System of spring roll production flow

A production process and spring roll technology, which is applied in food forming, food coating, and baked food segmentation/slicing, etc. It can solve the problems of technical difficulty in filling process, irregular product forming, and inaccurate filling quantity. , to achieve the effect of realizing industrialization requirements, low labor intensity and labor cost, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

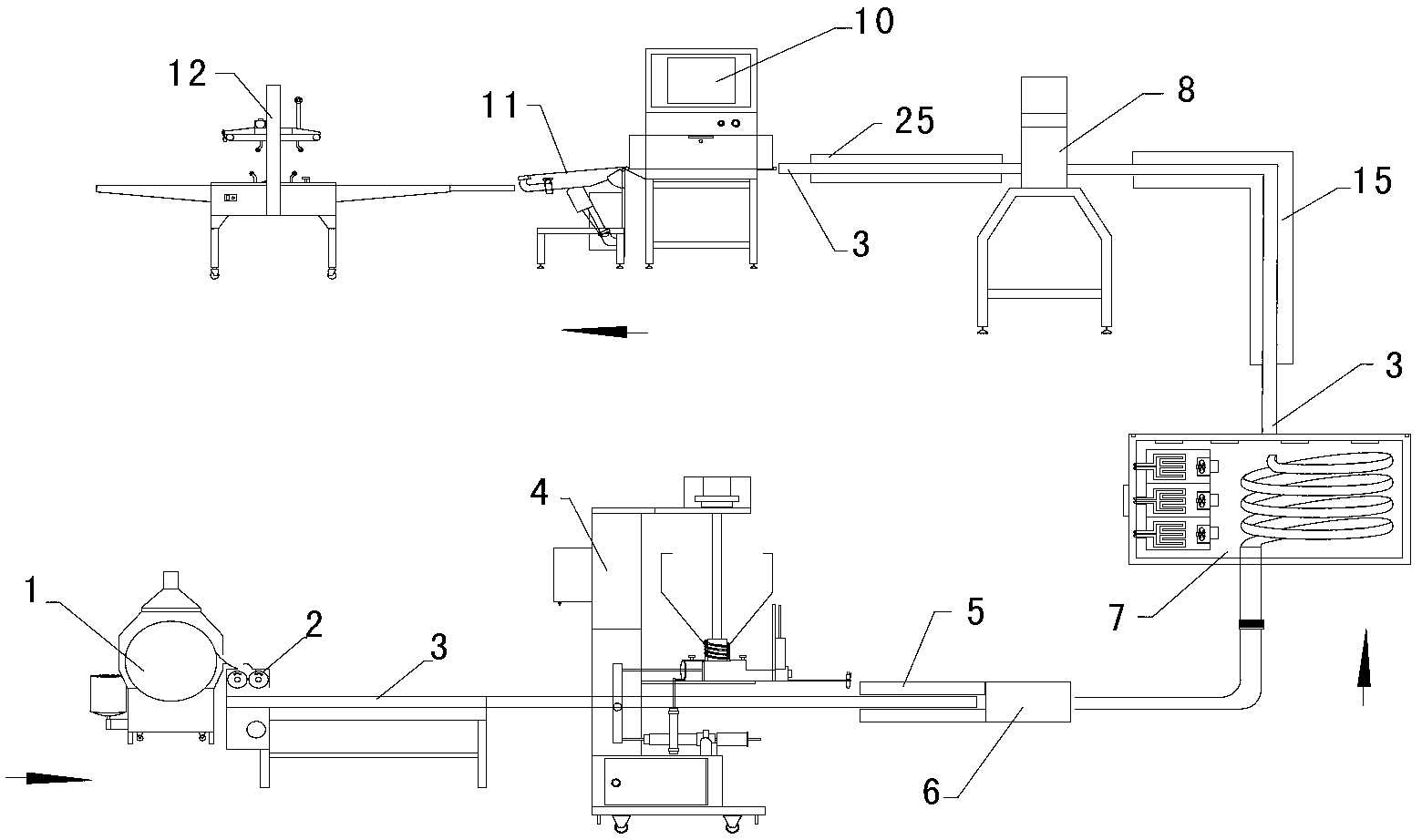

[0028] see figure 1 , the embodiment of the present invention is provided with leather making machine 1, leather cutting machine 2, conveyer belt 3, sinking machine 4, wrapping spring roll operating table 5, the first metering platform 6, quick freezer 7, metal detector 8, X-ray machine 10, conveyer belt Lifting platform 11, tape sealing machine 12, mantle film operating platform 15 and the second metering platform 25; the oven wheel box outlet of the leather making machine 1 is connected to the skin cutting machine 2, and the skin cutting machine 2 is connected with the sinking machine 4 through the conveyor belt 3 , the outlet of the propelling chamber of the sinking machine 4 is connected to the spring roll wrapping console 5 through the conveyor belt 3, one end of the metering platform 6 is connected to the spring roll wrapping console 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com