Patents

Literature

408results about "Baked article cutting/slicing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

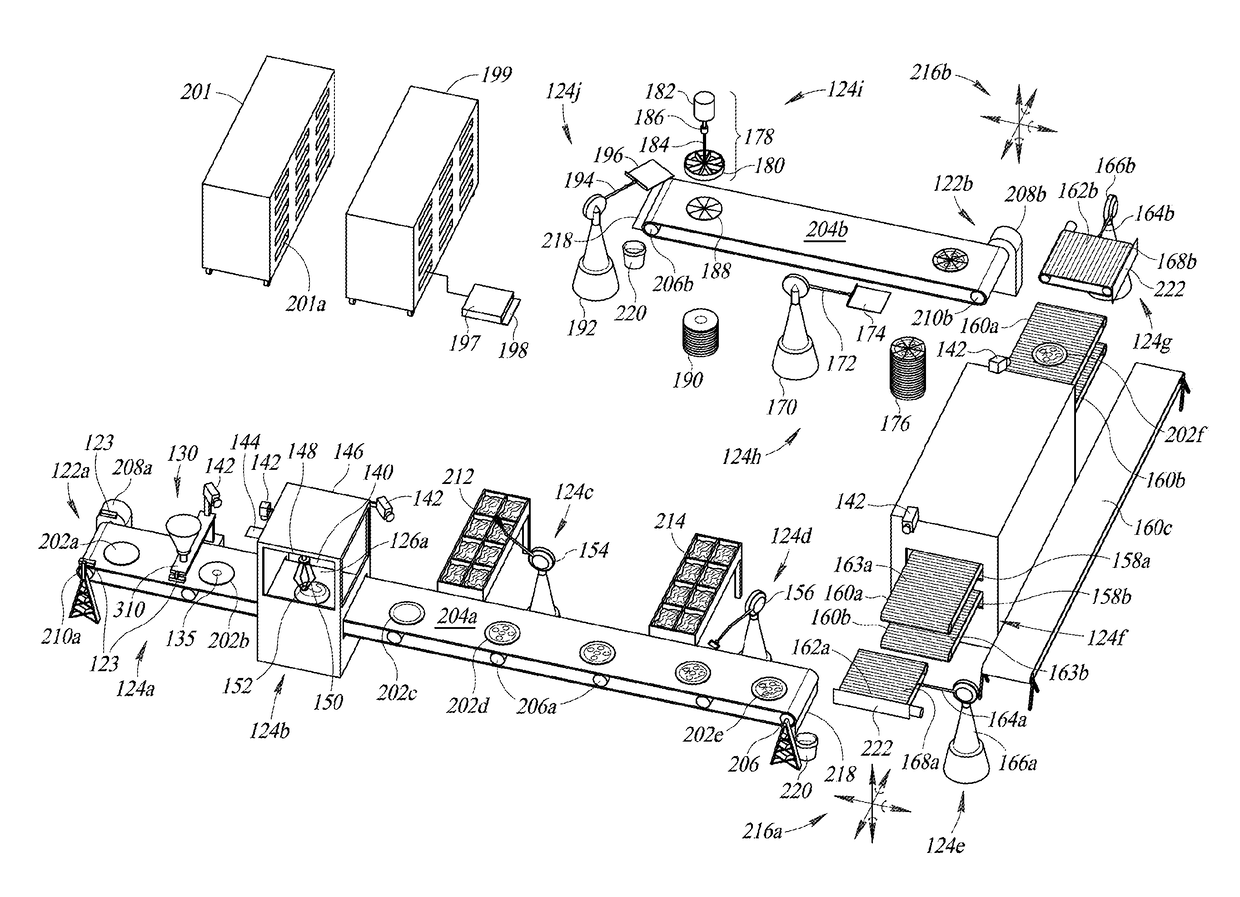

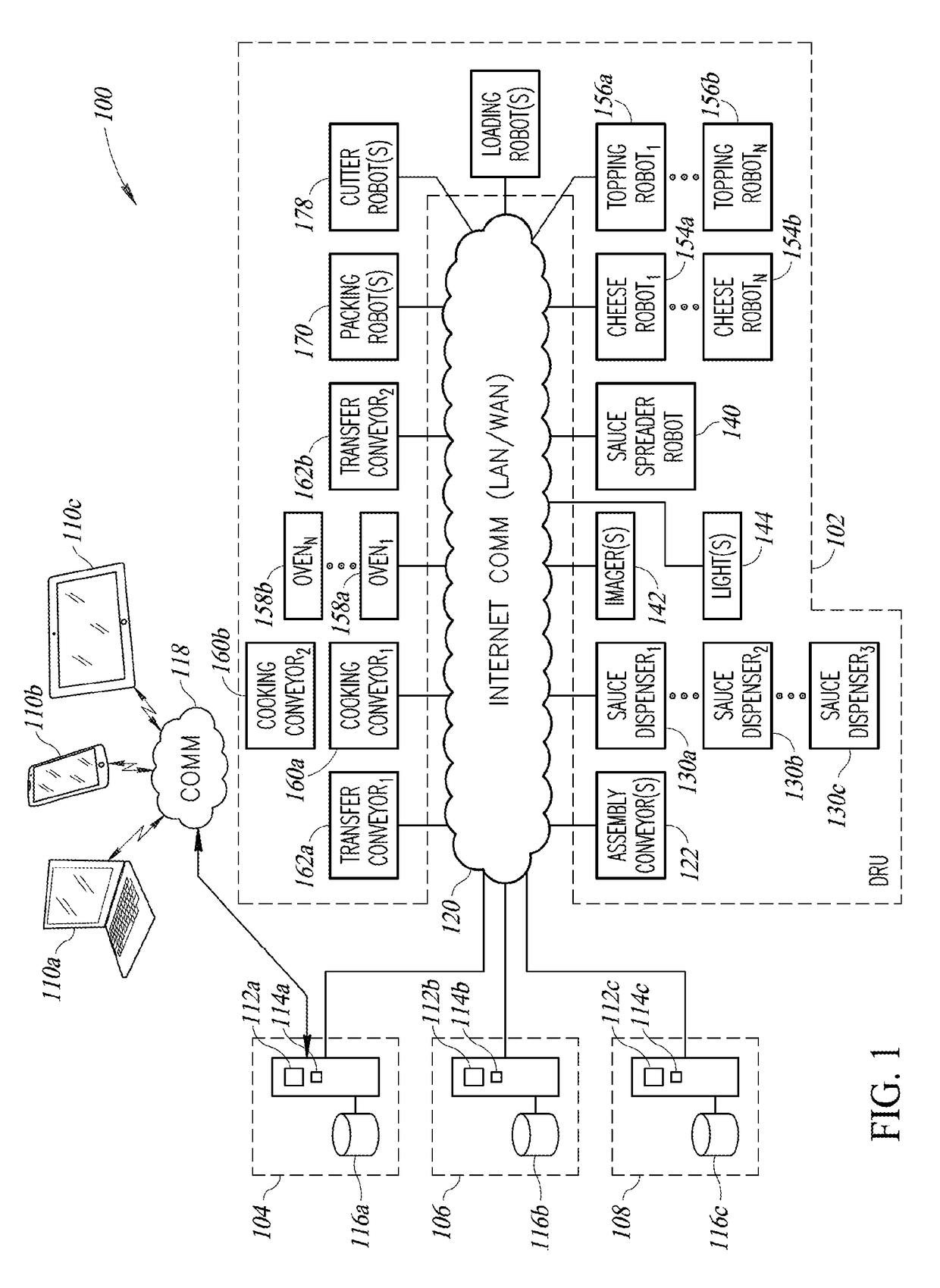

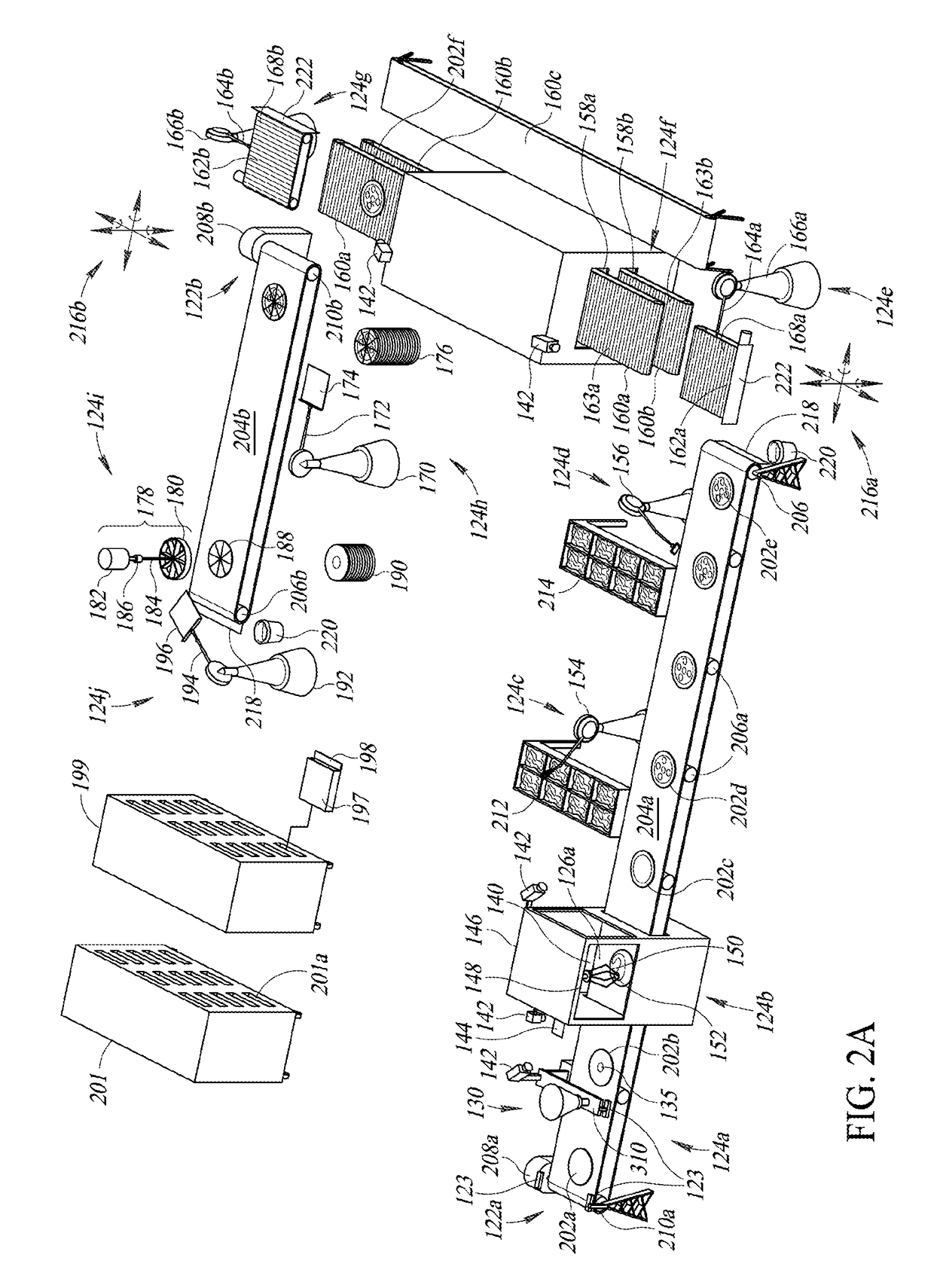

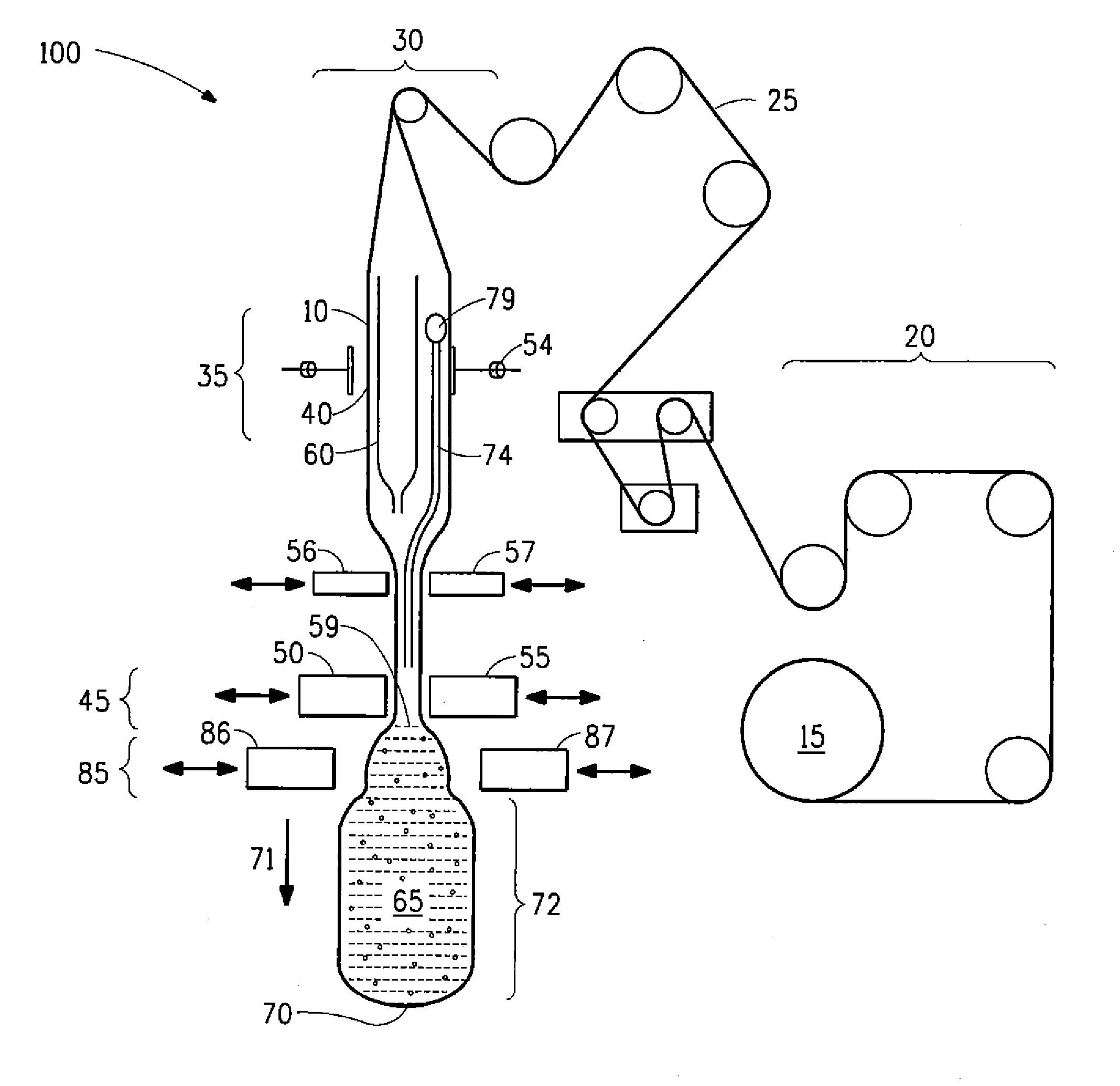

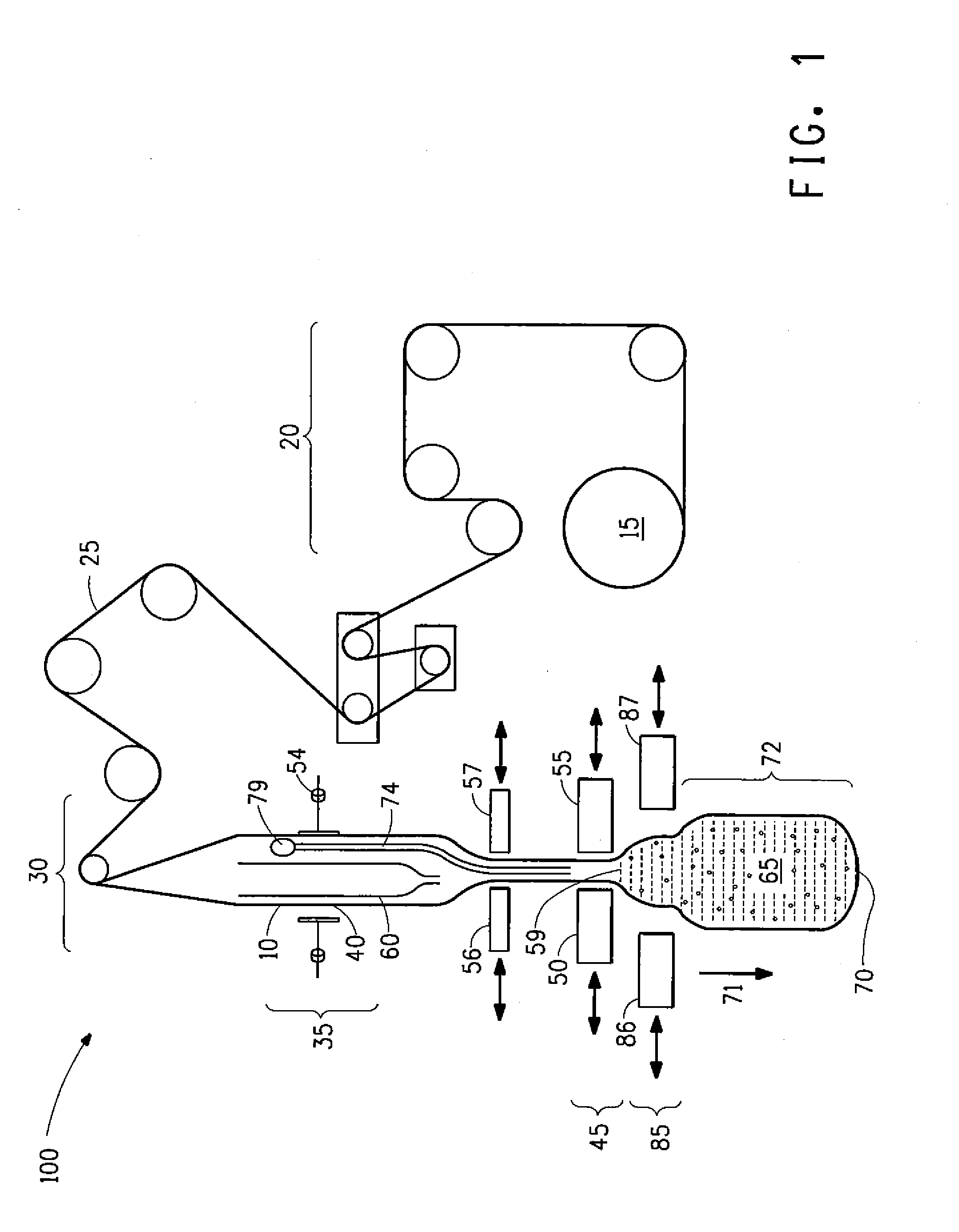

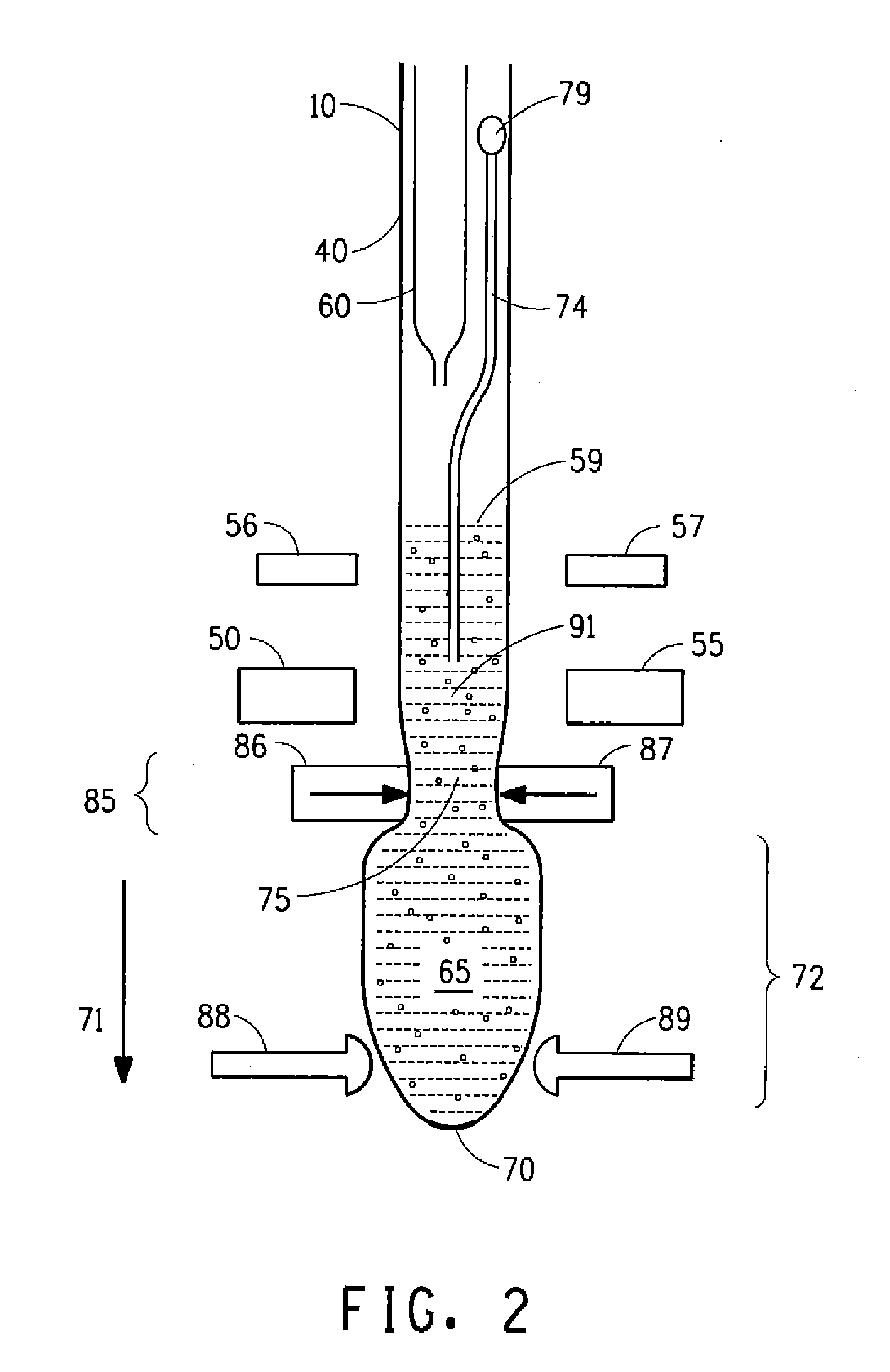

On-demand robotic food assembly and related systems, devices and methods

An on-demand robotic food assembly line can include one or more conveyors and one or more robots, operable to assemble food items in response to received orders for food items, and one or more ovens operable to, for example, partially cook assembled food items. The on-demand robotic food assembly line can optionally package the assembled and partially cooked food items in packaging, and optionally load the packaged partially cooked food items into portable cooking units (e.g., ovens) that are optionally loaded into racks that are, in turn, optionally loaded into delivery vehicles, where the food items are individually cooked under controlled conditions while en route to consumer destinations, such the cooking of each food item is completed just prior to arrival at the consumer destination location. A dynamic fulfillment queue for control of assembly is maintained based at least in part on estimated transit time for orders.

Owner:ZUME INC

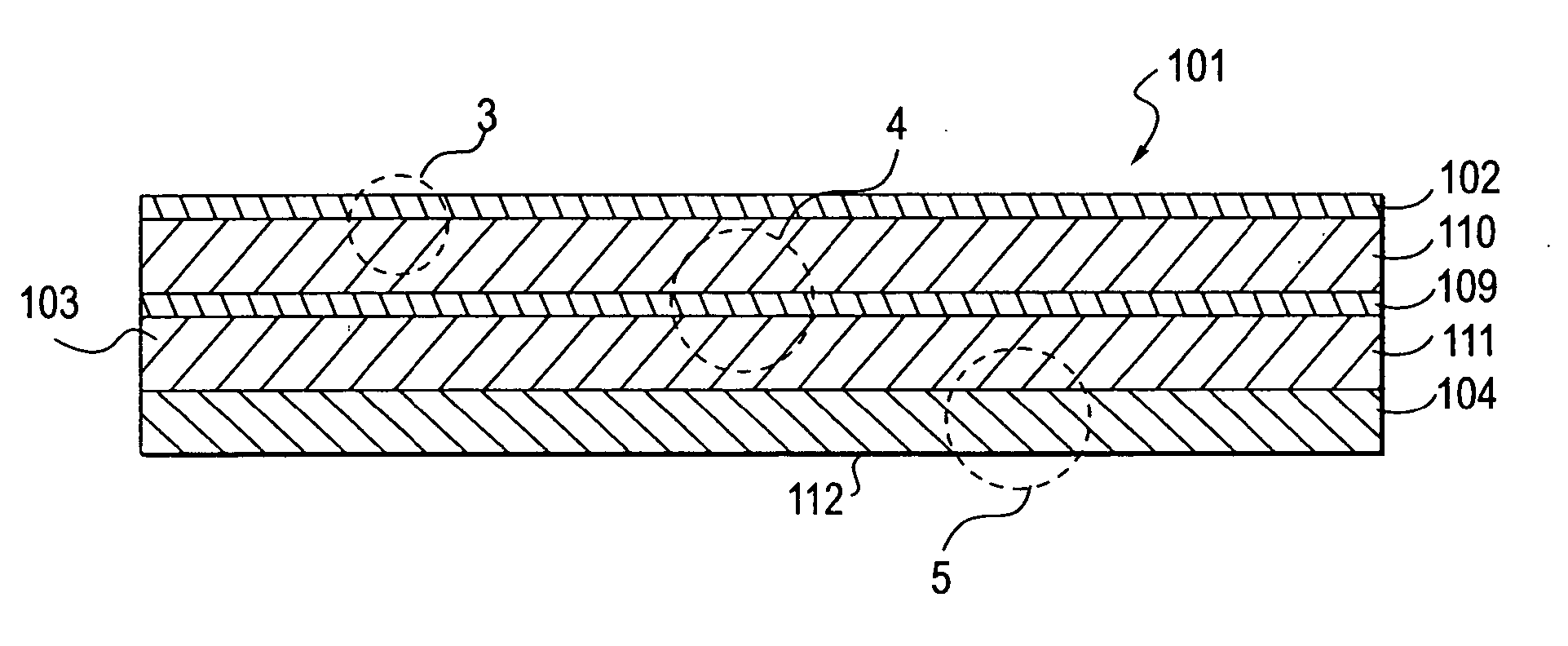

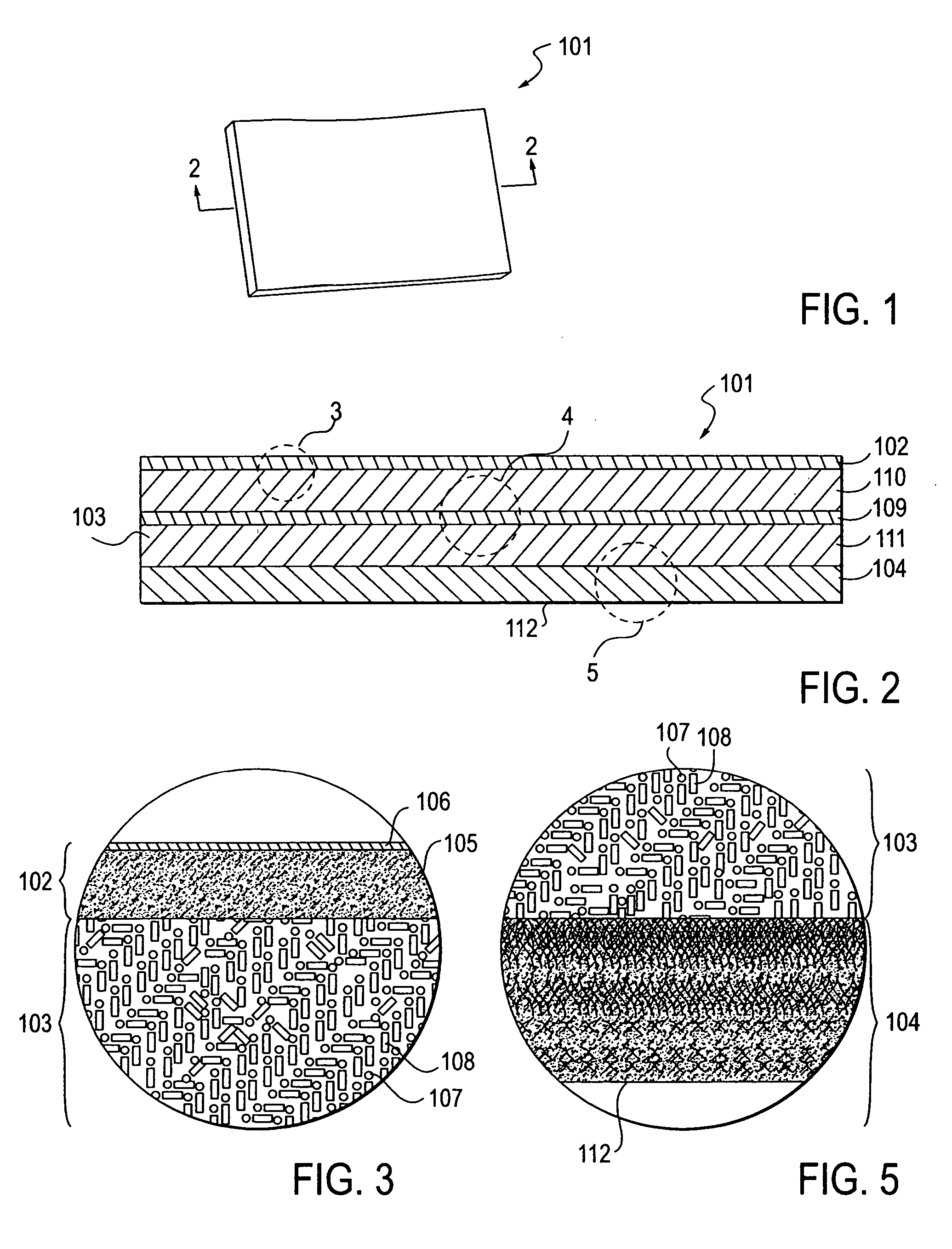

Wound dressing and apparatus for forming same

A multi-layered wound dressing includes a moisture-retaining portion for enhancing the healing of a wound. The wound dressing includes an intermediate layer that has both water soluble and water insoluble fibers. An apparatus that includes a cutting tool and a reservoir of liquid to pre-moisten a portion of the dressing may be used to manufacture the dressings.

