Patents

Literature

349results about "Pancakes baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

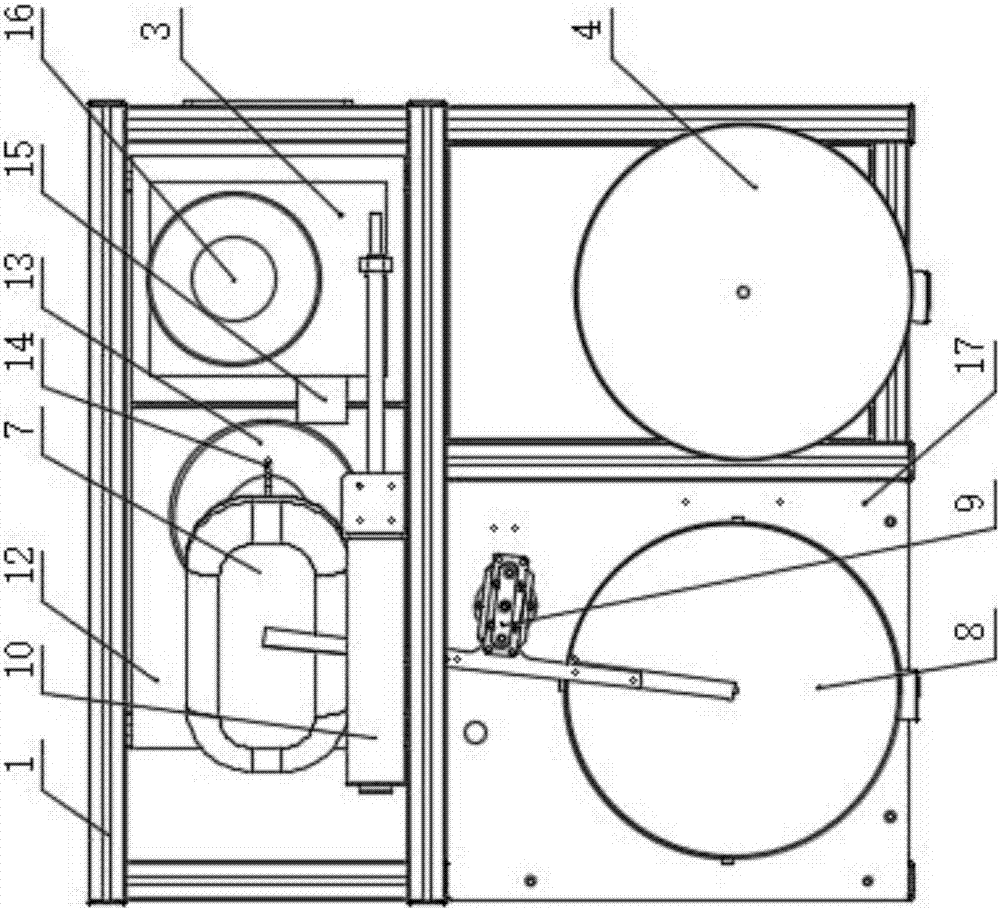

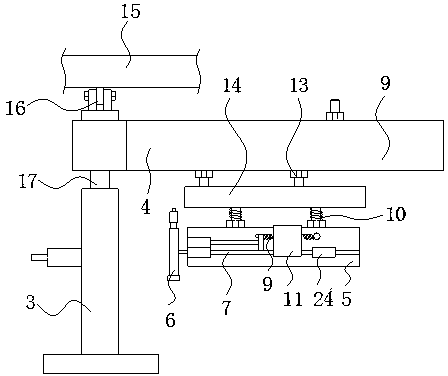

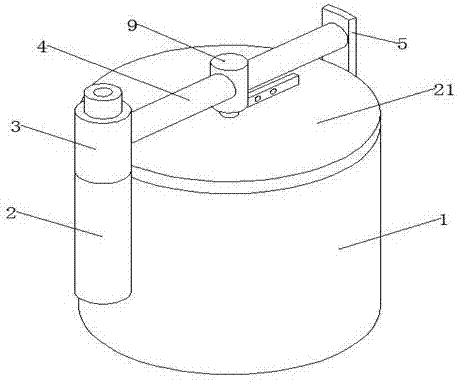

Full-automatic pancake machine

InactiveCN101584352AImprove processing efficiencyReduce labor intensityOil/fat bakingPancakes bakingRobot handElectric machinery

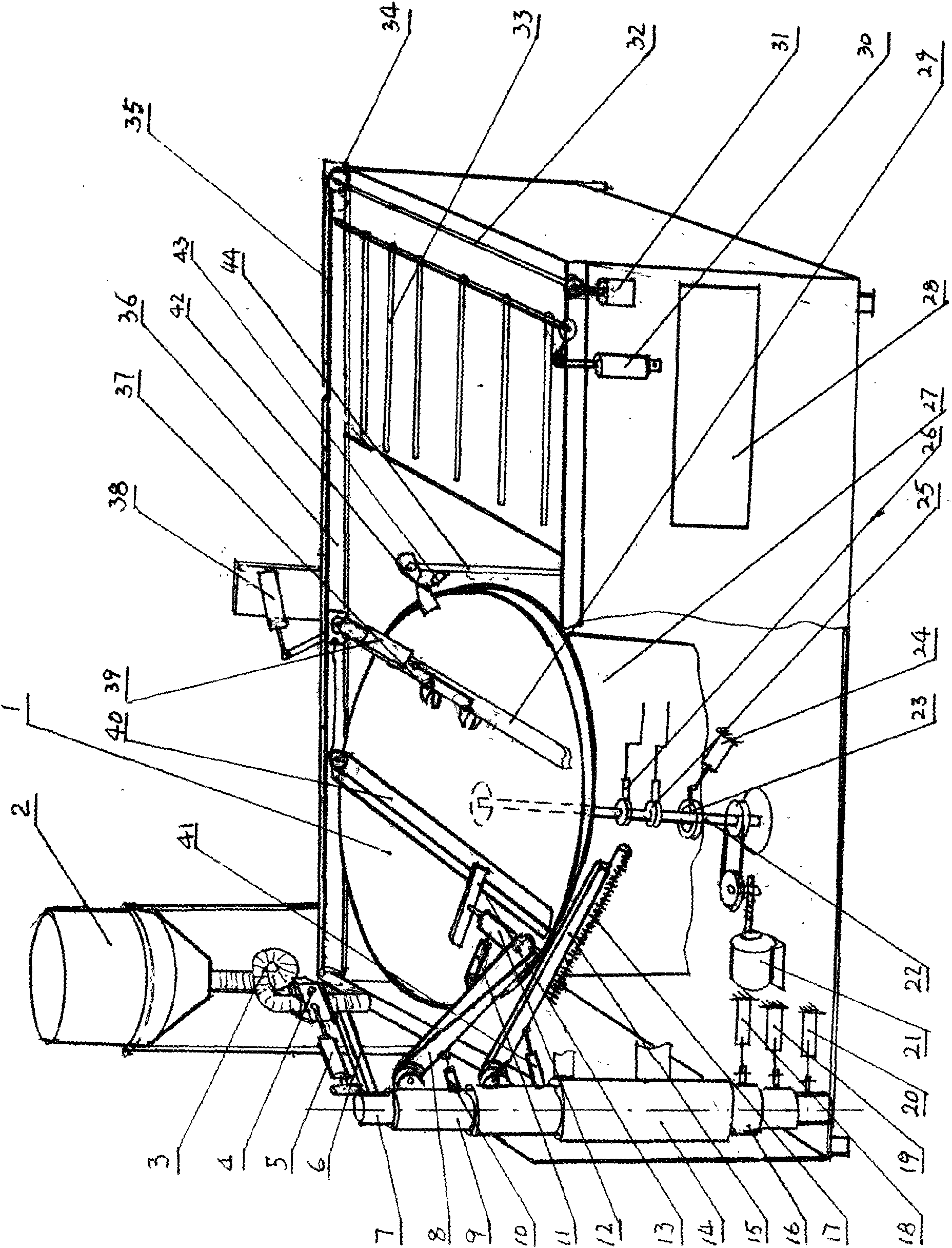

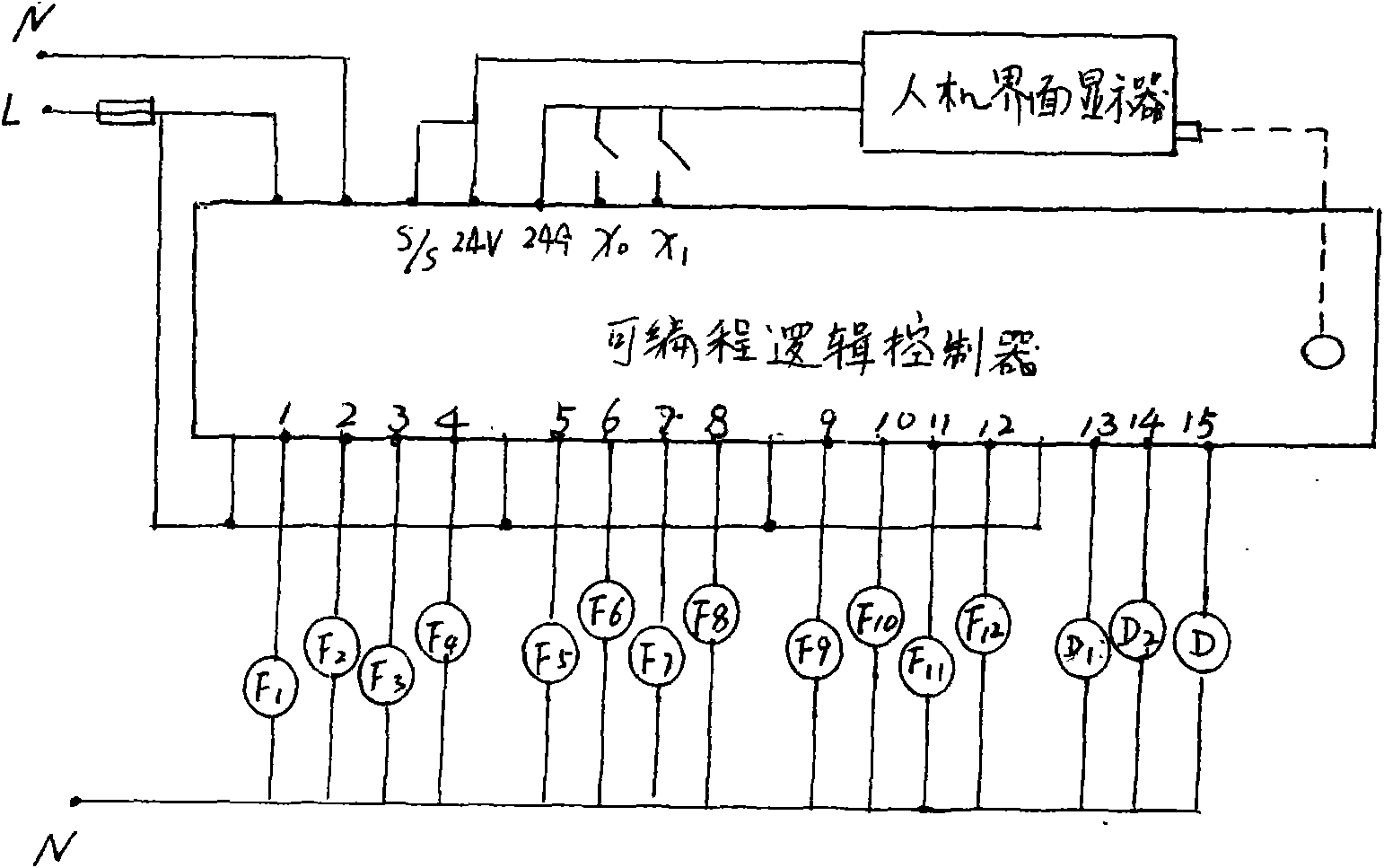

The invention discloses a full-automatic pancake machine, comprising a griddle heating and rotating under the drive of motor, an accumulator, a mechanical hand for polishing by simulating manual pancake making actions, a mechanical hand for feeding paste materials, a spreading mechanical hand, a raising mechanical hand, a pulling mechanical hand, a scraping mechanical hand, a turning-moving mechanical hand and an automatic controller. The automatic controller controls each mechanical hand to run according to program, thereby achieving the actions of simulating manual pancake making of the full-automatic pancake machine. All the manual operation procedures of pancake making in the invention are finished automatically, so that the pancake making is automatized, processing efficiency is improved, and labour intensity is reduced, besides, the made pancake still has the feeling of pancake made manually.

Owner:单传芹

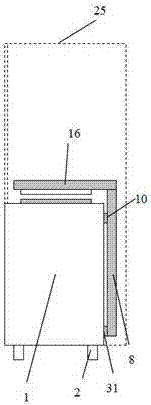

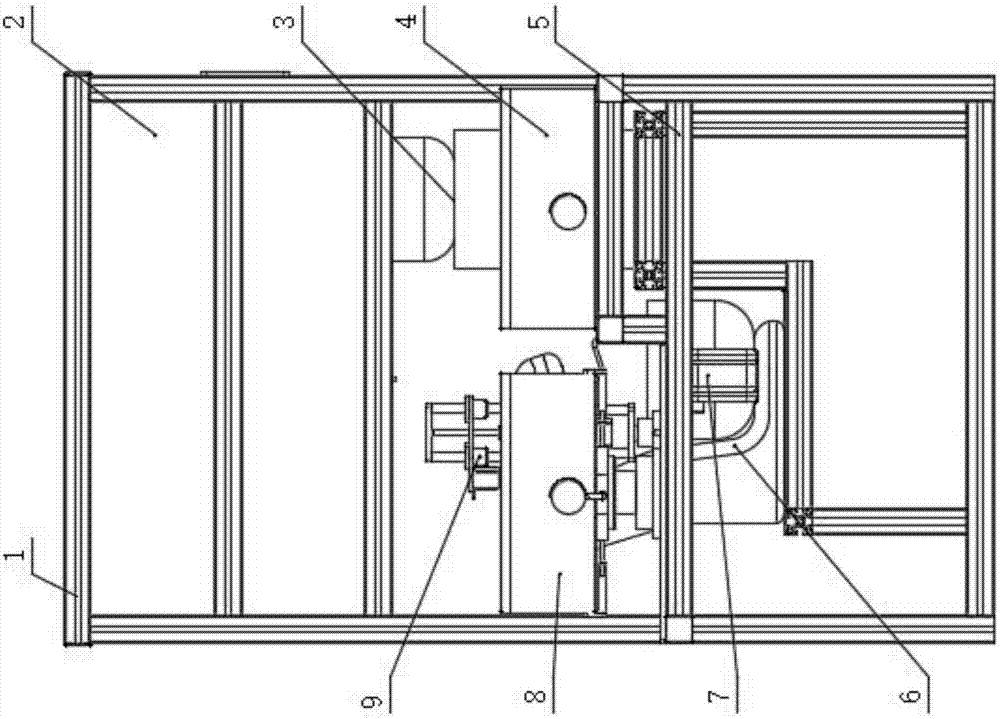

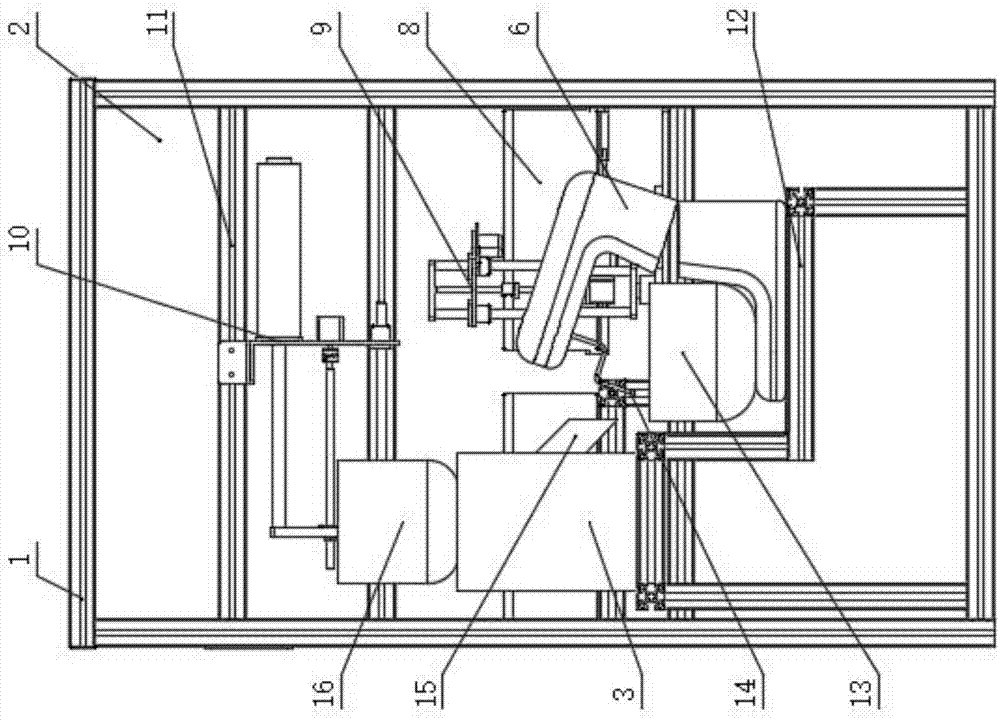

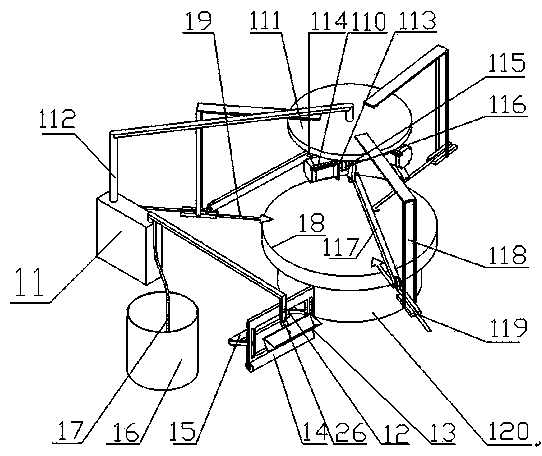

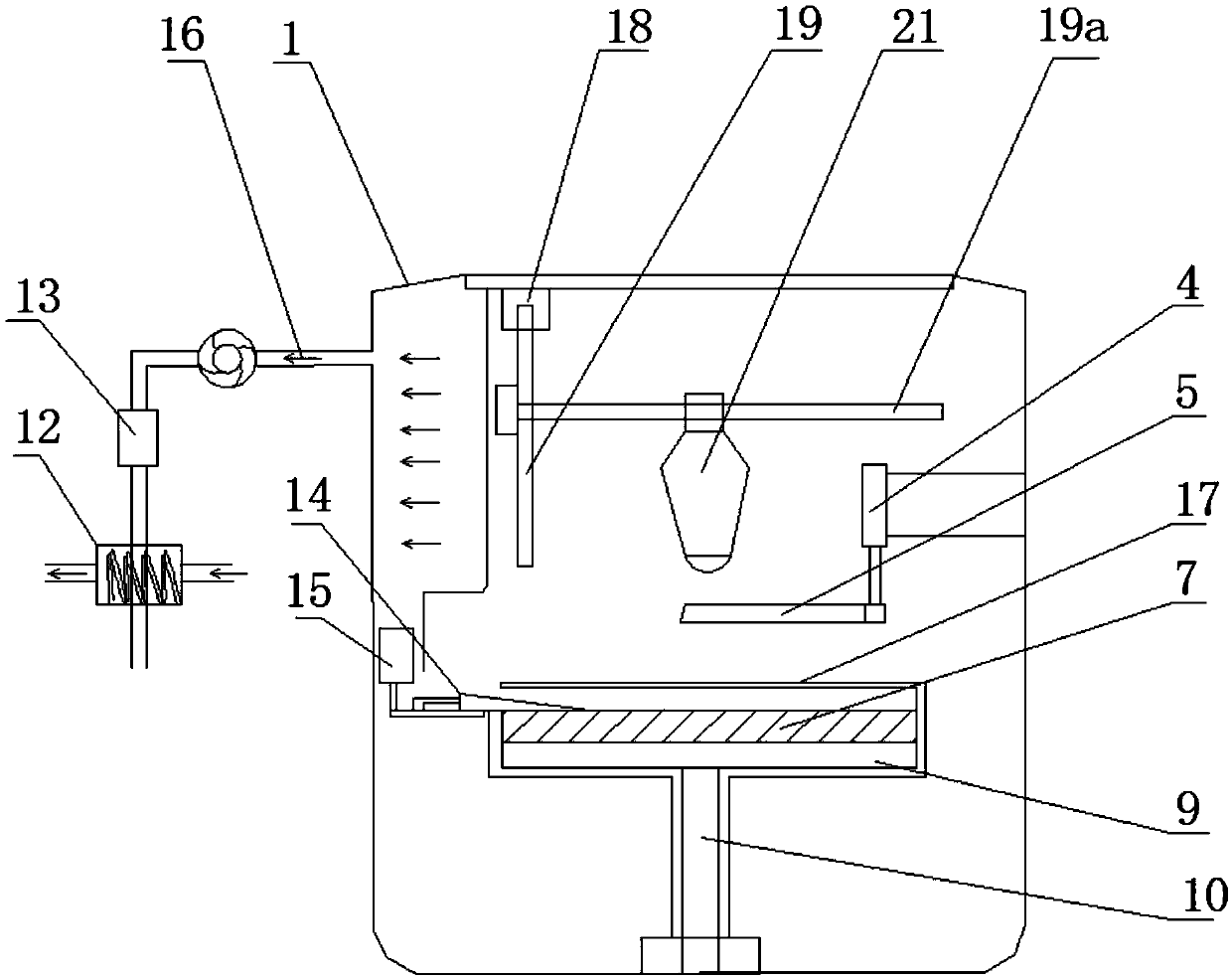

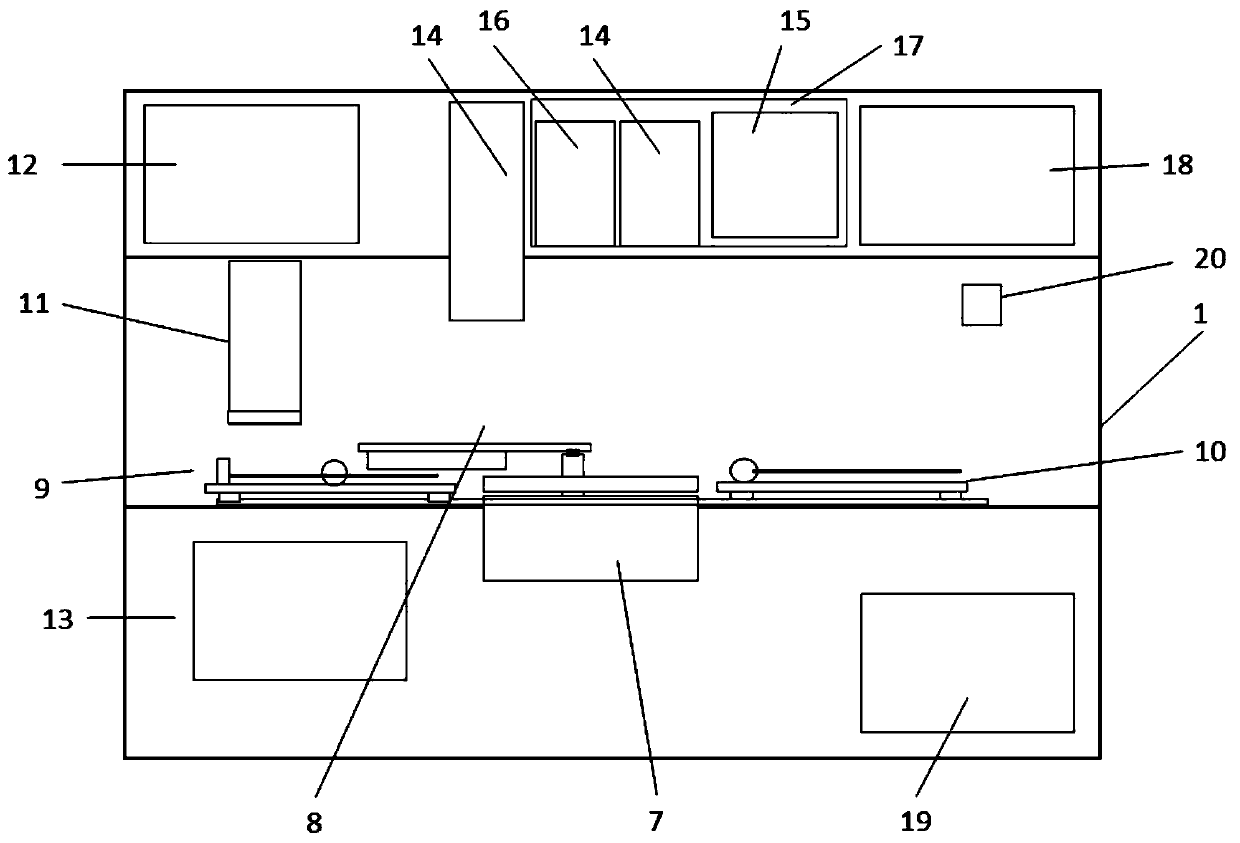

Pancake full automation joint production and network selling all-in-one machine

ActiveCN107114431ARealize online bookingAchieve interactionPaper-money testing devicesReservationsAdditive ingredientCash collection

The invention belongs to the technical field of food equipment, in particular relates to a pancake full automation joint production and network selling all-in-one machine. The machine comprises a machine body, wherein a pancake-making device is arranged on the machine body, an annular dual-channel storage egg shell removing and feeding device, a mobile wall hanging rail vehicle-mounted working platform device, a flipping folding end product packaging output device, fried pancake, fried fruit grate, sauces, a side ingredient storage alternative ration feeding device, and an electrical supply and control device; for solving the problems of complex pancake making process and labor expending, a full automation joint production and network selling all-in-one machine is provided, replacement of manual operations is achieved, all decentralized operations are combined together in one machine, and the production work of pancakes is completed. Cash is automatically collected by self-service under the intelligent control of an intelligent selling system, Internet lines are connected with the machine, online reservations, cash collections, and automatic vending are achieved through Internet, and online communication and interaction are achieved for the purchasers.

