Patents

Literature

339results about "Special goods baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

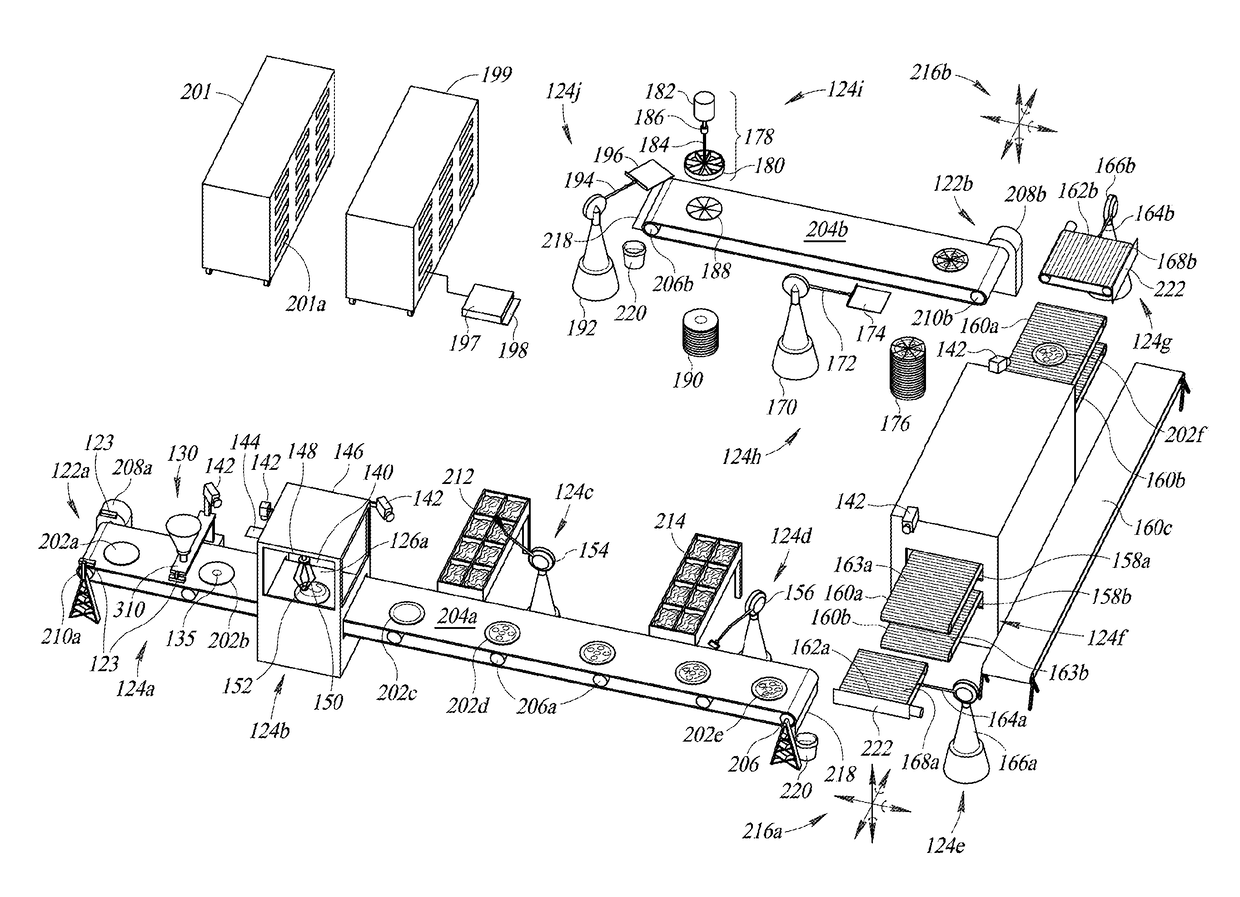

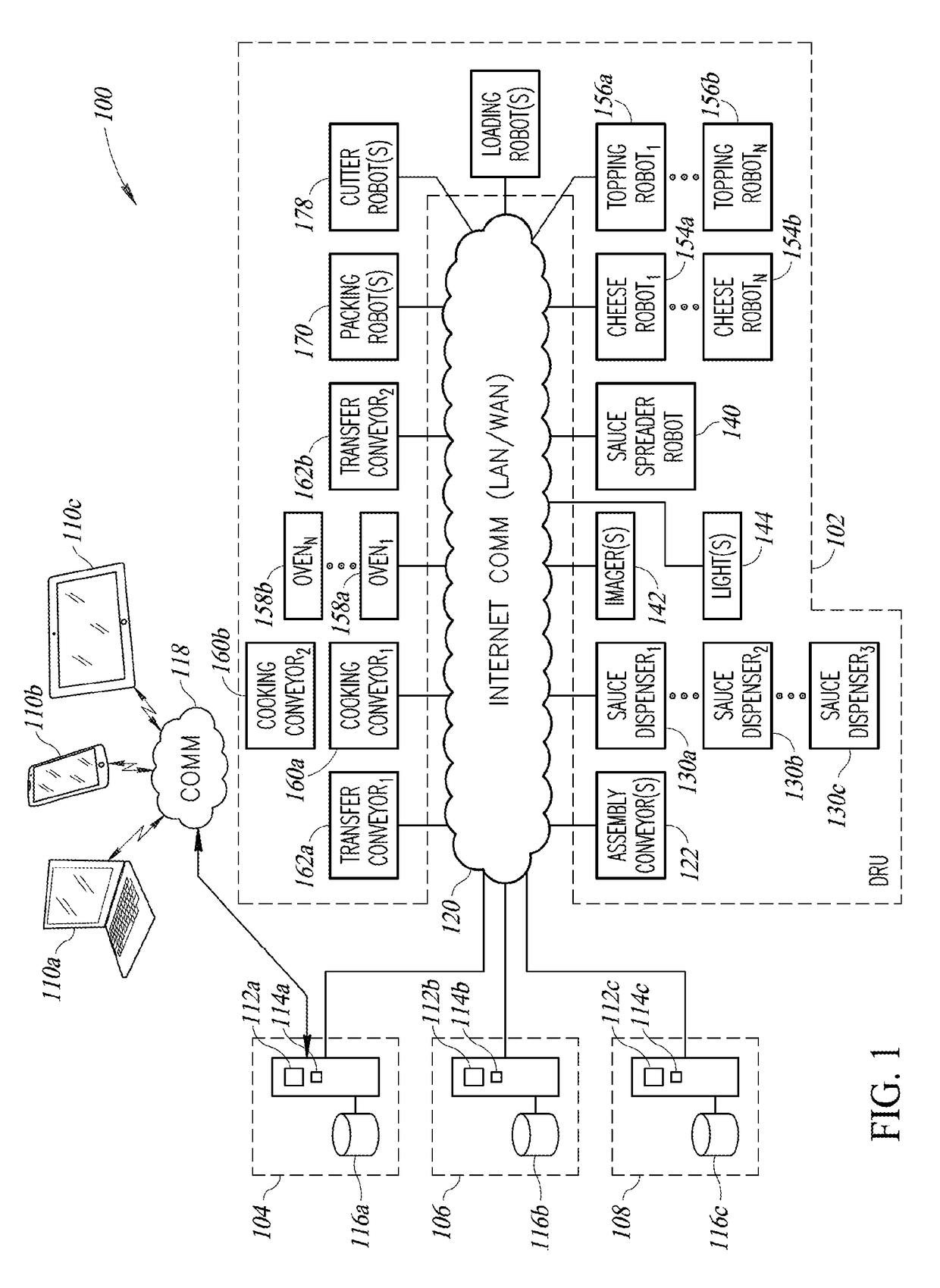

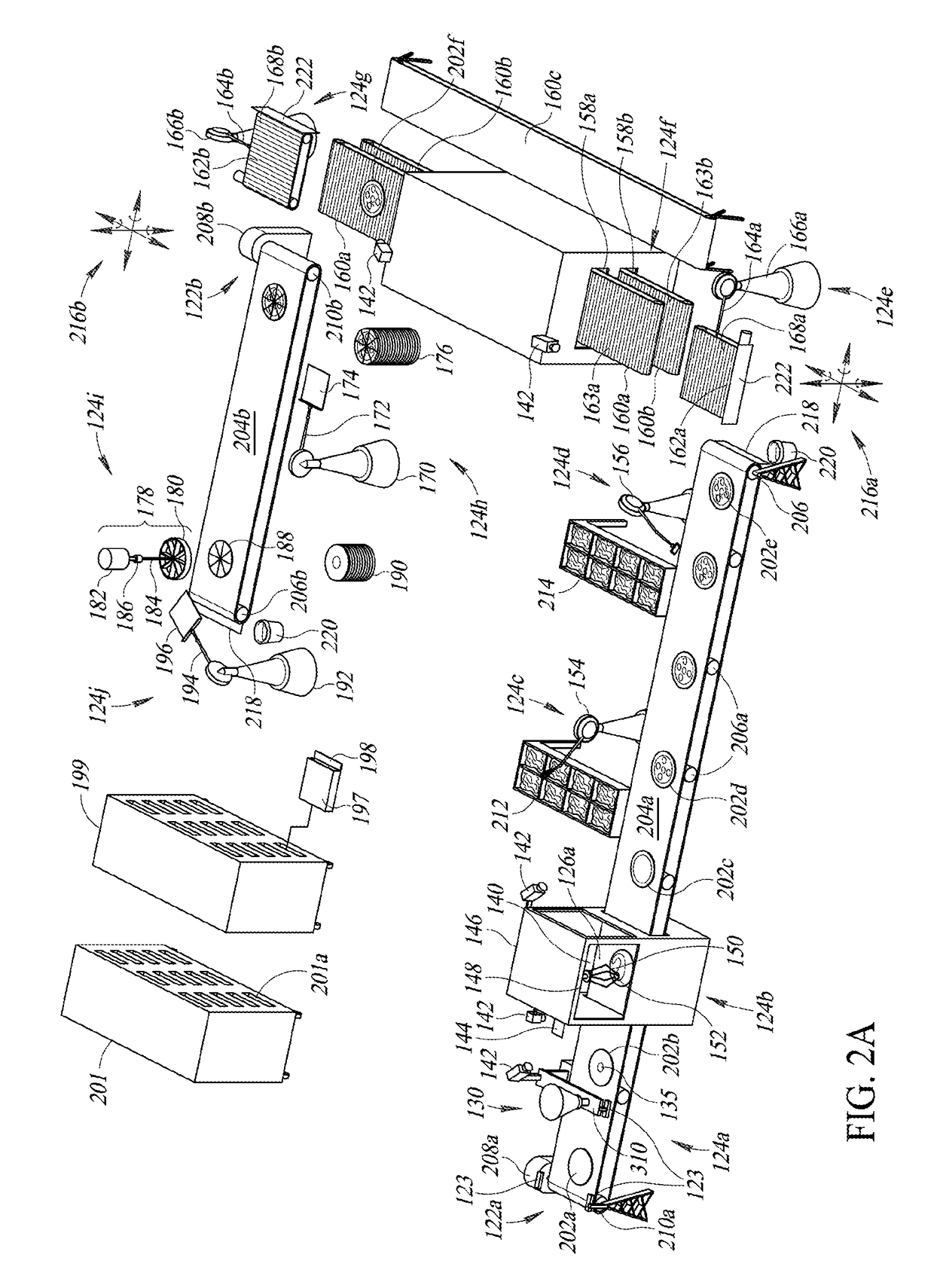

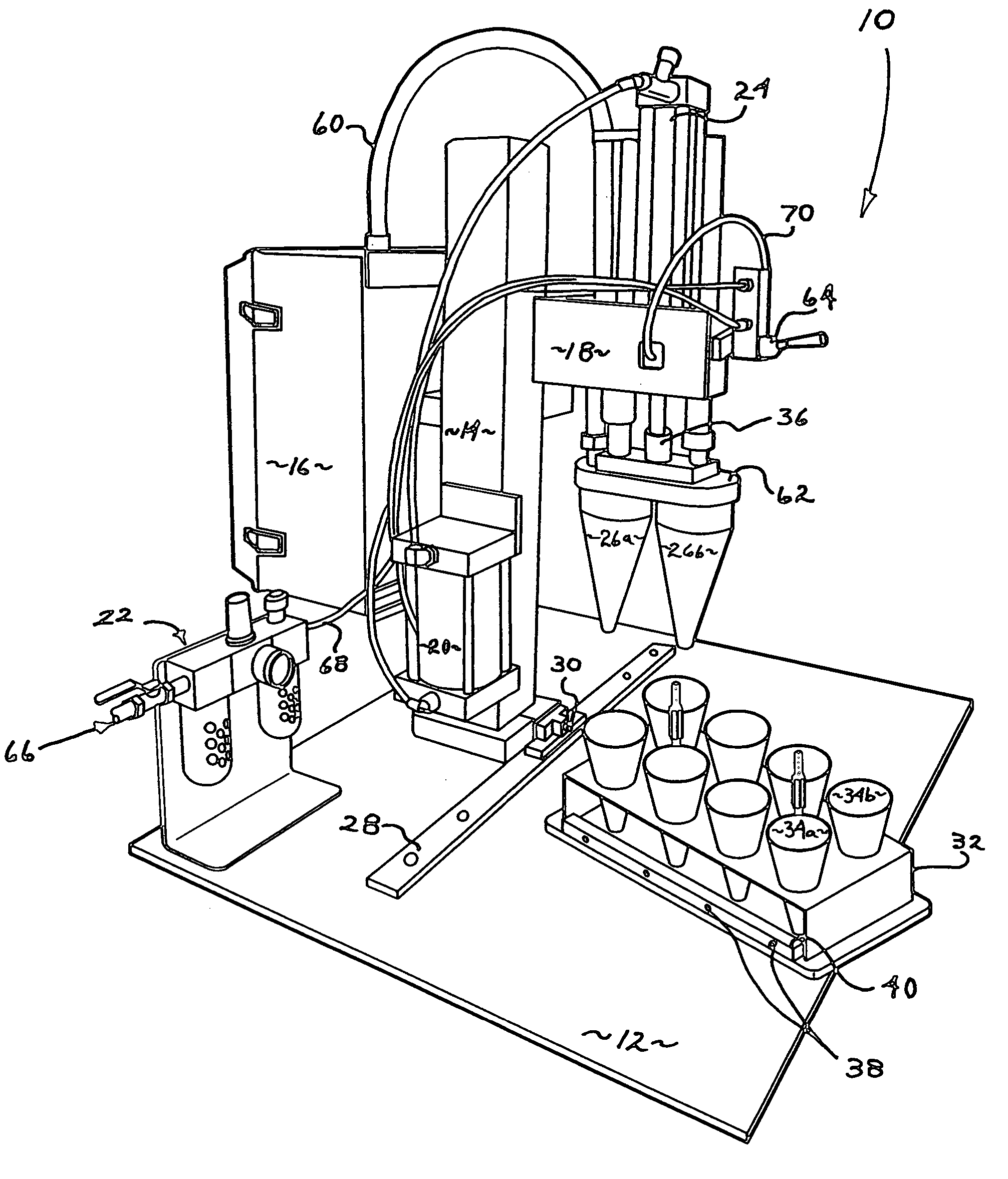

On-demand robotic food assembly and related systems, devices and methods

An on-demand robotic food assembly line can include one or more conveyors and one or more robots, operable to assemble food items in response to received orders for food items, and one or more ovens operable to, for example, partially cook assembled food items. The on-demand robotic food assembly line can optionally package the assembled and partially cooked food items in packaging, and optionally load the packaged partially cooked food items into portable cooking units (e.g., ovens) that are optionally loaded into racks that are, in turn, optionally loaded into delivery vehicles, where the food items are individually cooked under controlled conditions while en route to consumer destinations, such the cooking of each food item is completed just prior to arrival at the consumer destination location. A dynamic fulfillment queue for control of assembly is maintained based at least in part on estimated transit time for orders.

