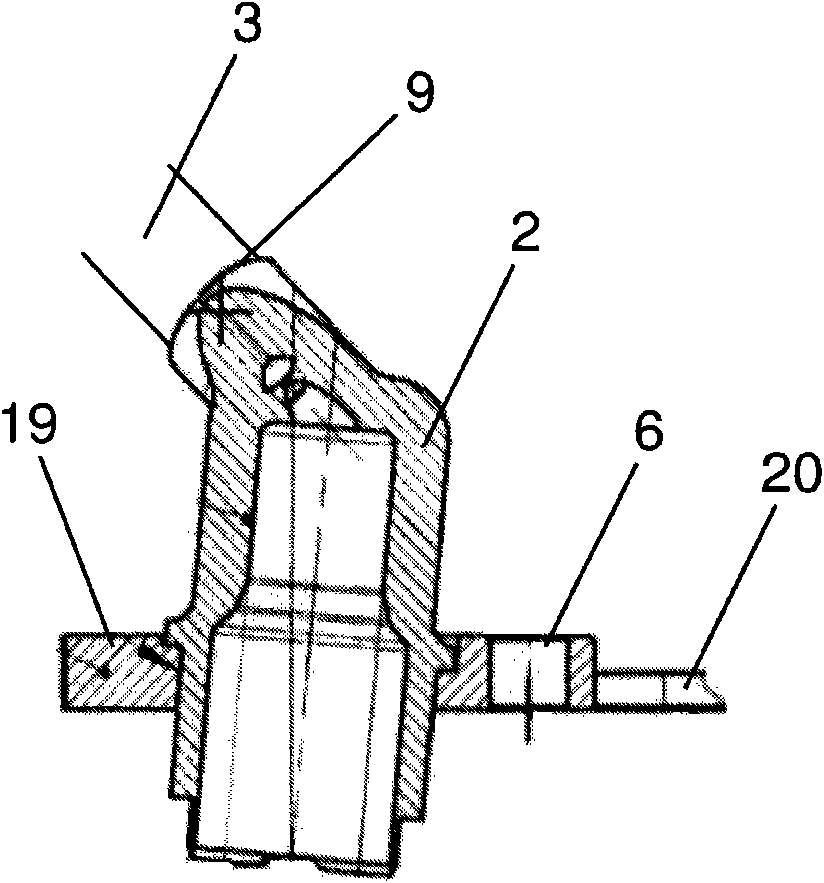

Component unit for a fuel system of an internal combustion engine and internal combustion engine

InactiveCN102042141APrevent leakageReduce shape changeLow pressure fuel injectionMachines/enginesInjectorExternal combustion engine

The present invention relates to a component units (100, 100') for a fuel system of an internal combustion engine, in particular for use in an internal combustion engine having direct injection, having at least one injector (1) which injects fuel, and / or at least one mounting (2), on which at least one injector (1), which injects fuel, is fixable, and having at least one fuel line (3), using which the injector (1) or the mounting (2) is connectable to a fuel distributor (4). It is provided that the injector (1) or the mounting (2) is connected to the fuel line (3) using a plug connection (9). Furthermore, at least one positioning aid is provided, which holds the injector (1) or the mounting (2) in a specified location.

Owner:GM GLOBAL TECH OPERATIONS LLC

Optical imaging lens assembly, image capturing unit and electronic device

An optical imaging lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element with positive refractive power has an object-side surface being convex. The second lens element has negative refractive power. At least one of two surfaces of the fourth lens element has at least one inflection point, and the two surfaces thereof are aspheric. The fifth lens element has an object-side surface being convex and an image-side surface having at least one inflection point, and the two surfaces thereof are aspheric. The sixth lens element has an image-side surface being concave, wherein the image-side surface of the sixth lens element has at least one convex shape in off-axial region, and the two surfaces thereof are aspheric.

Owner:LARGAN PRECISION

Disposable dental handpiece

A sterile, substantially maintenance free disposable dental handpiece is constructed from two shells and a center core, the center core having a flow deflector on one end. The shells are joined around the core with mating protrusions and / or tapered walls to form the body and head of the handpiece. A base is integrally-formed with the center core. The base has conduits that allow entry of light and pressurized air and / or water into the body. The head at the opposite end of the body from the base rotatably mounts an impeller assembly having an impeller shaft. The impeller shaft includes blades driven by the pressurized air. The blades can have cavities to reduce weight.