Owner:天津市津盈门科技研发有限公司

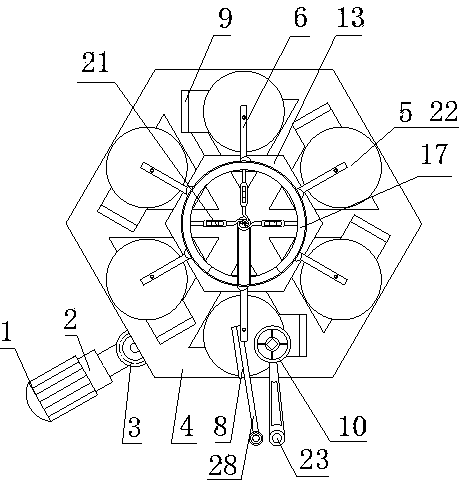

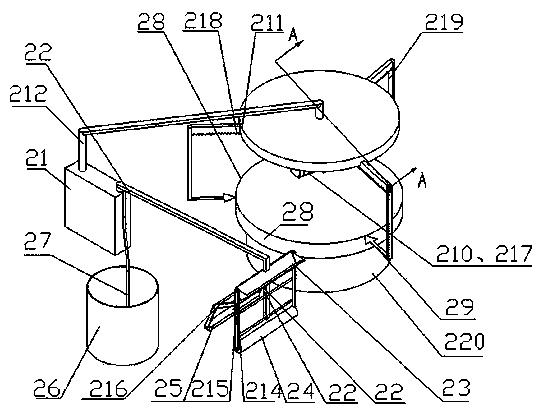

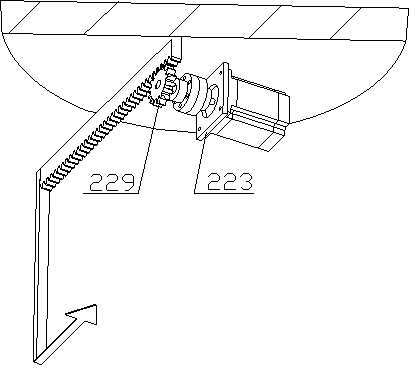

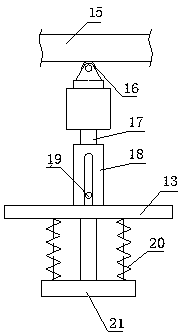

Automatic pancake machine

InactiveCN103734209AReduce thicknessTenacious feetOil/fat bakingPancakes bakingEngineeringHeating furnace

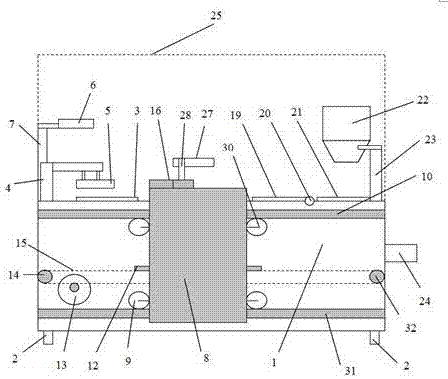

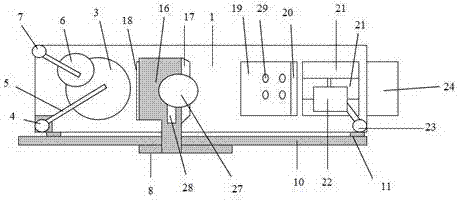

The invention relates to an automatic pancake machine which comprises a pancake spreading device, a heating and baking device and a power device, wherein the heating and baking device comprises more than one heating furnace; the heating furnace is fixedly arranged on a rotary disc, and is provided with flat plates; the pancake spreading device comprises scraping plates, and the scraping plates are respectively arranged at one side of each flat plate; the power device comprises a main driving part, a flat plate self-rotation driving part and a scraping plate lifting part, the main driving part is used for driving the rotary disc to rotate, and the flat plate self-rotation driving part is used for realizing the self-rotation of each plat plate; the lifting movement track line of each scraping plate comprises an ascending travel section track line and a return travel section track line; the return travel section track line at least comprises a return travel track line I and a return travel track line II; an included angle alpha between the return travel track line I and a time coordinate axis is greater than the included angle beta between the return travel track line II and the time coordinate axis. The automatic pancake machine has the advantages that the pancake is thin, the processing efficiency is high, the processing speed is high, and the scraping of pancake is complete.

Owner:尹相善

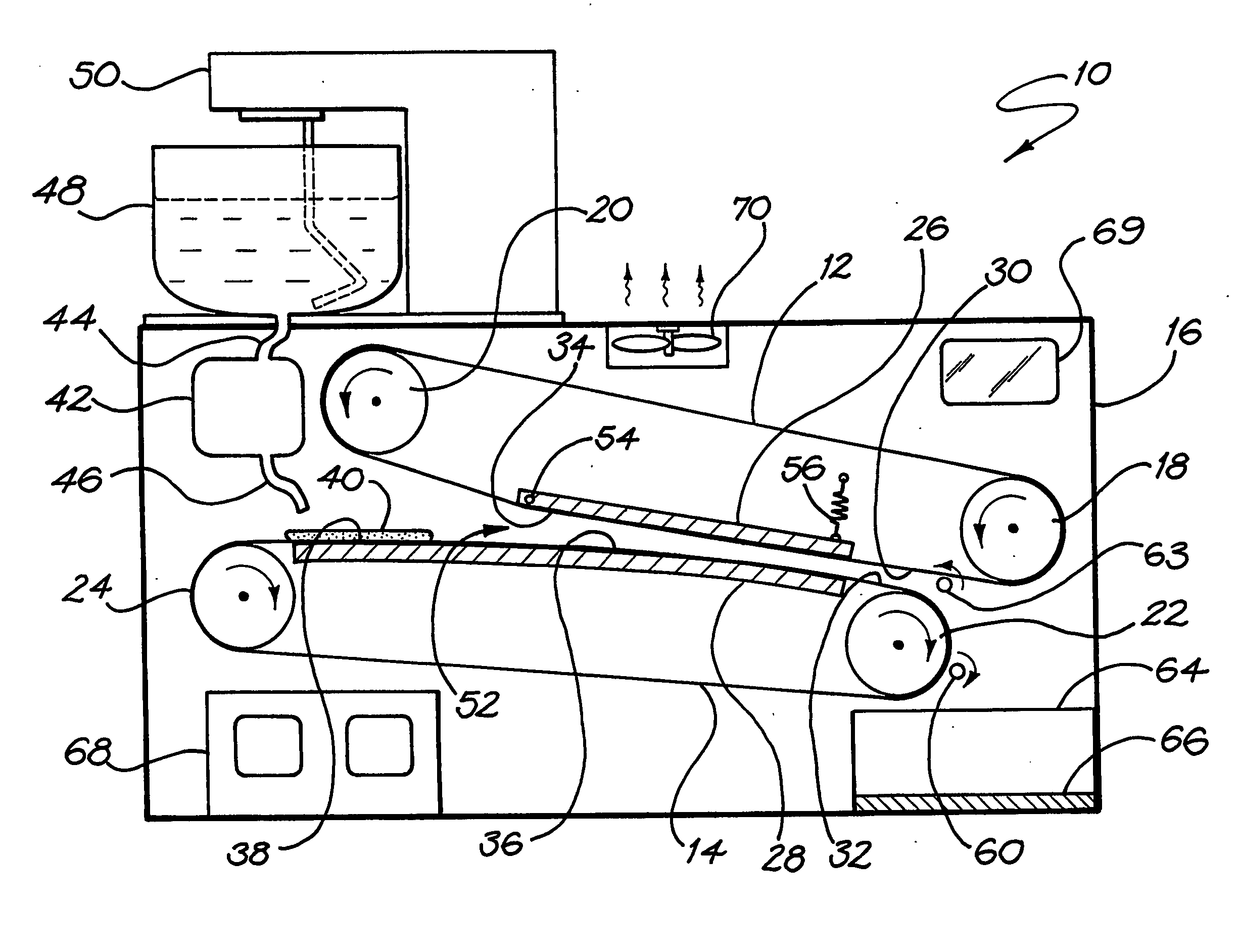

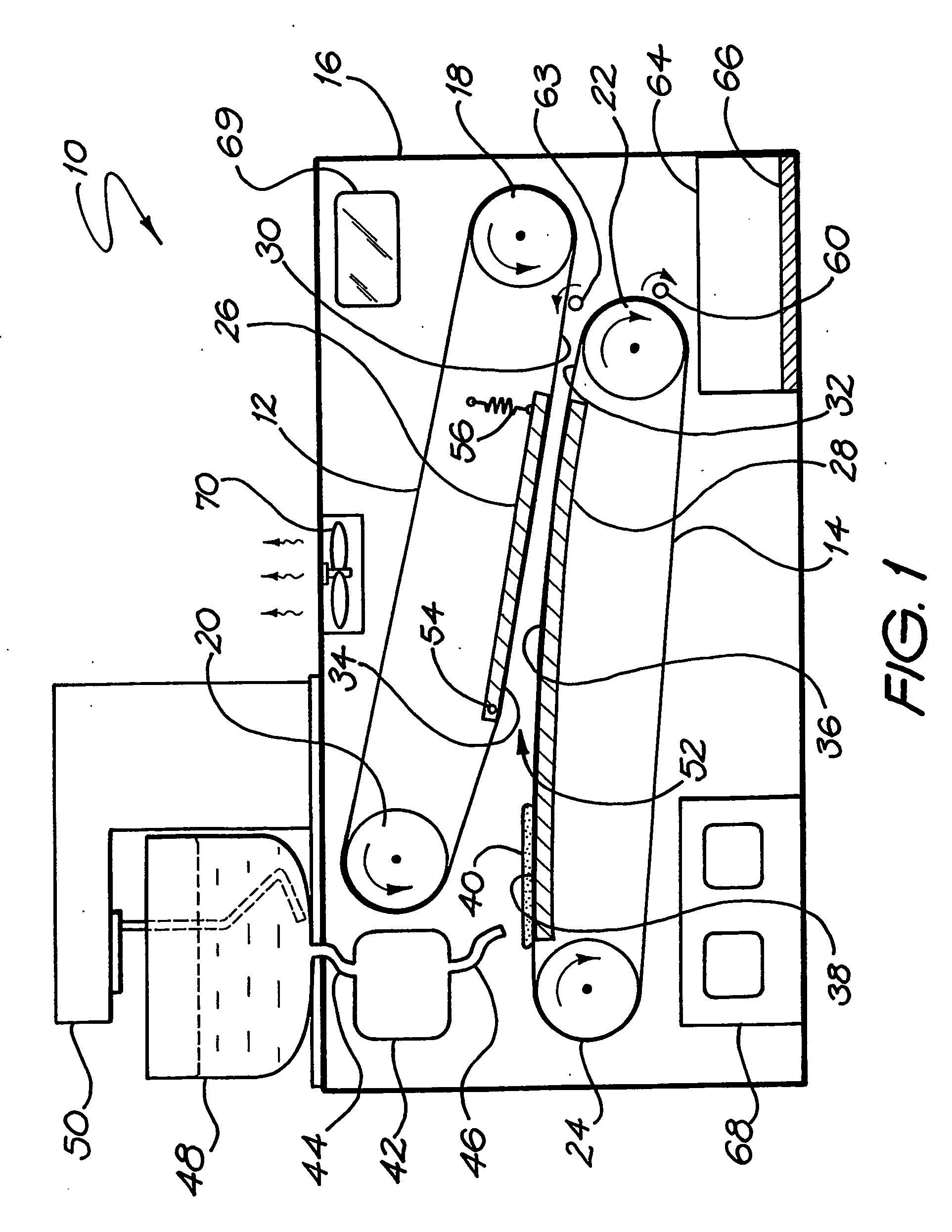

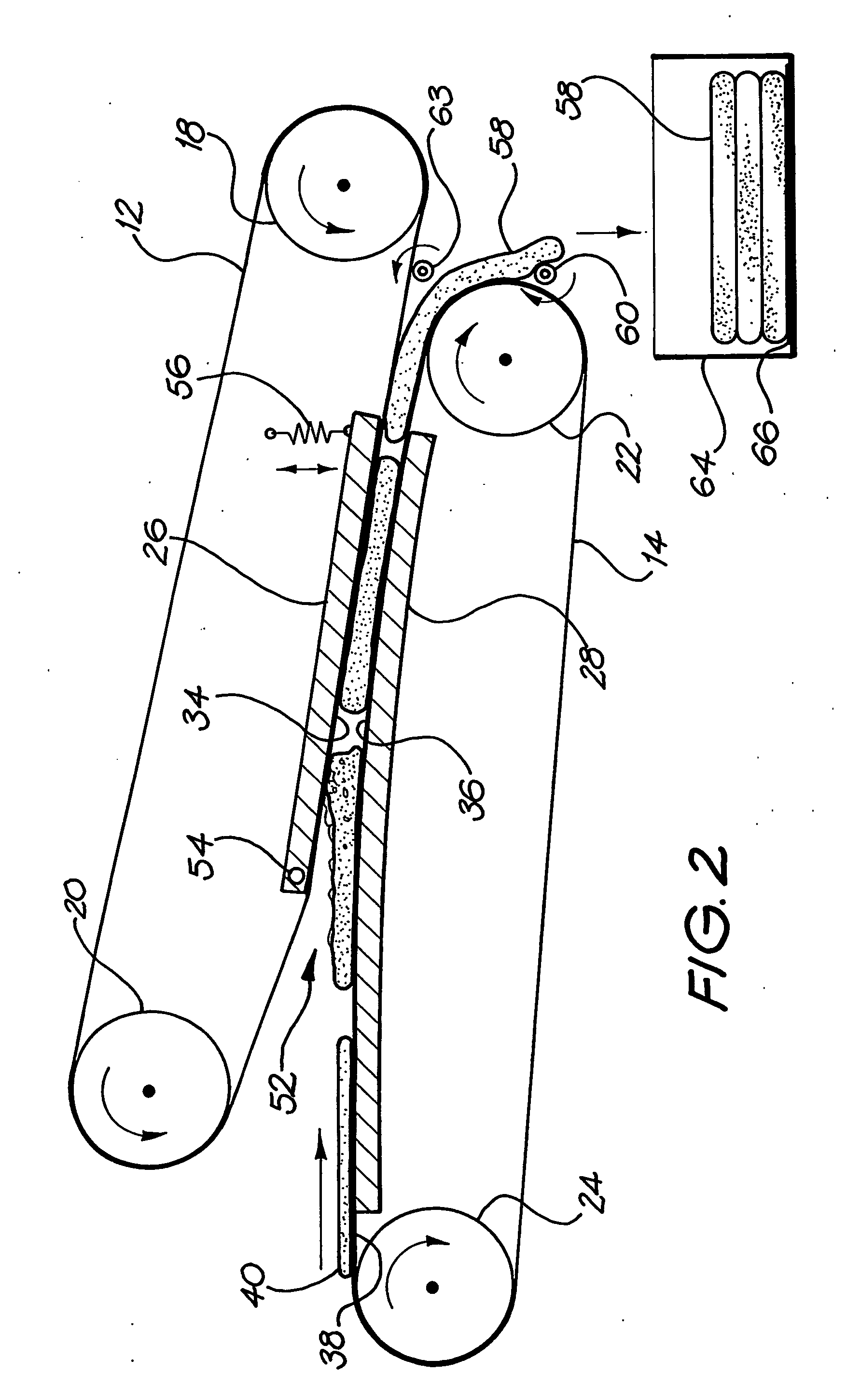

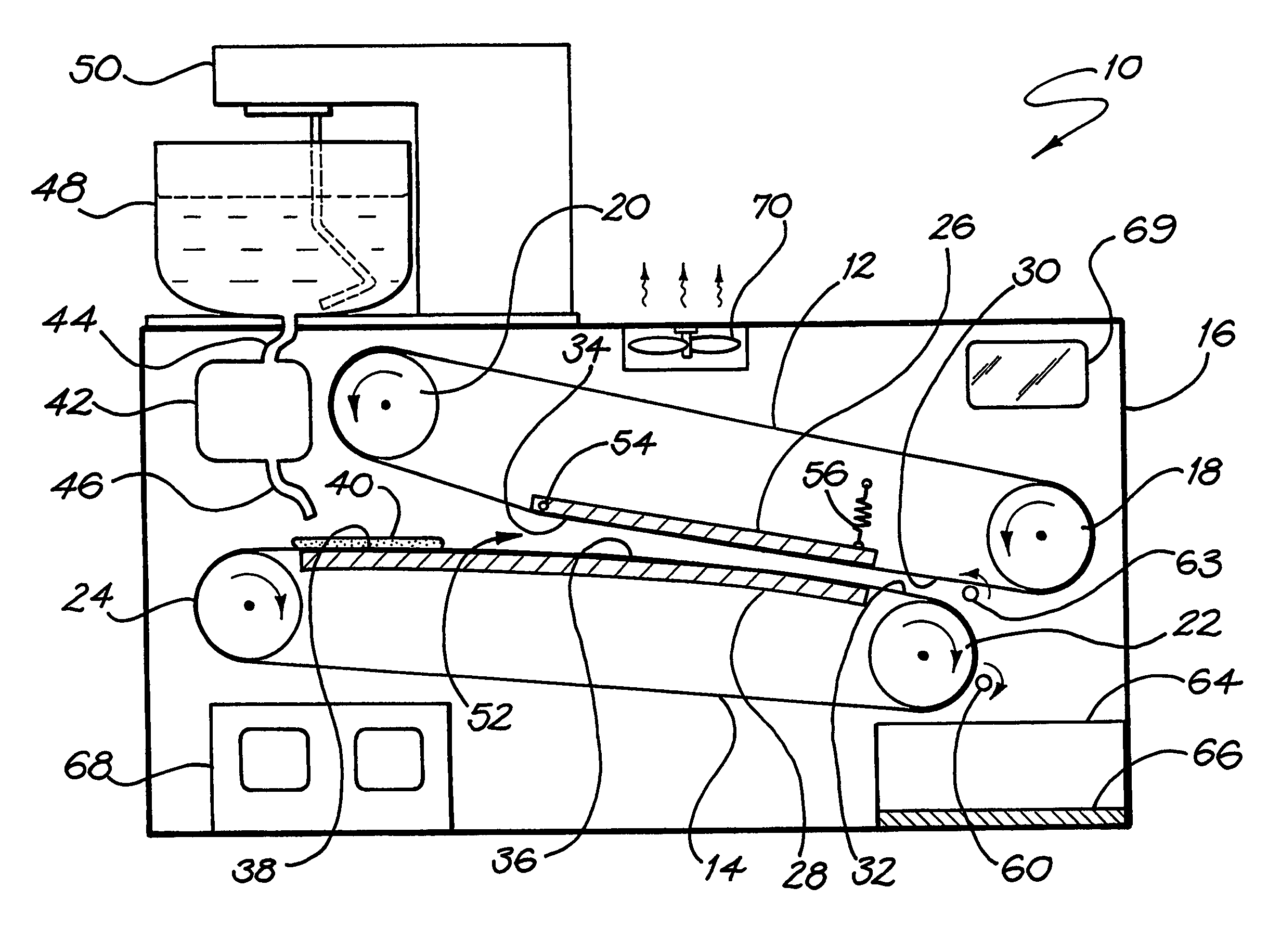

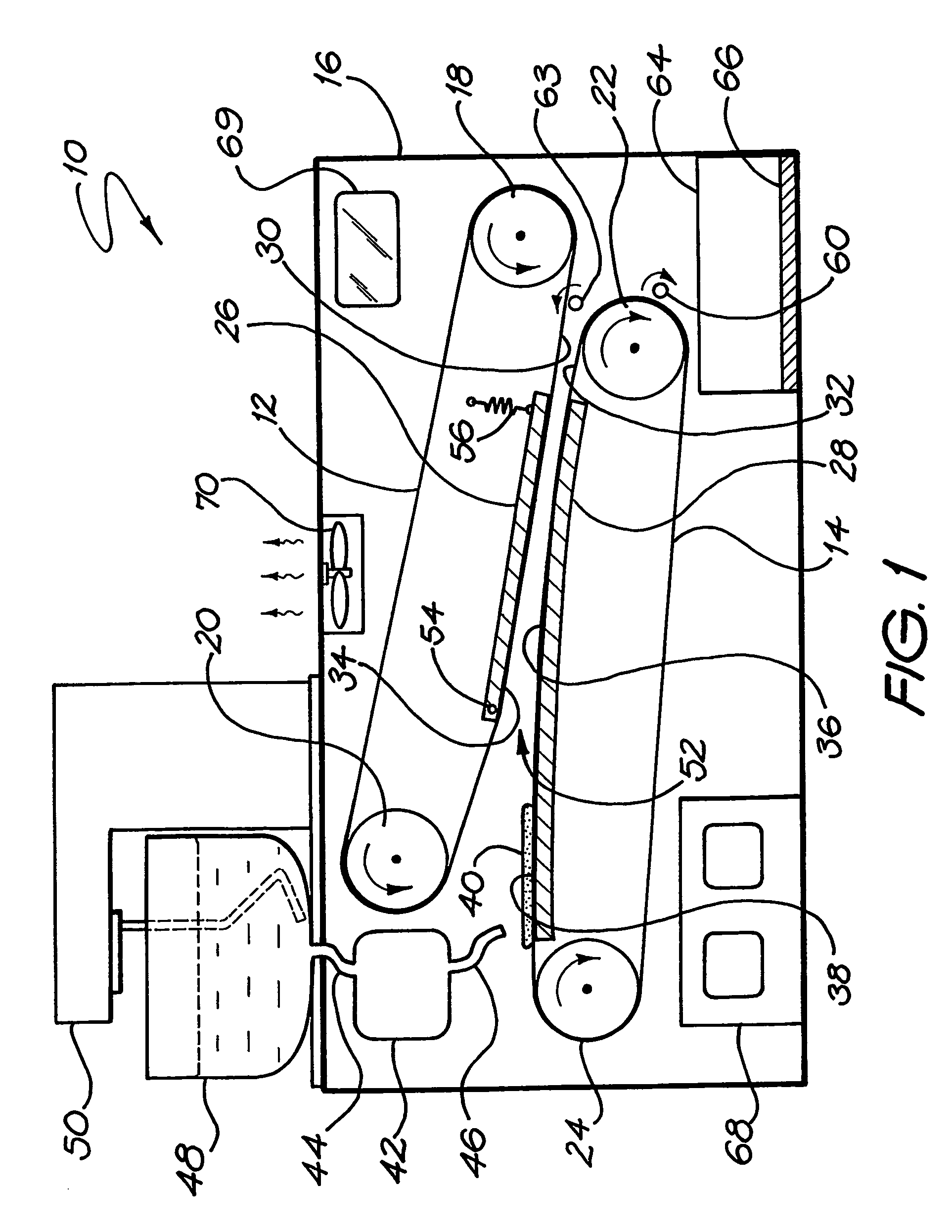

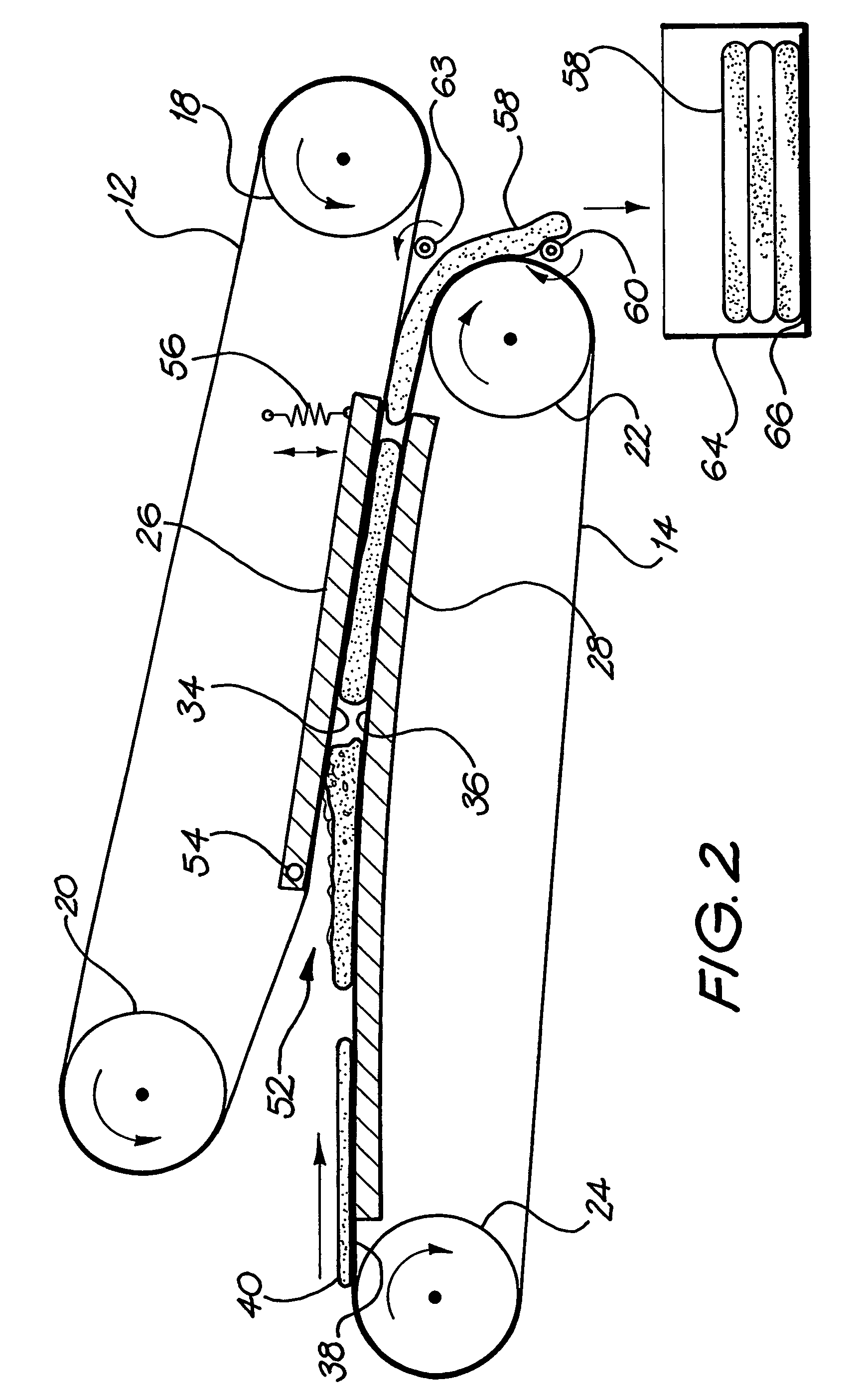

Automated belt cooking machine pancakes or the like

An automated belt cooking machine (10) for pancakes and the like food products has upper and lower overlapping, thermally conductive belts (12, 14), counter-rotatably mounted to a frame (16) so that, in use, a bottom run (30) of the upper belt (12) and a top run (32) of the lower belt (14) co-operate to convey food (40) to be cooked. The lower belt (14) extends a predetermined distance to one side of the upper belt (12) so as to provide a dispensing platform portion (38) for dispensing thereon the food to be cooked (40), so that the food (40) is conveyed towards a mouth (52) formed between the upper belt and lower belts (12, 14) and thereafter is conveyed sandwiched between the bottom and top run (30, 32). Upper and lower heating platens (26,28) are mounted to the frame (16) and are in thermal contact with the bottom and top run (30, 32), wherein the food to be cooked (40) is initially exposed to heat from the lower platen (28) conducted through the dispensing platform portion (38).

