Patents

Literature

43results about How to "Increase sanding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

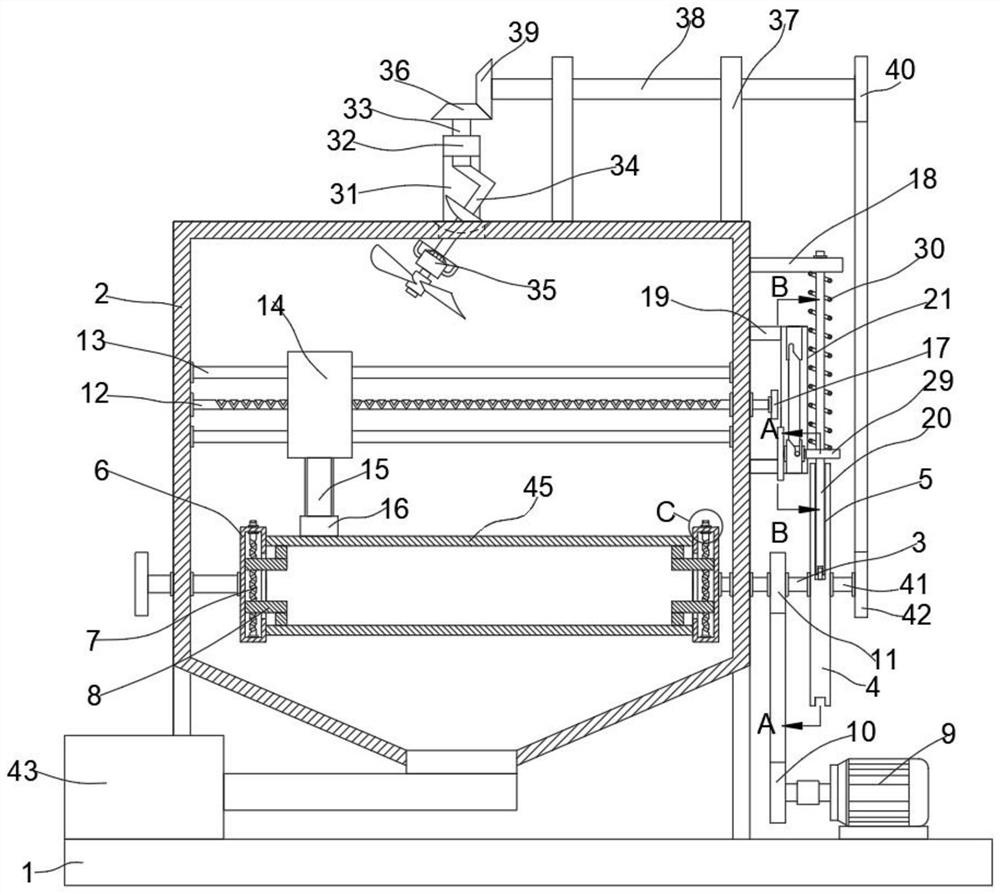

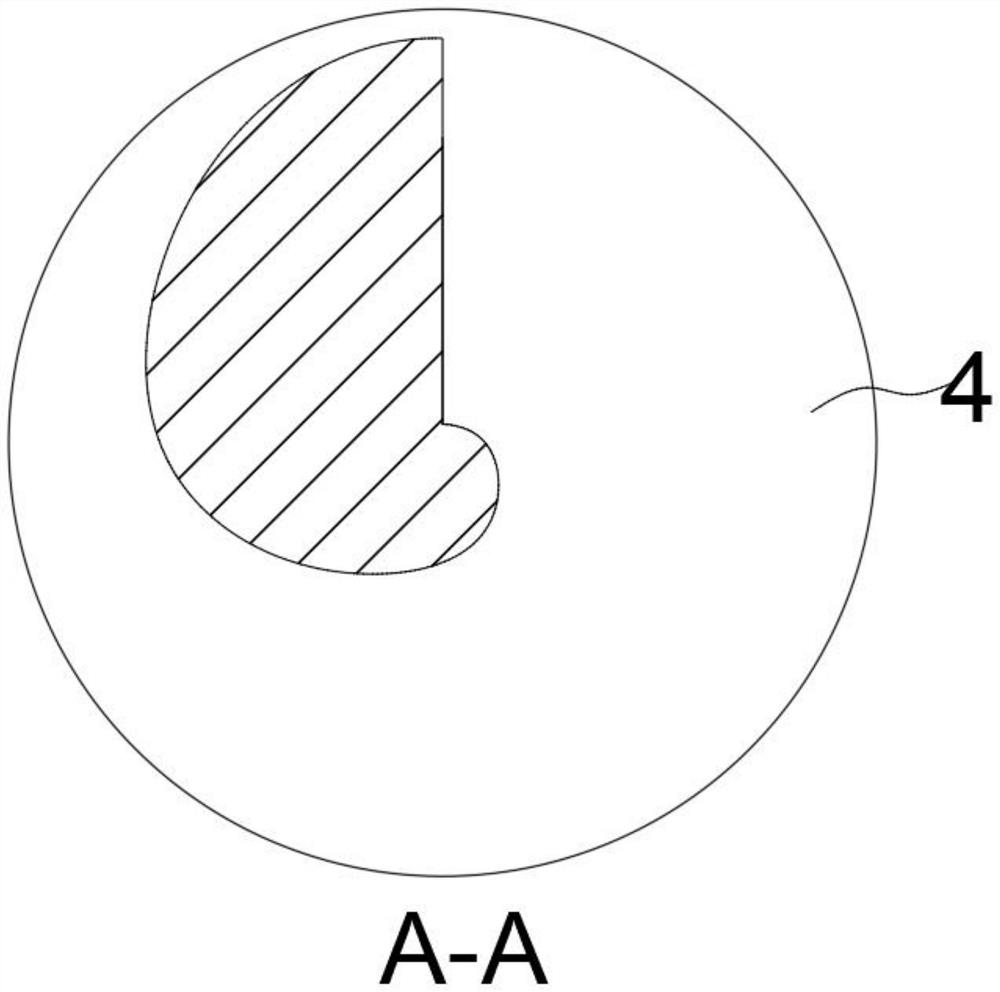

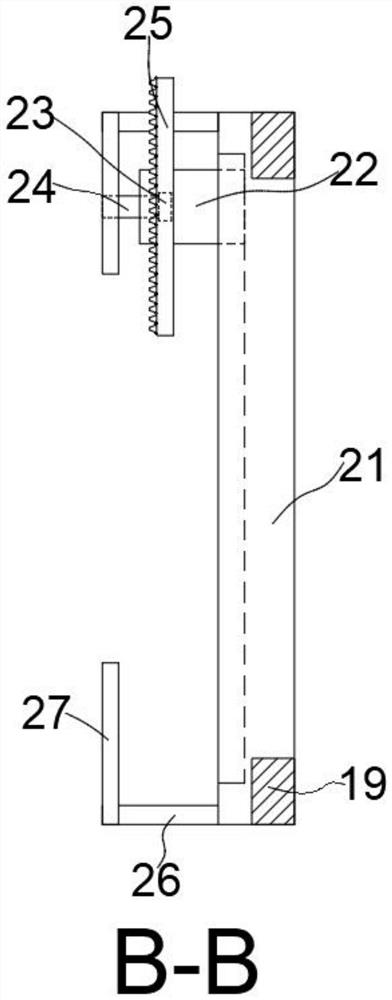

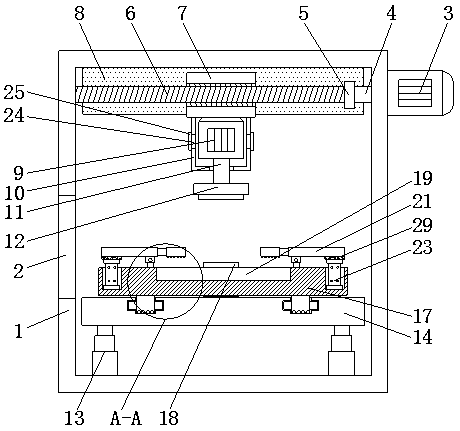

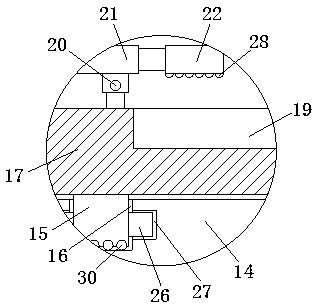

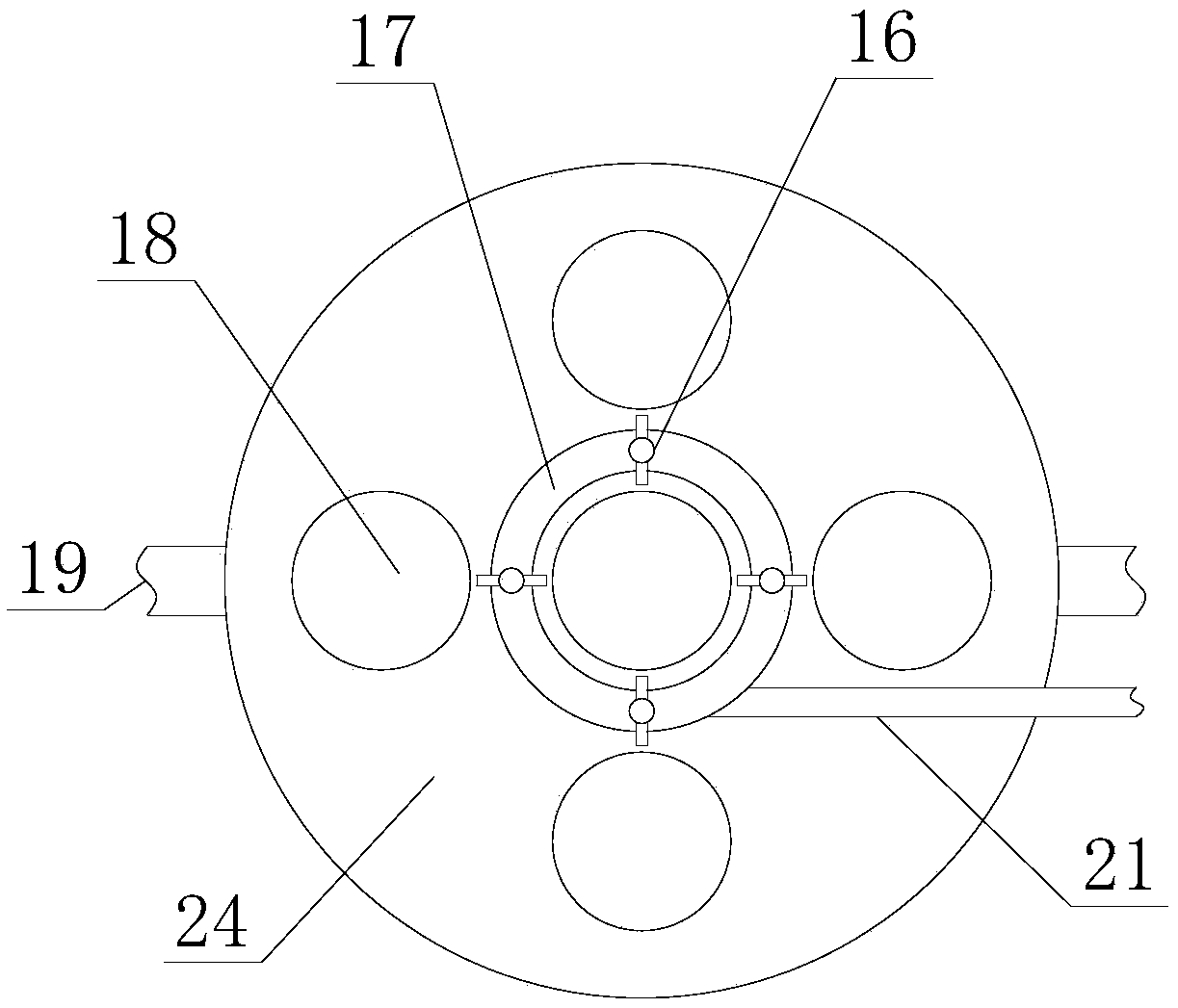

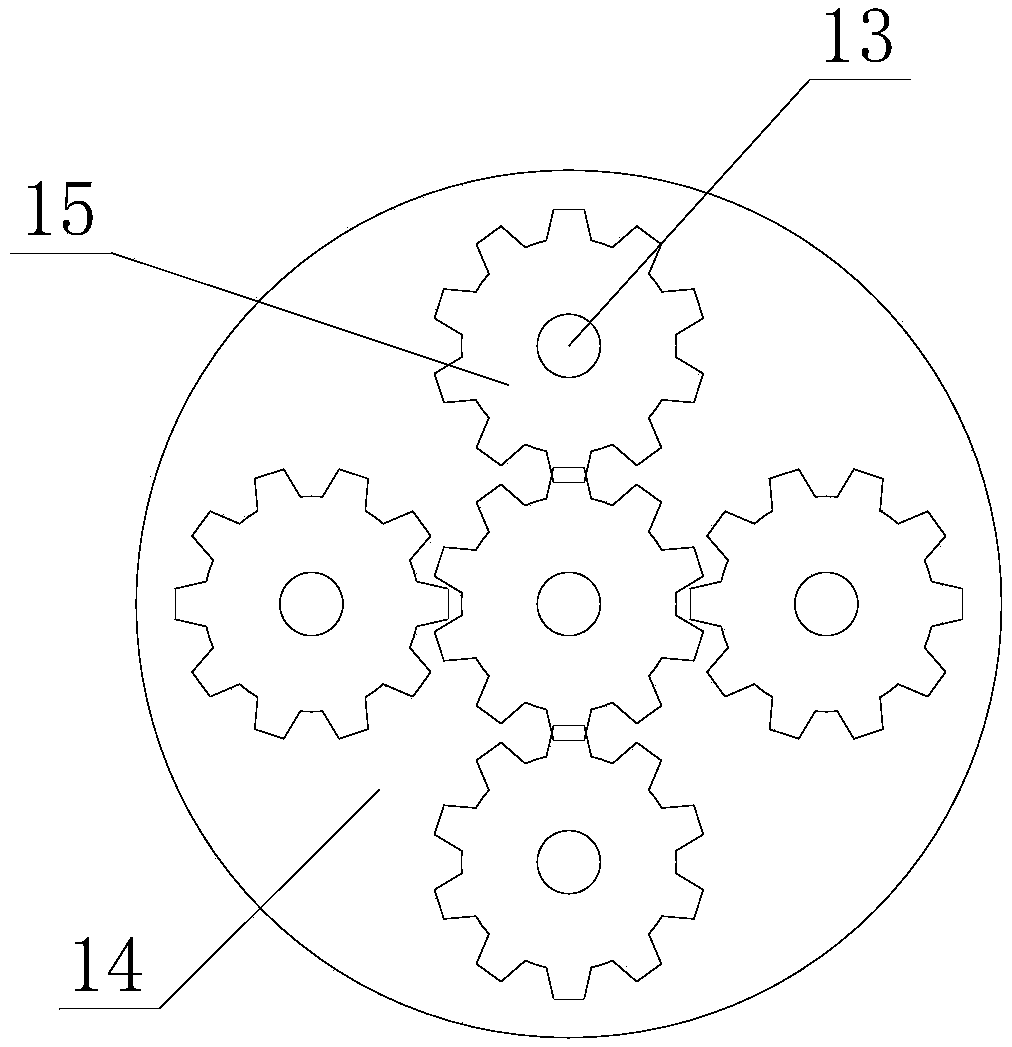

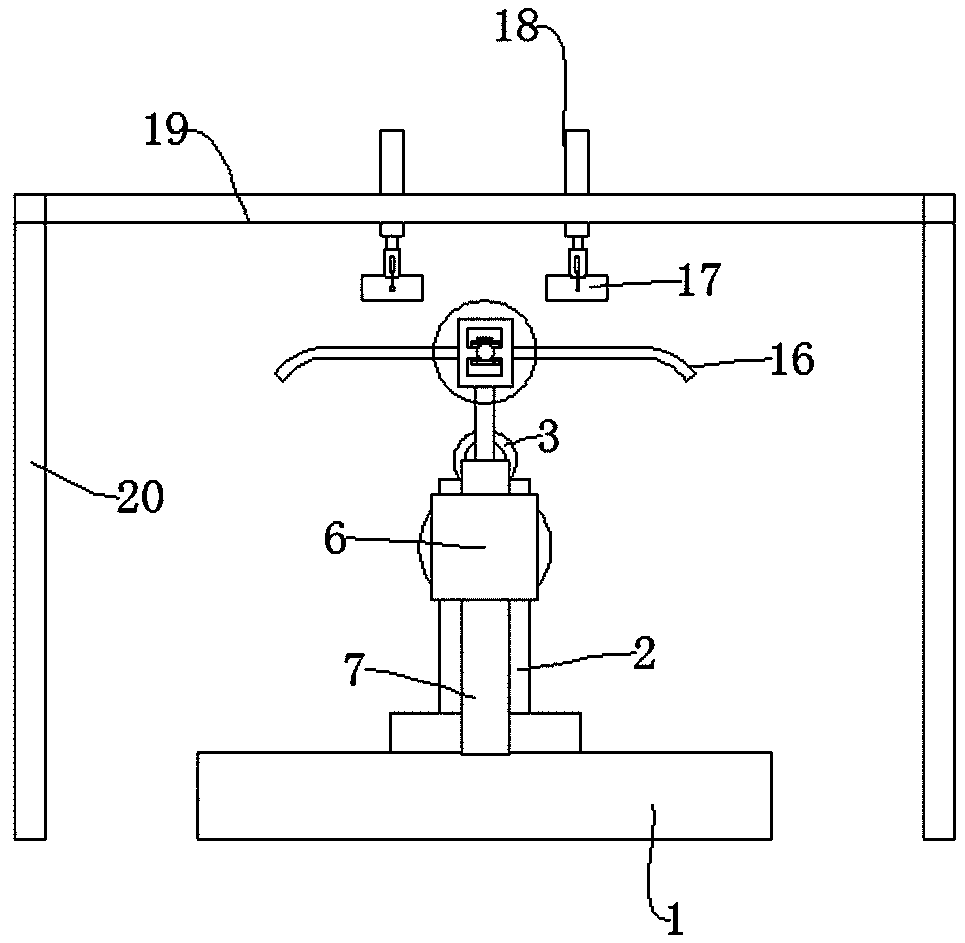

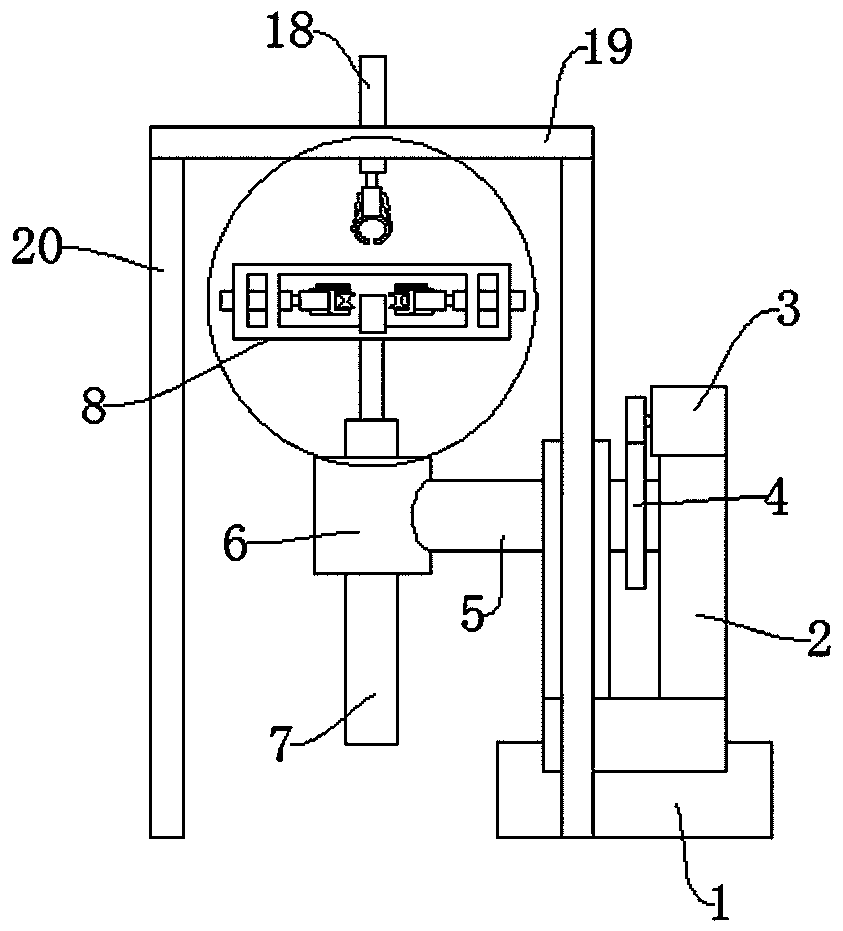

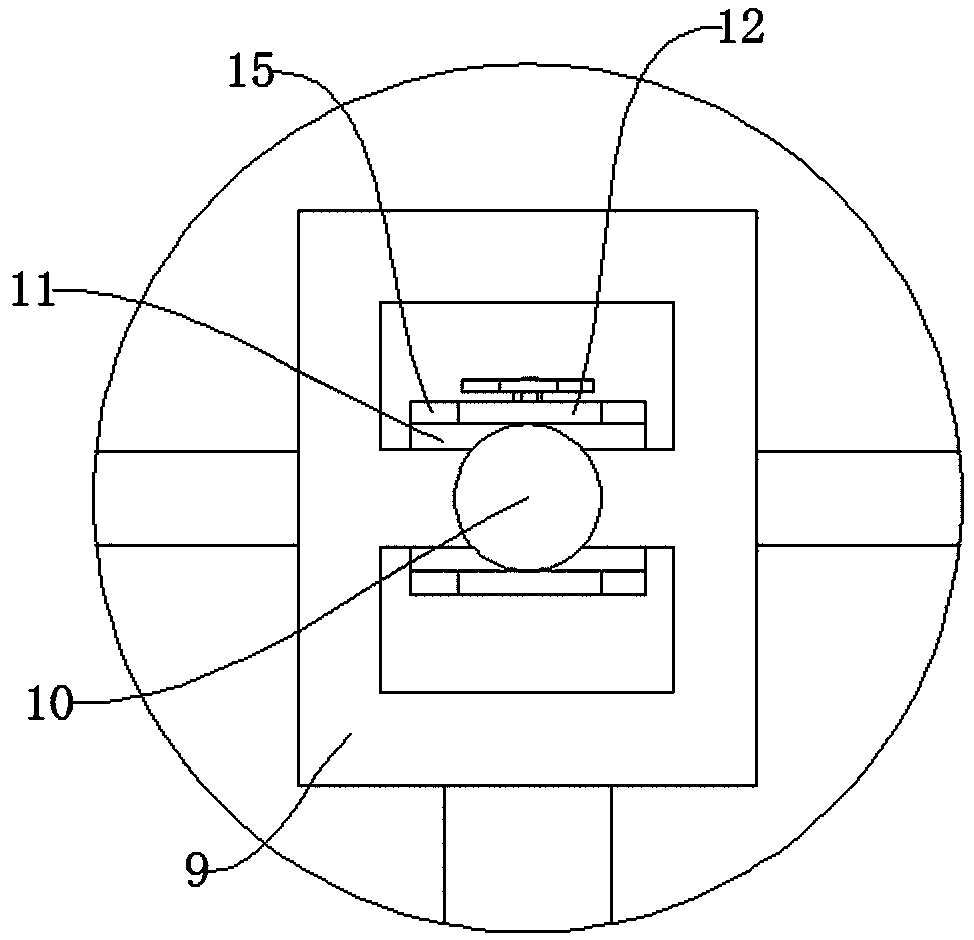

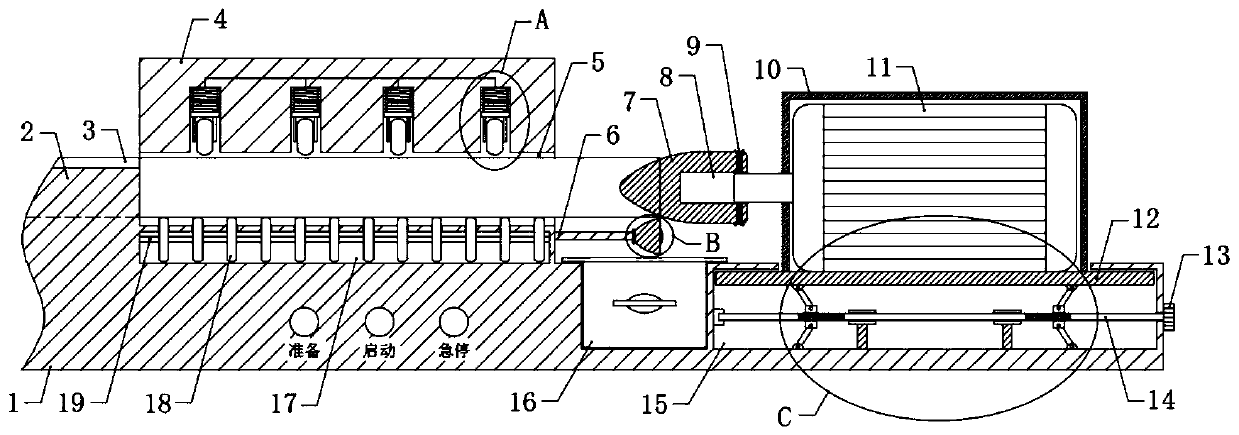

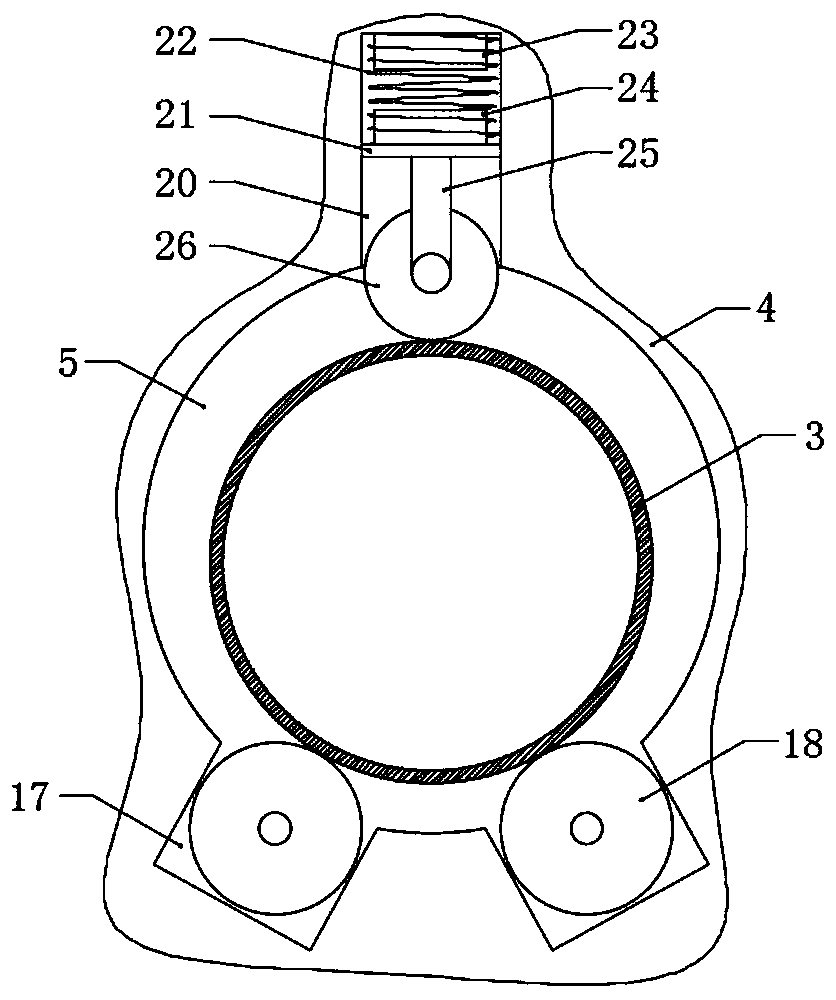

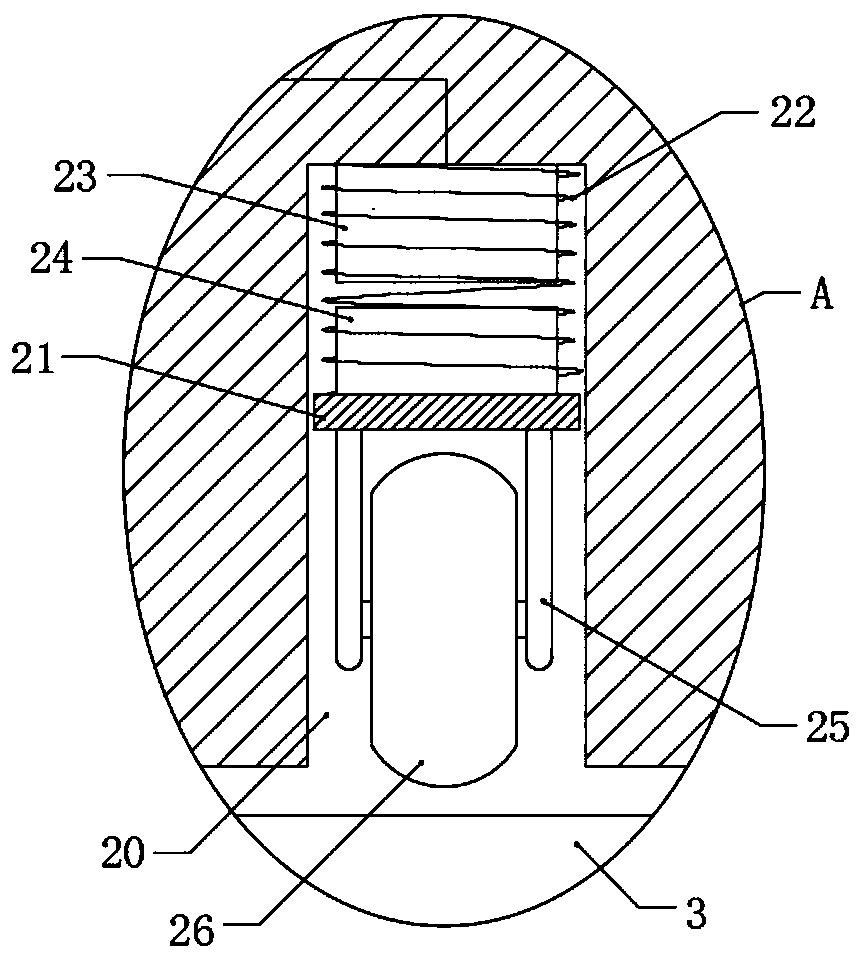

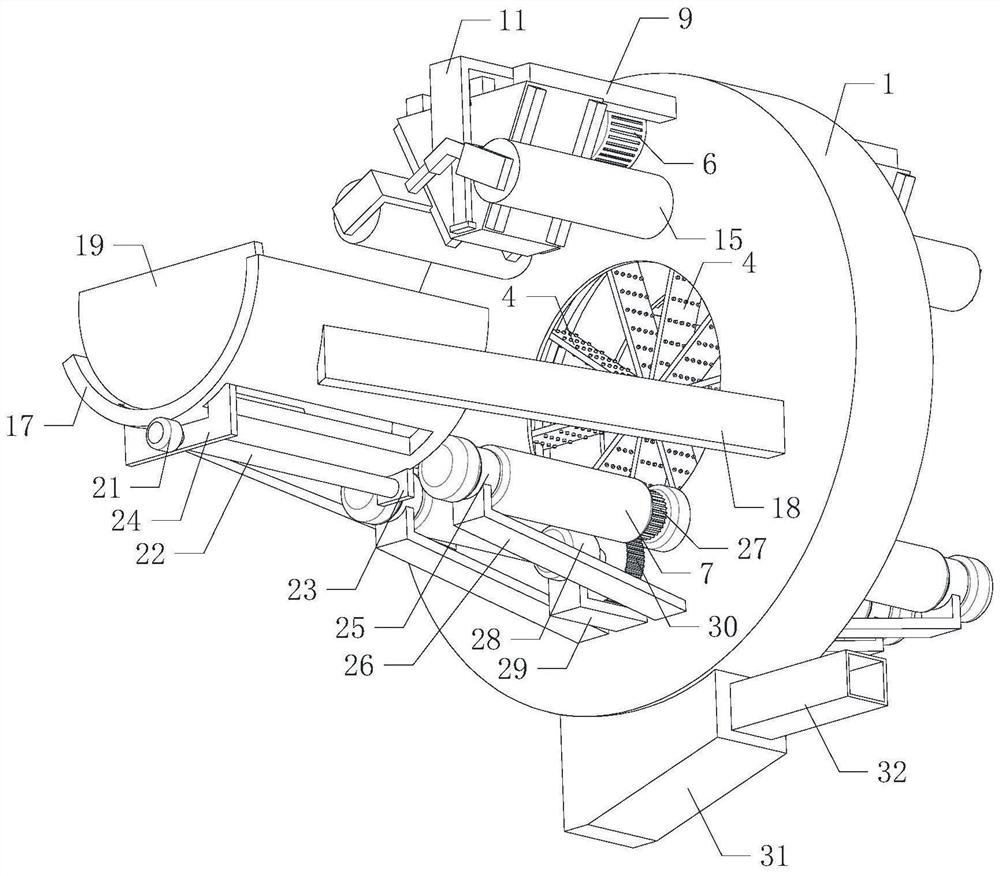

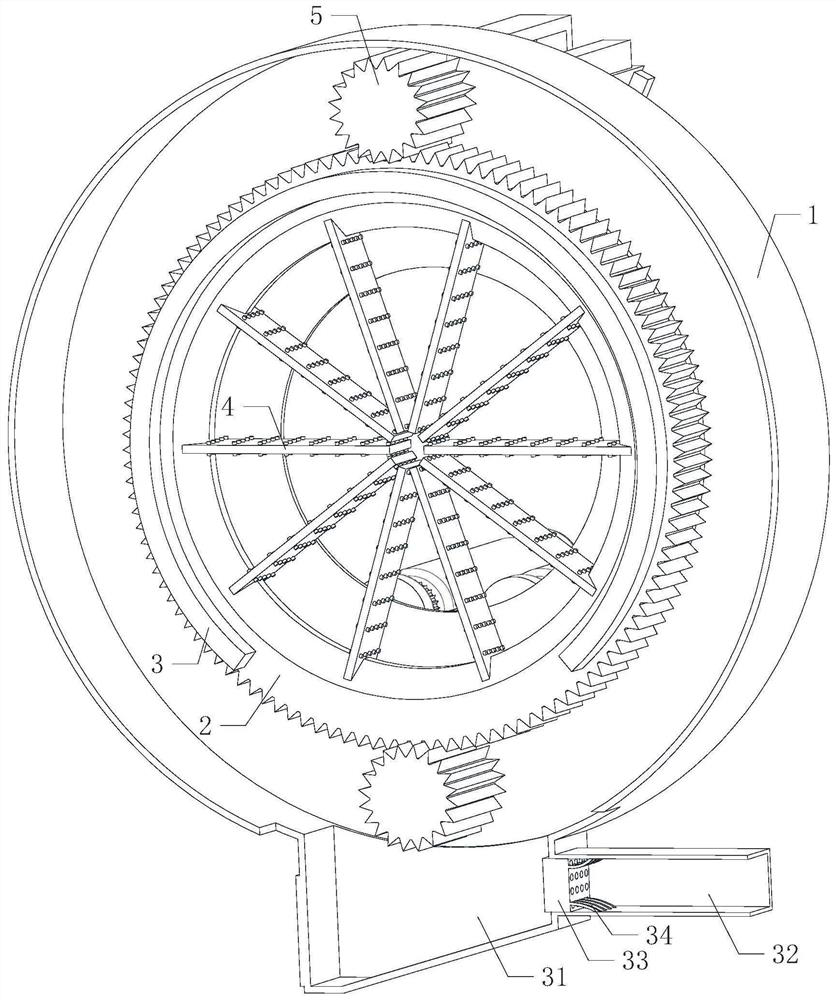

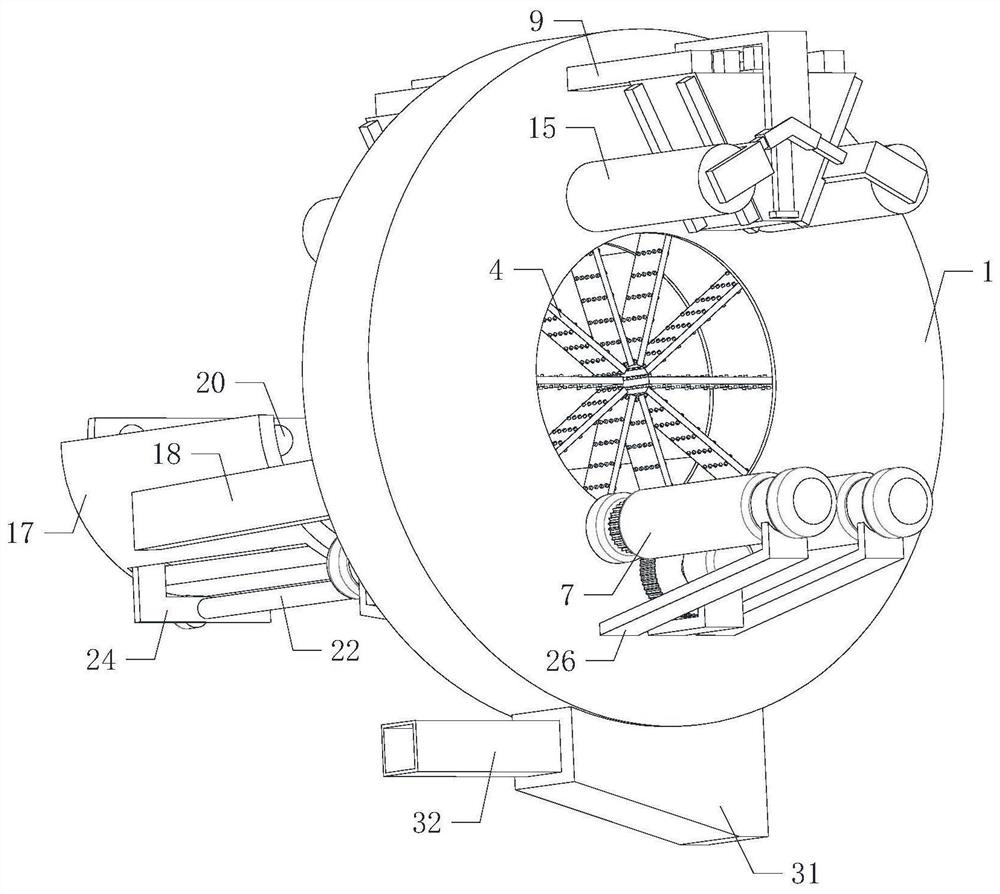

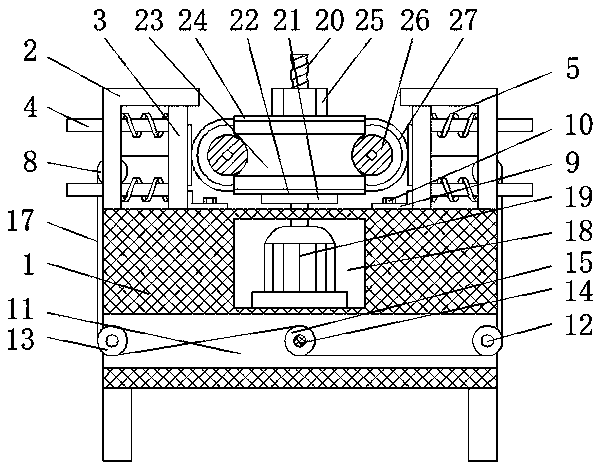

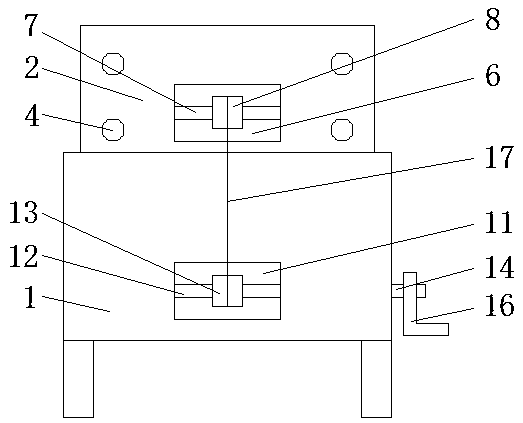

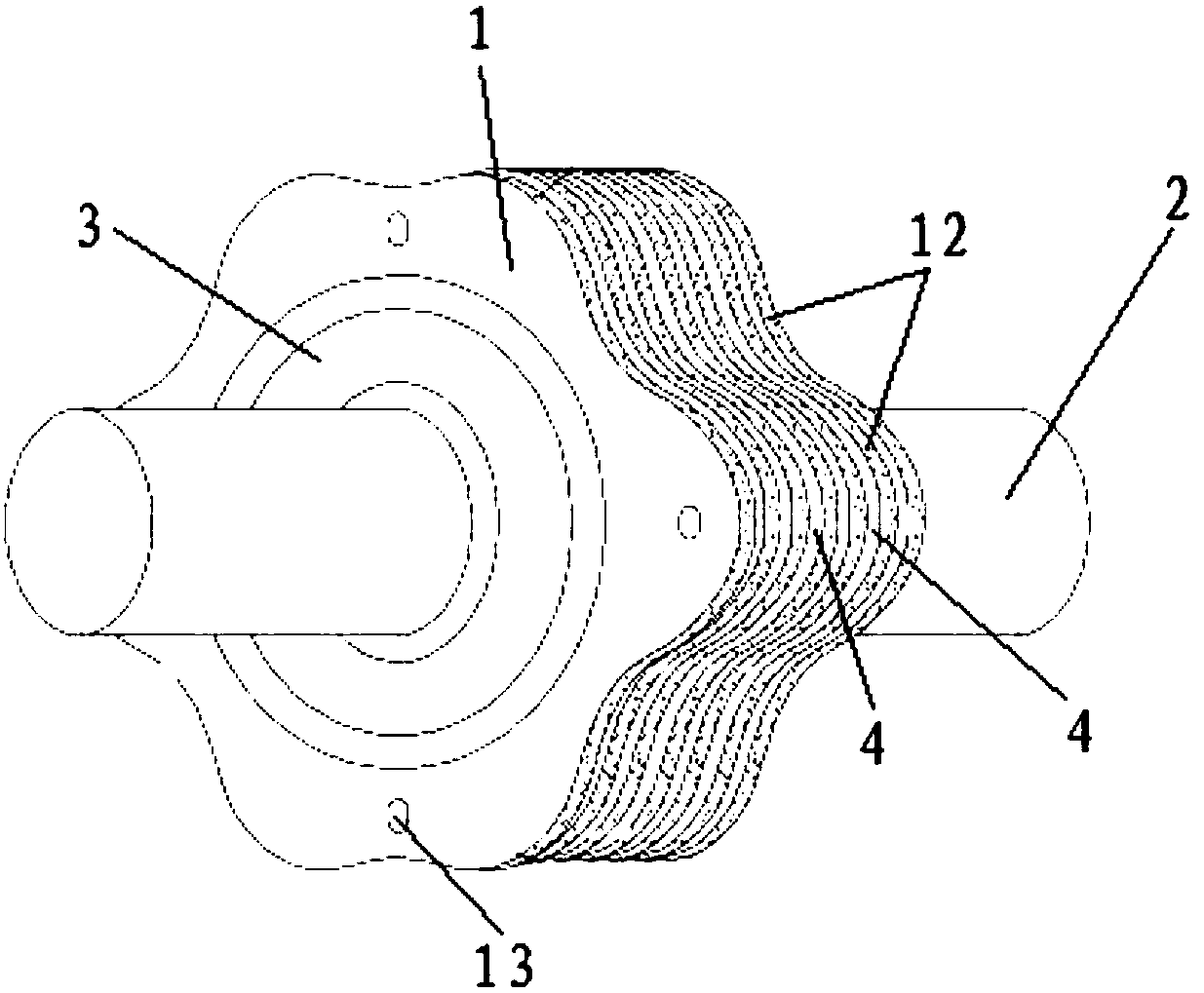

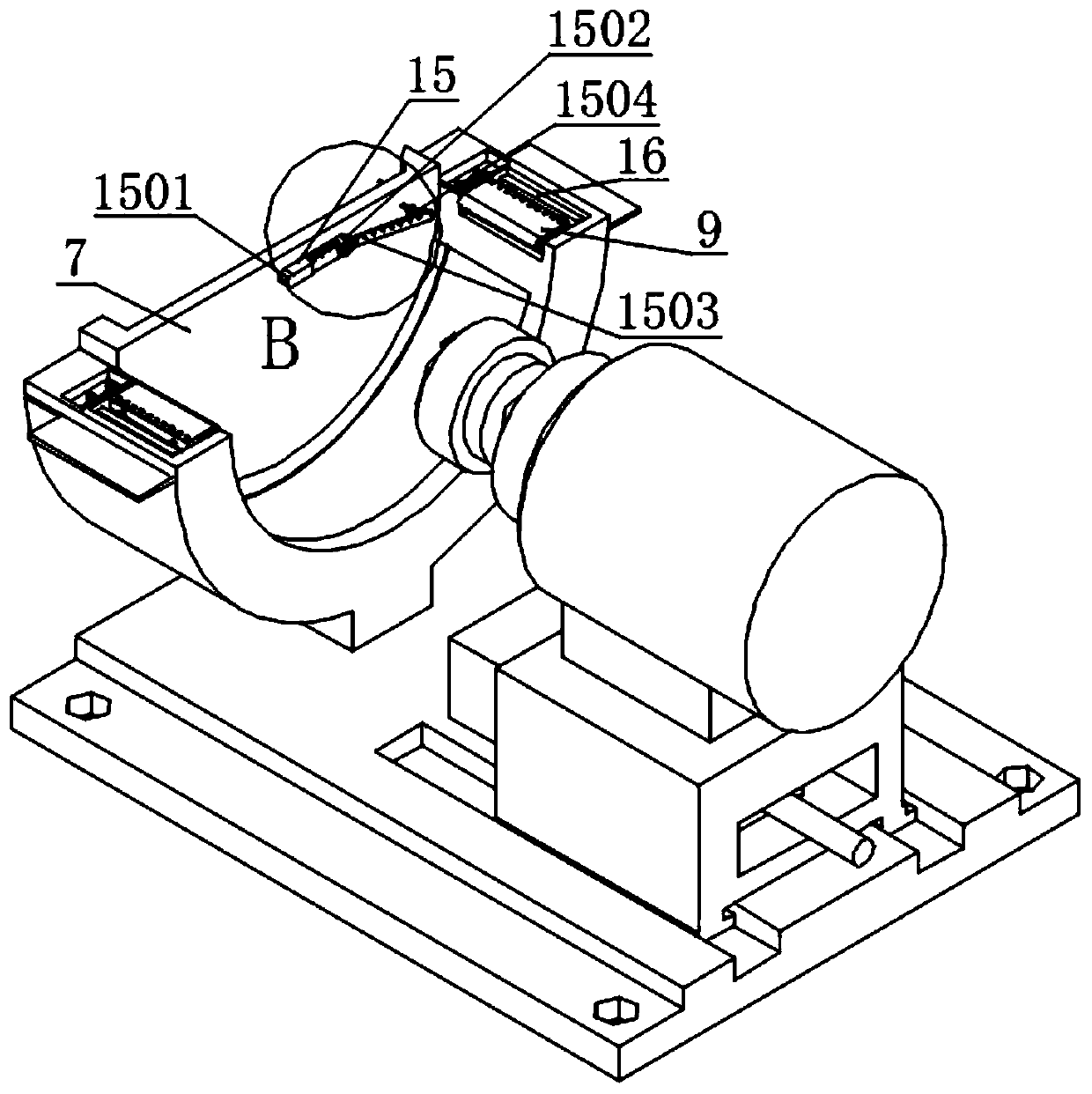

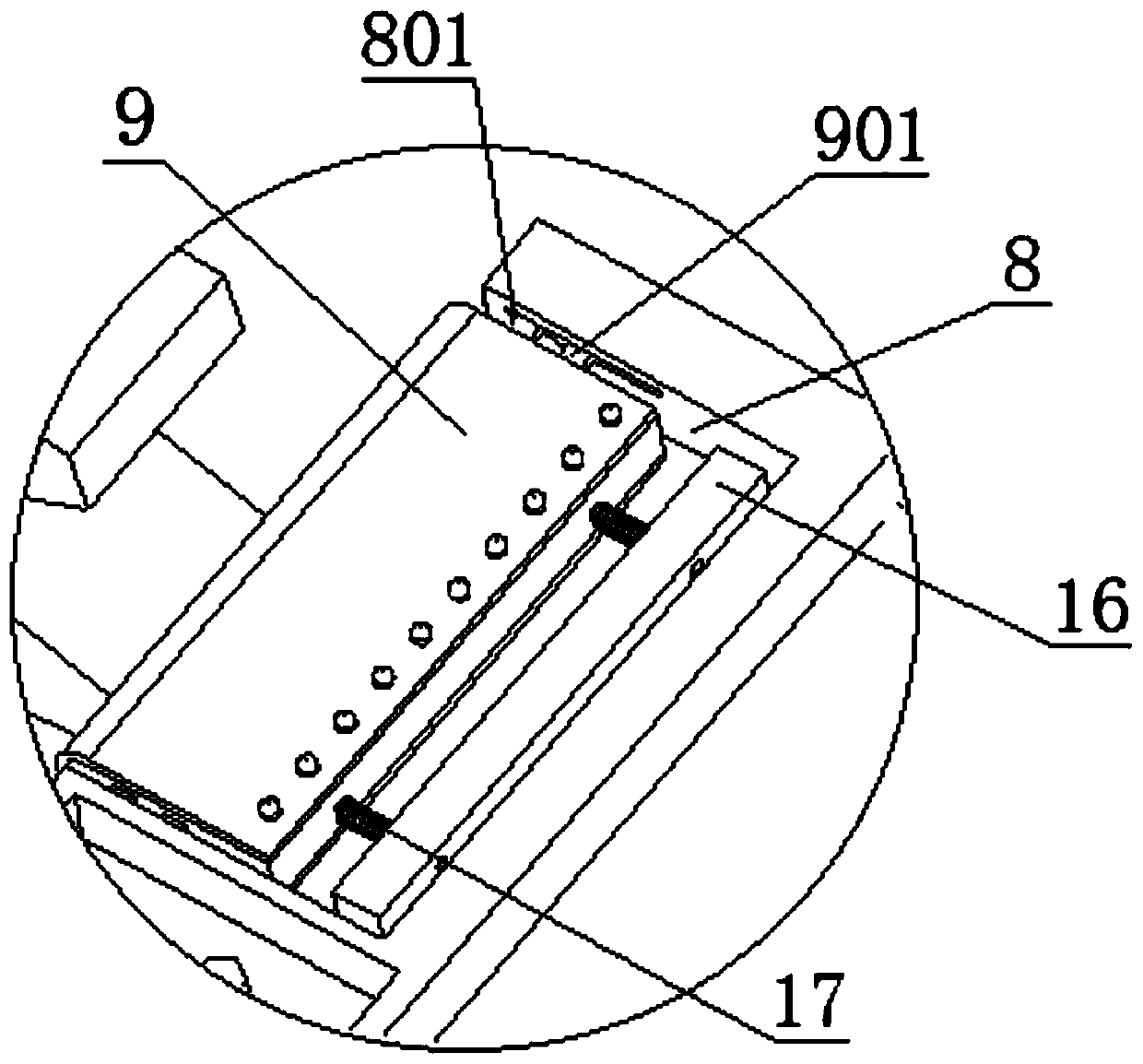

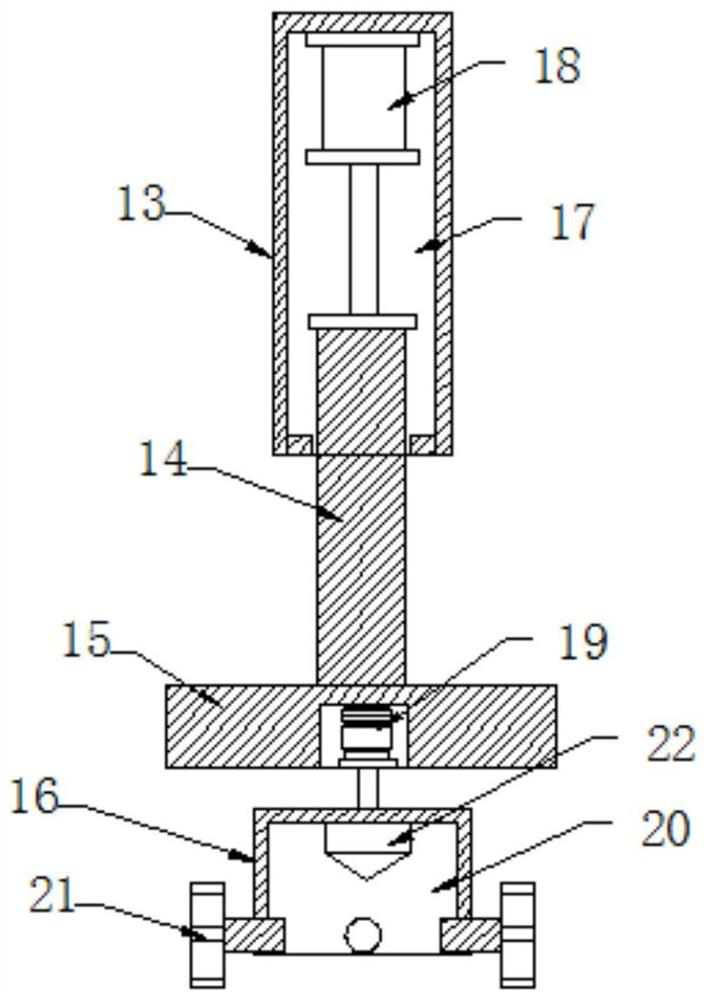

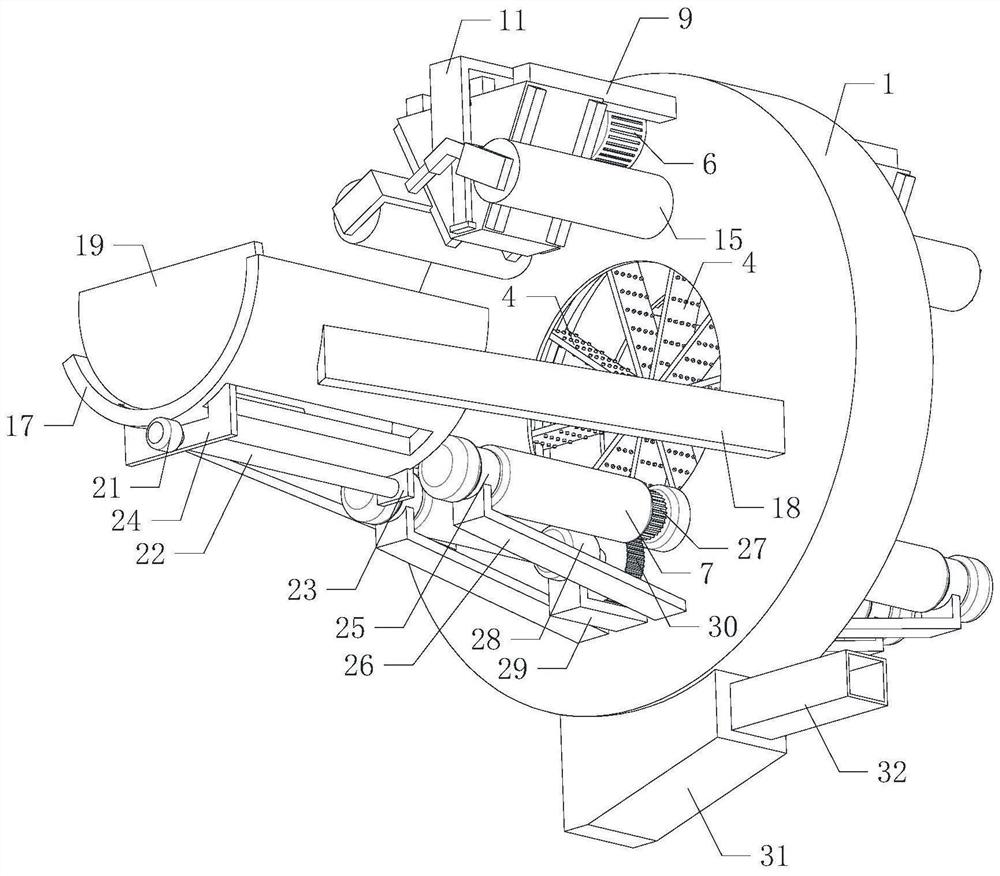

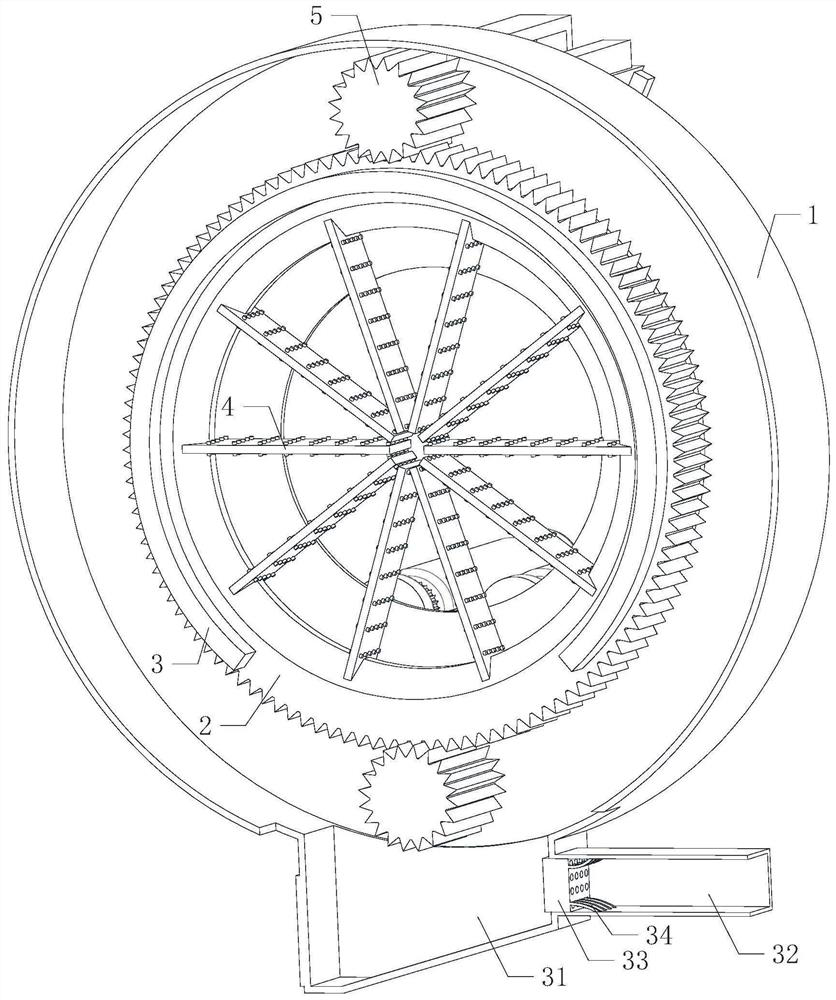

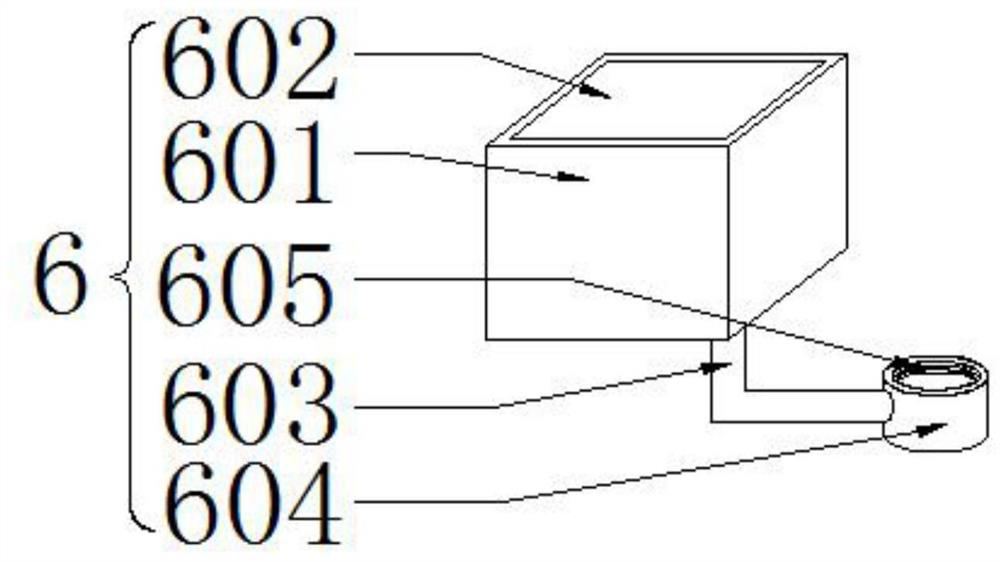

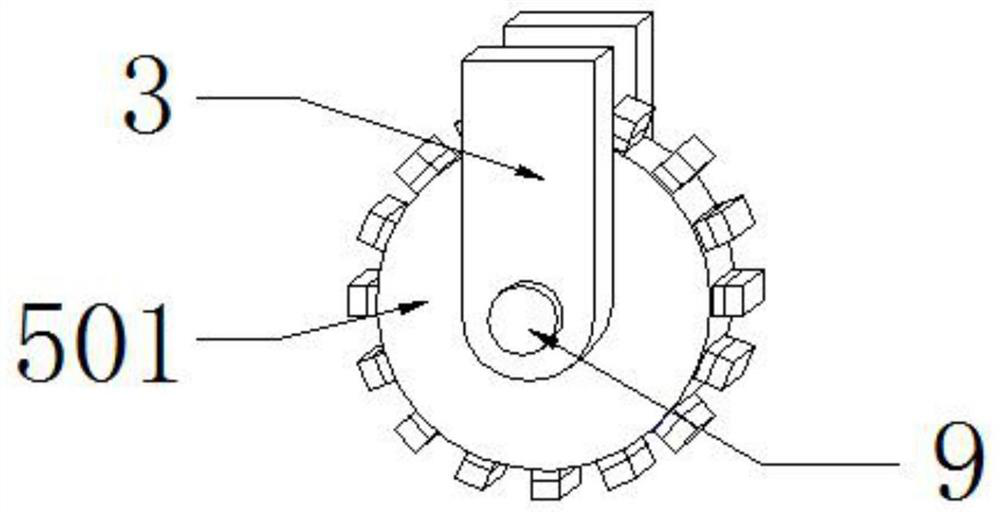

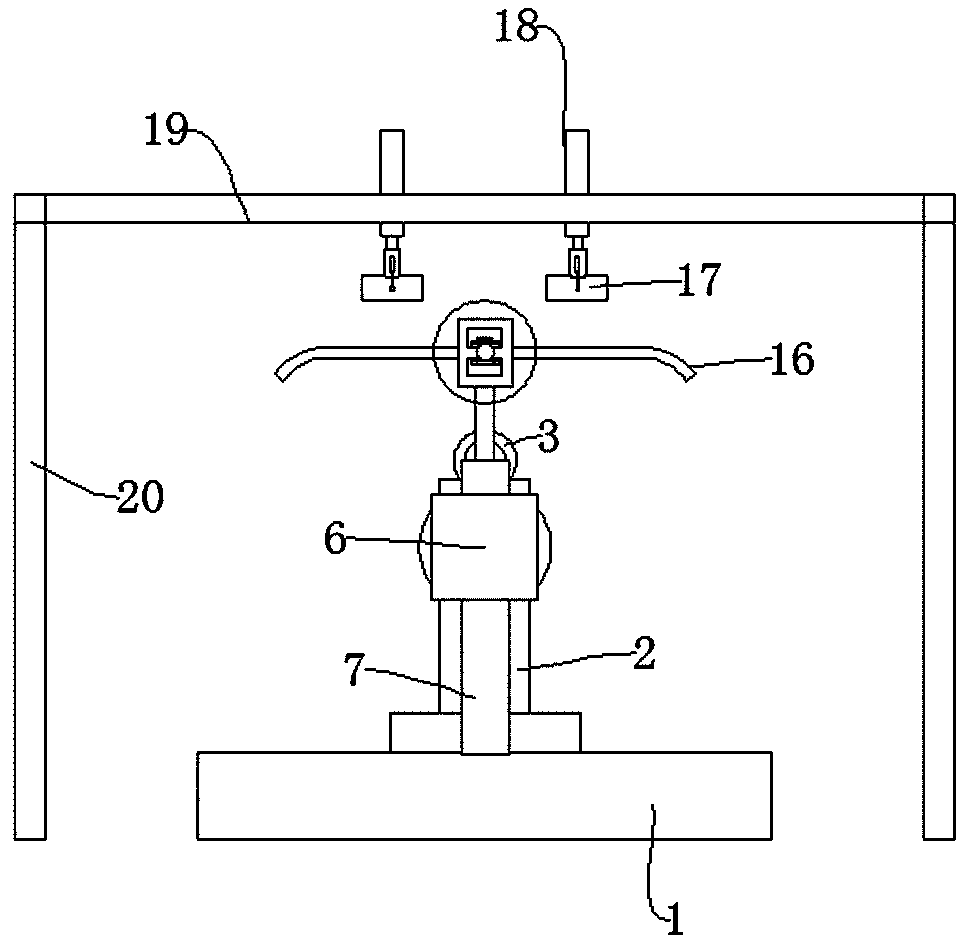

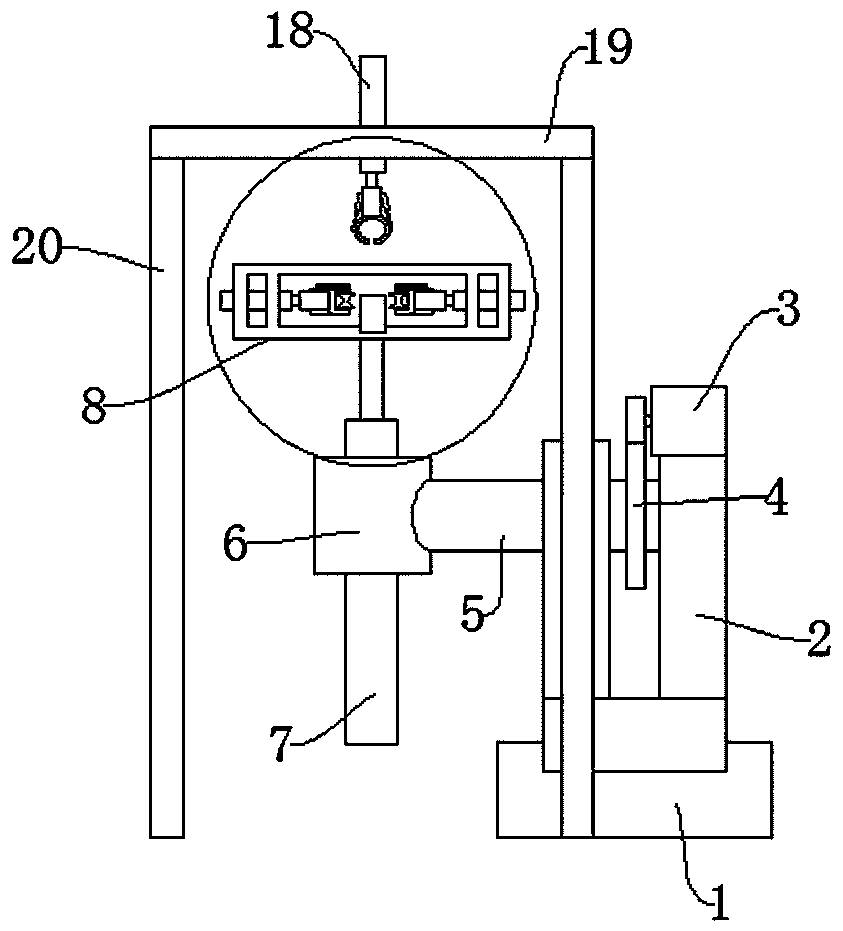

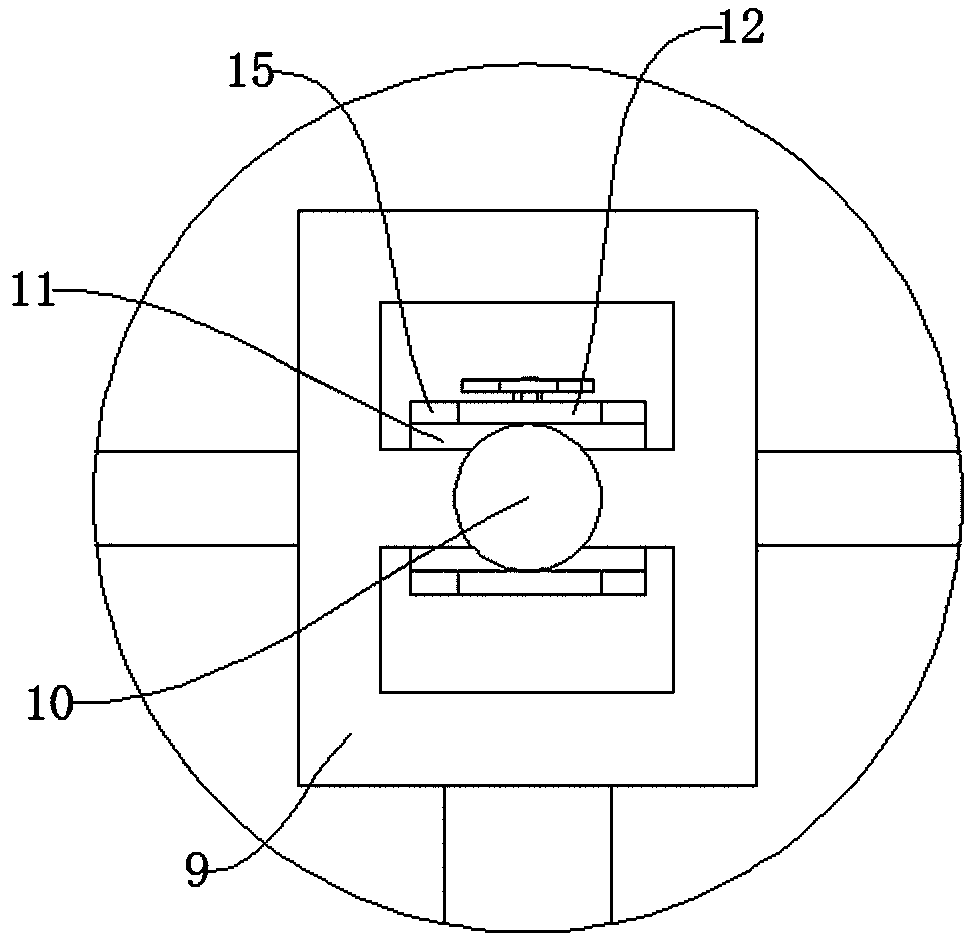

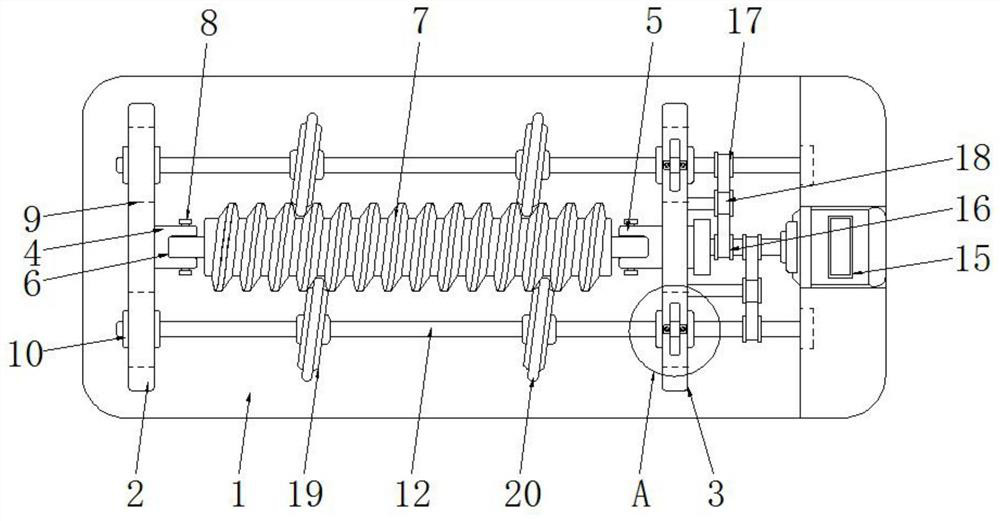

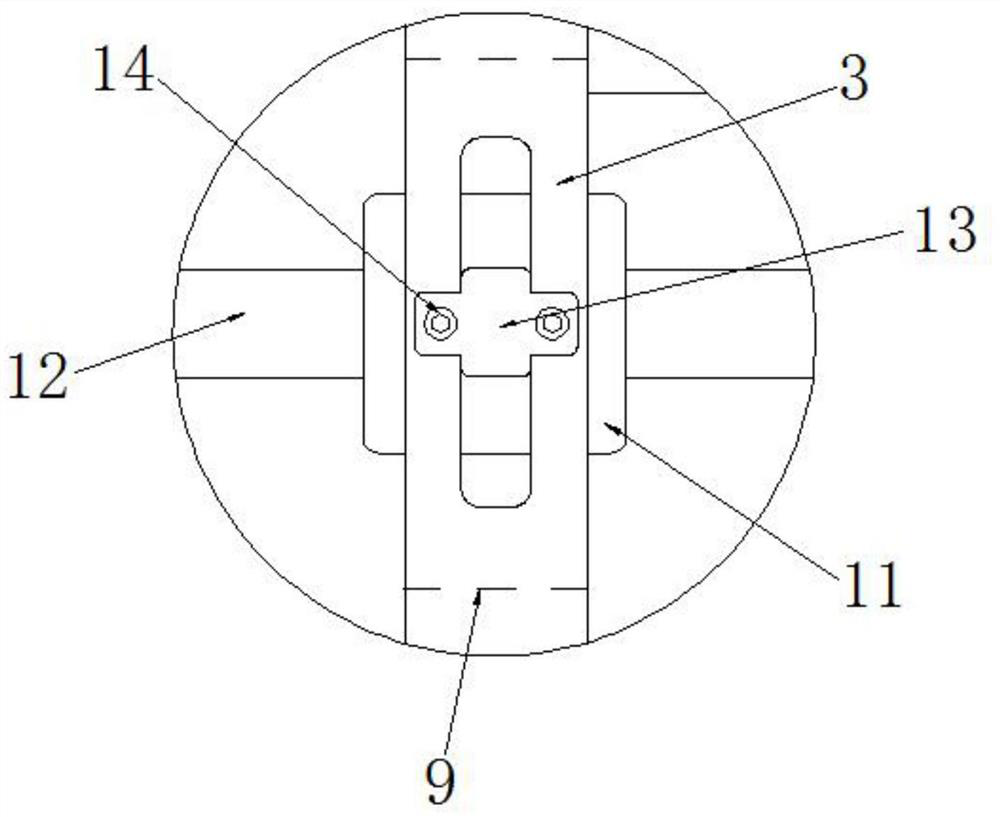

