A kind of rubber plate polishing device

A rubber plate and grinding wheel technology, which is applied in the direction of grinding drive devices, grinding machines, and grinding machine parts, etc., can solve the problems of uneven thickness of rubber plates, insufficient surface finish, and high labor intensity of workers, so as to save manpower and material resources, improve the grinding speed and quality, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

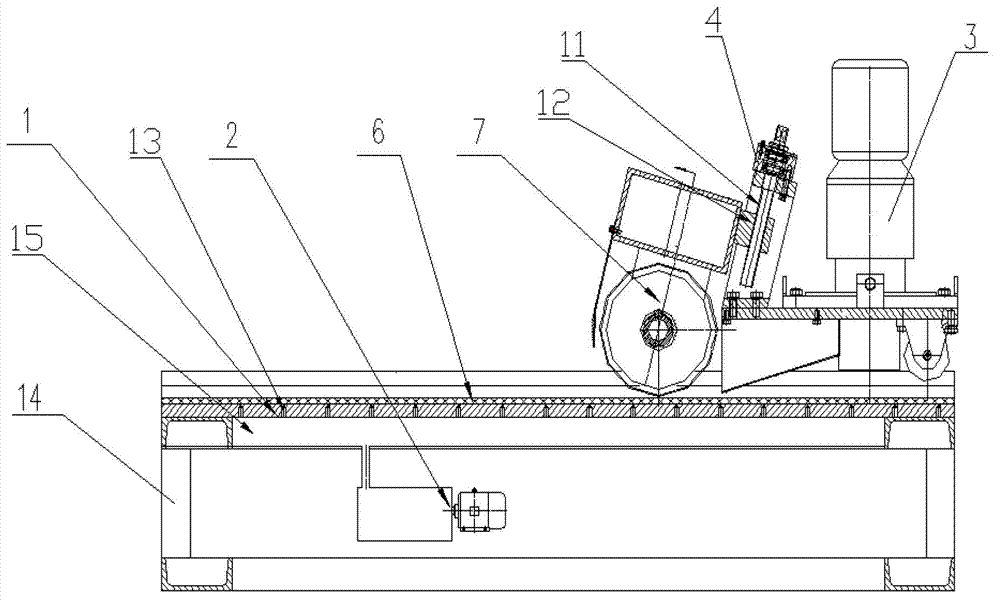

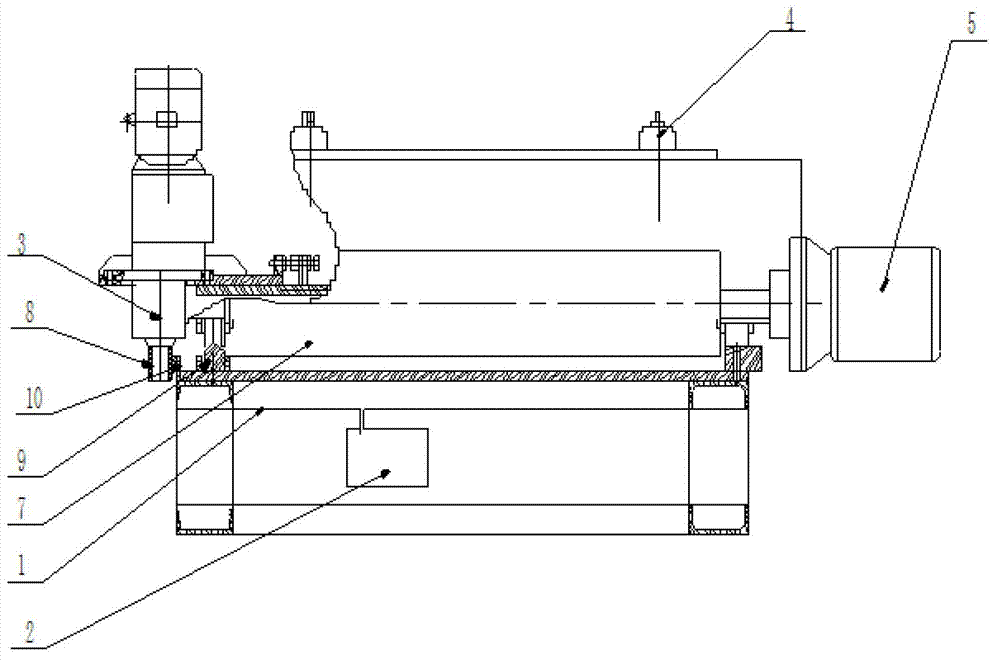

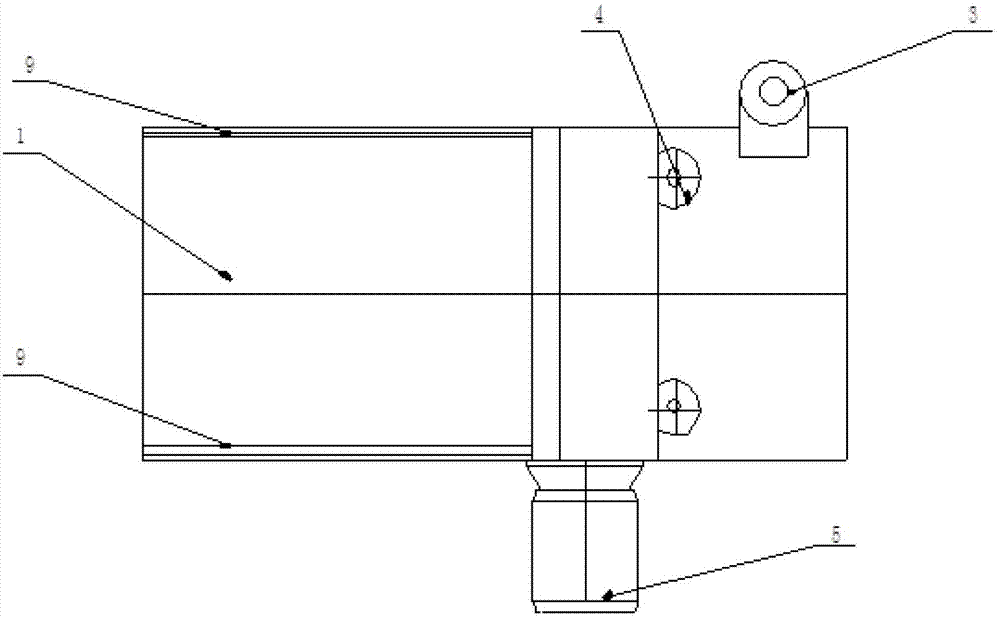

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] As shown in the figure, a rubber plate grinding device includes a frame 14, a rubber plate holder 1 is provided on the upper surface of the frame 14, guide rails 9 and racks 10 are provided on the edges of both sides of the rubber plate holder 1, Rubber plate holder 1 is provided with guide rail 9 and one side of rack 10 and is also provided with traveling device 3, and traveling device 3 is placed on guide rail, and the bottom of traveling device 3 is provided with gear 8, and gear 8 meshes with rack 10, and walking The front end of device 3 is provided with automatic distance adjustment device 4, and automatic distance adjustment device 4 front ends are provided with grinding wheel device, and grinding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com