Owner:SZYMANSKI MAREK

Automated belt cooking machine pancakes or the like

Owner:SZYMANSKI MAREK

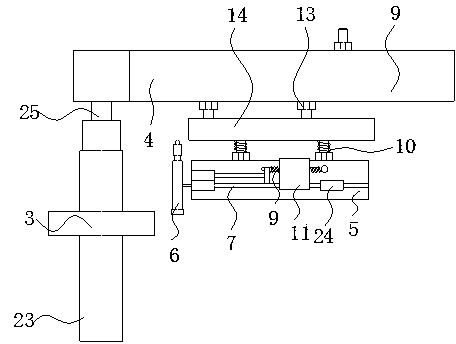

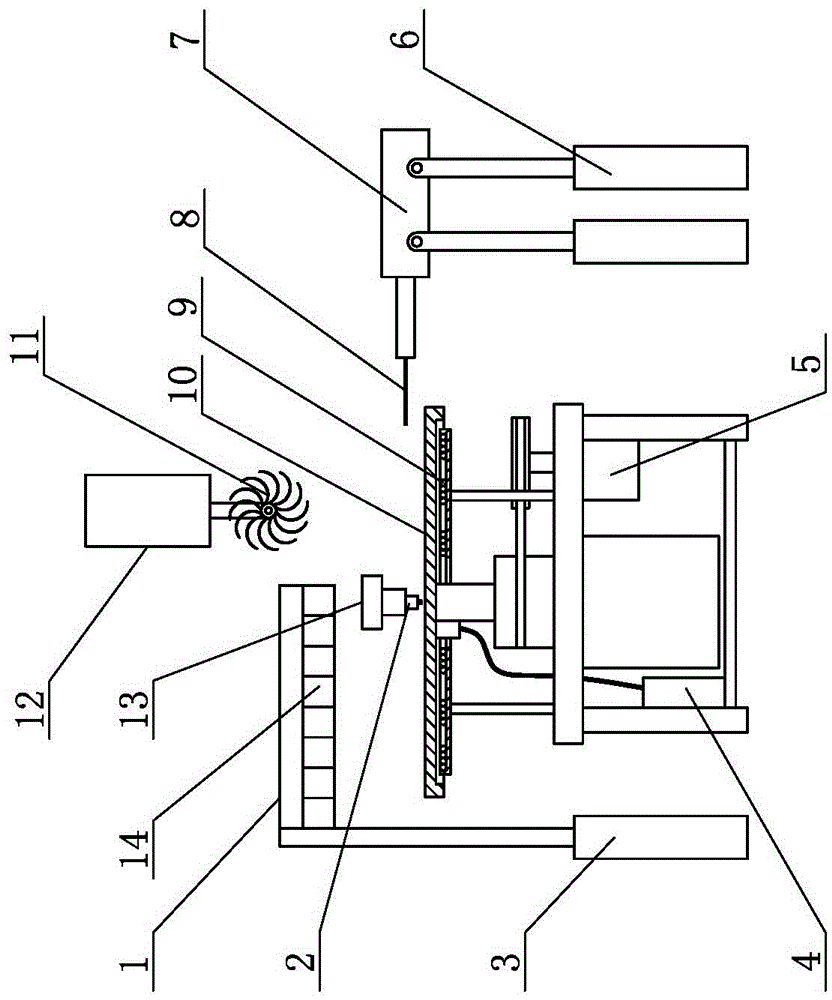

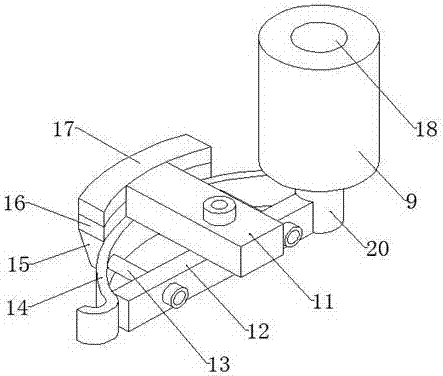

Chinese hamburger preparation system

ActiveCN107396944AAccurate distanceSatisfy taste needsOil/fat bakingPancakes bakingMeat burgerMechanical engineering

The invention relates to a Chinese hamburger preparation system. The system is characterized in that a griddle surface rotating mechanism is arranged at the front end of a support; a batter scrapping mechanism is arranged on the support beside the griddle surface rotating mechanism; a batter supplying mechanism is arranged at any position on the support; a griddle surface automatically rotates, and the batter supplying mechanism automatically conveys batter to the griddle surface; after being automatically positioned, a scraper plate is used for flattening the batter on the griddle surface. According to the Chinese hamburger preparation system, vertical movement and horizontal movement of the scraper plate and a shoveling knife are driven by a stepping motor, so that the control accuracy is high; a piston in a material barrel is driven by the stepping motor, and quantitative battery conveying is achieved; the system is simple in structure, and convenient to mount and maintain; the griddle surface is driven through a belt, so that the noise is low, and the abrasion is small; the griddle surface can be axially and radially fixed through a fixing block and a mounting block on a supporting plate, steady mounting is ensured, and a fixing rod can be adjusted to fit the fixation of the griddle surface with different size; the structures are matched with each other, so that the whole system is convenient, practical, convenient to mount and maintain, and applicable to different users in different conditions.

Owner:TIANJIN CHUANGZHI ROBOT TECH CO LTD

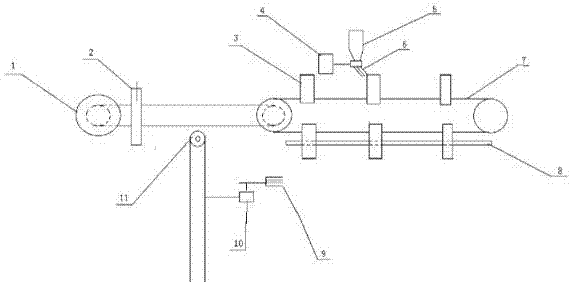

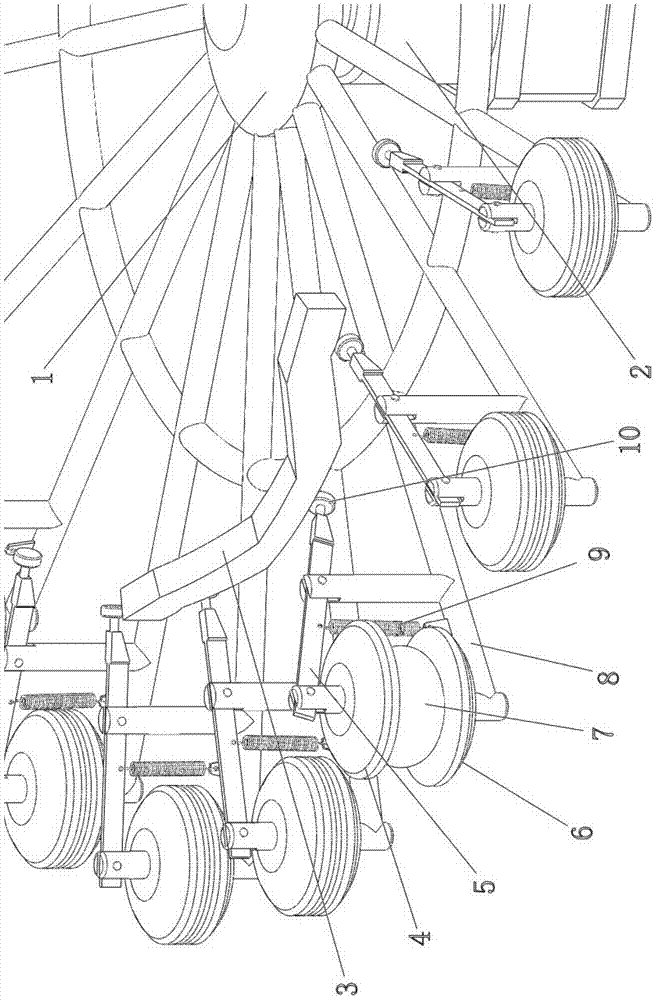

Full-automatic handwork-imitating pancake machine

ActiveCN103404547AReduce volumeIngenious ideaOil/fat bakingPancakes bakingAutomatic controlEngineering

The invention discloses a full-automatic handwork-imitating pancake machine which comprises a machine frame, a paste feeding part, a pancake raising part, a griddle and an automatic control part. The paste feeding part comprises a paste feeding tube and a paste feeding pipe communicated with the paste feeding tube which is connected with a paste feeding groove in the paste feeding part. The pancake raising part comprises a pancake scraper and a scraper moving part for driving the pancake scraper to move. The full-automatic handwork-imitating pancake machine is ingenious in design, finishes full-automatic pancake spreading operation through mechanical transmission and corresponding programs, is small in machine size and high in efficiency, effectively saves labor power, improves sanitary standard of pancakes and has good application prospects.

Owner:王同成

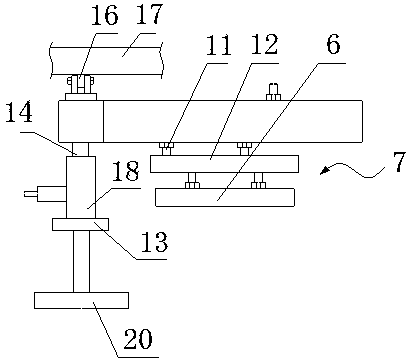

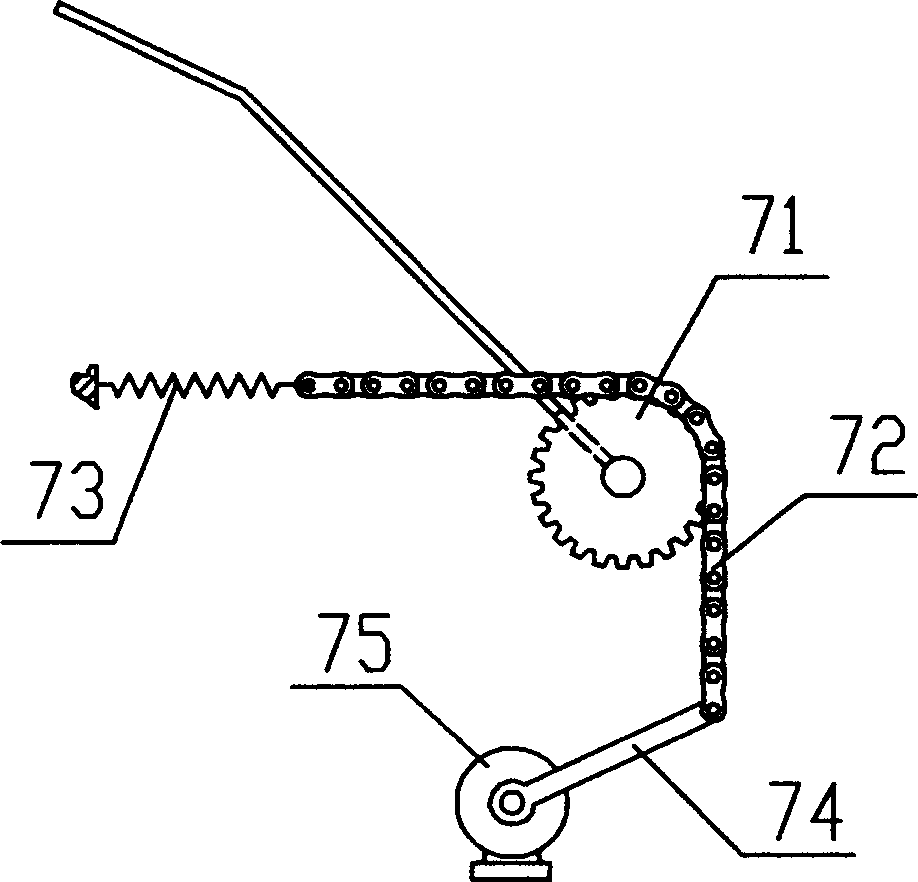

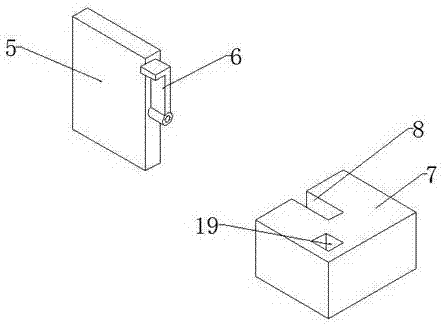

Pancake making device

InactiveCN103734210AAvoid breakingAvoid spillingOil/fat bakingPancakes bakingMechanical engineeringPhysics

A pancake making device comprises a support, wherein a scraper and a scraper lifting part which is used for driving the scraper to achieve a cyclical motion of rising and falling. The moving-track curve of the cyclical motion of rising and falling of the scraper comprises a rising part moving-track curve and a return part moving-track curve, wherein the return part moving-track curve comprises at least a return part moving-track curve I and a return part curve II. The alpha angle between the return part moving-track curve I and the time coordinate is larger than the beta angle between the return part moving-track curve II and the time coordinate. According to this arrangement, a plurality of functions such as the motion of rising and falling of the scraper, the transverse moving of a sub-scraper and the adjustment of heights of the scraper and the sub-scraper can be achieved. The pancake making device has the advantages of high integration and degree of automation, thereby effectively ensuring pancake making time by the scraper and uniformity of pancakes. Accordingly, pancakes made by the pancake making device are thin, tough and delicious. Compared with the prior art, cereal pancakes can be made by the pancake making device, which is an innovation in the industry.

Owner:尹相善

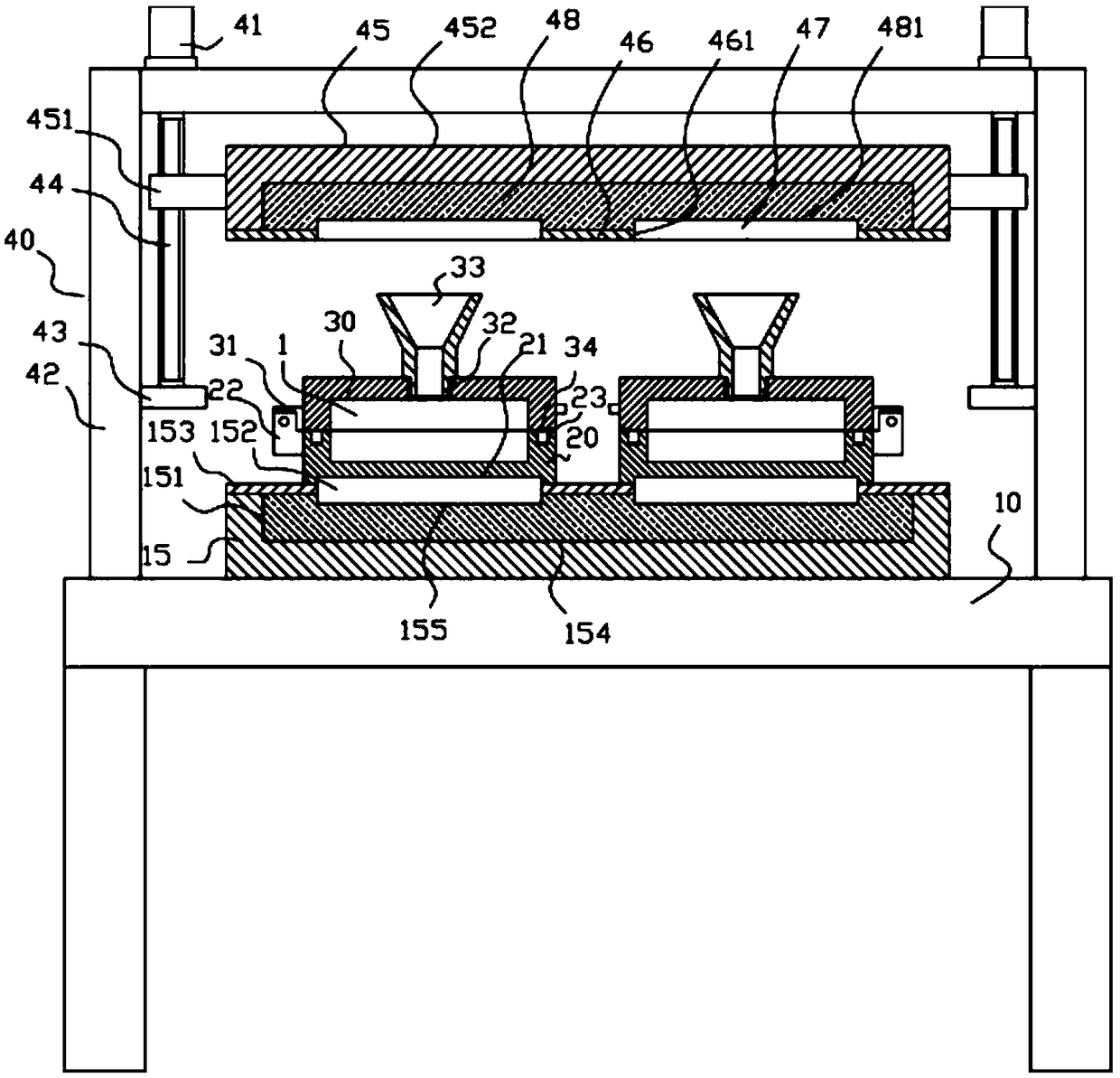

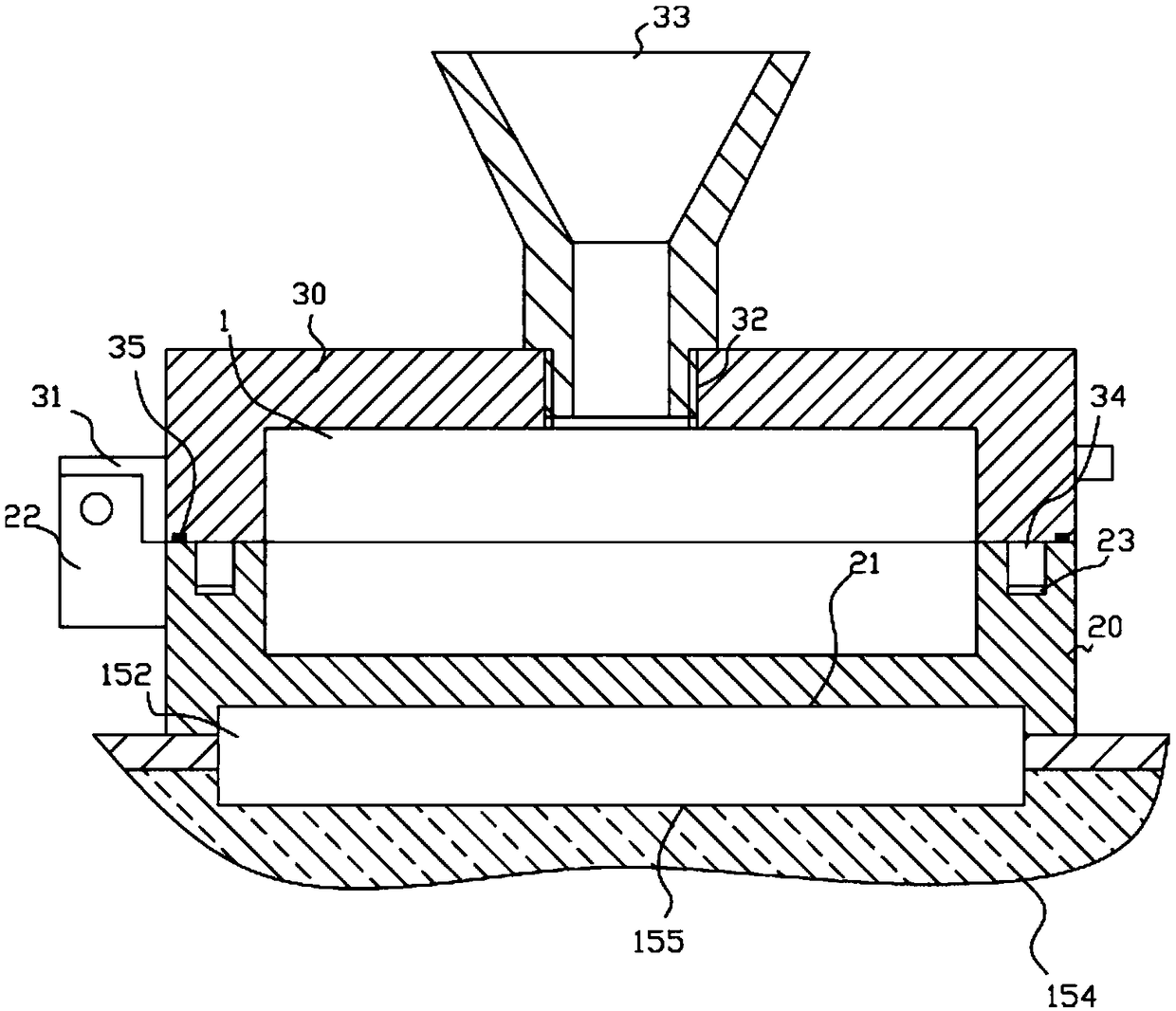

Pancake manufacturing device and operation method

InactiveCN107439624ABaked articles handlingOil/fat bakingMaterial resourcesUltimate tensile strength

The invention relates to a food processing equipment and its operating method, in particular to a pancake glutinous rice making equipment and its operating method. Present pancake glutinous rice balls are all artificially made, and there is a large labor intensity of personnel, and the human body as a potential source of pollution causes the pancake glutinous rice flour to have a hygienic hidden danger. The invention makes the pancake glutinous rice in a fully automatic way, without manual intervention in the production process to ensure hygiene, the thickness of the pancake is uniform, the production speed is fast, and it can be produced 24 hours a day, which greatly reduces the manpower and material resources required for making pancake glutinous rice Increased productivity and improved social efficiency.