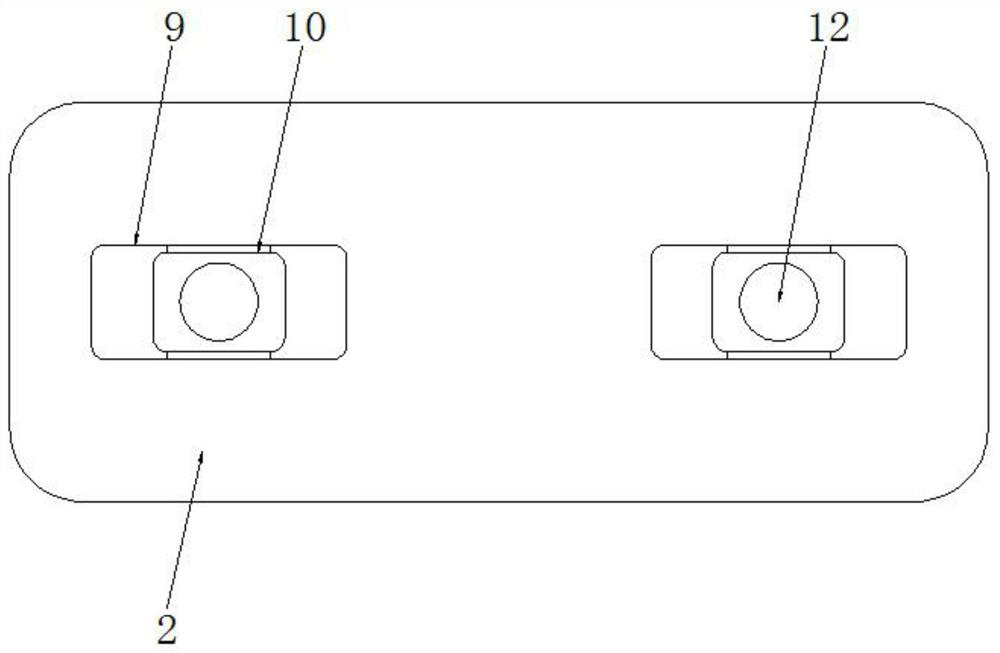

Efficient grinding equipment for pipeline finish machining and polishing

InactiveCN112207643AImprove sanding effectIncrease sanding speedRevolution surface grinding machinesGrinding drivesPolishingDust control

The invention discloses an efficient grinding equipment for pipeline finish machining and polishing. The efficient grinding equipment comprises a base, a shell is fixed to the top of the base, a clamping mechanism, a grinding mechanism and a dust removal mechanism are arranged inside the shell, a driving mechanism used for driving the clamping mechanism to rotate is fixed to the top of the base, and a transmission mechanism is arranged on the outer wall of the shell above the driving mechanism. According to the efficient grinding equipment for pipeline finish machining and polishing, by arranging the driving mechanism, the clamping mechanism, the grinding mechanism and the dust removal mechanism, the phenomenon of missing grinding of the surface of a circular pipe is avoided while the circular pipe is uniformly ground, the grinding effect and the grinding speed of the circular pipe are improved, and meanwhile, the effect of efficiently removing dust in the shell is achieved.

Owner:安徽京远机械有限公司

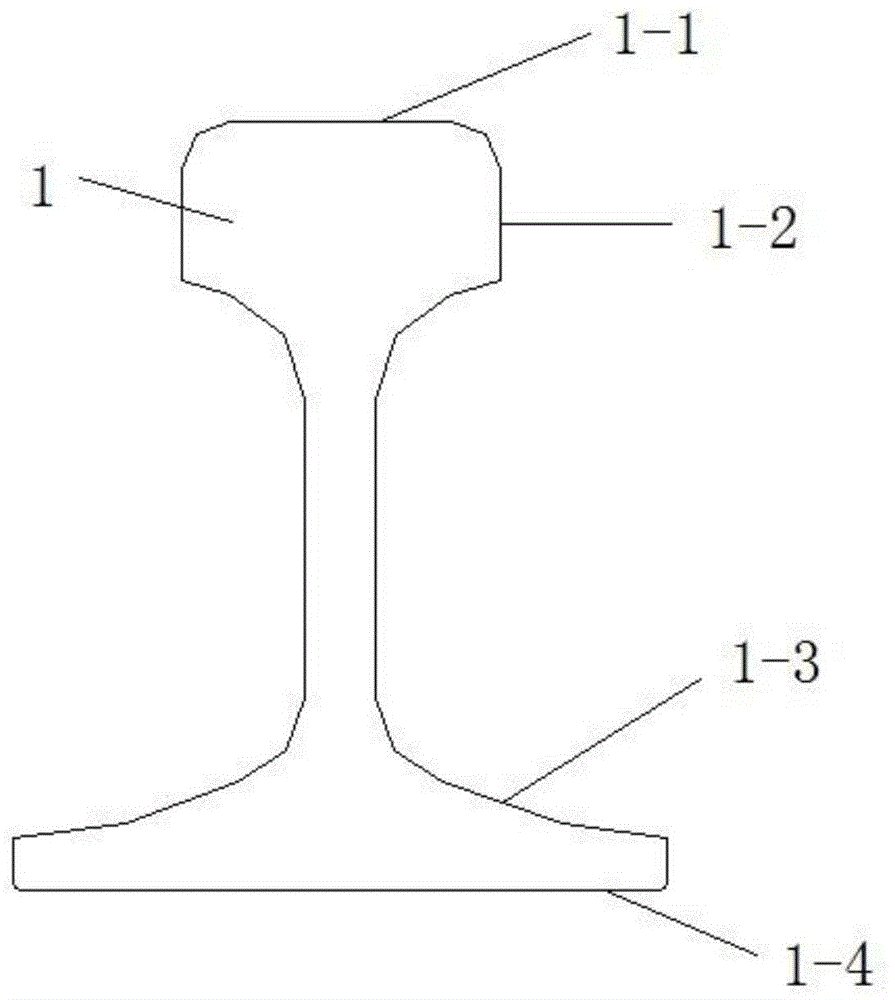

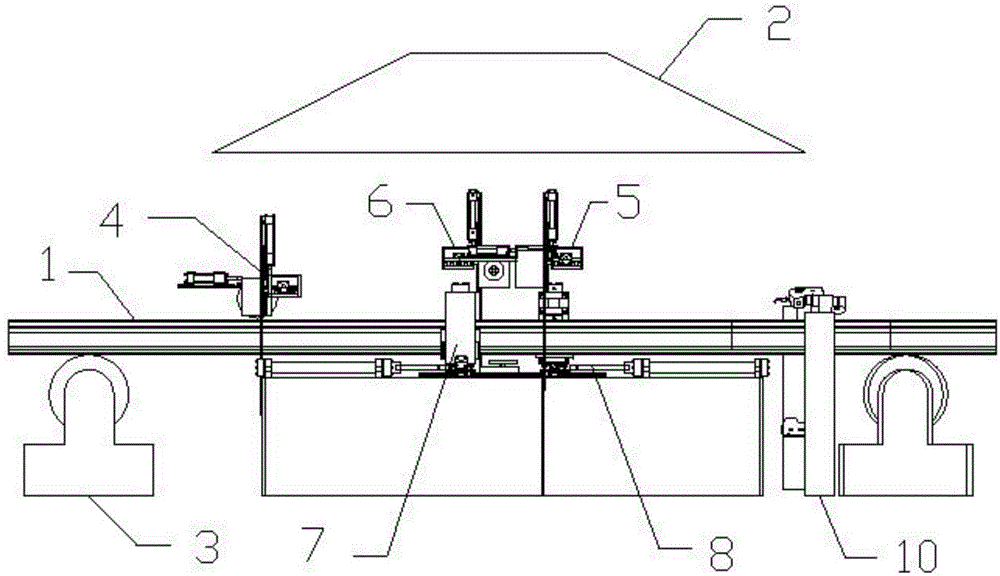

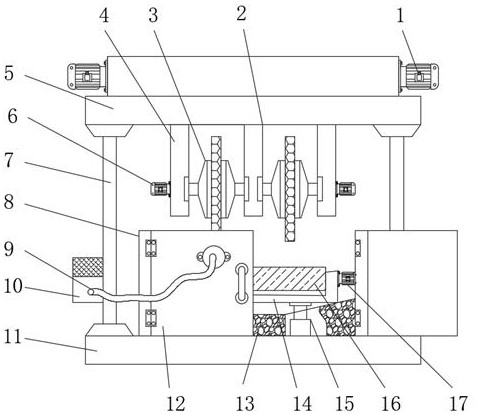

Steel rail grinding machine

InactiveCN104625930AImprove grinding speed and precisionKeep healthyGrinding feed controlGrinding machinesSurface grindingEngineering

The invention relates to a steel rail grinding machine which comprises a steel rail top surface grinding mechanism, a steel rail head side surface grinding mechanism, a steel rail triangular region grinding mechanism, a steel rail bottom grinding mechanism and a travelling line roller, wherein a steel rail is ground by the steel rail top surface grinding mechanism, the steel rail head grinding mechanism, the steel rail triangular region grinding mechanism and the steel rail bottom grinding mechanism in a process of sliding on the travelling line roller, wherein the steel rail bottom grinding mechanism comprises a center base, a base plate is fixedly connected onto the center base, a Z-direction oil cylinder and a Z-direction guide rail are arranged on the base plate, the Z-direction oil cylinder drives a Z-direction sliding base to reciprocate on the Z-direction guide rail; a Y-direction oil cylinder and a Y-direction guide rail are fixedly arranged on the top surface of the Z-direction sliding base, the Y-direction oil cylinder drives the Y-direction sliding base to reciprocate on the Y-direction guide rail; a hydraulic motor is vertically arranged inside the Y-direction sliding base, and an output shaft of the hydraulic motor is fixedly connected with a rail bottom grinding head.