Owner:MURPHY DAVID +2

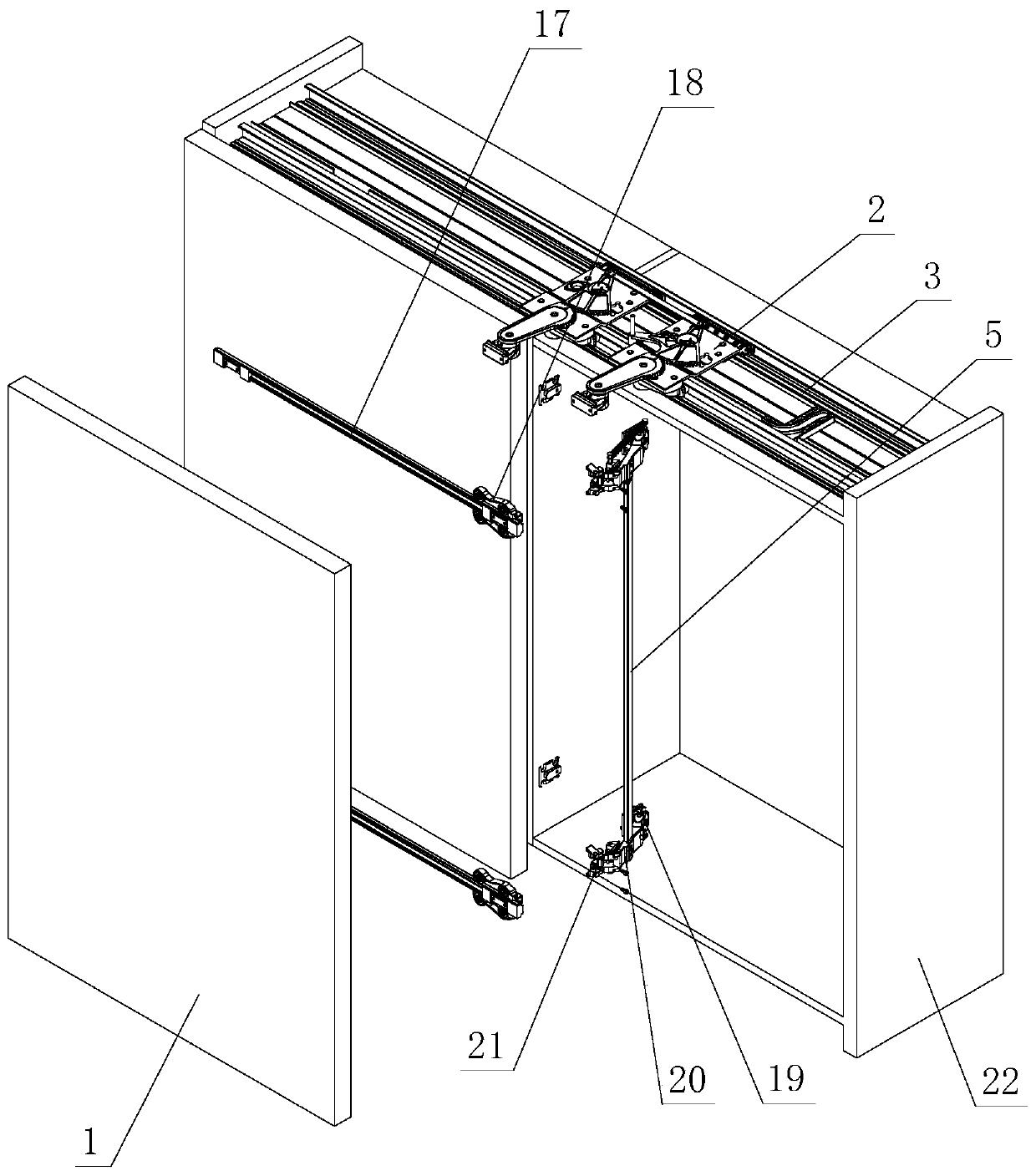

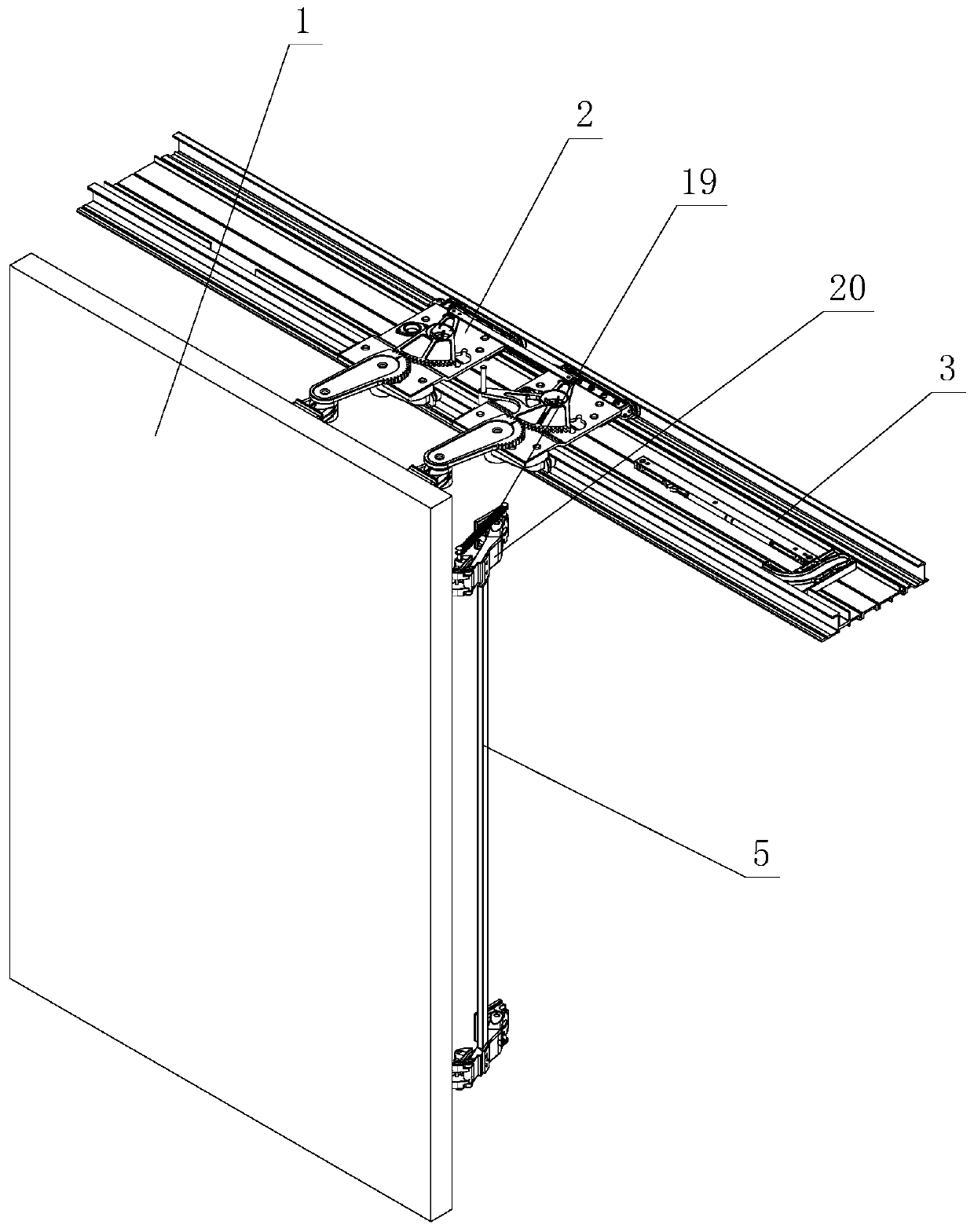

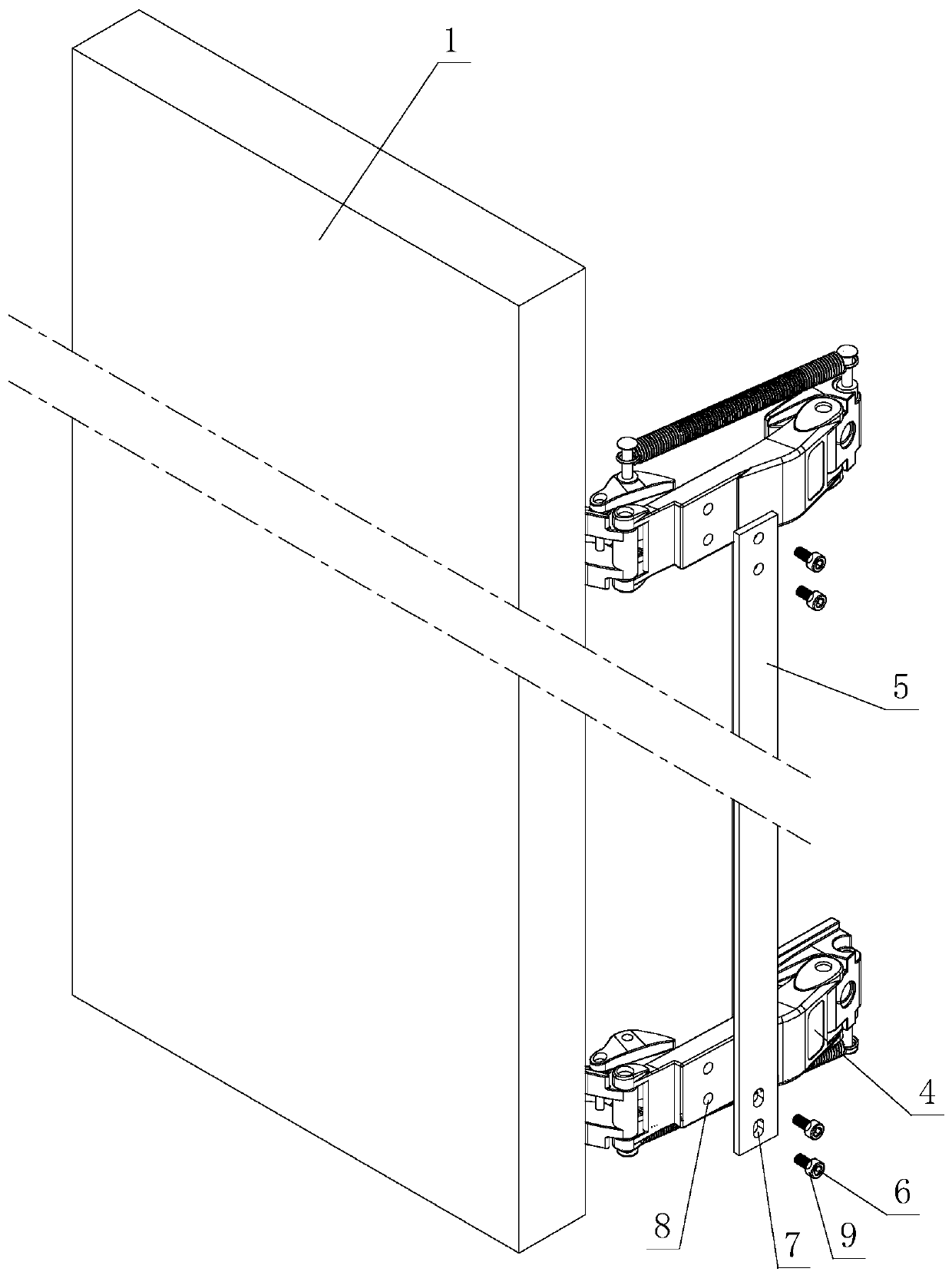

Synchronous adjusting mechanism for furniture

PendingCN110439432AImprove structural rationalityImprove the stability of useHingesWing arrangementsMechanical engineeringEngineering

The invention relates to a synchronous adjusting mechanism for furniture. The synchronous adjusting mechanism includes a furniture door body, a sliding device, and a guide sliding rail, wherein the sliding device is slidably arranged on the guide sliding rail and is rotatably or asway connected with the furniture door body; the furniture door body is rotatably or asway provided with at least two hinge devices; the furniture door body is movably opened and closed on the guide sliding rail through matching of the sliding device and the hinge devices; a synchronous rod is arranged between the atleast two hinge devices, and the hinge devices rotate or swing synchronously on the furniture door body through the synchronous rod; and an adjusting part is arranged on the synchronous rod and / or between the synchronous rod and the hinge devices, and the synchronous rod moves on the hinge devices through adjustment of the adjusting part to adjust the relative position between the synchronous rodand the at least two hinged devices. Through the improved synchronous adjusting mechanism, the synchronous adjusting mechanism has the characteristics of being simple and reasonable in structure, reliable in performance, long in service life, quick and convenient in disassembly and assembly process, smooth and steady, unhindered and labor-saving in opening and closing process, low in manufacturingcost, easy to produce, easy to realize, safe and reliable and the like, and the practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