Owner:邵萌

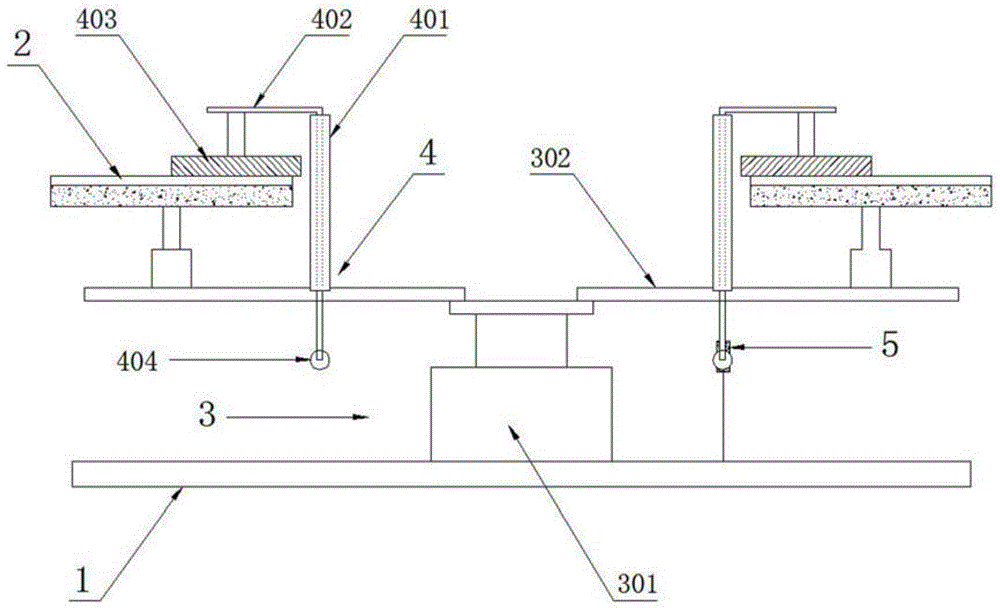

Double-sided heating type pancake machine

InactiveCN109122748ANice appearanceHeating evenlyOil/fat bakingPancakes bakingEngineeringSupport plane

The invention discloses a double-sided heating type pancake machine comprising a frame. A main bottom plate is fixed on the top surface of a top plate of the frame; a mounting groove is formed in themiddle part of the top surface of a main bottom frame; and heating blocks are fixed in the mounting groove. An upper support plate is fixed on the top surface of the main bottom frame; and the upper parts of the heating blocks extend out of a straight mounting slot of the upper support plate. Pancake bottom plates are fixed on the top surface of the upper support plate; and heating grooves are formed in the bottom of the pancake bottom plates. The upper part of the heating blocks are inserted and clamped into the heating grooves. Pancake top plates are hinged to the pancake bottom plates. An upper heating support frame is fixed on the top plate of the frame; adjusting motors are fixed to the top surfaces of two sides of a main connecting plate of the upper heating support frame; lower connecting plates are fixed to the lower parts of support plates at two sides of the upper heating support frame; lower ends of adjusting screw rods are hinged to the lower connecting plates; and upper ends of the adjusting screw rods are hinged to the main connecting plate. With the double-sided heating type pancake machine, a double-sided three-dimensional pancake can be made and has the beautiful appearance; and heating uniformity is ensured without overturning.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

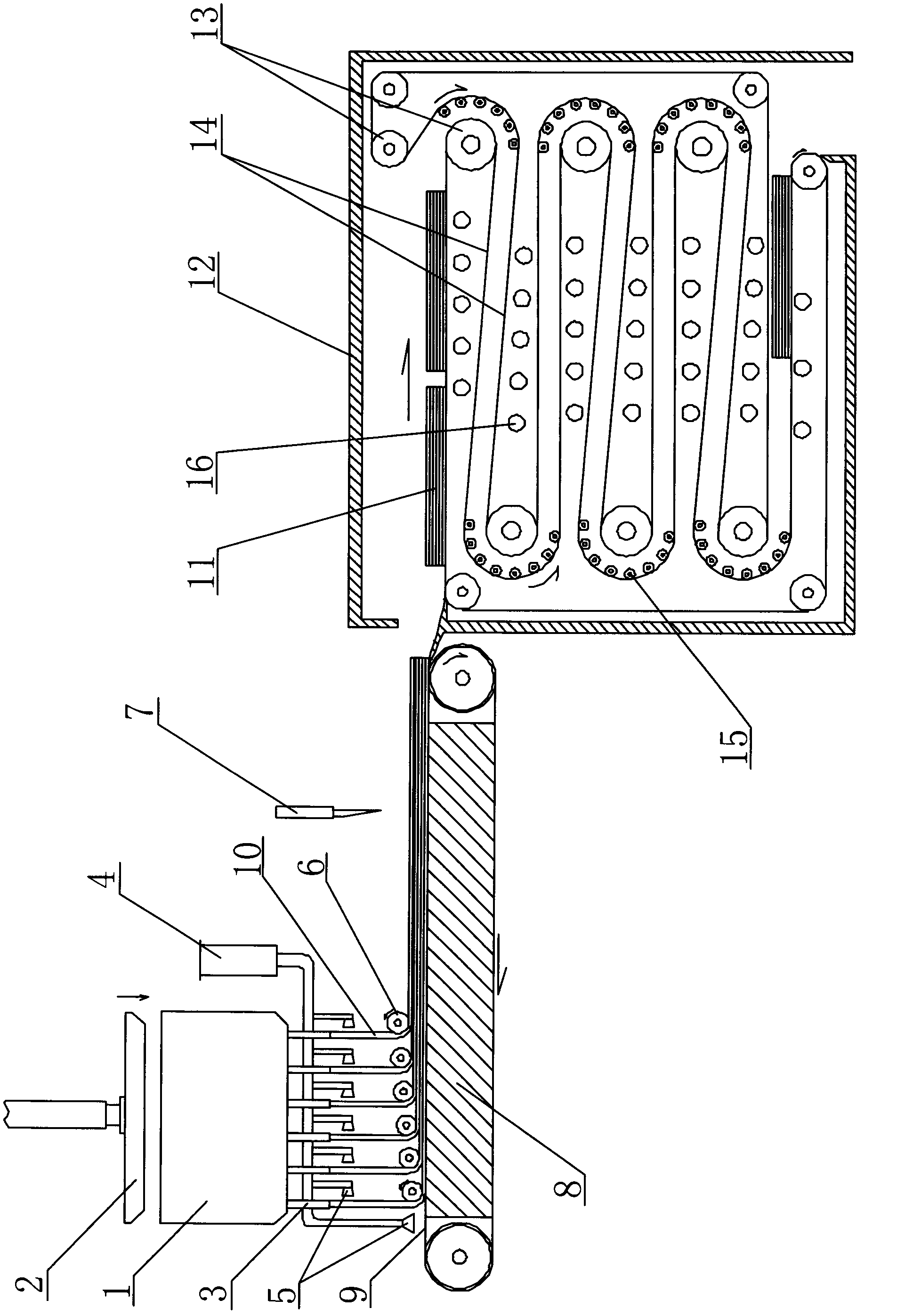

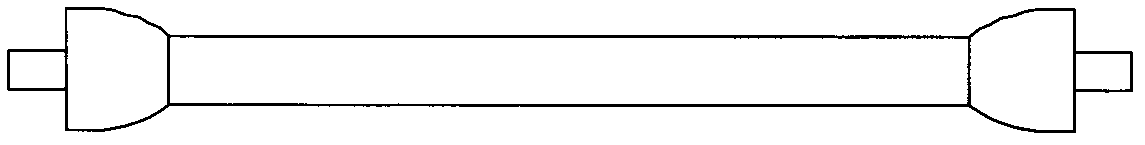

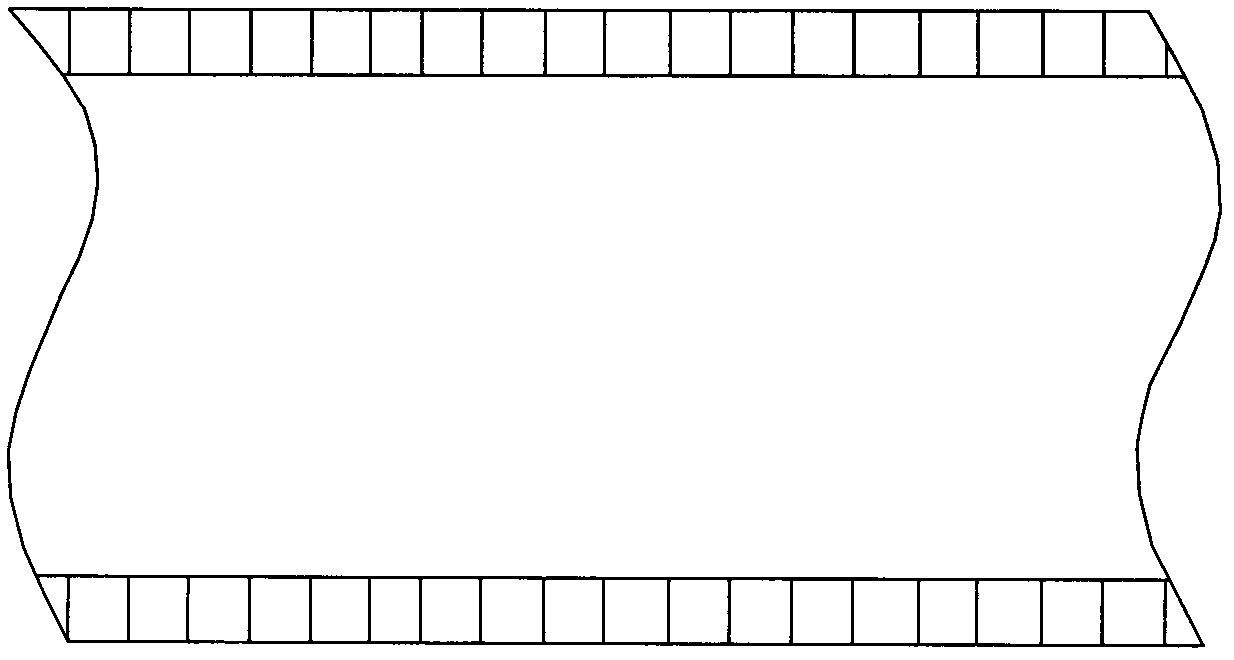

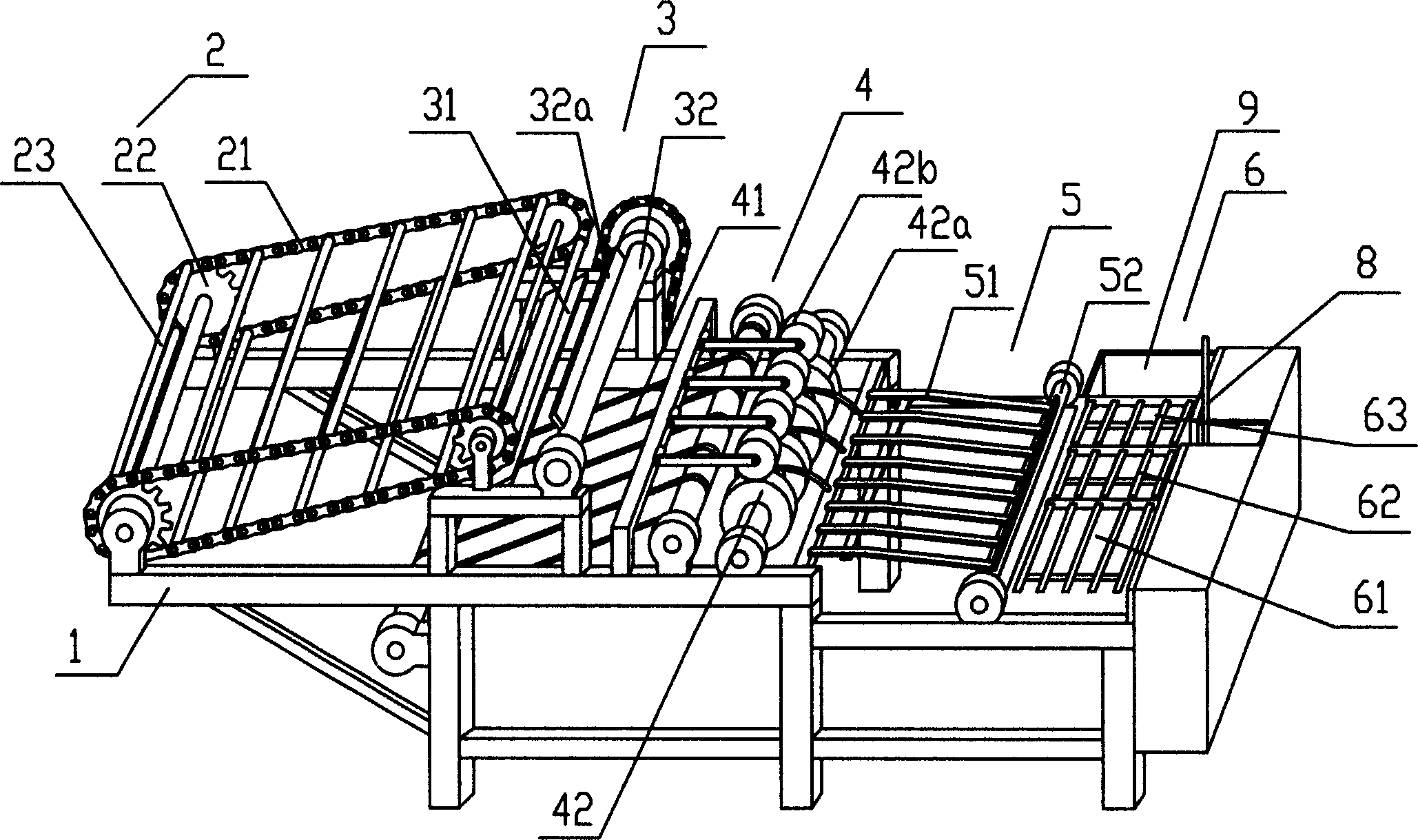

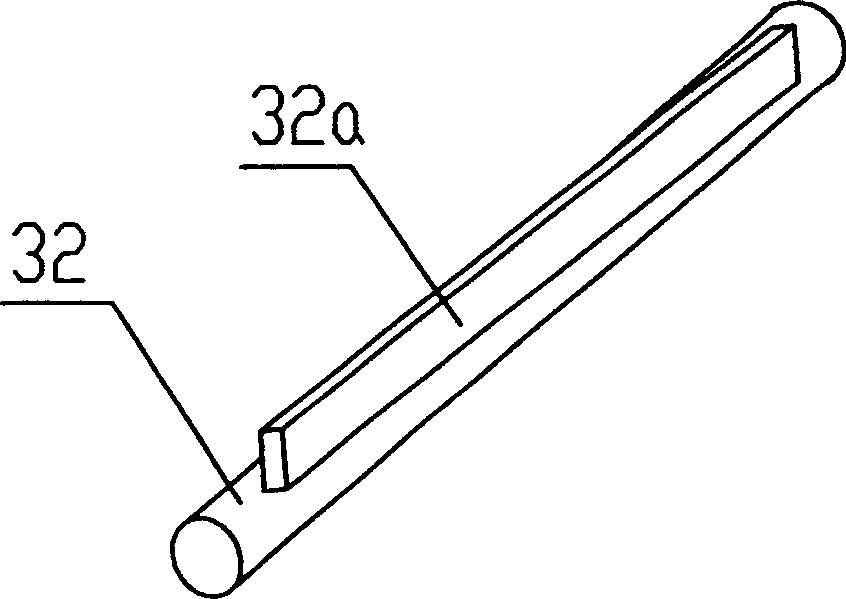

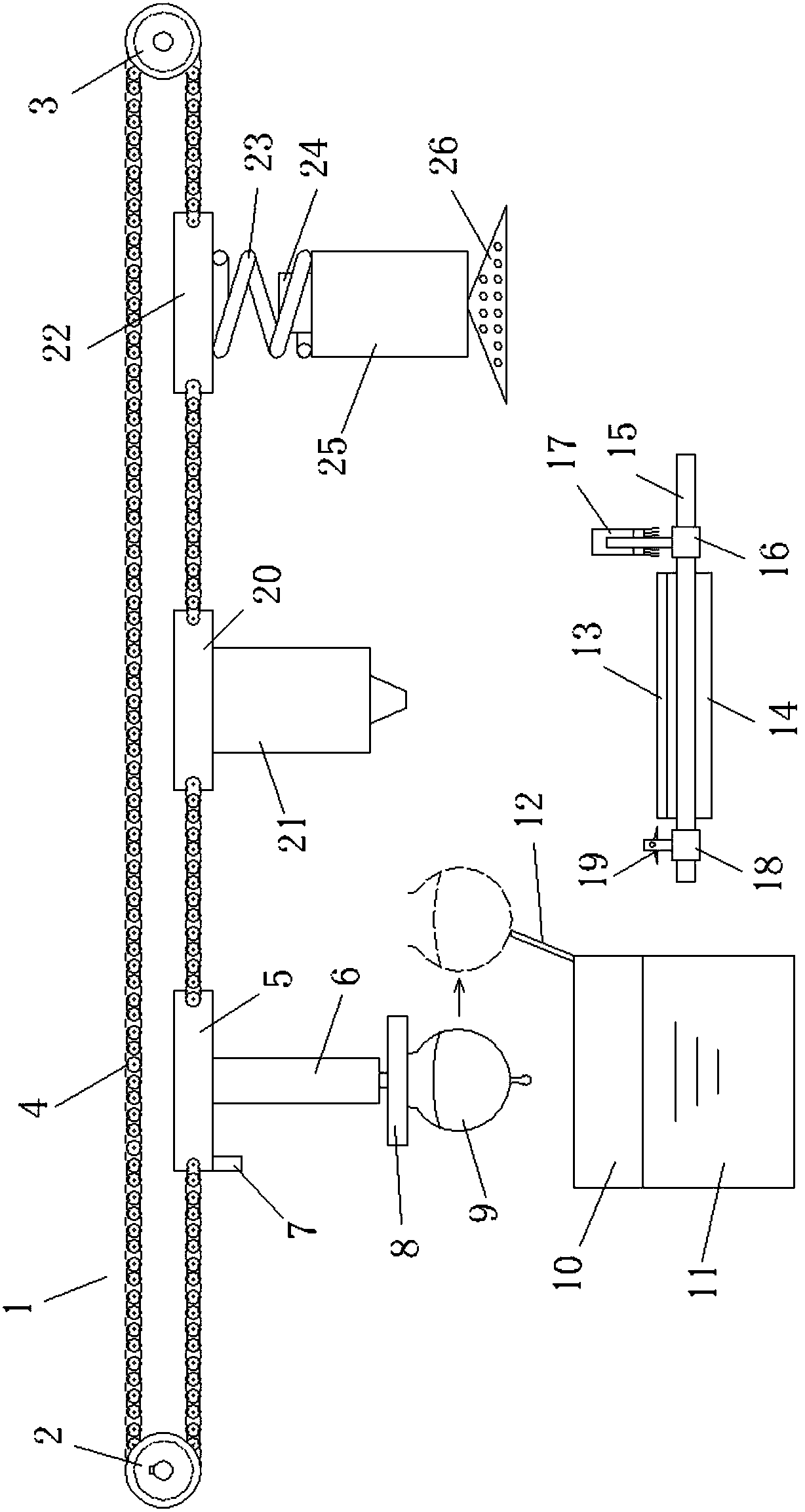

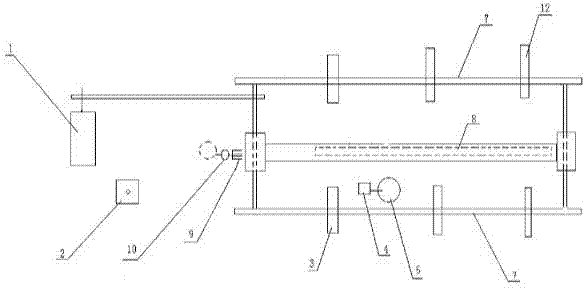

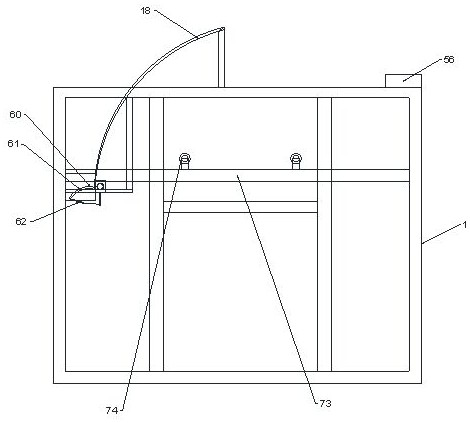

Fully automatic pancake cooking machine

InactiveCN102524344AAchieve mass productionGuaranteed tasteOil/fat bakingBakery productsButt jointSprocket

The invention relates to food processing equipment, in particular to a fully automatic pancake cooking machine, which mainly consists of a pancake making mechanism and a pancake cooking box, wherein the pancake making mechanism mainly comprises a facet making device, a facet oil spraying device, a facet guiding and pressing device, a transmission support table and a pancake fixing and cutting device, the pancake cooking box comprises a case with a pancake outlet and a pancake inlet, two parallel pancake conveying belts which are driven by a chain wheel and have a certain spacing are arranged in the case, and the two pancake conveying belts form continuous S-shaped paths through the chain wheel and a positioning supporting and pulling roller tooth, so a plurality of transmission layers are formed, electric heating pipes are arranged among all transmission layers, and the transmission tail end of the transmission support table of the pancake making mechanism is in butted joint with the pancake inlet of the pancake cooking box through connecting plates. The fully automatic pancake cooking machine has the effect and the obvious advantages that the traditional manual pancake making and pancake cooking processes can be completely replaced, the labor is saved, and in addition, the production efficiency is improved, so the mass production of the pancake cooking can be realized in a short time, and in addition, the mouth feeling and the quality can be ensured.

Owner:张志杰

Full-automatic intelligent pancake baking machine

InactiveCN104663751AHigh degree of automationImprove intelligencePancakes bakingBaking plantsHeating timeProcess engineering

Owner:余安涛

Equipment for cutting and folding flap jack

InactiveCN1600105AEasy to useReduce pollutionOil/fat bakingPancakes bakingProduction rateEngineering

A cutting-folding machine for thin pancake is composed of the first conveyer for conveying the thin pancake to cutting unit, the cutting unit for cutting the thin pancake by defined sizes, the second conveyer for conveying the cut pancake to its holder for pressing the pancake onto folding unit, and the folding unit with three folding plates for folding the pancake twice.

Owner:徐江军

Food folding equipment

ActiveCN108925596AImprove efficiencyImprove folding efficiencyConveyorsBaked articles handlingAssembly lineEngineering

The invention discloses food folding equipment. The food folding equipment comprises a cake transporting unit for transporting cakes and a cake folding unit for folding the cakes. Through adoption ofthe food folding equipment provided by the invention, the automation degree of the processing of the cakes is increased, the product quality is improved, and the processing and making cost of the products is reduced; and the food folding equipment is particularly suitable for assembly lines and large-scale production, and has favorable application prospect.