Owner:戚恒

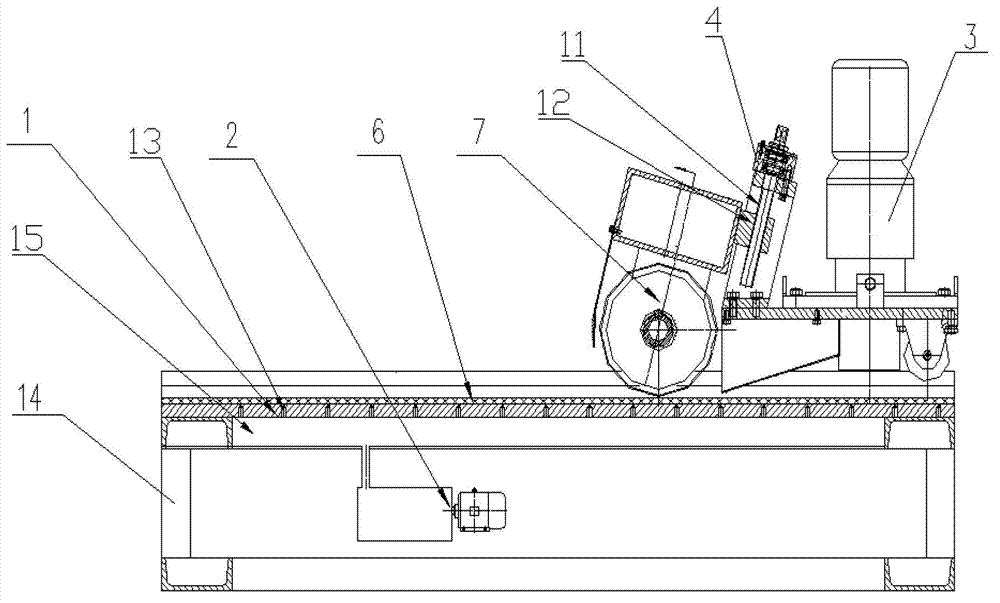

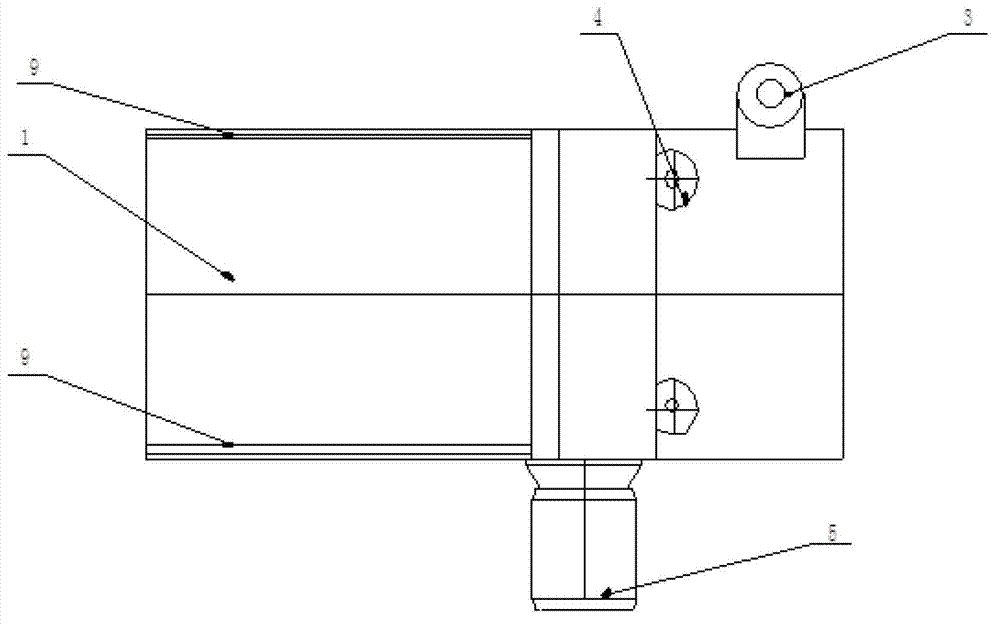

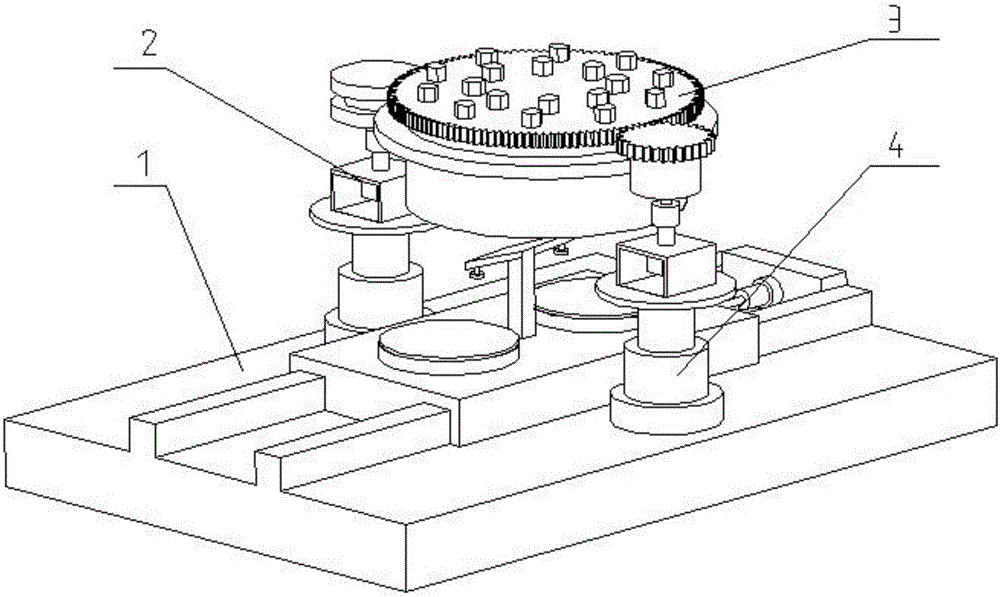

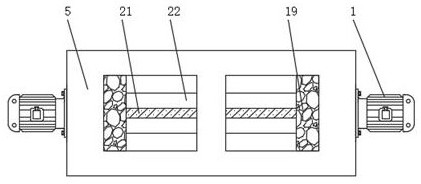

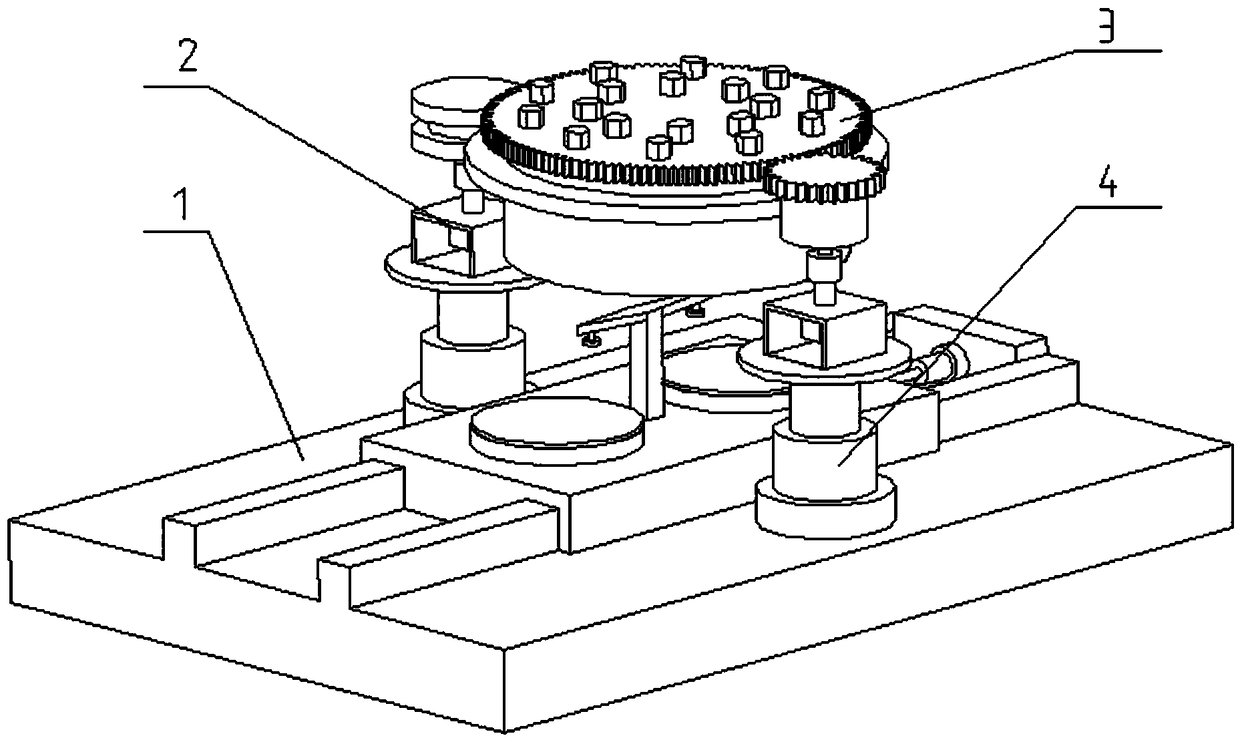

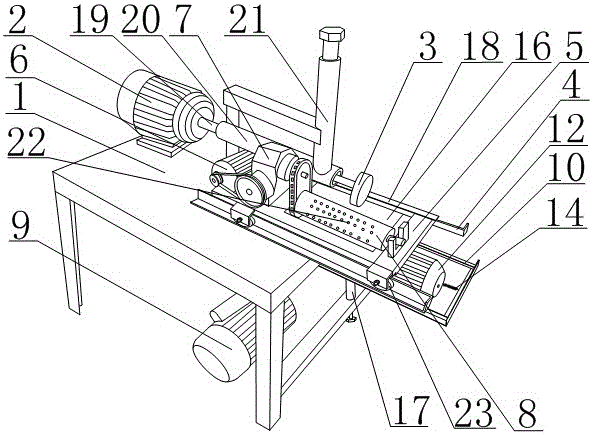

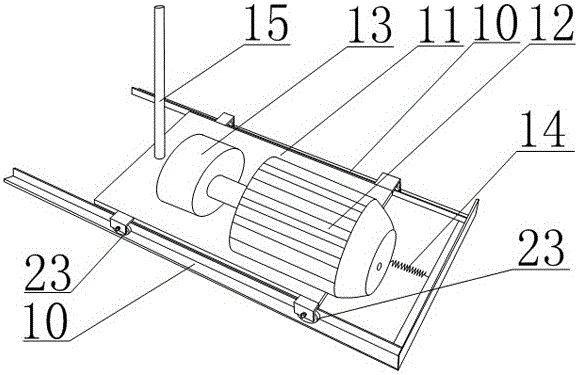

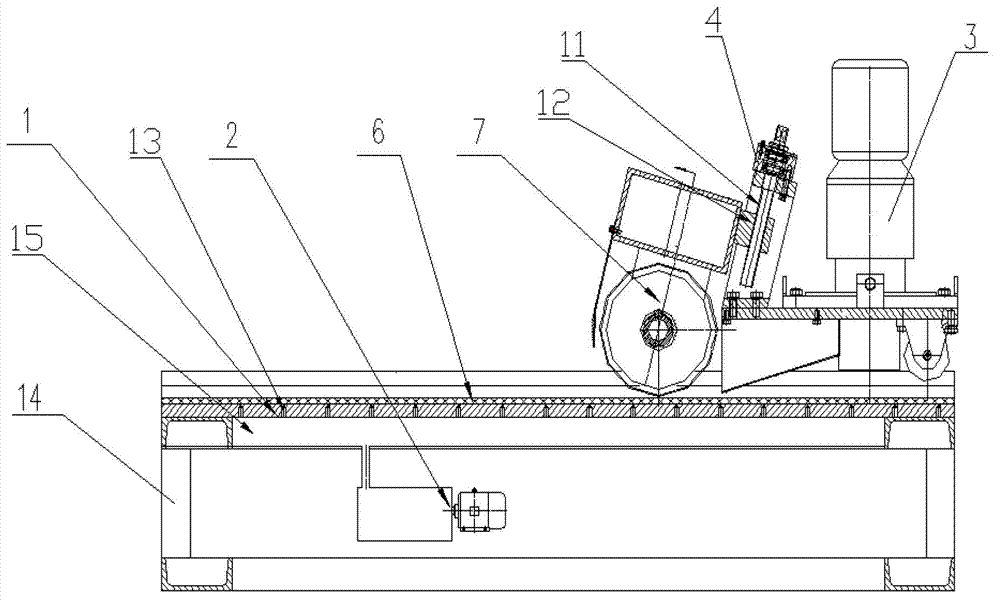

Rubber plate polishing device

ActiveCN102962735AImprove sanding speed and qualityReduce labor intensityGrinding drivesPlane surface grinding machinesEngineeringMaterial resources

The invention relates to the mechanical polishing field, in particular to a rubber plate polishing device. The rubber plate polishing device comprises a frame, wherein a rubber plate fixing apparatus is arranged on the upper surface of the frame; guide rails and racks are arranged at the edges of two unconnected sides of the rubber plate fixing apparatus; a walking device is arranged on one side of the rubber plate fixing apparatus with the guide rails and the racks; gears are arranged at the lower part of the walking device, engaged with the racks on the rubber plate fixing apparatus and placed on a wheel; an automatic distance adjusting device is arranged at the front end of the walking device; a polishing wheel device is arranged at the front end of the automatic distance adjusting device; the polishing wheel device is connected with a polishing wheel rotating device; and the polishing wheel rotating device drives a cylinder on the polishing wheel device to rotate. The rubber plate polishing device provided by the invention has the advantages that the whole rubber plate can be polished, the polishing speed of the rubber plate is effectively increased, the polishing quality of the rubber plate is effectively improved, the labor intensities of workers are greatly reduced and a great deal of manpower and material resources are saved.

Owner:YANTAI XINHAI MINING MACHINERY

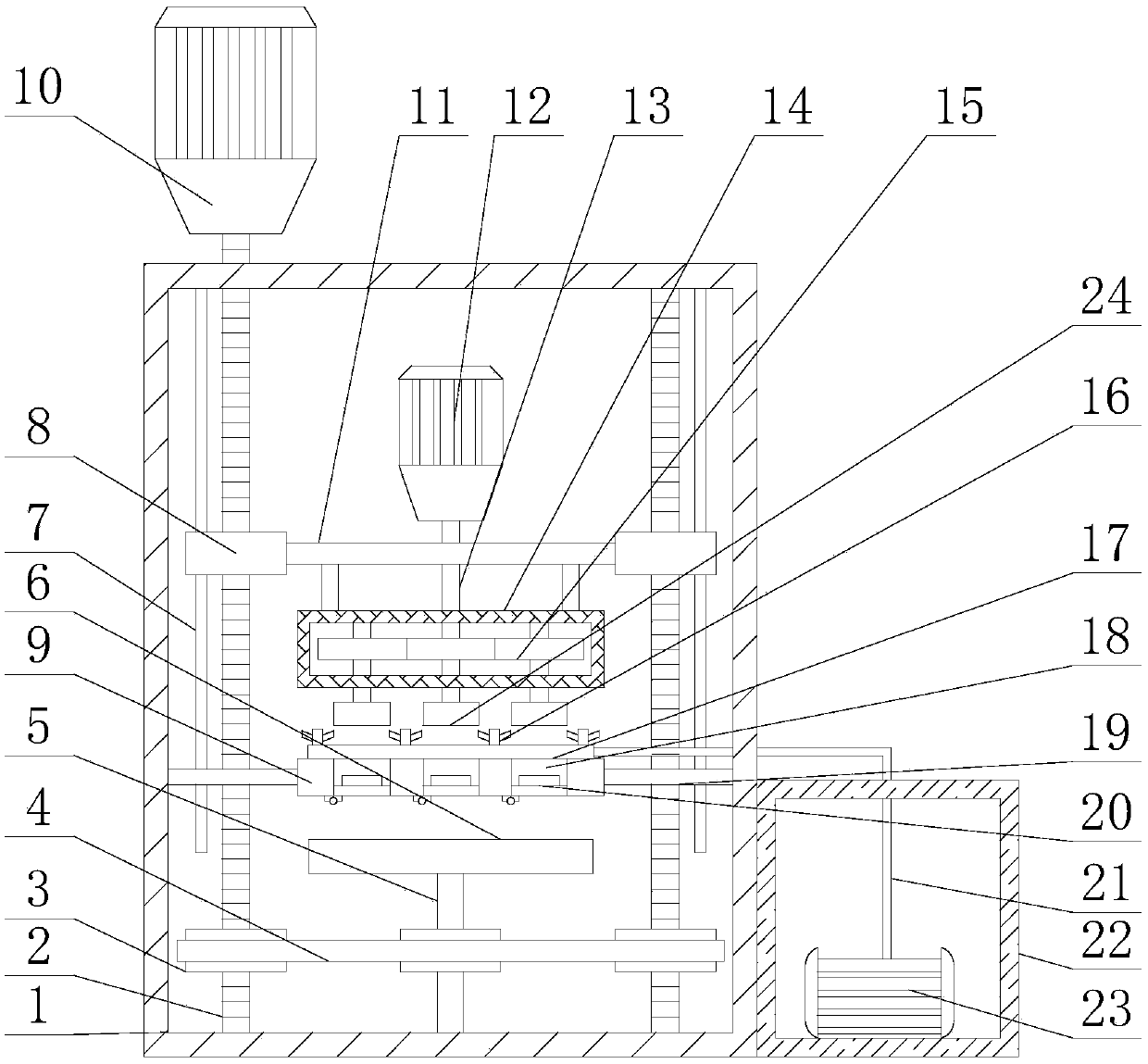

High-efficiency polishing device used for production of mechanical parts

InactiveCN108818259AEasy to polishEasy to useGrinding machinesGrinding work supportsEconomic benefitsElectric machinery

The invention discloses a high-efficiency polishing device used for production of mechanical parts. The high-efficiency polishing device comprises a shell; an opening is formed in the left side of theinner wall of the shell; the top part of the right side of the shell is fixedly provided with a driving motor; the output shaft of the driving motor is fixedly connected with a driving rotating shaft; and the left end of the driving rotating shaft penetrates through the shell, extends into the shell and is fixedly connected with a threaded rod. By installing the driving motor, the threaded rod, athreaded sleeve, a limiting baffle, a fixed block, sliding chutes, sliding blocks, a holding plate, a first air cylinder, rotating shafts, expansion links, pressing blocks and second air cylinders, the high-efficiency polishing device disclosed by the invention solves the problem that a traditional polishing device used for production of mechanical parts is often not thorough in polishing and lowin polishing efficiency; the high-efficiency polishing device is simple in structure and convenient to operate; a user can perform rapid grinding and use more conveniently; the grinding speed and thegrinding effect are improved; normal mechanical production and manufacturing is guaranteed; economic cost is reduced; and economic benefit is increased.

Owner:杨岩

Casting polishing device

InactiveCN109605224ASimple structureEasy to operateGrinding wheel securing apparatusGrinding machinesEngineeringWater tanks

The invention discloses a casting polishing device. The casting polishing device comprises a box body, threaded rods, chain wheels, a chain, a rotating rod, a polishing disc, guiding rods, sliding blocks, a mounting plate, a first motor, a transverse plate, a second motor, shaft rods, a circular frame, gears, atomizing nozzles, an annular guiding pipe, through holes, a connecting rod, brushes, a water guiding pipe, a water tank, a water suction pump and clamp sleeves. According to the casting polishing device, the threaded rods, the chain wheels, the clamp sleeves, the grinding disc, the shaftrods and the gears are arranged and mutually matched so that castings can be better polished, the working intensity of a worker is greatly lowered, the polishing speed is increased, the polishing efficiency is improved, and meanwhile, a large amount of time is also shortened; and the mounting plate, the brushes, the atomizing nozzles and the annular guiding pipe are arranged and mutually matchedso that the castings can be well cleared and cooled, clearing difficulty is greatly lowered, and meanwhile, the practicability of the polishing device is also improved.

