Grinding equipment for gear tooth outer circle face burr polishing machining after gear shaping machining

A technology of tooth processing and outer circular surface, applied in metal processing equipment, grinding/polishing equipment, grinding frame, etc., can solve the problems of poor elastic buffering, gear deformation, breaking, etc., to achieve reasonable structure, prevent breakage, etc. Tooth and crusher seat, the effect of increasing the grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

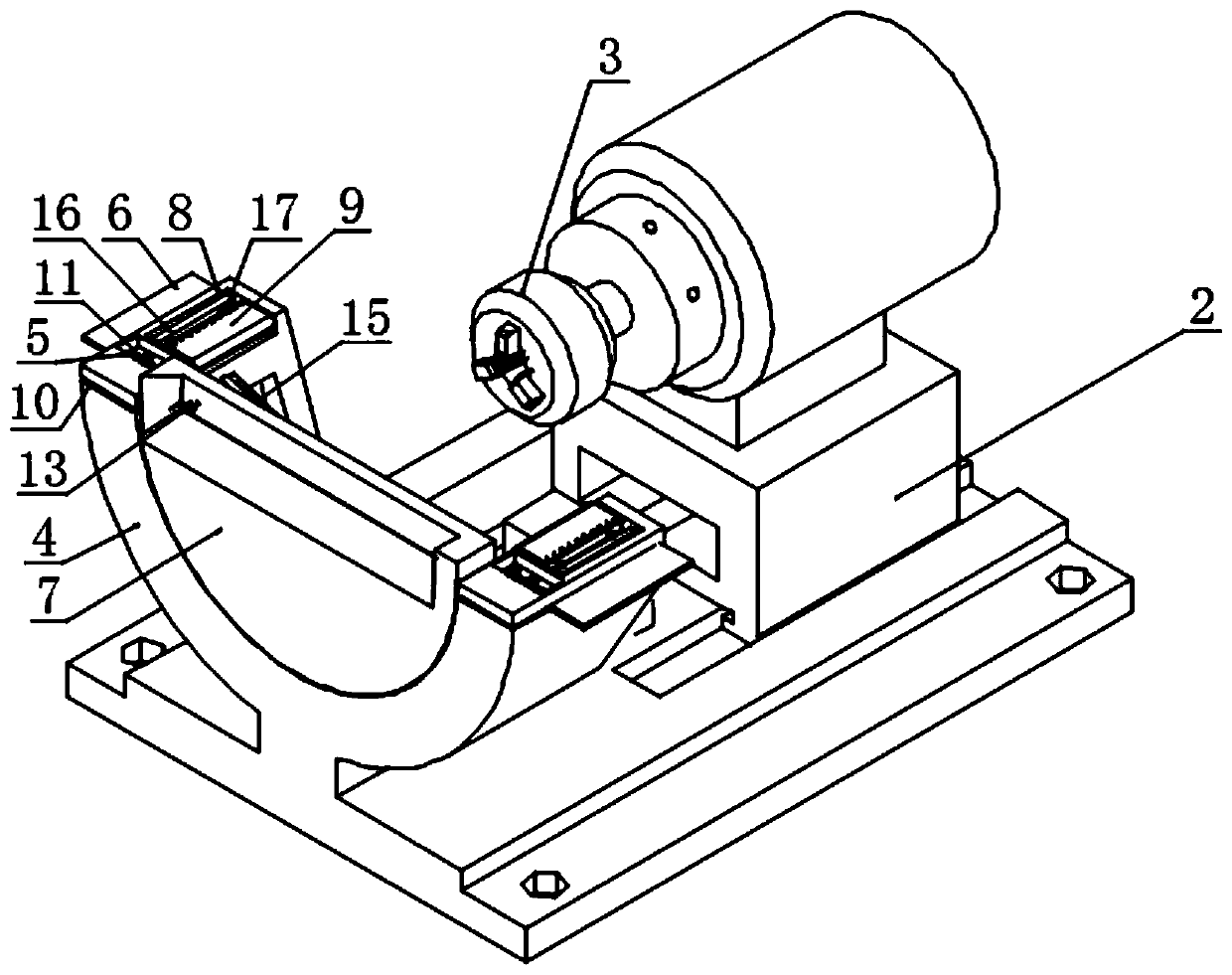