Owner:POLYREMEDY

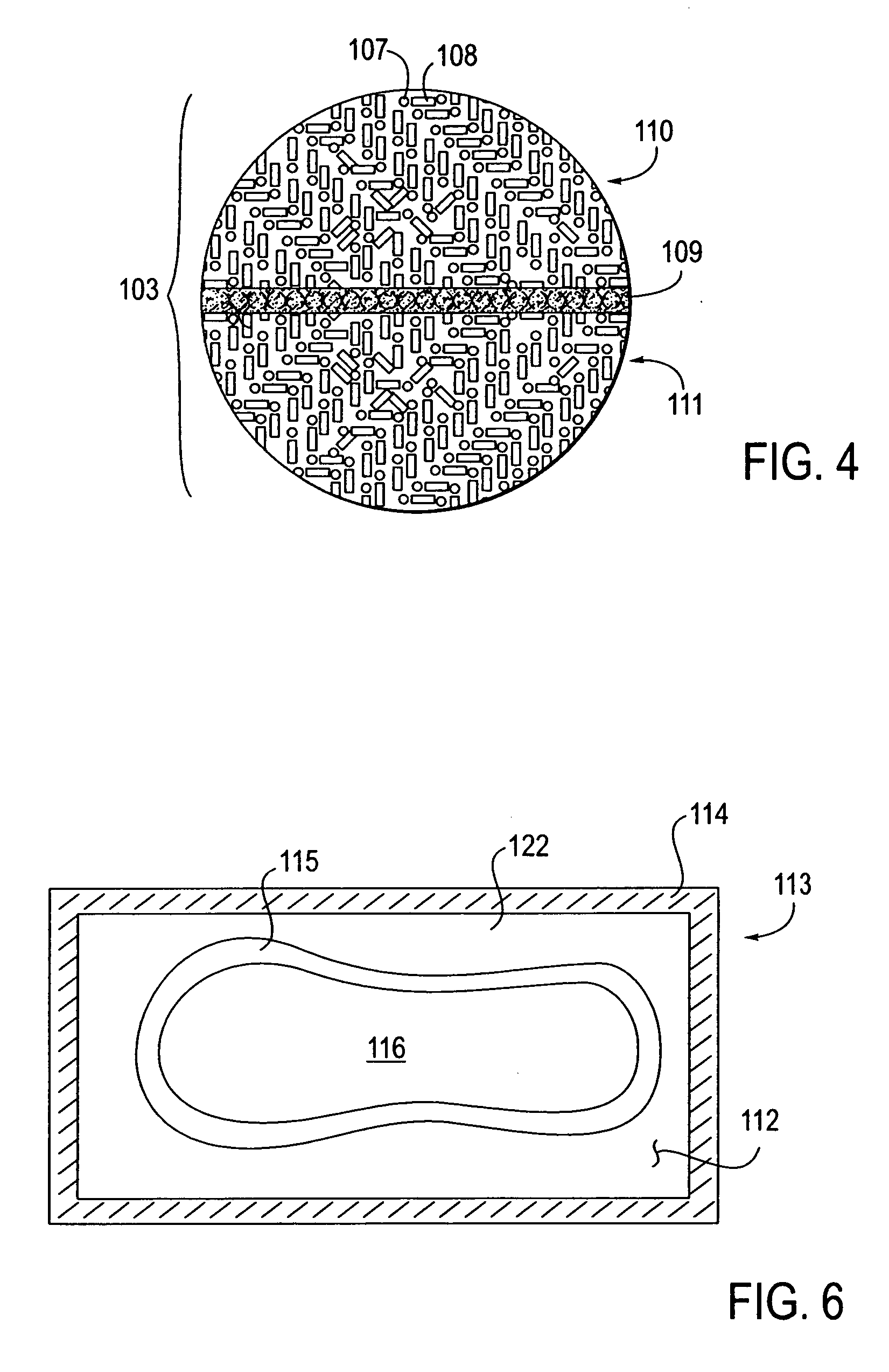

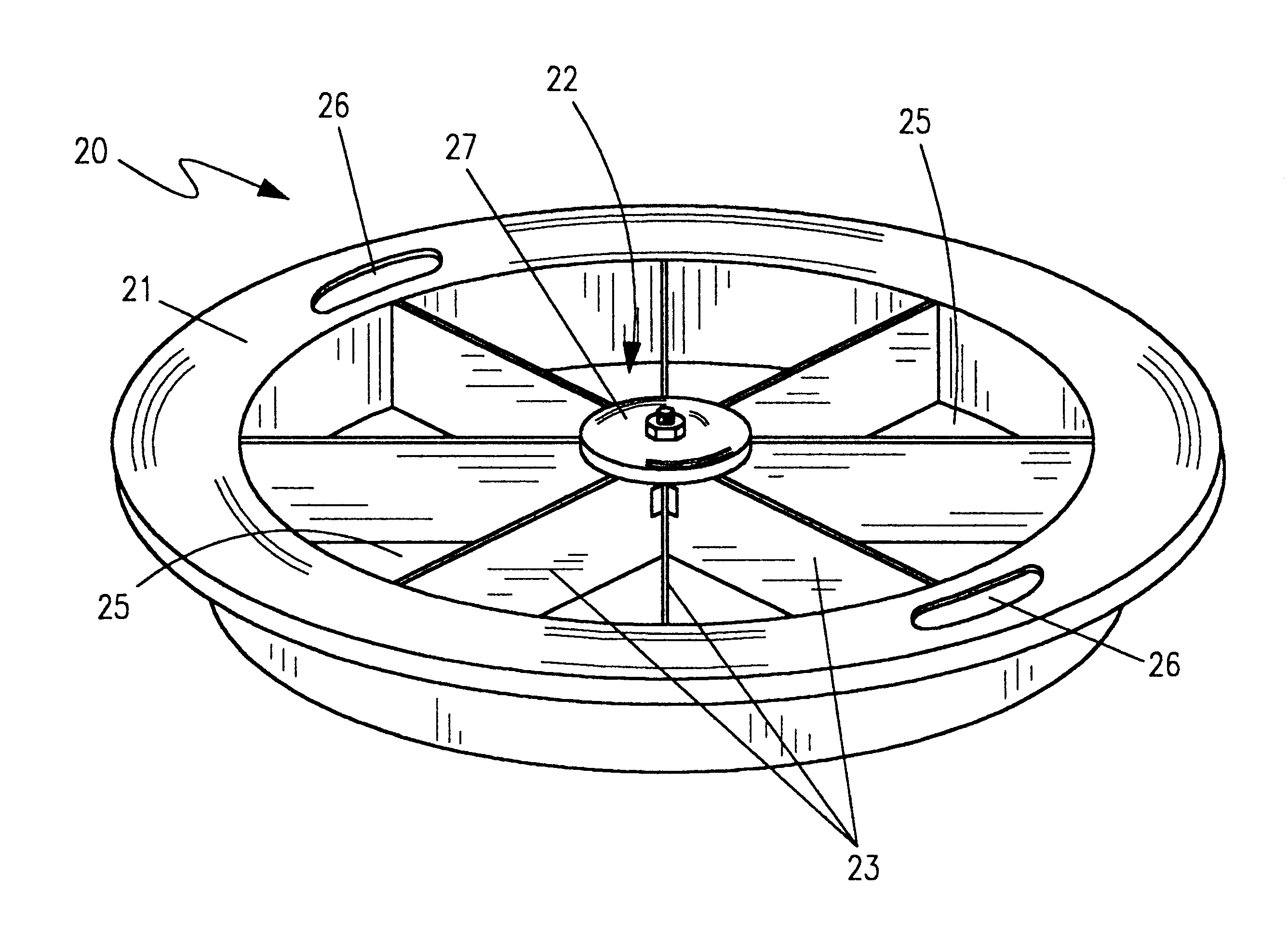

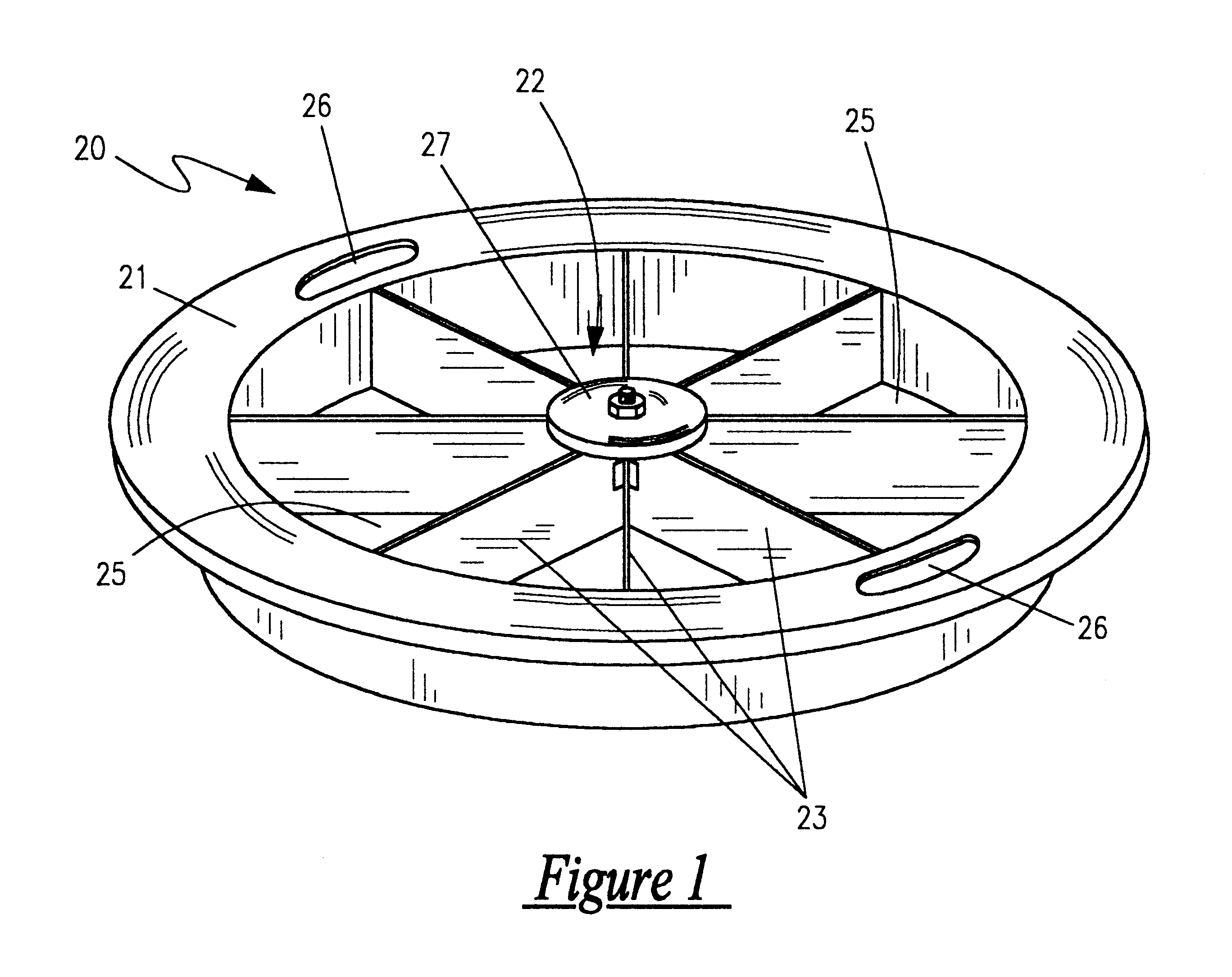

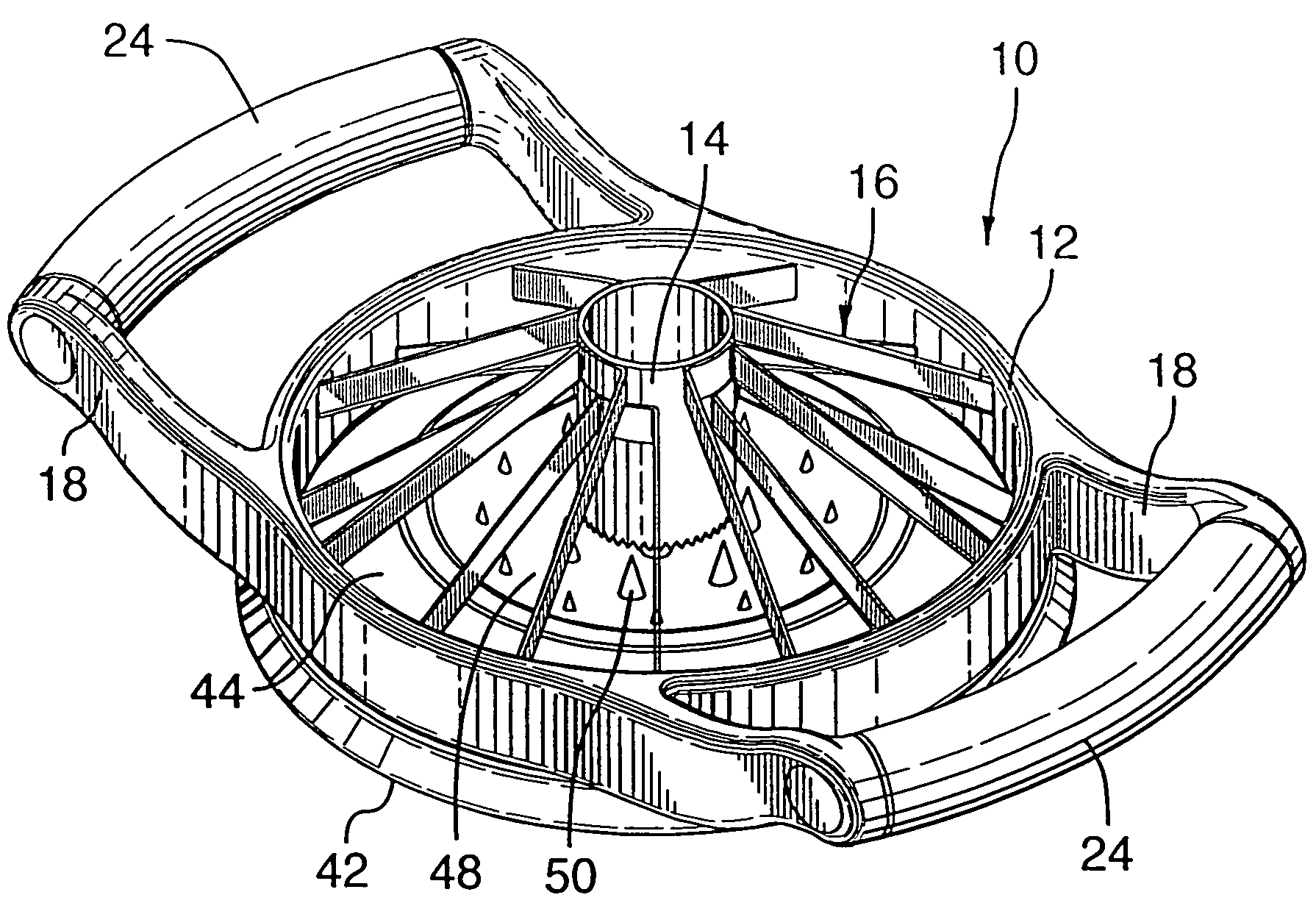

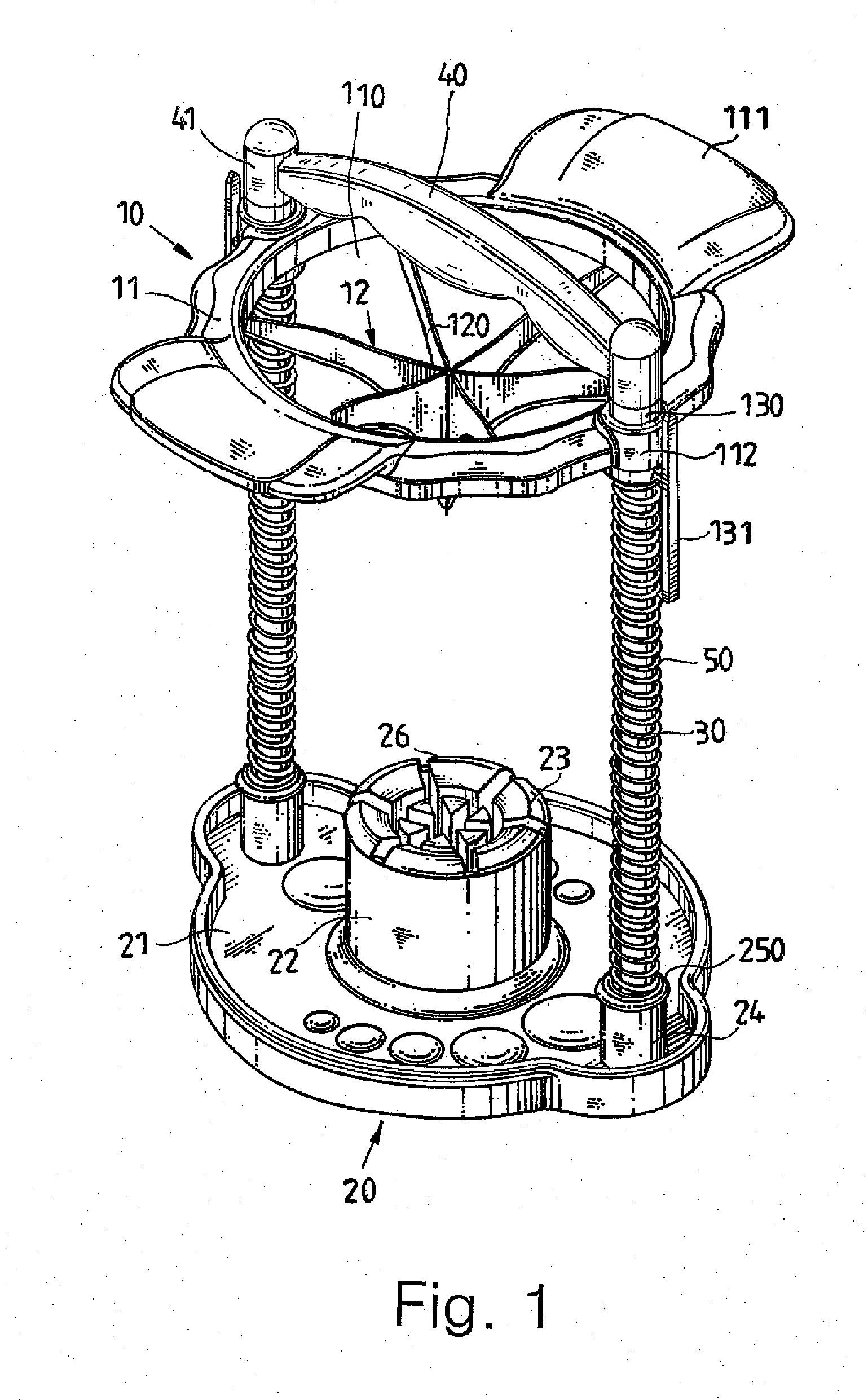

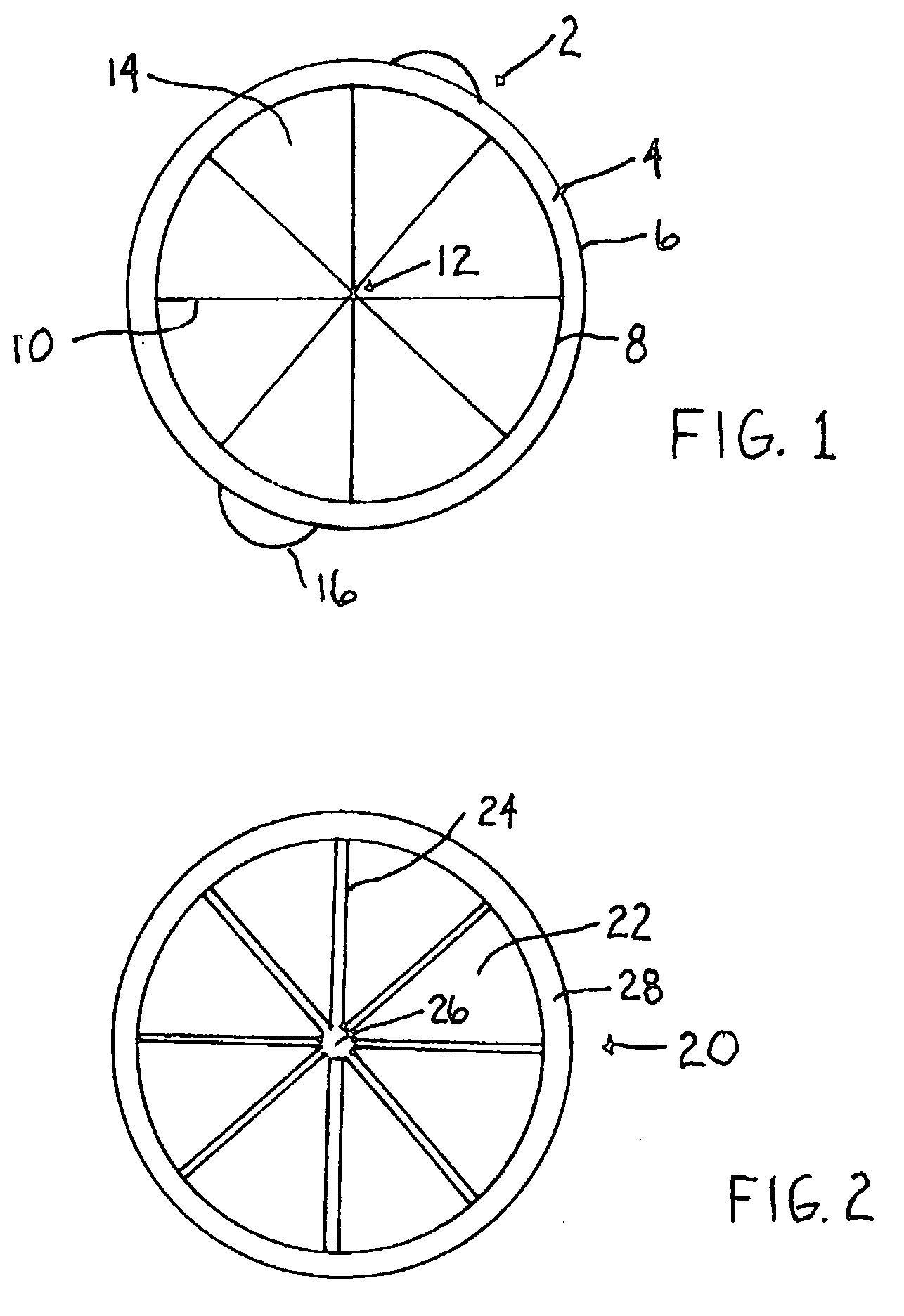

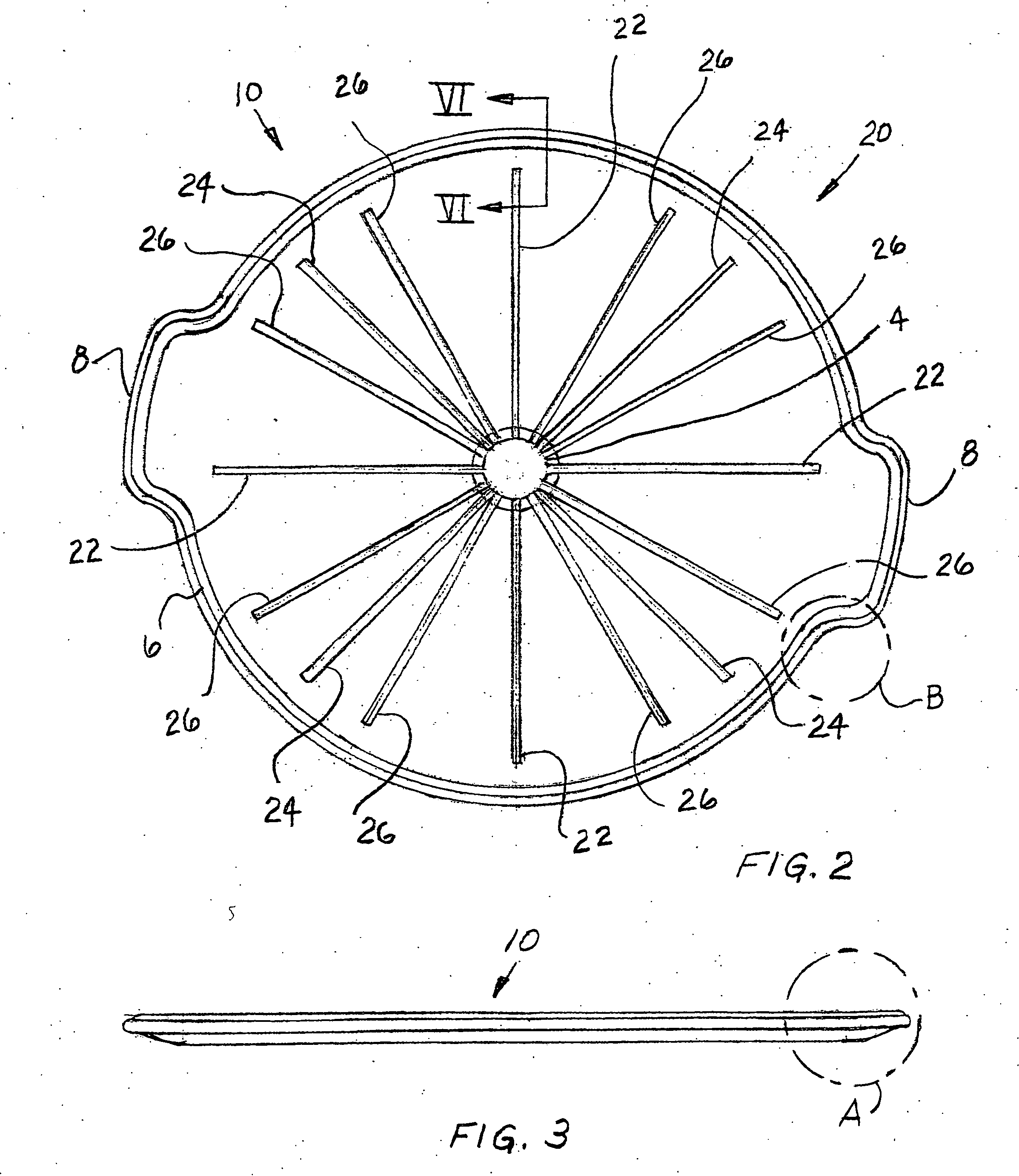

Even-slice pizza cutter

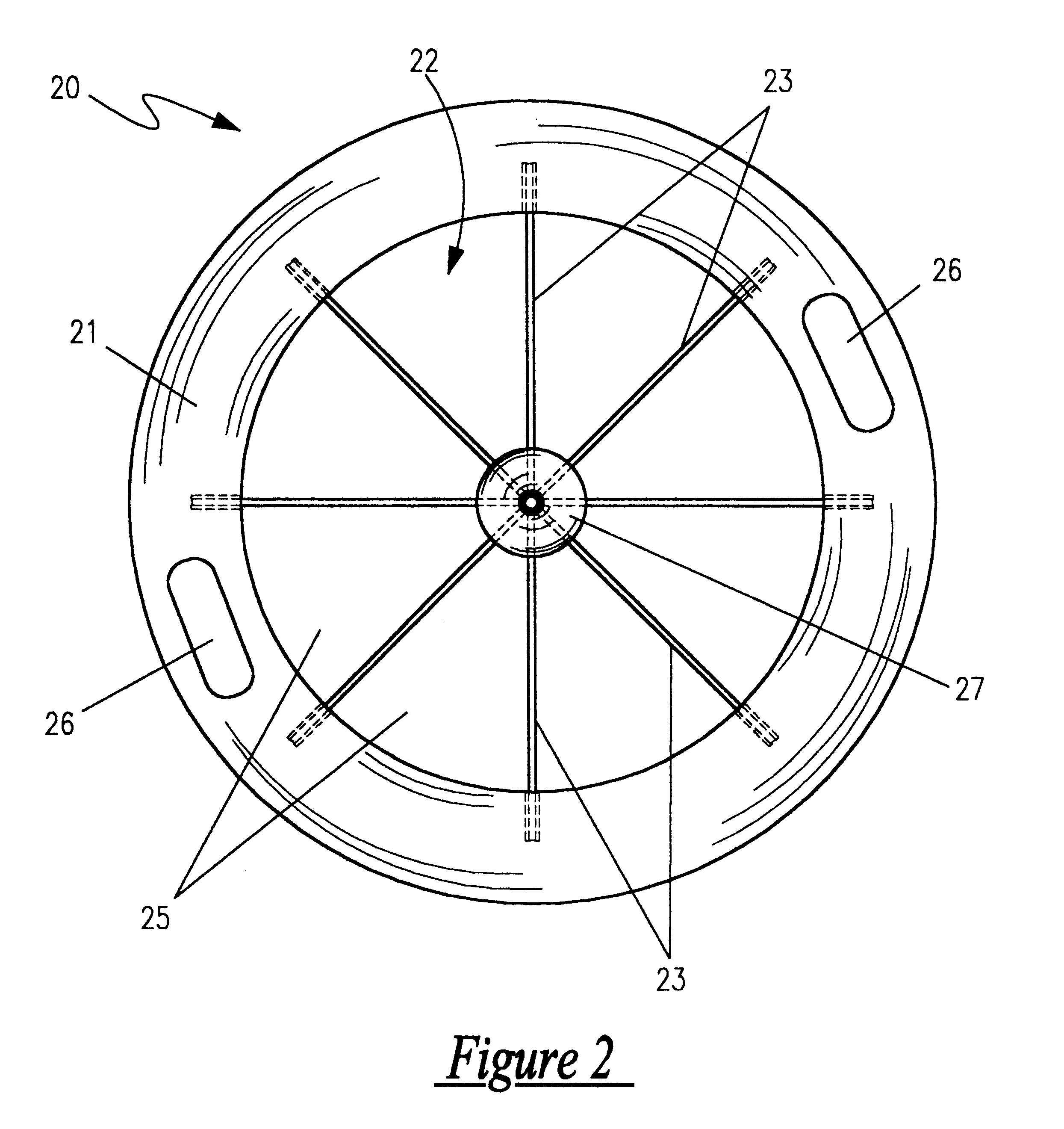

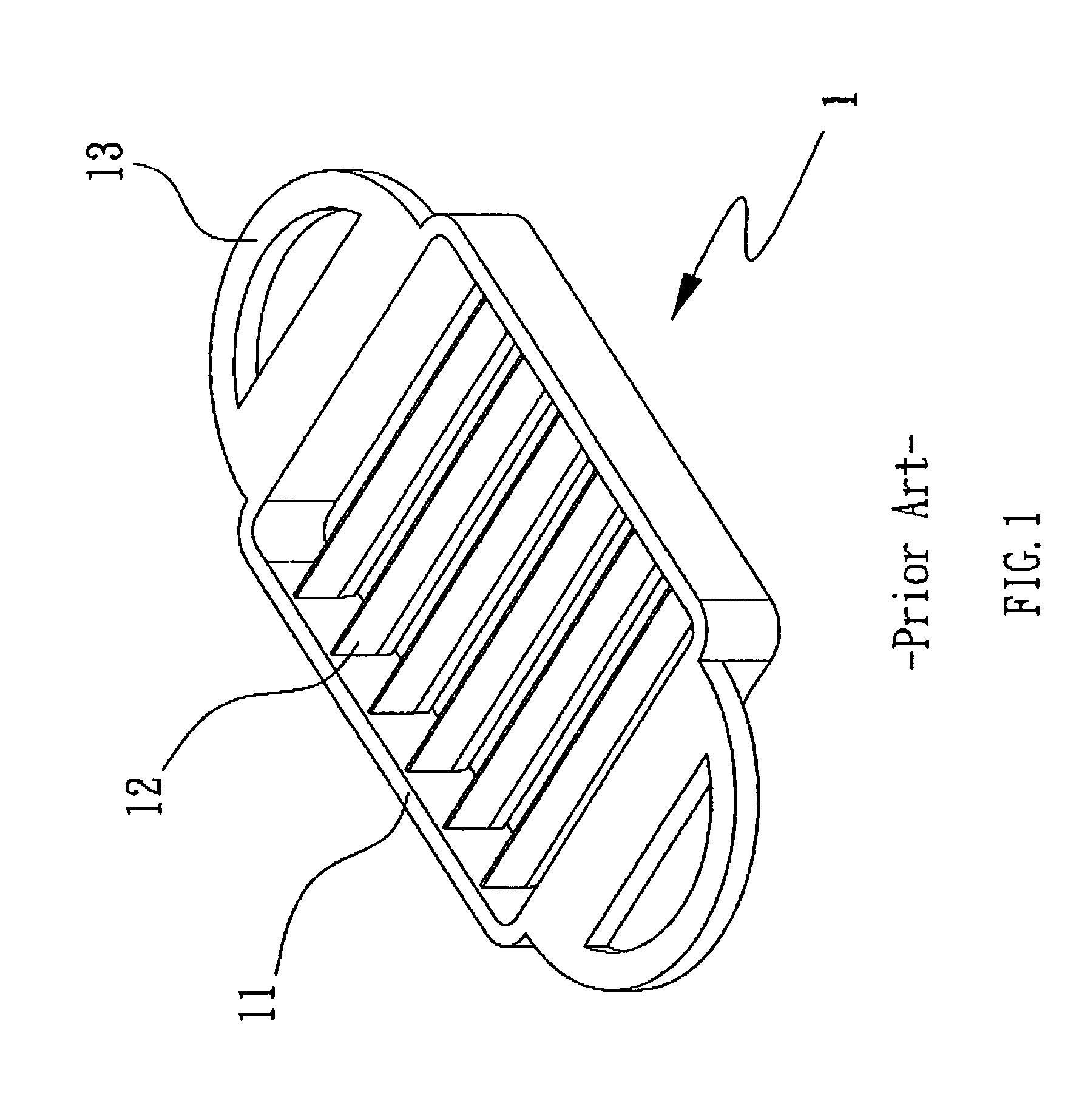

InactiveUS6557260B1Avoid dangerAvoid problemsDough dividingBaked article cutting/slicingKnife bladesEngineering

Disclosed is a pizza cutting device that allows the user to cut a pizza in uniform, evenly-sized pieces on a consistent basis. The cutter consists of a circular frame that has a series of blades spanning across its hollow interior diameter. Sized so that the entire pizza fits within the interior diameter, the user simply presses down on a pair of handles located on the outside of the frame and the blades cut the pizza into uniform, even slices.

Owner:MORRIS KENNETH A

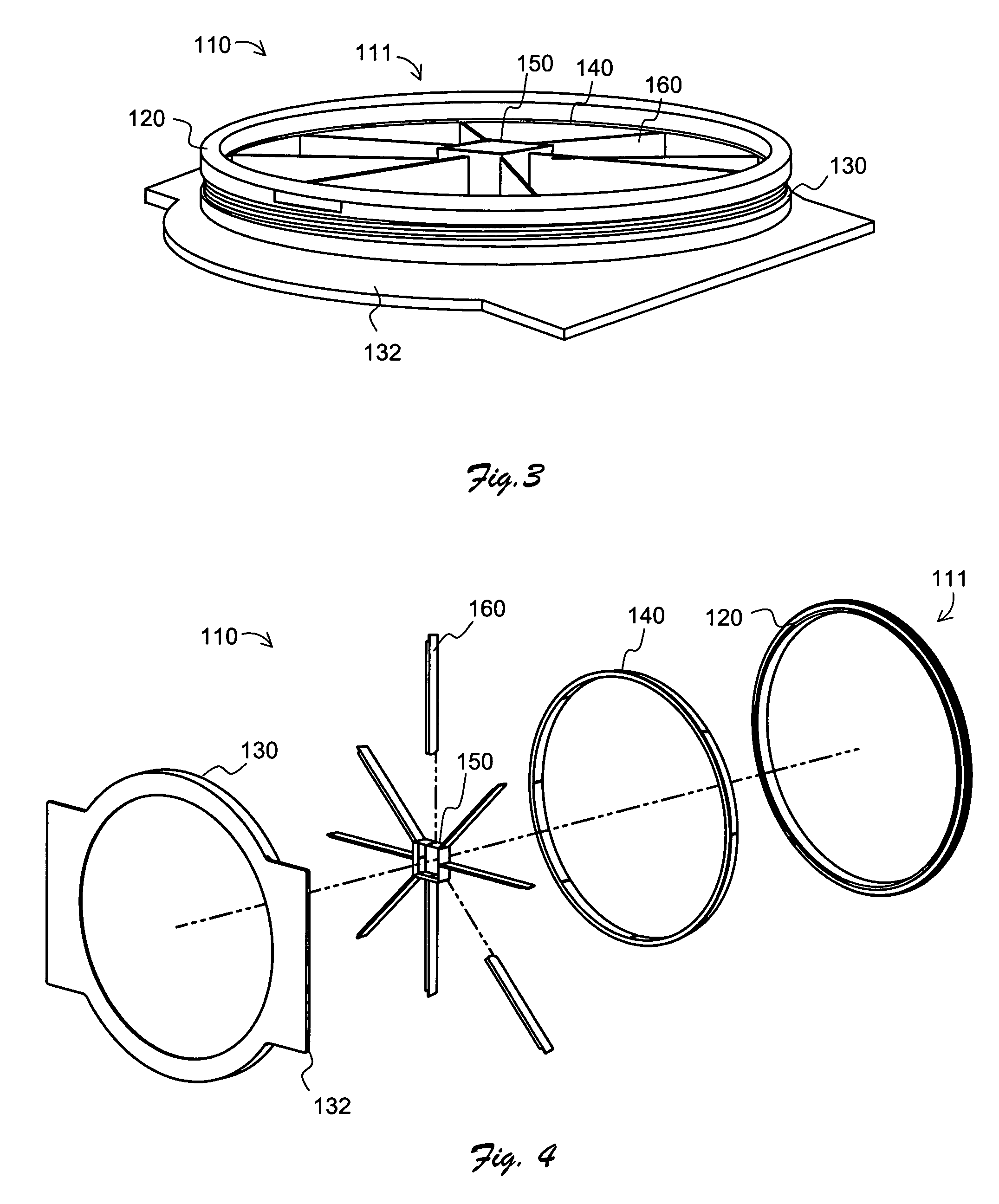

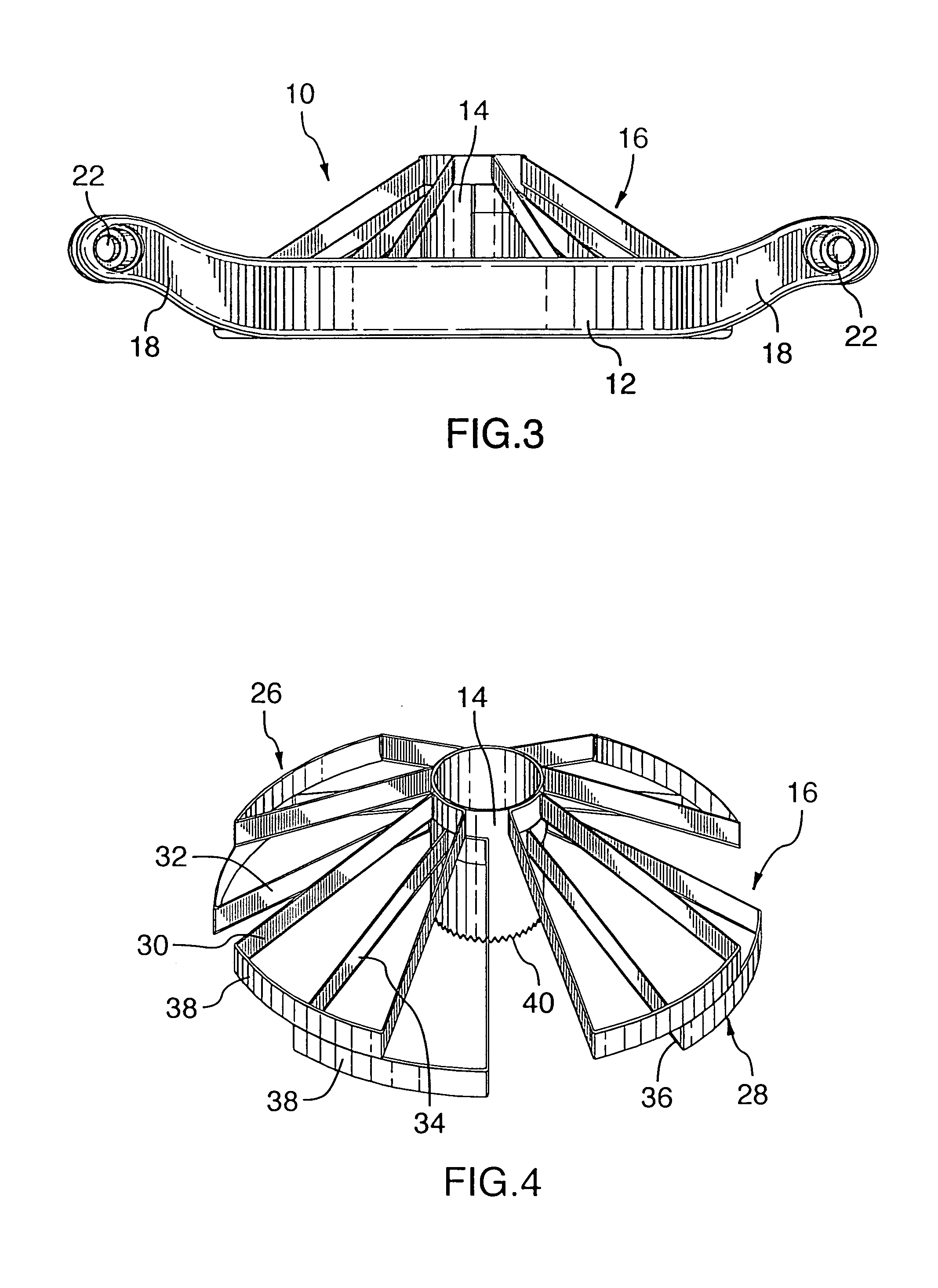

Knife assembly

A knife assembly for use in a food cutting apparatus includes a compression ring adapted for threaded engagement with a base ring. The compression ring includes a threaded collar that tapers thinner towards its leading edge. The blade support ring tapers thinner towards a leading edge of the support ring sidewall. The blade support ring includes a sidewall having a plurality of blade second end receiving slots. At least two blades are connected at their first ends to a central cutter element and at their second ends to the blade support ring. As the compression ring engages the base ring, the advancing and opposing surfaces of the tapered sidewall of the compression ring and the tapered sidewall of the blade support ring cooperate imparting a compressive force against the ends of the blades, securing the blade with respect to the compression ring and the cutter element.

Owner:JENSEN RALIEGH J

Apparatus for coring into and cutting food items

Owner:BROWNE & CO LTD

Fruit Cutter that Cuts Fruit Exactly and Smoothly

InactiveUS20080168660A1Easy to cutCuts a fruit exactly and smoothlyKitchen fruit stoningJuice extractionEngineeringMechanical engineering

A fruit cutter includes a fixed seat, and a cutting device movable relative to the fixed seat. The cutting device includes a movable seat and a blade unit. The blade unit includes a plurality of cutting blades. The cutting blades have an intersection provided with a sharp tapered drilling portion. Each of the cutting blades has a mediate portion provided with a concave guide edge. Thus, the drilling portion of the cutting blades is inserted into the central portion of the fruit to pierce the fruit, while the cutting blades of the blade unit extend from the central portion toward the rim of the fruit to cut and separate the fruit by guidance of the guide edge of each of the cutting blades, so that the fruit is cut into multiple parts easily and quickly.

Owner:LEE CHIH CHENG

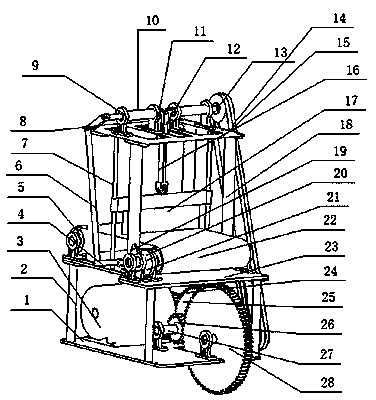

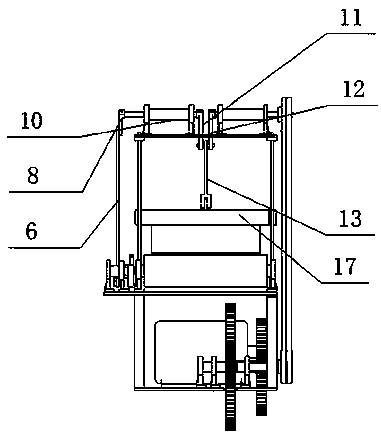

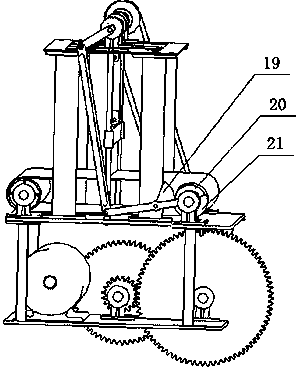

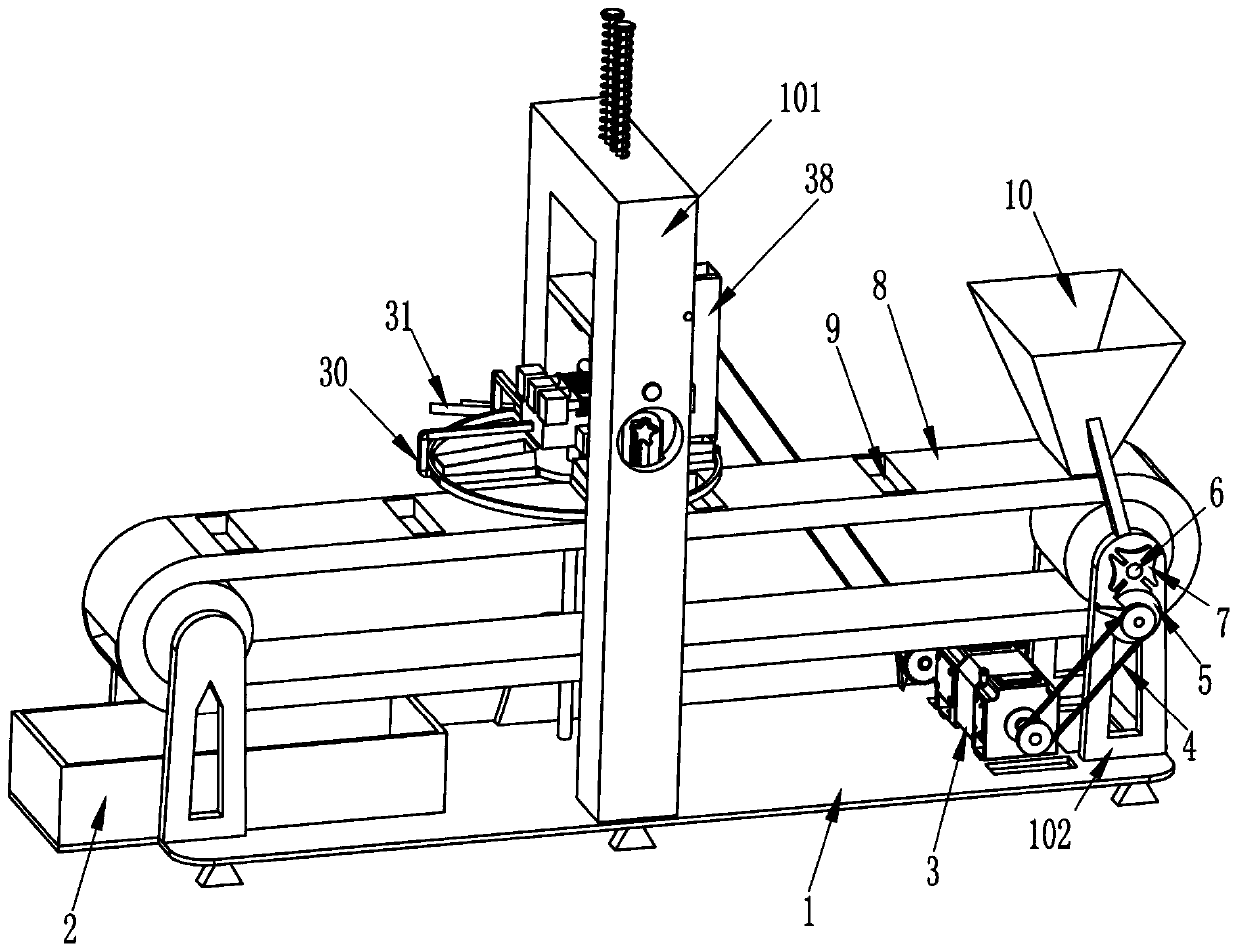

Automatic feeding pastry slicer

InactiveCN103862499AImprove work efficiencyGuaranteed slicing effectMetal working apparatusBaked article cutting/slicingEngineeringFriction force

Owner:KUNMING UNIV OF SCI & TECH

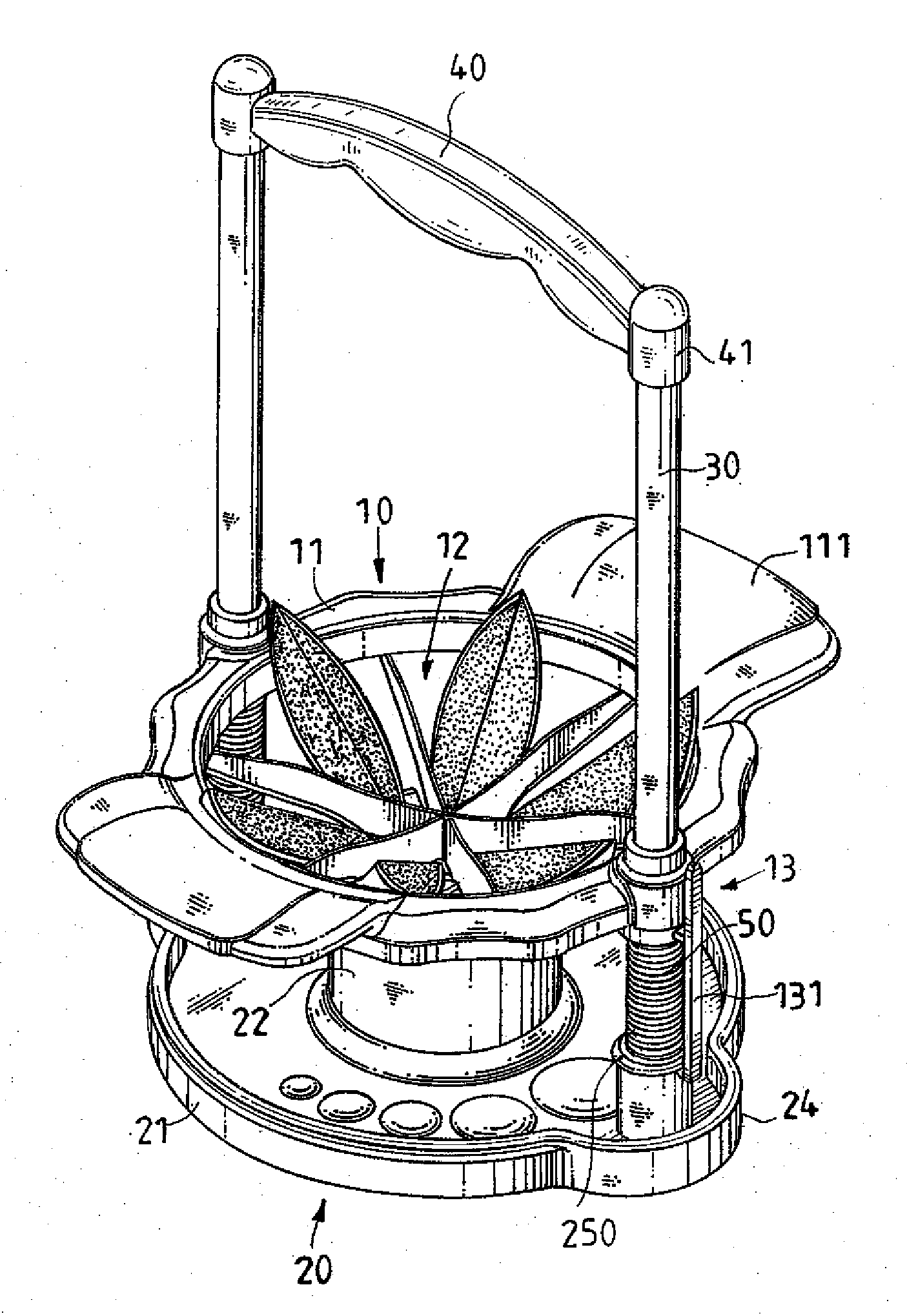

Sectioning device and method of use

A sectioning device for sectioning food and non-food items includes a frame, a cutter removably positioned on the frame and press means positioned on the frame for pushing an item against and through the cutter. The sectioning device also includes means for moving, in a single continuous motion, at least one of the cutter and the press means between a neutral position and a sectioning position. The press means and the cutter are configured such that an item to be sectioned, positioned between the cutter and the press means is sectioned in its entirety upon movement from the neutral position to the sectioning position.