Owner:镇江市丹徒区石马机械铸造厂

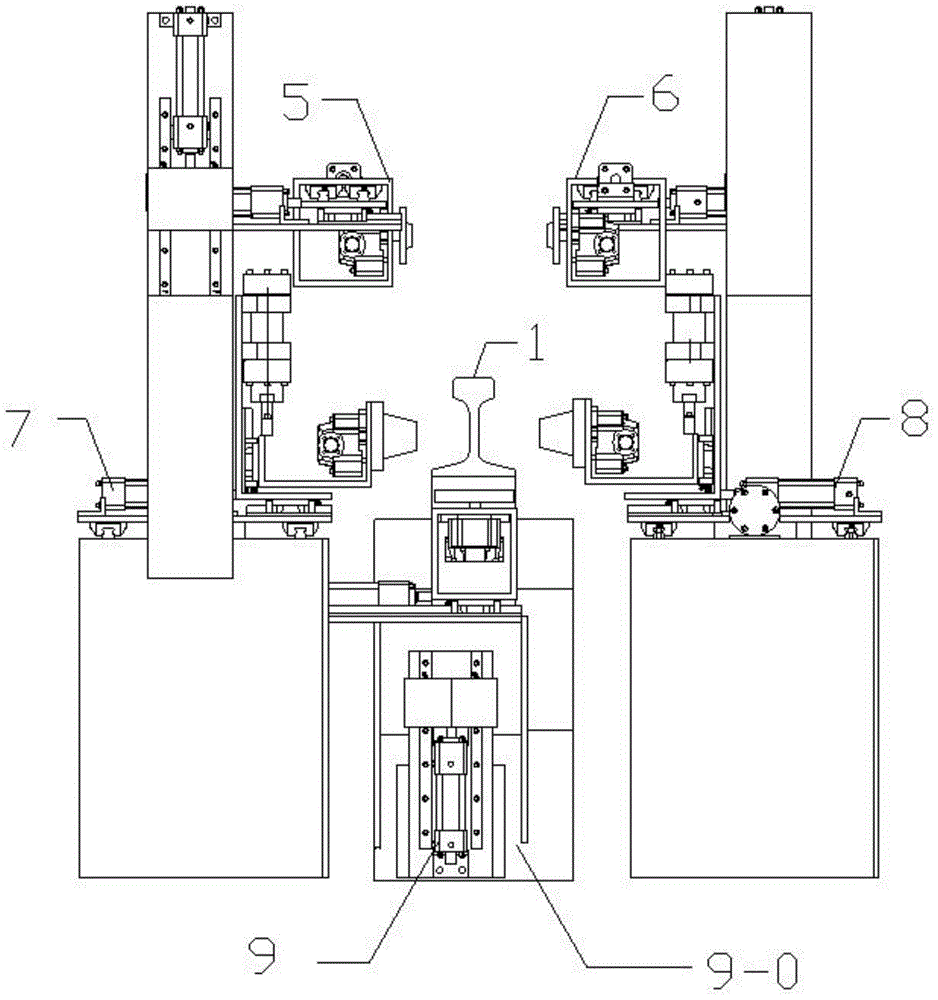

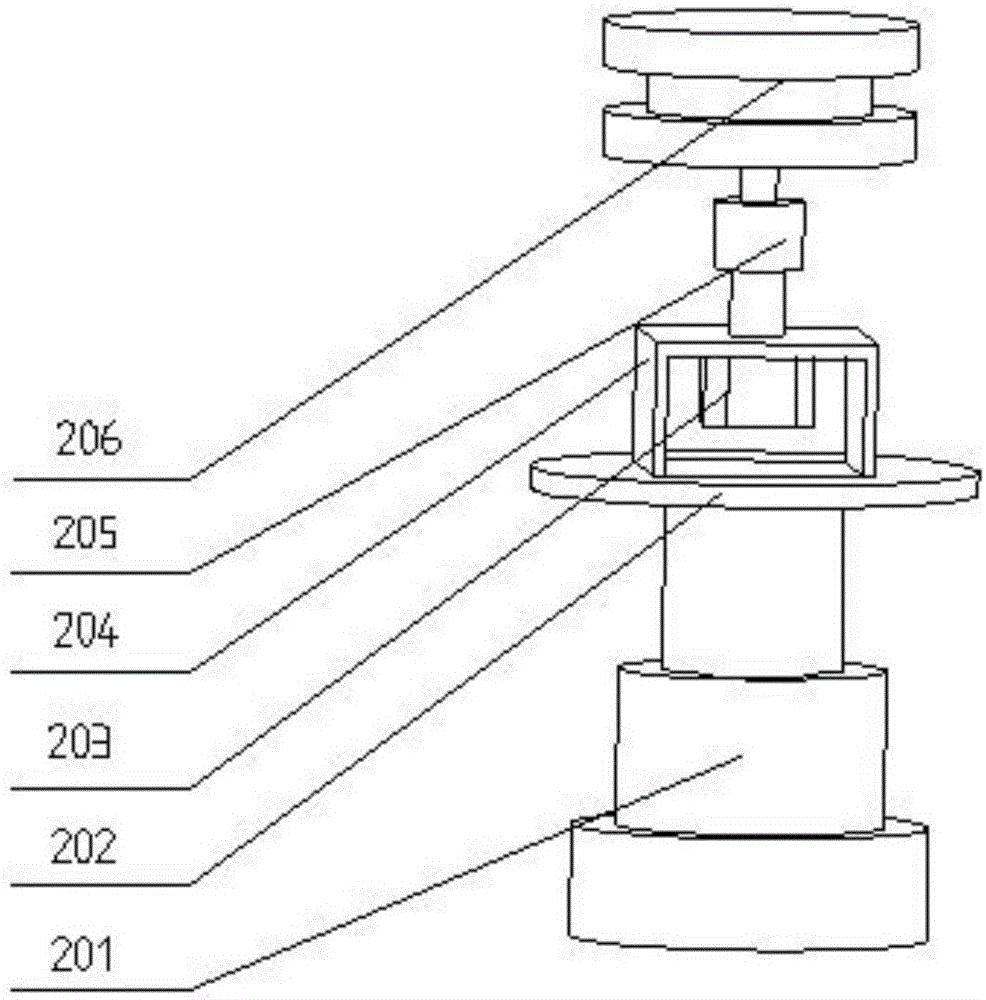

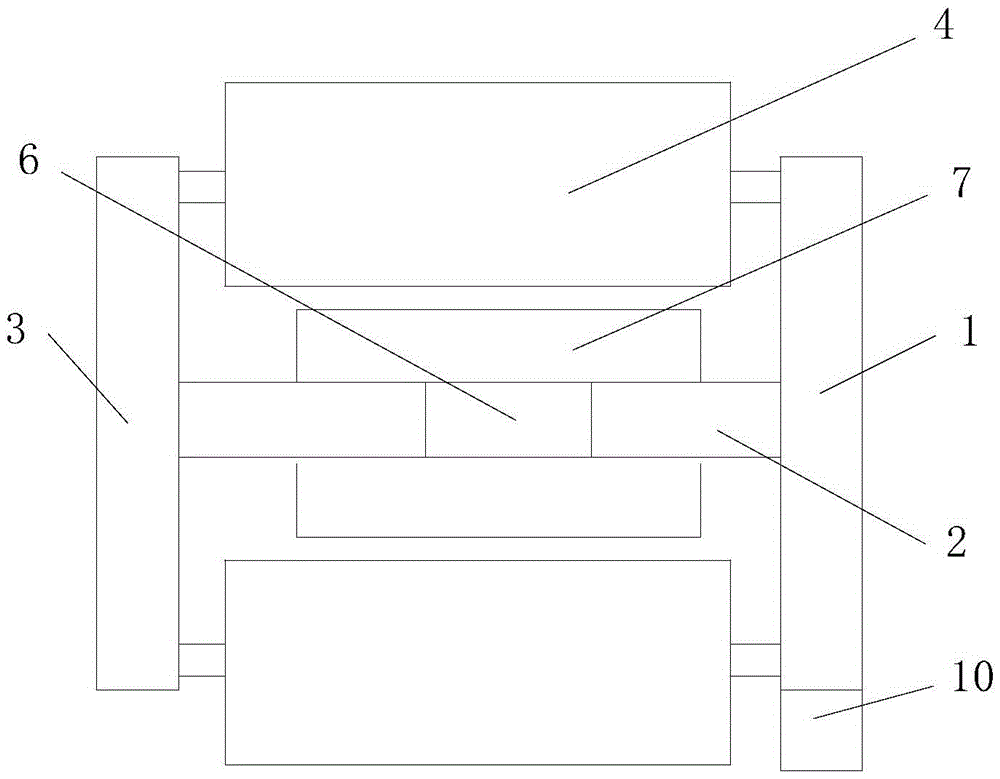

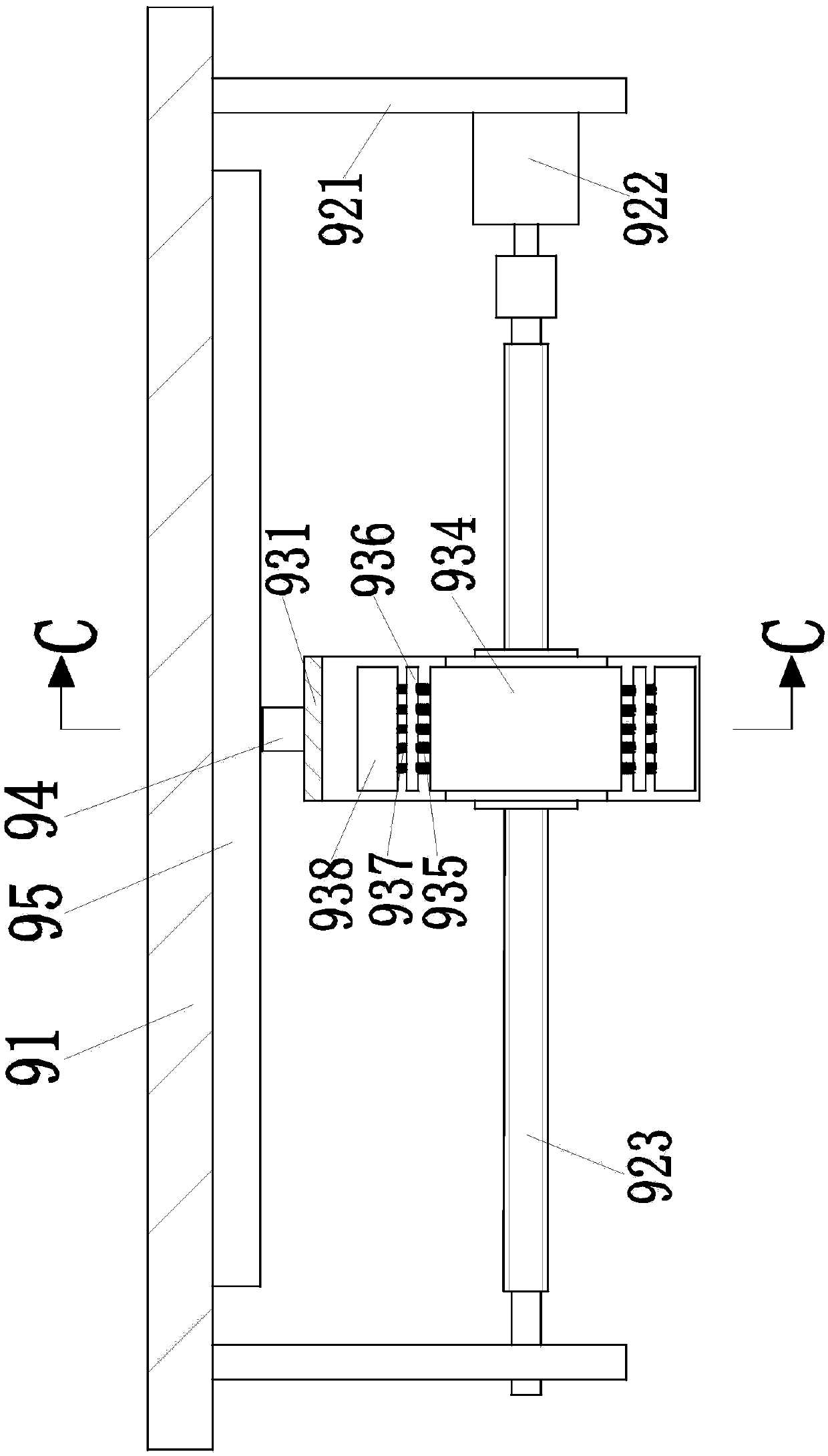

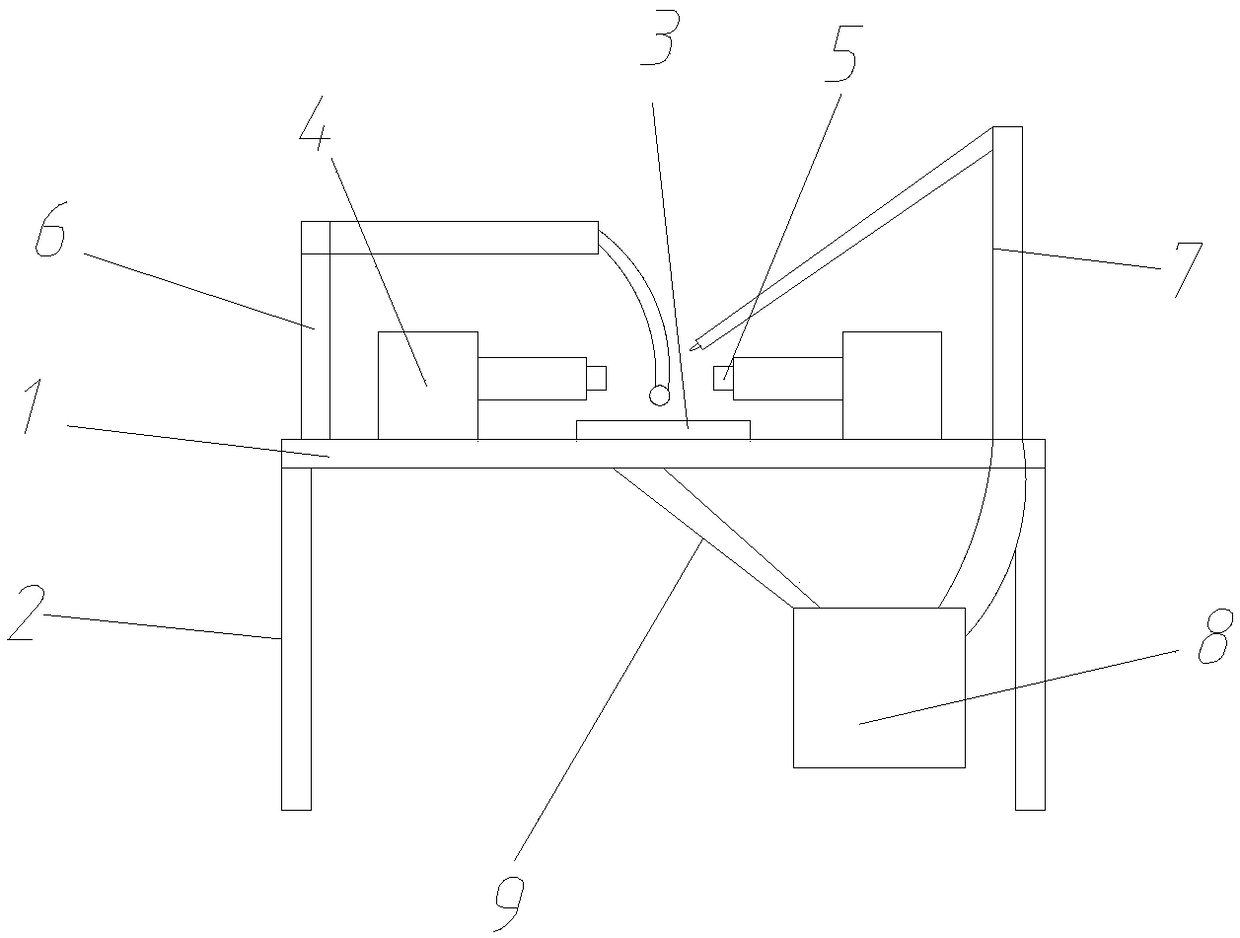

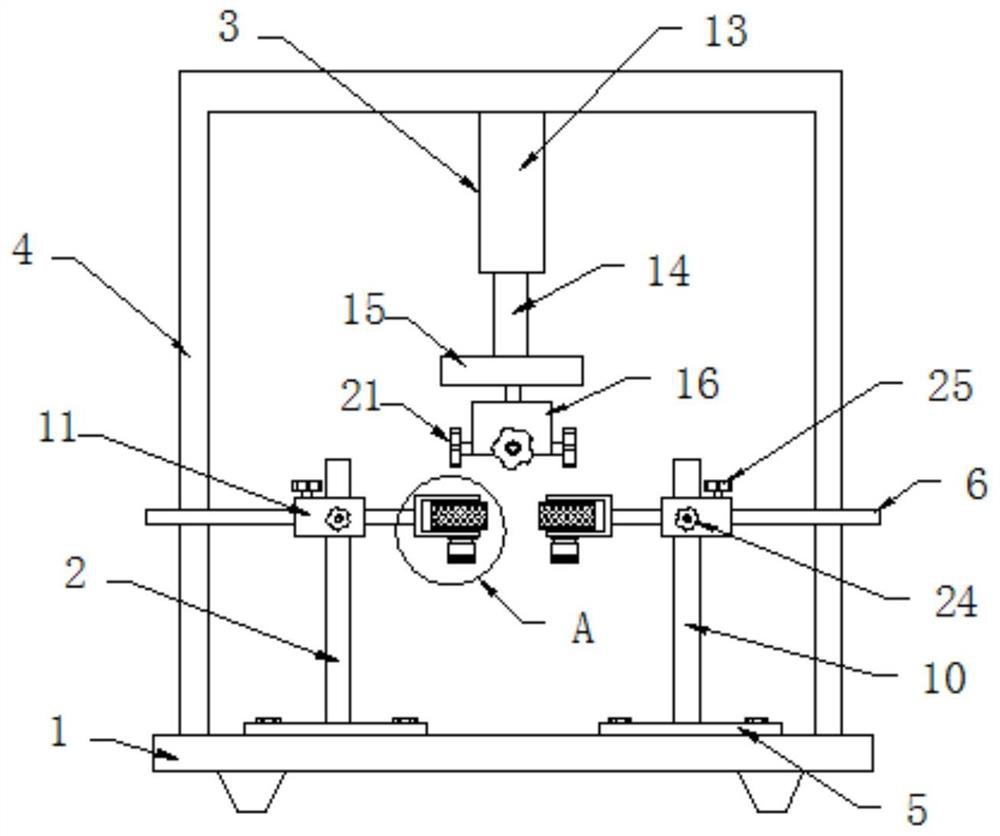

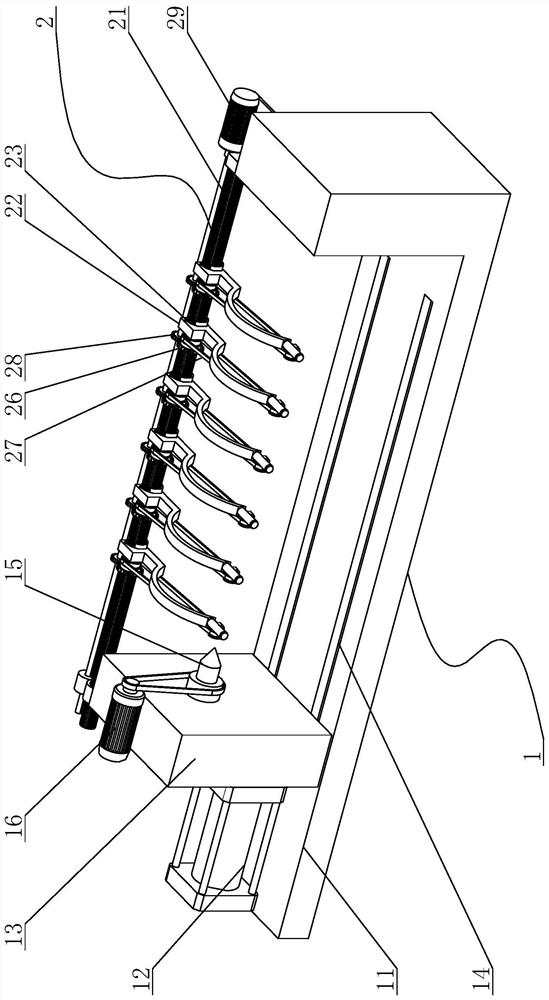

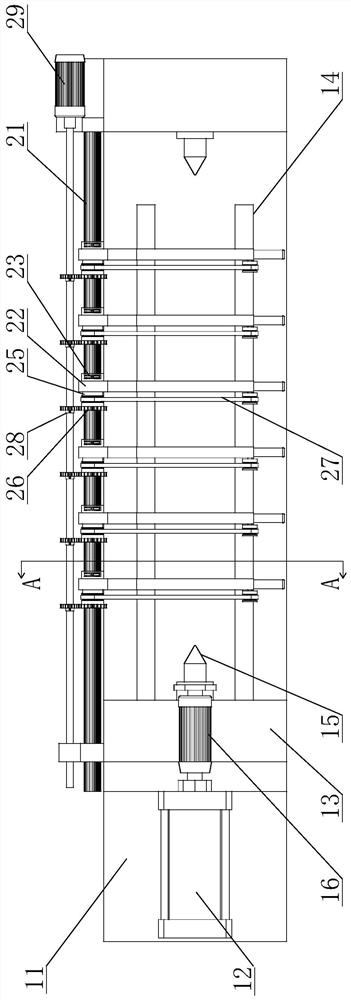

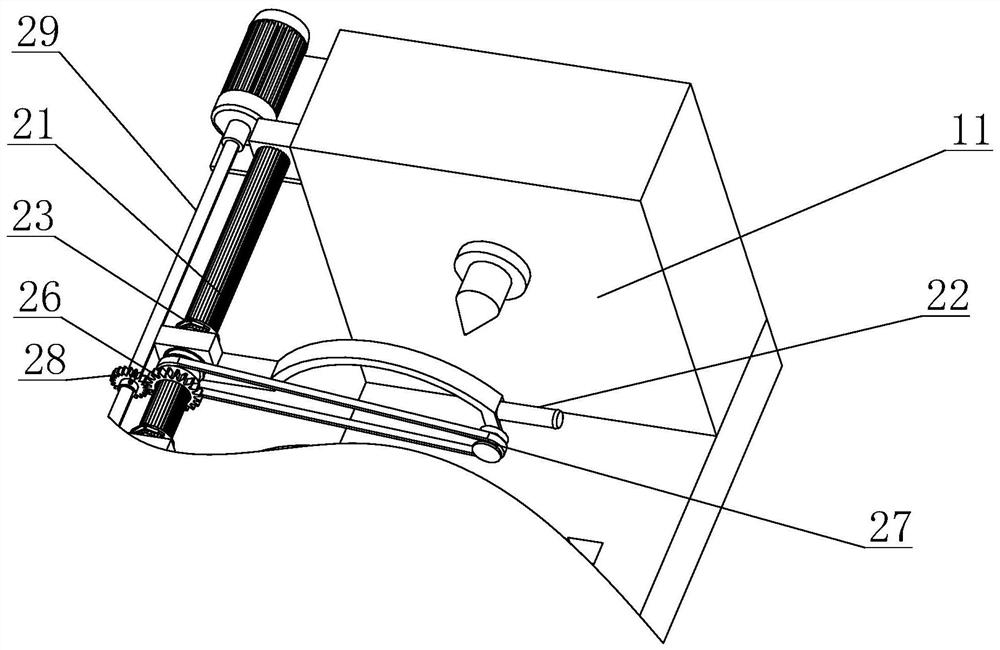

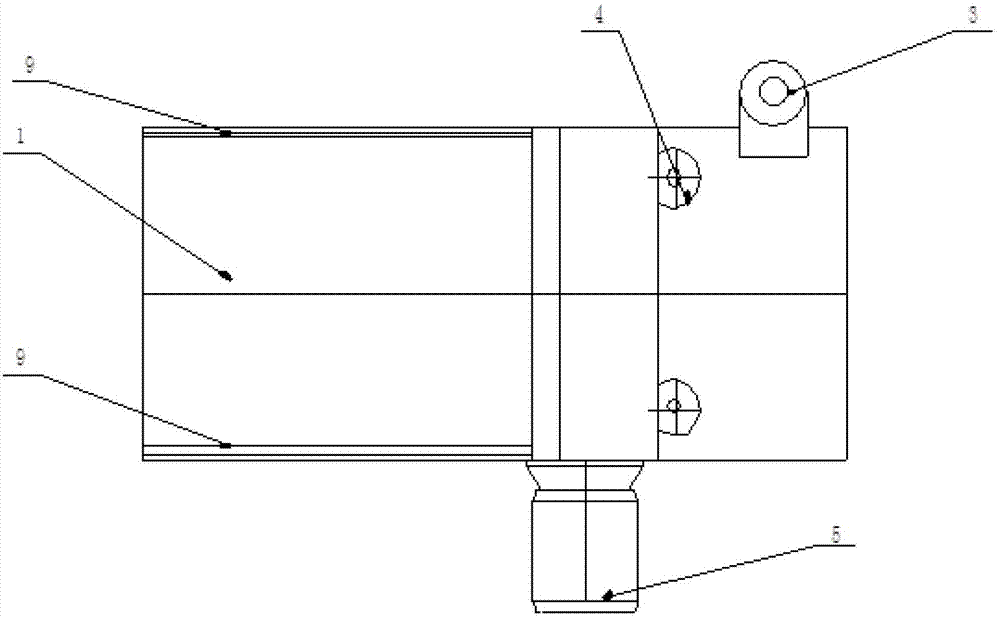

Pantograph slide plate double-head grinding device and grinding method thereof

ActiveCN108942521AReduce labor intensityIncrease sanding speedGrinding drivesGrinding machinesDrive shaftSlide plate

The invention discloses a pantograph slide plate double-head grinding device. The pantograph slide plate double-head grinding device comprises a flat plate type linear motor fixedly arranged on the ground and supports. The upper end of a rotor of the flat plate type linear motor is fixedly provided with a mounting column. A transmission shaft is mounted on the side face of the mounting column in arolling mode. The upper end of the mounting column is fixedly provided with a rotation motor driving the transmission shaft to rotate through a transmission mechanism I. One end of the transmission shaft I is fixedly provided with a push rod motor. A grinding mechanism is fixedly mounted on the head of a push rod of the push rod motor. A cross beam fixedly mounted on the supports is arranged above the grinding mechanism. The pantograph slide plate double-head grinding device has the beneficial effects that through the pantograph slide plate double-head grinding device and a grinding method thereof, the two side faces of a pantograph slide plate can be ground simultaneously; the pantograph slide plate does not need to be fixed manually in the grinding process; grinding workers are liberated; the labor intensity of the grinding workers is reduced; the grinding speed and efficiency are remarkably improved; time and labor are saved; and the pantograph slide plate double-head grinding device is good in practicality.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

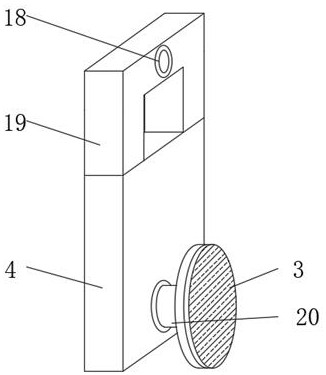

De-burring device for steel pipe orifice

ActiveCN110883629AWon't hurtIncrease sanding speedEdge grinding machinesGrinding drivesElectric machineryEngineering

The invention discloses a de-burring device for a steel pipe orifice. The de-burring device for the steel pipe orifice comprises a base; a fixed table is fixedly mounted on the base; a limiting hole is formed in the fixed table; a plurality of electromagnetic compacting mechanisms are embedded into the upper hole wall of the limiting hole; two supporting mechanisms are symmetrically embedded intothe lower hole wall of the limiting hole; an adjusting groove is formed in the base; an adjusting mechanism is mounted in the adjusting groove; and a grinding motor is fixedly mounted on the adjustingmechanism. According to the de-burring device for the steel pipe orifice, a steel pipe cannot shake greatly when being ground through the electromagnetic compacting mechanisms and the supporting mechanism; the situations of pipe orifice deformation and excessive grinding are reduced; through a rubber pressing wheel and a supporting wheel, the steel pipe is fixed non-destructively and certain rotating resistance is provided for the steel pipe, so that the steel pipe rotates relative to a grinding cone and a grinding post; the grinding speed is increased; and the device can be matched with thesteel pipes with different pipe diameters for grinding by adjusting the height of the grinding motor through the adjusting mechanism and changing the installation depth of the grinding cone.

Owner:TAIZHOU ANN WELDING EQUIP CO LTD

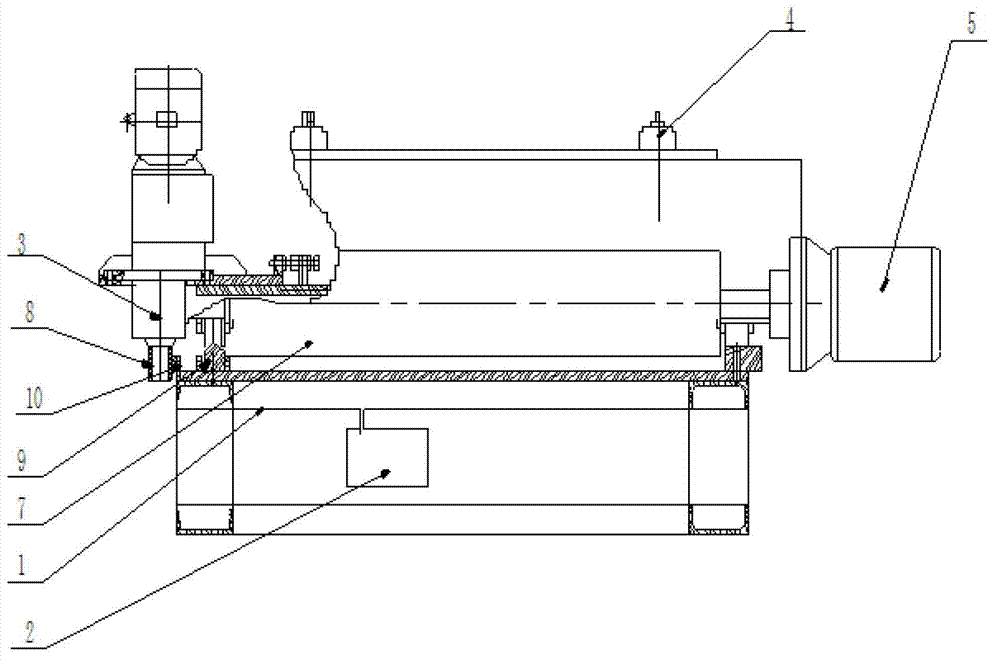

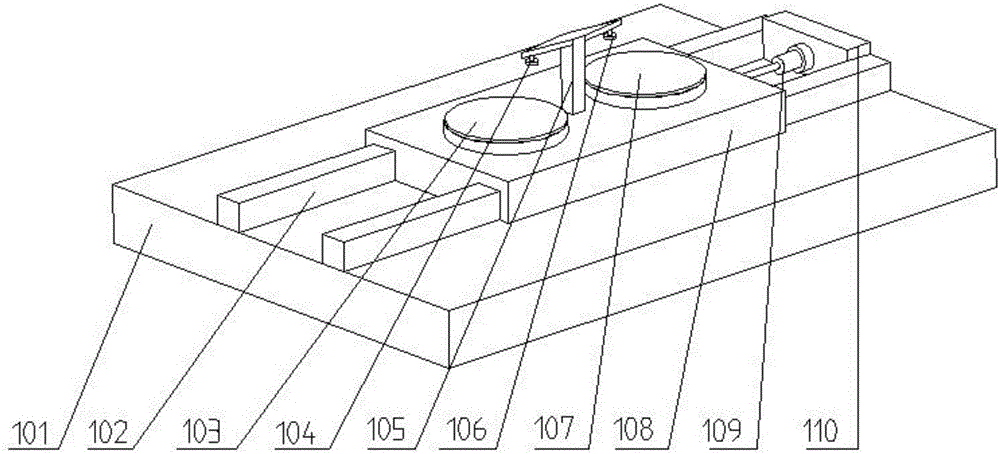

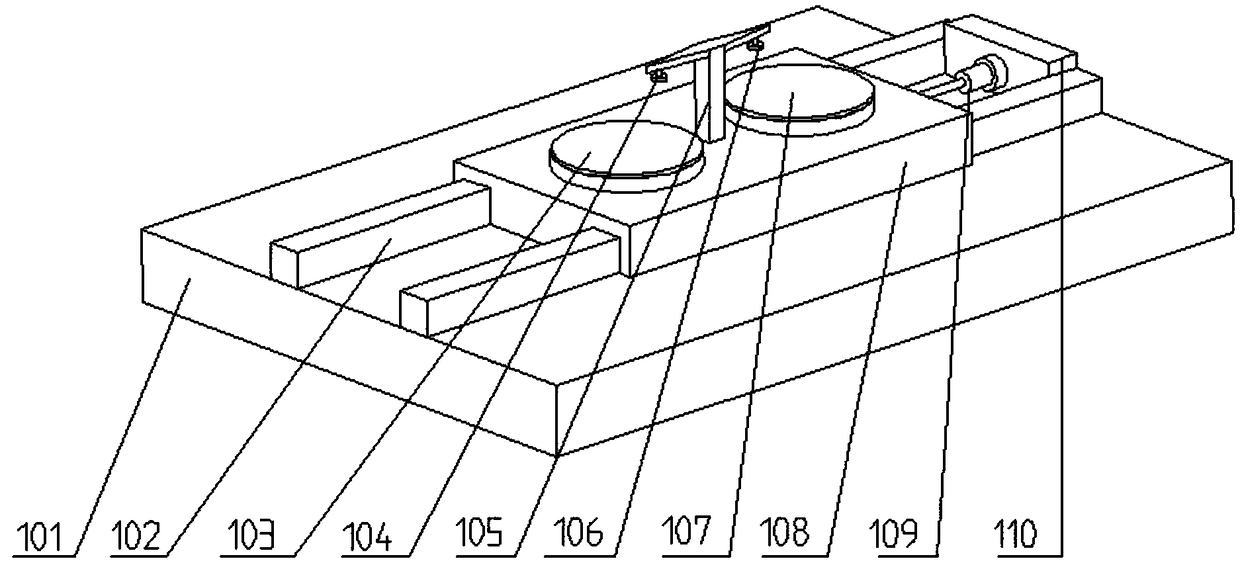

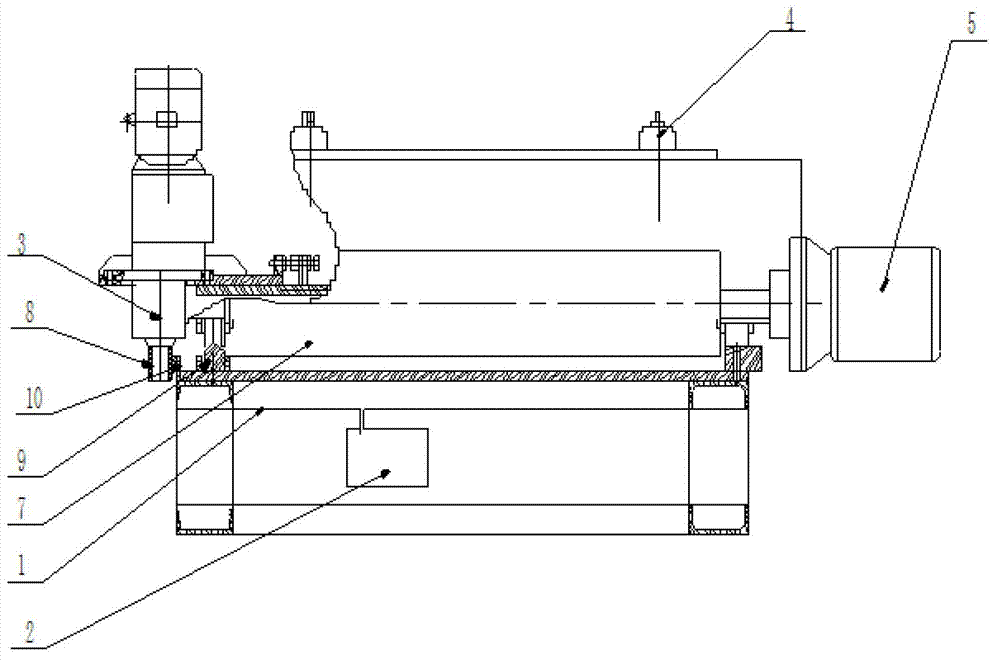

Platinum electrode polishing device

ActiveCN106826471AIncrease sanding speedImprove sanding qualityGrinding carriagesGrinding drivesPlatinumEngineering

The invention relates to a platinum electrode polishing device and belongs to the field of electric experiment devices. The platinum electrode polishing device comprises a platinum electrode polishing base assembly, a left lifting assembly, a platinum electrode mounting rack assembly and a right lifting assembly and is characterized in that the left lifting assembly and the right lifting assembly are mounted on the platinum electrode polishing base assembly, and the platinum electrode mounting rack assembly is mounted on the left lifting assembly and the right lifting assembly. The platinum electrode polishing device has the benefits as follows: compared with a conventional platinum electrode polishing device, the device remarkably increases polishing speeds and quality.