Owner:泾县集知佳工业设计有限公司

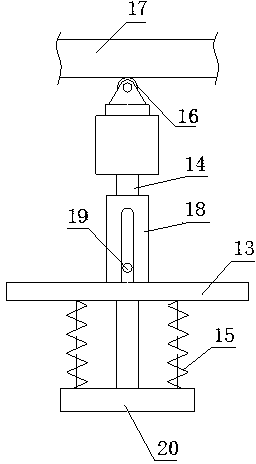

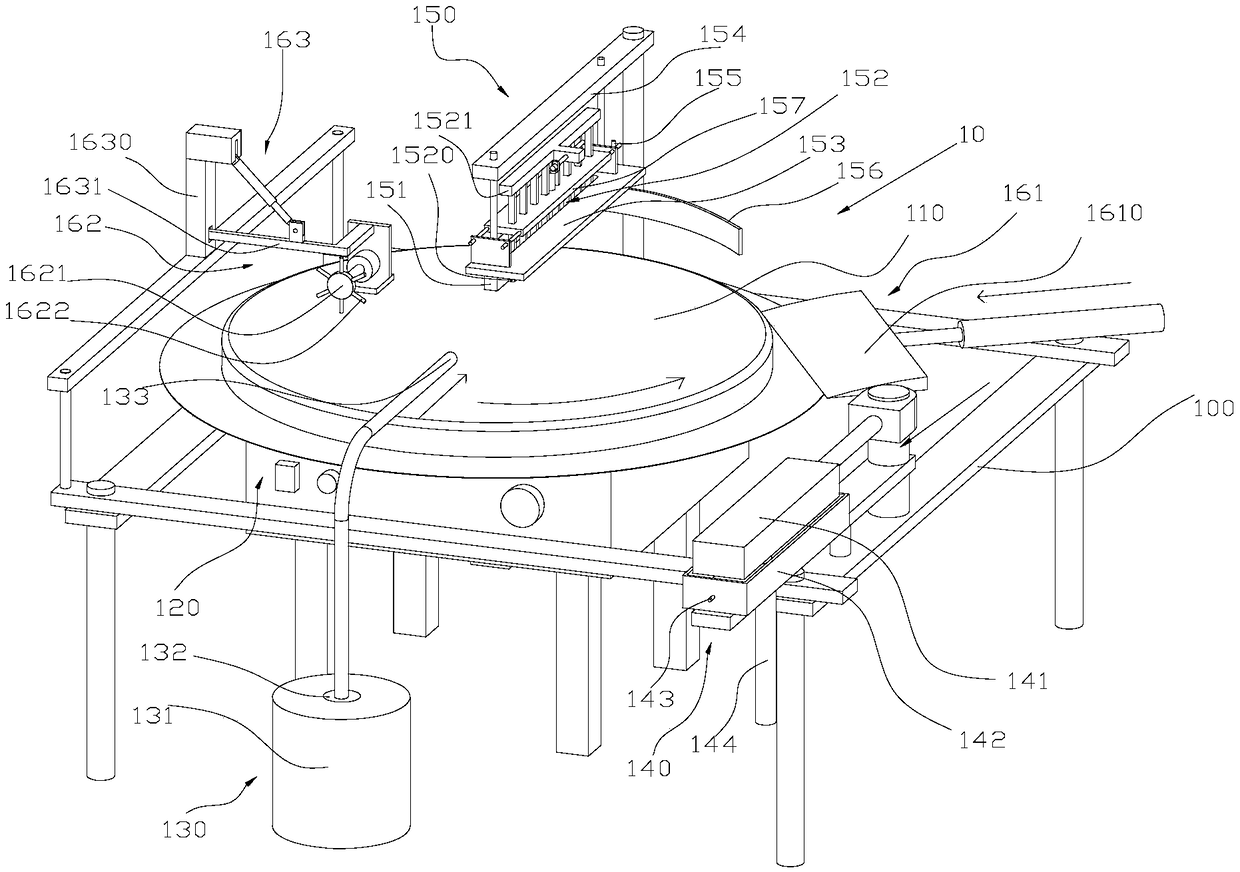

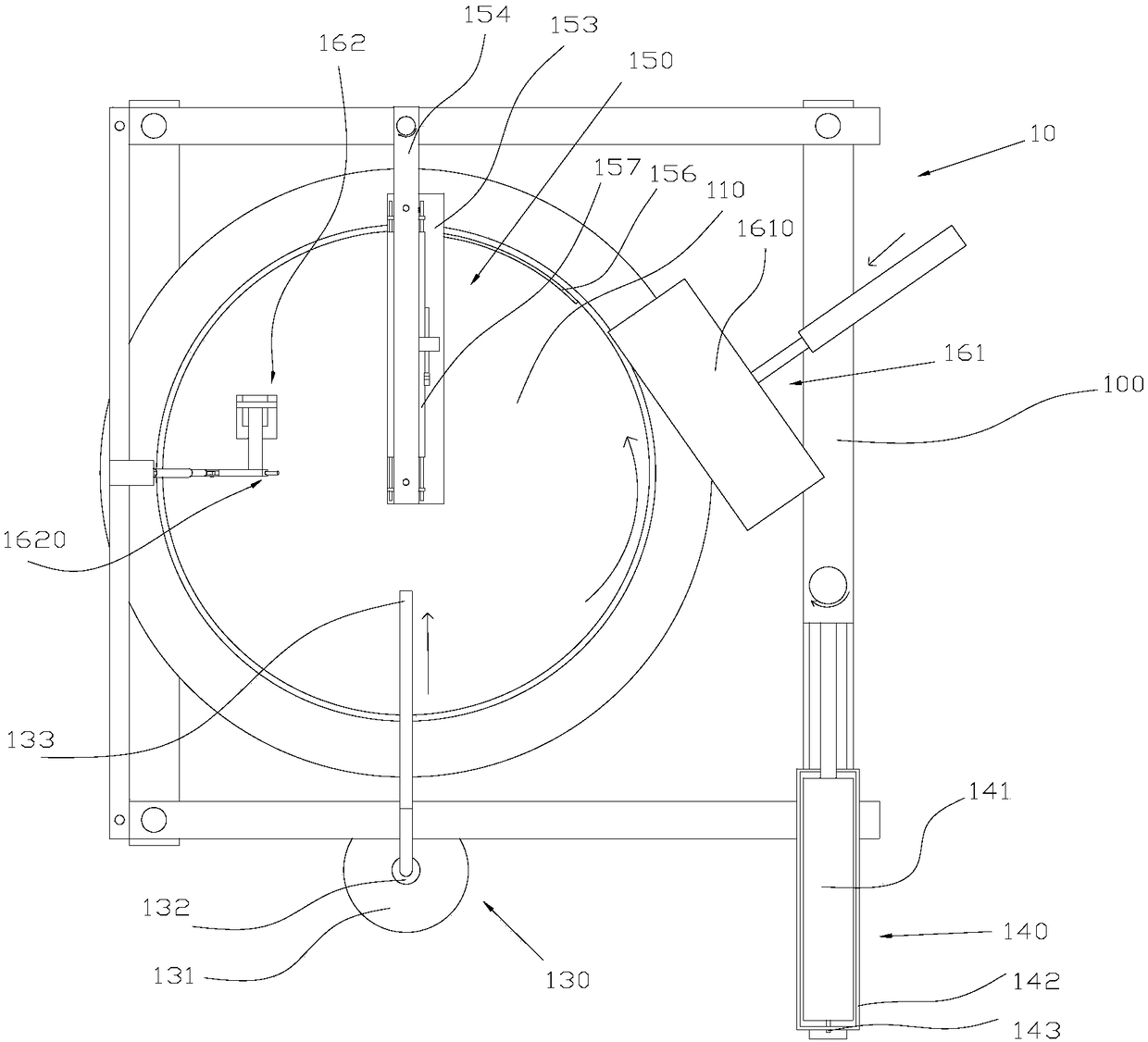

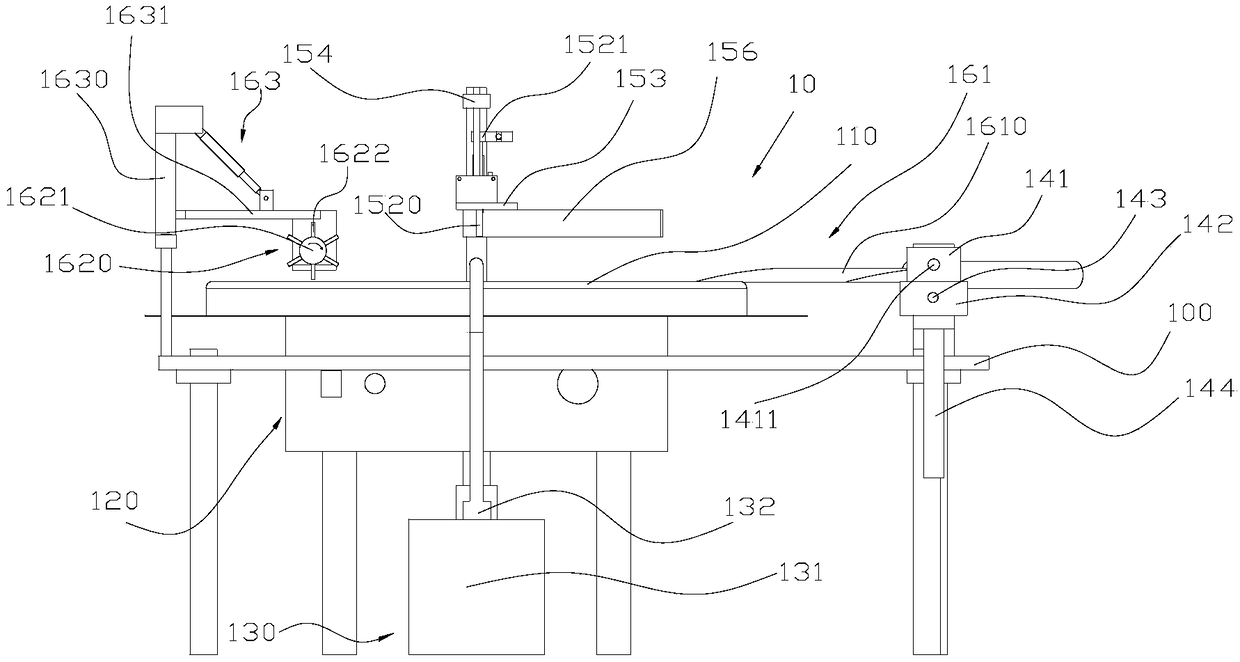

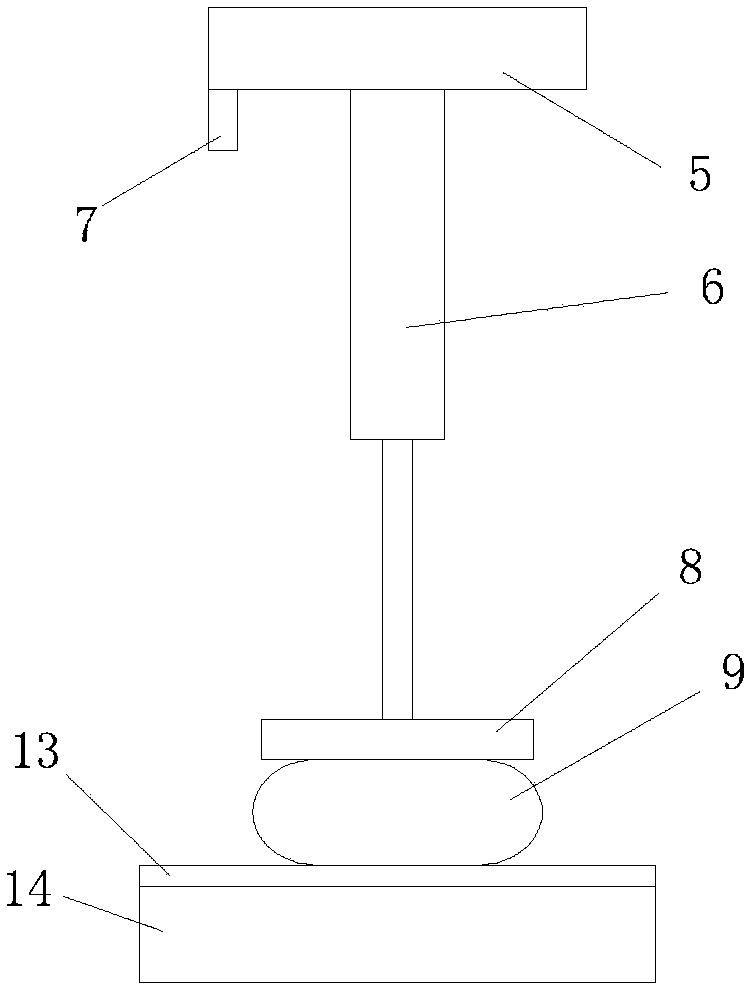

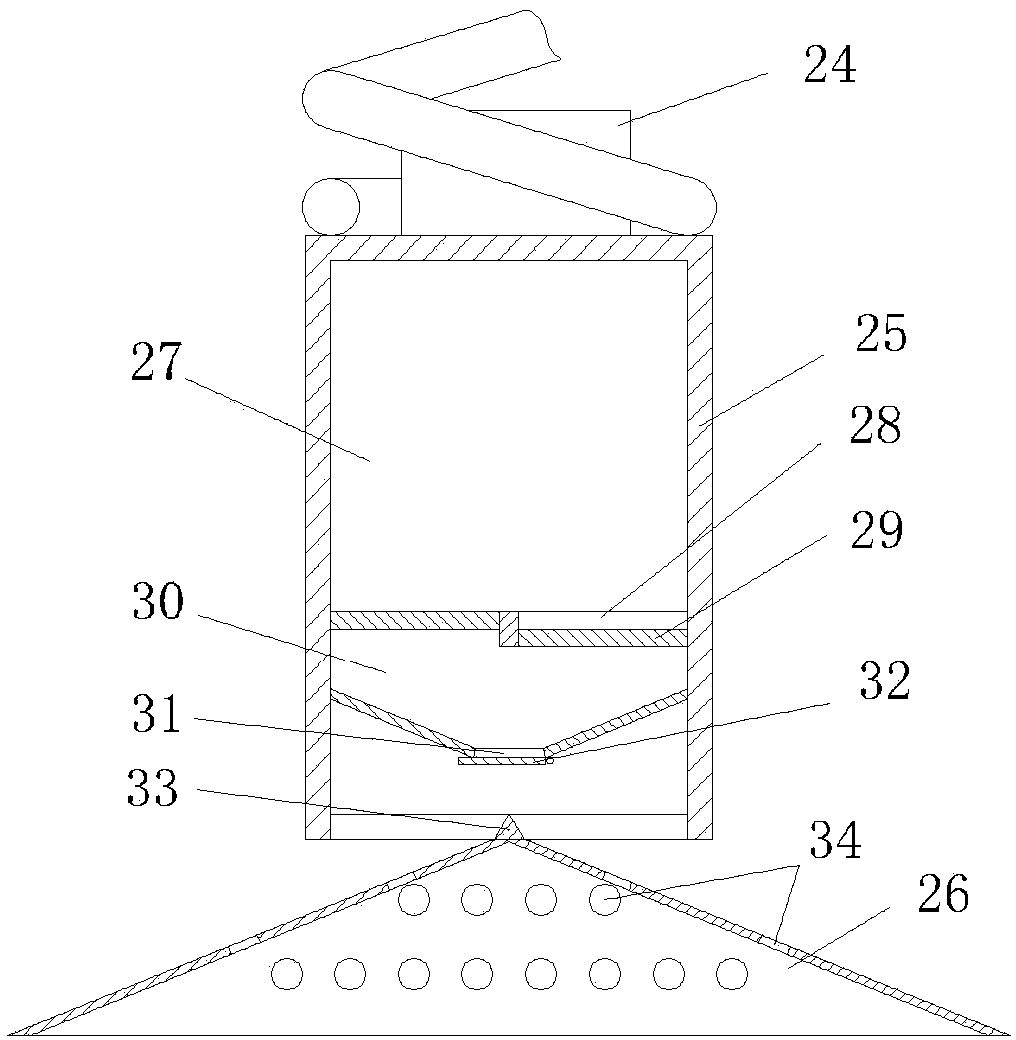

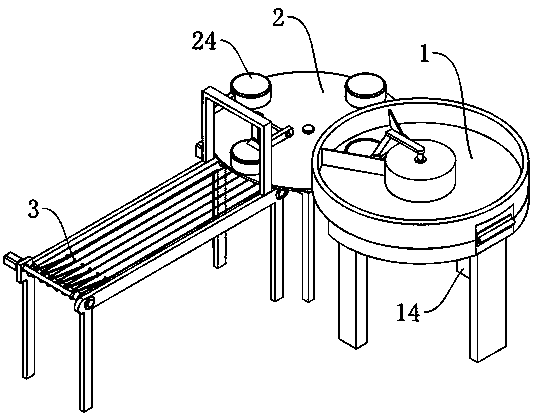

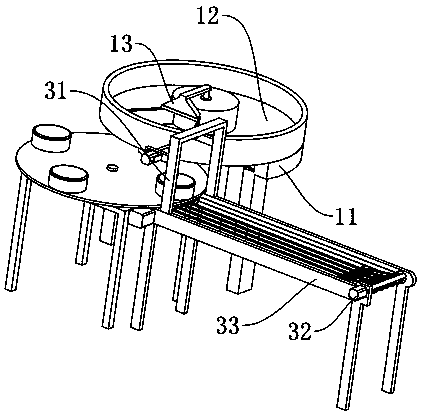

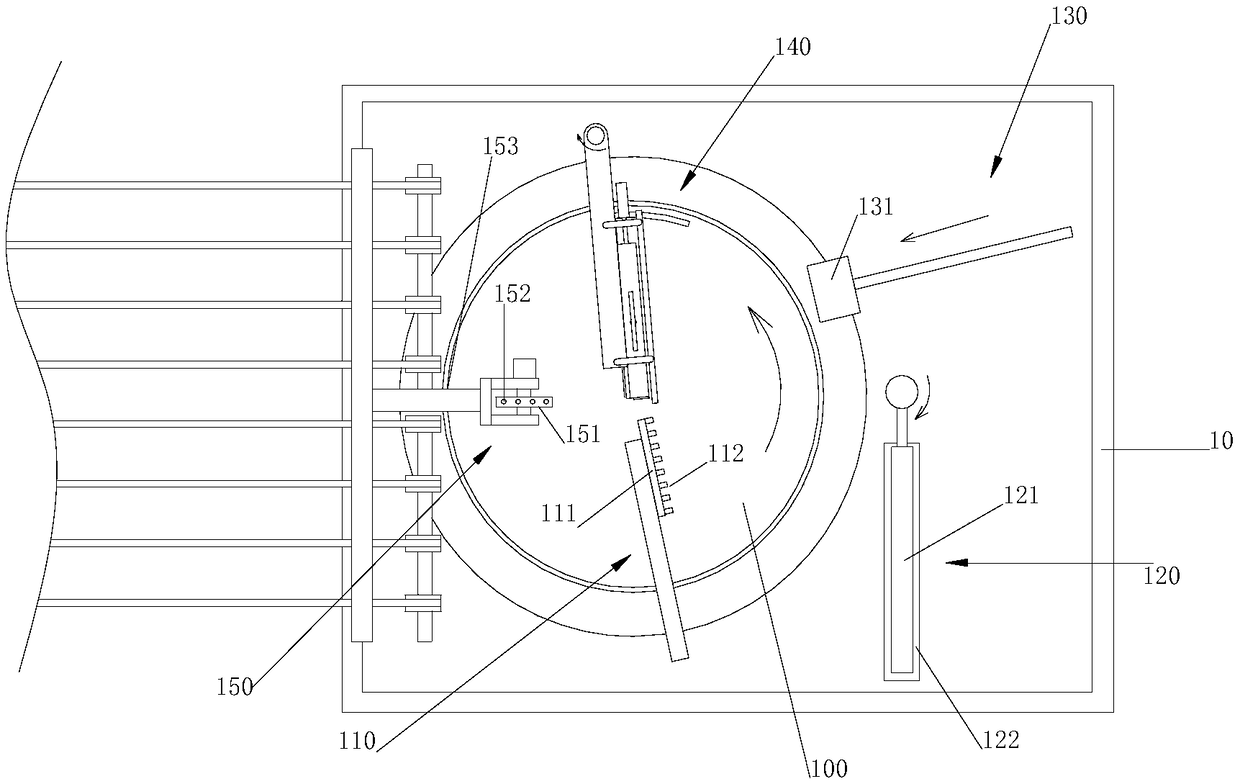

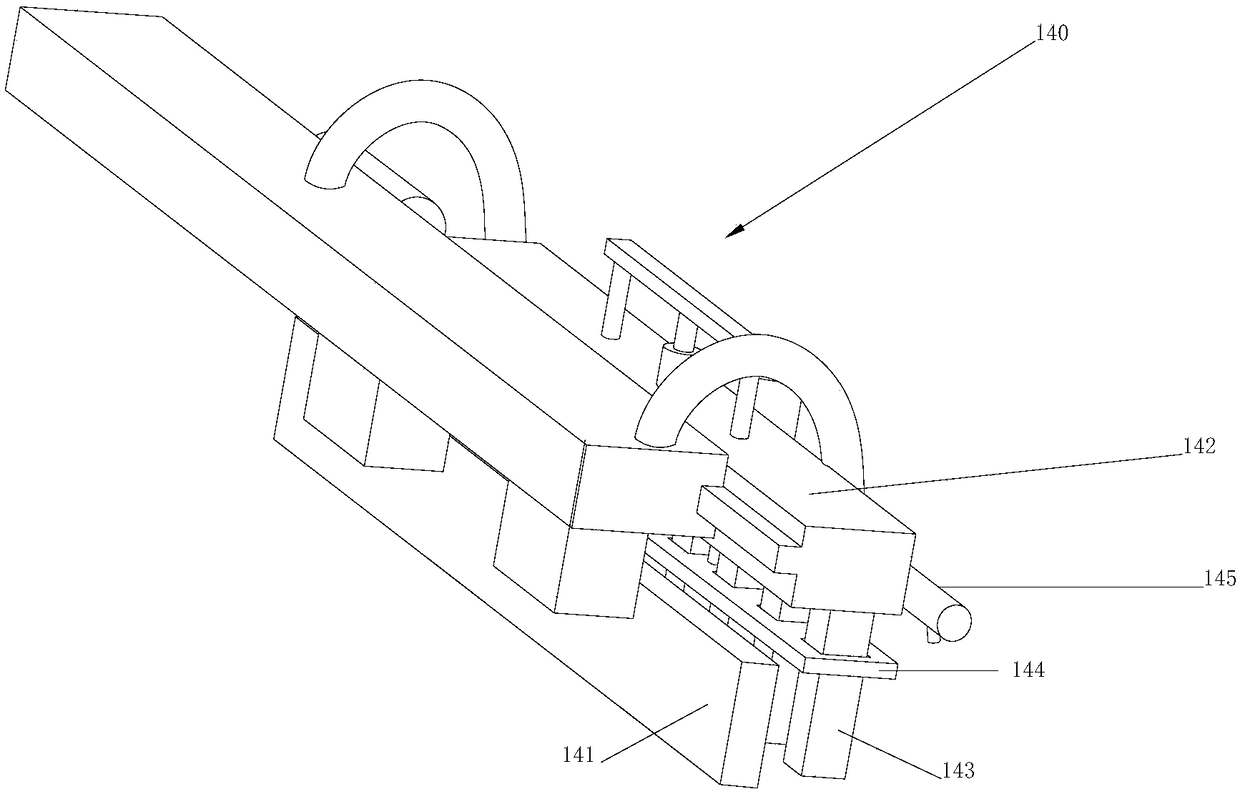

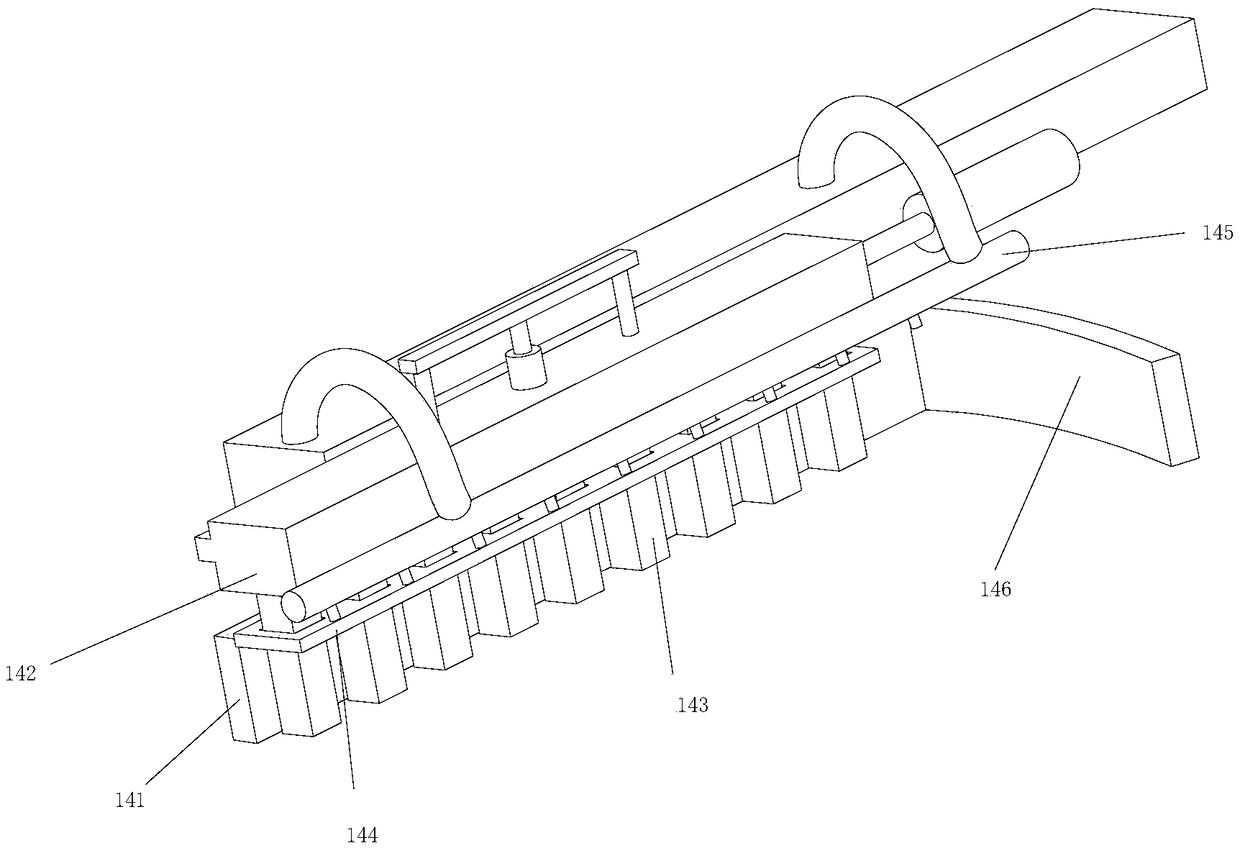

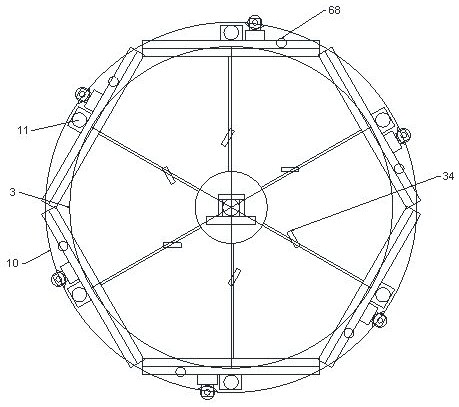

Fully-automatic line production type multi-griddle pancake machine

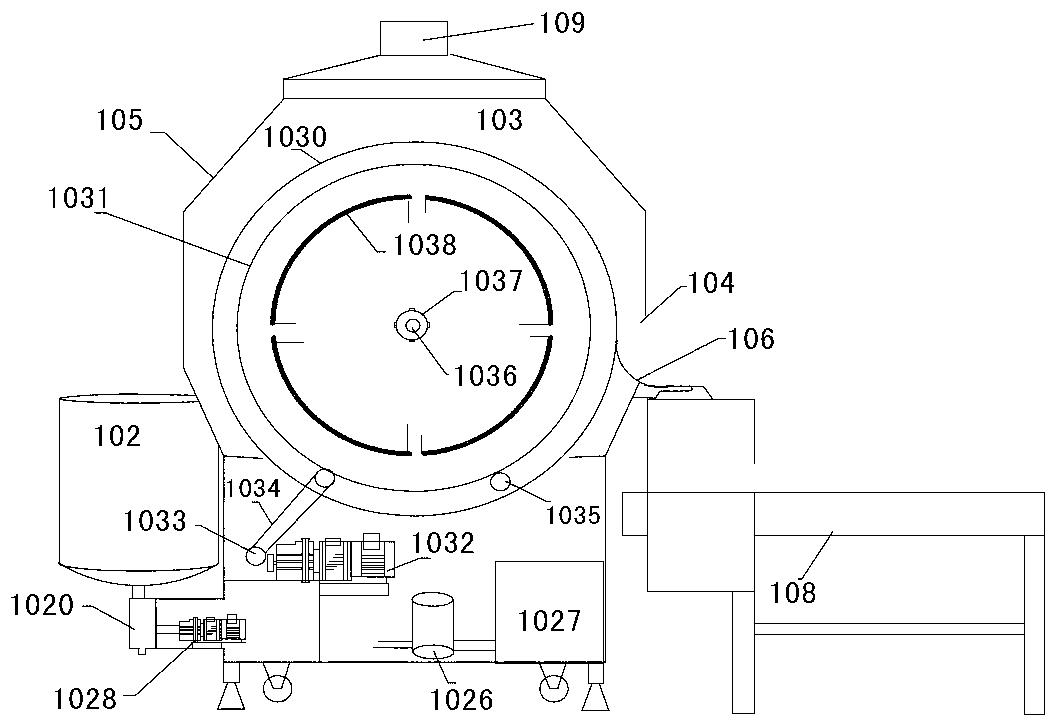

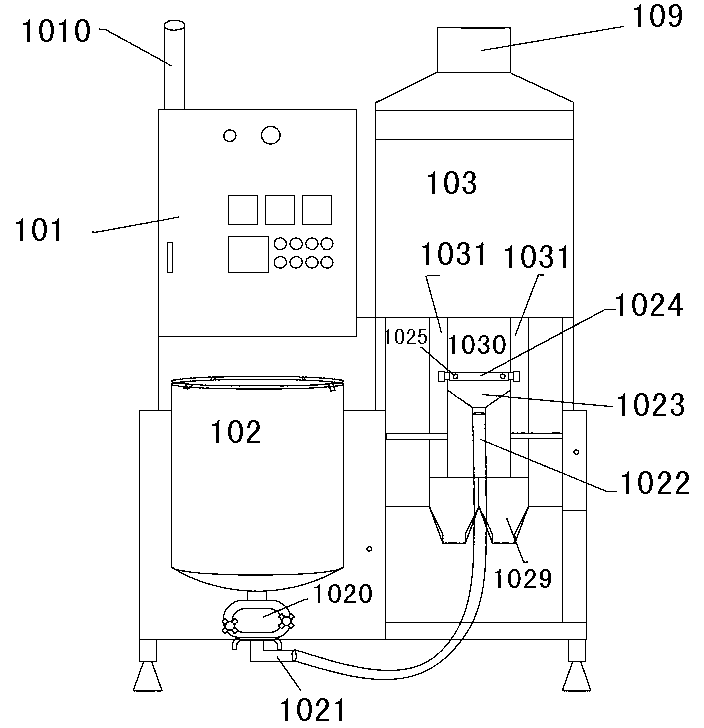

InactiveCN104824080AHigh degree of automationEasy to operateCylindrical cake bakingPancakes bakingEngineeringFully automatic

The invention discloses a fully-automatic line production type multi-griddle pancake machine. The fully-automatic line production type multi-griddle pancake machine is characterized by comprising a griddle rotary device, multiple griddles, multiple paste scraping devices, multiple paste homogenizing mechanisms, a fixed point ascending and descending table, a scraper and propelling device, a pancake grasping and conveying device, an oil applying device and a paste spraying device, wherein the multiple griddles rotate around the griddle rotary device and rotate by themselves; the multiple paste scraping devices and the multiple paste homogenizing mechanisms are matched with the griddles; the fixed point ascending and descending table is used for lifting and putting down the paste scraping devices at a fixed point; the scraper and propelling device, the pancake grasping and conveying device, the oil applying device and the paste spraying device are linked with the griddle rotary device and provide a continuous production process of line production type lifting up, grasping, oil applying and pancake paste spraying in the rotary process of the griddle rotary device. The fully-automatic line production type multi-griddle pancake machine has the advantages that the degree of automation is high, operation is easy, production efficiency is high due to the line production type, one machine can finish paste spraying, making and lifting up of pancakes, any coarse cereals can be made into pancakes through multiple times of rotary scraping, pancakes have better texture and are good in taste, machine making of pure coarse cereal pancakes is really achieved, and made pancakes have the quality of manual pancakes.