Owner:EDIBLE IP LLC

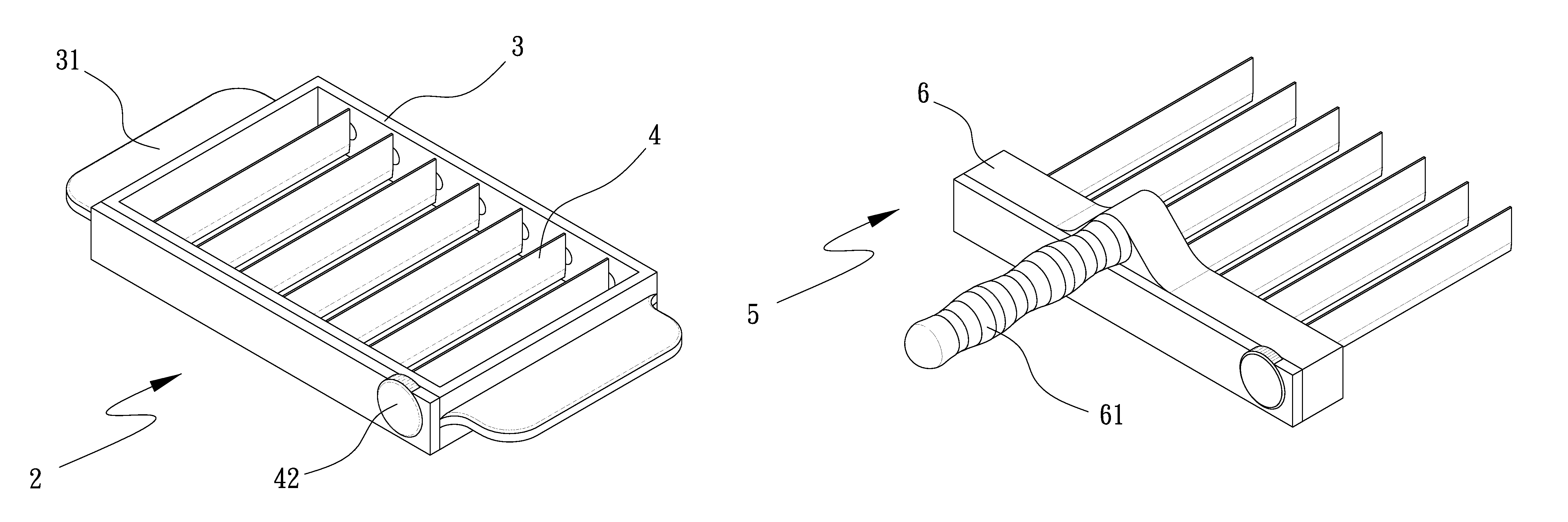

Portable slicer for food products

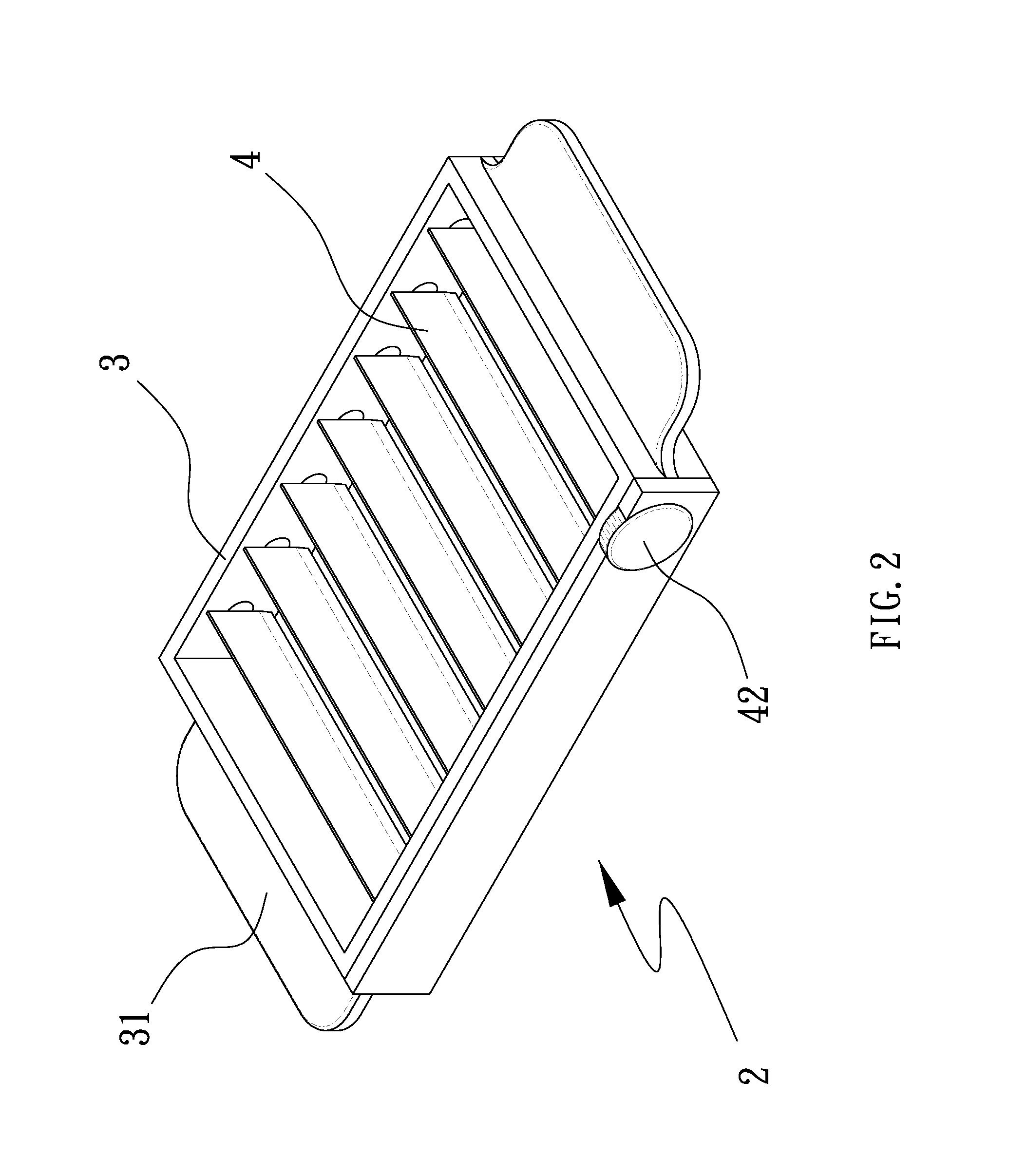

InactiveUS20070022611A1Quick and efficient slicingEasy to useDough dividingMetal working apparatusEngineeringMechanical engineering

Disclosed is a portable slicer for food products comprising a base having an upper surface defined by an elongate seat and a circumferential edge, the upper surface being selectively, longitudinally recessed to form the elongate seat lowered from and surrounded by the edge, the upper surface being vertically spaced apart to form a plurality of channels in lengthwise columns and widthwise rows. A frame is foldably connected to the base, the frame having one or more blades aligned to fit in the channels.

Owner:VERBIEST STACY

Culinary cutting tool

A culinary tool includes a base member that has a planar bottom surface and an arcuate top surface for fitting an entire roll of cookie dough thereon. The top surface is contoured symmetrically to an outer surface of the roll of cookie dough. The base member has oppositely seated longitudinal sides equidistantly spaced from the longitudinal axis thereof. The base member is provided with grooves equidistantly spaced along a length thereof. The grooves traverse a length of the roll of cookie dough, extend downwardly from the top surface, and terminate above the bottom surface. A slicing section is pivotally conjoined to opposed base member ends, is rearwardly offset from a base member center, and is repeatedly pivotal along a fulcrum axis such that the slicing section penetrates through the grooves so that the roll of cookie dough becomes completely severed into disc-shaped segments defined by the grooves.

Owner:THUNE JR DANIEL

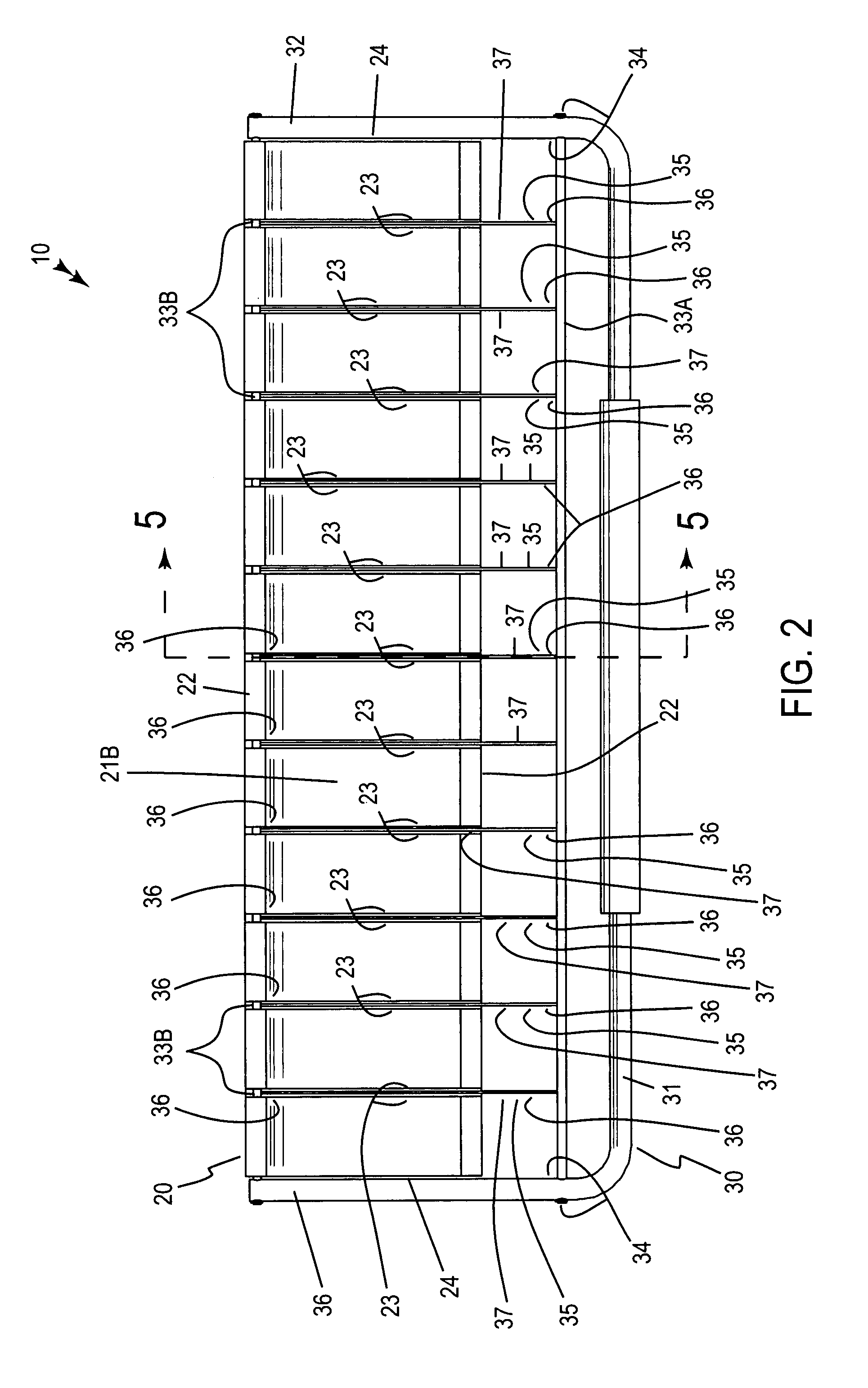

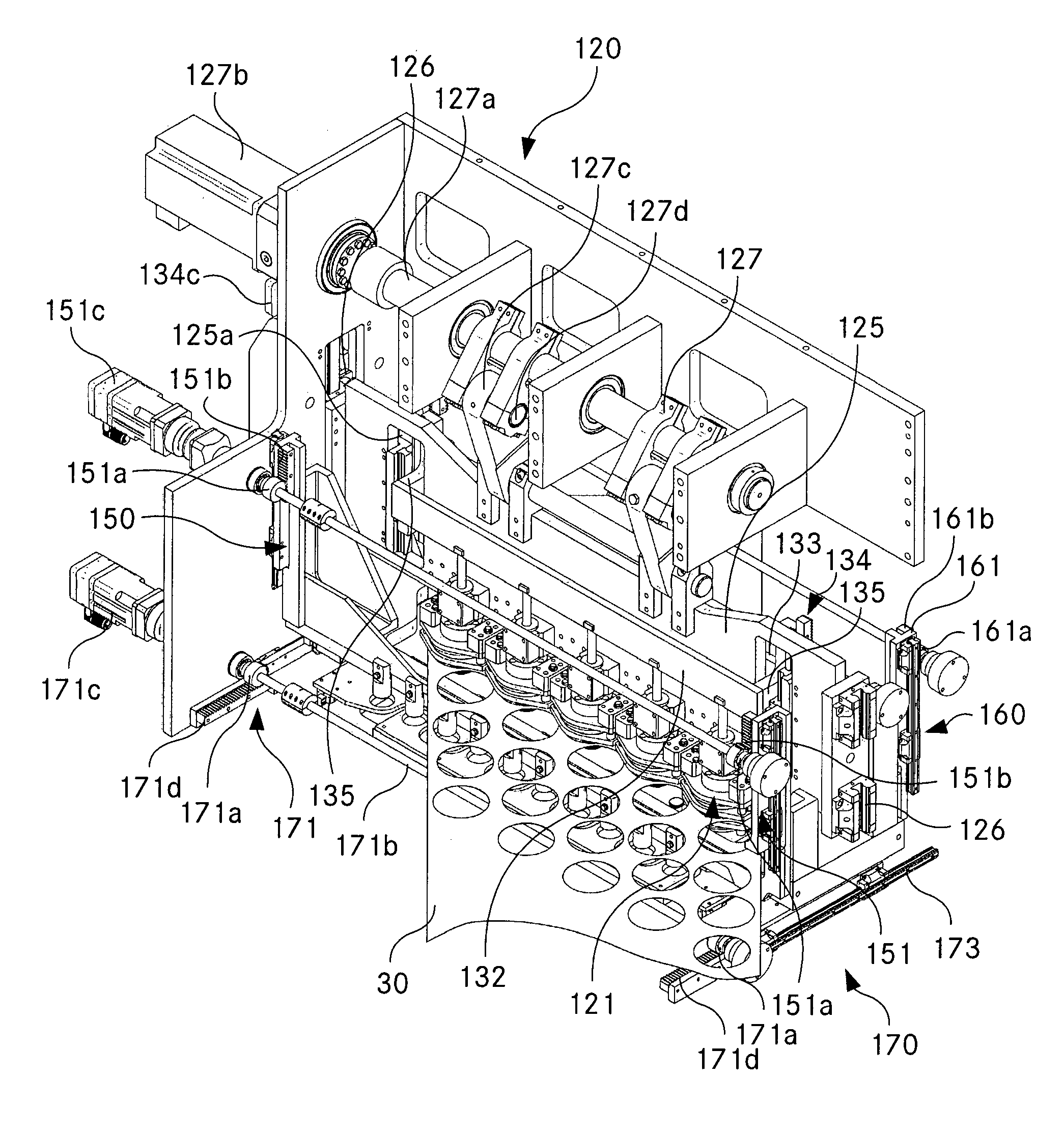

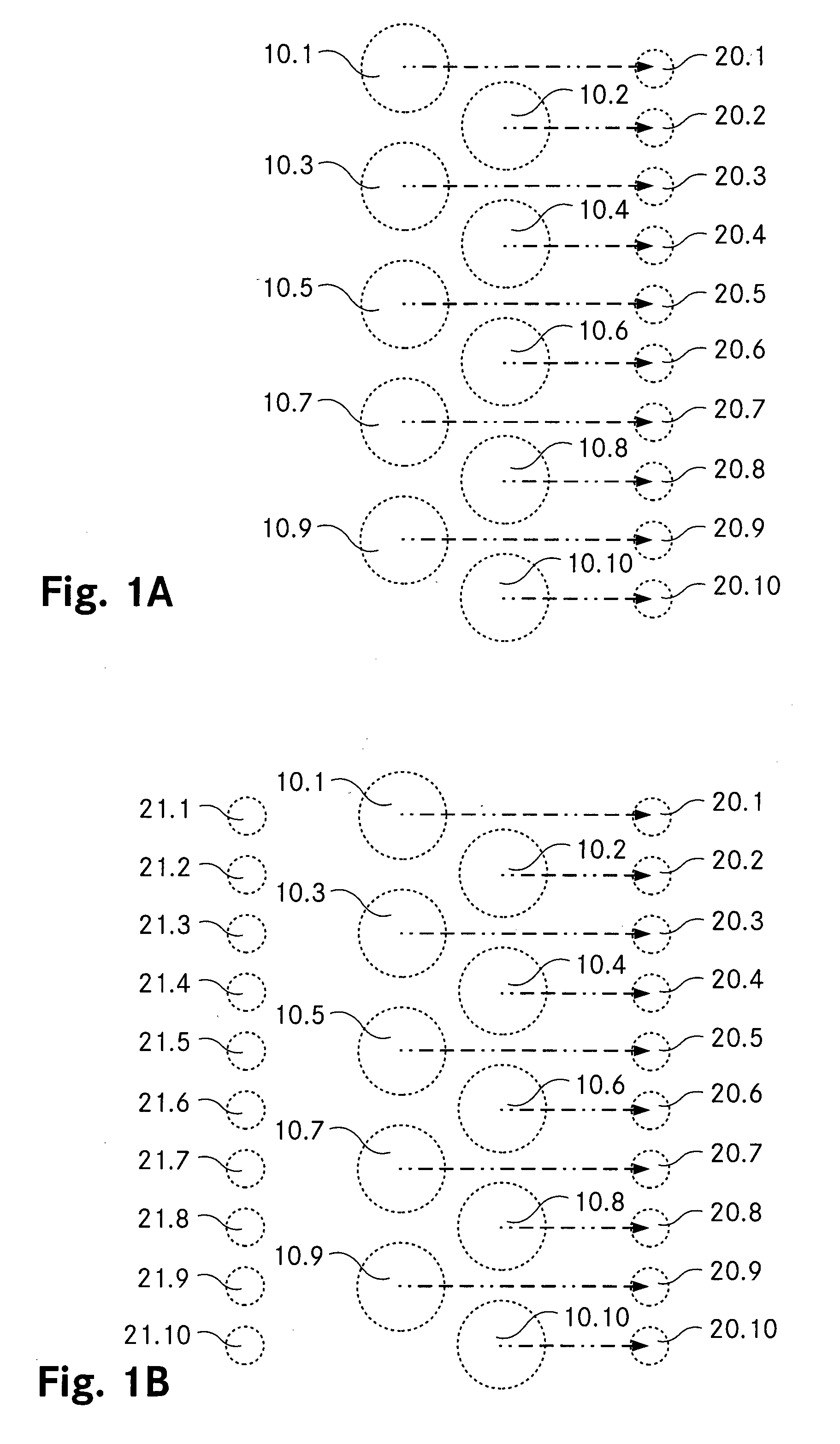

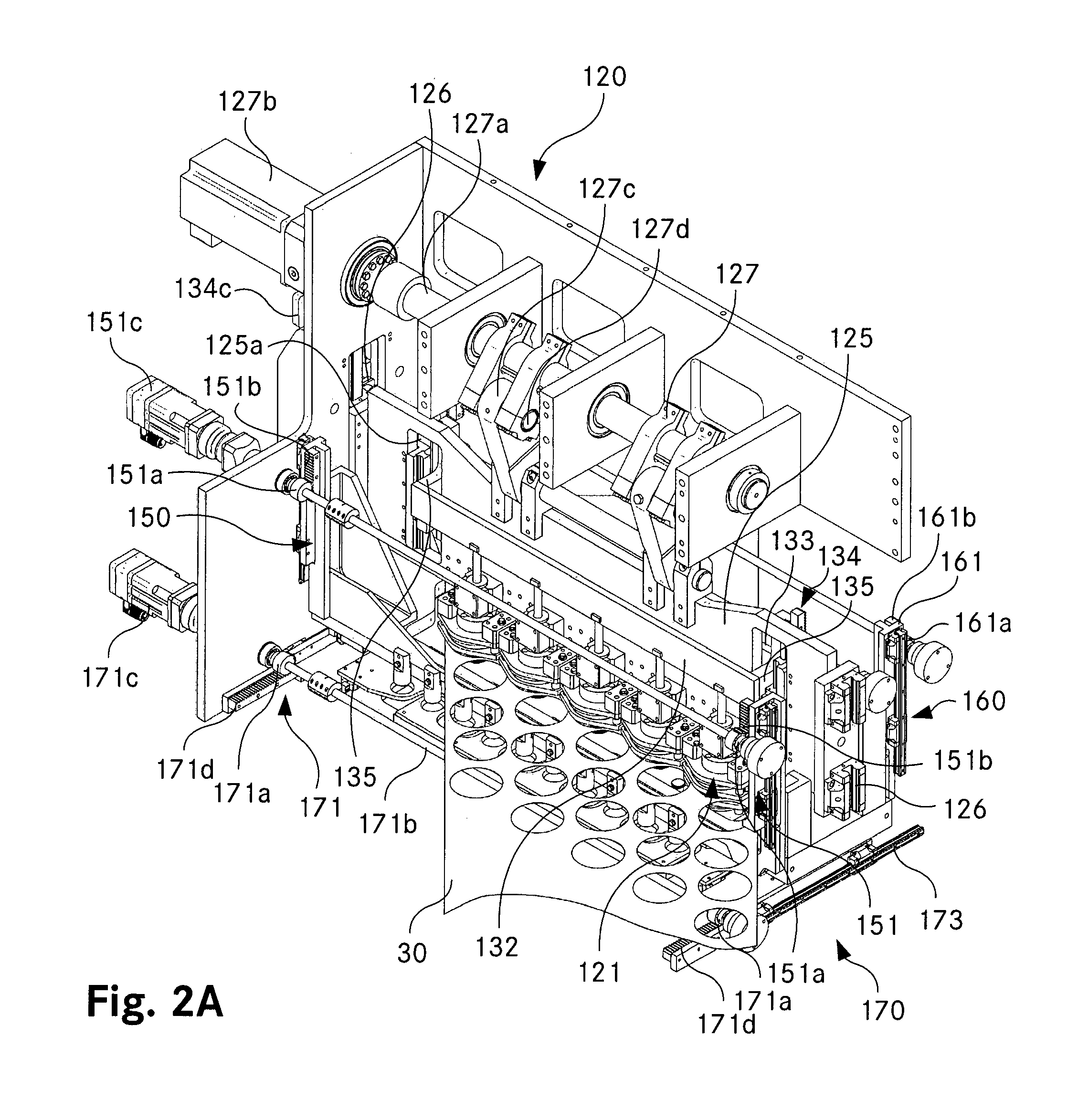

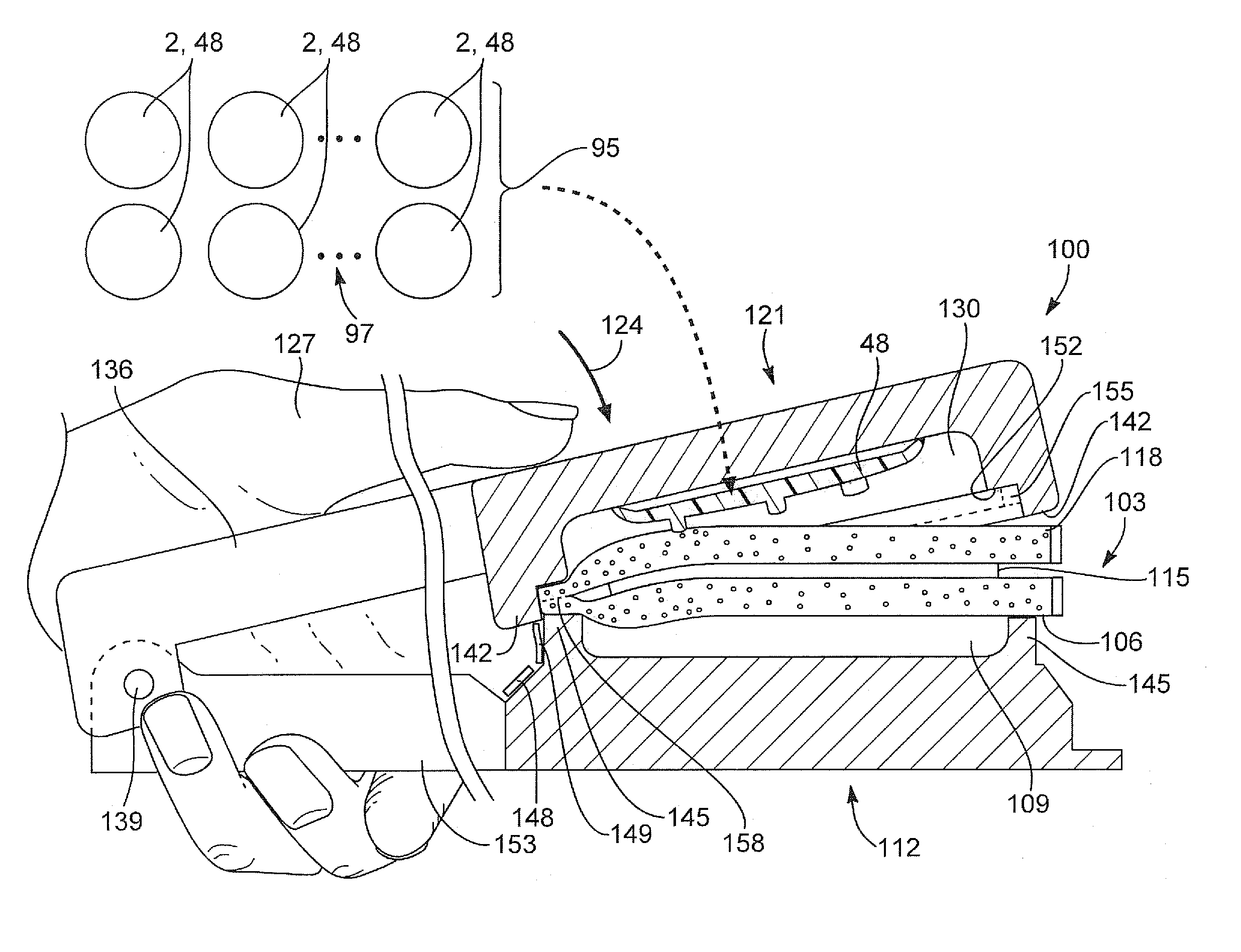

Apparatus and method for manufacturing filters and inserting the filters into single dose capsules for preparing beverages

ActiveUS20150020481A1Small footprintEasy constructionAssembly machinesCartridge filtersPunchingEngineering

An apparatus for manufacturing filters and inserting the filters into single dose capsules for preparing beverages comprises a punching and forming device for punching material portions from a sheet material and forming the material portions to assume the form of a beaker-shaped filters, an insertion device arranged in a distance of the punching and forming device along a work flow direction for inserting the formed filters into the capsules, a first transport device (175, 176) for accepting a plurality of formed filters from the punching and forming device and transporting the accepted filters to the insertion device, a second transport device (177) for accepting a plurality of formed filters from the punching and forming device and transporting the accepted filters to the insertion device. The first transport device (175, 176) and the second transport device (177) are movable with respect to each other. This allows for increased flexibility when feeding a plurality of filters of the punching and forming device to the insertion device. Furthermore, it allows for geometries of the punching and forming device and of the insertion device where the respective distances between neighbouring punching and forming tools as well as neighbouring insertion tools may be different.

Owner:RYCHIGER

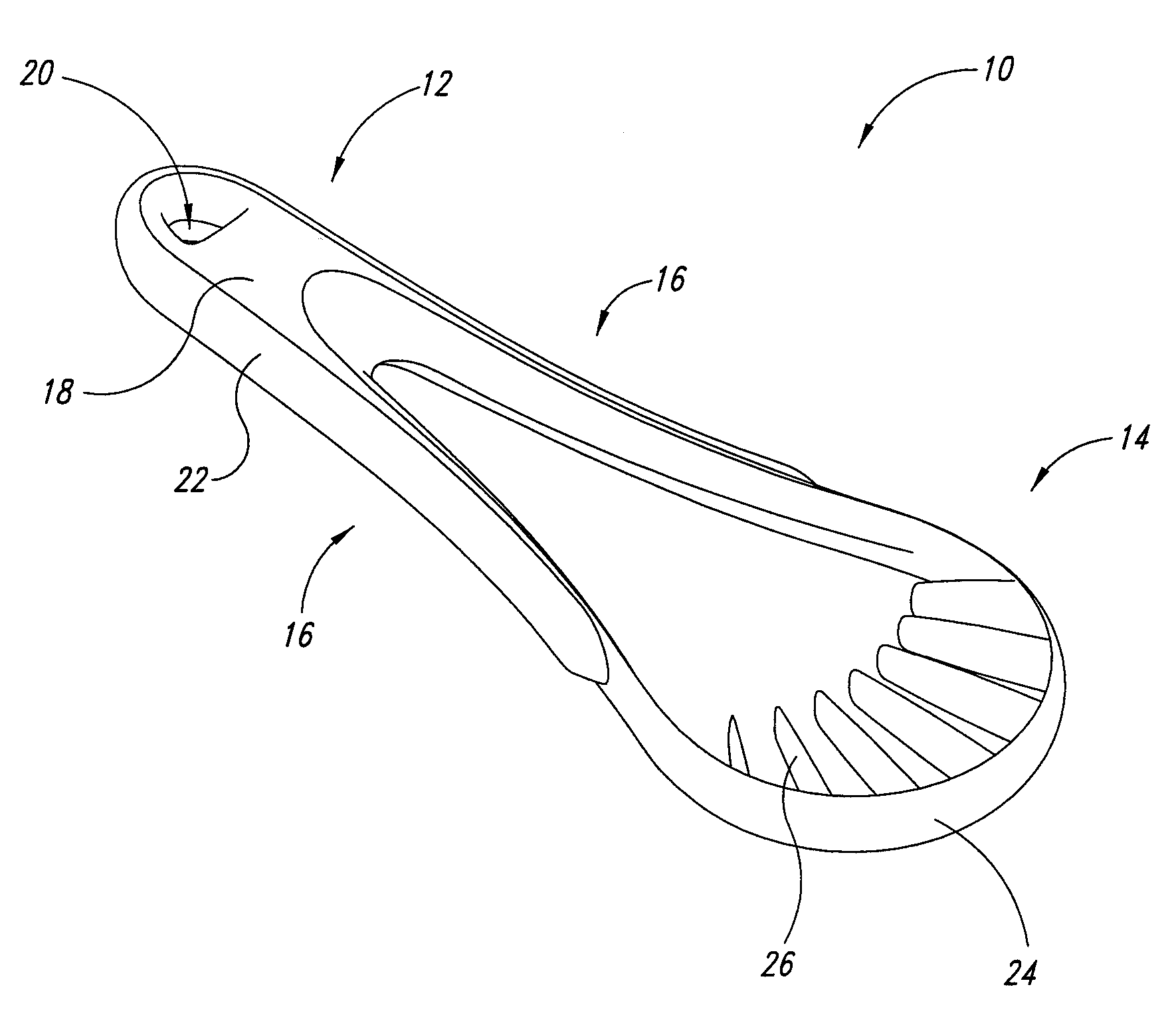

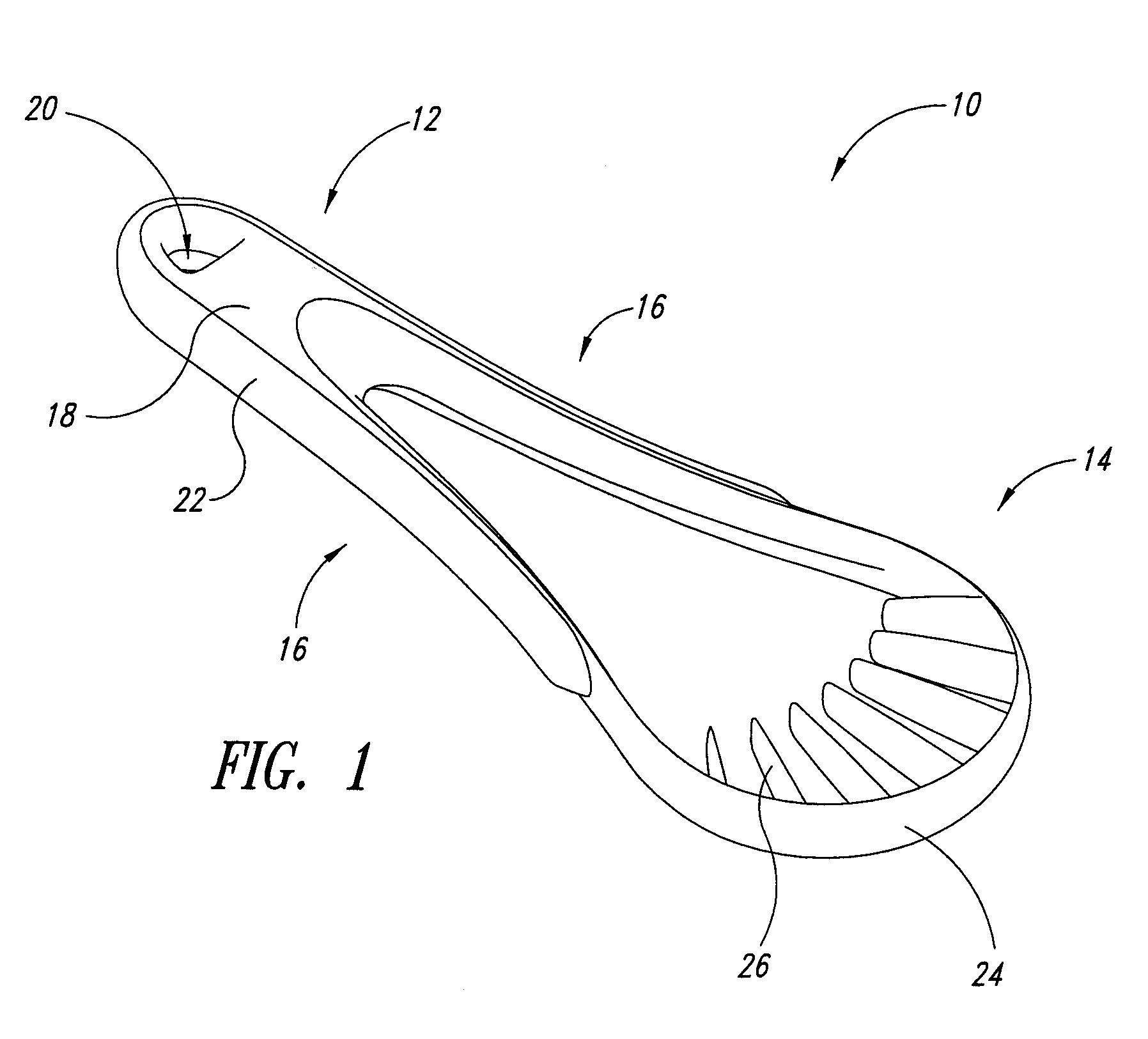

Devices and methods for use in preparing certain fruits for consumption

Devices for removing and / or slicing a meat of fruit are disclosed. In one embodiment, the device has a handle portion and a working portion having an elongated blade and a pair of lateral extensions. The elongated blade has a cross-sectional shape adapted to facilitate movement of the elongated blade through the meat of the fruit. The working portion of the device has a resting configuration in which the elongated blade has a first radius of curvature, and at least one of the lateral extensions is manipulable under a manual force during use to deform the working portion from the resting configuration to a displaced configuration in which the elongated blade has a second radius of curvature, selectively conforming to the curvature of the skin before and as the elongated blade moves through the meat of the fruit.