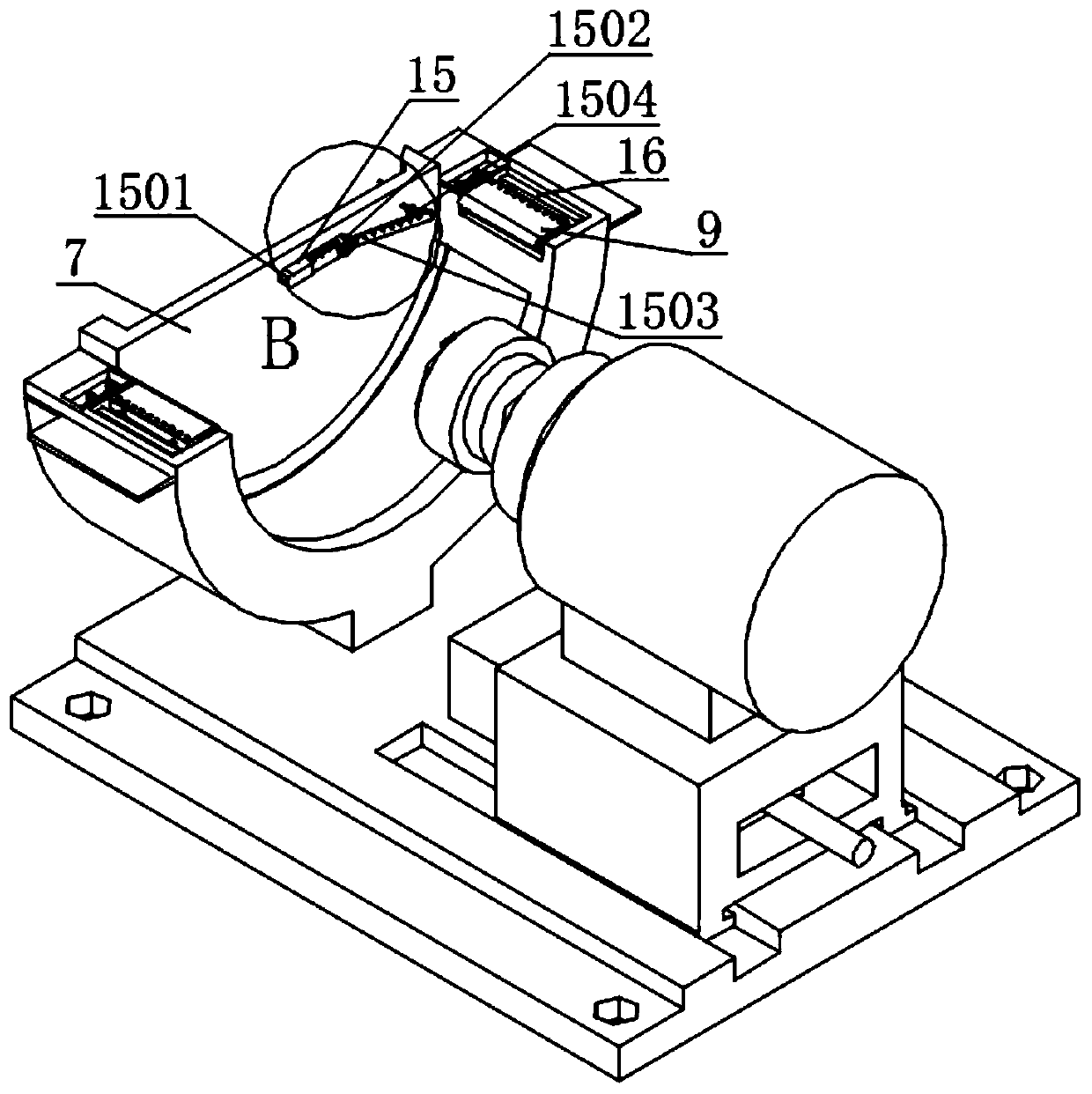

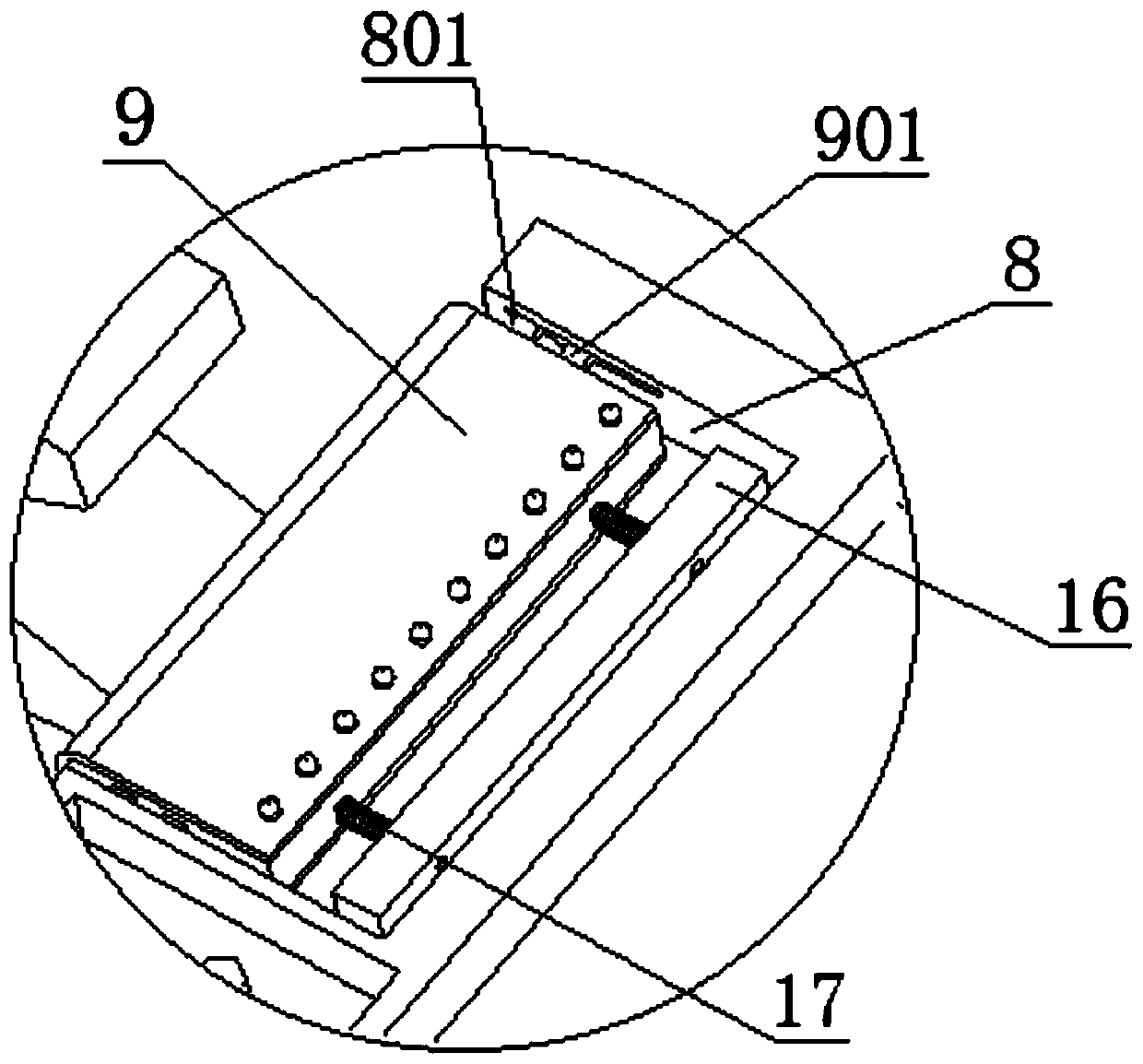

[0029] as attached figure 1 to attach Figure 9 Shown:

[0030] The invention provides grinding equipment for grinding and grinding burrs on the outer circular surface of gear teeth after gear shaping processing, including: a base 1, a moving tailstock 2, a three-jaw chuck 3, a grinding seat 4, a locking groove 5, and a moving emery cloth seat Plate 6, outer end cover 7, emery cloth seat moving groove 8, guide groove 801, first emery cloth seat assembly 9, guide rod 901, solid block 902, emery cloth 903, moving plate installation groove 10, compression bolt 11, screw thread Sleeve 12, handwheel rotating rod 13, circular socket 1301, inner end cover 14, second emery cloth seat assembly 15, first connecting section 1501, hinge shaft 1502, second connecting section 1503, supporting spring 1504, supporting plate 16 and a spring seat 17; the top rear side of the base 1 is equipped with a moving tailstock 2 through the cooperation of screw chute, and a motor is located on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com