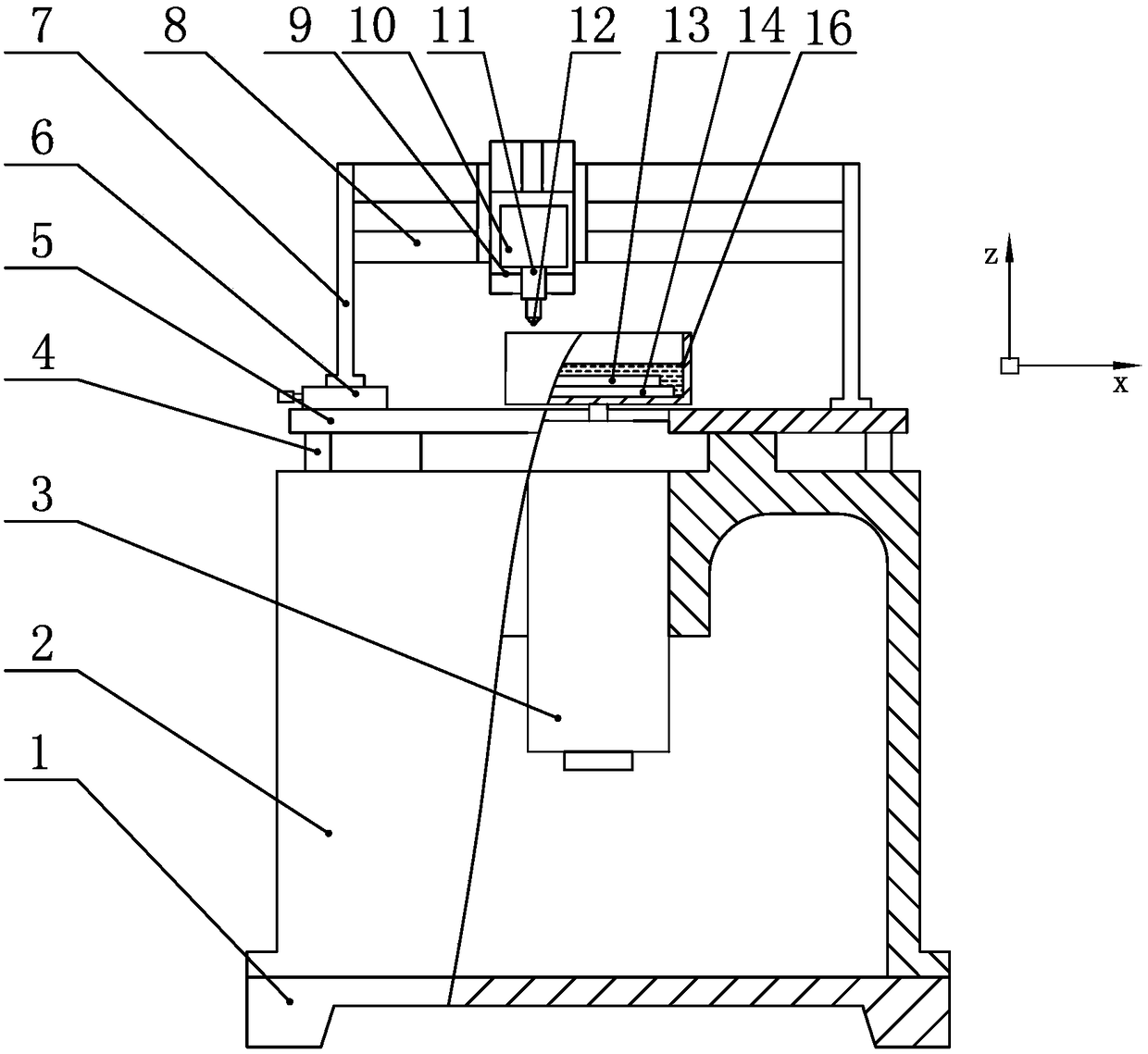

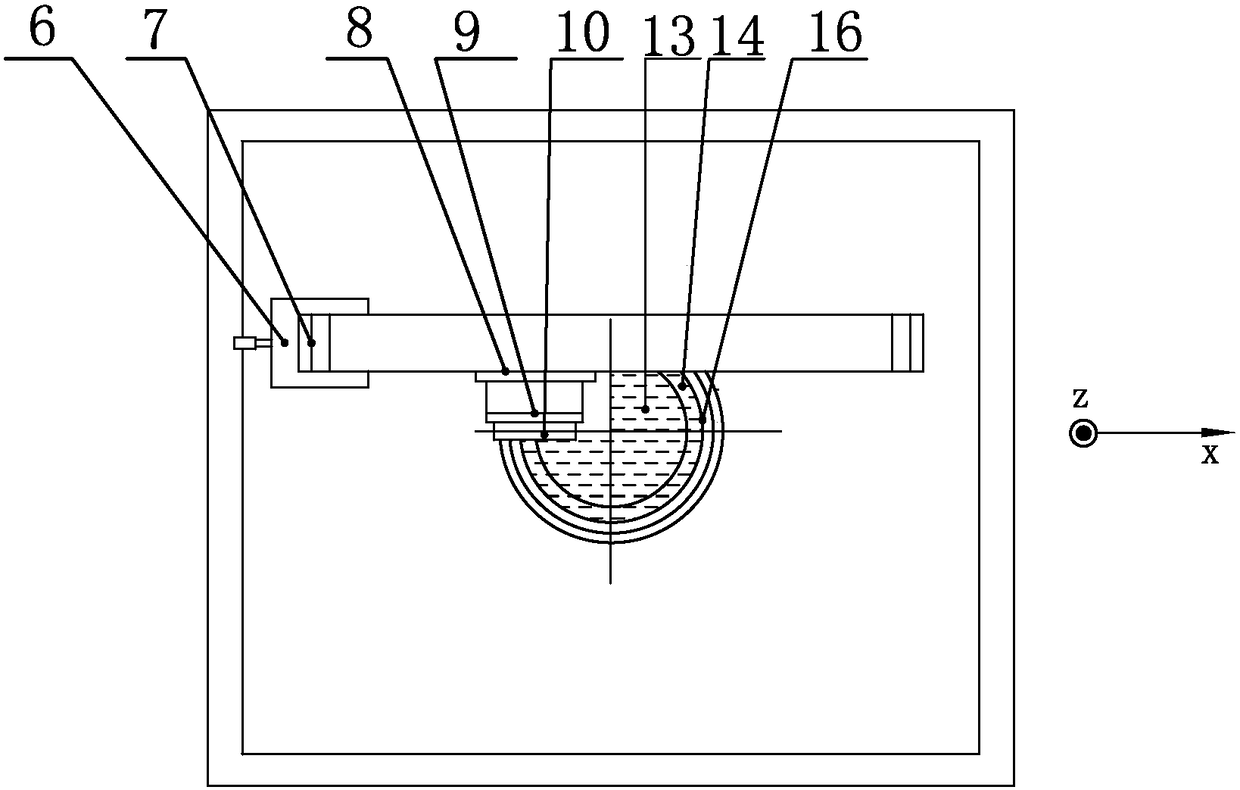

A high-speed lubrication performance testing machine for pre-repairing friction pairs and its application

ActiveCN105738276BGuaranteed shape accuracyGuaranteed positioning accuracyUsing mechanical meansMaterial analysisElectricityLubrication

The invention discloses a high-speed lubricating performance testing machine for pre-grinding a friction pair and application thereof.The high-speed lubricating performance testing machine mainly comprises a fixing base, a workbench, an electric spindle, an anti-splashing box, a friction disk, an X-direction feeding device, a Z-direction feeding device, a clamping device, an opposite-grinding tool, a disk grinding device, a measurement system, a cutter alignment instrument and the like.After the surface of the friction disk is ground through the disk grinding device, the electric spindle drives the friction disk to rotate; after the surface of the friction disk is ground through the disk grinding device, a proper quantity of lubricating agent is placed in the anti-splashing box, the electric spindle drives the friction disk to rotate, the Z-direction feeding device and the X-direction feeding device drive the opposite-grinding tool and the friction disk to make contact with each other for friction testing, pressure between the opposite-grinding tool and the friction disk is kept constant in the testing process, and the testing system acquires data in the process.By means of the high-speed lubricating performance testing machine, high-speed friction testing stability and accuracy can be effectively improved.