Owner:CHEFN

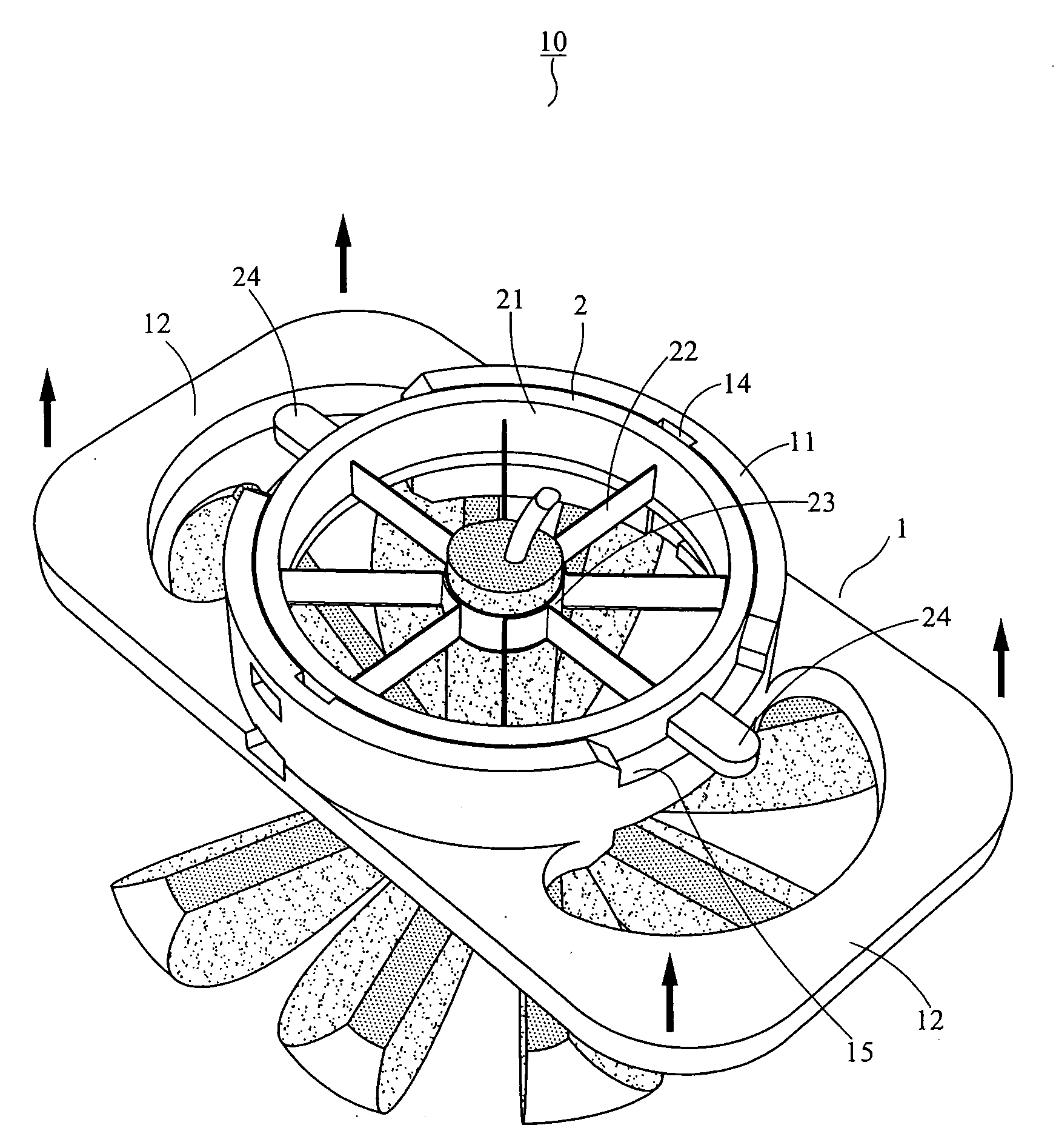

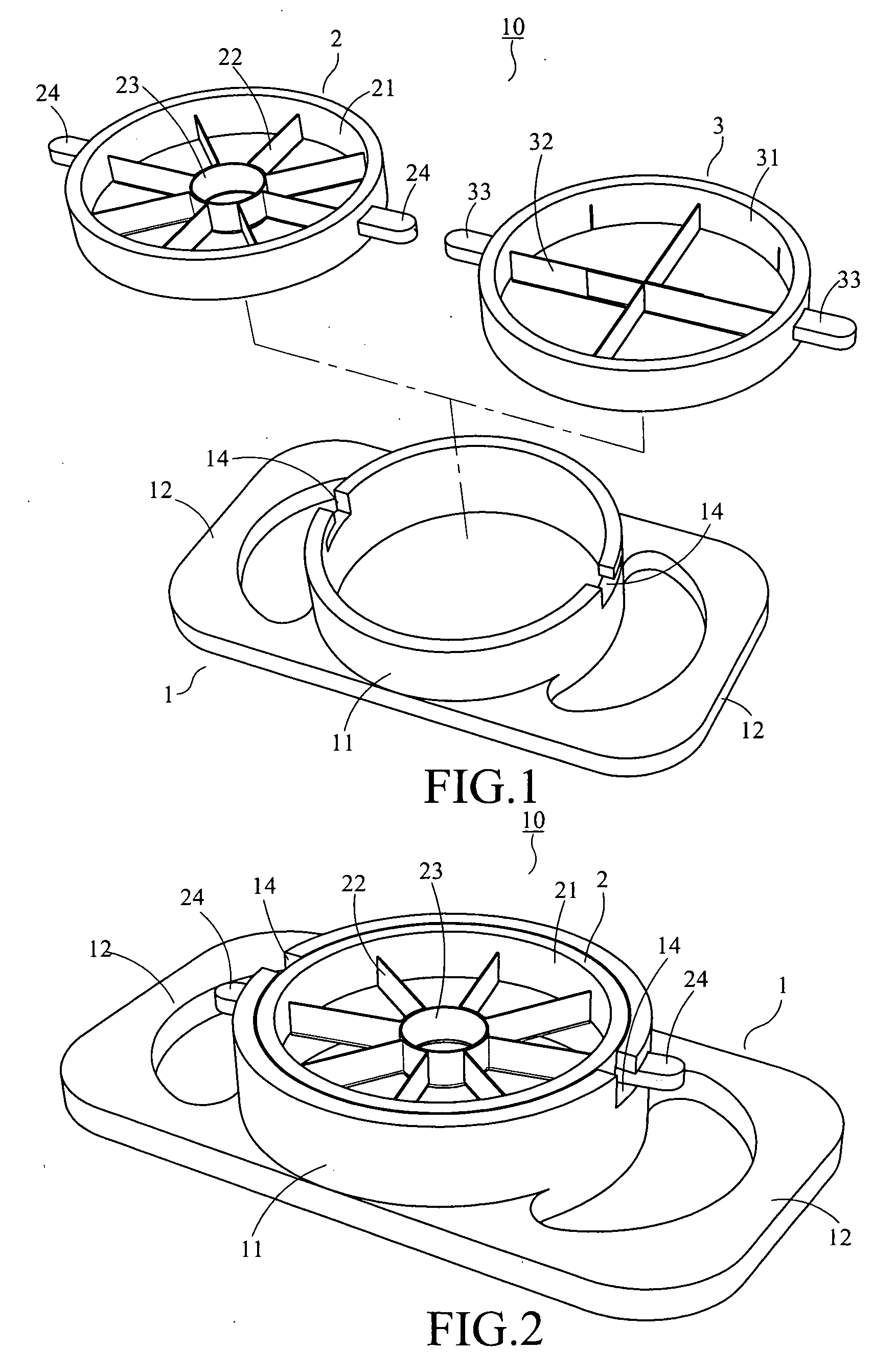

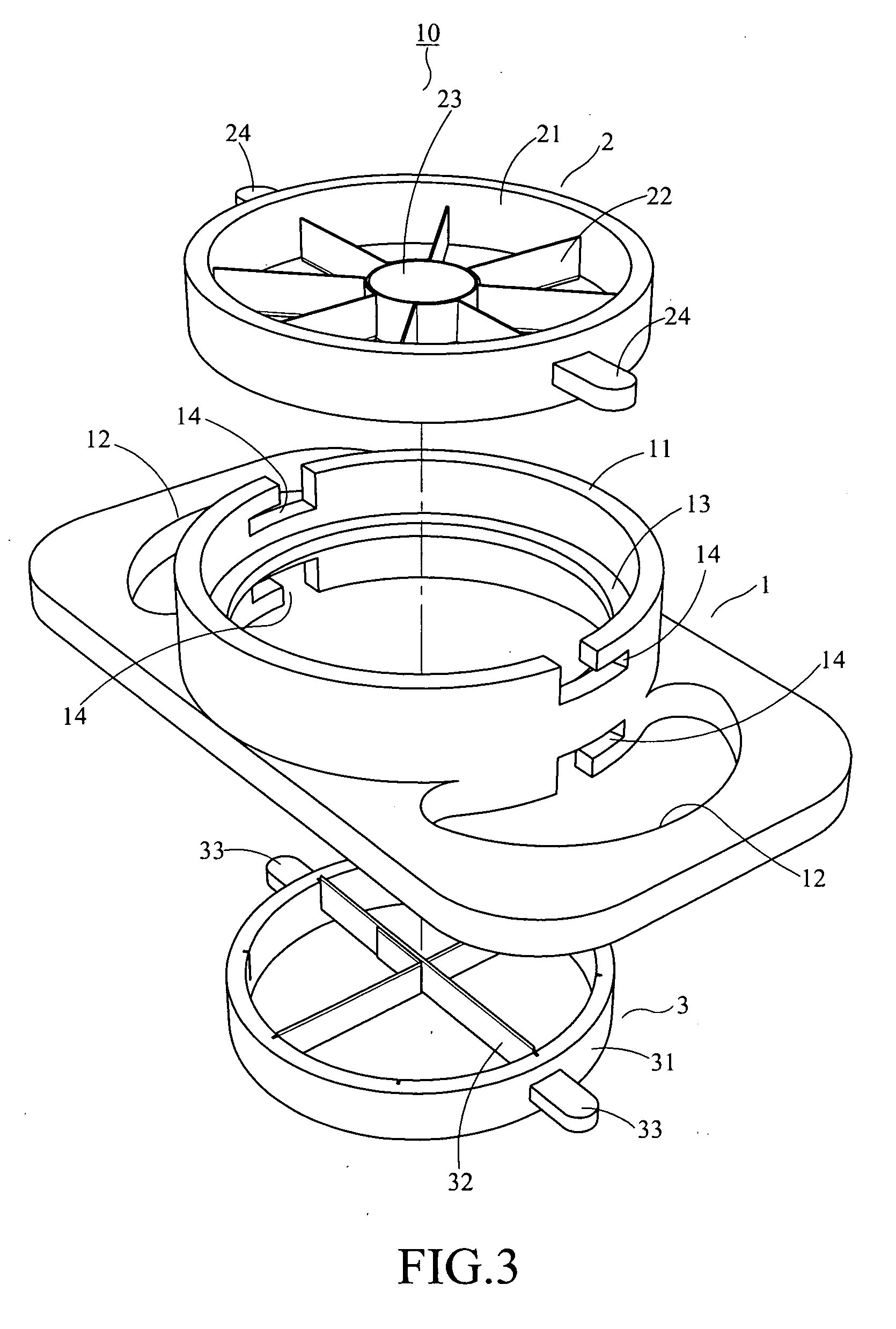

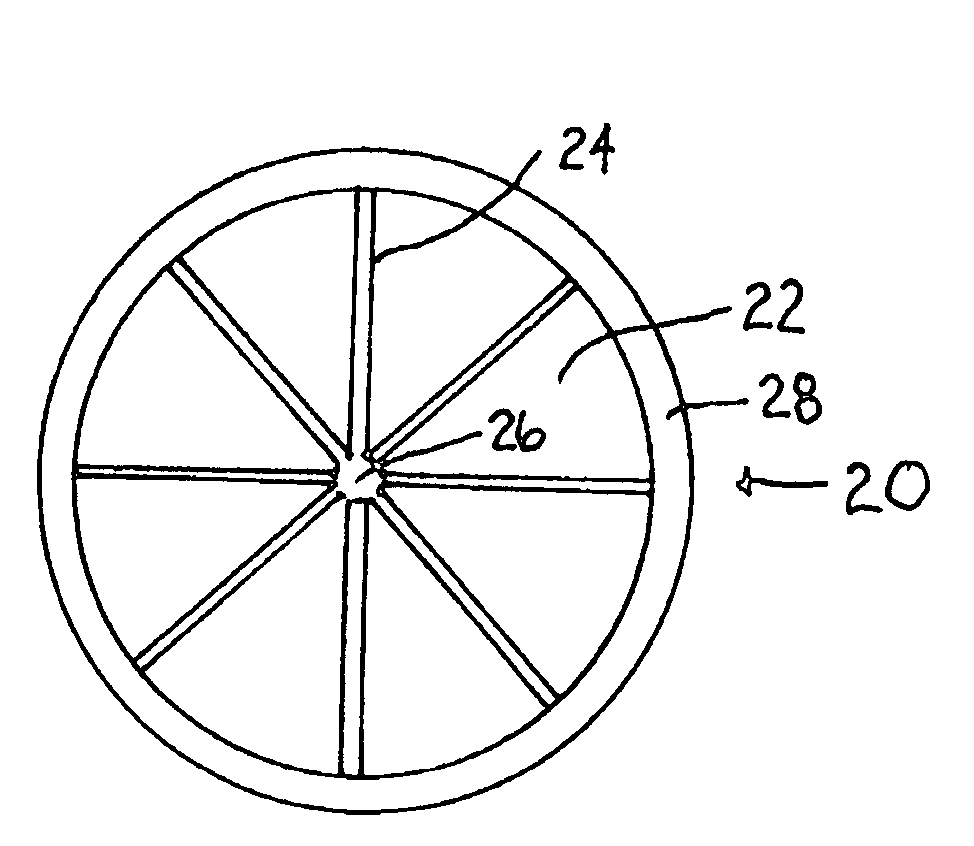

Manual fruit slicer with interchangeable cutting and coring disks

InactiveUS20060254058A1Easy to splitReduce the possibilityDough dividingMetal working apparatusCircular discEngineering

The present invention is aimed to provide a manual fruit slicer with interchangeable cutting and coring base. It has the practical functions as replacement of disks, reverted said edges onto the base, and a plurality of said edges can be received in the base. In use, a manual fruit slicer comprises a base, and disks. A hollowed annular sleeve is protruded out from the base around its center with two jug-ears extended out from both of its ends. A disk is designed as an annular edge frame disposed inside the hollowed annular sleeve. It is characterized by L type grooves formed through the upper or lower section being adapted to the handles protruded out from the outer wall of the disk to fix in place. The handles are also designed for a user's grip.

Owner:CHANG MING SHIH

Process and apparatus for pouch-forming with optimized fill-accuracy and headspace

ActiveUS20100215813A1Fruit and vegetables preservationPackaging by pressurising/gasifyingMaterials scienceSurgery

