Synchronous adjusting mechanism for furniture

A technology of synchronous adjustment and furniture, which is applied in the direction of building components, wing fan layout, building structure, etc., can solve the problems that large-shaped furniture cabinets cannot be widely used, shake up and down, and the storage space of the cabinet is limited. To achieve the effect of improving structural rationality and use stability, increasing connection strength and reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

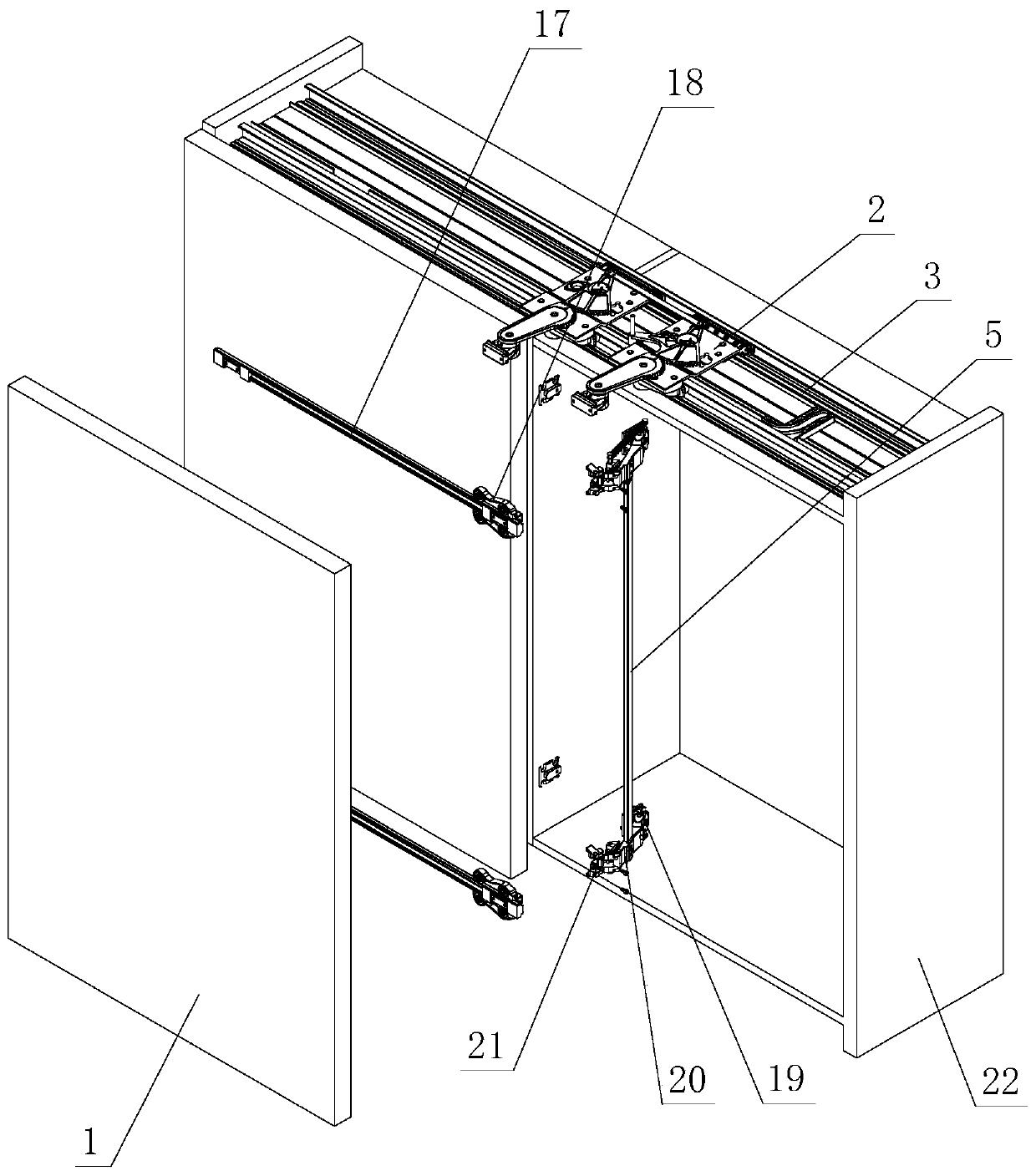

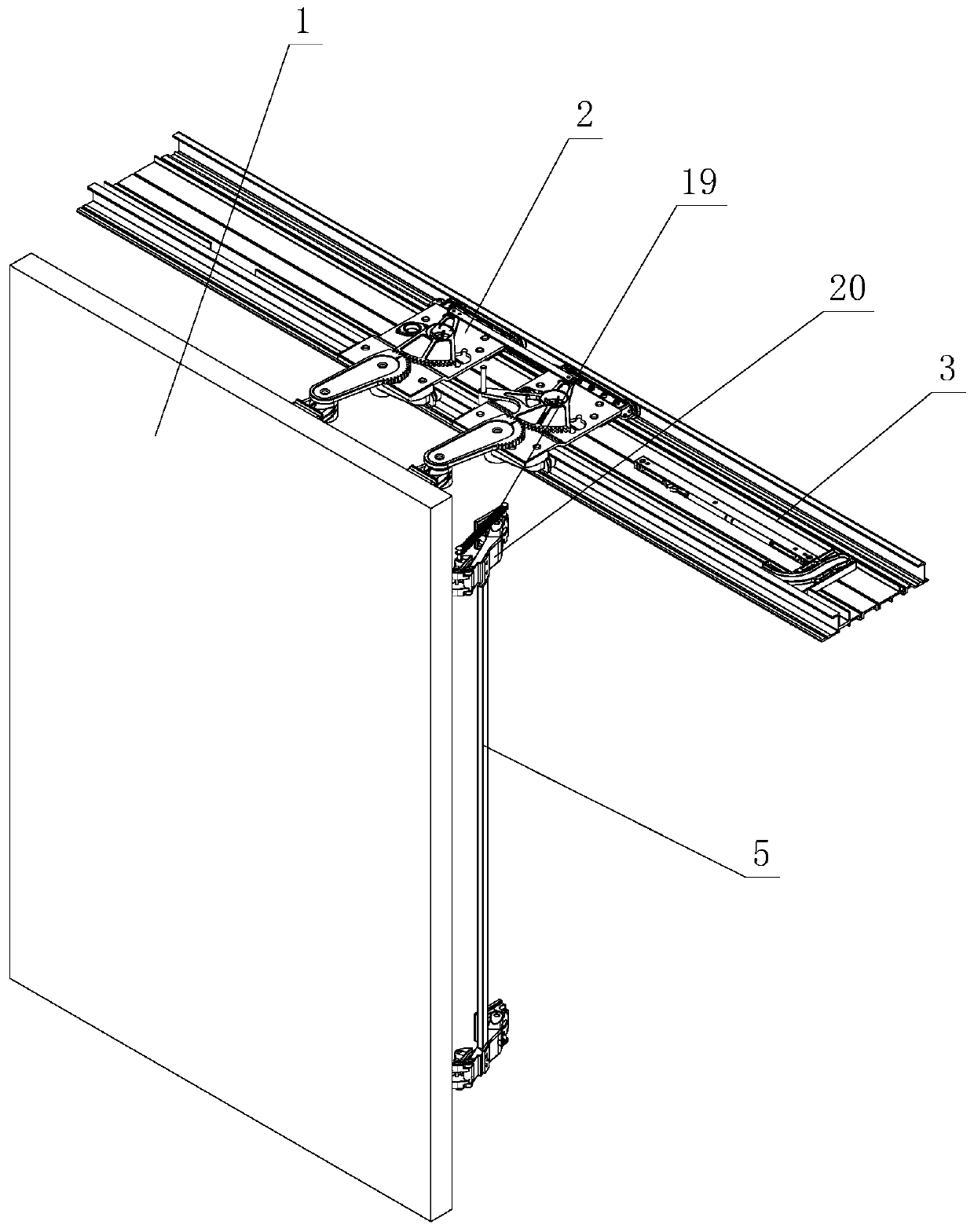

[0041] see Figure 1-Figure 4 , a synchronous adjustment mechanism for furniture, including a furniture door body 1, a sliding device 2, and a guide rail 3, the sliding device 2 is slidably arranged on the guide rail 3, and is connected with the furniture door body 1 in rotation or swing; the furniture door At least two hinge devices 4 are arranged on the body 1 to rotate or swing; the furniture door body 1 is opened and closed on the guide rail 3 through the cooperative activities of the sliding device 2 and the hinge device 4; wherein, at least two hinge devices 4 There is a synchronous lever 5 between them, and it rotates or swings synchronously on the furniture door 1 through the synchronous lever 5; an adjusting member is arranged on the synchronous lever 5, and / or between the synchronous lever 5 and the hinge device 4, synchronously The rod 5 moves on the hinge device 4 through the adjustment of the adjusting member, so as to adjust the relative position between the sync...

no. 2 example

[0052] see Figure 5 , Image 6 , this is a synchronous adjustment mechanism for furniture, which is different from the first embodiment in that: the adjustment part is provided with an adjustment part 6 .

[0053] The action part 6 is adjusted by a tool or manually, and the driving adjustment member moves between the synchronization rod 5 and at least two hinge devices 4, and the adjustment member locks or releases the connection between the synchronization rod 5 and at least two hinge devices 4 when it is active. Relative position, displacement occurs when the relative position between the synchronization rod 5 and at least two hinge devices 4 is released, so as to adjust the relative position between the synchronization rod 5 and the at least two hinge devices 4 .