Owner:郭玉良 +1

Thin pancake machine

The invention provides a thin pancake machine. The thin pancake machine comprises a flat iron plate, a starch adhesive barrel, a material dipping device and a conveying device, wherein the material dipping device is mounted on the conveying device, and comprises a material dipping head which can be extruded to be deformed and an extruding mechanism; micro holes which can adhere starch adhesive areformed in the surface of the material dipping head; and the extruding mechanism cooperates with the flat iron plate, so that the material dipping head can be extruded until the material dipping headis deformed, and the adhered starch adhesive is flat spread on the flat iron plate. Through adoption of the thin pancake machine disclosed by the invention, thin pancakes can be automatically made, sothat labor is saved, and the efficiency is high.

Owner:邵嘉阳

Fully-automatic pancake maker capable of realizing single-piece production and customization

The invention provides a fully-automatic pancake machine capable of realizing single-piece production and customization. The fully-automatic pancake machine comprises a hopper, a flat iron plate, an egg adding device, a vegetable box, a folding table, a sausage adding device and a bagging device, wherein the hopper integrally moves on an assembly beam; a bevel ring gear is mounted at the bottom ofthe flat iron plate and is driven by a small motor to rotate; a shovel rod is arranged on the left side of the flat iron plate and a scraping plate is arranged on the right side of the flat iron plate; the egg adding device comprises an egg storage box and an egg sucking device; belt pulleys are respectively mounted at the top and the inner part of the egg storage box; a belt is mounted on the belt pulleys; egg grids are arranged on the surface of the belt; the egg sucking device and the hopper are assembled together; the folding table is mounted on the right side of the flat iron plate; a flipping device and the hopper are mounted together, and the flipping device is suspended above the flat iron plate and the folding table; the vegetable box is mounted above the folding table; a sausagesupporting plate is arranged on a chain of the sausage adding device; the sausage supporting plate is connected with a negative pressure device; and the bagging device is mounted below turn-down plates under the folding table. According to the scheme disclosed by the invention, processes from feeding to obtaining finished products are all completed by a mechanical structure; the fully-automatic pancake machine is high in automation degree and capable of supporting customization of flavor; and pancakes are not exposed to the external environment before being made into finished products, so that the pancakes are clean and sanitary.