Owner:LIQUI BOX

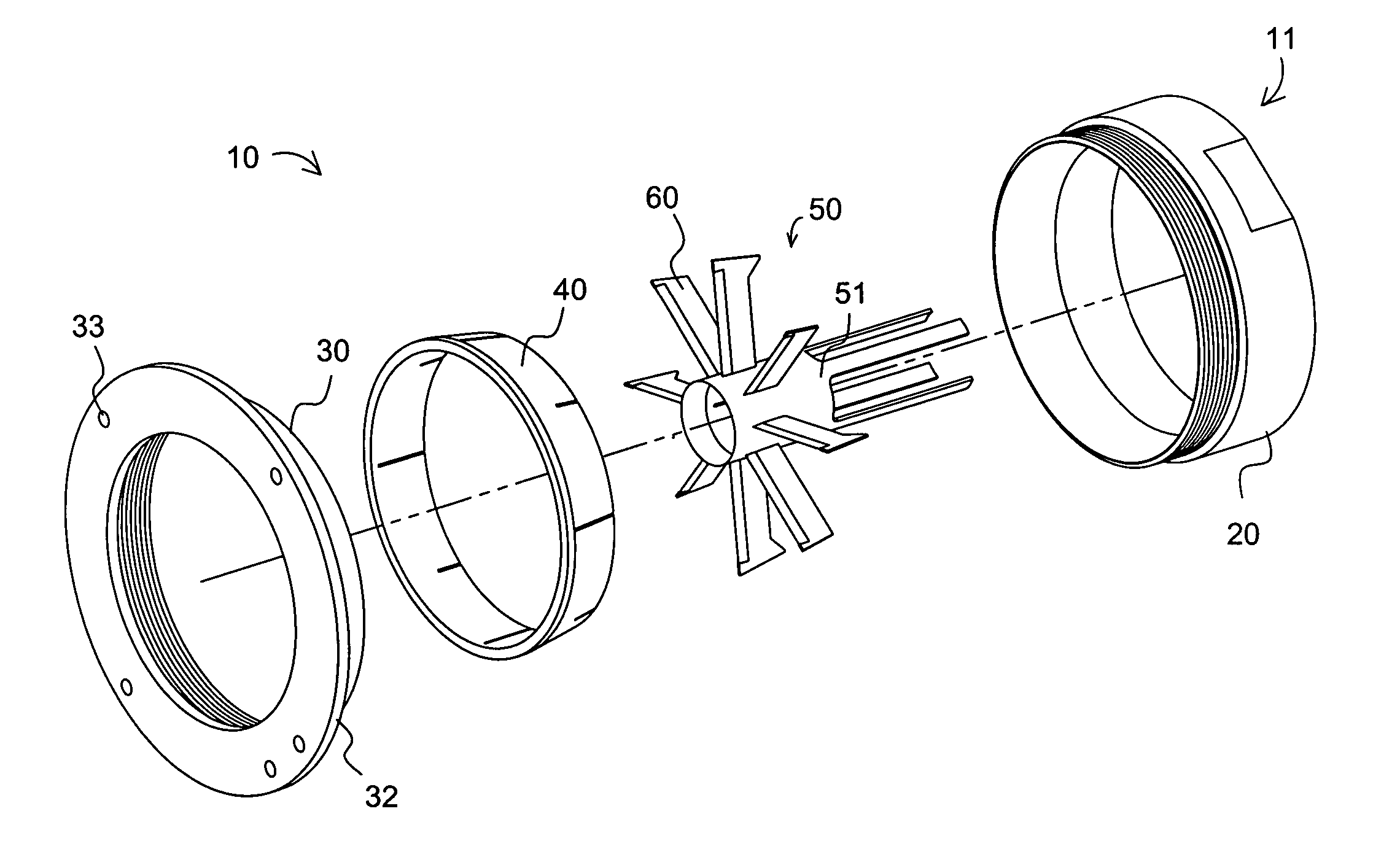

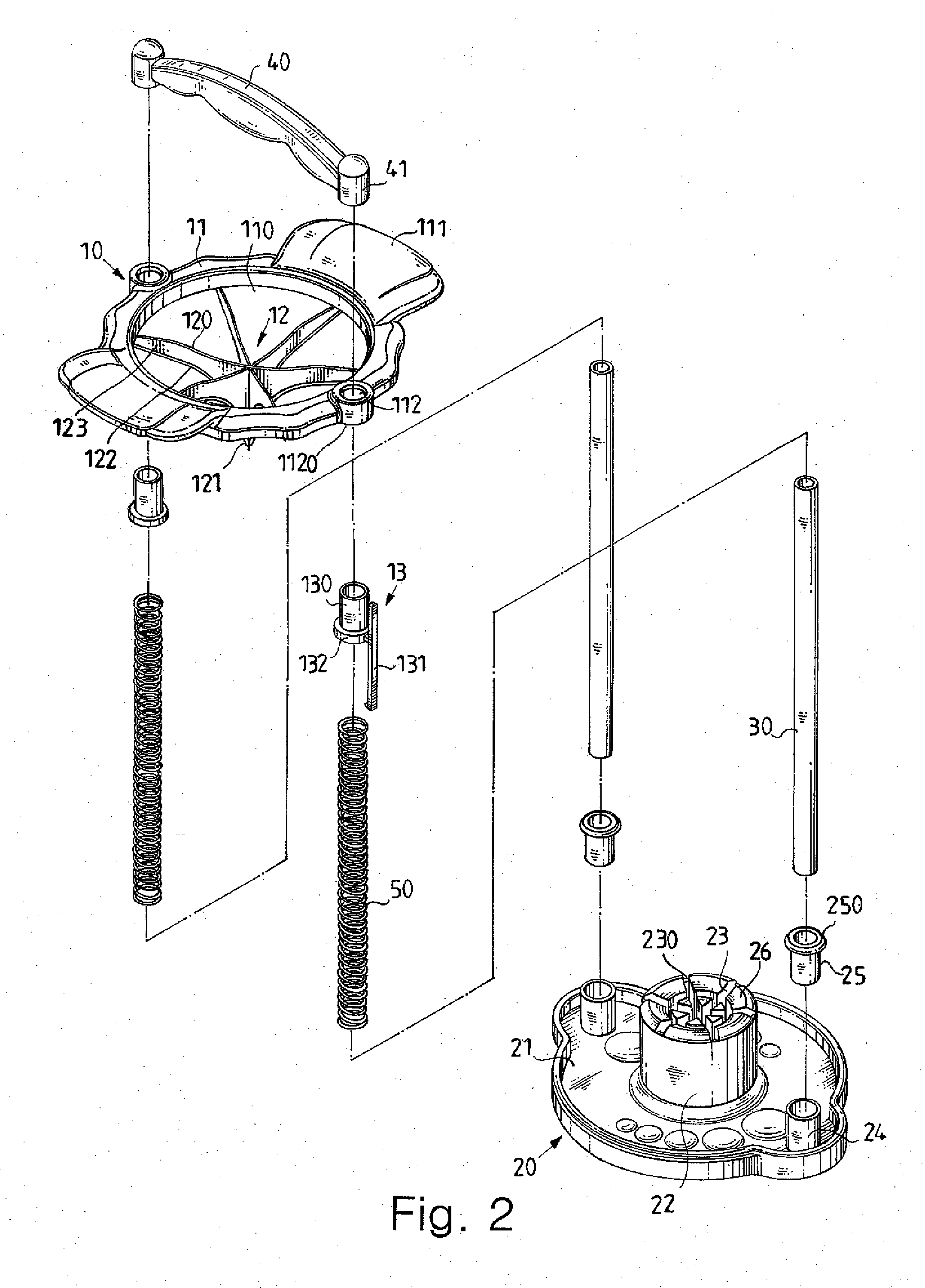

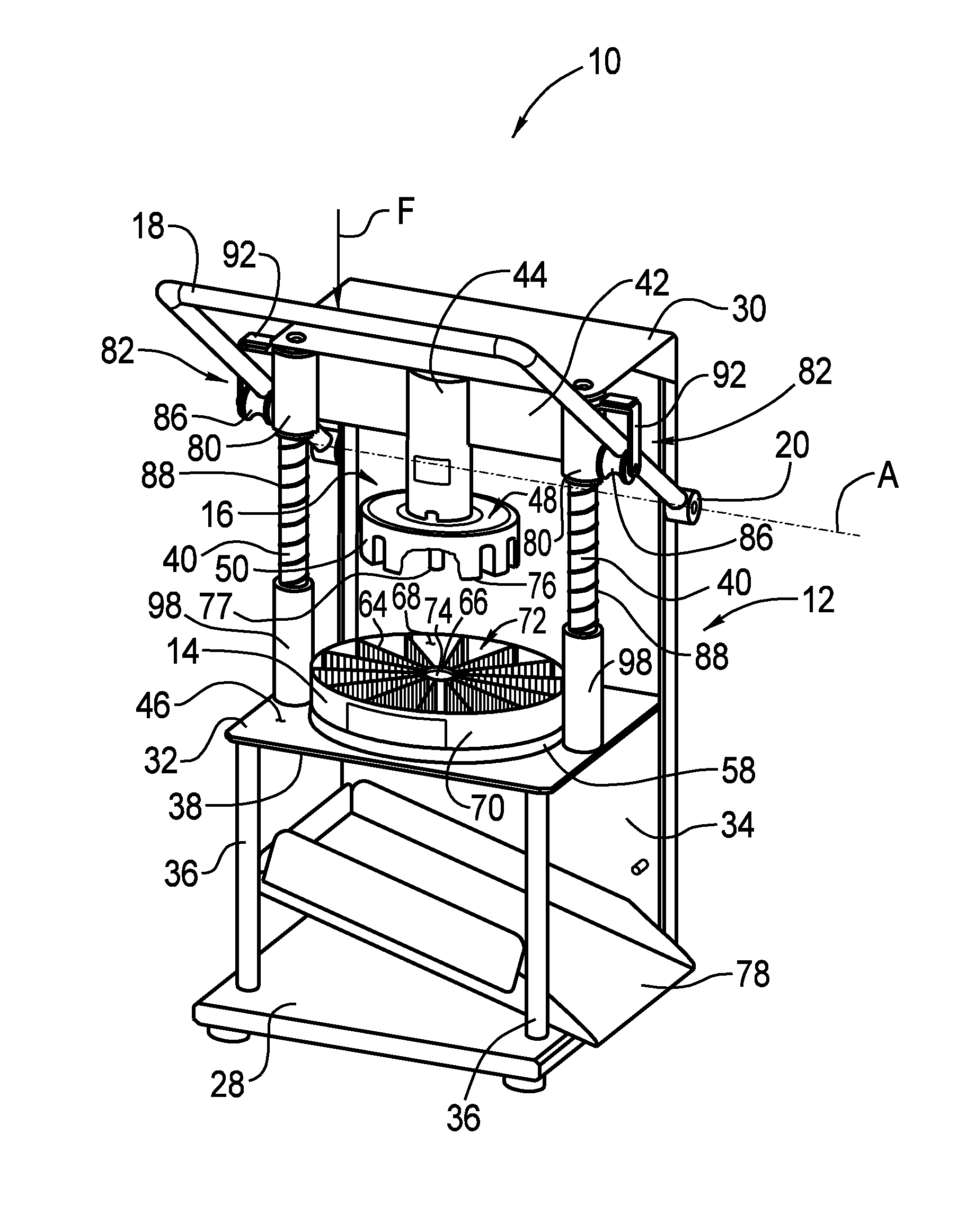

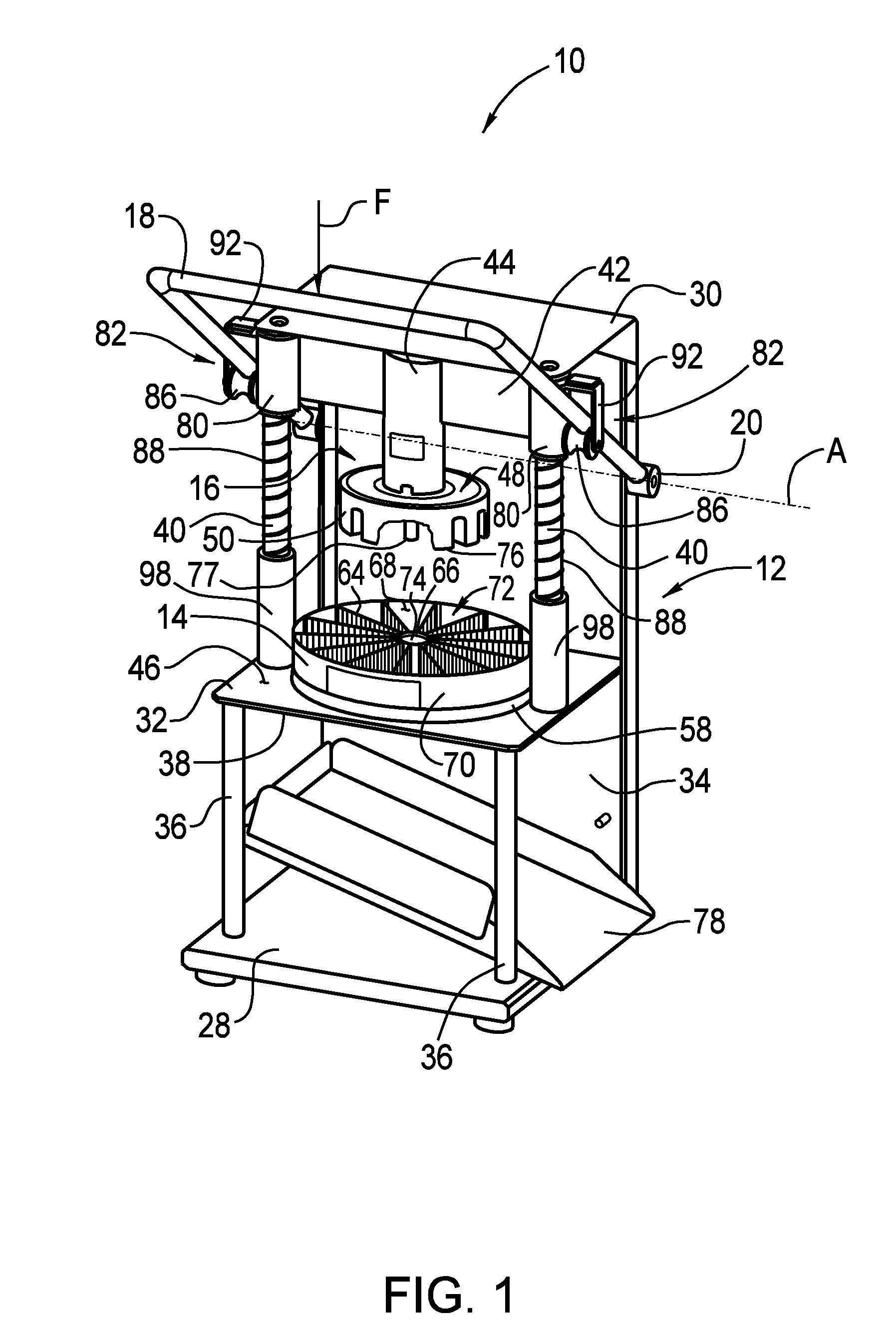

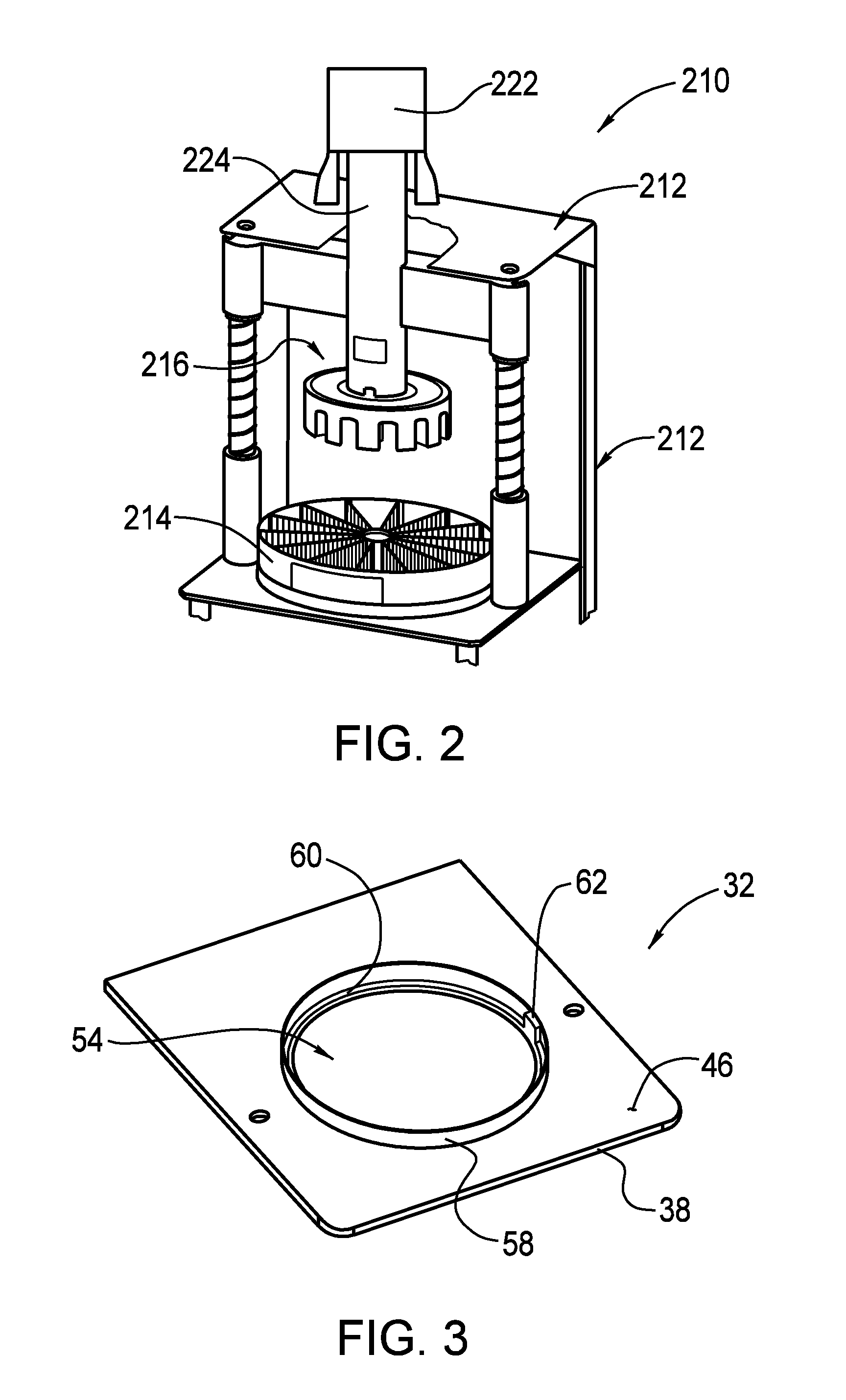

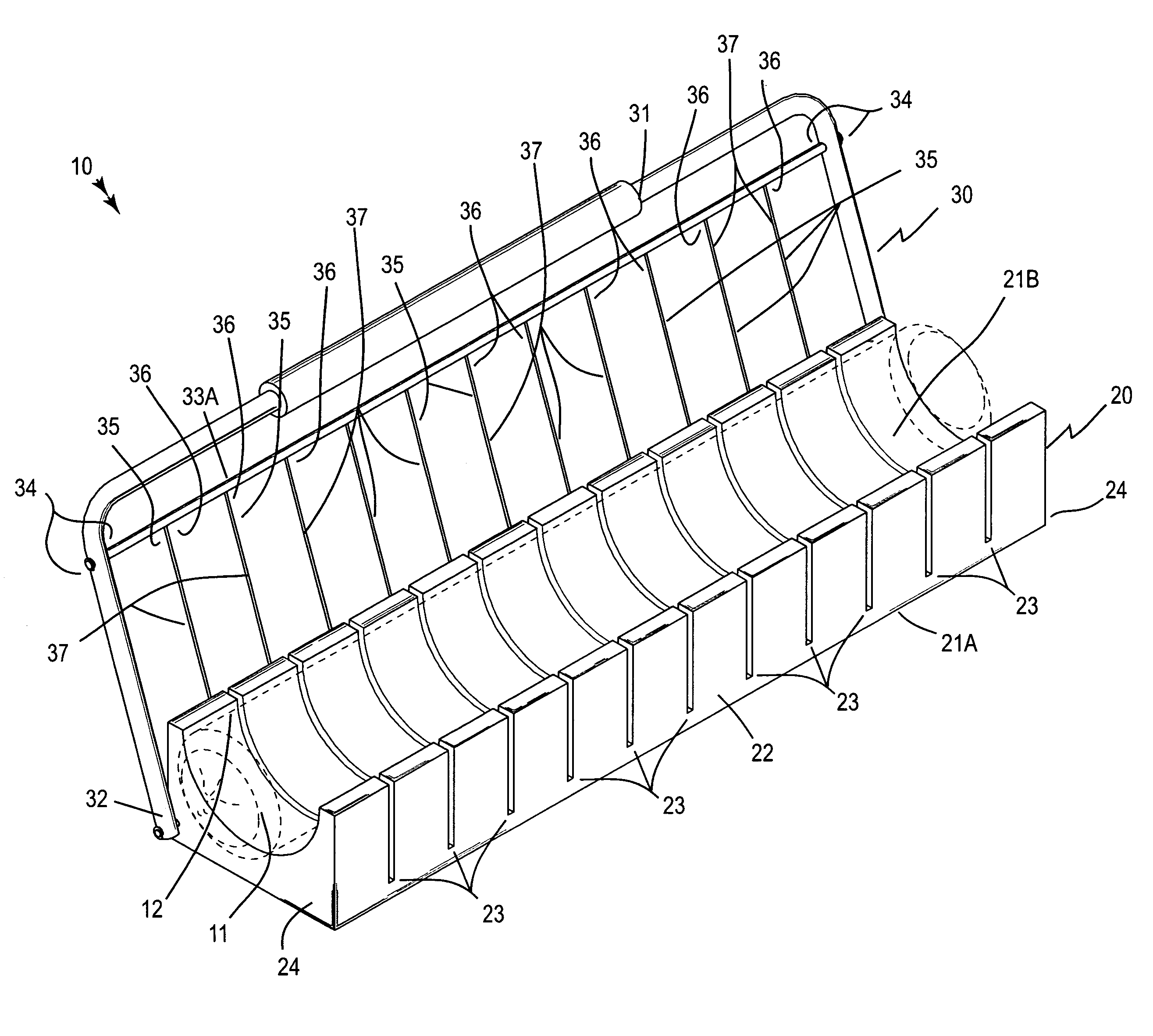

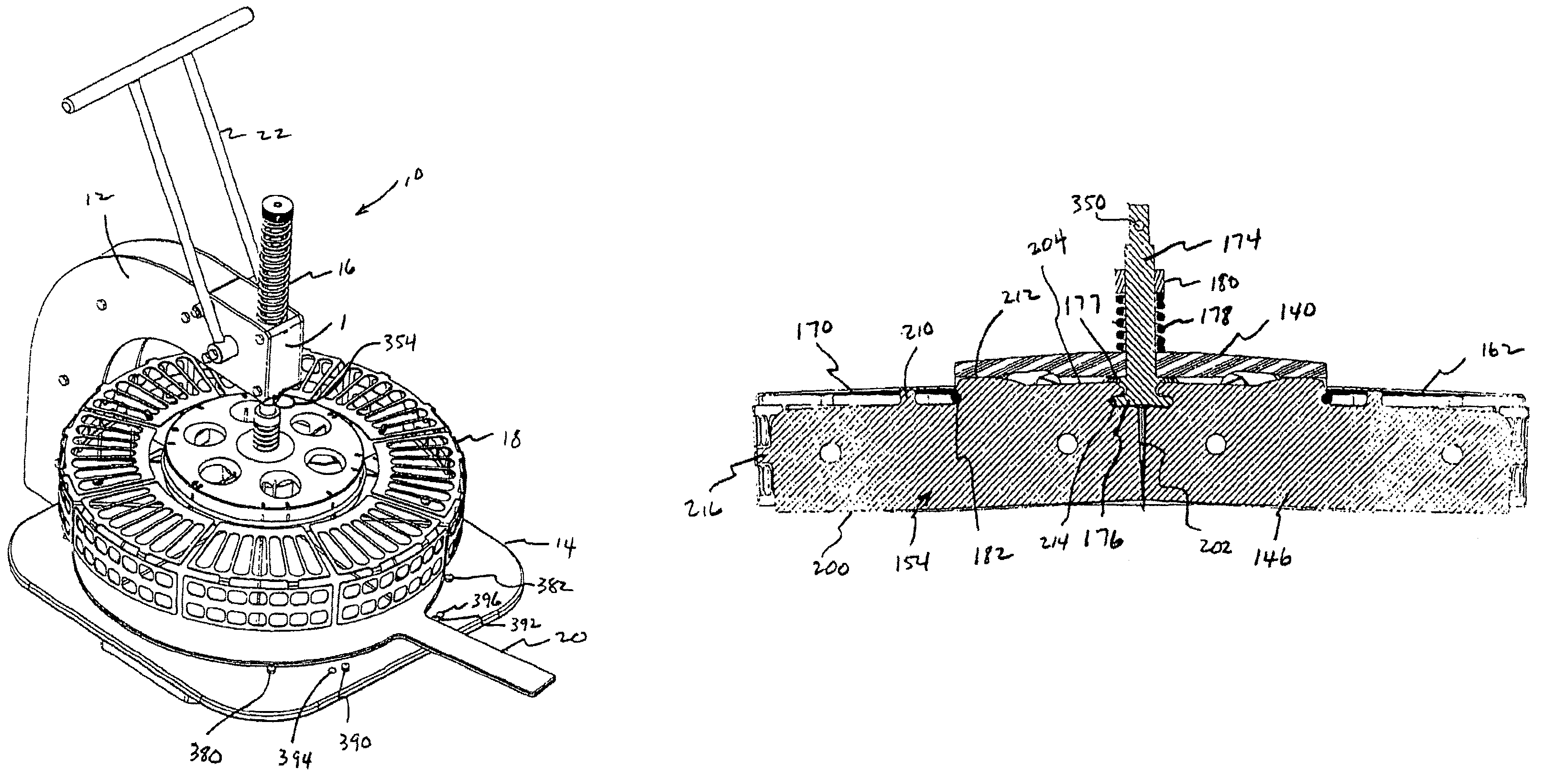

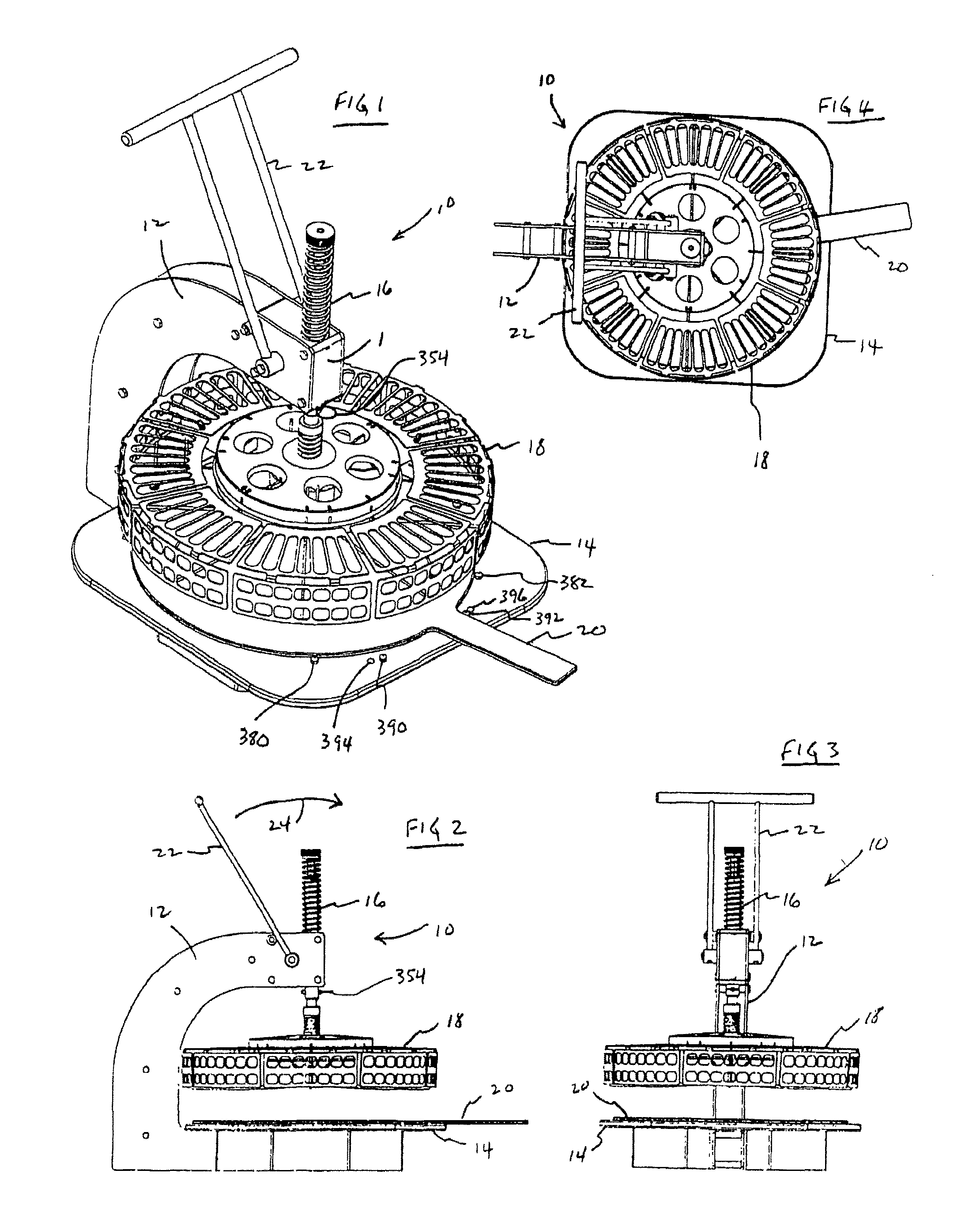

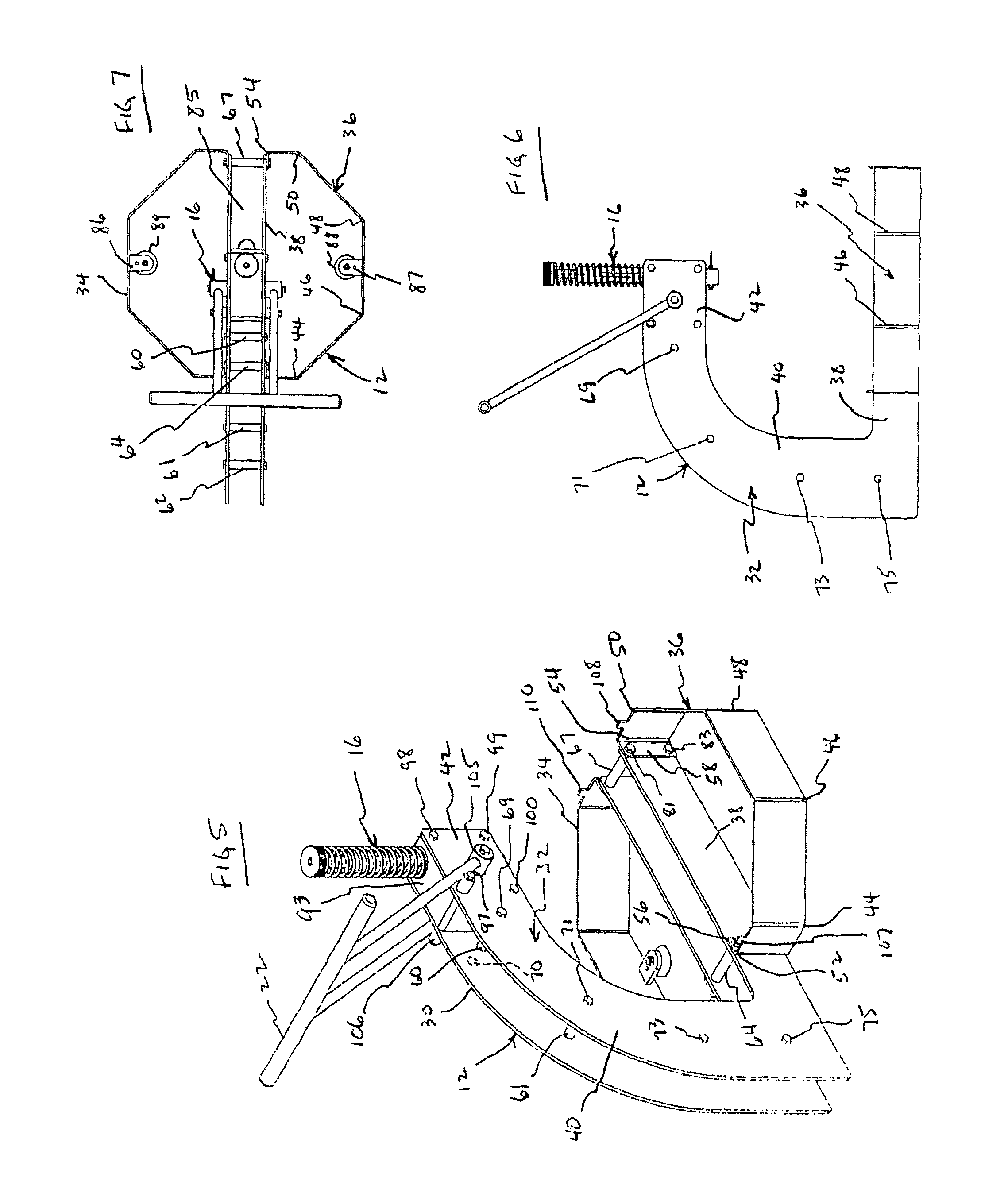

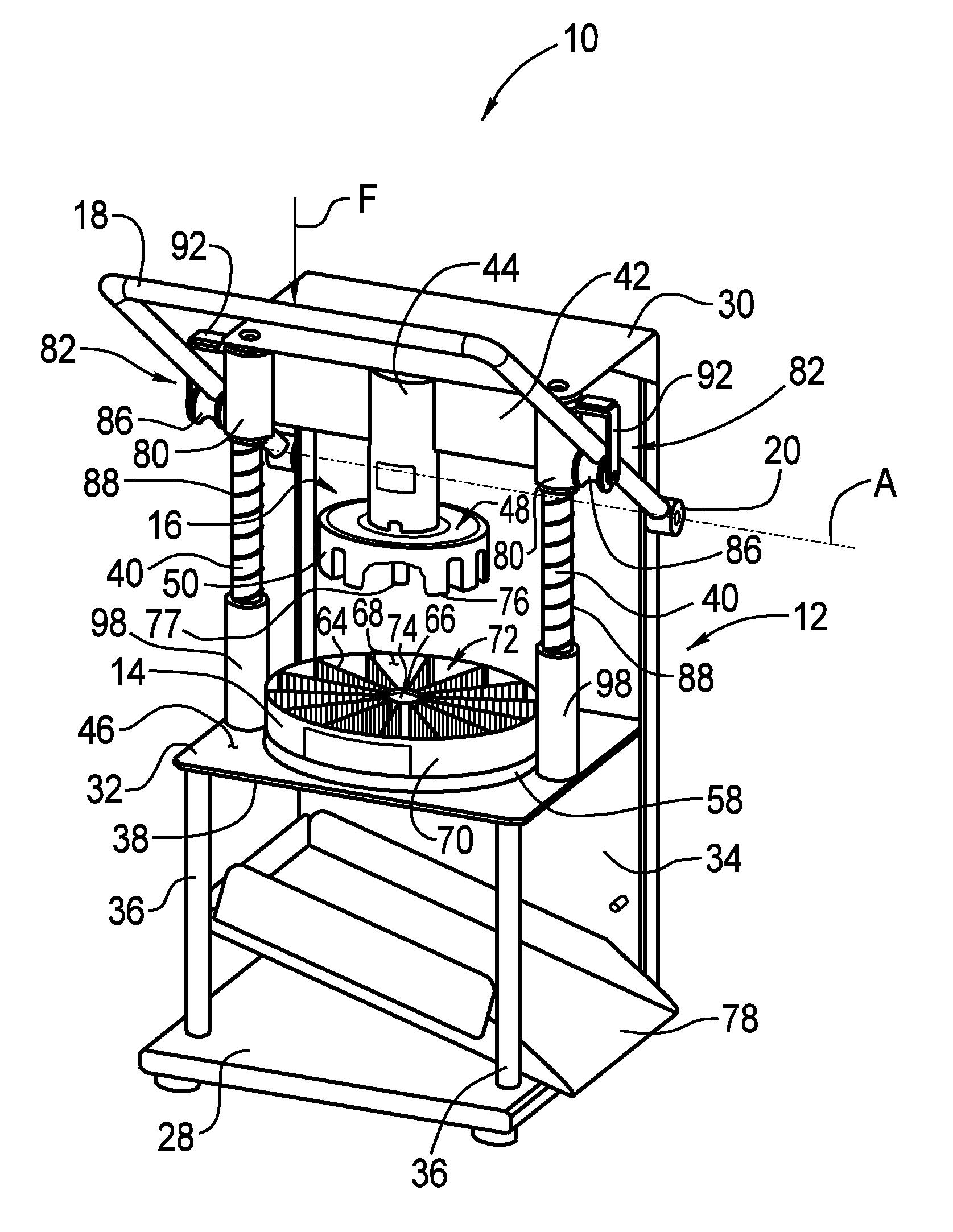

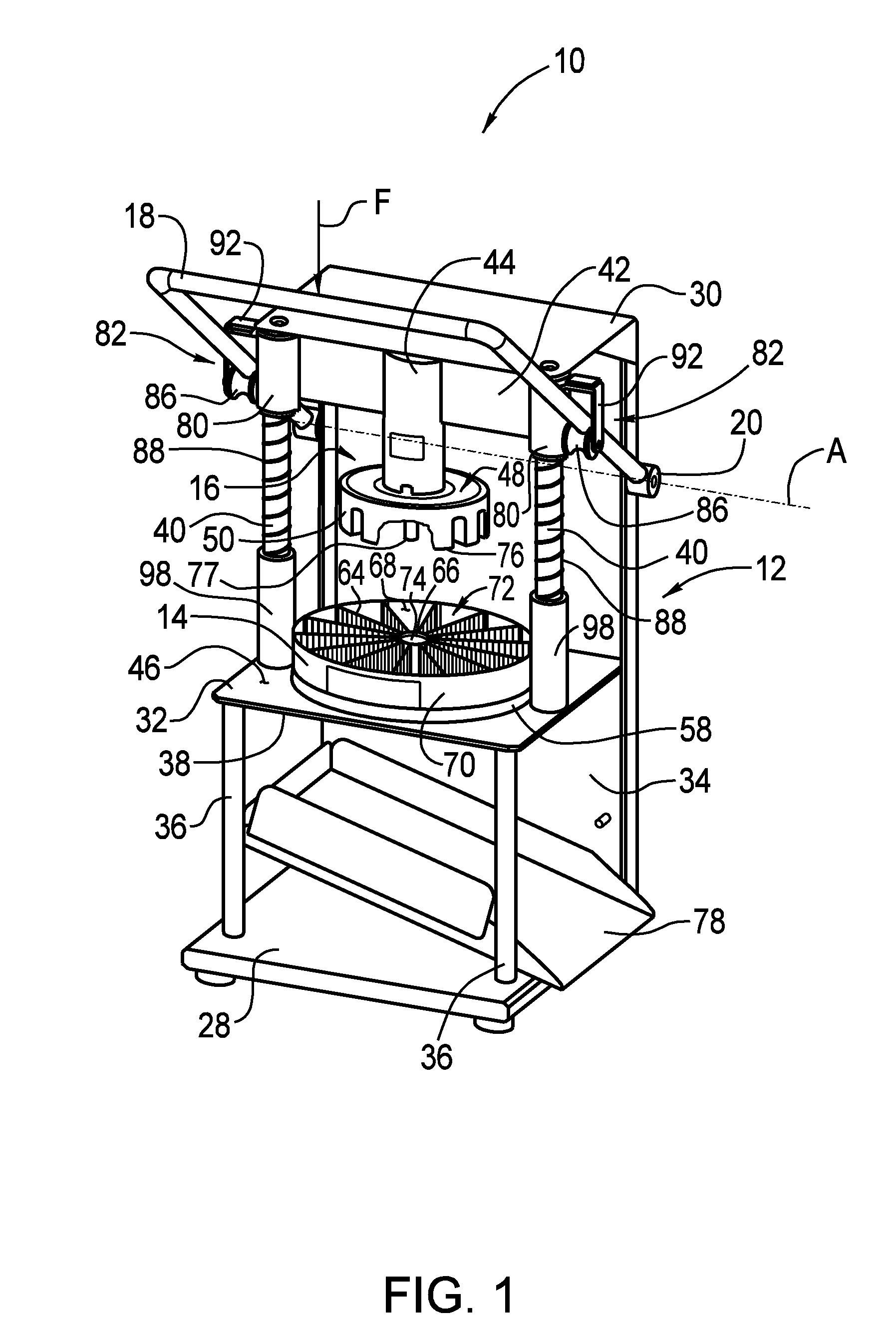

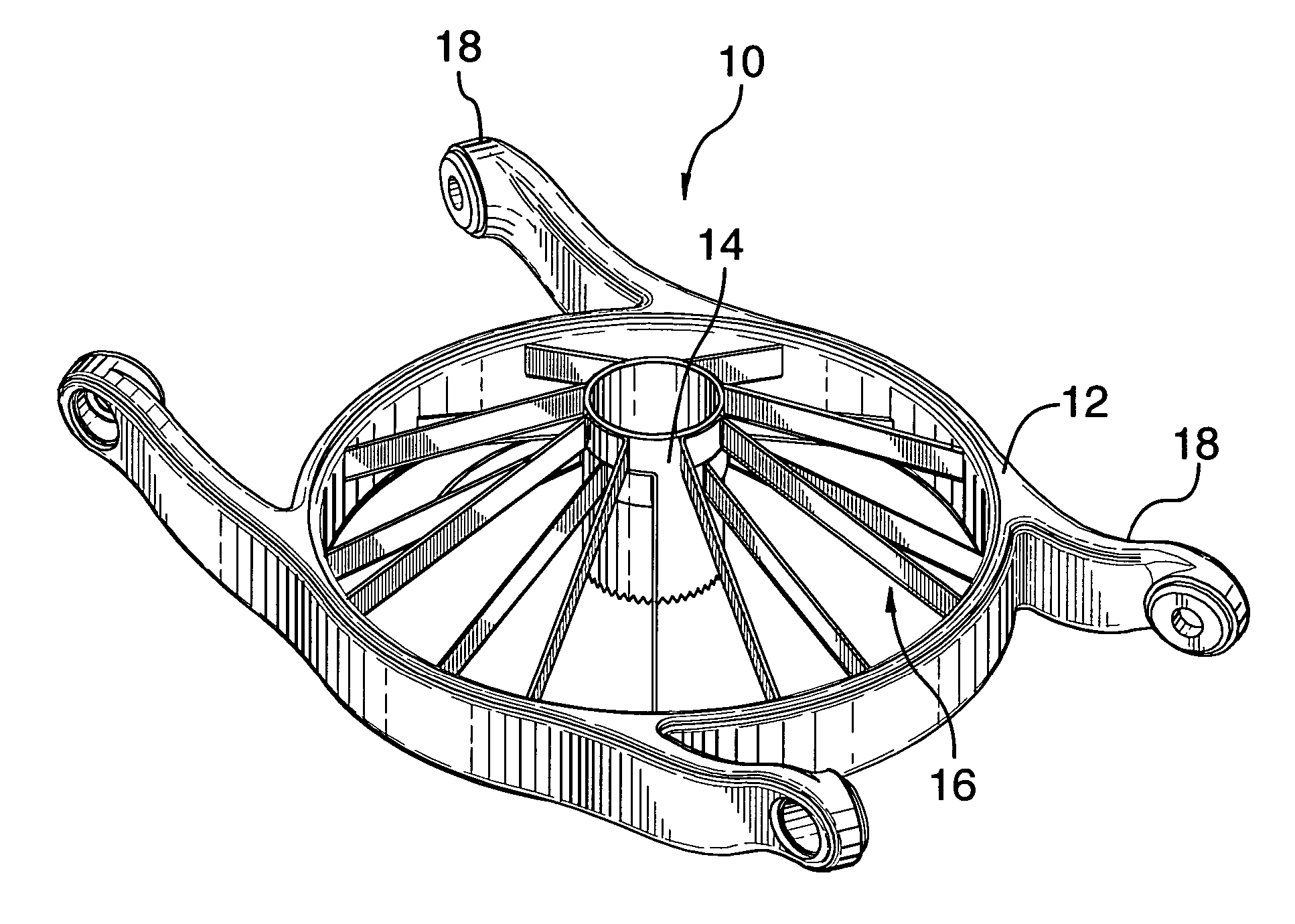

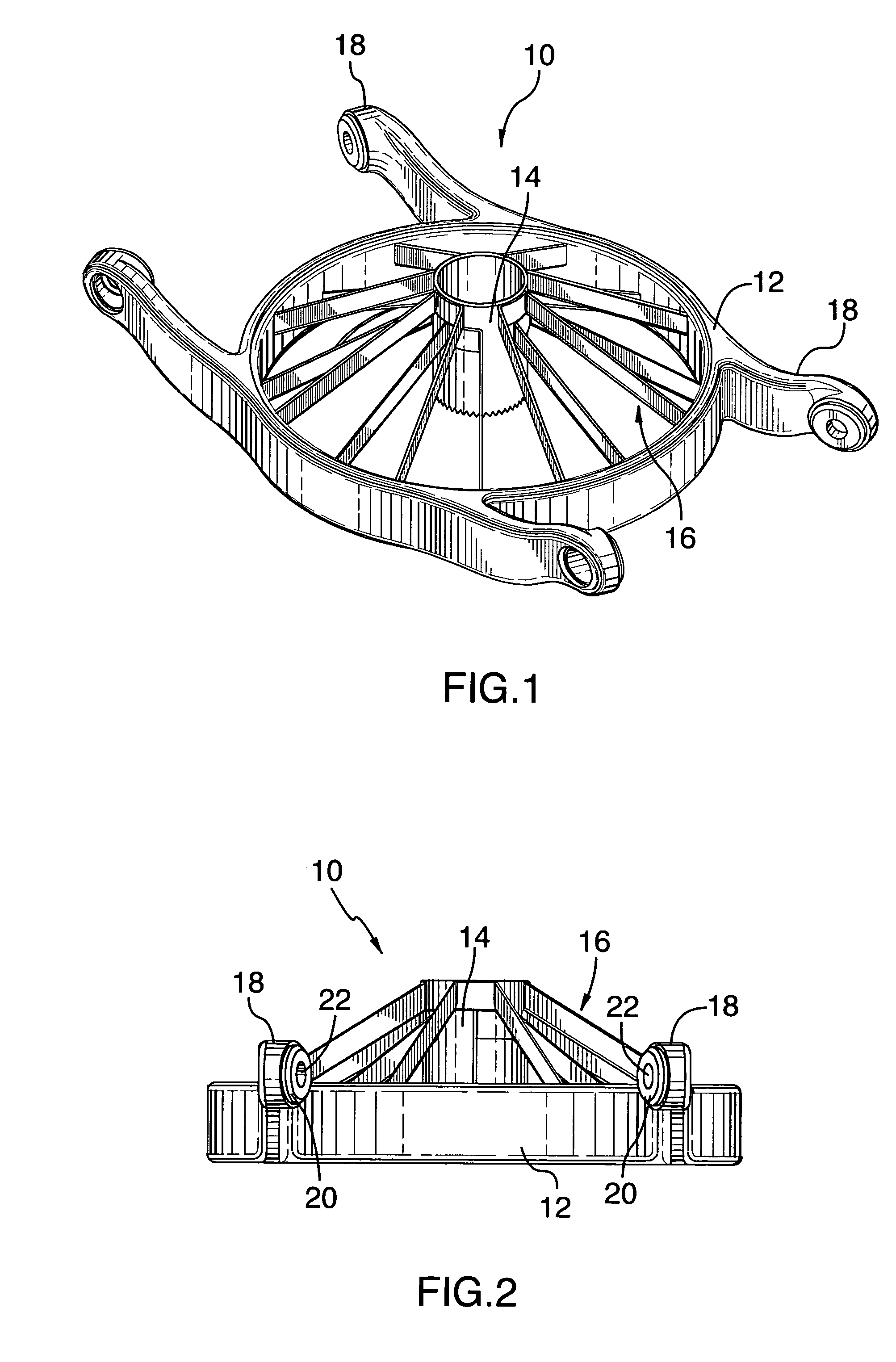

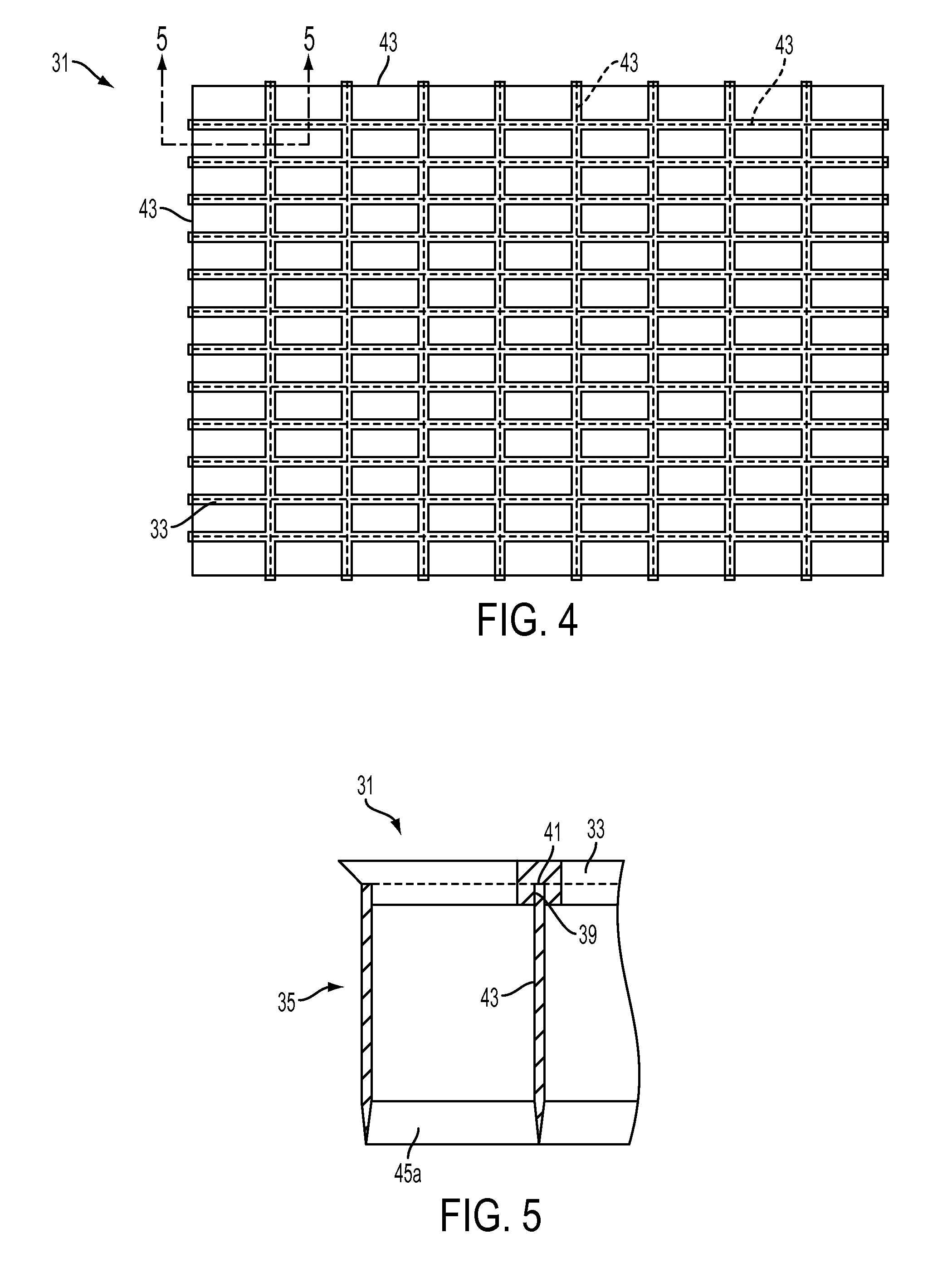

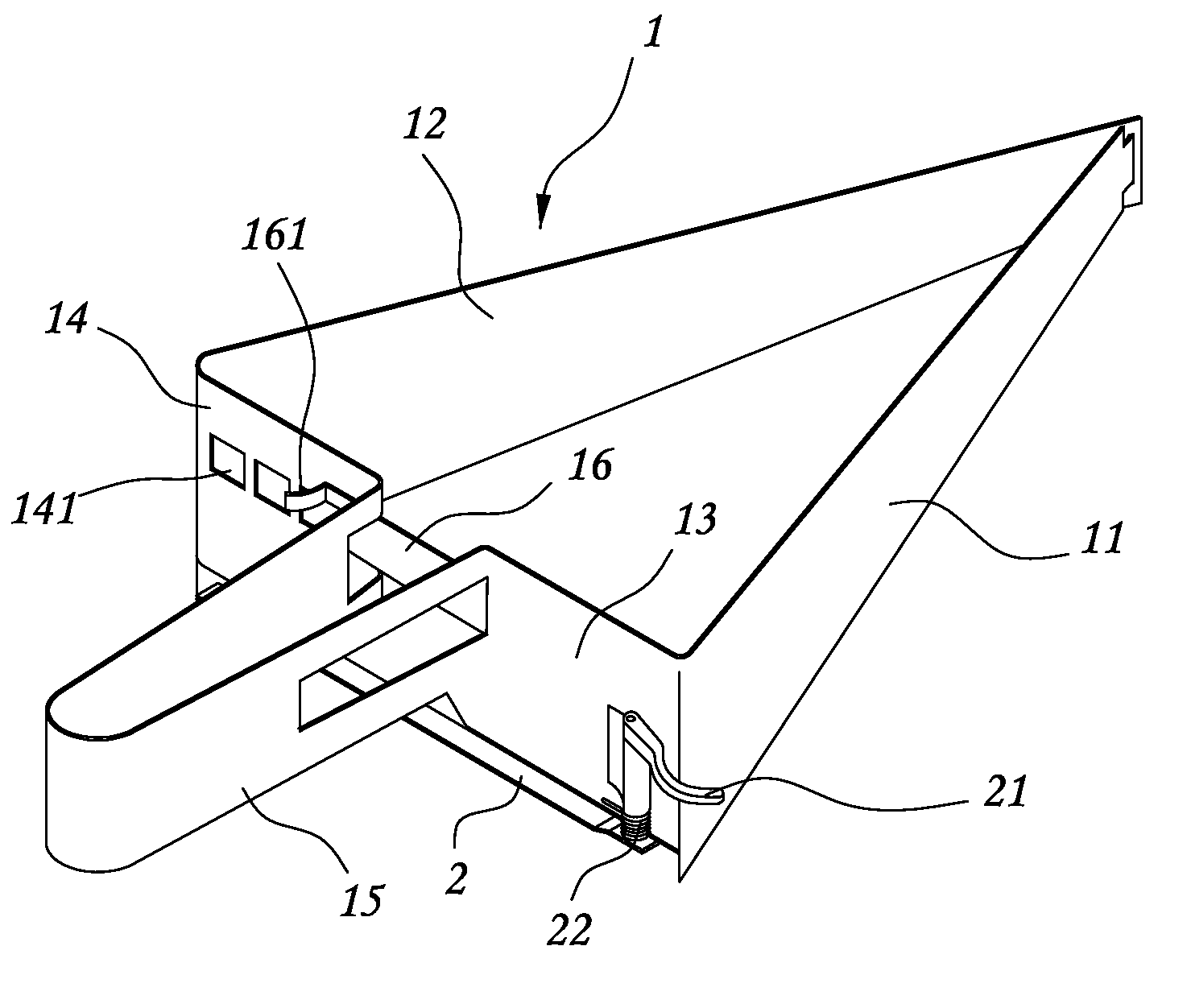

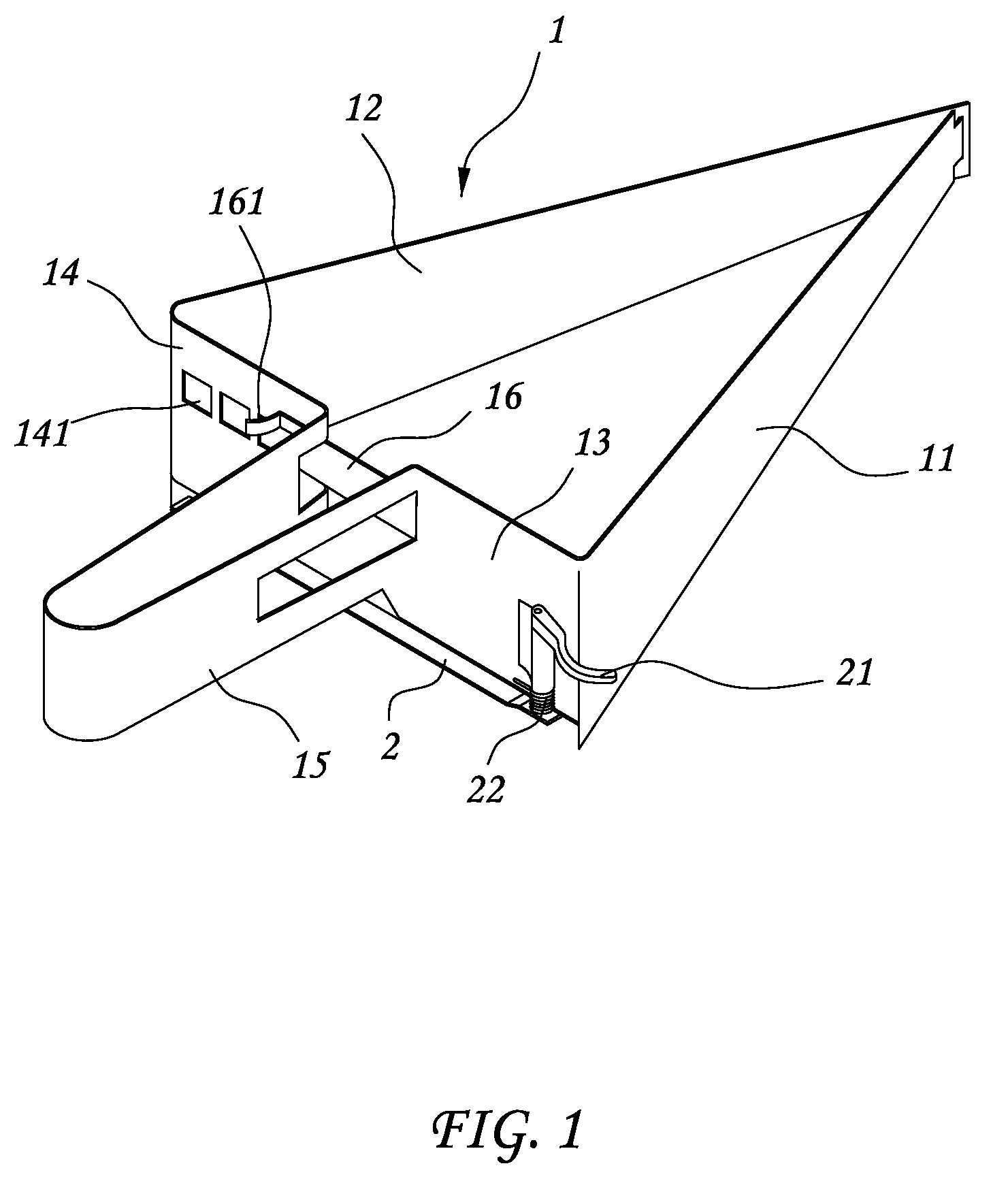

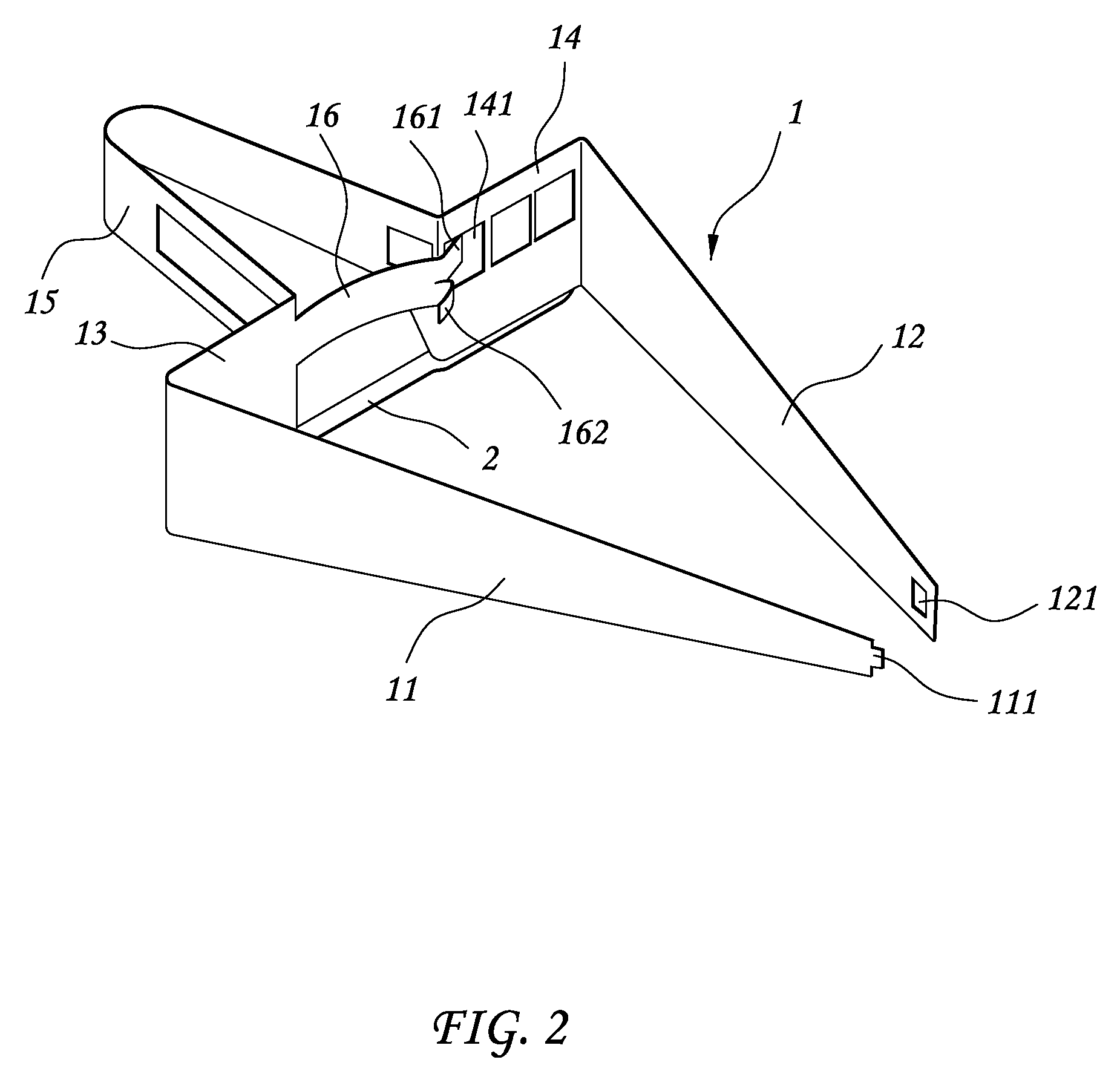

Pizza cutting apparatus

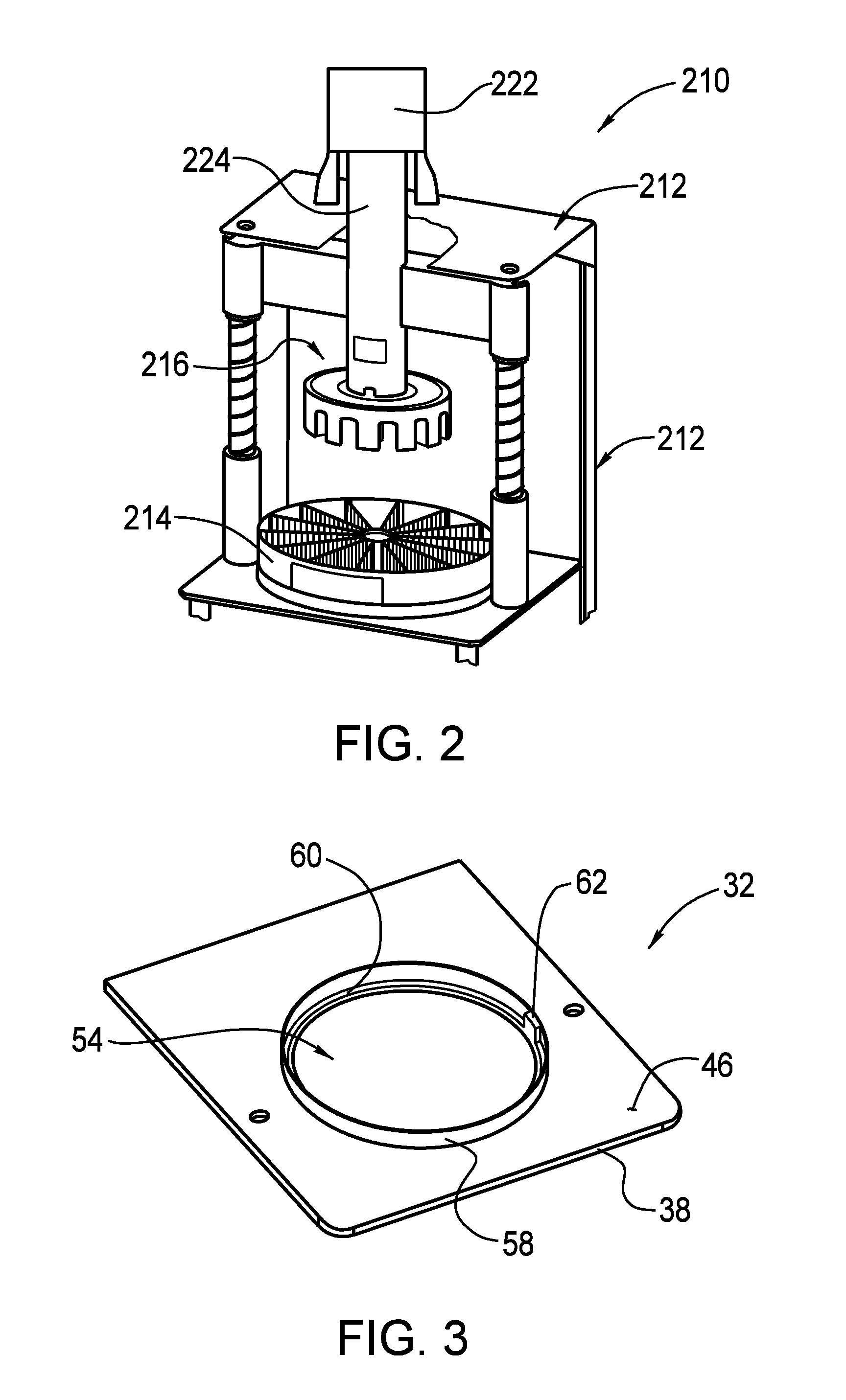

ActiveUS7984667B2Disassembling the pizza cutting apparatusShaping toolsDough dividingEngineeringActuator

A pizza cutting apparatus and portions of the apparatus, and methods of forming the apparatus and of disassembly. The apparatus includes a simple frame assembly made from sheet metal, an actuator assembly and a cutting assembly. The cutting assembly includes a central hub, a number of attached blade and guard combinations, a shaft with a flange and an elastic band. Each blade includes two spaced apart openings, one to receive the flange and the other to be engaged by the band so as to restrain the blades mounted in the hub. Each guard includes perforations for easy gripping by an operator. A blade is removed by having the operator safely grip each guard to stretch the band so as to disengage the blade from the flange and then return and rotate the blade to disengage the blade from the band.

Owner:QUANTUM TECHN SERVICES

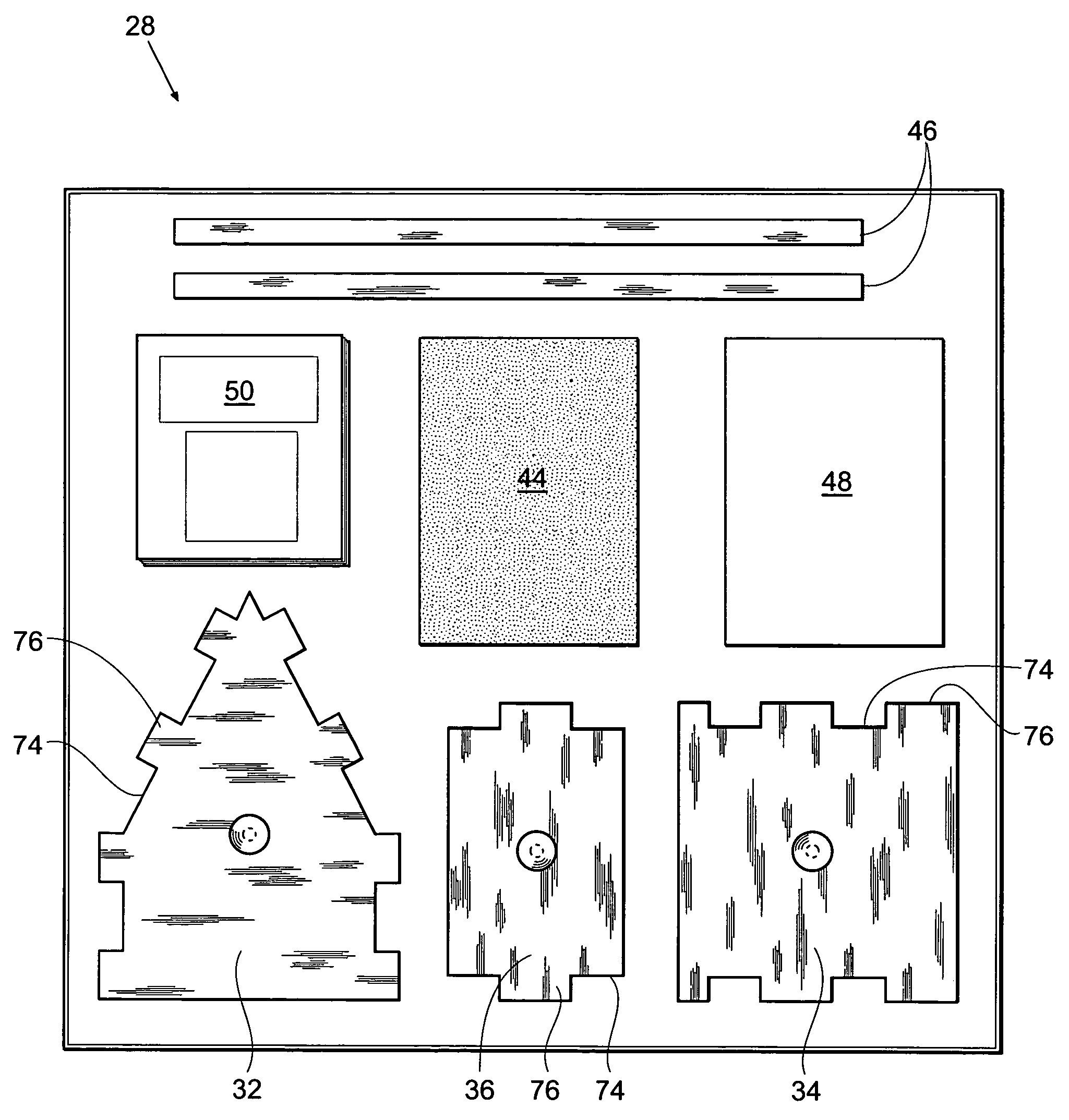

Systems and methods for building an interlocking decorative house

InactiveUS7210920B2Acceptable degree of stabilityFit tightlyMouldsFrozen sweetsEngineeringDovetail joint

A special tabbed pattern is integrated into a series of forms. The forms may be cookie cutters adapted to cut baked dough or other material set to desired density to provide a series of panels corresponding to the cutters. Alternatively, the forms may be molds, e.g, adapted to receive melted chocolate which is allowed to cool and set to form a series of panels corresponding to the molds. The panels are adapted to be joined together to form a decorative structure. The tabs are sized and positioned to provide a dovetail joint along each edge of the structure. The protruding tabs or ends are of a slightly smaller dimension than the notches that they fit inside of to provide a secure fit. This self-interlocking design allows each individual piece of the structure to be fitted together, one at a time, while maintaining an acceptable degree of stability throughout the assembly process.

Owner:KOLZ DEBRA A

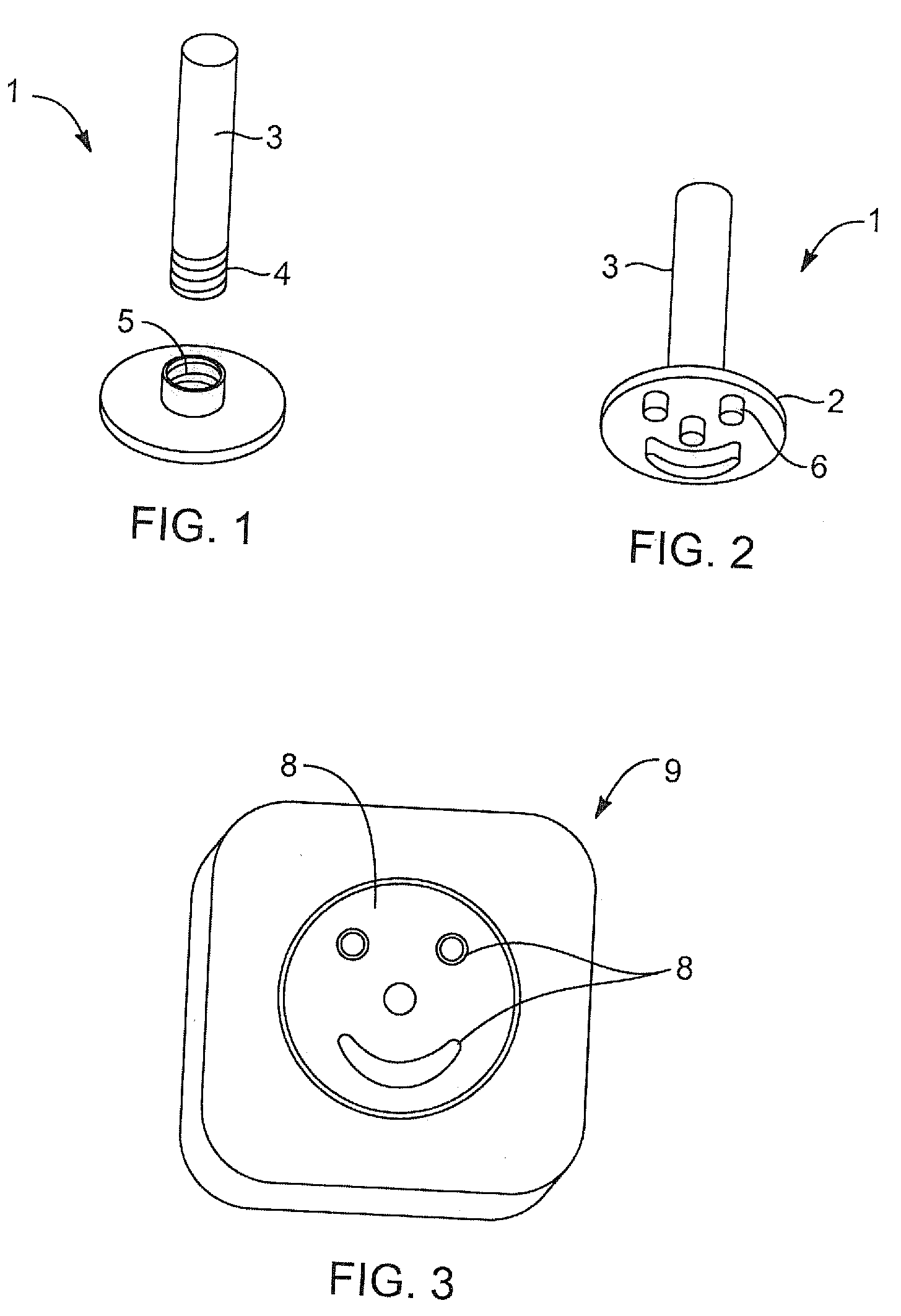

Apparatus, system, and method for a bread cutter and impression devices

InactiveUS20080241326A1Easy to shapeImprove lookConfectionerySweetmeatsAdditive ingredientEngineering

A sandwich sealing crust removing method and apparatus also include bread marking and imaging mechanisms for one or more of indenting, embossing, coloring, cutting, and forming. The apparatus is capable of cutting the crust from a prepared sandwich having filling ingredients between at least two slices of bread in the sandwich. The cut edge area on the sandwich is also sealed to insure that the filling ingredients stay within a pocket formed in the bread. One or more element of the apparatus is also capable of embossing images onto the sandwich and / or a bread slice(s). One of a plurality of devices has removably coupled marking elements that can be used on sandwiches. The marking elements may include one or more removably coupled elements for shaping, marking, embossing, cutting, coloring, indenting, and / or other mechanism(s).