[0054] There are at least two synchronous rods 5, at least two synchronous rods 5 are respectively positioned and connected with at least two hinge devices 4, and an intermediate moving part 10 is slidably arra...

no. 3 example

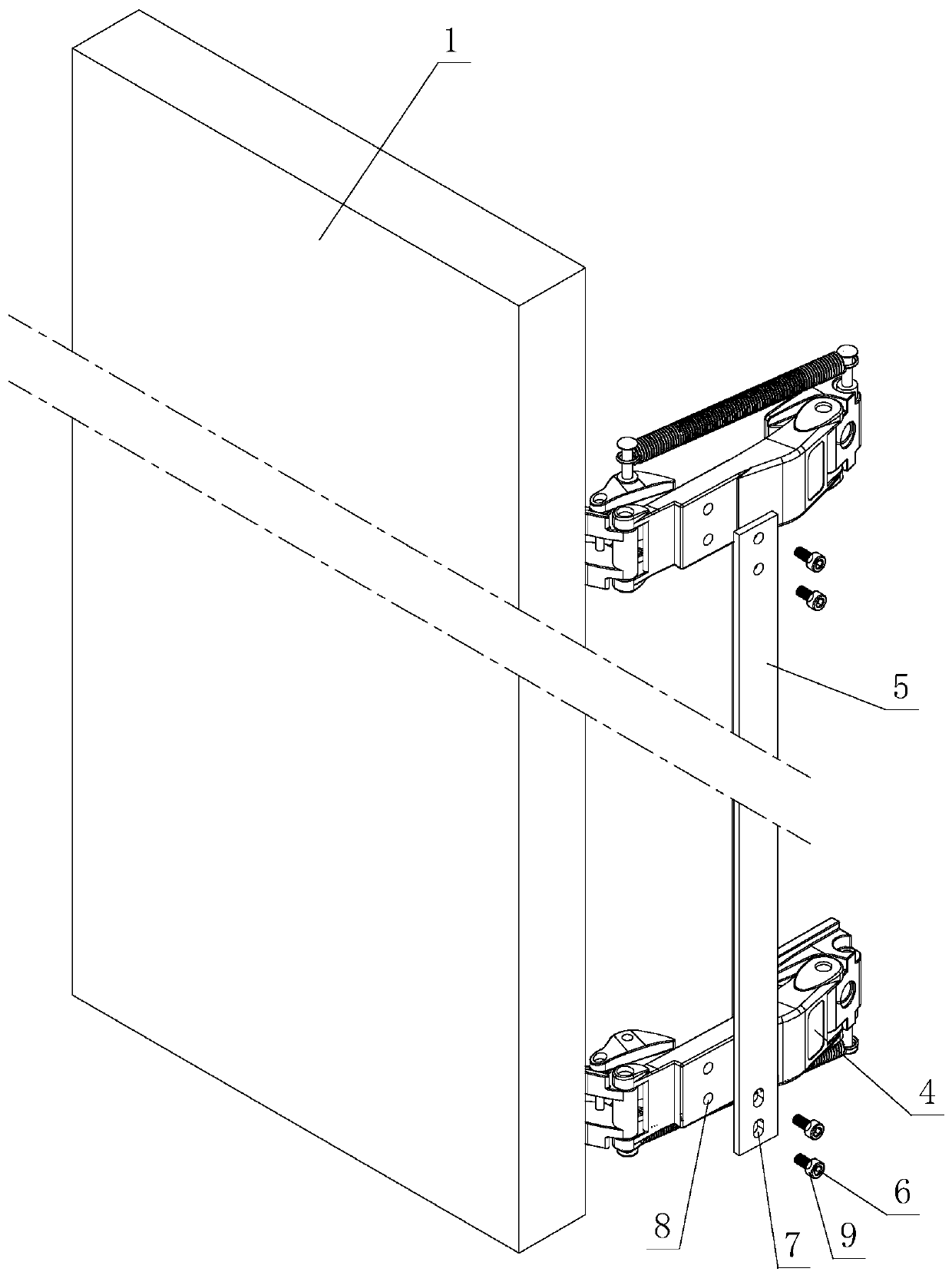

[0059] see Figure 7-Figure 9 , this is a synchronous adjustment mechanism for furniture, which is different from the first embodiment in that: the adjustment part is provided with an adjustment part 6 .

[0060] The action part 6 is adjusted by a tool or manually, and the driving adjustment part moves between the synchronization rod 5 and at least two hinge devices 4. The relative position between the synchronization rod 5 and at least two hinge devices 4 .

[0061] A connector 11 is fixedly arranged on the synchronous rod 5, and the movable guide part 7 is a threaded position and is arranged on the connector 11. The hinge device 4 is provided with a connecting part 8, or the movable guide part 7 is a threaded position and is arranged on the hinge. On the device 4, the connecting part 11 is provided with a connecting part 8; the adjusting part is a screw adjusting part 12, and is positioned and rotated on the thread position by the action of the adjusting part 6, and is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com