Owner:宗文涛

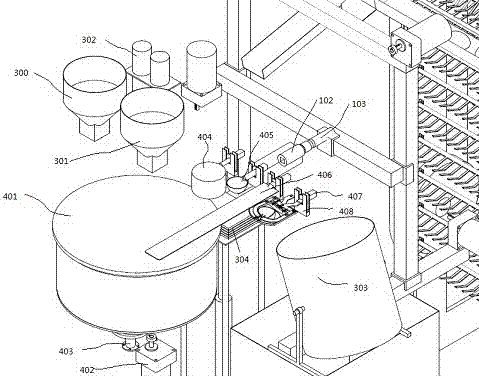

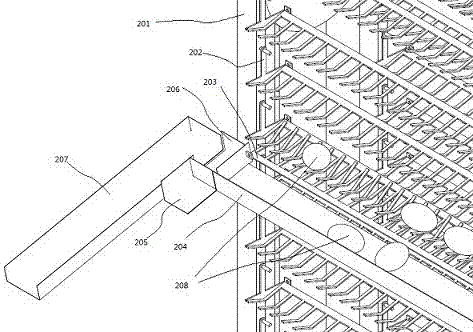

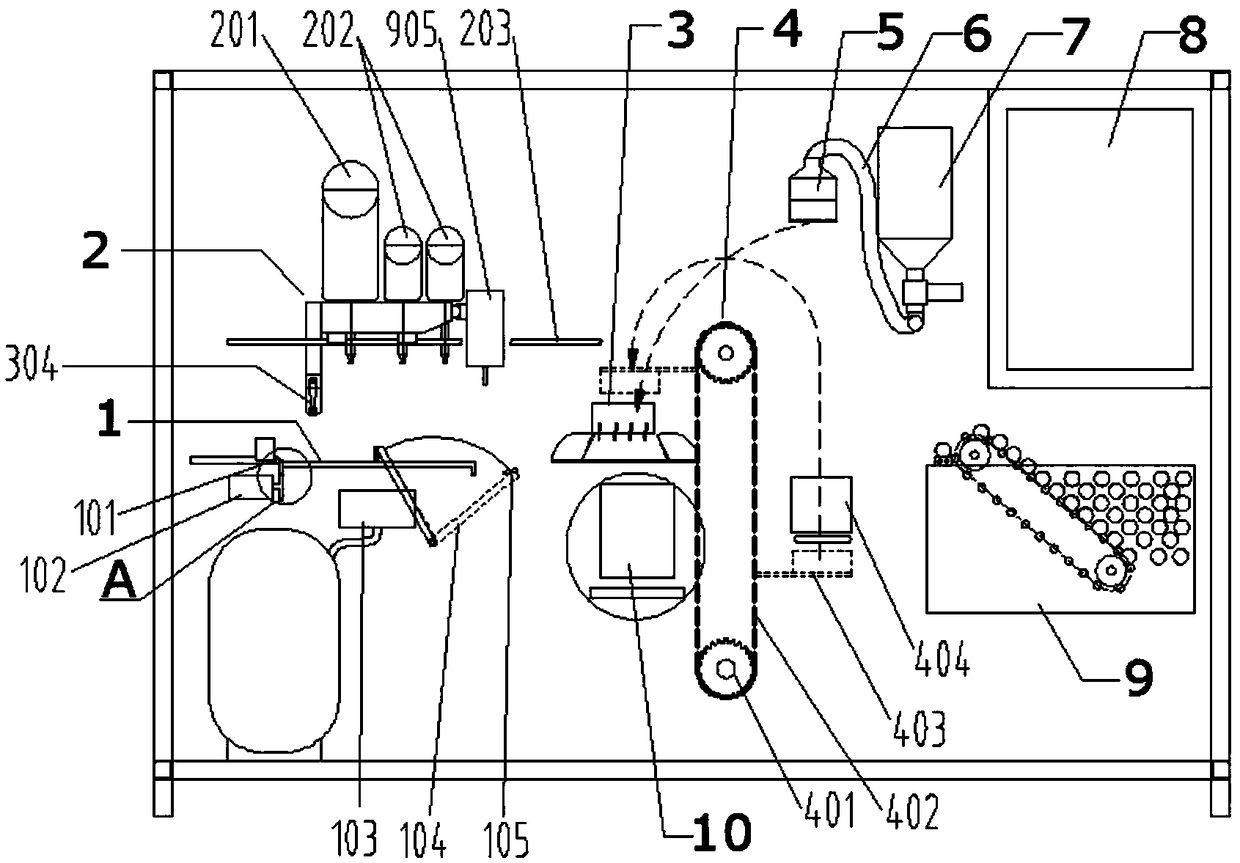

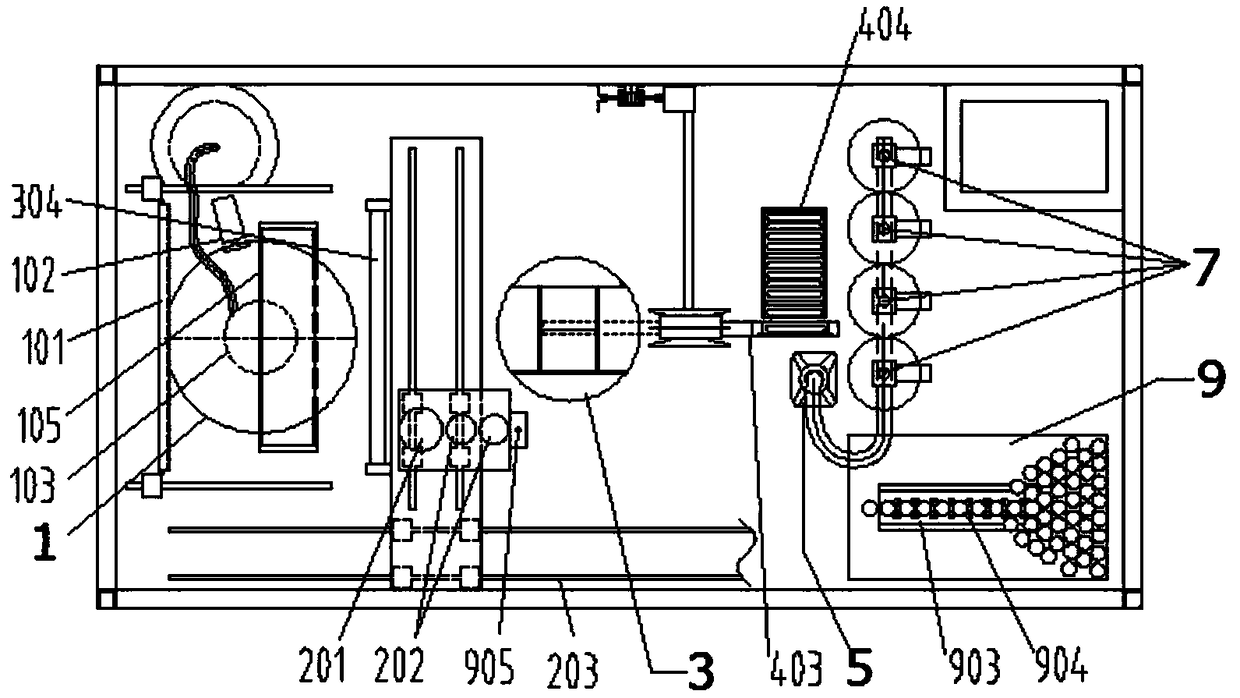

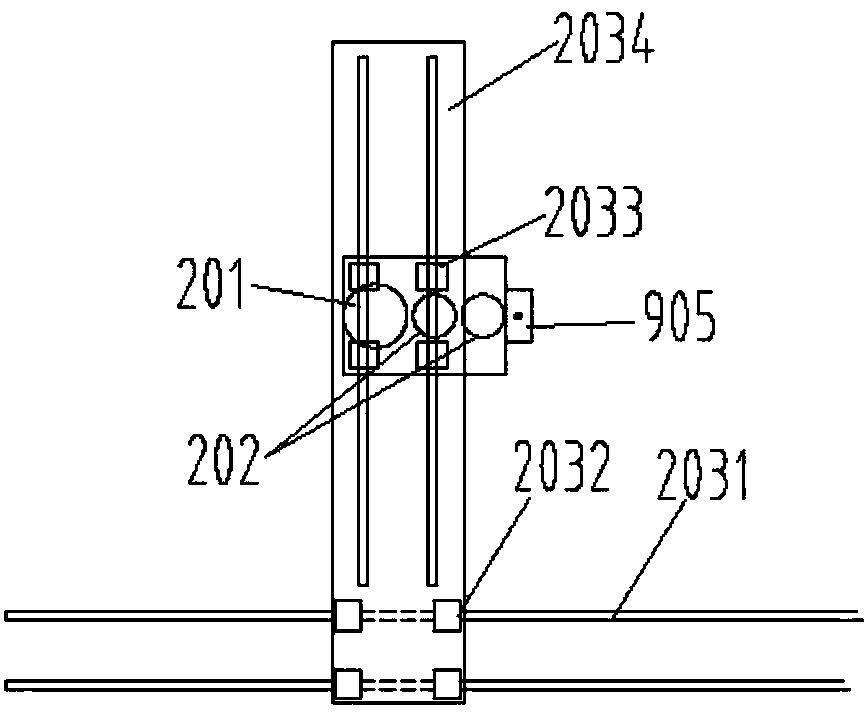

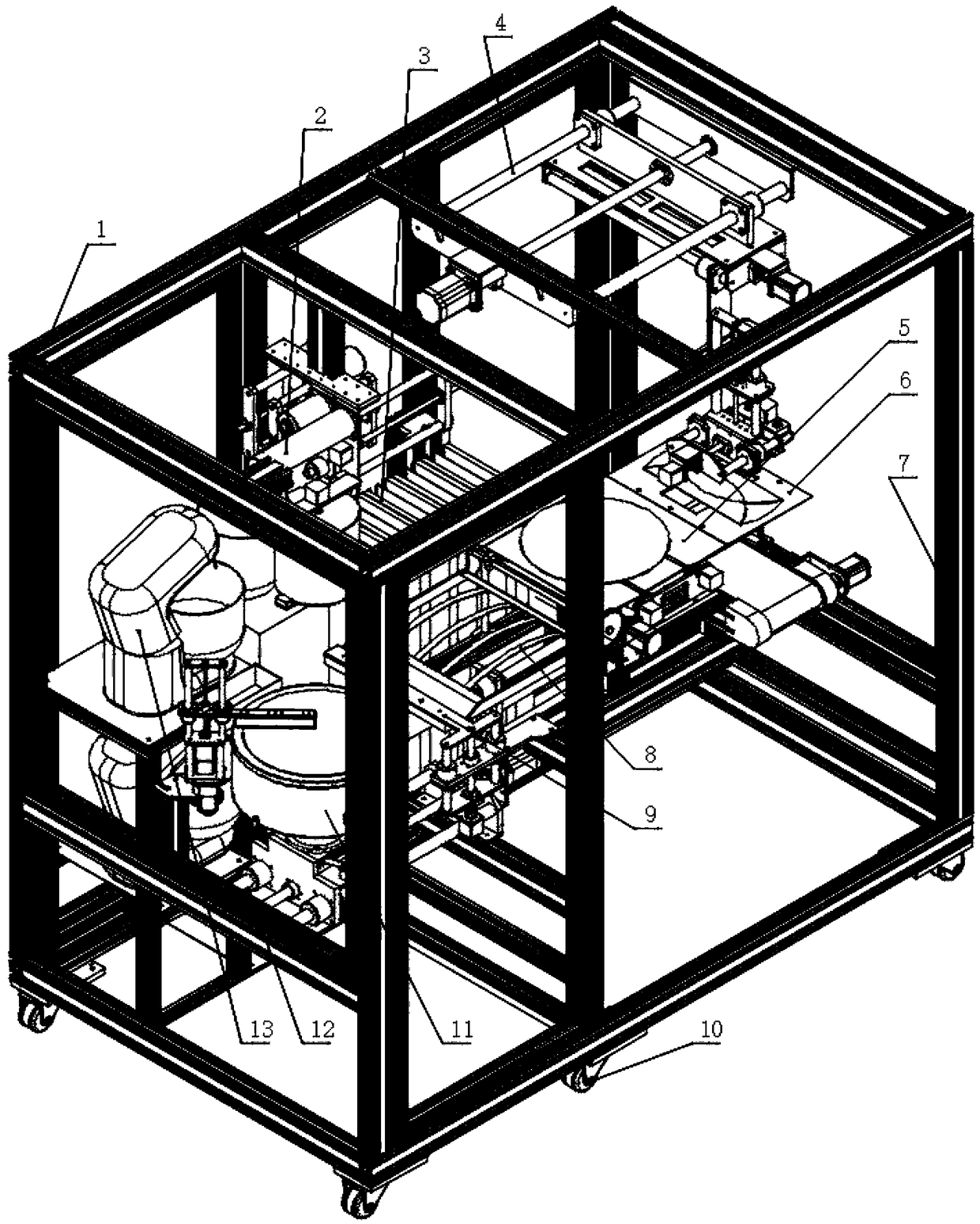

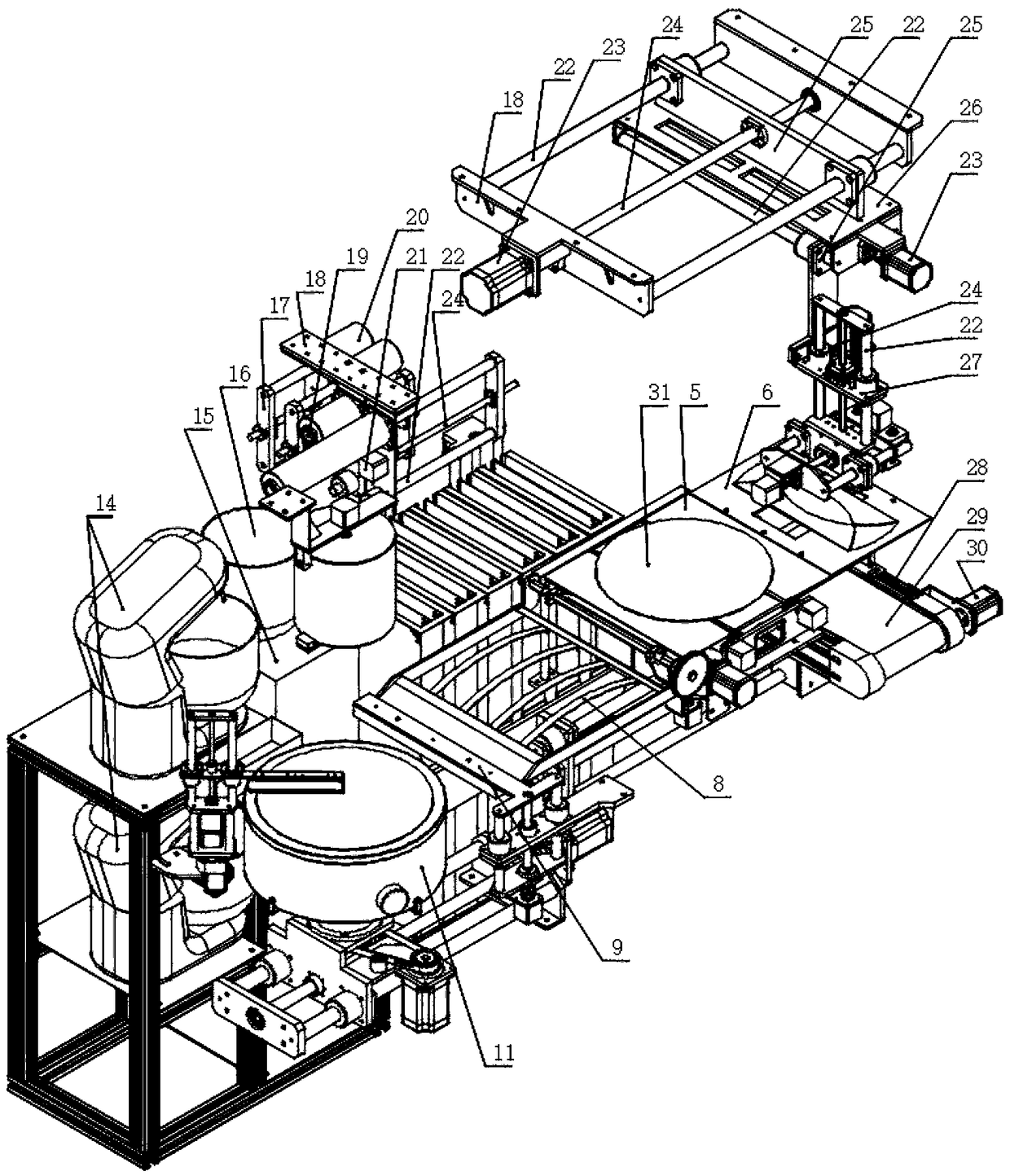

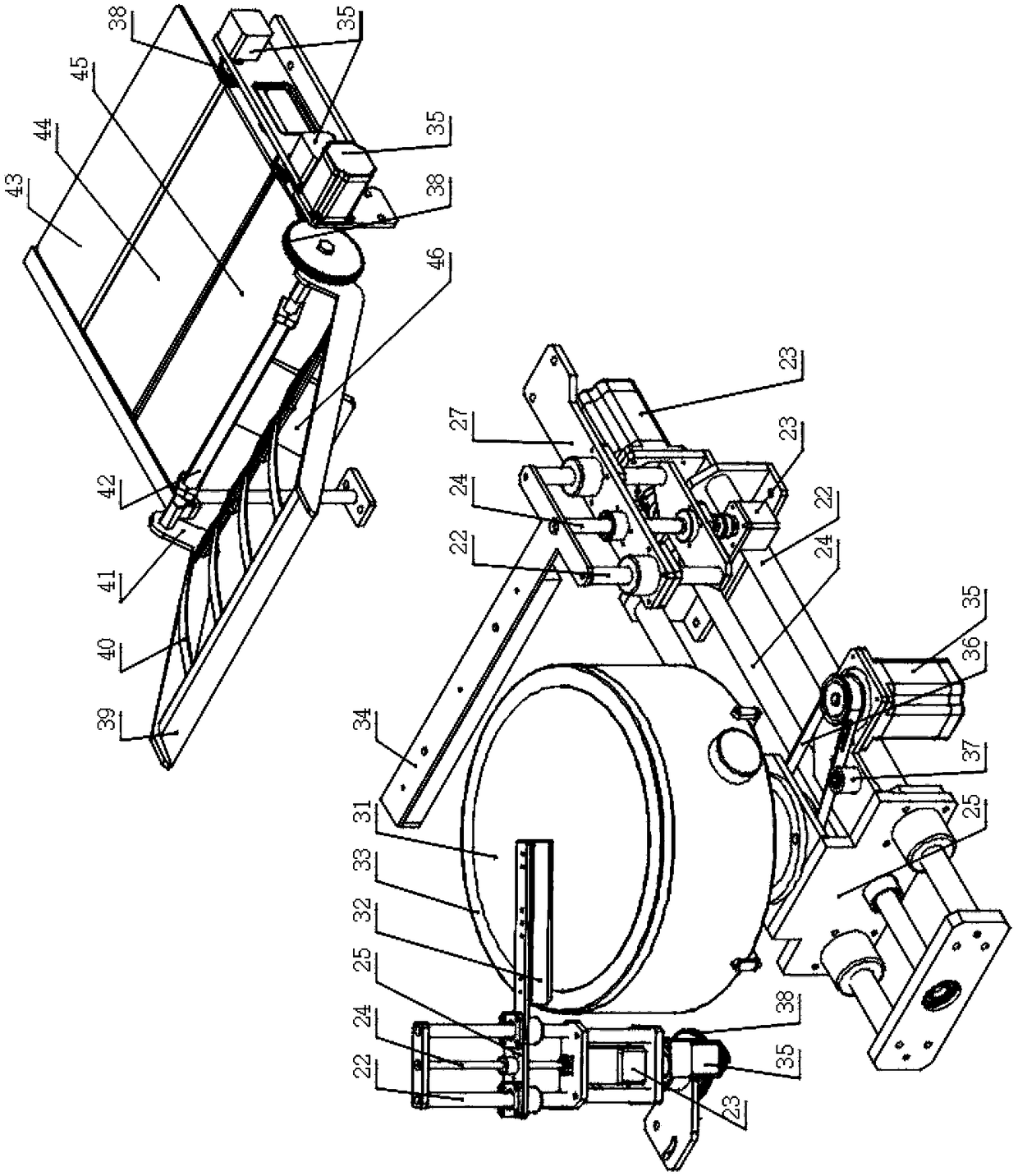

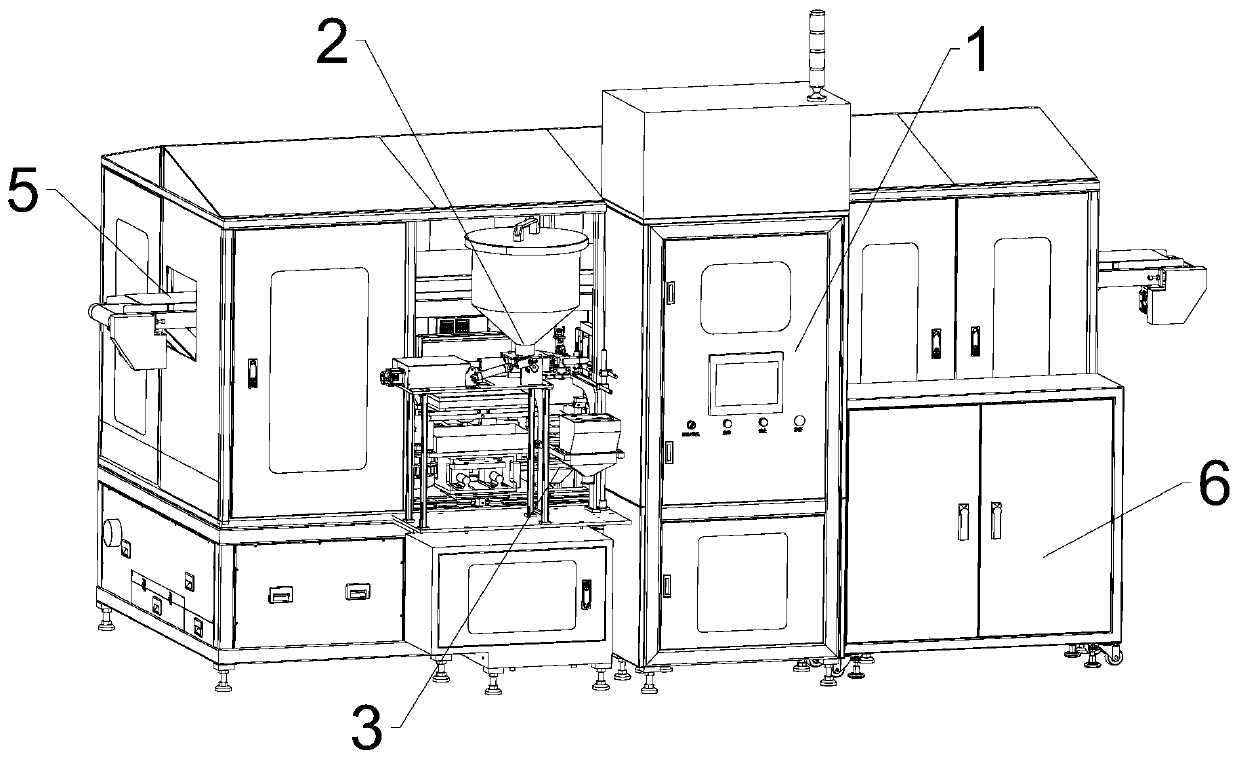

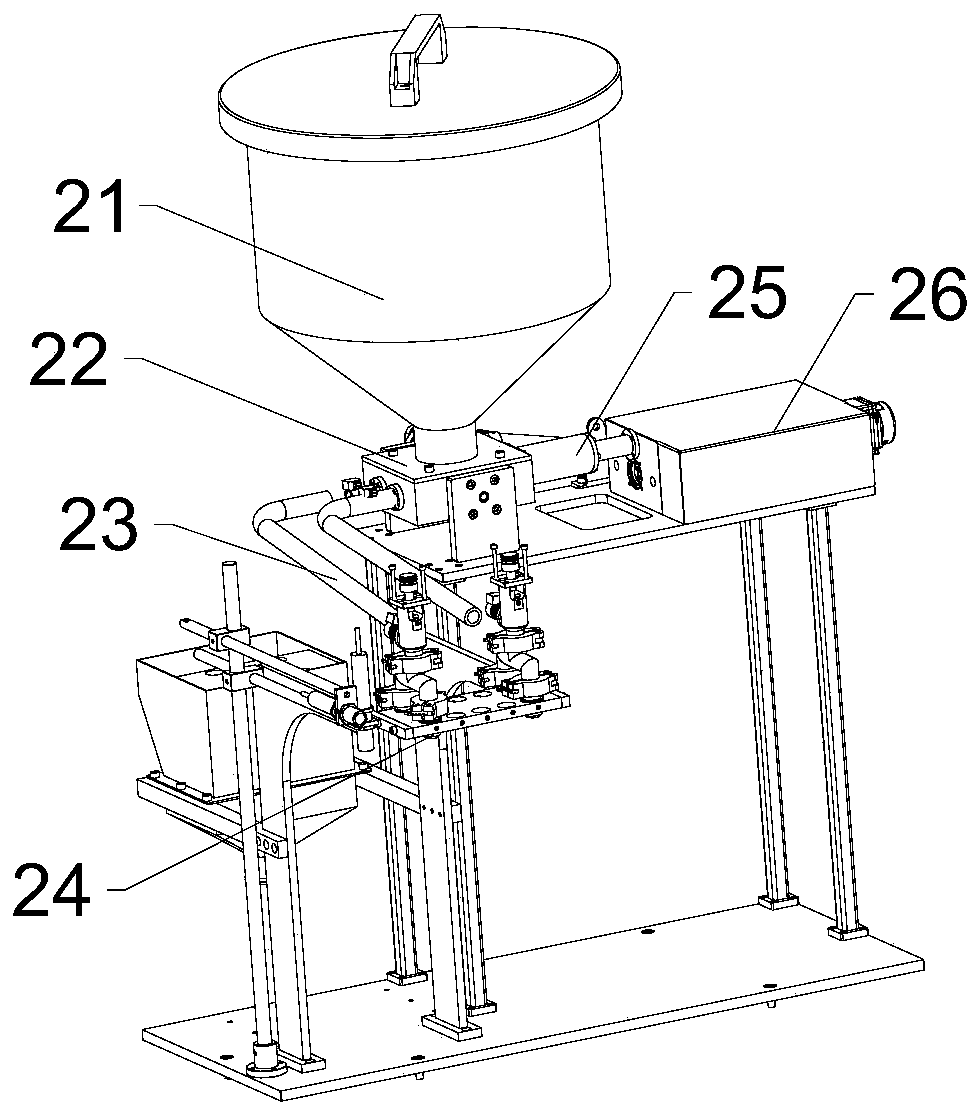

Automatic spreading and selling system for pancakes rolled with crisp fritters

PendingCN109258729AThere will be no bumping problemAvoid the problem of spoiled defective productsBaked articles handlingOil/fat bakingFlavorControl system

The invention relates to an automatic spreading and selling system for pancakes rolled with crisp fritters. A raw material unit is used for processing batter, a batter unit is used for supplying the batter, egg liquid and seasoning, a spreading unit is used for preparing one or two of the batter and the egg liquid into pancake crusts, a turning and folding unit is used for turning and folding thepancake crusts, a crisp fritter storage unit is used for storing the crisp fritters, and a picking and putting unit is used for picking and putting the crisp fritters and removing products processed by the turning and folding unit. The automatic spreading and selling system has the advantages that the raw material unit, the spreading unit, the batter unit, the turning and folding unit, the crisp fritter storage unit, the picking and putting unit and a discharge unit are organically integrated, precise control is realized by a control system, and various problems in the prior art are solved; the automatic spreading and selling system is convenient to mount and maintain, has a good effect, and can completely recover the flavors of manmade pancakes rolled with the crisp fritters.

Owner:TIANJIN CHUANGZHI ROBOT TECH CO LTD

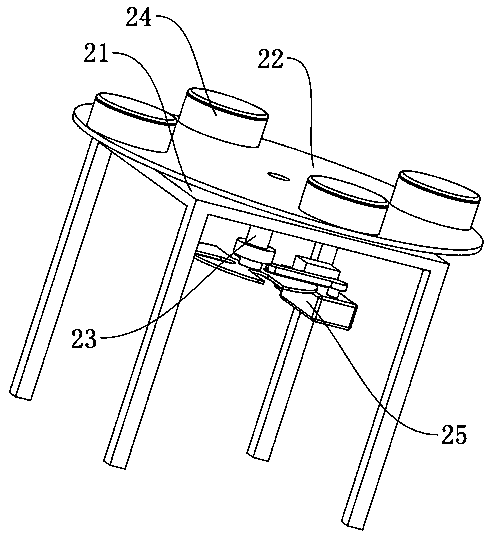

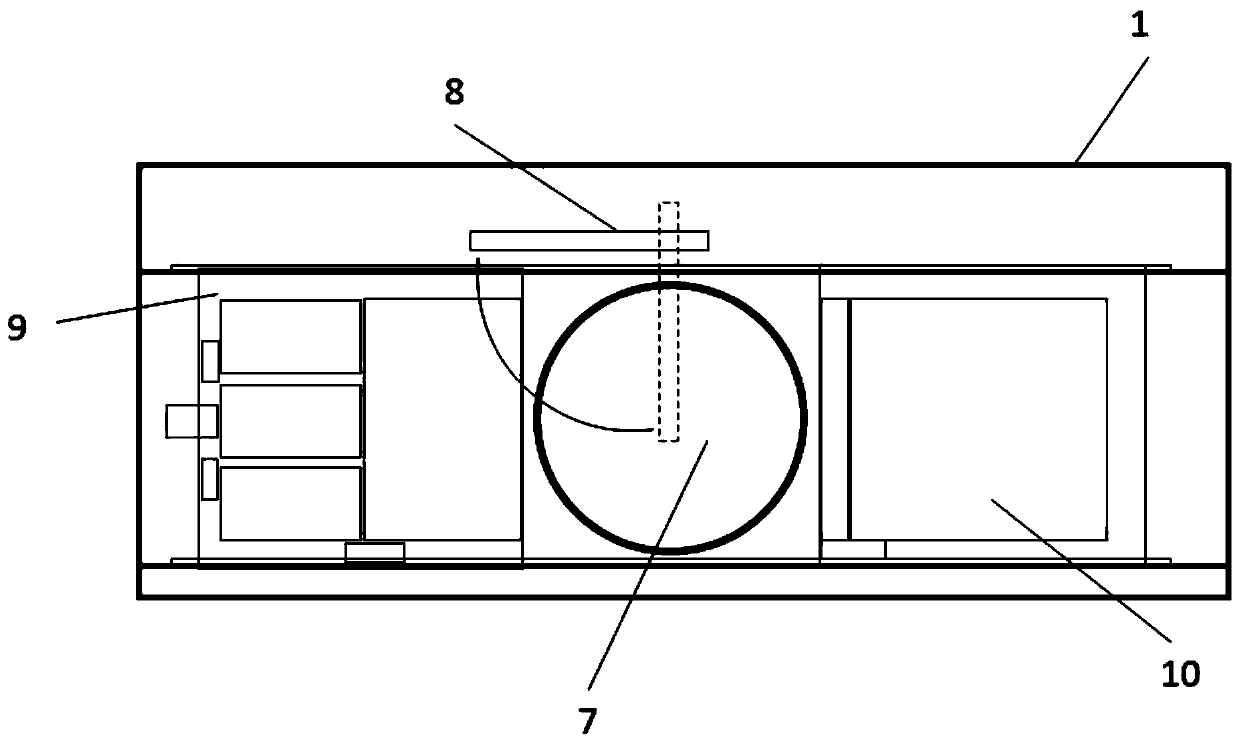

Automatic pancake forming equipment

InactiveCN109452332AIncrease production speedOil/fat bakingPancakes bakingEngineeringFood processing

The invention relates to the field of food processing, in particular to automatic pancake forming equipment. The equipment comprises a batter feeding device, a pancake forming device and a pancake discharging device, the pancake forming device comprises a workbench, a rotating disc and a first driving component used for driving the rotating disc to rotate, the rotating disc is horizontally arranged at the top end of the workbench, the first driving component is arranged at the bottom end of the workbench, the bottom end of the rotating disc is provided with a rotating shaft used for connectingthe first driving component, the rotating shaft passes through the workbench and is in transmission connection with the first driving component, the rotating shaft is in shaft connection with the workbench, the top end of the rotary disc is provided with four heating components at equal intervals for heating batter to form pancakes, the heating components are of a circular structure, the batter feeding device is arranged at one side of the workbench, the pancake discharging device is arranged at the other side of the workbench, and the pancake discharging device is arranged adjacent to the batter feeding device, thereby completing the automatic production of the pancakes and accelerating the production speed.

Owner:李和菊

Fried corn pancake and its manufacturing method

A corn pancake using corn as its main component is prepared by pancake cooking machine. Its advantages are good enjoyment for eating it and rich nutrients.

Owner:李凤光

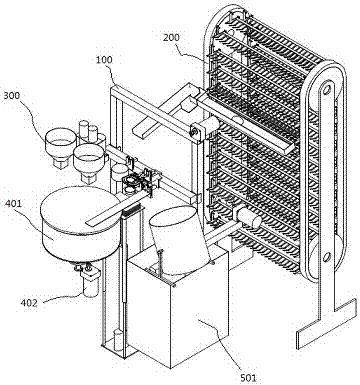

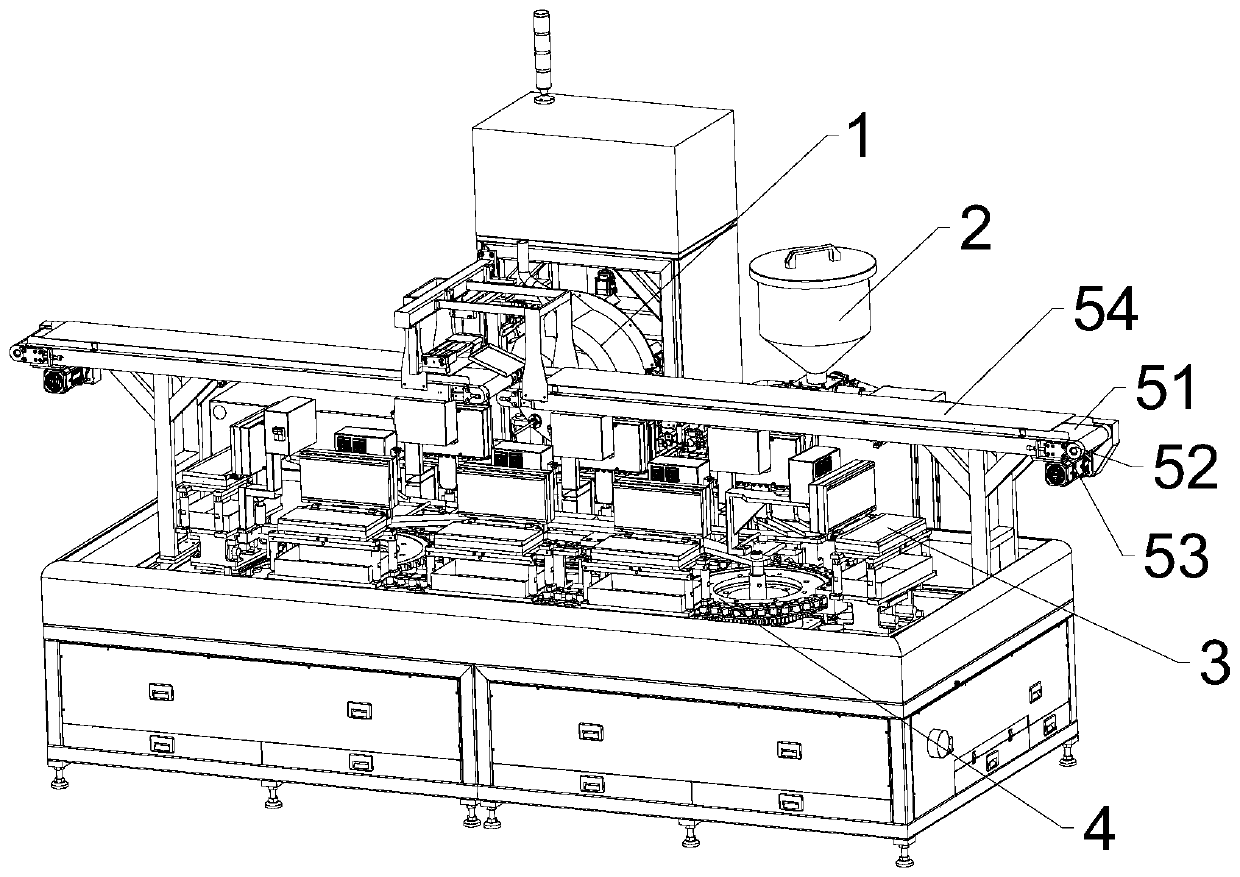

Egg roll processing equipment

PendingCN111150008ARealize automatic productionIncrease productivityOil/fat bakingPancakes bakingBiotechnologyMechanical engineering

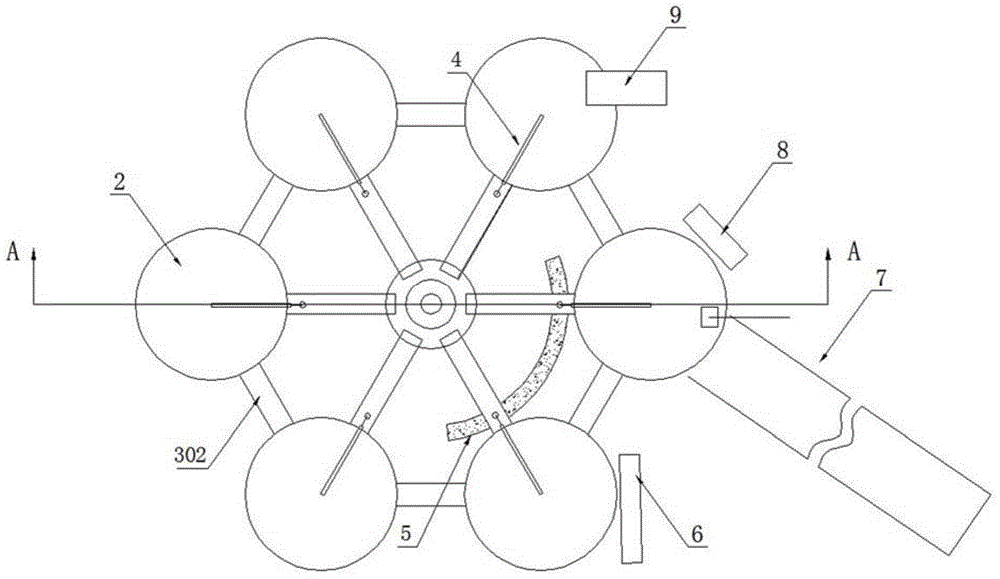

The invention discloses egg roll processing equipment. The egg roll processing equipment comprises a baking plate mechanism, a baking plate circulating mechanism and an egg roll forming mechanism, wherein the baking plate mechanism comprises a plurality of baking plates which are provided with grouting positions and rolling positions and used for making egg roll wrappers from a slurry dripping onto the baking plates by a grouting mechanism; the plurality of the baking plates are fixedly arranged on the baking plate circulating mechanism; the baking plate circulating mechanism drives the bakingplates to circularly rotate and controls the baking plates to be opened and closed; and the egg roll forming mechanism is arranged at the rolling positions and used for rolling egg roll wrapper on the baking plates to form egg rolls. The egg roll processing equipment provided by the invention comprises the grouting mechanism, the baking plate mechanism, the baking plate circulating mechanism, theegg roll forming mechanism and a discharging mechanism; automatic production of egg rolls is achieved; and the production efficiency is greatly improved. The baking plate mechanism is fixedly arranged on the baking plate circulating mechanism; opening and closing of the baking plates are achieved under driving of the baking plate circulating mechanism; the baking plate mechanism is matched with the grouting mechanism to make the egg roll wrappers; and the consistency of the egg roll wrappers is effectively improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

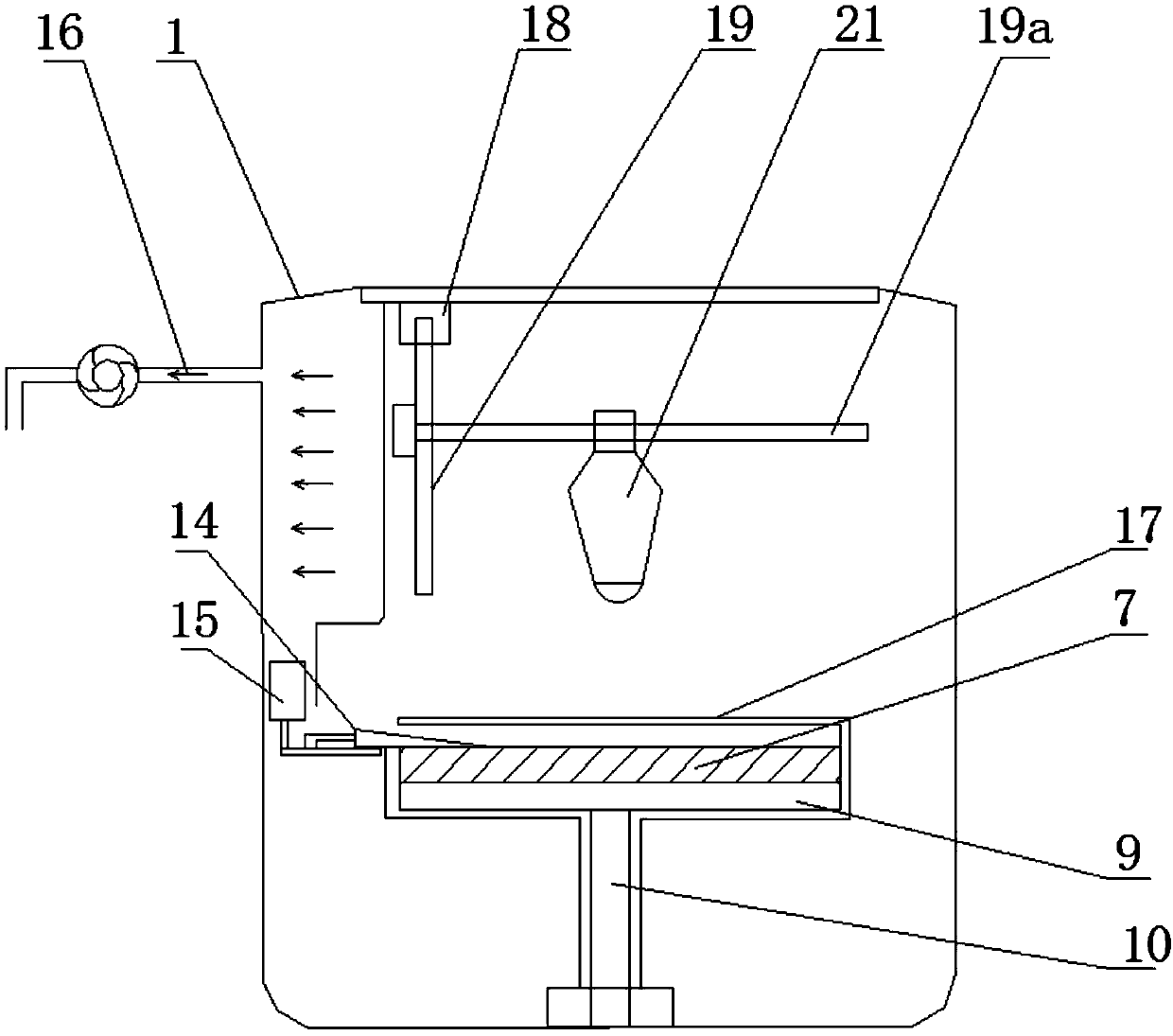

Automatic food production system

ActiveCN109051125AIncrease productivityImprove reliabilityPackagingPancakes bakingProcess engineering

The invention relates to an automatic food production system for producing cake. The automatic food production system comprises a food cooking device, wherein the food cooking device comprises a pan with a horizontally arranged pan face, a feeding device for arranging flour on the pan face, a distributing device for spreading the flour on the pan face, a separating device for separating cooked cake from the pan face, a discharging device for discharging the separated cake and a control device for regulating and controlling running states of all the parts, wherein the pan is rotationally mounted on a rack A; a heating mechanism for heating the pan is arranged on the rack A; the flour is spread on the pan to be cooked and shaped; and a driving mechanism A1 drives the pan to rotate. The provided technical scheme can be applied to automatic production equipment for cake food to effectively improve the production efficiency and reliability of the cake.

Owner:胡转香

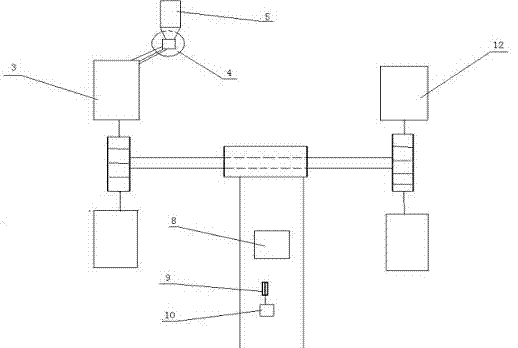

System of spring roll production flow

ActiveCN103250750AReduce labor intensitySame sizePreservation by coolingOil/fat bakingX-rayEngineering

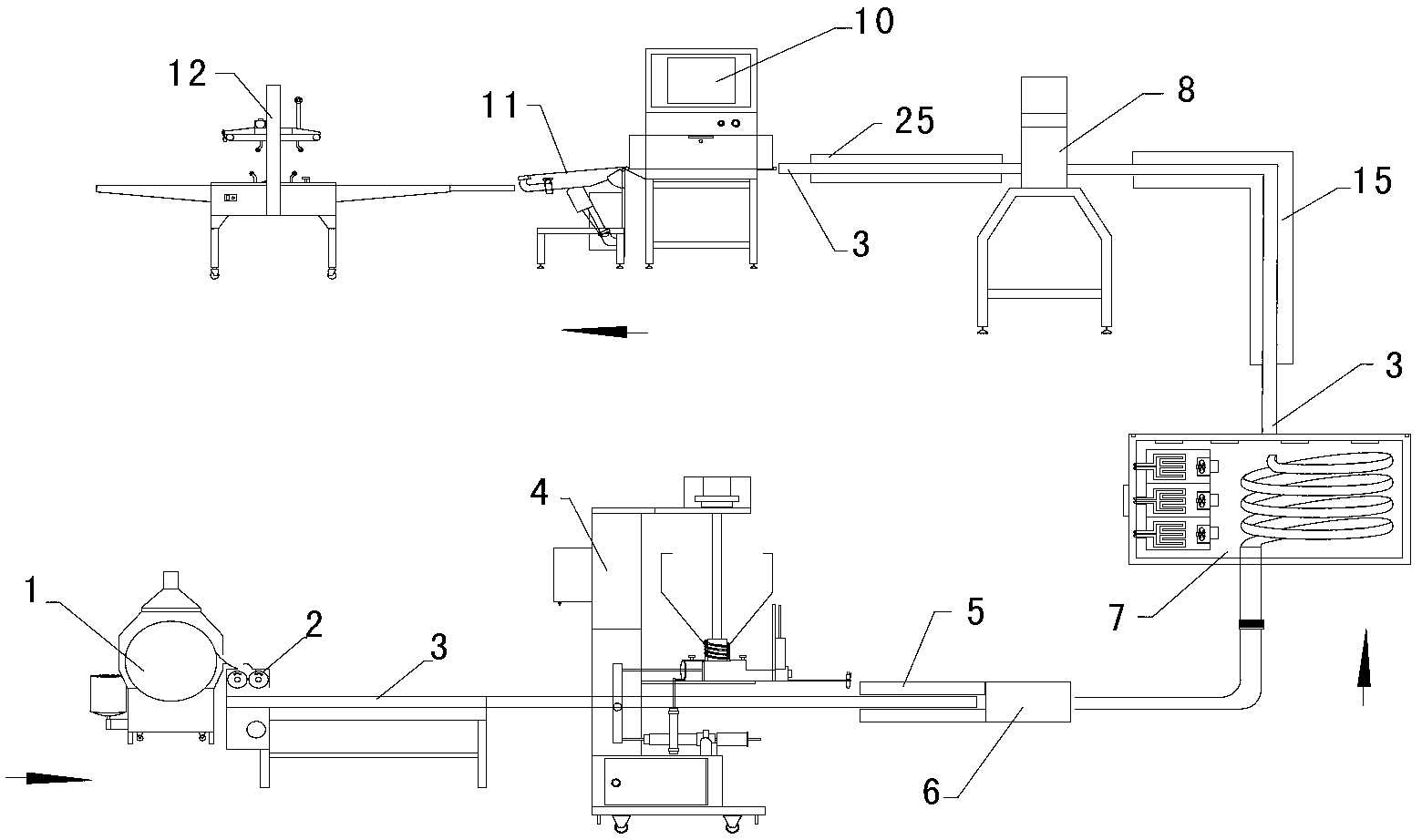

The invention discloses a system of a spring roll production flow and relates to food machinery. The system of the spring roll production flow is provided with a skin producing machine, a skin cutting machine, a conveying belt, a filling discharging machine, a spring roll making operating platform, a first metering platform, an instant freezer, a metal detector, an X-ray machine, a conveying belt lifting platform, an adhesive tap sealing machine, a film covering operating platform and a second metering platform. An outlet of a baking roller box of the skin producing machine is connected with the skin cutting machine, the skin cutting machine is connected with the filling discharging machine through the conveying belt, an outlet of a propelling cavity of the filling discharging machine is connected with the spring roll making operating platform through the conveying belt, one end of the first metering platform is connected with the spring roll making operating platform, the other end of the first metering platform is connected with the instant freezer through the conveying belt, a conveying belt outlet of the instant freezer is connected with the conveying belt, the film covering operating platform is arranged between the instant freezer and the metal detector, the second metering platform is connected with the metal detector, one end of the X-ray machine is connected with the second metering platform through the conveying belt, the other end of the X-ray machine is connected with the conveying belt lifting platform, and the conveying belt lifting platform is connected with the adhesive tap sealing machine.