Owner:EKBERG LANE

Fruit and vegetables slicing apparatus structure

A handheld fruit and vegetables slicing apparatus having a plurality of linked together rotatable knives connected to a frame. One of the knives being attached to a rotatable adjustment element on the frame, such that when the adjustment element is rotated the plurality of knives rotate from an original upright state to a flat state for rinsing.

Owner:LO KUO HUNG +1

Sectioning device and method of use

A sectioning device for sectioning food and non-food items includes a frame, a cutter removably positioned on the frame and press means positioned on the frame for pushing an item against and through the cutter. The sectioning device also includes means for moving, in a single continuous motion, at least one of the cutter and the press means between a neutral position and a sectioning position. The press means and the cutter are configured such that an item to be sectioned, positioned between the cutter and the press means is sectioned in its entirety upon movement from the neutral position to the sectioning position.

Owner:EDIBLE IP LLC

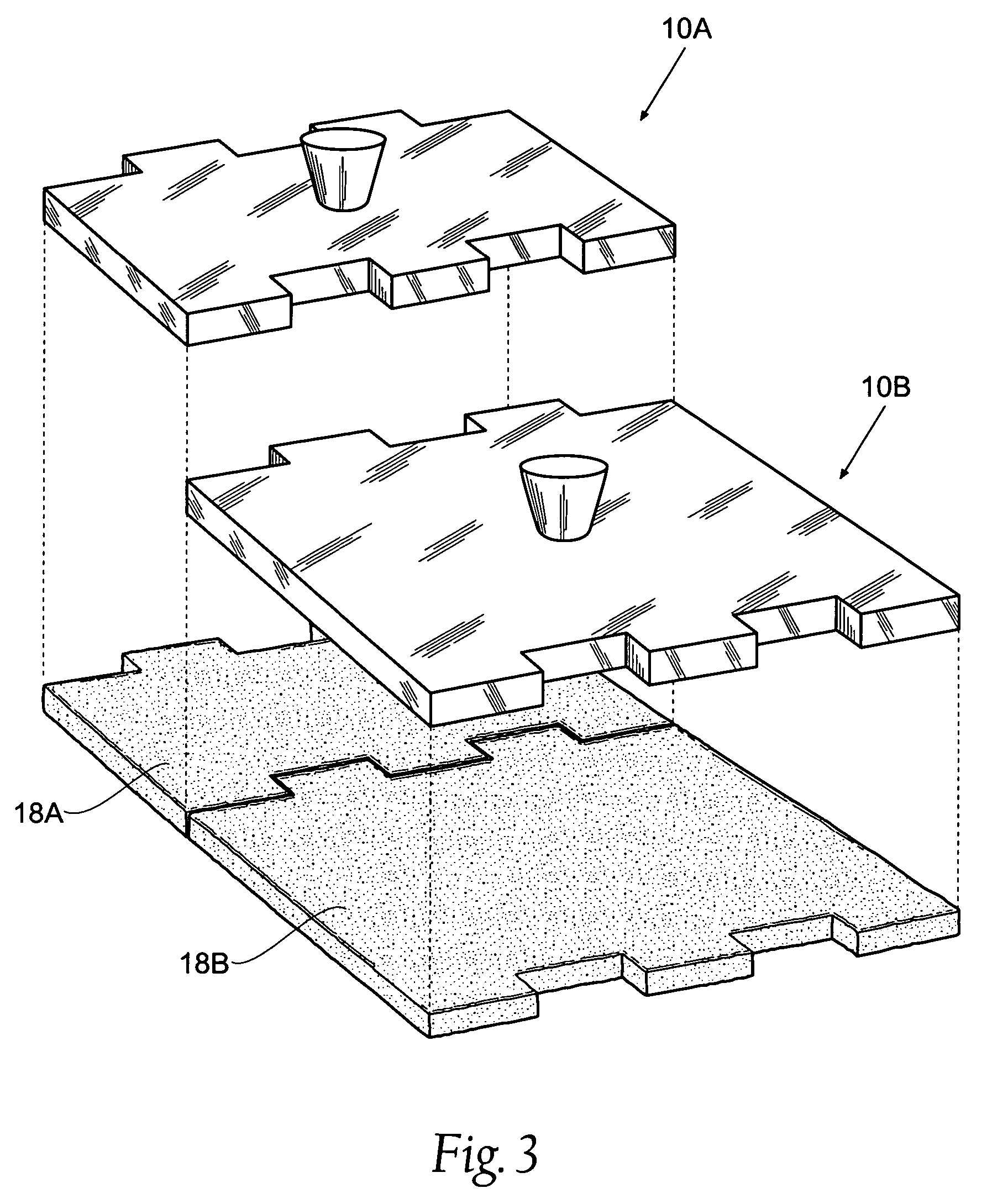

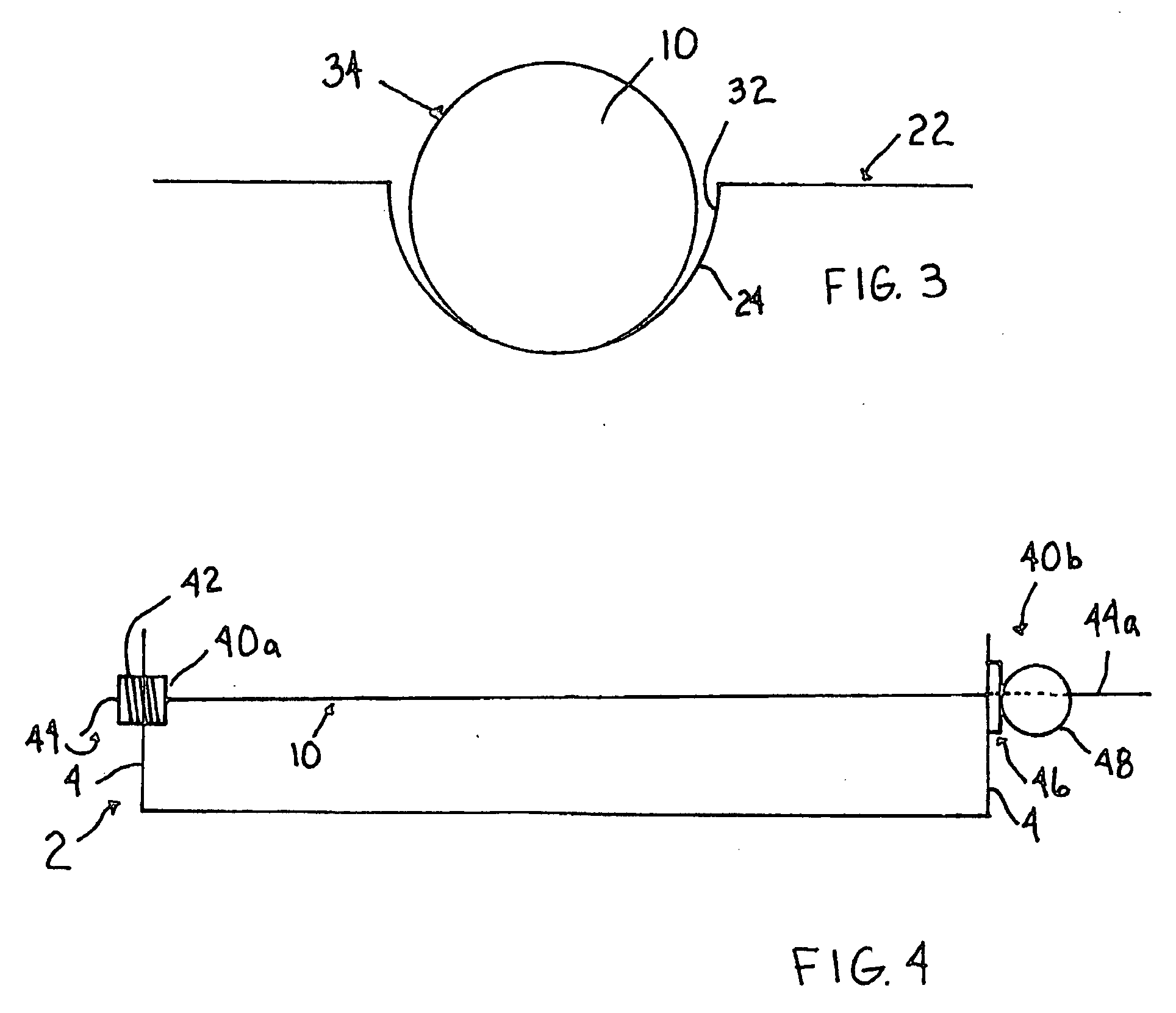

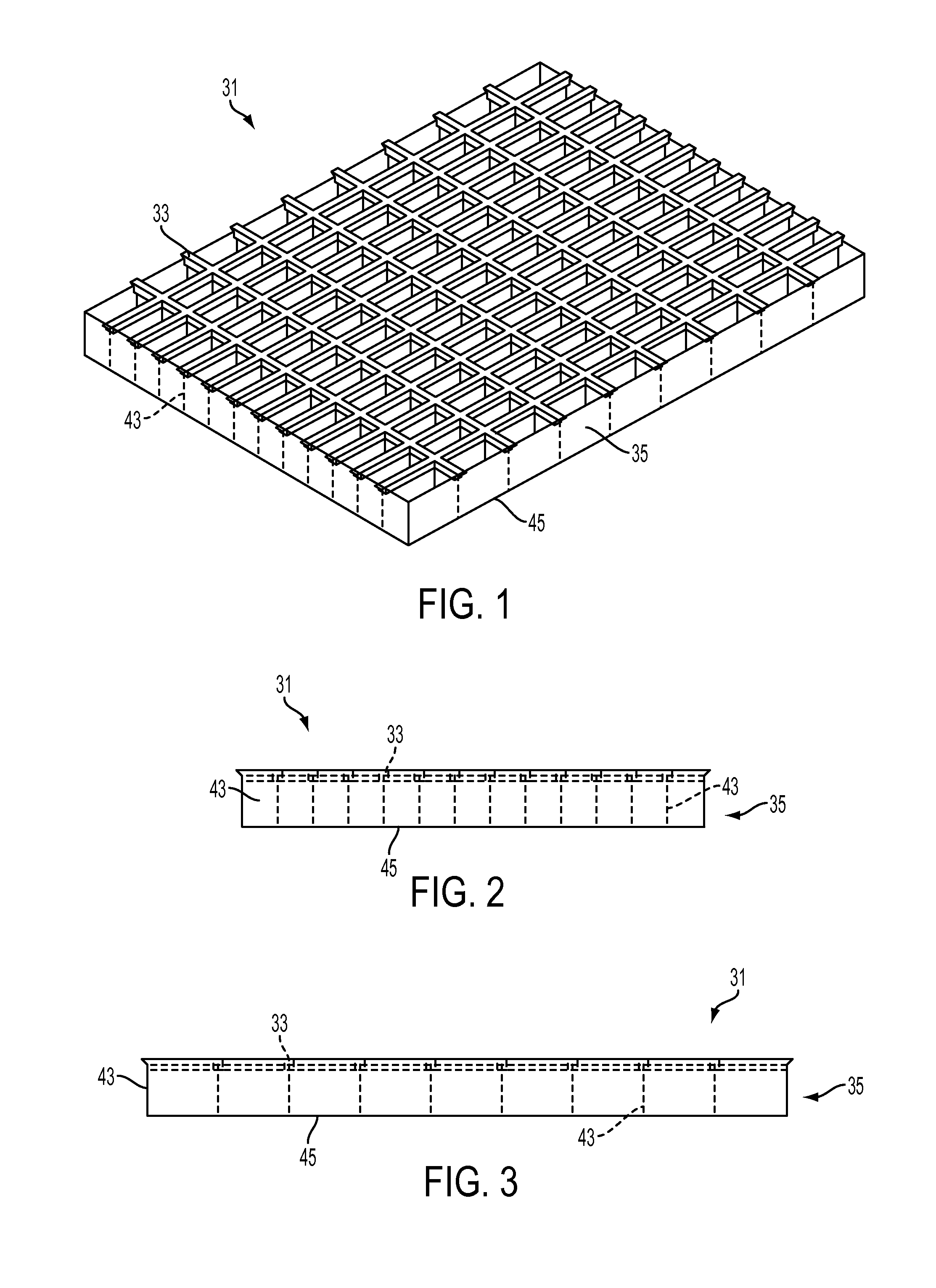

Sectioning device with adjustable cutting filament

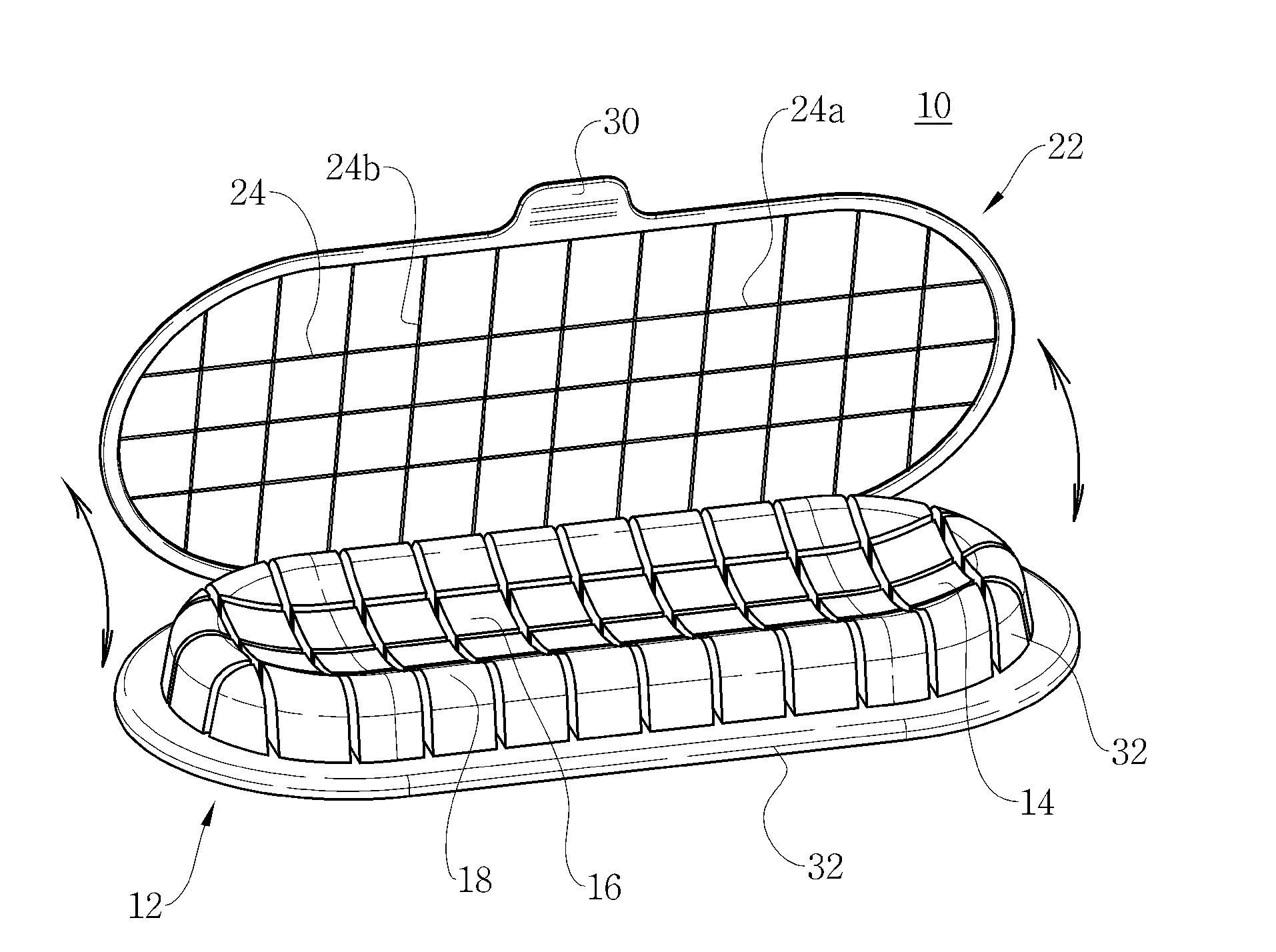

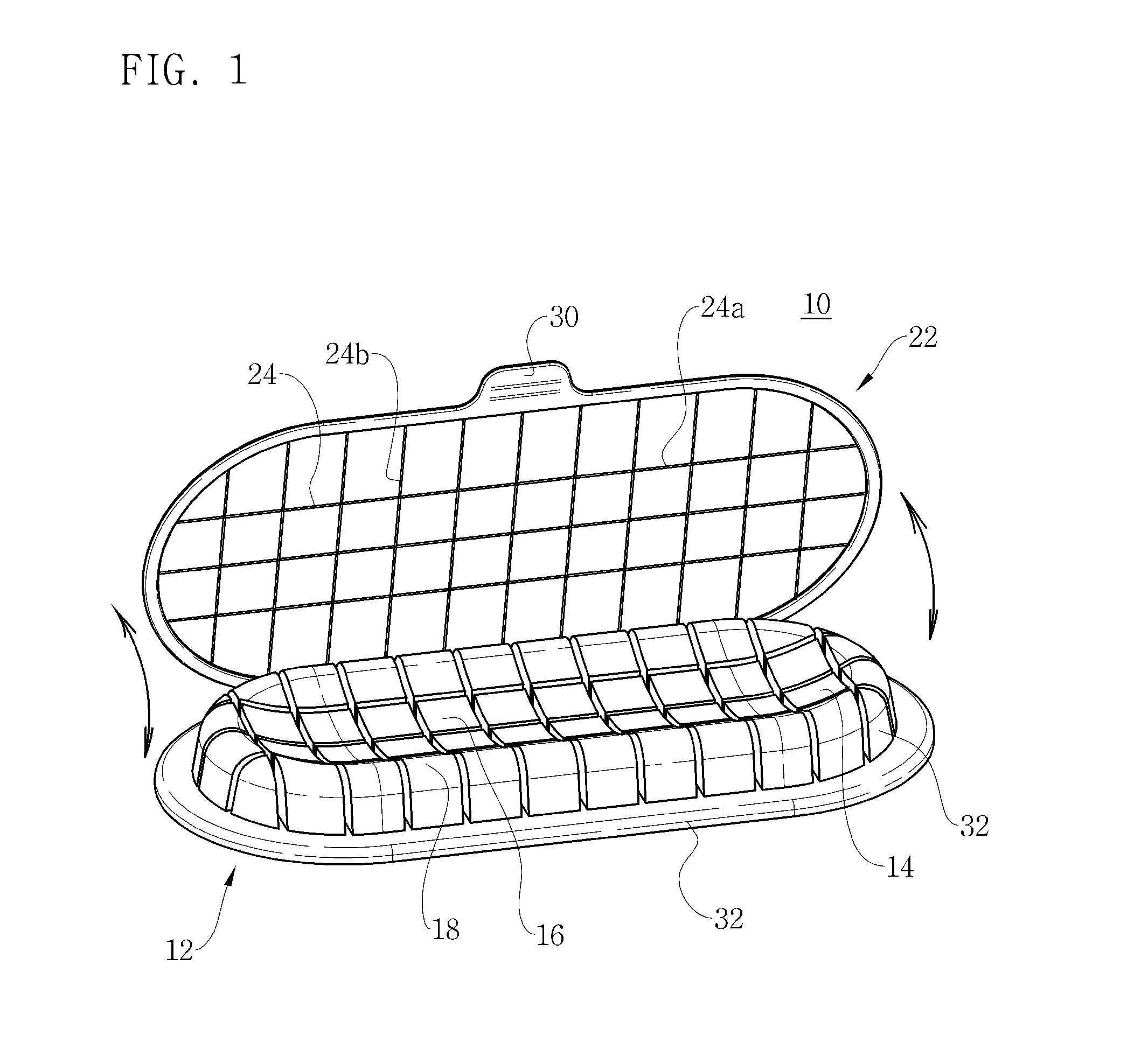

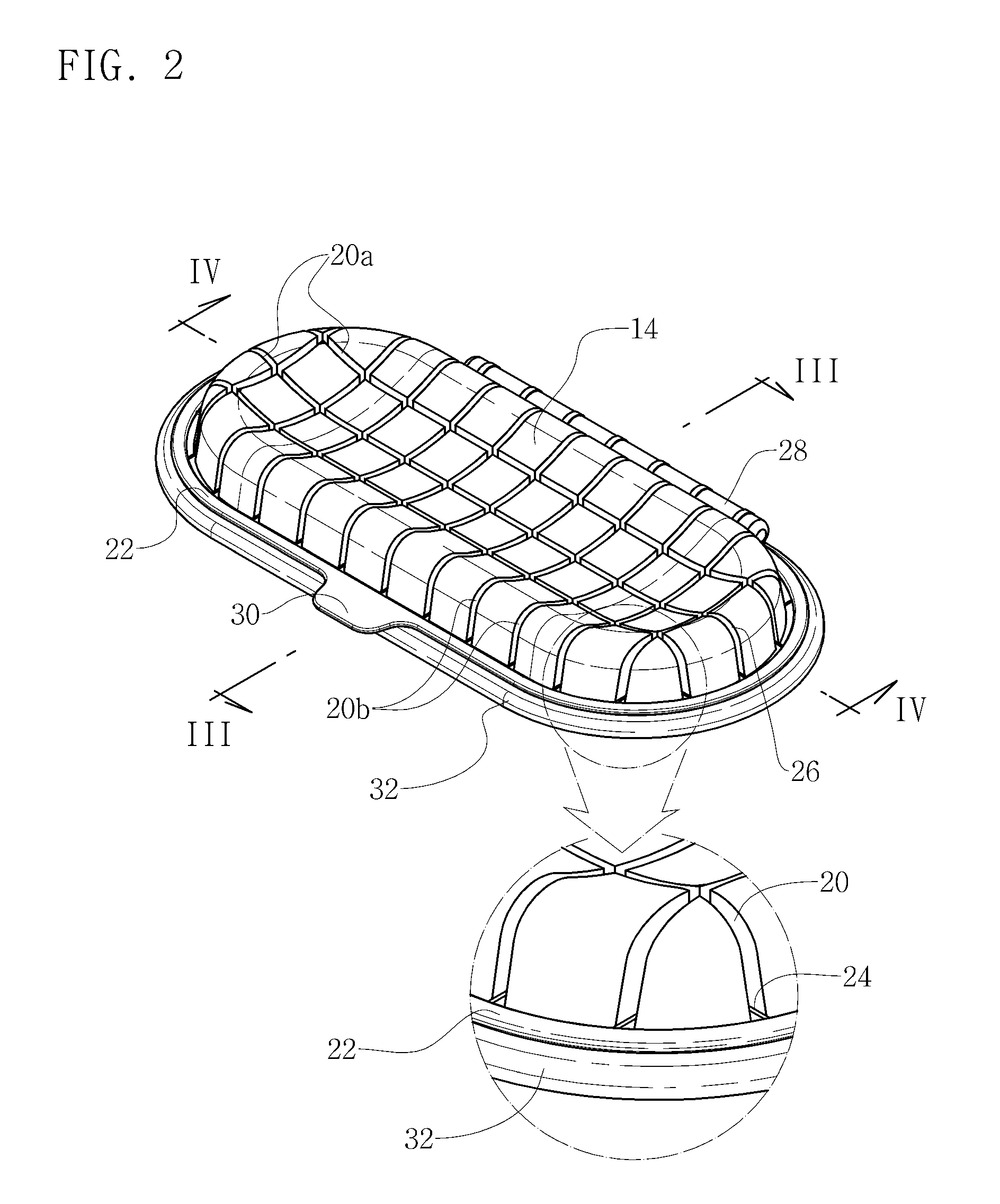

InactiveUS20080216628A1Metal working apparatusBaked article cutting/slicingSoft solidsSupport surface

A tool slices or cuts baked goods or soft solid or cheesy foods into sized segments. The tool has a cutting frame and a supporting base. The frame has an open geometric cross-section structure that has multiple slicing filaments extending across an area circumscribed by the frame. At least some of the multiple slicing filaments overlap to segment the item to be cut into distinct pieces. The supporting base has a series of depressions therein that correspond to a configuration of the slicing filaments. When the cutting frame is overlaid on the supporting base, at least a portion of the filaments resides in the depressions of the supporting frame and below a supporting surface of the supporting frame to assure that individual filaments can pass completely through the items to be cut.

Owner:HAMILTON JOHN MICHAEL

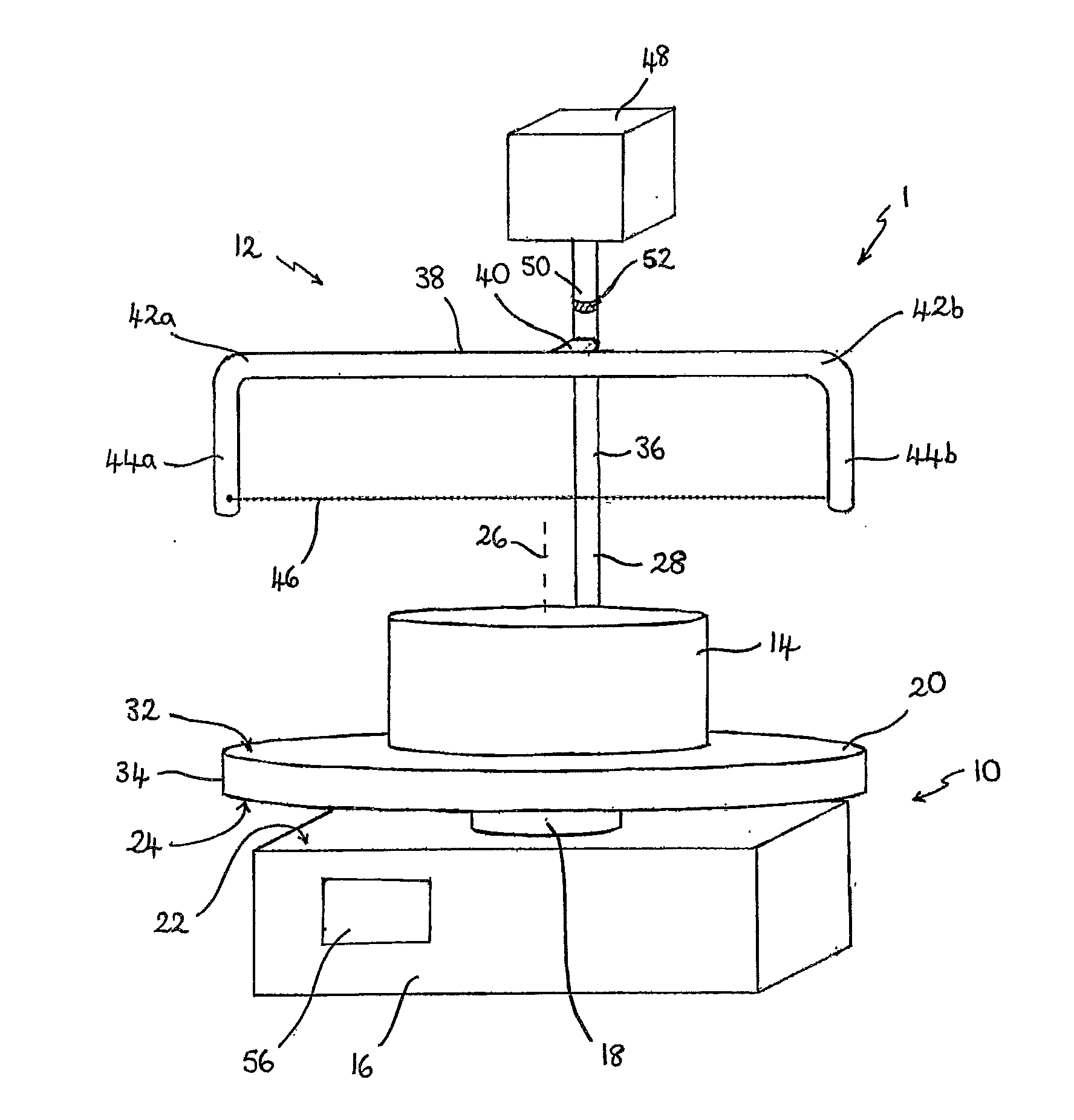

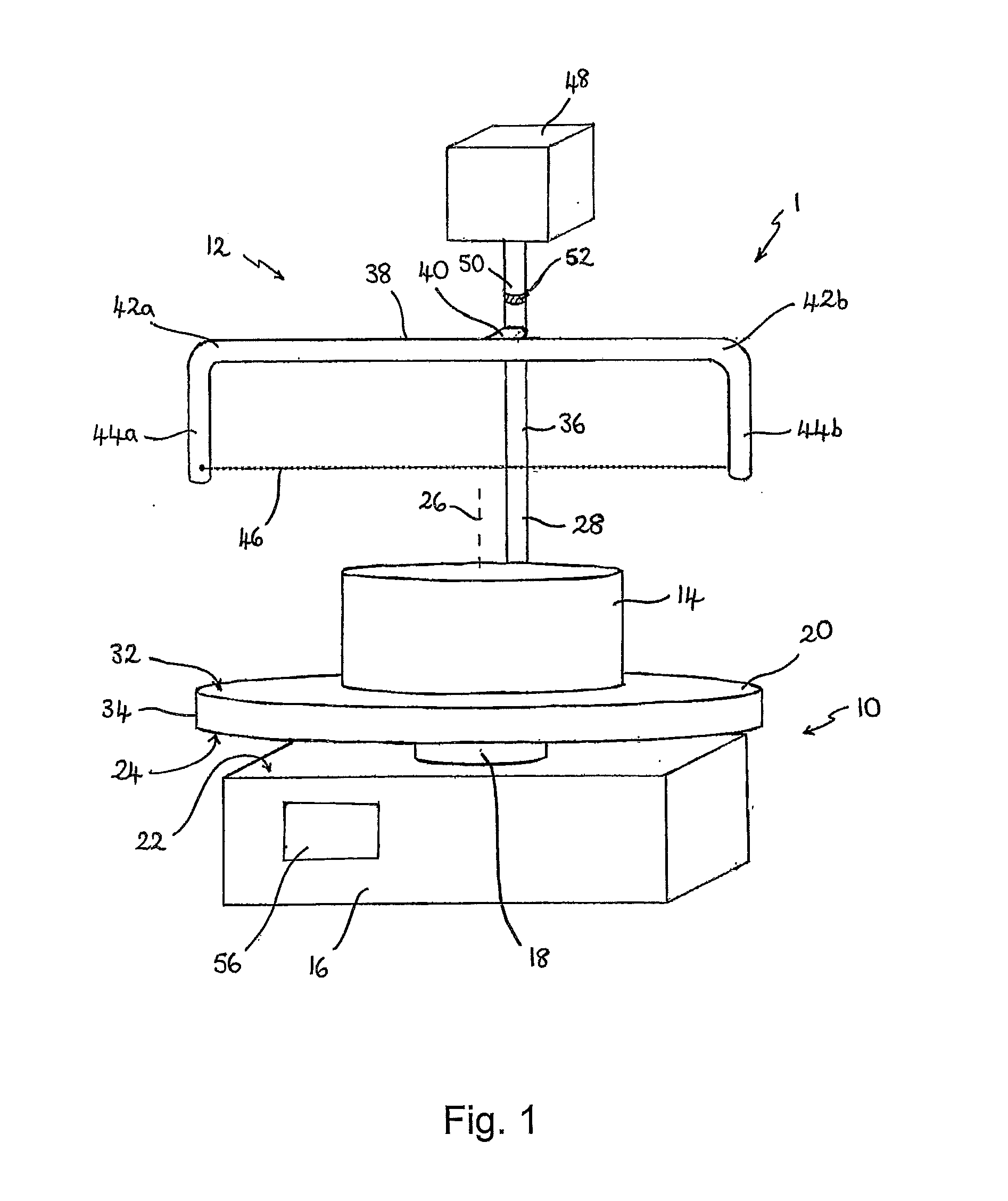

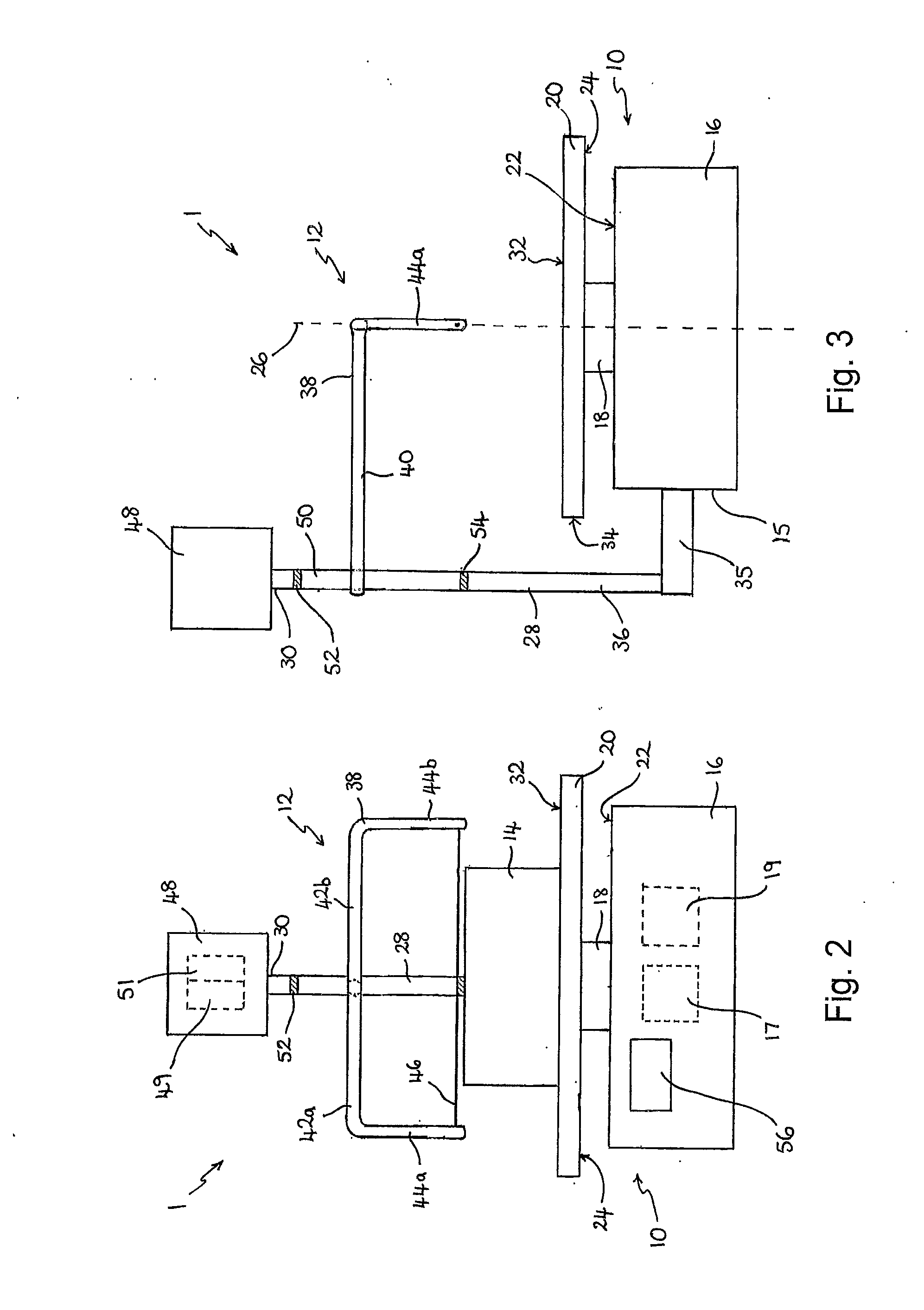

Cutting apparatus and method

InactiveUS20130152749A1Automatic control devicesCross-cut reciprocating sawsSupport surfacePlane parallel

This invention relates to an apparatus for cutting a foodstuff into portions, and a method of portioning foodstuffs. A cutting apparatus (1) for foodstuffs (14) comprises a support surface (20) for supporting a foodstuff (14), a retaining member (38) movable relative to the support (20) surface between a first position at a first distance from said surface and a second position at a second distance from said surface, and cutting means (46) secured to the retaining member (38) such that, in use, when the retaining member (38) is moved from the first position to the second position, the cutting means (469 cuts the foodstuff (14) placed on the support surface (20), wherein the cutting means (46) and support surface (20) are movable relative to each other, at least a component of the movement being in a plane parallel to the support surface (20), such that, in use, two or more cuts can be made in the foodstuff (14) at different positions.

Owner:SALADOR NOREEN +1

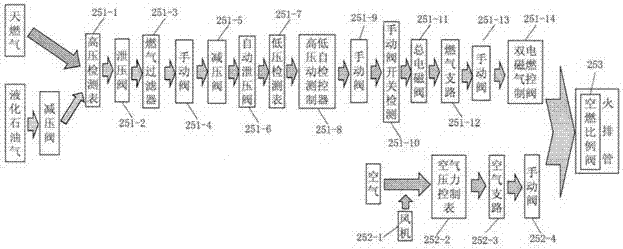

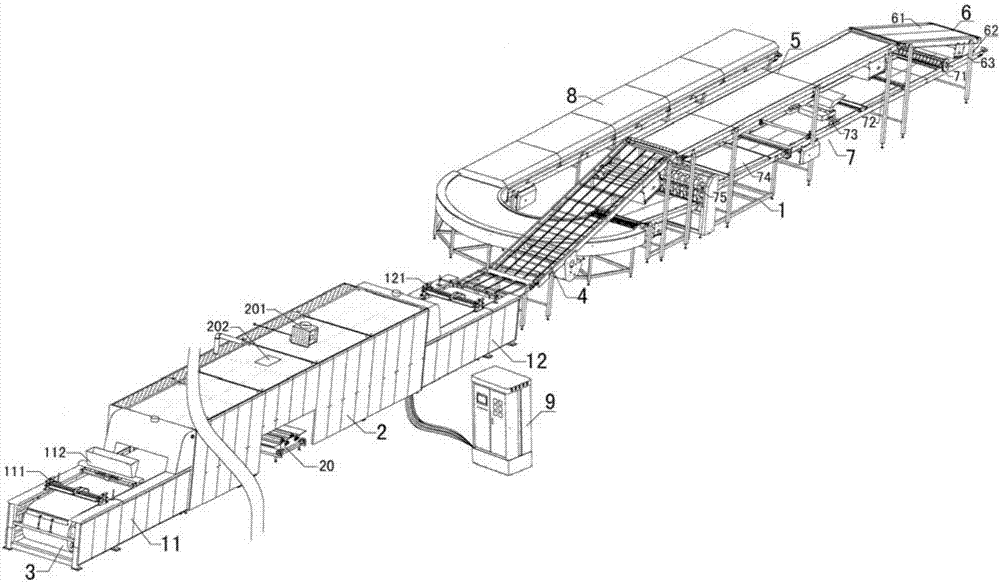

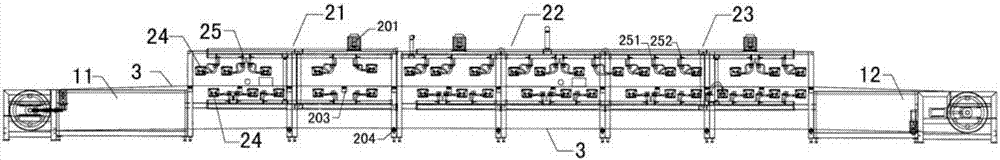

Full-automatic pocket cake baking production line and production processing method

InactiveCN107212037AGood conditionGreat tasteBaked article fillingBaking surface cleaning/greasingProgrammable logic controllerMolding machine

The invention discloses a full-automatic pocket cake baking production line and production processing method. The full-automatic pocket cake baking production line comprises a furnace inlet platform, a furnace outlet platform, a tunnel oven, a steel belt, a net chain conveying belt, a cooling transmission belt, a turning and rolling mechanism, a sandwich forming mechanism, a sterilization mechanism, a frame and a PLC (programmable logic controller) control box, the cooling transmission belt and the sandwich forming mechanism are arranged on the upper layer and the lower layer of the frame, the turning and rolling mechanism is connected with the cooling transmission belt and the sandwich forming mechanism, the tunnel oven is provided with a preheating area, a baking coloring area and a moisture control area, so that baking quality is controlled, a first pneumatic oil spray machine, a grouting machine, a second pneumatic oil spray machine, an automatic steel belt cleaning mechanism, an arc-shaped turning plate, a cutting slitting machine, a turnover mechanism, a paste machine, a laminating mechanism, a continuous forming separation mechanism and the sterilization mechanism are sequentially arranged on the production line, the PLC control box is connected with devices of the production line in a controlled manner, and intelligent control is achieved.