Owner:天津市航硕自动化技术有限公司

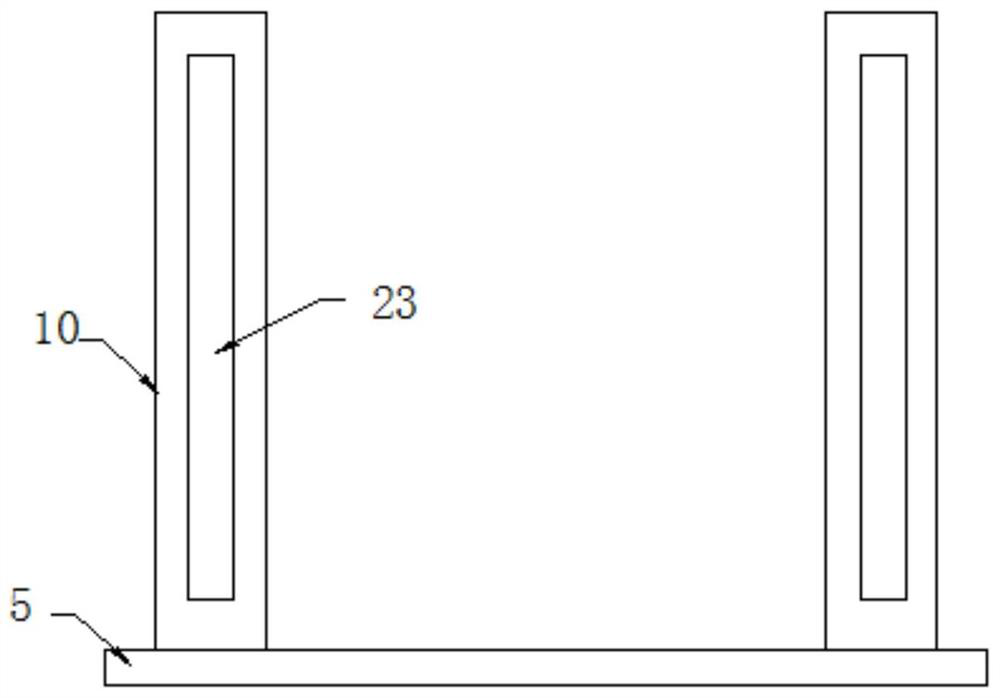

Polishing device for film color-changing sheet

PendingCN112318280AHigh sanding consistencyFit closelyGrinding carriagesOptical surface grinding machinesMechanical engineeringOptics

The invention discloses a polishing device for a film color-changing sheet. The polishing device comprises a top plate and a bottom plate, the top plate and the bottom plate are connected through a vertical frame, a clamping mechanism used for clamping the film color-changing sheet is installed below the top plate, and a polishing mechanism used for polishing the film color-changing sheet is arranged above the bottom plate. The clamping mechanism comprises a fixed plate and two movable plates, the fixed plate is located on the center line below the top plate, the two movable plates are symmetrically arranged at the two sides of the fixed plate, and clamping plates are arranged at the opposite sides of the fixed plate and the movable plates; and the polishing mechanism comprises a lifting roller frame and a polishing roller shaft. The polishing device is suitable for polishing the film color-changing sheet, the device can clamp two lenses at the same time and synchronously polish the two lenses at the same time, and therefore the polishing efficiency and speed are improved, meanwhile, by means of the double-lens polishing manner, the polishing consistency of the device on the two lenses is higher, and the coincidence degree of the two lenses is higher.

Owner:江苏黄金屋光学眼镜有限公司

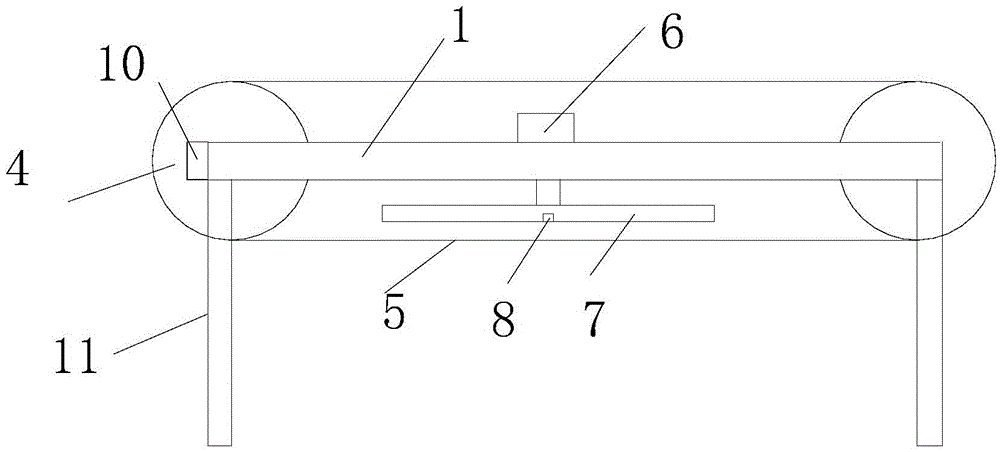

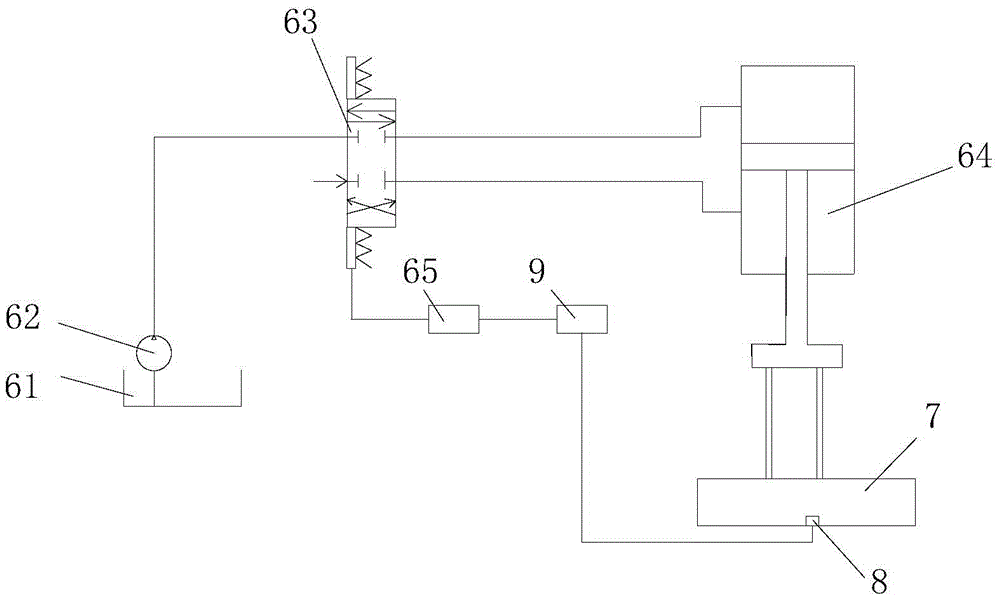

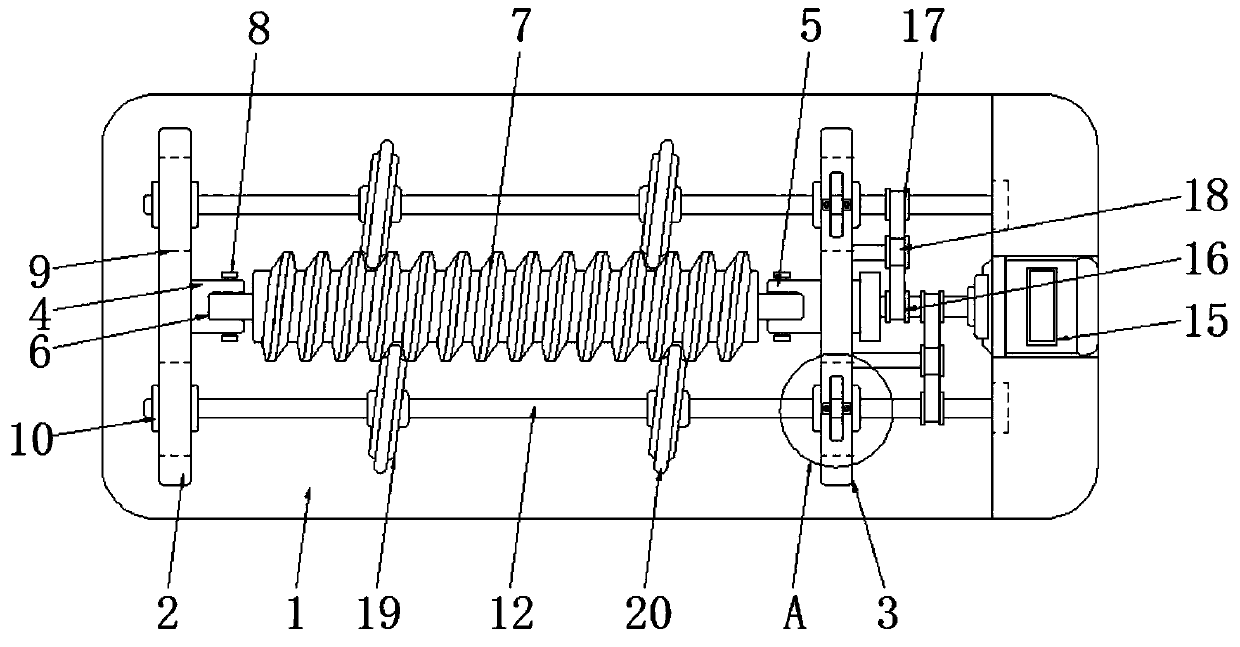

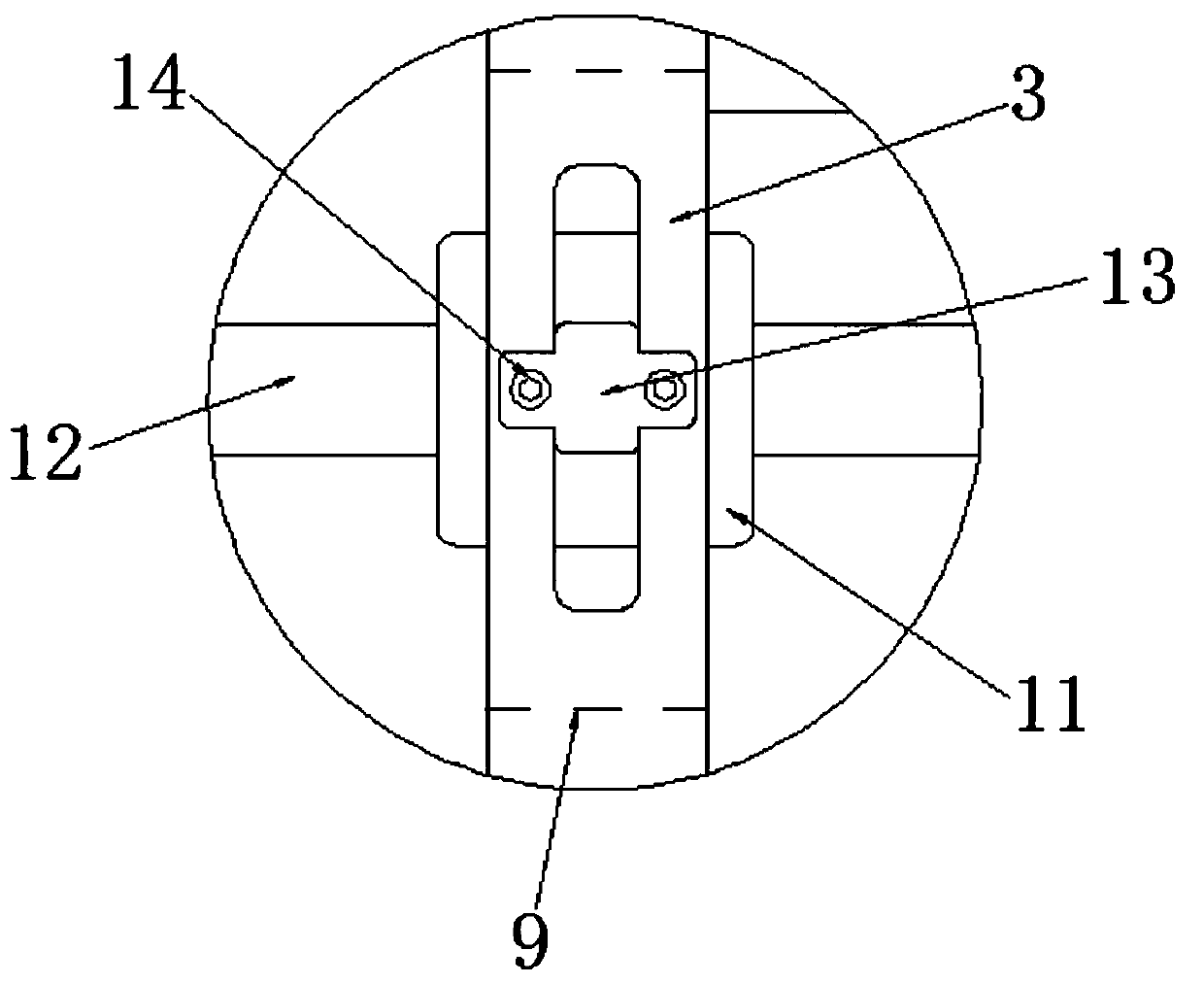

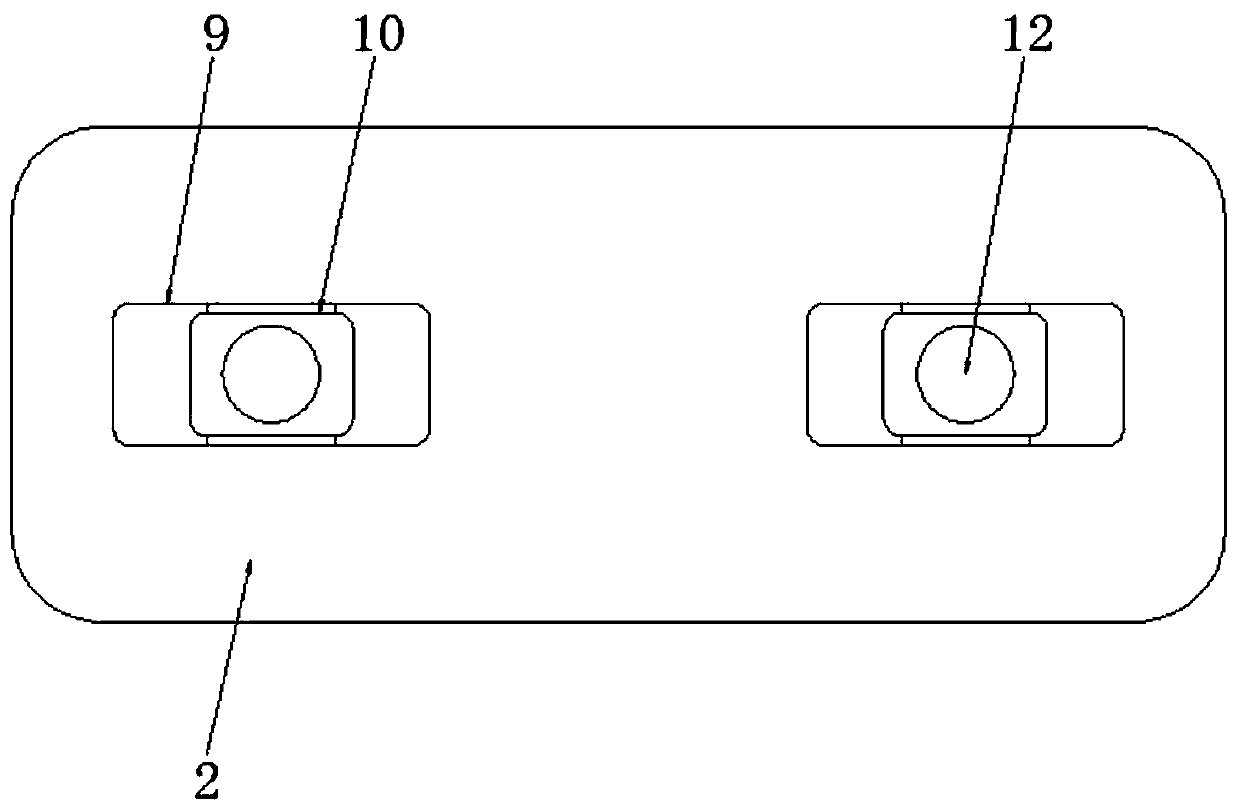

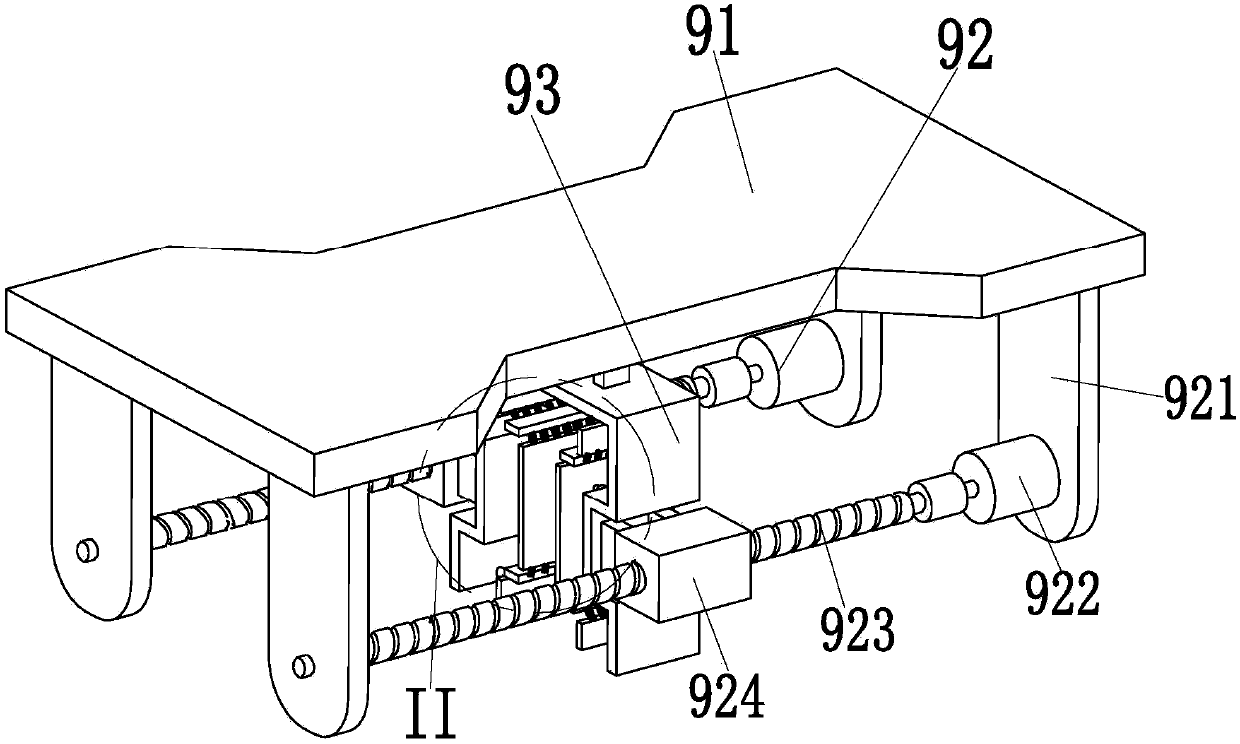

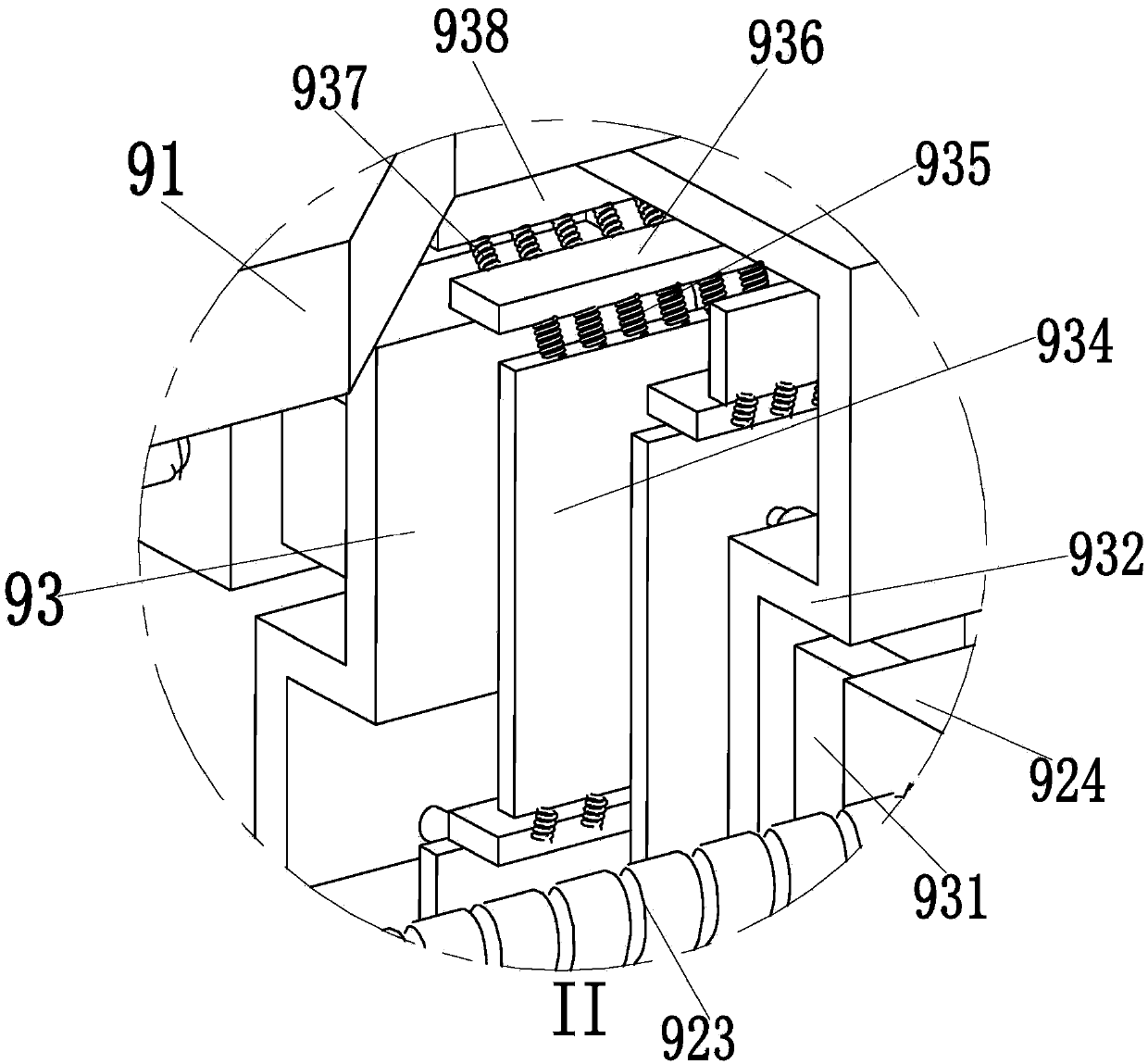

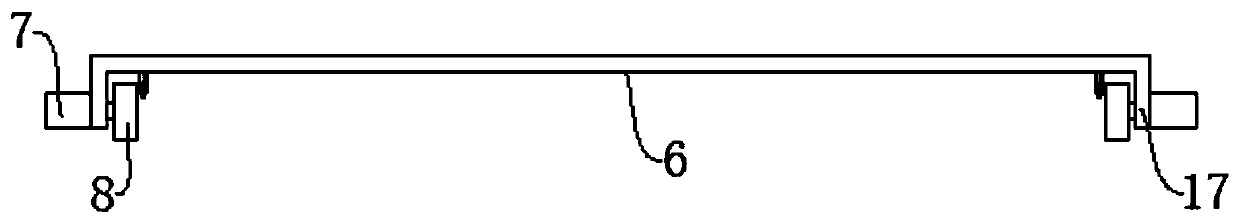

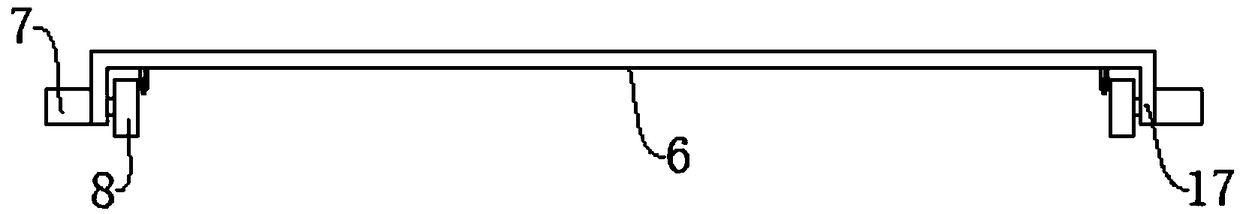

Polishing device of leather polisher for shoemaking

InactiveCN105615145AQuality assuranceReduce labor intensityShoemaking devicesSolesGrain structurePhysics

The invention discloses a polishing device of a leather polisher for shoemaking. The polishing device comprises a left beam (1), wherein a transverse beam (2) is connected with the middle of the left beam (1), the transverse beam (2) is connected with a right beam (3), two ends of both the left beam (1) and the right beam (3) are connected with rollers (4) which are connected with each other through a belt (5), the transverse beam (2) is provided with a hydraulic device (6), the extending end of the hydraulic device (6) is connected with a compressing plate (7), a pressure piece (8) which is arranged at the bottom surface of the compressing plate (7) is connected with a controller (9), the controller (9) is connected with the hydraulic device (6), an infrared sensor (10) arranged at the front end of the left beam (1) is connected with the hydraulic device (6), and the outside surface of the belt (5) is of a transverse sand grain structure.

Owner:湖州练市辉煌鞋业有限公司

Electric power assisted worm grinding process

The invention discloses an electric power assisted worm grinding process and relates to the technical field of worm processing. The electric power assisted worm grinding process comprises the step of(1), pretreatment of a worm, specifically, spraying a rust remover to the surface of the worm to be ground, conducting simple grinding on the surface of the worm through abrasive paper, cleaning the worm in clean water, soaking the worm in 60-80% alcohol liquid for 5-10 min and then taking out and draining off the worm. According to the electric power assisted worm grinding process, before grinding, the surface of the worm is soaked through alcohol to remove impurities on the surface of the worm; an oxidation film on the surface of the worm is removed through acid treatment to prevent the grinding process from being impeded by the oxidation film; and finally, the surface of the worm is softened through normalizing treatment, at the moment, the surface and the interiors of tooth gaps of theworm can be ground through back-and-forth cooperation of a plurality of grinding cams on a grinding device, and burrs and protrusions on the softened surface of the worm are ground and removed. Through the electric power assisted worm grinding process, the grinding speed is increased, and the grinding precision is improved.

Owner:煌太阳科技有限公司

A platinum electrode grinding device

ActiveCN106826471BIncrease sanding speedImprove sanding qualityGrinding carriagesGrinding drivesPlatinumEngineering

The invention relates to a platinum electrode polishing device and belongs to the field of electric experiment devices. The platinum electrode polishing device comprises a platinum electrode polishing base assembly, a left lifting assembly, a platinum electrode mounting rack assembly and a right lifting assembly and is characterized in that the left lifting assembly and the right lifting assembly are mounted on the platinum electrode polishing base assembly, and the platinum electrode mounting rack assembly is mounted on the left lifting assembly and the right lifting assembly. The platinum electrode polishing device has the benefits as follows: compared with a conventional platinum electrode polishing device, the device remarkably increases polishing speeds and quality.