Owner:HUAQIAO UNIVERSITY

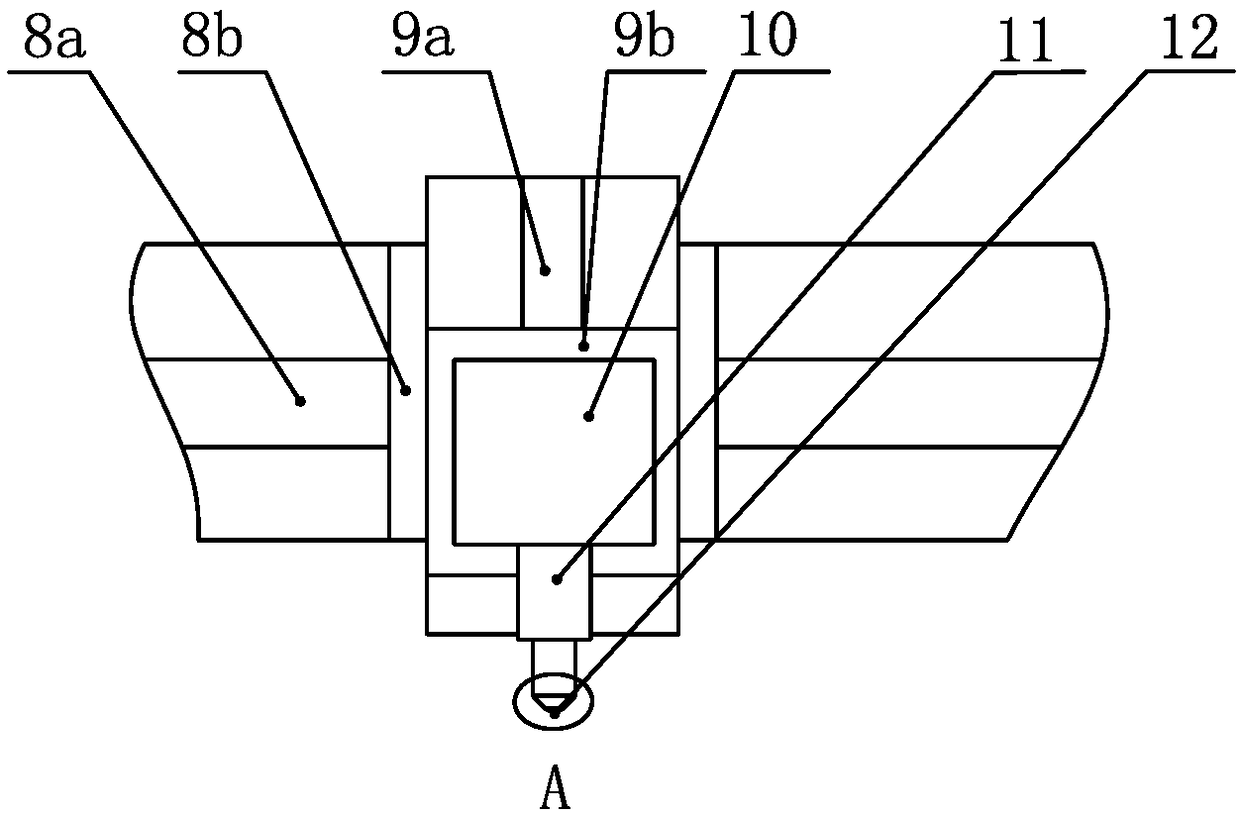

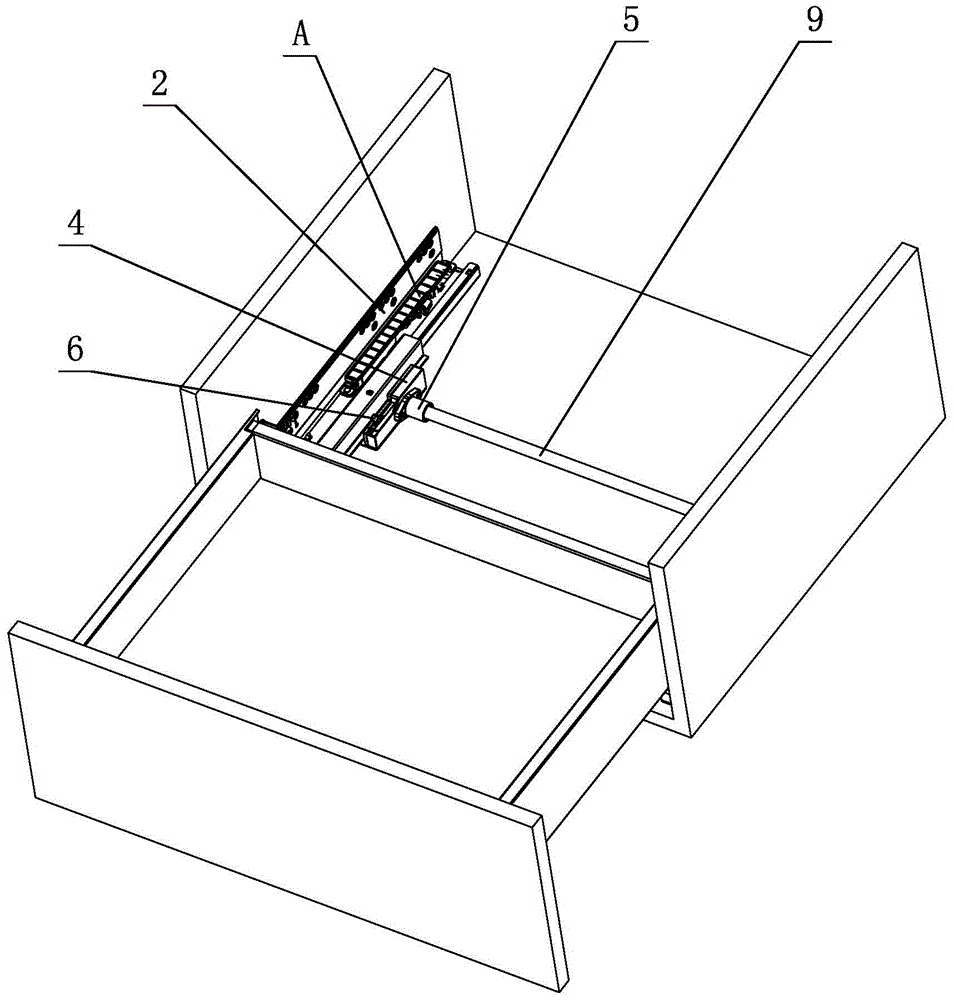

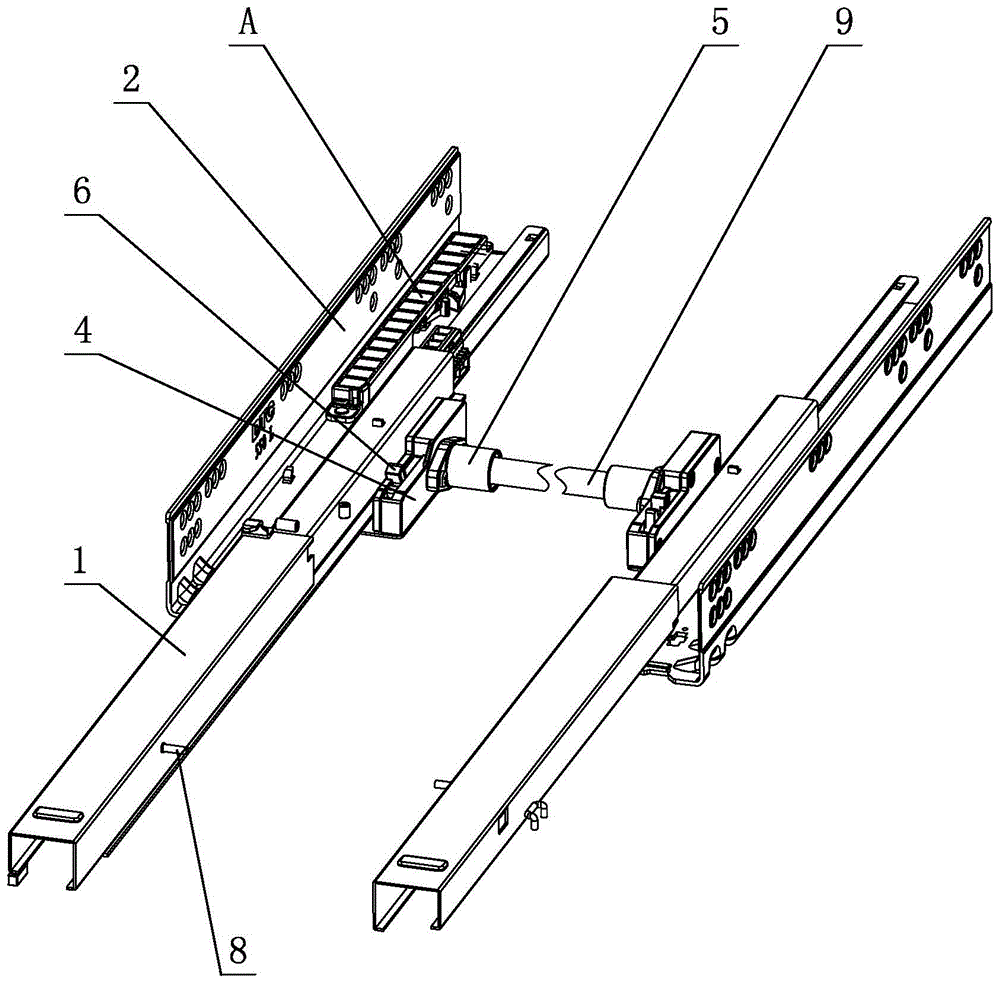

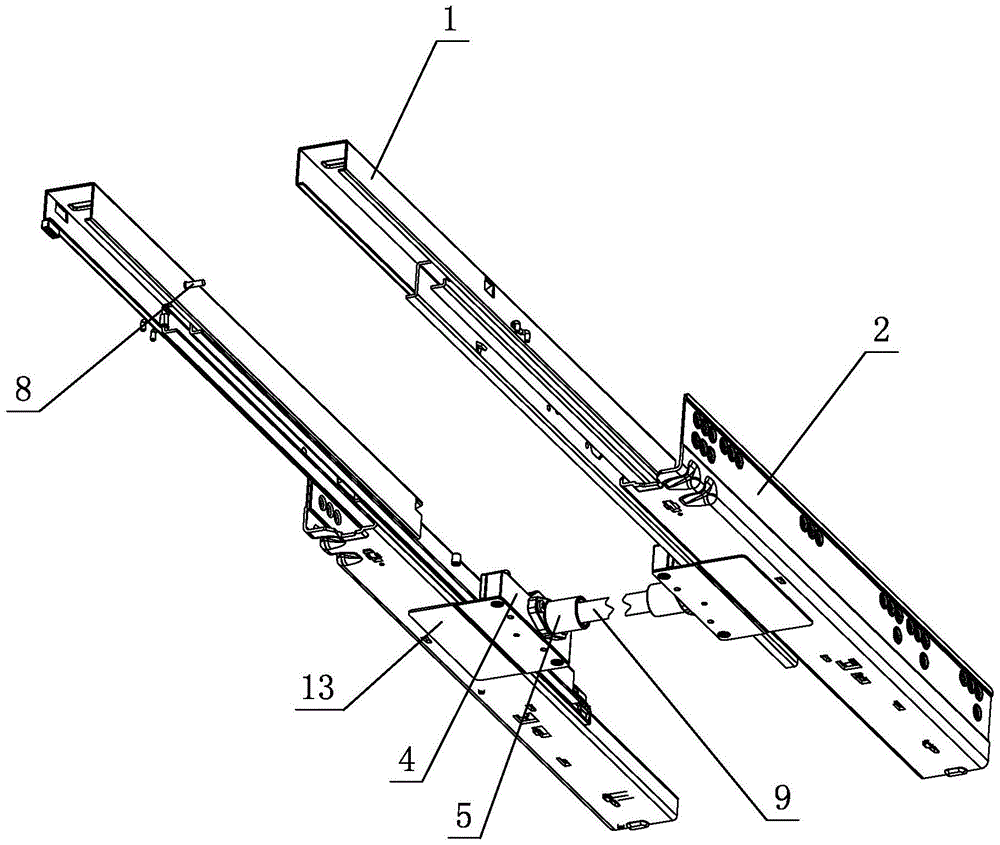

An Auxiliary Stabilizing Mechanism of a Drawer Slide Rail Synchronization Device

An auxiliary stabilization mechanism of drawer sliding rail synchronizers comprises sliding rail assemblies arranged on a left cabinet side board and a right cabinet side board respectively. Each sliding rail assembly comprises a movable sliding rail and a fixed sliding rail. The synchronizers are arranged on the movable sliding rails or the fixed sliding rails on the left side and the right side. Each synchronizer comprises a moving piece, a sliding groove seat and an auxiliary stabilization piece, wherein each moving piece is arranged on the corresponding sliding groove seat and provided with a rack, each sliding groove seat rotates relative to the corresponding rack and is provided with a gear component meshed with the corresponding rack in positioning mode, and each moving piece at least linearly slides on the corresponding sliding groove seat through meshing between the corresponding rack and the corresponding gear component. A shifting piece is arranged on each fixed sliding rail or each moving sliding rail, wherein at least one stroke of each shifting piece acts on the corresponding moving piece when the corresponding sliding rail assembly moves. A rotary connecting rod is arranged between the left gear component and the right gear component, and the left sliding rail assembly and the right sliding rail assembly are opened and closed synchronously through transmission connection between the gear components and the rotary connecting rod. One end of each auxiliary stabilization piece is arranged on a fixed part of a drawer, the other end of each auxiliary stabilization piece is arranged on the rotary connecting rod in a clearance and sleeve joint mode, and the rotary connecting rod is rotated in a positioned mode on the auxiliary stabilization pieces when the drawer is opened or closed.