Owner:福建省亿焙机械有限公司

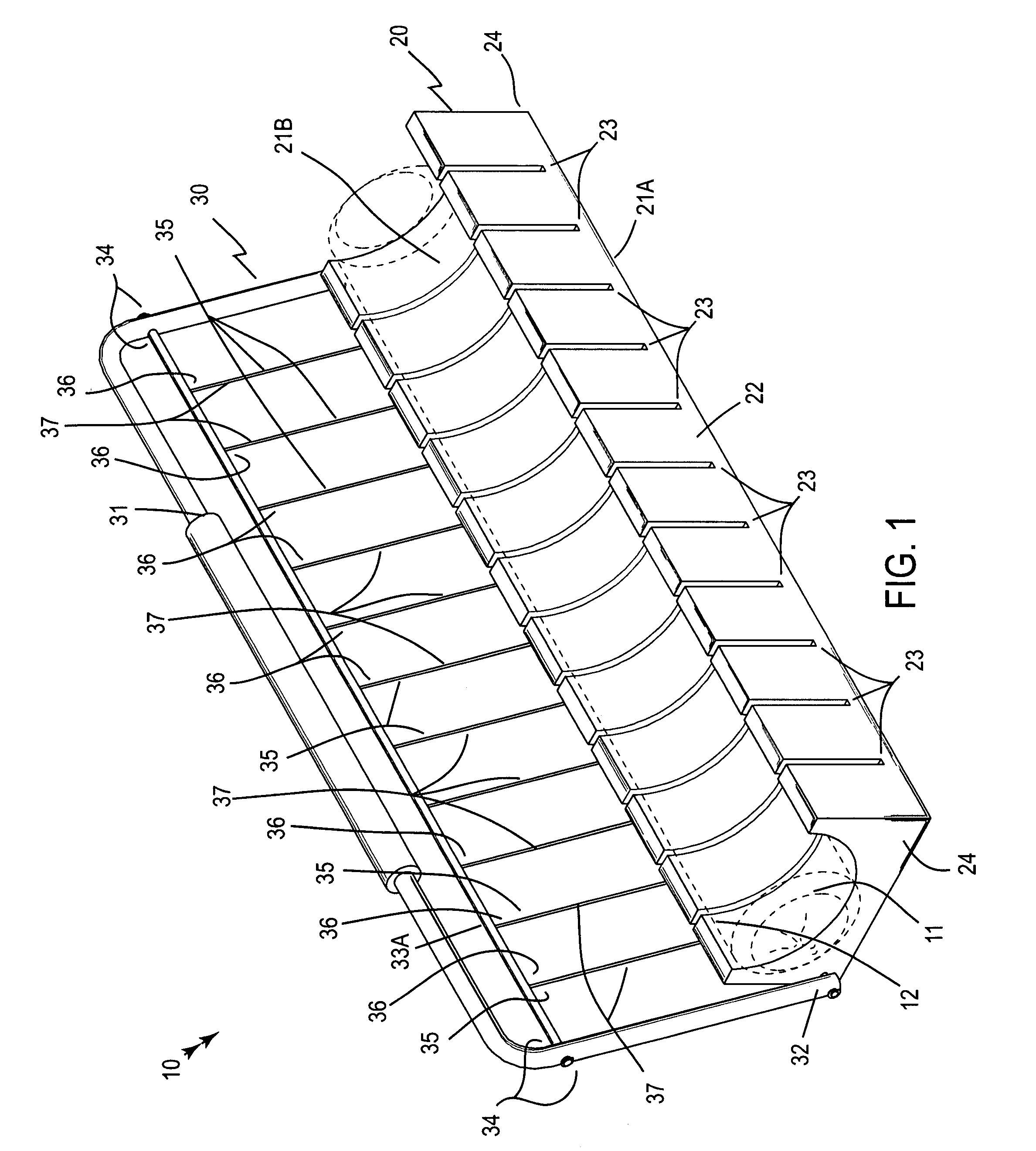

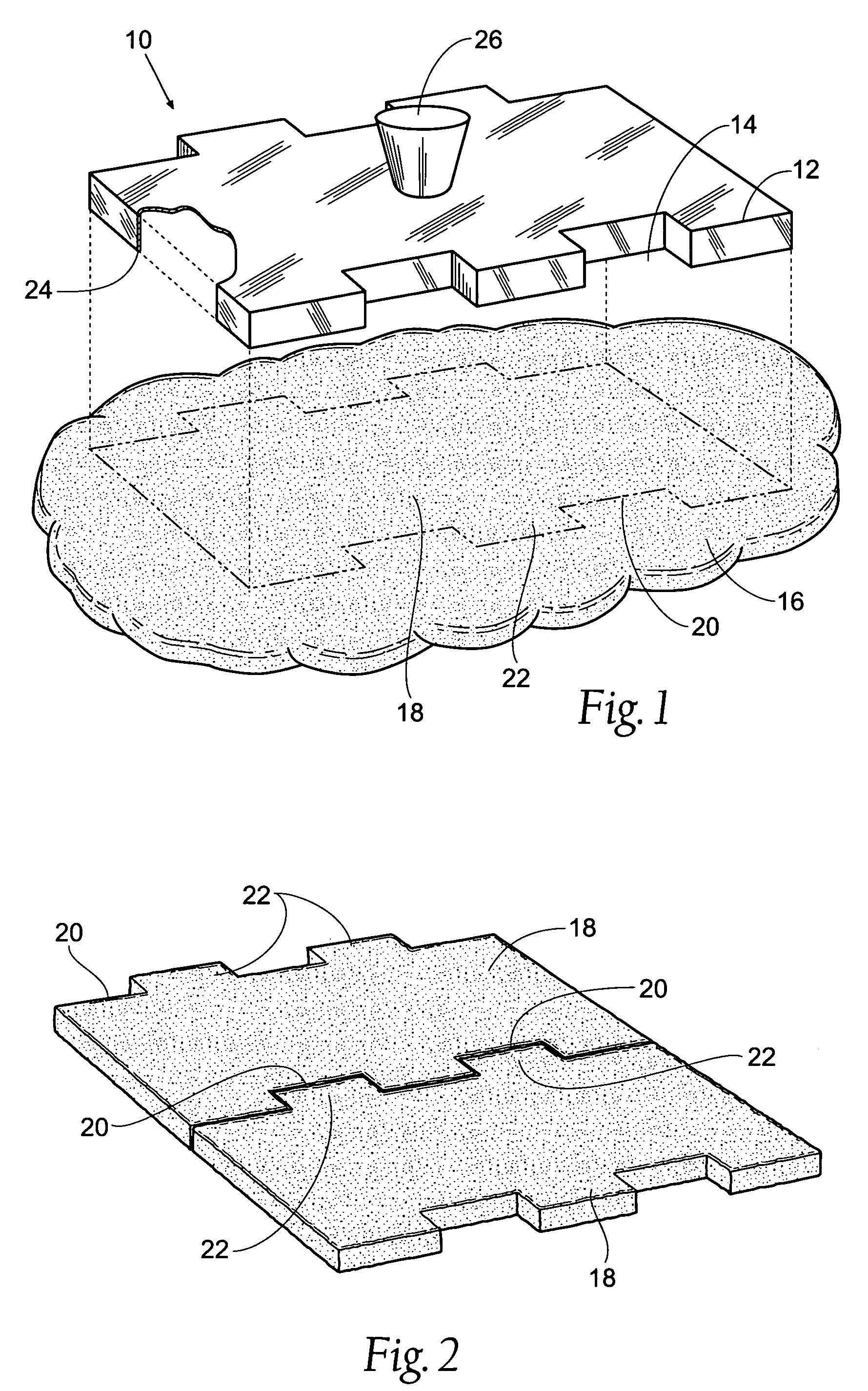

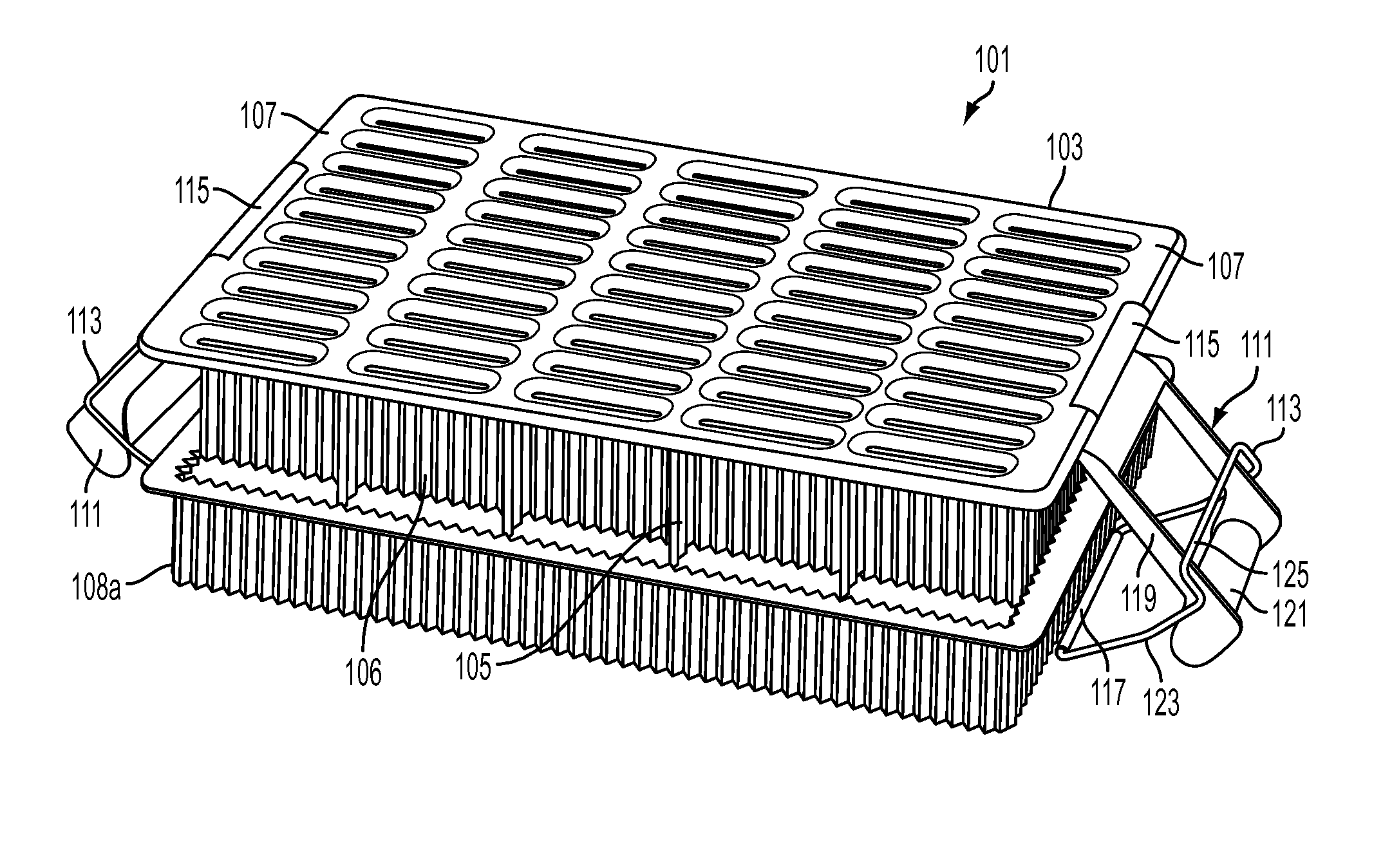

Apparatus for baking, cutting and serving

An apparatus for at least one of supporting and containing a preselected food product to be at least one of baked, cut and served. The apparatus comprises a base member having a predetermined shape and a predetermined size. There are a plurality of elongated grooves extending from a point closely adjacent an outer edge of the apparatus to a point on an axially opposed outer edge of the apparatus and from an upper surface thereof to a predetermined depth. The plurality of the elongated grooves enabling a cutting means to pass completely through such preselected food product.

Owner:CARLSON EDWARD SCOTT +1

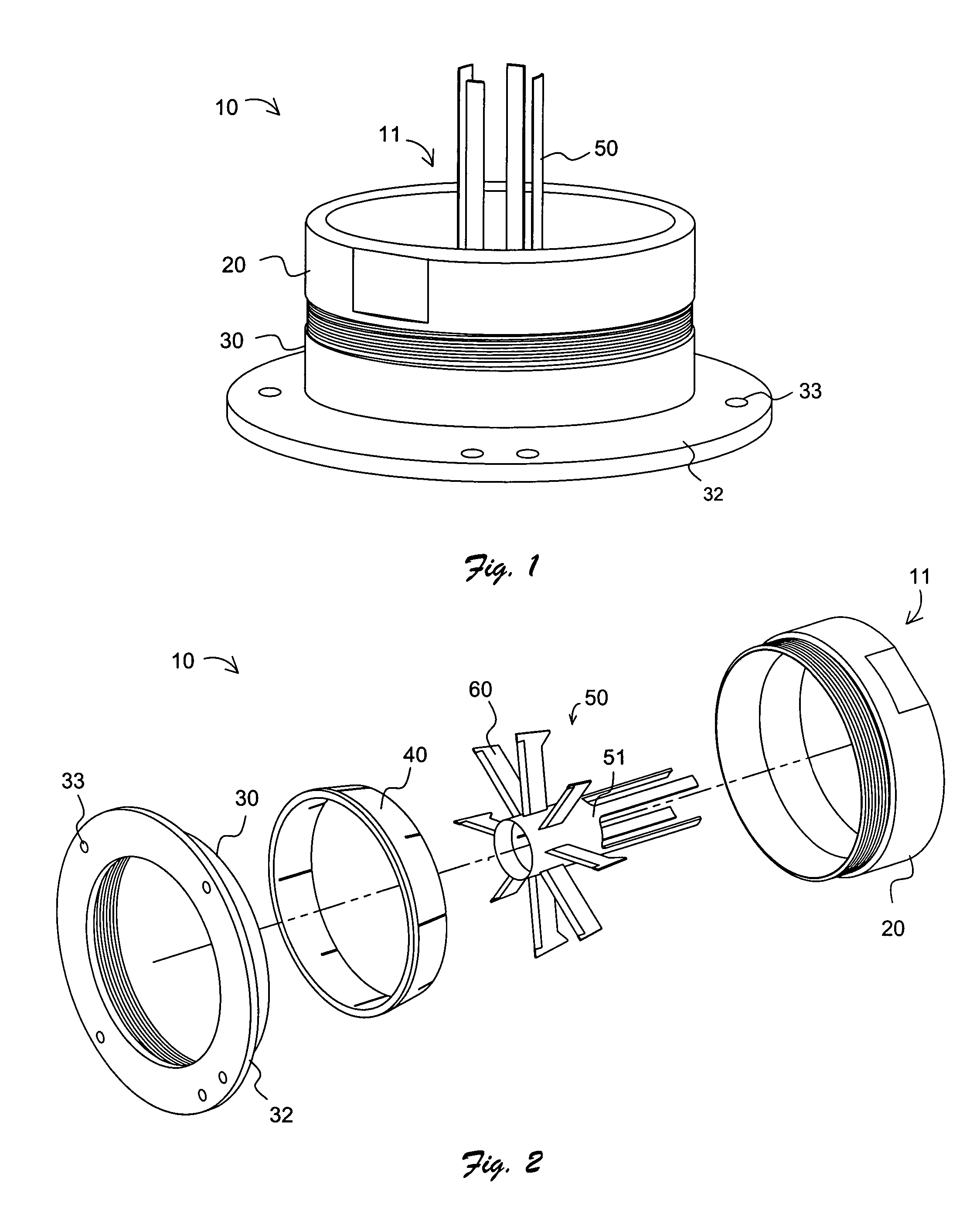

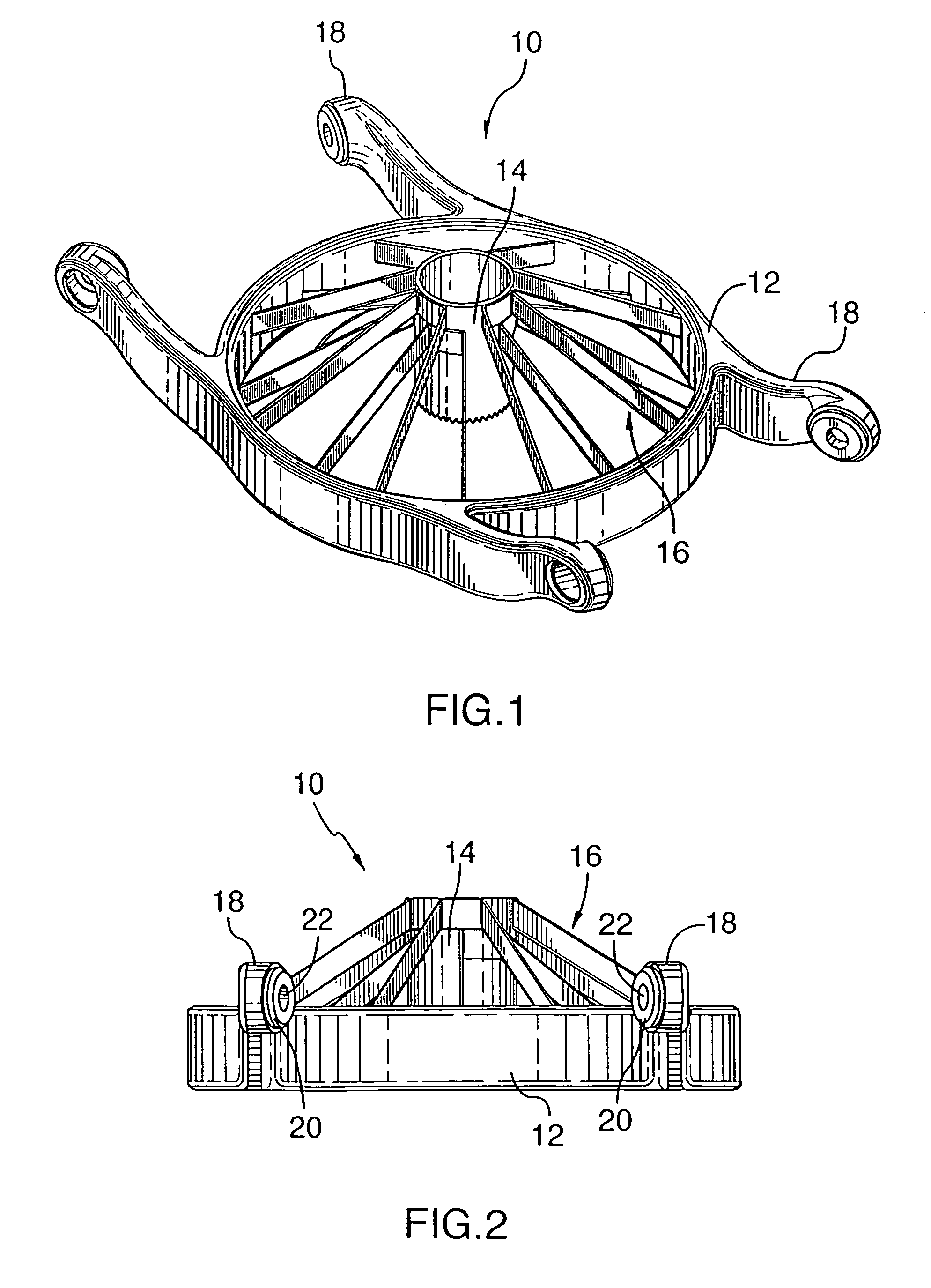

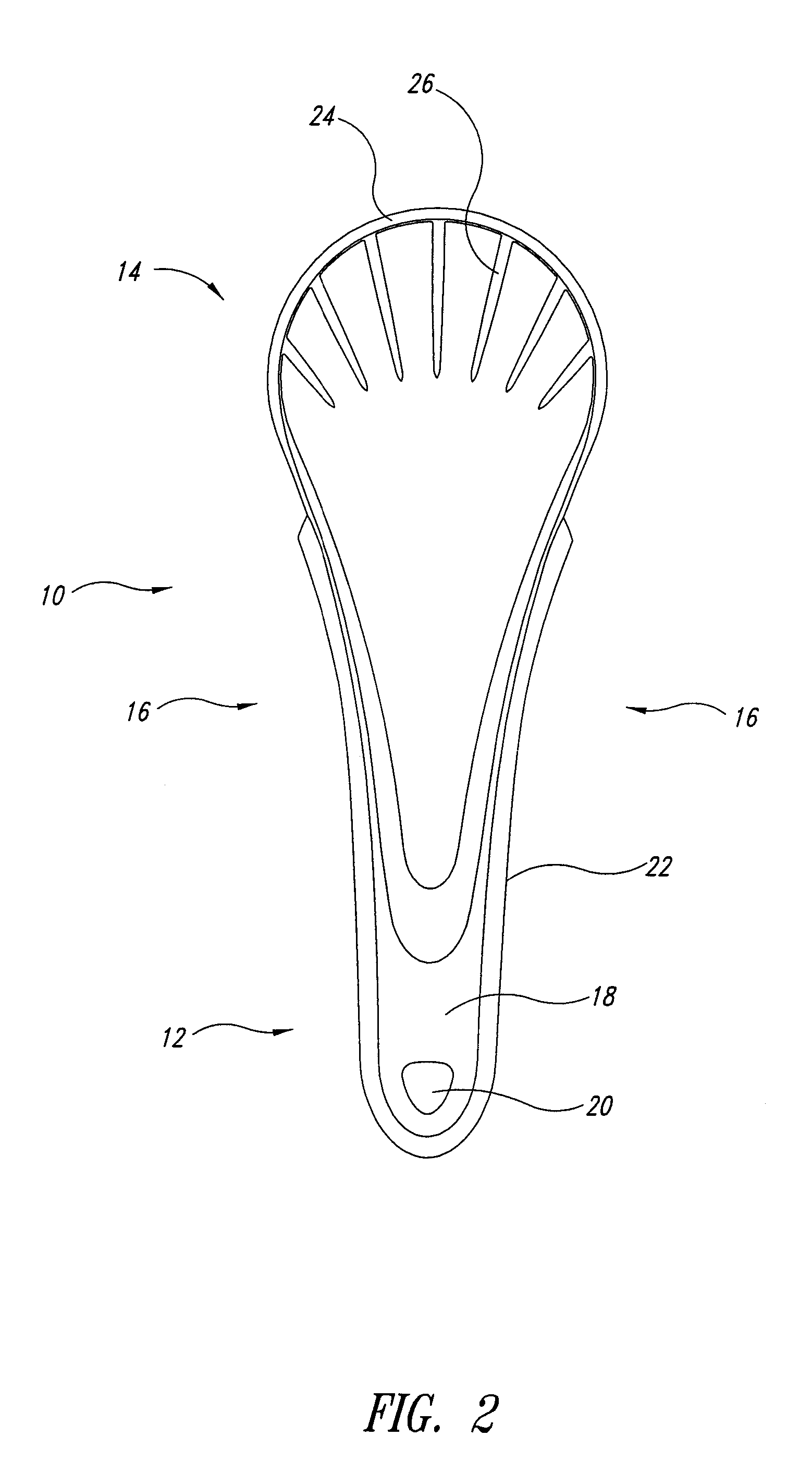

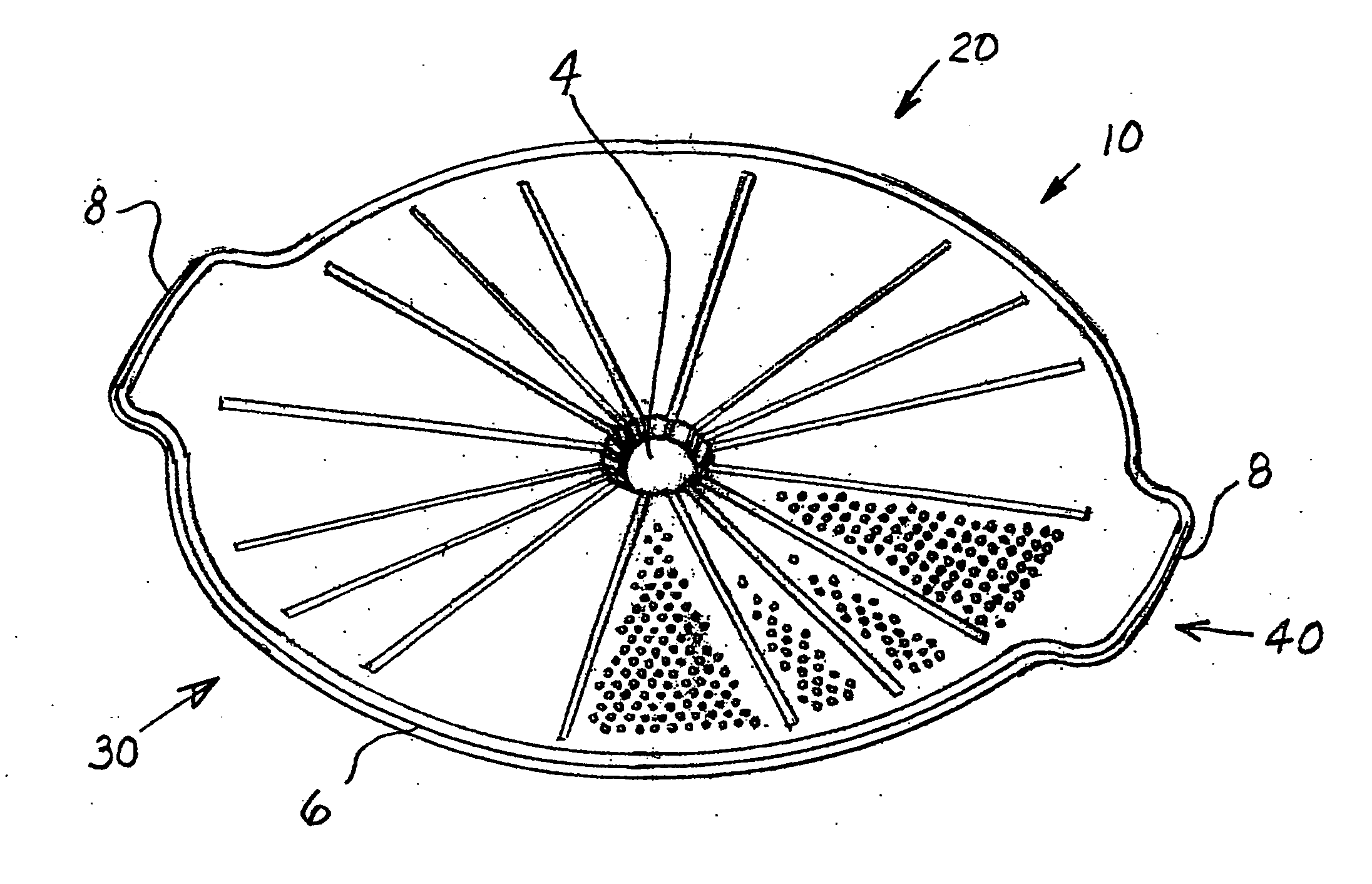

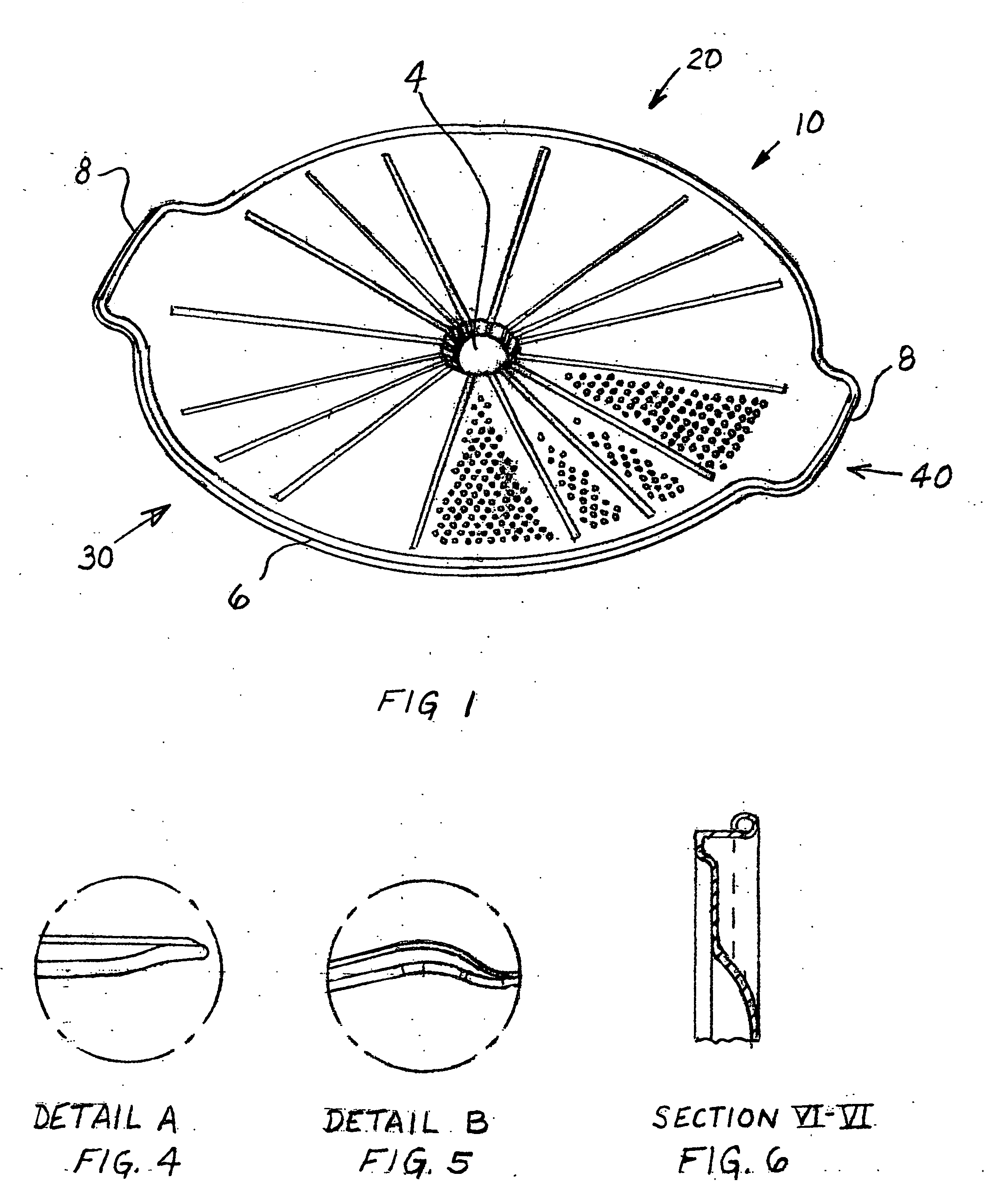

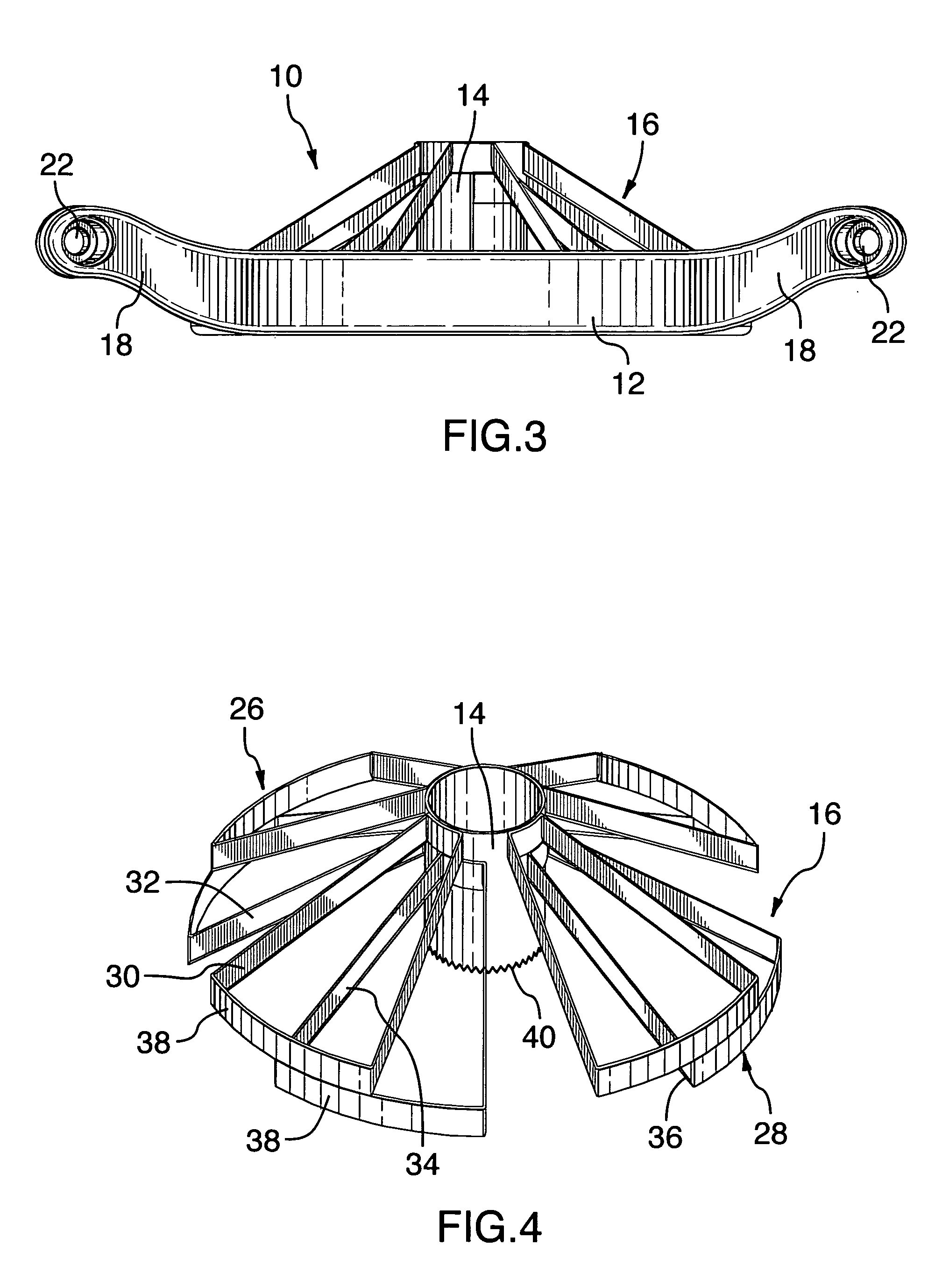

Apparatus for coring into and cutting food items

The present invention provides for an apparatus for coring and slicing a food item comprising: a) a peripheral member; b) a coring element; and c) a plurality of blades extending radially of the coring element to the peripheral member, in spaced relation about the coring element. The apparatus may be combined with a base for securing the food item. Methods of constructing the apparatus are also encompassed by the present invention.

Owner:BROWNE & CO LTD

System, method and apparatus for cutting foods

Owner:HAVISHAM BOYE & BROWN LLC

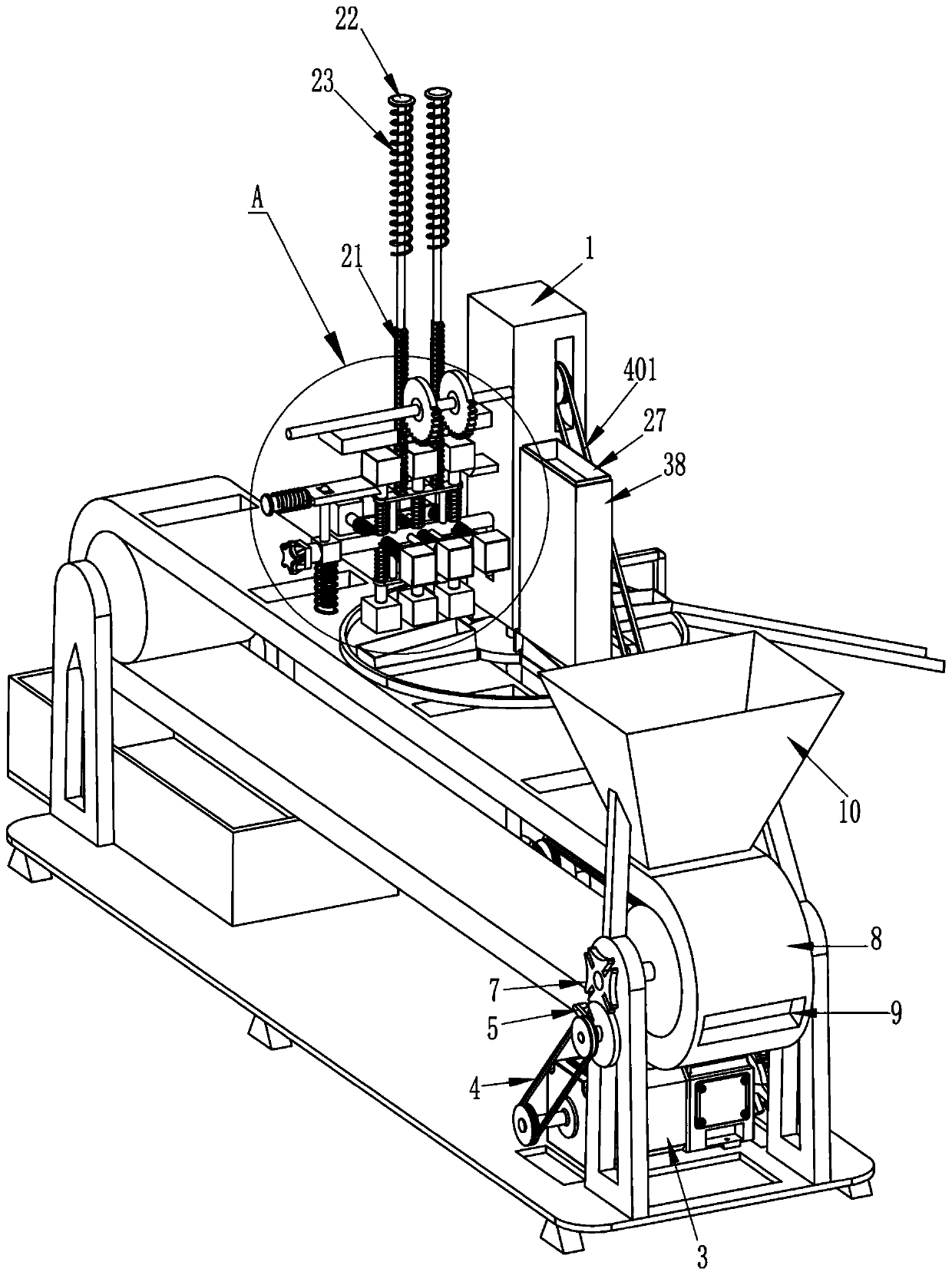

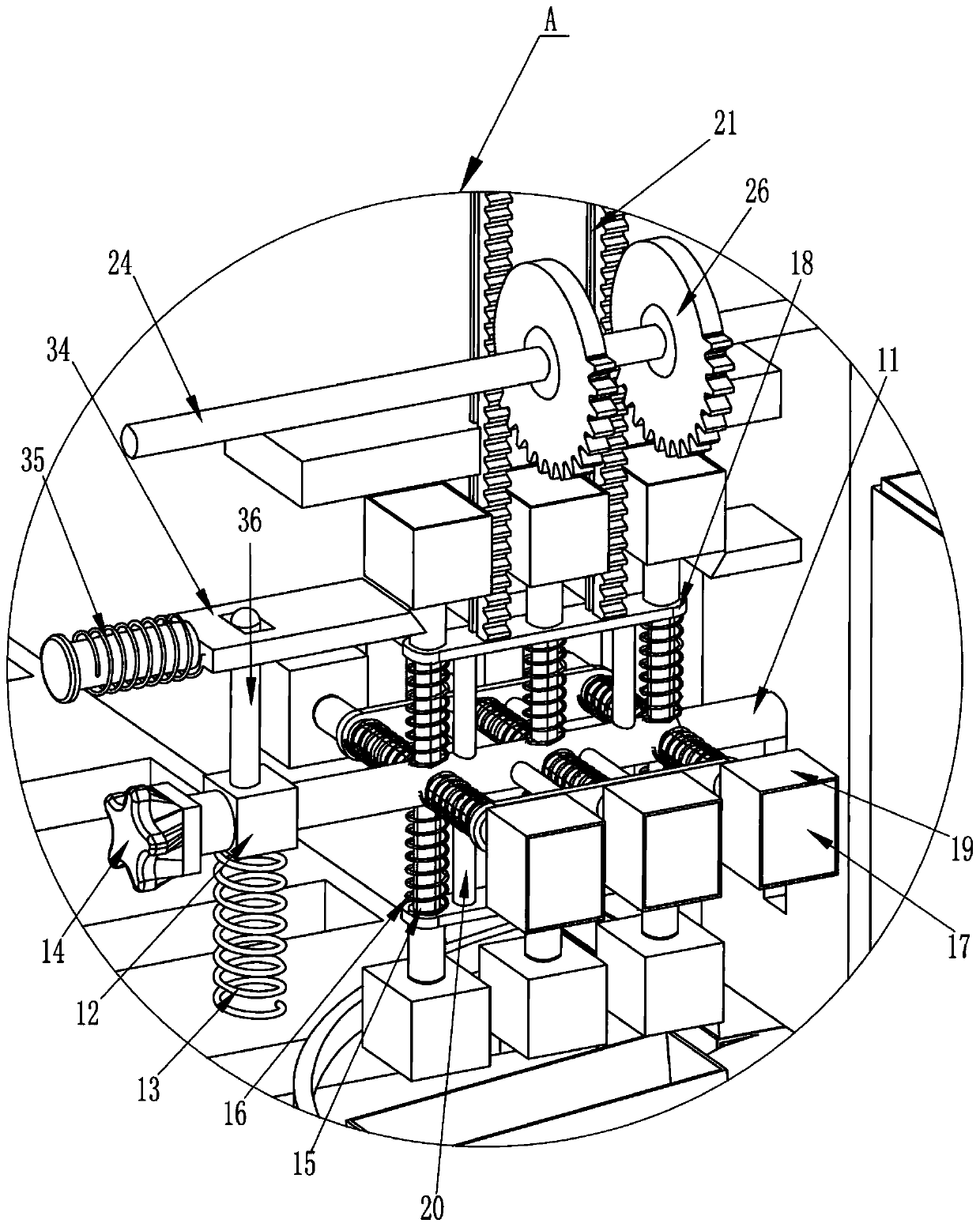

Cutting equipment capable of cutting murraya paniculata cakes into different shapes

ActiveCN111037621AMetal working apparatusBaked article cutting/slicingStructural engineeringMurraya paniculata

The invention relates to cutting equipment, in particular to cutting equipment capable of cutting murraya paniculata cakes into different shapes. The technical problem is how to design cutting equipment capable of cutting murraya paniculata cakes into different shapes conveniently, wherein the cutting equipment can cut the murraya paniculata cakes into different shapes as required without other machines, is low in cost and does not need manual operation. The cutting equipment capable of cutting the murraya paniculata cakes into the different shapes comprises a bottom plate, one side of the bottom plate is symmetrically and fixedly connected with two support plate, and an n-shaped support plate is installed in the middle of one side of the bottom plate. According to the cutting equipment, the murraya paniculata cakes are poured into a feeding hopper to fall into a first groove, a double-shaft motor is started, then, the murraya paniculata cakes can be moved to the positions below forming boxes, the forming boxes move downwards to conduct cutting forming on the murraya paniculata cakes, the murraya paniculata cakes does not need to be subjected to manual cutting forming, operation isconvenient, and in addition, by pulling a second rotary shaft to rotate, the forming boxes for the murraya paniculata cakes needing to be cut into shapes can be adjusted as required.

