Full-automatic grinding process for waste tire

A waste tire, fully automatic technology, applied in the direction of grinding machines, manufacturing tools, grinding racks, etc., can solve the problems of low efficiency, heavy labor, difficult to guarantee, etc., to achieve the effect of improving grinding efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

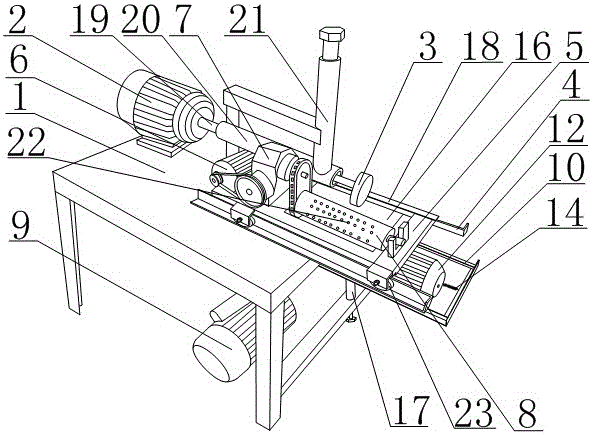

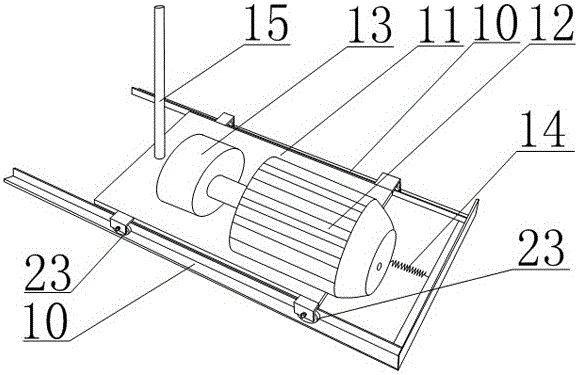

[0022] Such as Figures 1 to 2As shown, the present invention is a fully automatic grinding process for waste tires. The workbench 1 is welded by steel plates, section steel, etc., and is mainly used to provide an operation plane and install various components. A grinding wheel motor 2 is installed on the workbench 1. , the output shaft of the grinding wheel motor 2 drives the upper grinding wheel 3, and the upper grinding wheel 3 is used as a part for grinding the steel wire belt. The pressing device 21 acts on the fixed cylinder 20; two parallel upper guide rails 4 are arranged on the workbench 1, and the two upper guide rails 4 are parallel to the output shaft of the grinding wheel motor 2, and an upper slide plate 5 is installed on the upper guide rail 4 , the upper slide plate 5 can reciprocate on the upper guide rail 4, and a drive motor 9 is installed under the workbench 1, and the drive motor 9 drives the upper slide plate 5 to do reciprocating motion on the upper guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com