Owner:天津市航硕自动化技术有限公司

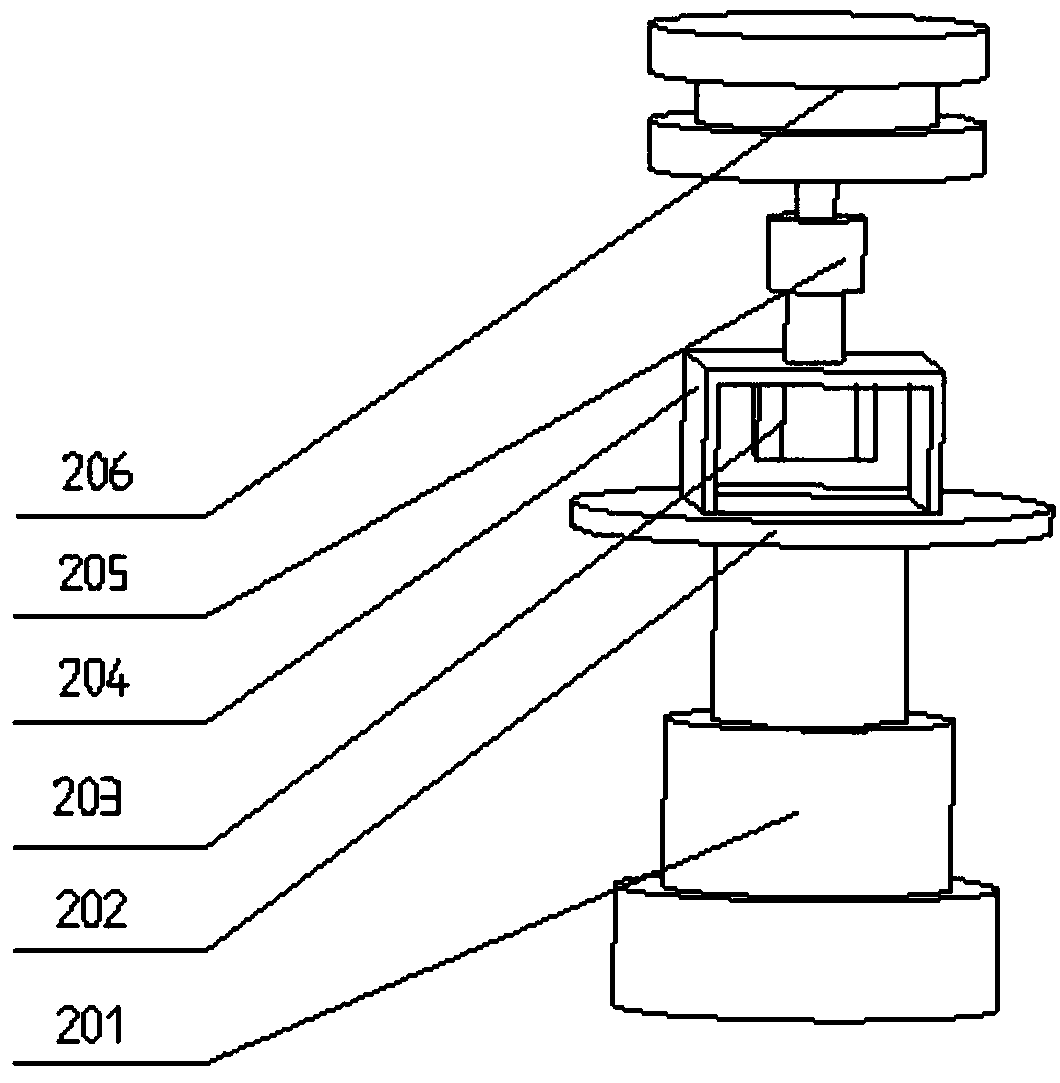

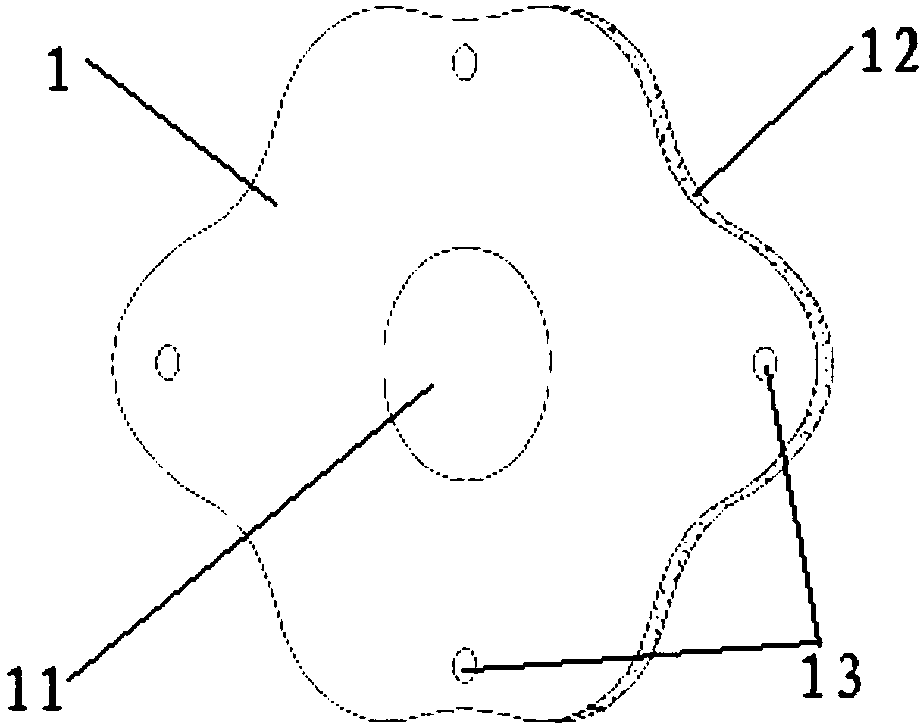

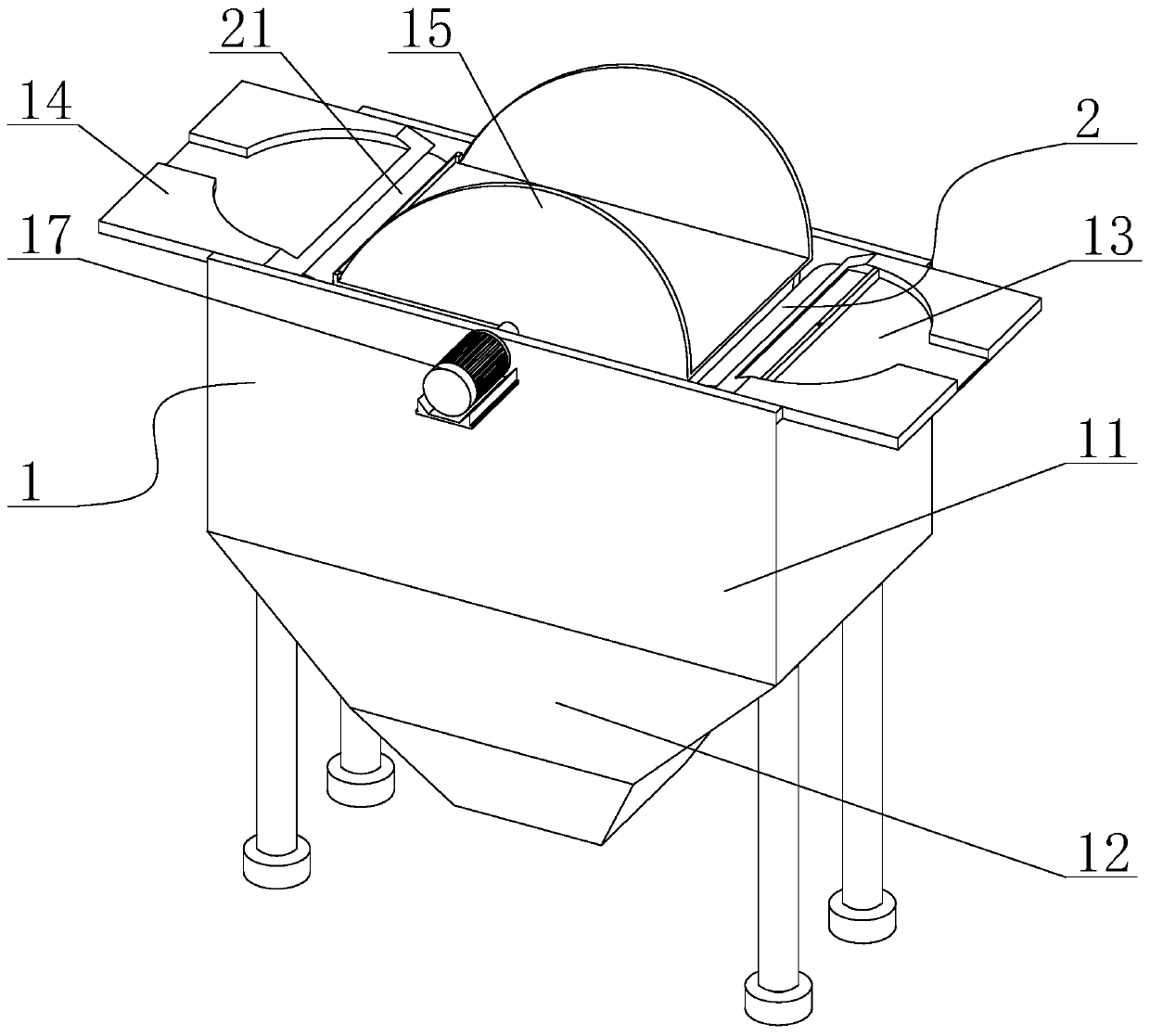

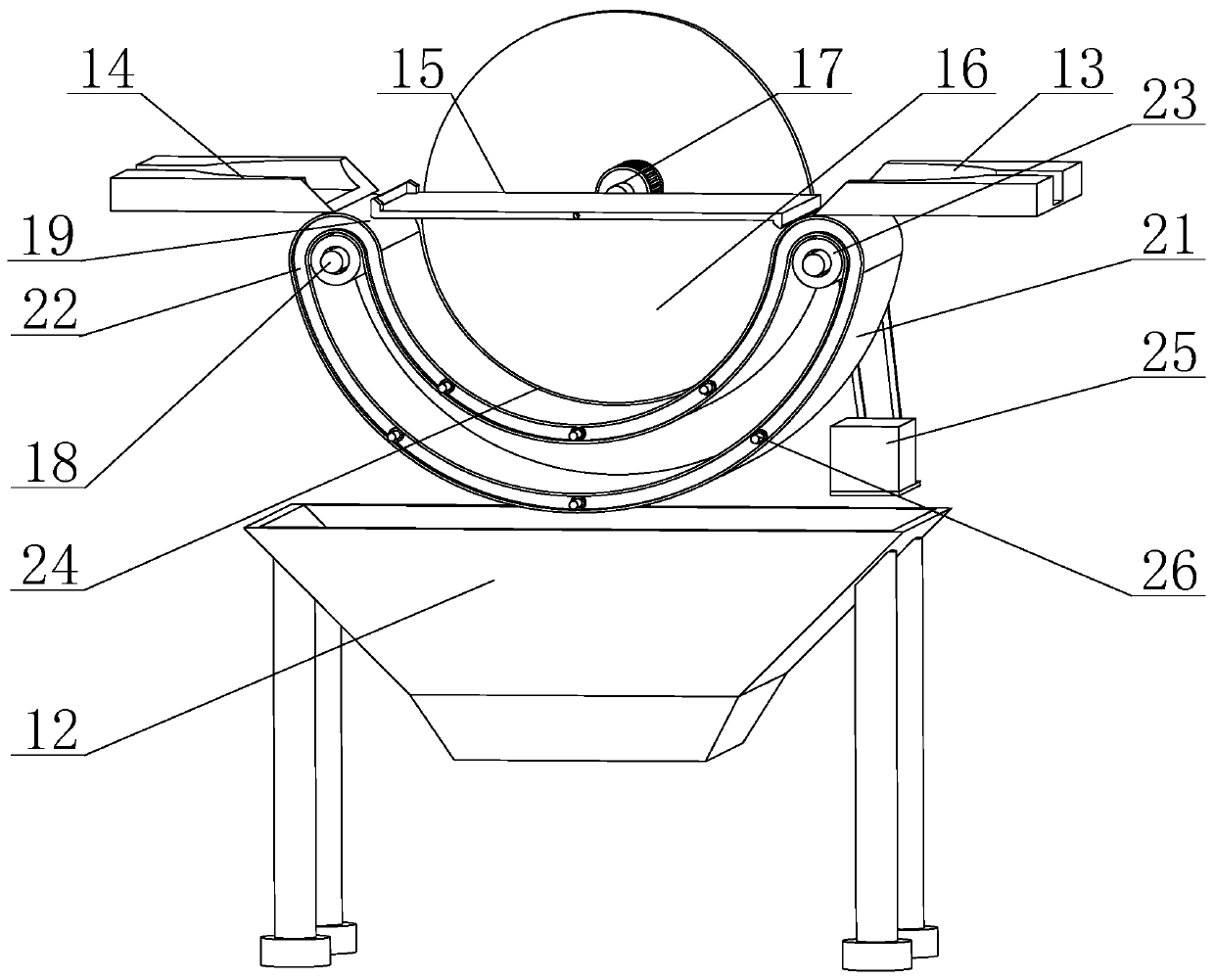

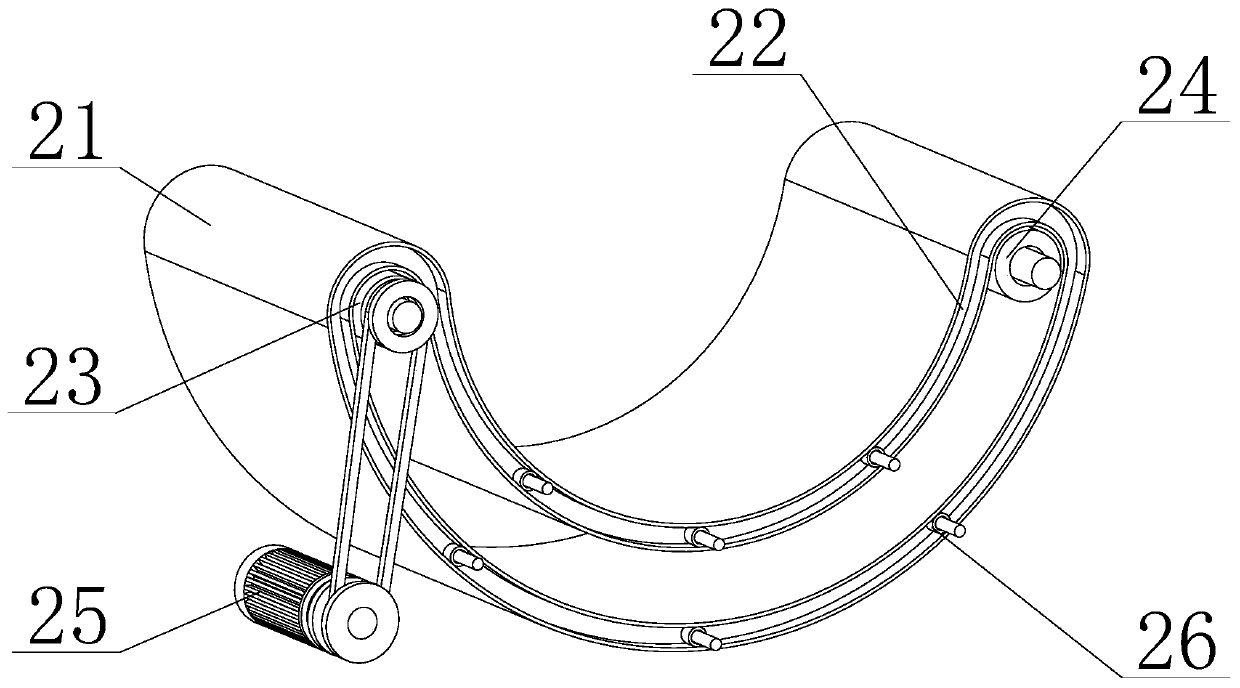

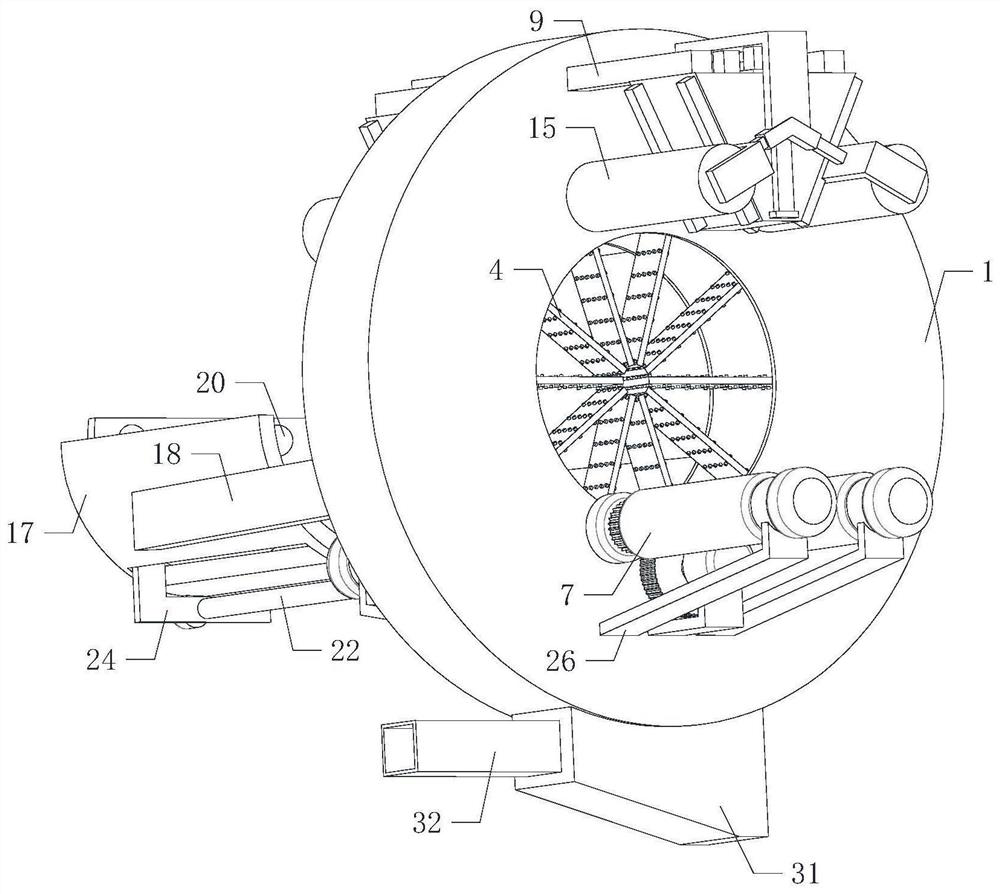

Grinding and polishing machine tool for hydrogen cylinder machining

ActiveCN113523924ASimplify the grinding methodImprove sanding uniformityGrinding carriagesRevolution surface grinding machinesEngineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a grinding and polishing machine tool for hydrogen cylinder machining. The grinding and polishing machine tool comprises a support ring and an outer gear ring, wherein the support ring is in an annular groove shape, and the notch of the support ring faces the axis direction of the support ring; and the circumferential inner wall of the outer gear ring is set to be conical, two arc-shaped guide rails are symmetrically arranged on the outer gear ring in a sliding manner, openings of the arc-shaped guide rails face downwards, and the outer walls of the arc-shaped guide rails are fixed to the inner wall of the support ring. The machine tool can effectively simplify the grinding mode of a hydrogen cylinder, improve the grinding speed and the working efficiency, save manpower, improve the grinding uniformity of the outer surface of the hydrogen cylinder and effectively improve the grinding quality.

Owner:山东奥扬新能源科技股份有限公司

Full-automatic grinding process for waste tire

InactiveCN105127866ARealize deliveryReduce labor intensityGrinding carriagesGrinding drivesEngineeringDrive motor

The invention discloses a full-automatic grinding process for a waste tire. A workbench is adopted in the full-automatic grinding process. An upper grinding wheel motor is installed on the workbench and drives an upper grinding wheel. Two parallel upper guide rails are installed on the workbench. An upper sliding plate moving along the upper guide rails is installed on the upper guide rails. A stepping motor is installed on the upper sliding plate and drives a drum through a speed reducing mechanism. The rotating axis of the drum is parallel to the rotating axis of the upper grinding wheel. A drive motor is installed below the workbench and drives the upper sliding plate to reciprocate on the upper guide rails. The structure is simple, and design is ingenious; the grinding speed of a steel wire belt can be greatly increased, the grinding quality of the steel wire belt can be greatly improved, and a large amount of labor cost is reduced.

Owner:CHENGDU KELIFU SCI & TECH

Bearing grinding device of abrasive and grinding machine

PendingCN108214128AIncrease sanding speedImprove grinding accuracyGrinding carriagesRevolution surface grinding machinesEngineeringSlide plate

The invention relates to the technical field of part grinding equipment, and discloses a bearing grinding device of an abrasive and grinding machine. The bearing grinding device comprises a base, wherein fixing plates are fixedly arranged in the middles of the two sides of the top of the base, sliding plates which are positioned on one sides of the fixing plates are slidably connected to the middle of the top end of the base, limiting rods are fixedly arranged at the four corners of one sides, close to the fixing plates, of the sliding plates, the number of the limiting rods is four, and one ends of the four limiting rods penetrate through one sides of the fixing plates. According to the bearing grinding device, the screw rods are connected to the output shaft of a positive and negative motor, a bearing inner ring is fixed on the screw rods through a fixing baffle, a lower gasket, an upper gasket and a fixing nut, and forward and reverse rotation of the bearing inner ring is driven bya positive and negative motor, two grinding tool grinding wheels are arranged on the two sides of the bearing inner ring, and the grinding tool grinding wheels are driven by a one-way motor to rotate,and grinding and machining of a single grinding tool grinding wheel are avoided, and therefore the grinding speed and the grinding precision of the bearing grinding device of the abrasive and grinding machine are improved.

Owner:FORTURE TOOLS CO LTD

Intelligent grinding device for adjustable rail surface

InactiveCN108015643AExpand the grinding rangeImprove grinding effectGrinding carriagesGrinding machinesEngineeringAutomation

The invention relates to an intelligent grinding device for an adjustable rail surface. The intelligent grinding device comprises a grinding support plate, and the right and left sides of the lower end of the grinding support plate are symmetrically provided with two moving mechanisms of which the inner sides are provided with two grinding branched chains separately; the two grinding branched chains are connected by welding, and the position between the two grinding branched chains is used for arranging a rail required for grinding; the upper ends of the two grinding branched chains are weldedwith two movable sliding columns separately, and the upper ends of the two movable sliding columns are provided with two movable sliding chutes in a sliding fit manner; the upper ends of the two movable sliding chutes are welded with the lower end faces of the grinding support plates separately; under the auxiliary limit of the two movable sliding columns and the two movable sliding chutes, the two grinding branched chains are driven by the two moving mechanisms to move back and forth for stable grinding; each moving mechanism comprises two grinding lugs welded with the lower end of the grinding support plate symmetrically. According to the intelligent grinding device provided by the invention, the full-automatic grinding function of the rail can be achieved, and manual operation is not required; and the degree of automation is high.

Owner:陈金辉

Carborundum grinding wheels for polishing and device

PendingCN107671752AImprove uniformityIncrease sanding speedBonded abrasive wheelsPolishingGrinding wheel

The invention relates to a soft belt polishing tool, and discloses carborundum grinding wheels for polishing and a device. Installation holes are formed in the centers of the carborundum grinding wheels; a plurality of continuous S-shaped polishing surfaces are arranged on outer contours of the carborundum grinding wheels; and carborundums are arranged on the S-shaped polishing surfaces. The carborundum grinding wheel device for polishing comprises at least two carborundum grinding wheels for polishing, a connecting shaft, a clamping device and spacers. According to the discloses carborundum grinding wheels for polishing and the device provided by the invention, the carborundum grinding wheels welded with the carborundums and the S-shaped polishing surfaces are adopted, so that the uniformity and the polishing speed of the polishing surfaces are improved, the device is durable, and the cost is saved; and through arranging the spacers, a gap is formed between each two adjacent carborundum grinding wheels and is used for recovering polishing dust produced during a polishing process, so that the occurrence of the phenomenon that a soft belt is heated and sticky due to the accumulationof the polishing dust is effectively prevented, a polishing effect is ensured, and the production efficiency and the product quality are improved.

Owner:青岛百瑞福橡塑有限公司

Grinding equipment for gear tooth outer circle face burr polishing machining after gear shaping machining

InactiveCN109794823AIncrease sanding speedImprove intensive readingEdge grinding machinesGrinding carriagesGear wheelEngineering

The invention provides grinding equipment for gear tooth outer circle face burr polishing machining after gear shaping machining. The grinding equipment comprises a circular plug seat, an inner end cover, second abrasive cloth seat assemblies, a first connecting section, a hinge shaft, a second connecting section, a supporting spring, a supporting plate and a spring seat; and a movable tailstock is mounted on the rear side of the top face of a base in a screw and sliding groove matched mode, and a motor is located at the top of the movable tailstock. Through a bilateral polishing mode, the polishing speed is increased, the polishing precision is improved, bilateral first abrasive cloth seat assemblies are each of an elastic movable structure and thus make contact with the outer circle of agear in a telescopic mode in the deburring process, the situations of tooth breaking and seat crushing can be prevented, and two polishing seats can be subjected to left-right spacing adjustment; andthe grinding equipment can further be suitable for polishing gear teeth, with various gear diameter dimensions, at the outer circle of the gear, and is reasonable in structure, flexible and good in practicability.

Owner:青岛理工大学(临沂)管理委员会办公室

Iron casting grinding device

InactiveCN109290897AReduce workloadIncrease sanding speedGrinding machinesGrinding work supportsWater pipeManipulator

The invention discloses an iron casting grinding device. The iron casting grinding device comprises a bottom plate, a grinding table, clamping air cylinders, a ball grinding mechanical arm and a cooling water pipe. The bottom plate is horizontally arranged, and two supporting columns are fixedly and vertically arranged on the two side edges of the bottom of the bottom plate. The grinding table isarranged at the center position of the bottom plate. The totally two clamping air cylinders are arranged and arranged on the two sides of the grinding table in a left-right-symmetry manner. Two telescopic rods stretch and contract towards the center position, and clamping blocks are fixed to the top ends of the telescopic rods. The ball grinding mechanical arm is arranged on one side of the bottomplate, the cooling water pipe is arranged at the other end of the bottom plate, the ball grinding mechanical arm and the cooling water pipe are arranged at the two side positions of the grinding table correspondingly, and the cooling water pipe communicates with a water tank arranged at the lower end of the bottom plate. The iron casting grinding device has the beneficial effects that the arranged clamping air cylinders can tightly clamp an iron casting on the grinding table, when the ball grinding mechanical arm conducts grinding, the cooling water pipe can spray water to the ball grinding mechanical arm for cooling, the workload of needed manual work is reduced, and the grinding speed is increased.

Owner:江苏翔盟精密铸造有限公司

Polishing device for copper balls

InactiveCN111185842AImprove grinding efficiencyIncrease sanding speedEdge grinding machinesGrinding carriagesPolishingMaterials science

The invention relates to a polishing device for copper balls. The polishing device for copper balls comprises a box body assembly, wherein a polishing assembly is arranged in the box body assembly, the polishing assembly comprises a conveying belt which is in a downward concave shape, and the conveying belt drives the thrown copper balls and polishing pills to rotate, roll and rub each other for polishing. Side baffle plates are arranged on the two sides of the downward concave conveying belt, first gaps are formed between the side baffle plates and the conveying belt and used for dischargingscraps and sundries polished from the copper balls, a turnover plate is used for bringing the polished copper balls and the polishing pills on the conveying belt upwards, but a second gap between theturnover plate and the conveying belt is used for leaking the polishing pills, so that the polishing pills repeatedly polish the copper balls on the conveying belt. The polishing pills and the copperballs are mixed together by the downward concave conveying belt to be fully overturned and mutually rubbed and polished, so that the copper balls are polished clean, a large number of copper balls canbe processed and polished at one time, and the polishing efficiency and the polishing speed are increased.