Owner:江西桔娃食品有限公司

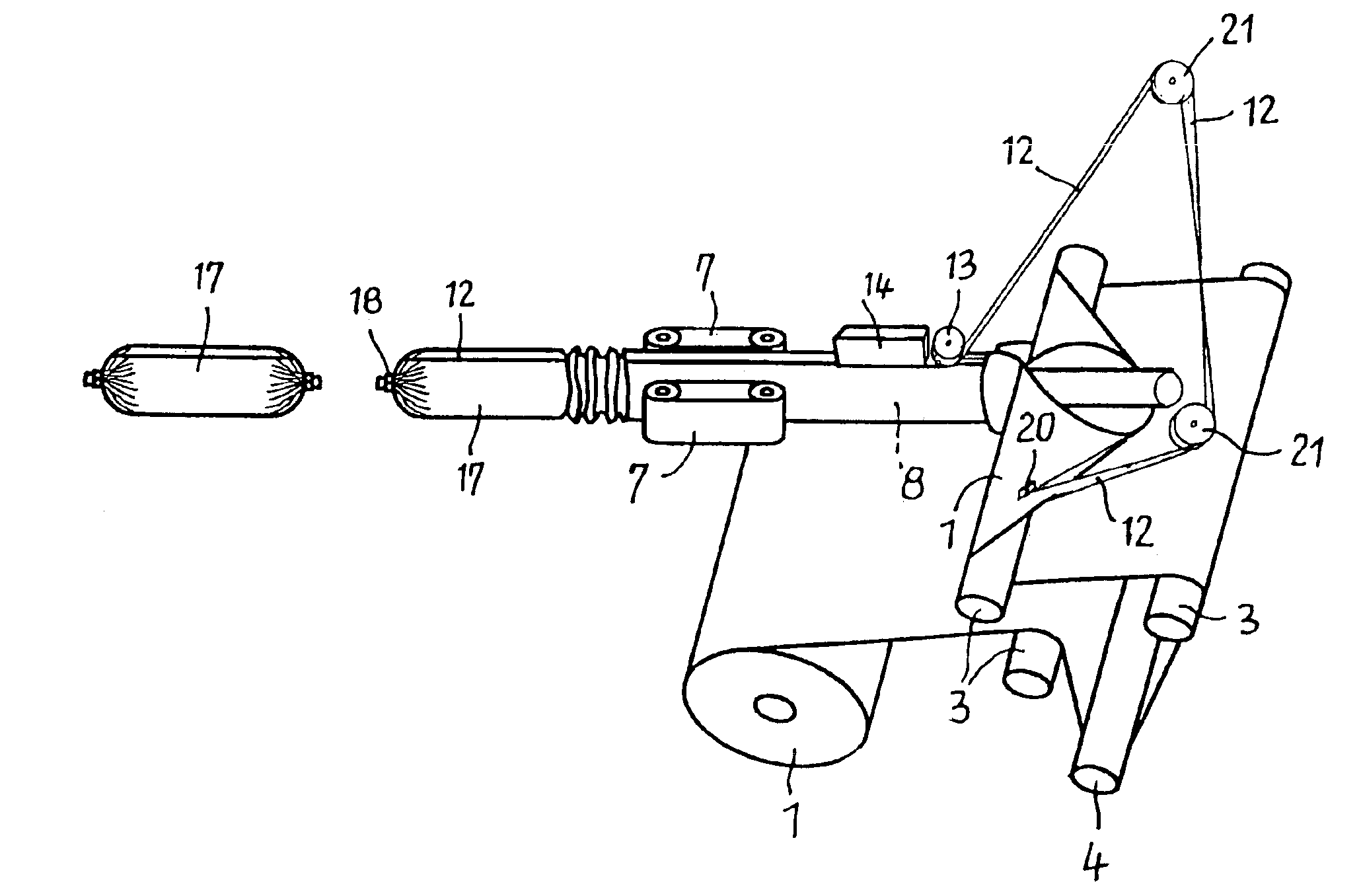

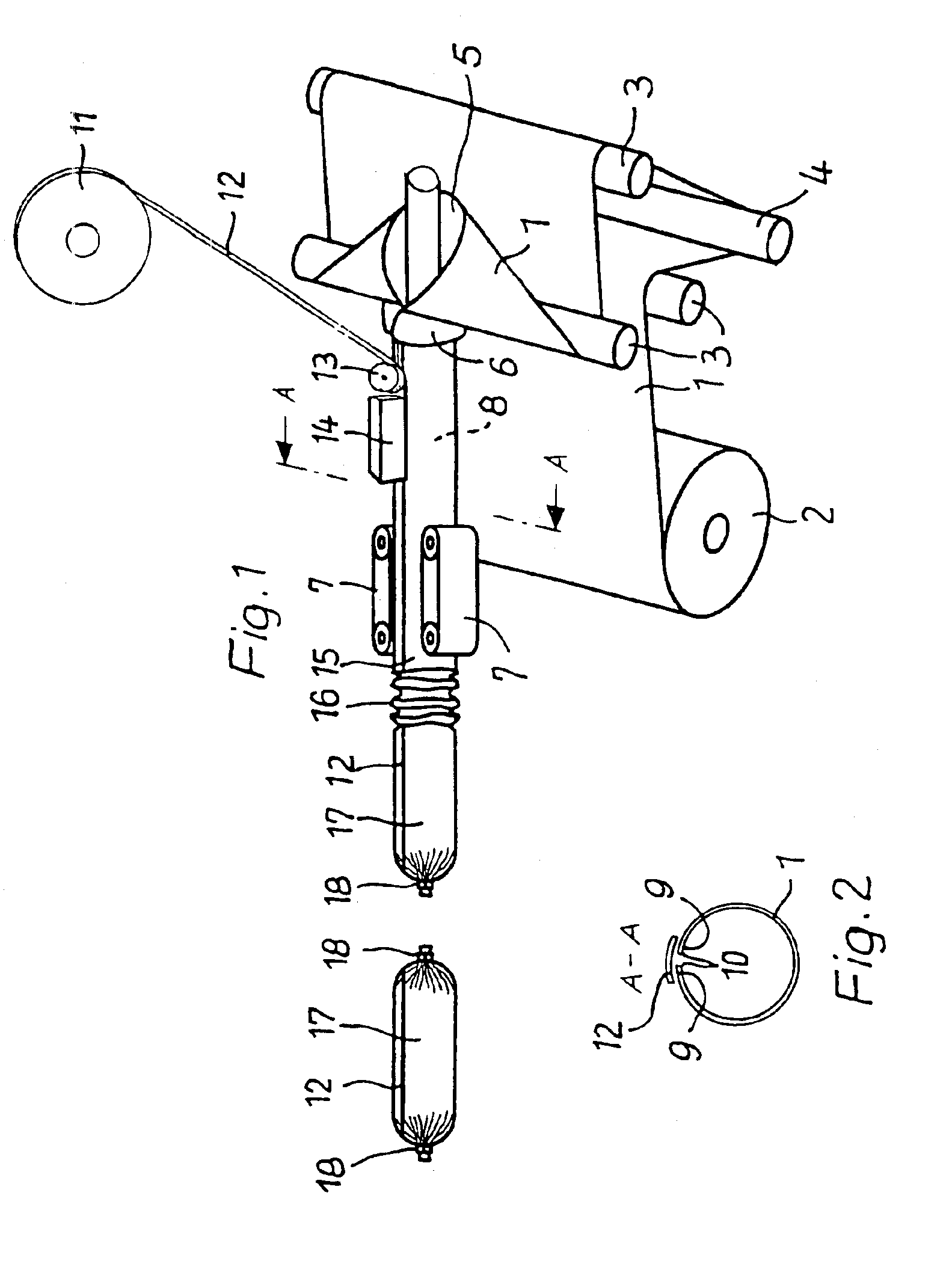

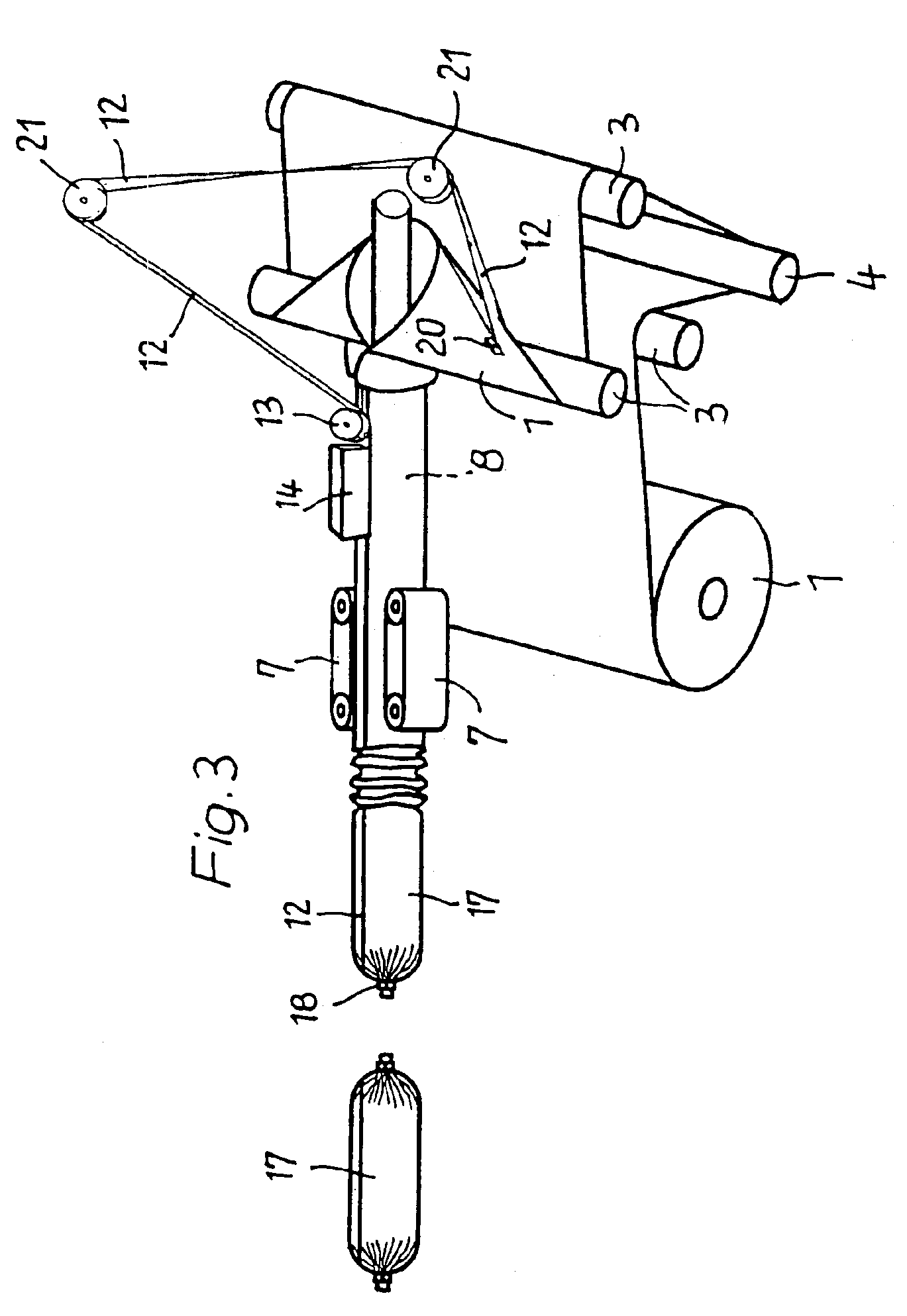

Method for producing a casing

InactiveUS7059102B2Small sizeCan be without delayWrapper twisting/gatheringSausage makingBand shapeEngineering

Owner:POLY CLIP SYST

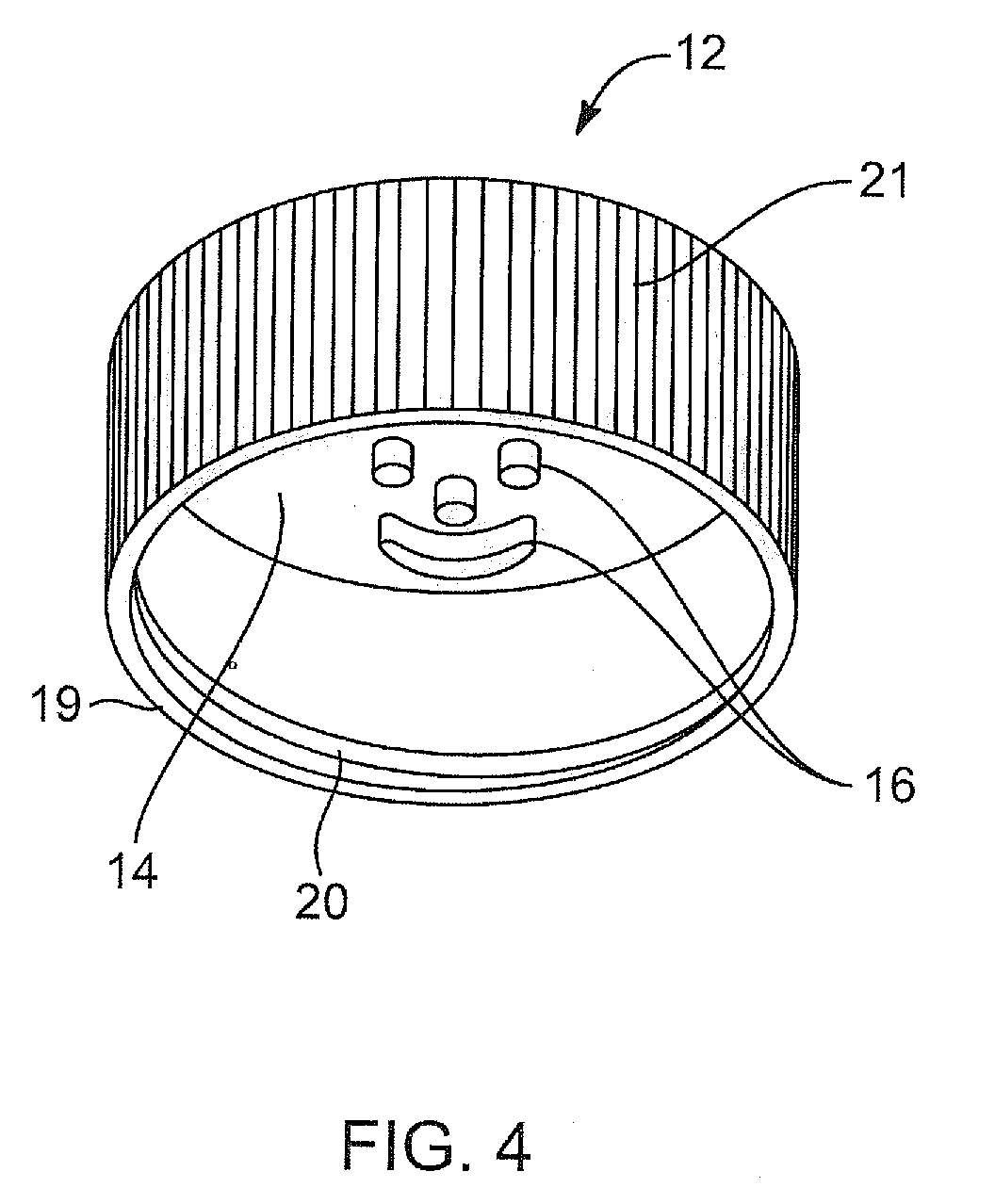

Adjustable cake cutter

InactiveUS7913396B2Prevent fallingPractical to useFruit stoningDough dividingEngineeringMechanical engineering

An adjustable cake cutter includes an one-piece cutter body that allows adjustment of the cut size, and a bearing bar pivoted to the cutter body and turnable to the bottom side of the space defined within the cutter body to bear the cut piece of cake for enabling the user to carry the cut piece of cake to a dish directly with the adjustable cake cutter.

Owner:WEI SHAO TSUNG

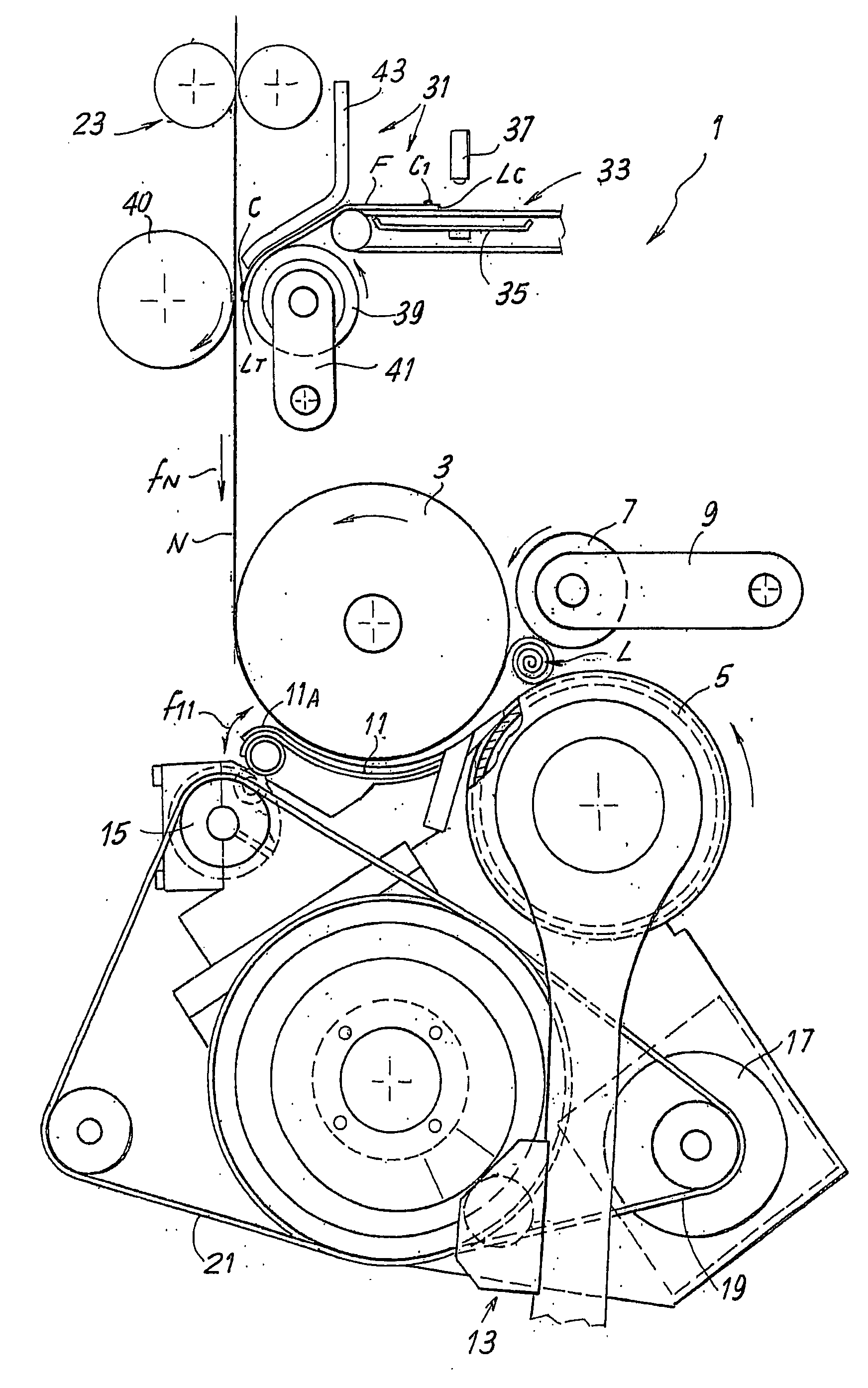

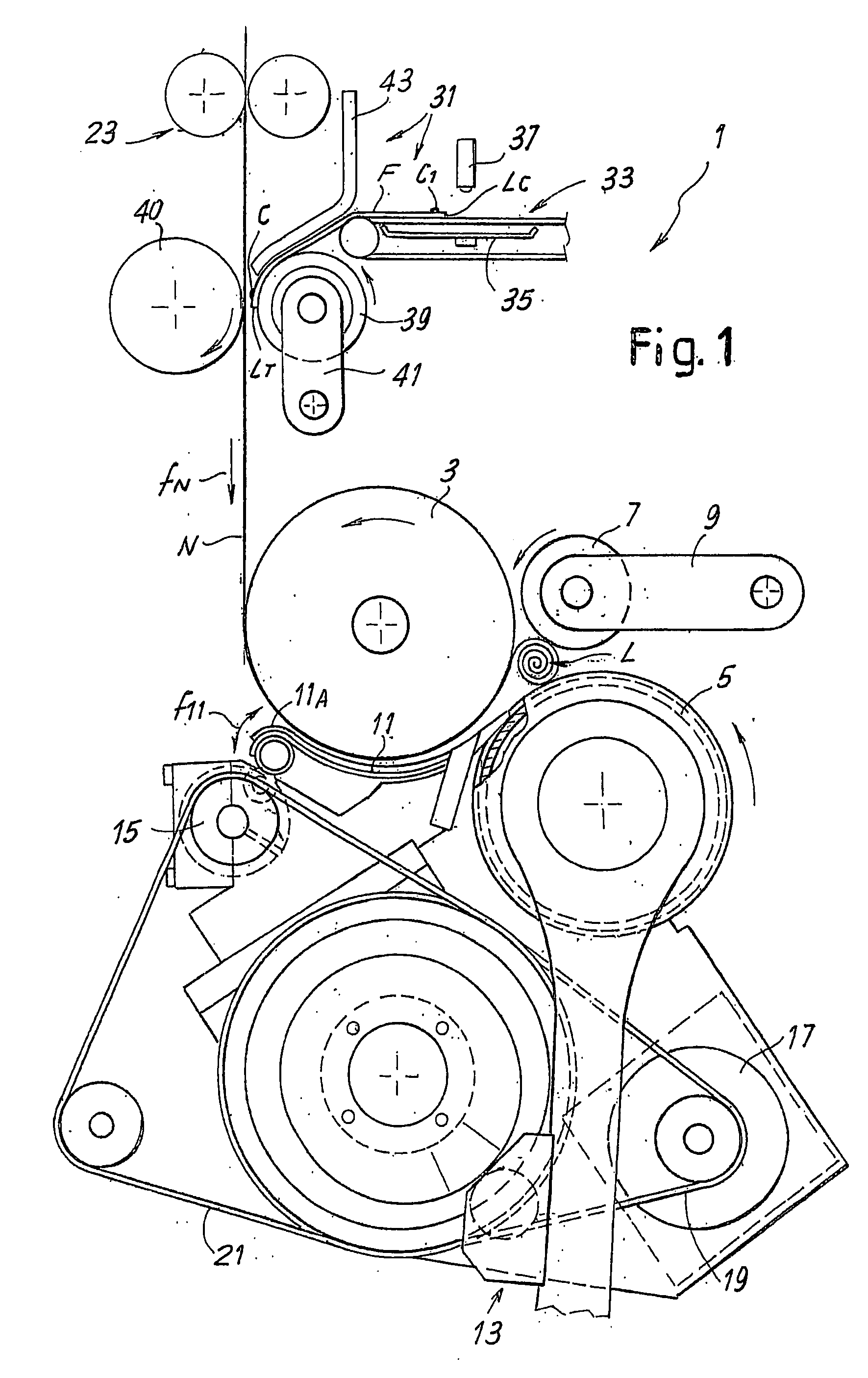

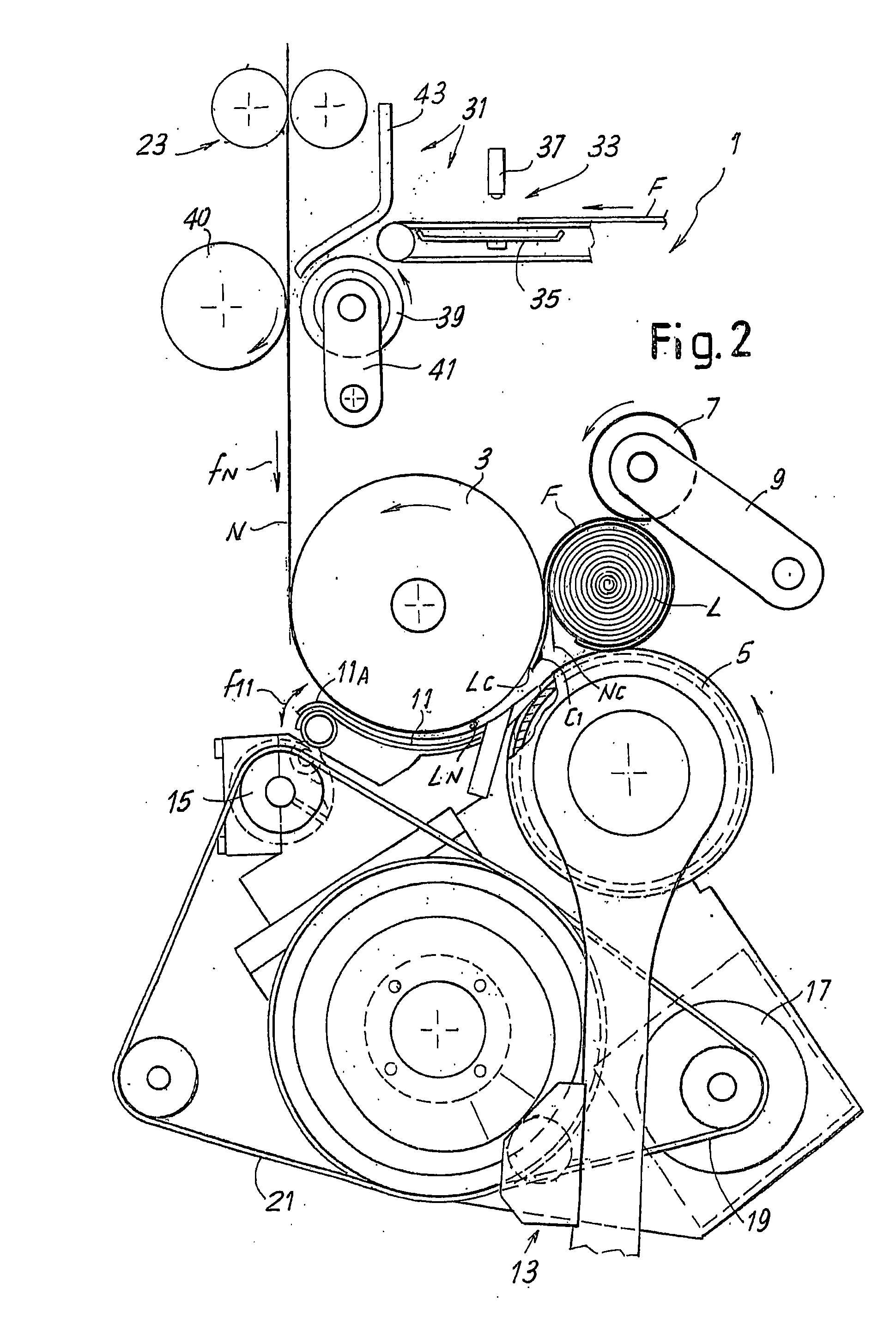

Method and device for manufacturing rolls of web material with an outer wrapping

ActiveUS20100101185A1Increase speedImprove productivityWrapper folding/bending apparatusFilament handlingEngineeringConductor Coil

A rewinder machine for the production of rolls of web material is described, comprising: a winder unit (3, 5, 7); a path for delivering the web material (N) to said winder unit; a system for continuously feeding said web material into said winder unit; a distributor (31) of a sheet material (F) for wrapping the rolls formed by said winder unit, installed and operated so as to deliver a length of sheet material to said winder unit on completion of the winding of each roll without stopping the forward feed of the web material.

Owner:FABIO PERINI SPA +1

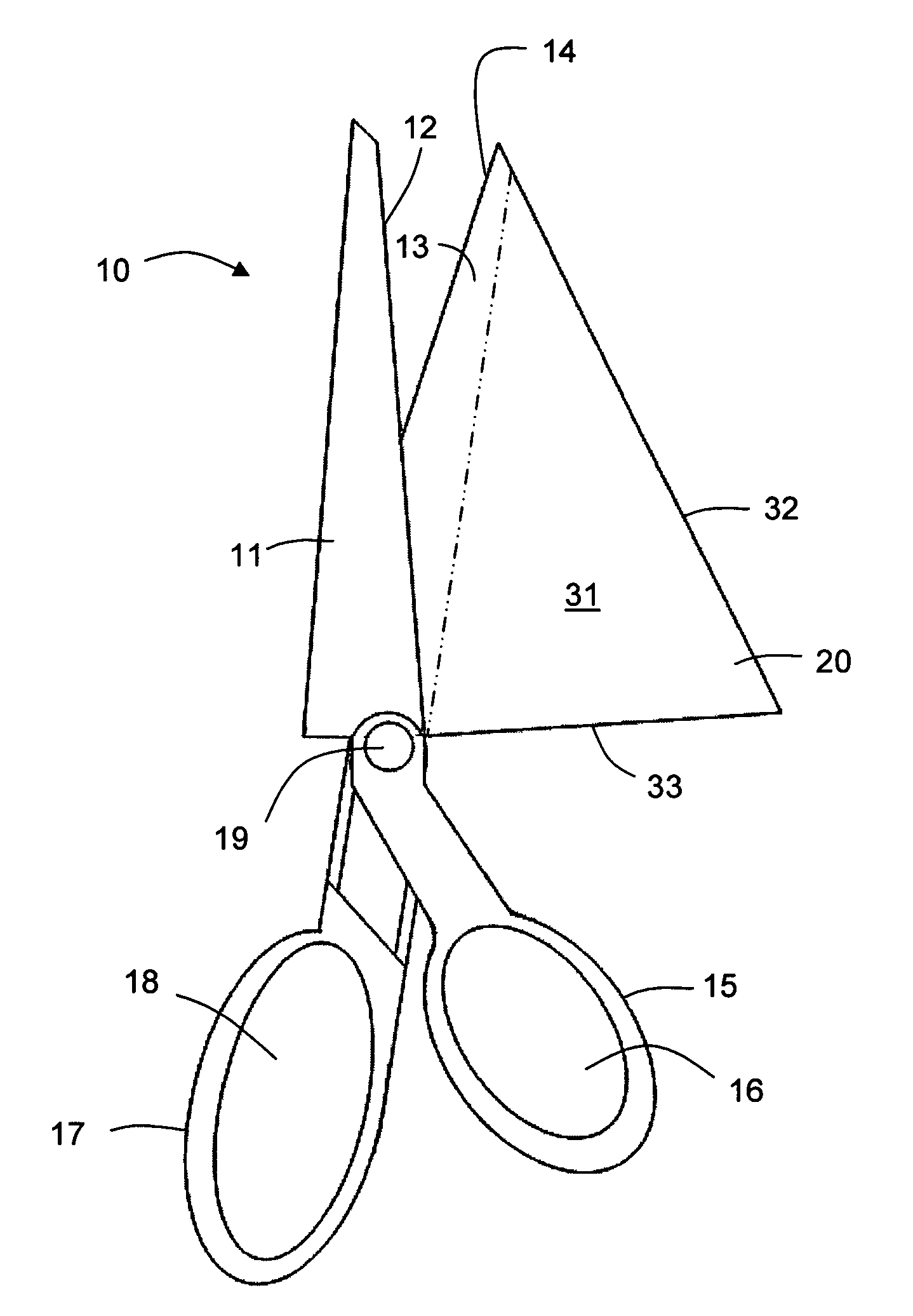

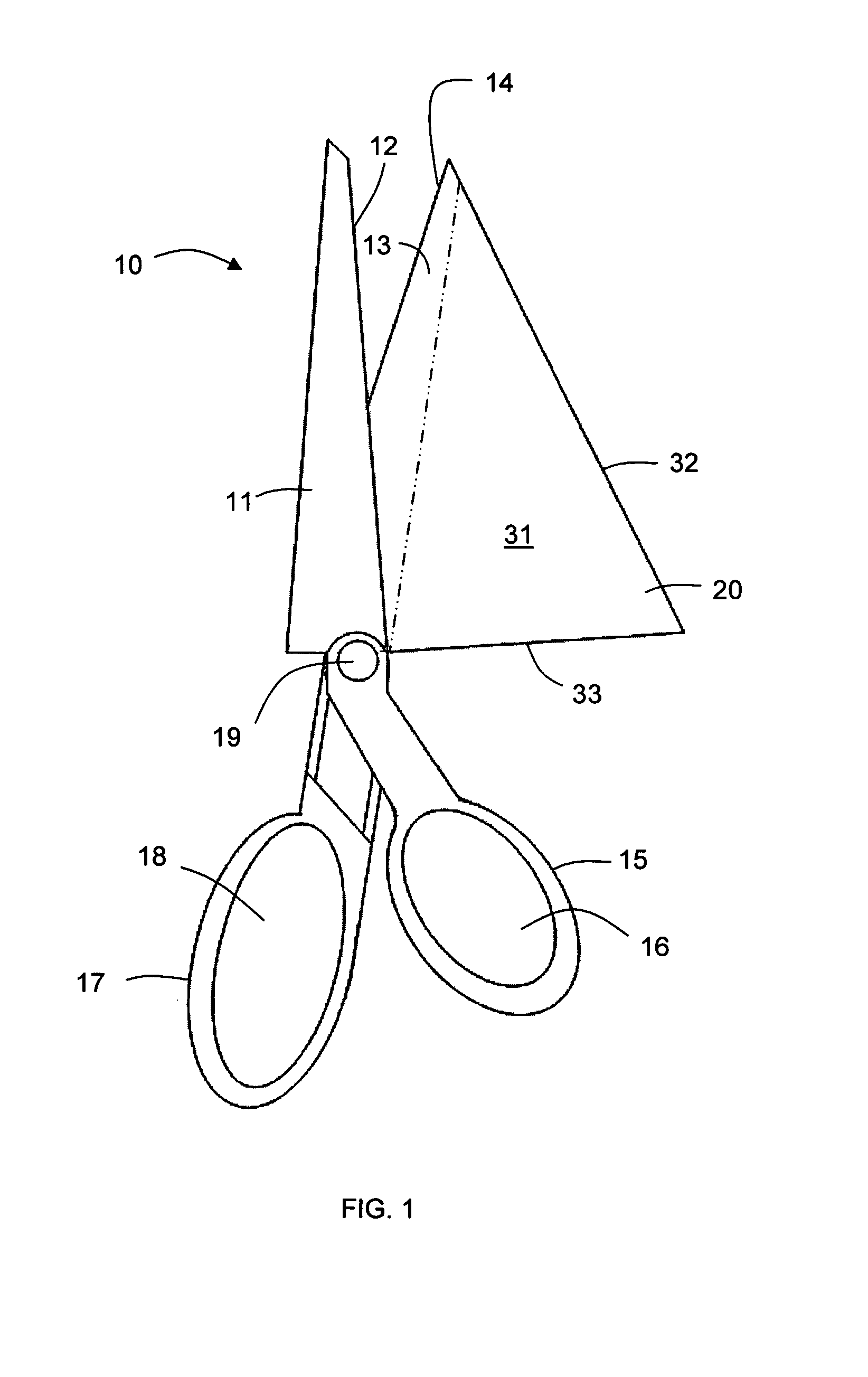

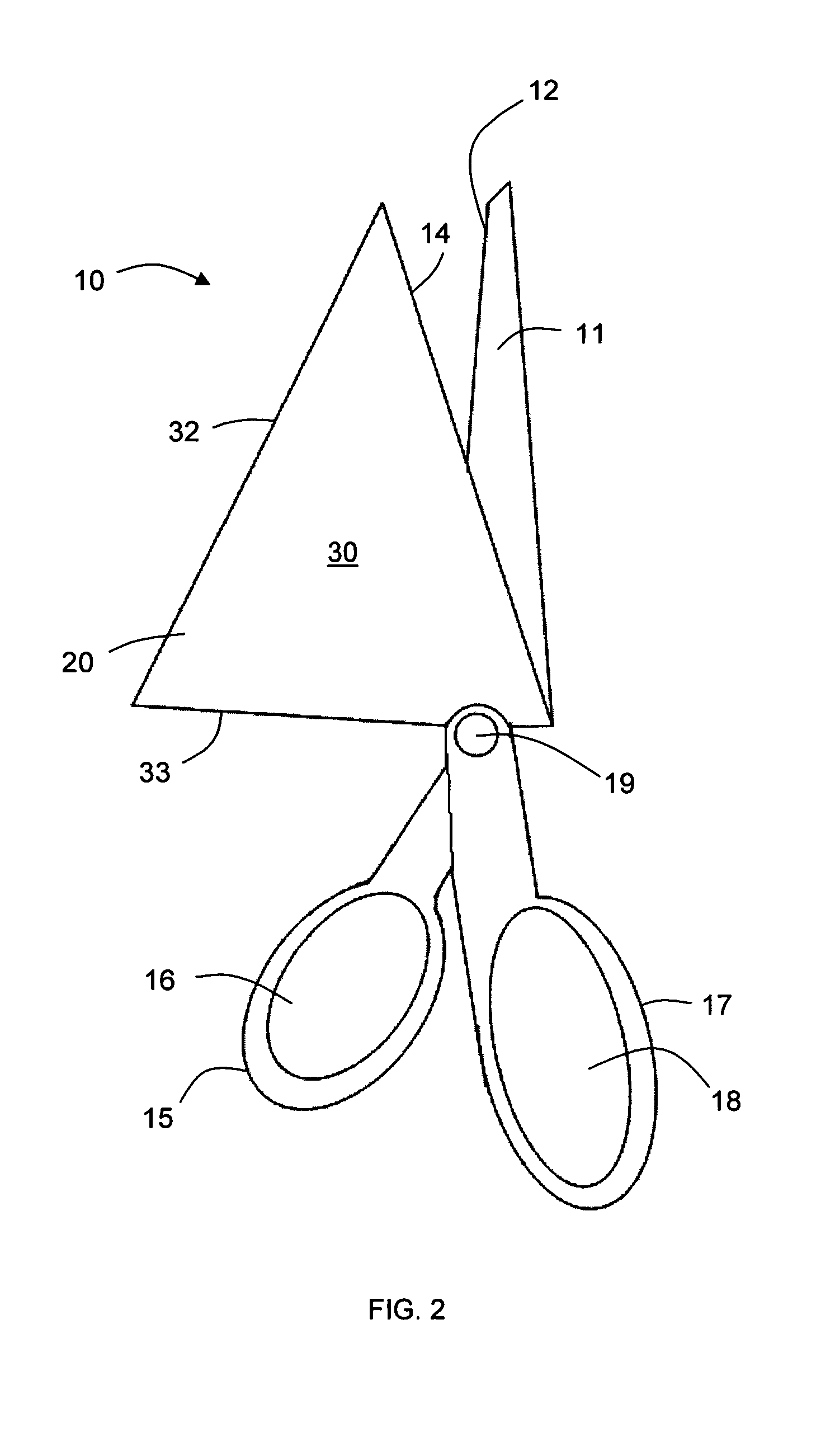

Pizza cutting and serving device

InactiveUS20080134517A1Easy to holdEasy to storeDough dividingMetal working apparatusMechanical engineeringPolymer

A cutting and serving device for pizza and similarly-shaped foods allows a user to cut a pizza into slices and serve the slices with one hand. Scissors cut the crust and toppings of the pizza and a spatula-like serving surface, projecting outward from the scissors, slides under and supports the cut slices. In the preferred embodiment, the serving surface extends vertically from the pizza. Alternatively, the serving surface extends horizontally from the scissors and is inserted under the pizza to receive the slice when it is cut. Preferably, the scissor blades and serving surface are coated with a non-stick clear polymer. The scissor blades may be held together by a swivel pin or by a hinge. The device may be collapsible for easy storage.

Owner:KISS S&C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com