Owner:伍志勇

Optical imaging lens assembly, image capturing unit and electronic device

ActiveUS10890738B2Optimize space utilizationReduce shape changeOptical elementsOphthalmologyOptical axis

An optical imaging lens assembly includes five lens elements, which are, in order from an object side to an image side: a first lens element, a second lens element, a third lens element, a fourth lens element and a fifth lens element. The first lens element with positive refractive power has an object-side surface being convex in a paraxial region thereof. The third lens element has negative refractive power. The fifth lens element has negative refractive power.

Owner:LARGAN PRECISION

Printing oil ink and production method of coating film using the oil ink

The present invention provides a printing ink can reduce shape changes of printing pattern in consecutive printing using gravure offset printing. Said printing ink is used in gravure offset printing. In gravure offset printing, this ink is filled in printing plates with concave pattern, transfer filled ink to blankets for printing which have silicone rubber on surface, transfer ink from blankets to transferrer. Said printing ink at least includes powder component which comprise inorganic or organic powder, when including one or two kinds of rosin and solvent component which selected from group consist of acrylic resin and methyl acrylic resin, solvent component comprising more than one or two kinds of glycols solvent.

Owner:MITSUBISHI MATERIALS CORP

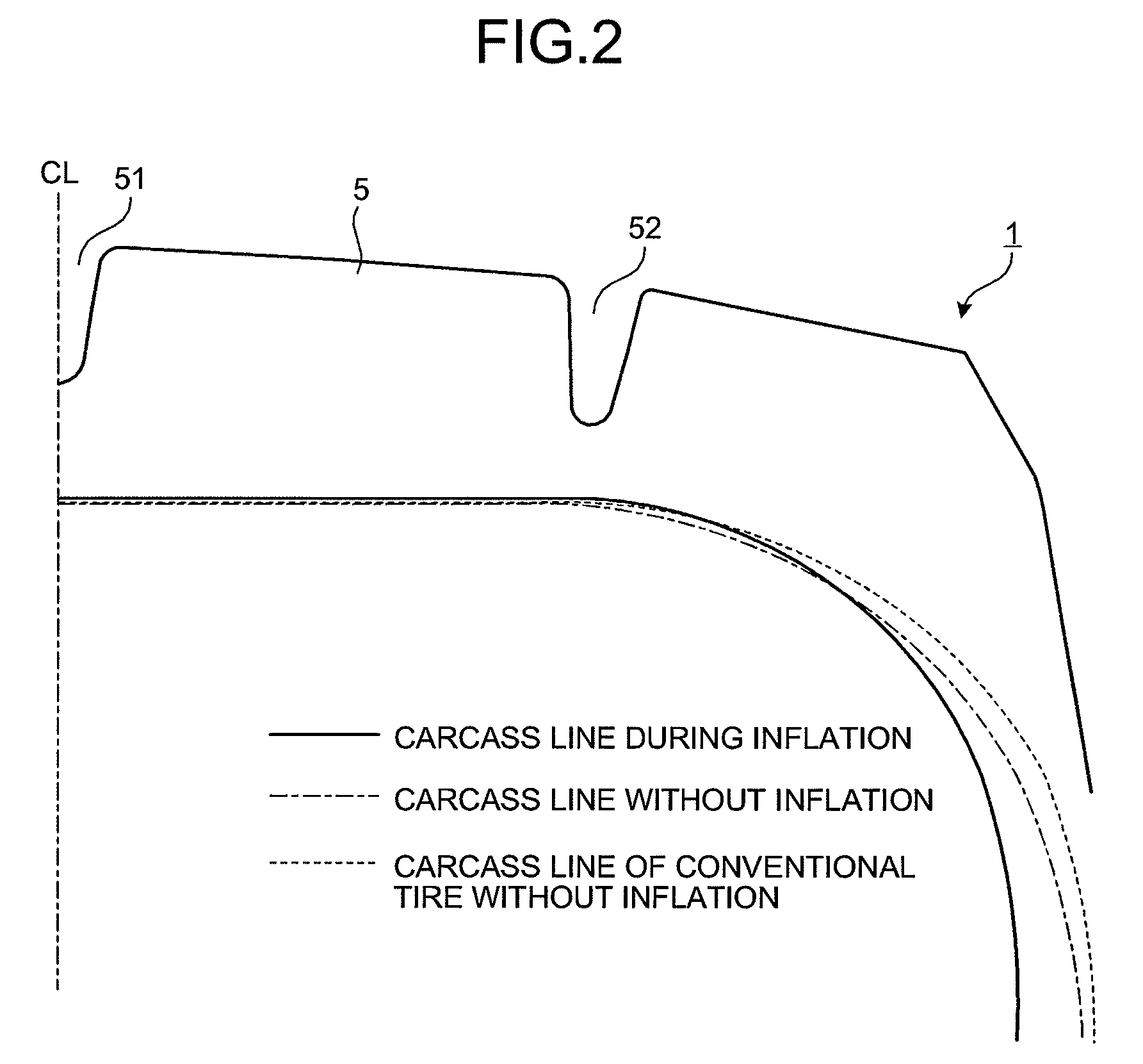

Pneumatic tire

ActiveUS8146633B2Relieve pressureAvoid crackingHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com