Owner:WUWEI HUANJIANG COPPER IND

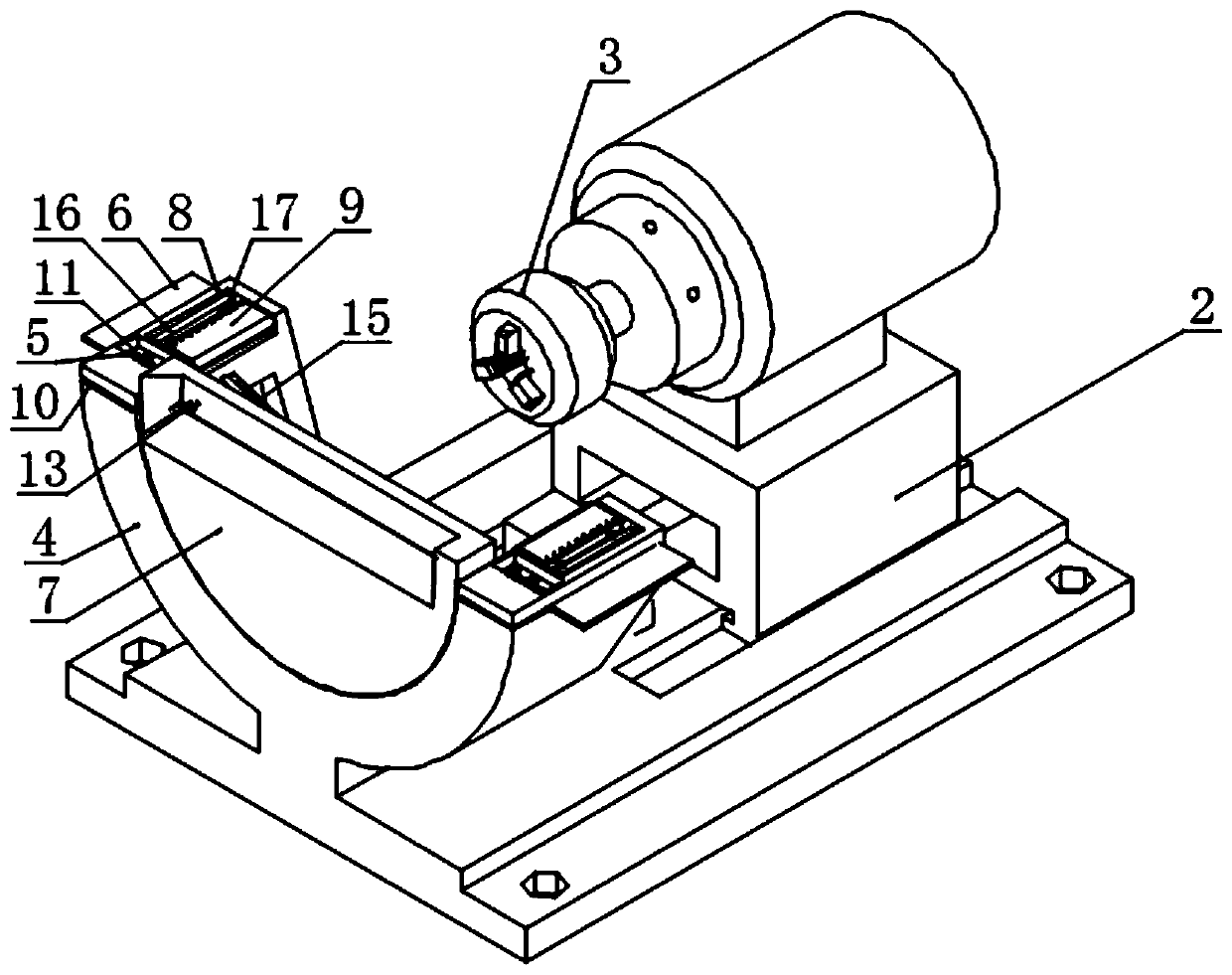

A metal pipe grinding device

ActiveCN108381345BReasonable structural designIncrease sanding speedGrinding drivesBelt grinding machinesPipe fittingElectric machinery

Owner:湖南冶盈金属材料有限公司

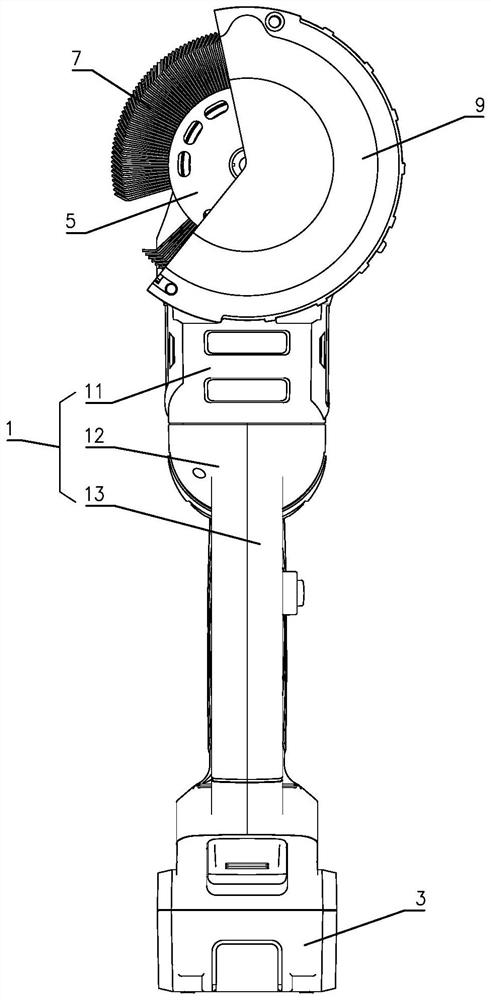

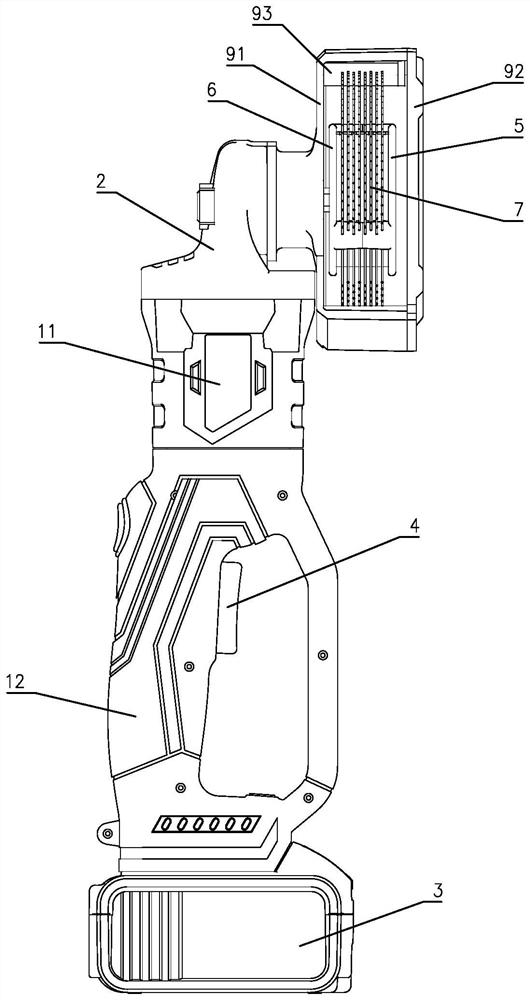

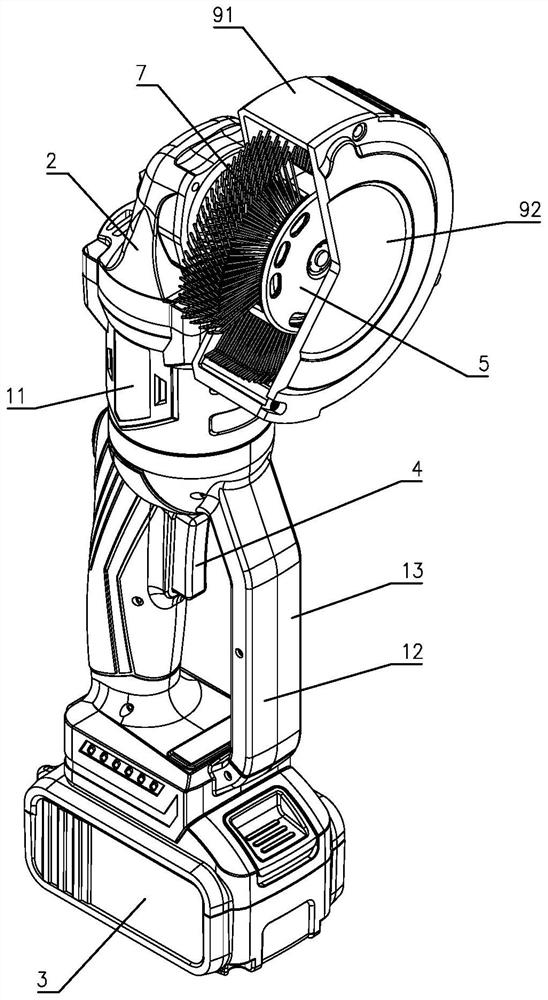

Multifunctional electric grinding machine

PendingCN113977420ASimple structureEasy to operateGrinding carriagesPortable grinding machinesElectric machineEngineering

The invention relates to a multifunctional electric grinding machine which comprises a main body, a motor and a battery are correspondingly arranged at the upper end and the lower end of the main body, a control device connected with the motor and the battery is arranged in the main body, and a grinding device is installed on an output shaft of the motor; the grinding device comprises a front buckling piece and a rear buckling piece which are buckled with each other, and a grinding wheel clamped between the front buckling piece and the rear buckling piece; the front buckling piece and the rear buckling piece are fixed to the output shaft of the motor through mounting holes formed along the axis; the grinding wheel comprises a supporting ring; densely-distributed steel wires are arranged on the supporting ring; each steel wire is arranged in the radial direction of the supporting ring; the end, away from the supporting ring, of the steel wire is provided with a polishing contact formed through bending, and the bending direction of the polishing contact is consistent with the rotating direction of the grinding wheel. The multifunctional electric grinding machine has the advantages of being simple in structure, convenient to operate and control, high in functionality, good in adaptability and high in grinding efficiency.

Owner:北京永逸舒克防腐蚀技术有限公司 +1

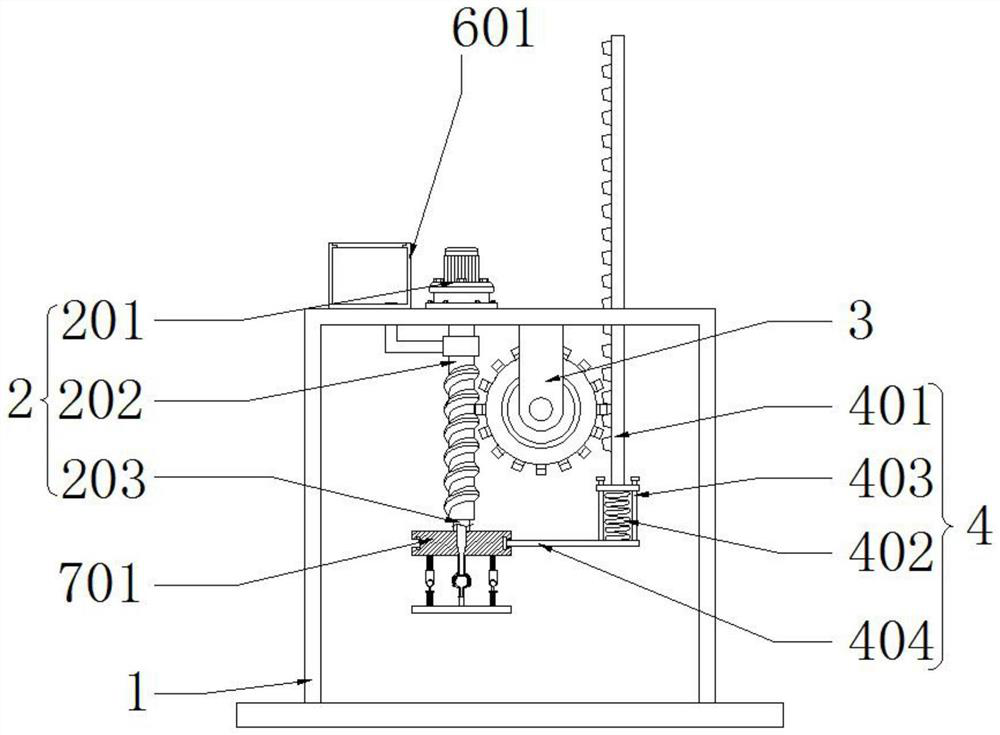

Grinding device for crankshaft remanufacturing

ActiveCN110842705BRealize synchronous rotation grindingIncrease sanding speedGrinding drivesBelt grinding machinesRatchetGear wheel

The invention relates to a grinding device for crankshaft remanufacturing. The grinding device comprises a clamping assembly used for clamping the two ends of a crankshaft and driving the crankshaft to rotate, wherein the distance between the two ends of the clamping assembly can be adjusted; and the clamping assembly is provided with a plurality of grinding assemblies used for grinding shaft necks at different positions of the crankshaft at the same time. According to the grinding device, a plurality of sets of arch-shaped rods and grinding belts are arranged on a ratchet wheel rod, the arch-shaped rods drive the grinding belts to transversely move along the ratchet wheel rod, and one-to-one correspondence with the shaft necks of the crankshaft below is achieved; meanwhile, the arch-shaped rods and pawls for locking rotation of the arch-shaped rods are rotated, and the grinding belts can make contact with the shaft necks of the crankshaft; each set of grinding belts correspond to oneshaft neck of the crankshaft, the grinding belts are driven to rotate through transmission of a power rod, a first gear, a second gear and a transmission belt wheel, and multi-set synchronous rotationgrinding is achieved; and the multiple grinding belts conduct grinding at the same time, the grinding speed is increased, and the work efficiency is improved.

Owner:WUHU DINGHENG MATERIAL TECH

A grinding and polishing machine tool for processing hydrogen cylinders

ActiveCN113523924BSimplify the grinding methodImprove sanding uniformityGrinding carriagesRevolution surface grinding machinesEngineeringMechanical equipment

The present invention relates to the technical field of mechanical equipment, in particular to a grinding and polishing machine tool for hydrogen cylinder processing, which includes a support ring, the support ring is in the shape of an annular groove, and its notch faces the axis of the support ring; the outer gear ring, the The circumferential inner wall of the outer gear ring is set in a tapered shape, and two arc-shaped guide rails are symmetrically slid on the outer gear ring, the opening of the arc-shaped guide rails faces downward, and the outer wall of the arc-shaped guide rails is fixed on the support ring On the inner wall; this equipment can effectively simplify the grinding method of the hydrogen cylinder, improve the grinding speed and work efficiency, and save manpower. At the same time, the grinding uniformity of the outer surface of the hydrogen cylinder is improved, and the grinding quality is effectively improved.

Owner:山东奥扬新能源科技股份有限公司

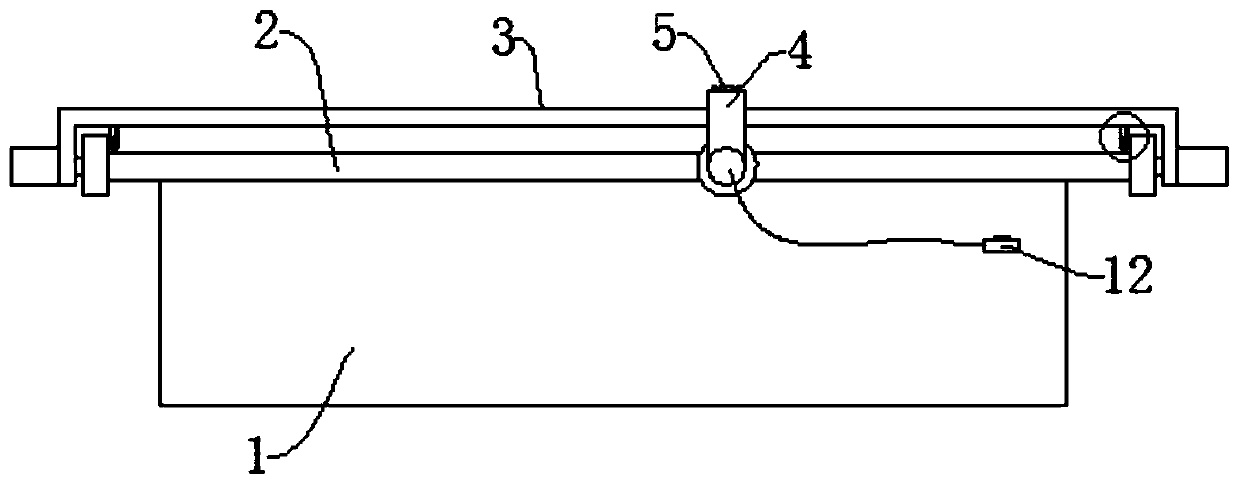

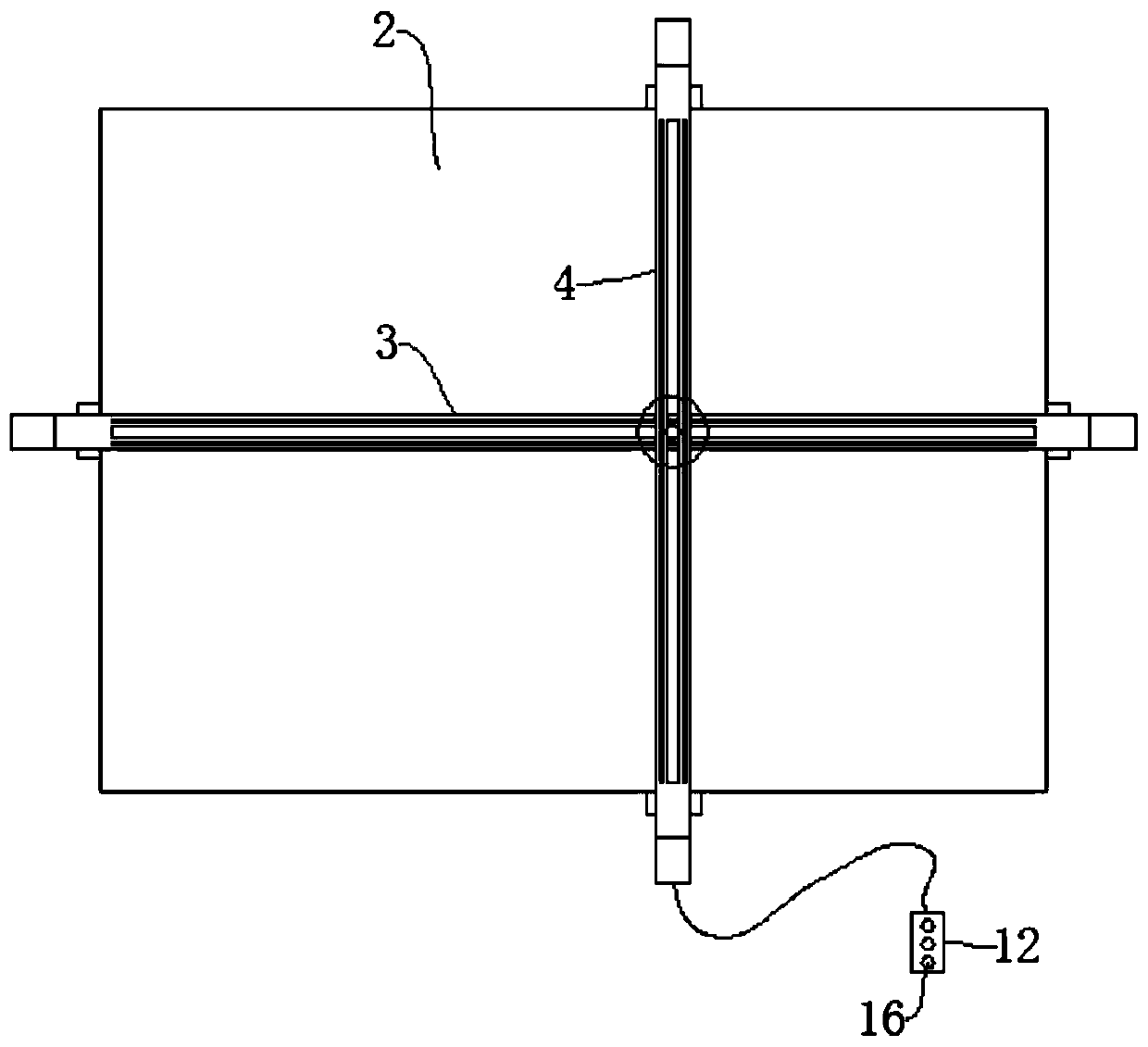

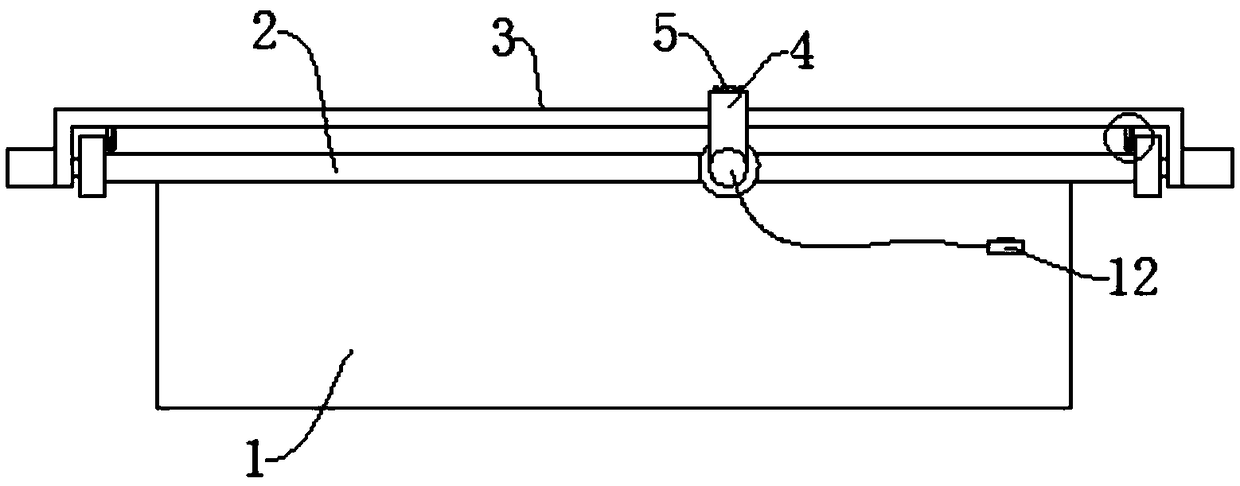

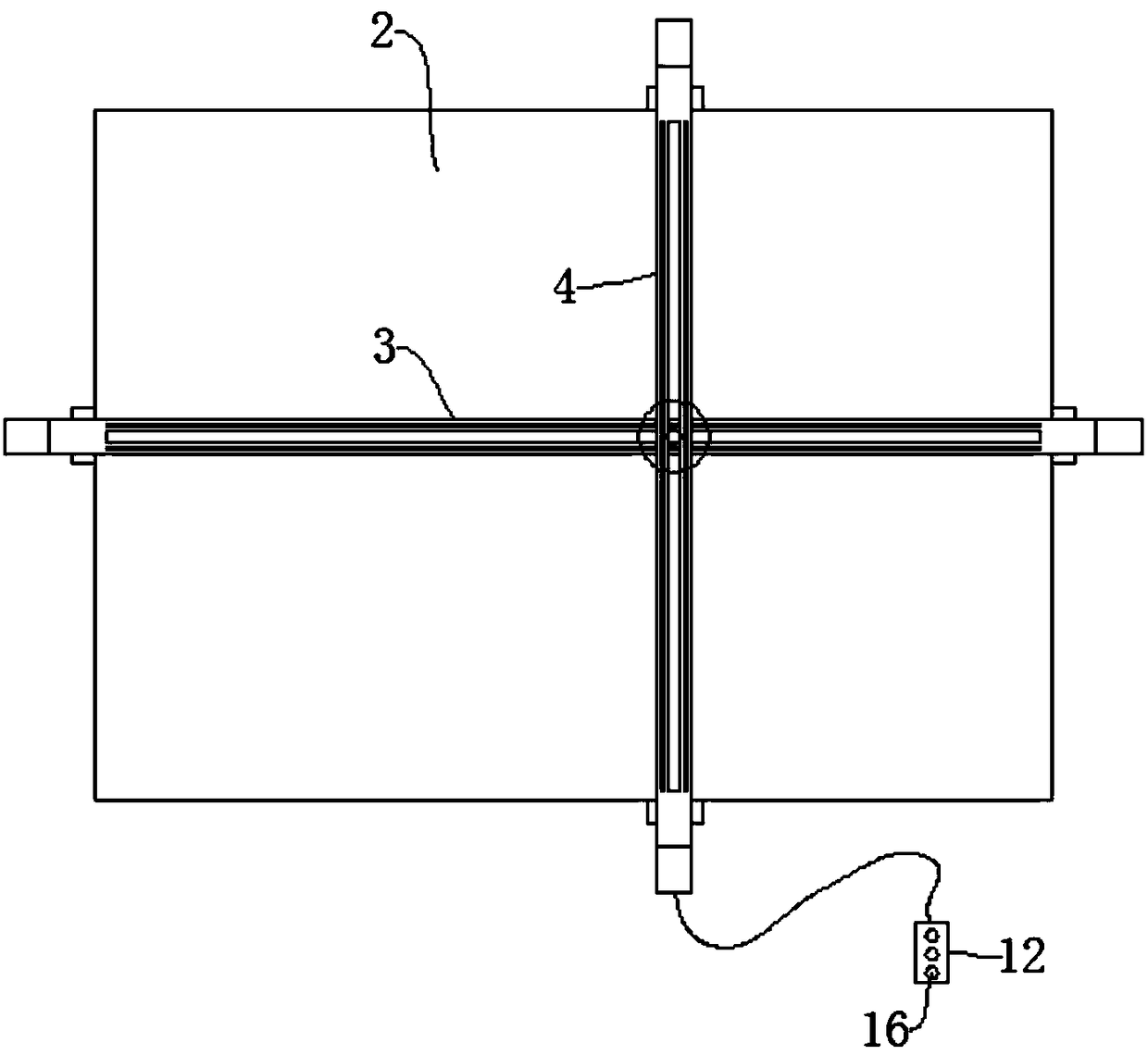

A new type of circuit board fast edging machine

ActiveCN109048598BIncrease sanding speedImprove grinding efficiencyEdge grinding machinesEngineeringGrinding

The invention discloses a novel circuit board rapid edge grinding machine. The novel circuit board rapid edge grinding machine comprises a workbench and a circuit board fixedly installed on the workbench, a first edge grinding mechanism and a second edge grinding mechanism are arranged on the upper surface of the circuit board in a crossed mode, the first edge grinding mechanism and the second edge grinding mechanism are connected with each other through a connecting propeller in a sliding mode, the first edge grinding mechanism is used for grinding one opposite edge of the circuit board, andthe second edge grinding mechanism is used for grinding the other opposite edge of the circuit board. The novel circuit board rapid edge grinding machine has the beneficial effects that the novel circuit board rapid edge grinding machine can be used for grinding four edges of the circuit board at the same time, and therefore polishing of the circuit board can be completed only by taking the time used for grinding only one edge, so that the grinding speed and efficiency can be greatly improved, the cost of time and material resources is greatly reduced, and the practicability is good.

Owner:敬鹏(常熟)电子有限公司

Novel circuit board rapid edge grinding machine

ActiveCN109048598AImprove the speed and efficiency of grindingMaterial cost reductionEdge grinding machinesMaterial resourcesEngineering

The invention discloses a novel circuit board rapid edge grinding machine. The novel circuit board rapid edge grinding machine comprises a workbench and a circuit board fixedly installed on the workbench, a first edge grinding mechanism and a second edge grinding mechanism are arranged on the upper surface of the circuit board in a crossed mode, the first edge grinding mechanism and the second edge grinding mechanism are connected with each other through a connecting propeller in a sliding mode, the first edge grinding mechanism is used for grinding one opposite edge of the circuit board, andthe second edge grinding mechanism is used for grinding the other opposite edge of the circuit board. The novel circuit board rapid edge grinding machine has the beneficial effects that the novel circuit board rapid edge grinding machine can be used for grinding four edges of the circuit board at the same time, and therefore polishing of the circuit board can be completed only by taking the time used for grinding only one edge, so that the grinding speed and efficiency can be greatly improved, the cost of time and material resources is greatly reduced, and the practicability is good.

Owner:东阳市天齐知识产权运营有限公司

A kind of rubber plate polishing device

ActiveCN102962735BIncrease sanding speedImprove sanding qualityGrinding drivesPlane surface grinding machinesEngineeringMaterial resources

The invention relates to the mechanical polishing field, in particular to a rubber plate polishing device. The rubber plate polishing device comprises a frame, wherein a rubber plate fixing apparatus is arranged on the upper surface of the frame; guide rails and racks are arranged at the edges of two unconnected sides of the rubber plate fixing apparatus; a walking device is arranged on one side of the rubber plate fixing apparatus with the guide rails and the racks; gears are arranged at the lower part of the walking device, engaged with the racks on the rubber plate fixing apparatus and placed on a wheel; an automatic distance adjusting device is arranged at the front end of the walking device; a polishing wheel device is arranged at the front end of the automatic distance adjusting device; the polishing wheel device is connected with a polishing wheel rotating device; and the polishing wheel rotating device drives a cylinder on the polishing wheel device to rotate. The rubber plate polishing device provided by the invention has the advantages that the whole rubber plate can be polished, the polishing speed of the rubber plate is effectively increased, the polishing quality of the rubber plate is effectively improved, the labor intensities of workers are greatly reduced and a great deal of manpower and material resources are saved.

Owner:YANTAI XINHAI MINING MACHINERY

Medical instrument shell polishing machine

InactiveCN113649902AImprove energy efficiencyIncrease sanding speedGrinding drivesGrinding machinesGear wheelEngineering

The invention relates to a medical instrument shell polishing machine which comprises an equipment shell and a gear assembly, the upper wall of the equipment shell is sequentially provided with a power assembly, a supporting frame and a lifting adjusting assembly from left to right, the lower end of the supporting frame is connected with the gear assembly through a mounting pin, and the exterior of the power assembly is connected with an auxiliary material assembly; and angle auxiliary assemblies are arranged on the periphery of an angle rotating assembly, and the gear assembly comprises a wheel disc, a steel ball, a second spring and gear teeth. The medical instrument shell polishing machine has the beneficial effects that polishing and lifting can be achieved through one power, the energy utilization rate is increased, the equipment can make a polishing disc continuously and tightly make contact with a medical instrument shell to facilitate polishing, the angle of the polishing disc of the equipment can be adjusted, so that large-area contact between the polishing disc and the medical instrument shell is facilitated, and a transmission part of the equipment can conduct contraction protection, damage caused by too large meshing force is prevented, the equipment can assist in polishing through concentrated sulfuric acid, and the polishing speed is increased.

Owner:段平泉

A pantograph slide double-head grinding device and grinding method thereof

ActiveCN108942521BReduce labor intensityIncrease sanding speedGrinding drivesGrinding machinesMotor driveDrive shaft

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

A kind of electric power-assisted worm grinding process

The invention discloses an electric power assisted worm grinding process and relates to the technical field of worm processing. The electric power assisted worm grinding process comprises the step of(1), pretreatment of a worm, specifically, spraying a rust remover to the surface of the worm to be ground, conducting simple grinding on the surface of the worm through abrasive paper, cleaning the worm in clean water, soaking the worm in 60-80% alcohol liquid for 5-10 min and then taking out and draining off the worm. According to the electric power assisted worm grinding process, before grinding, the surface of the worm is soaked through alcohol to remove impurities on the surface of the worm; an oxidation film on the surface of the worm is removed through acid treatment to prevent the grinding process from being impeded by the oxidation film; and finally, the surface of the worm is softened through normalizing treatment, at the moment, the surface and the interiors of tooth gaps of theworm can be ground through back-and-forth cooperation of a plurality of grinding cams on a grinding device, and burrs and protrusions on the softened surface of the worm are ground and removed. Through the electric power assisted worm grinding process, the grinding speed is increased, and the grinding precision is improved.

Owner:煌太阳科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com