Owner:漳州市孚美实业有限公司

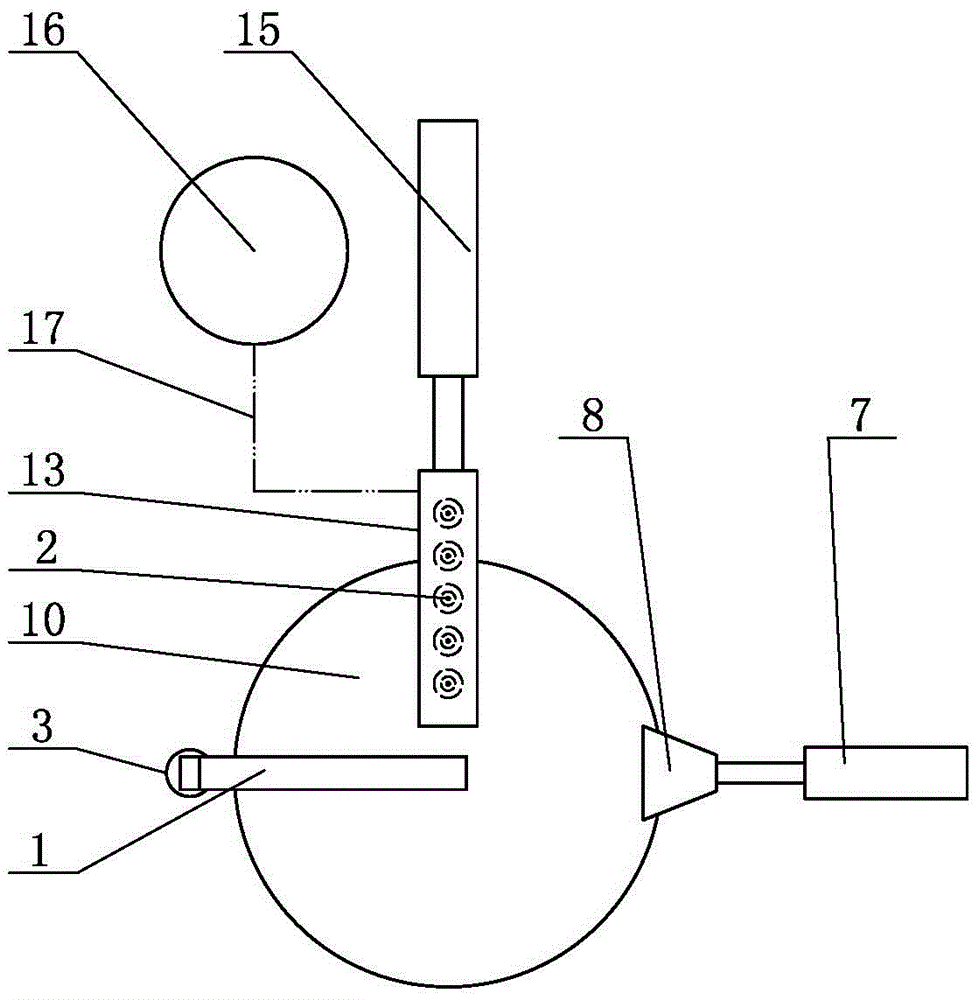

Jianbing making machine

ActiveCN108669108AServe evenlyOmit the scraper partBaking ovenOil/fat bakingSlurryBiomedical engineering

The invention relates to the technical field of catering equipment, in particular to a jianbing making machine. The jianbing making machine comprises a 3D printing feed device, batter can be fed uniformly by the 3D printing feed device, and even a scraper part can be omitted. The 3D printing feed device can move in any position of a flat iron plate, the part lack of the batter can be supplementedas required, jianbing in various shapes can be formed as required, and diet fun is increased.

Owner:邵嘉阳

Automatic electromagnetic pancake production equipment

InactiveCN106417416AImprove pass rateHeating evenlyOil/fat bakingPancakes bakingEnvironmental resistanceHeat control

The invention discloses automatic electromagnetic pancake production equipment, and belongs to the field of automatic production equipment of pancakes. The automatic electromagnetic pancake production equipment is characterized by comprising the following parts: a metal pancake making plate, a rotary-plate rotating power device, an electromagnetic heating device, a batter distributing device, a uniform scraping device and a pancake dishing-off device. The electromagnetic heating mode is utilized to replace conventional gas or coal combustion heating so as to ensure more uniform heating; thus, no artificial heat control is required, and the use of the equipment is convenient and environmentally friendly. After performing of a large amount of experience summarization and equipment operation experiments, the inventor has come to the conclusion that only scientific technical parameters can ensure perfect match of the batter distributing step, the uniform scraping step and the pancake dishing-off step during the production processes of the pancakes so as to ensure that the shaped pancakes are thin and not cracked, as well as wholly cooked. Tests have proven that the qualified rates of the pancakes produced by the equipment are up to 95% or higher.

Owner:山东蓬发厨具科技有限公司

Full-automatic square pancake flipping machine

InactiveCN103109883AHas an artificial tasteWith tasteOil/fat bakingPancakes bakingEngineeringProviding material

The invention aims at providing an automatic pancake flipping scraping machine which simulates the whole actions of flipping scrapping pancakes by hand. The full-automatic square pancake flipping machine is high in automation degree and is capable of producing continuously, and the pancakes produced are more tasty than the pancakes made by hand. The scheme of the full-automatic square pancake machine includes that four griddles are arranged on a rotation plate, the griddles are provided with heat sources by conduction oil, a cleaning oiling device is arranged outside the rotation plate, the device is used for cleaning and oiling for surfaces of the griddles, a flipping scrapping device is capable of providing materials, shaping the materials by flipping and scrapping, filling water for cooling and cleaning and maintaining the self, and the continuous production is guaranteed.

Owner:时培峰

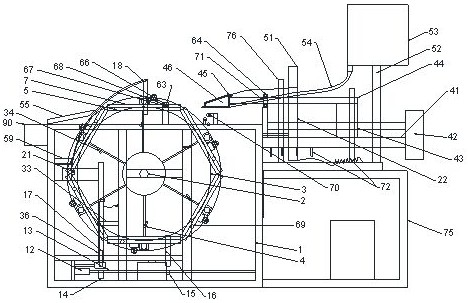

Full-automatic egg roll making machine

PendingCN112120048AImprove processing efficiencySimple structureOil/fat bakingPancakes bakingElectric machineryMachine

The invention belongs to the technical field of egg roll processing equipment, and particularly discloses a full-automatic egg roll making machine. The full-automatic egg roll making machine comprisesa mounting frame, wherein a rotary drum is connected to the mounting frame through a bearing, six reinforcing rods are symmetrically arranged at the front end of the rotary drum, six lower dies are evenly arranged on the rotary drum, an upper die is mounted on the lower dies through connecting shafts, and a pin is arranged on the upper die. The pin is mounted on the upper die through a first spring, a circular ring is arranged at the front end of the rotary drum, pin holes are correspondingly formed in the circular ring, a first motor is arranged on one side of the bottom end of the mountingframe, and a first cam and a second cam are arranged on a driving roller of the first motor; a first driving device and a second driving device are arranged on the mounting frame at the upper end of the first motor; and a sliding table is arranged on one side of the mounting frame, a pulley is arranged on one sides of the pin through a connecting rod, a rivet mechanism is arranged at the bottom end of the sliding table, and a feeding-discharging device is arranged on the right side of the mounting frame. The full-automatic egg roll making machine can automatically charge and discharge for eggroll processing and manufacturing, improves the egg roll processing efficiency, and is high in practicability.

Owner:上海尚记智能科技有限公司

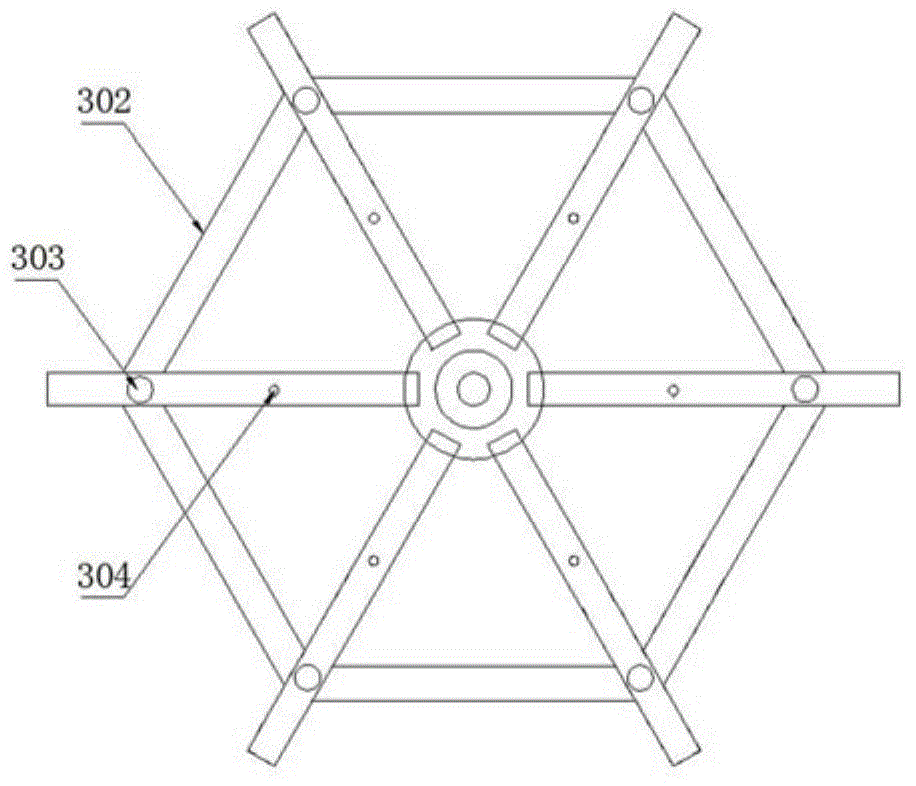

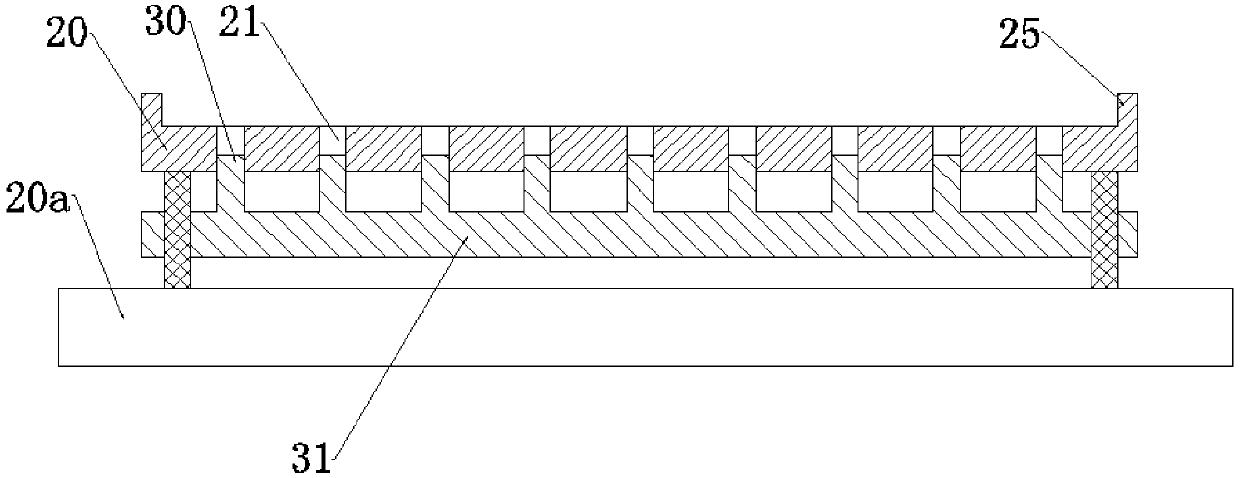

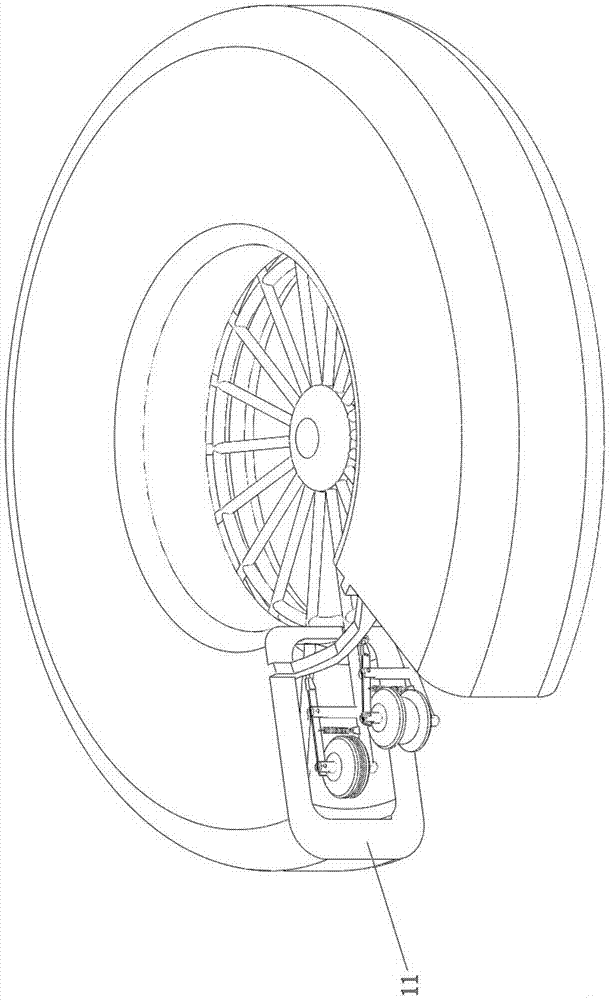

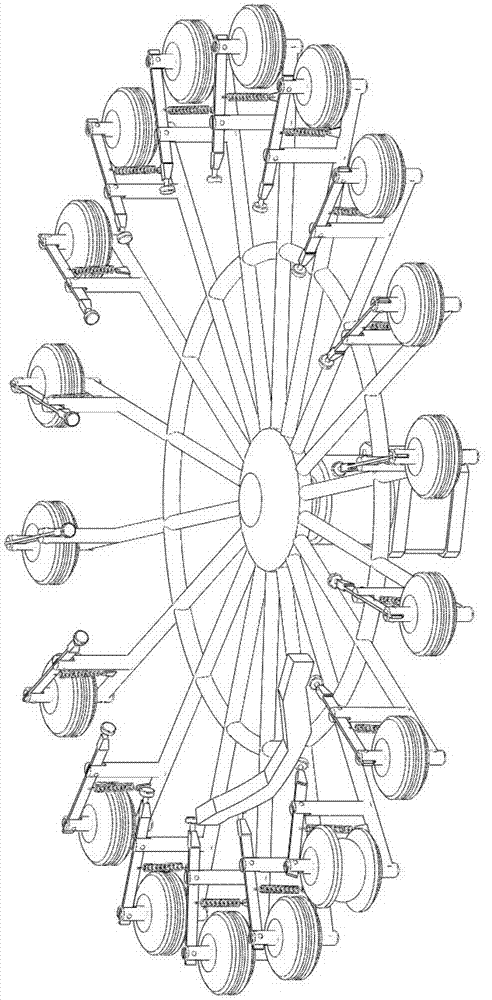

Efficient and energy-saving numerical control flapjack baking machine

ActiveCN103493859AAvoid pollutionStable quality and hygieneFood processingBaking ovenNumerical controlElectric machinery

The invention provides an efficient and energy-saving numerical control flapjack baking machine, and relates to the technical field of foodstuff processing machinery. In order to control the temperature and time in the baking process of flapjacks, the efficient and energy-saving numerical control flapjack baking machine adopts the following measures that a plurality of flapjack clamps evenly form an annular array along the circumference and are arranged on an umbrella frame, an arc-shaped convex bar (3) is arranged on a sliding wheel (10) of one flapjack clamp in the annular flapjack clamp array, and the umbrella frame (1) is arranged on a rotating shaft of a stepping motor (the stepping motor is provided with a reduction box). The stepping motor is connected with a stepping motor drive circuit, and the steeping motor drive circuit is connected with a stepping motor controller. According to the structure of each flapjack clamp, a lower heating plate (6) is arranged on a clamp frame (8), an upper heating plate (4) is hinged to one end of the a carrier bar (5), the carrier bar (5) is hinged to the clamp frame (8), a tension spring (9) is arranged between the clamp frame (8) and the carrier bar (5) and is used for enabling a flapjack mould (7) to be clamped by the upper heating plate (4) and the lower heating plate (6), the sliding wheel (10) is arranged at the other end of the carrier bar (5) and is used for opening the flapjack clamp. In this way, the advantages that the flapjacks are made to be stable in quality and hygienic are ensured.

Owner:启东市天汾电动工具技术创新中心

Automatic pancake machine

ActiveCN107183095ATiming automatic feedingEasy to operateOil/fat bakingPancakes bakingEngineeringRotation around a fixed axis

The invention relates to an automatic pancake machine. The automatic pancake machine comprises a stove, a fixation shaft, a shaft sleeve, a support arm, a fixation plate, a fixation pin, a fixation base, a groove, a sleeve, a shaft sleeve, a support shaft, a cross shaft, adjusting screws, an arc shovel, an arc hopper, a feeding pump, a batter box, a motor, a pin groove and a bearing; the fixation shaft is welded to the side wall of the stove, the shaft sleeve is arranged on the fixation shaft in a sleeving mode and fixed through a nut, the shaft sleeve rotates around the fixation shaft, the support arm is welded to the shaft sleeve, the tail end of the support arm is connected with the sleeve, the sleeve is connected with the fixation plate through the support arm, the fixation pin is installed on the side wall of the fixation plate; and the fixation base is welded to the side wall of the stove at the opposite side of the fixation shaft, the groove is formed in one side of the fixation base, the fixation plate is inserted in the groove, the motor is arranged in the sleeve, the support shaft is fixed to the middle of the top of the cross shaft through the screws, the tail end of the support shaft is connected with the feeding pump, and the batter box is arranged at the top of the feeding pump. The automatic pancake machine is simple and convenient to operate, safe, reliable and suitable for popularization and application.

Owner:南通北外滩建设工程有限公司

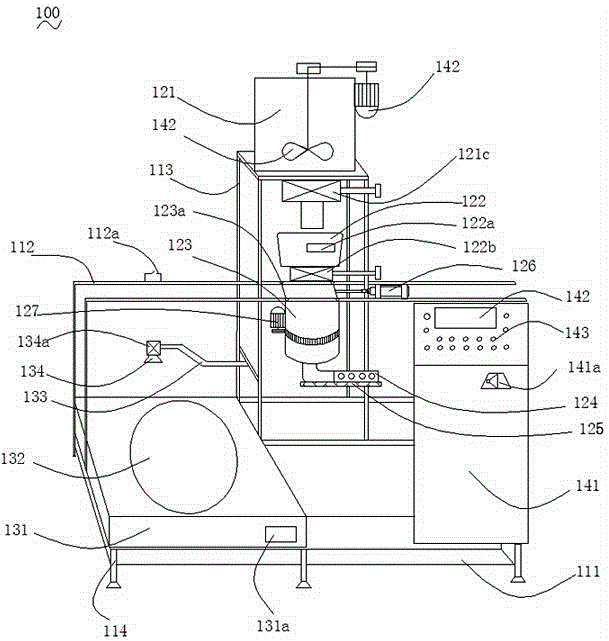

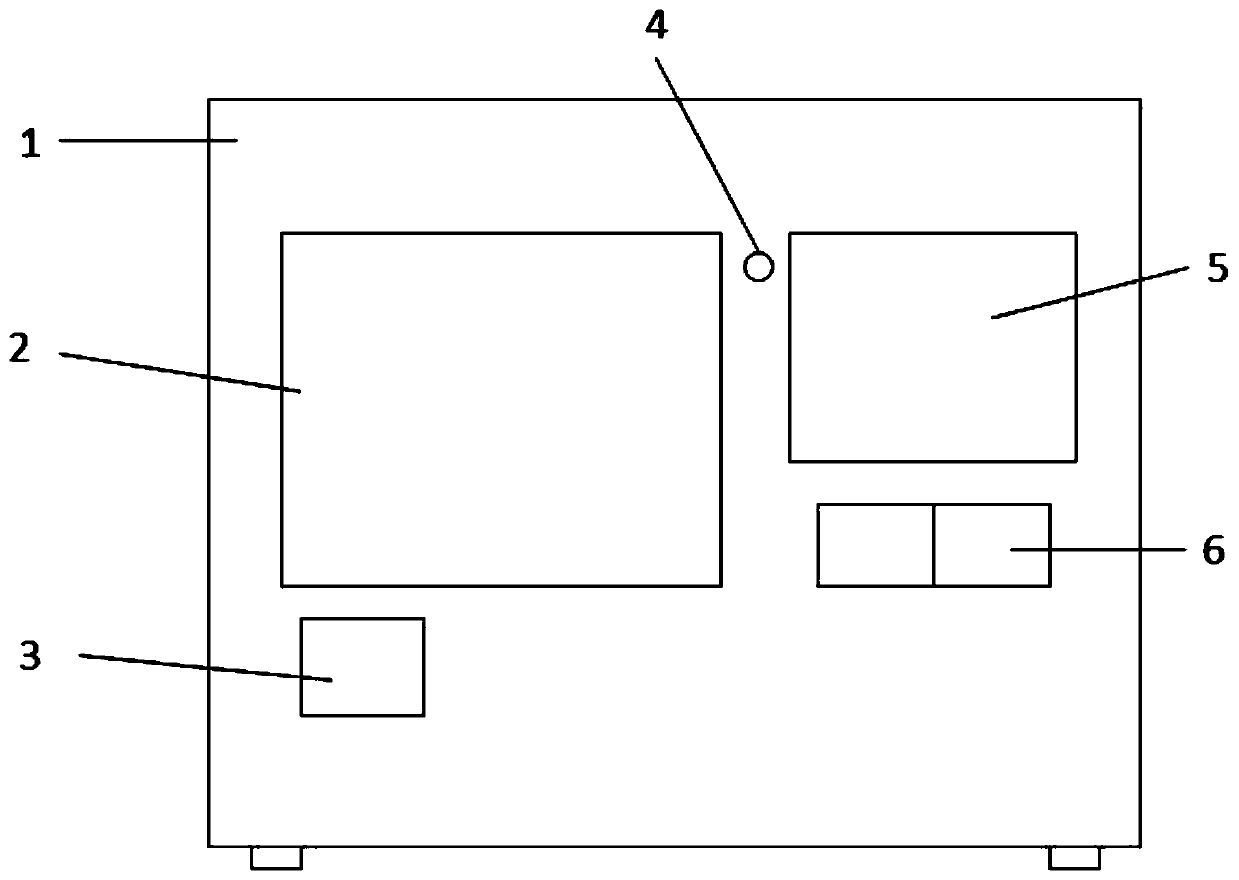

Automatic producing and selling equipment for pancake rolled with crisp fritters

InactiveCN110047203AStrong supply capacityReduce operating costsCoin-freed apparatus detailsOil/fat bakingPaymentControl system

The invention relates to automatic producing and selling equipment for a pancake rolled with crisp fritters. The equipment comprises a frame casing, wherein the frame casing is provided with an observation window, a delivery port, a user operation panel and a payment module panel, the frame casing is internally provided with a lower layer, a middle layer and an upper layer, the middle layer insidethe frame casing is provided with a rotating griddle, a pancake spreading mechanism is arranged above the rotating griddle, the upper layer inside the frame casing is provided with a material feedingmechanism, a pancake turning mechanism is arranged on one side of the rotating griddle, a pancake folding mechanism is arranged on the other side of the rotating griddle, a packaging and shipping mechanism is arranged below the pancake folding mechanism inside the frame casing, a packaging and sorting mechanism is arranged above the pancake folding mechanism inside the frame casing, and a controlsystem is also arranged in the frame casing. The scheme of the invention has the beneficial effect that the equipment has strong supply capacity, convenience, sanitation and low operation cost.

Owner:王挺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com