Owner:ZUME INC

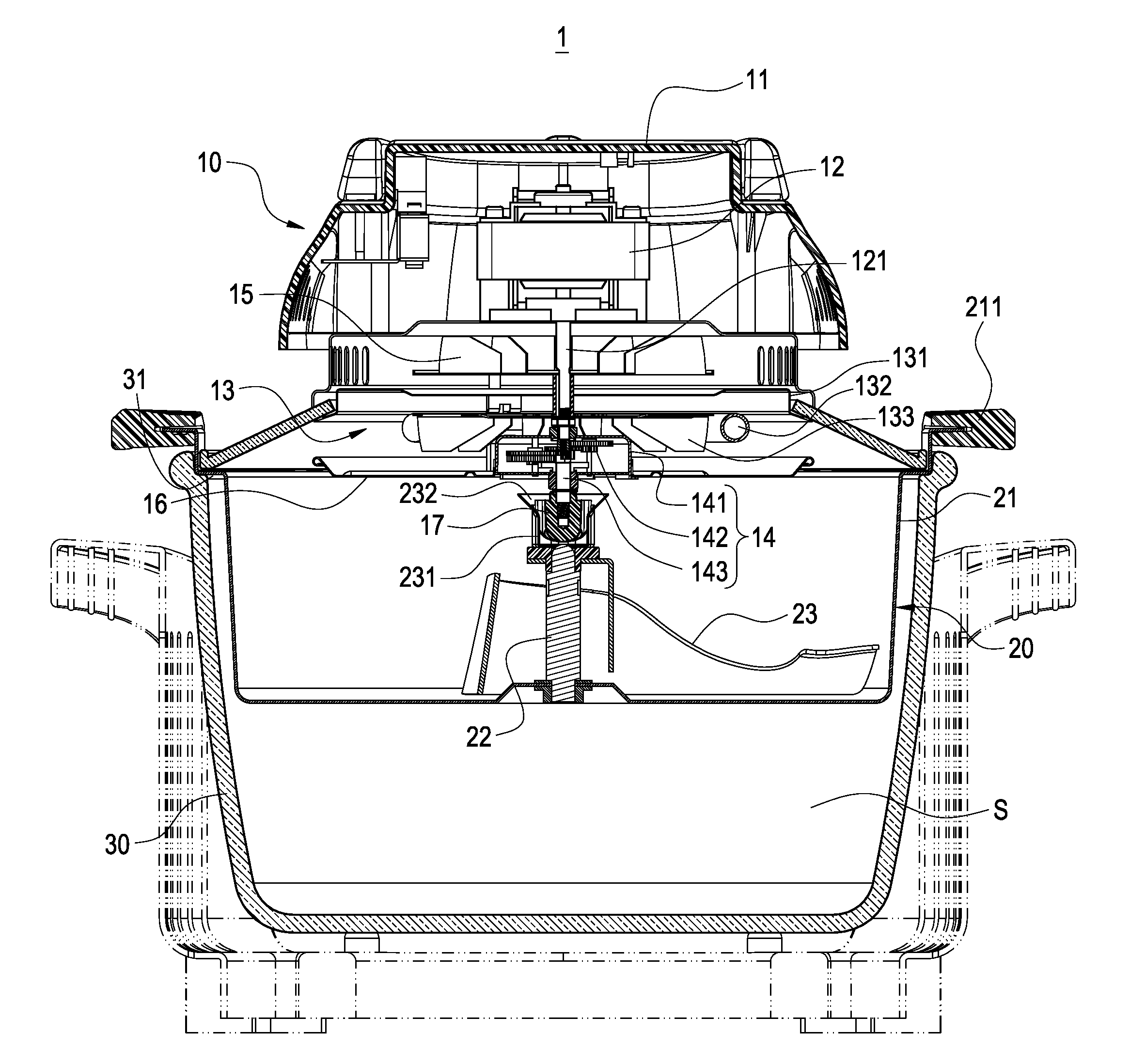

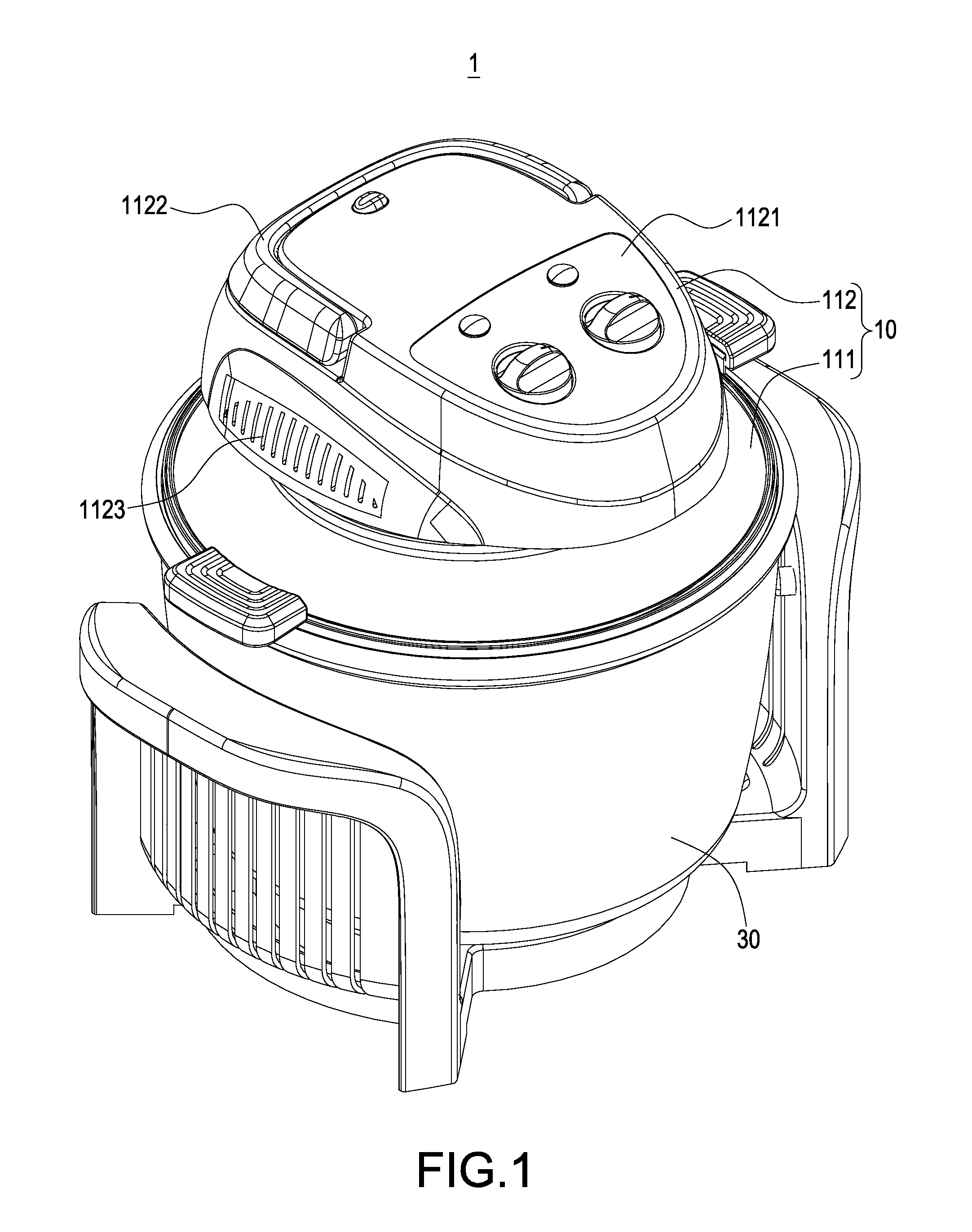

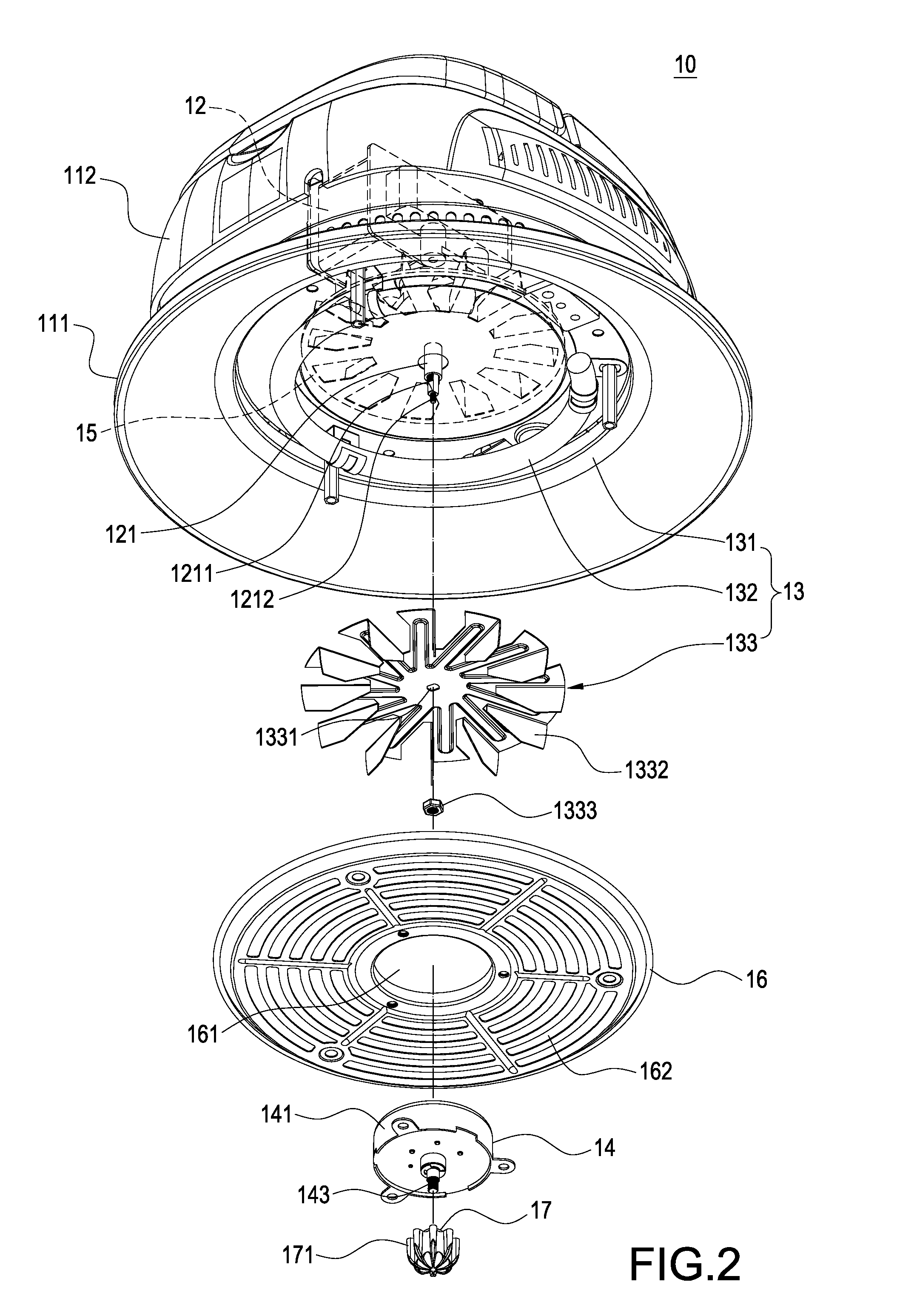

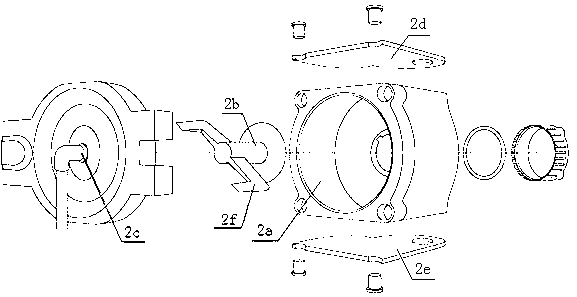

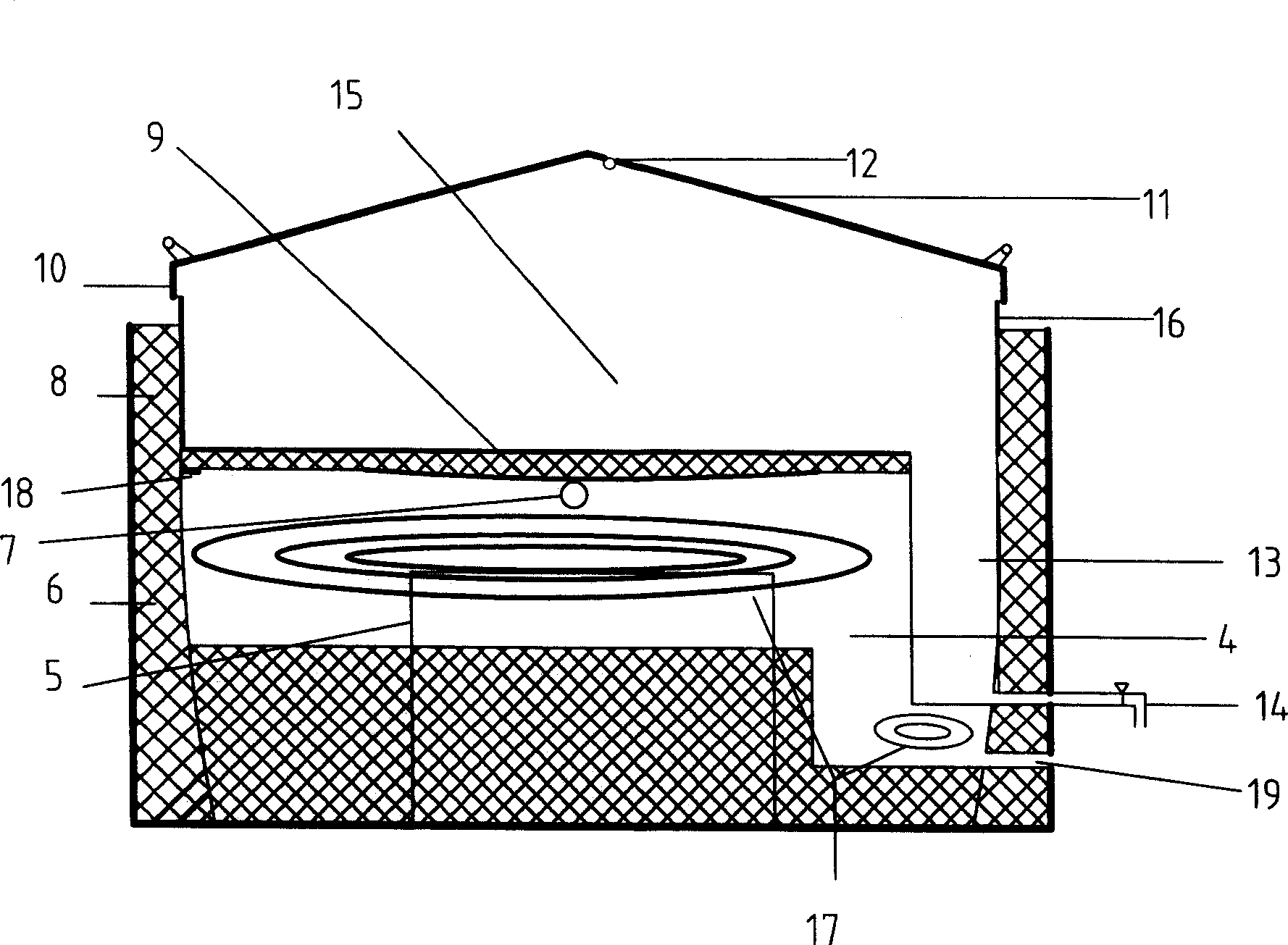

Frying-and-baking oven and heating cover assembly thereof

InactiveUS20110214574A1Improve convenienceImprove functionalityDomestic stoves or rangesDrying solid materials with heatCooking & bakingImpeller

A frying-and-baking oven includes a baking outer pot, a heating cover assembly covering the outer pot, and a frying inner pot disposed between the outer pot and the heat cover assembly. The heating cover assembly includes a cover, an actuator, a hot-air supplying module, and a speed-reducing mechanism. The actuator has a driving shaft. The hot-air supplying module has an air-blowing impeller and a heating element. The driving shaft drives the air-blowing impeller to blow the hot airflow generated by the heating element. The driving shaft also drives a transmission shaft of the speed-reducing mechanism and in turn a stirring member to rotate at a low speed, thereby stirring food materials in the inner pot. With this arrangement, the food materials received in the inner pot can be stirred automatically and cooked sufficiently. Further, the oven can cook the food materials by baking or frying, which increases the functionality and convenience thereof.

Owner:TALL & STOUT INDAL CORP

Stand-alone self-supporting disposable baking containers and methods of manufacture

Owner:REYNOLDS CONSUMER PROD INC

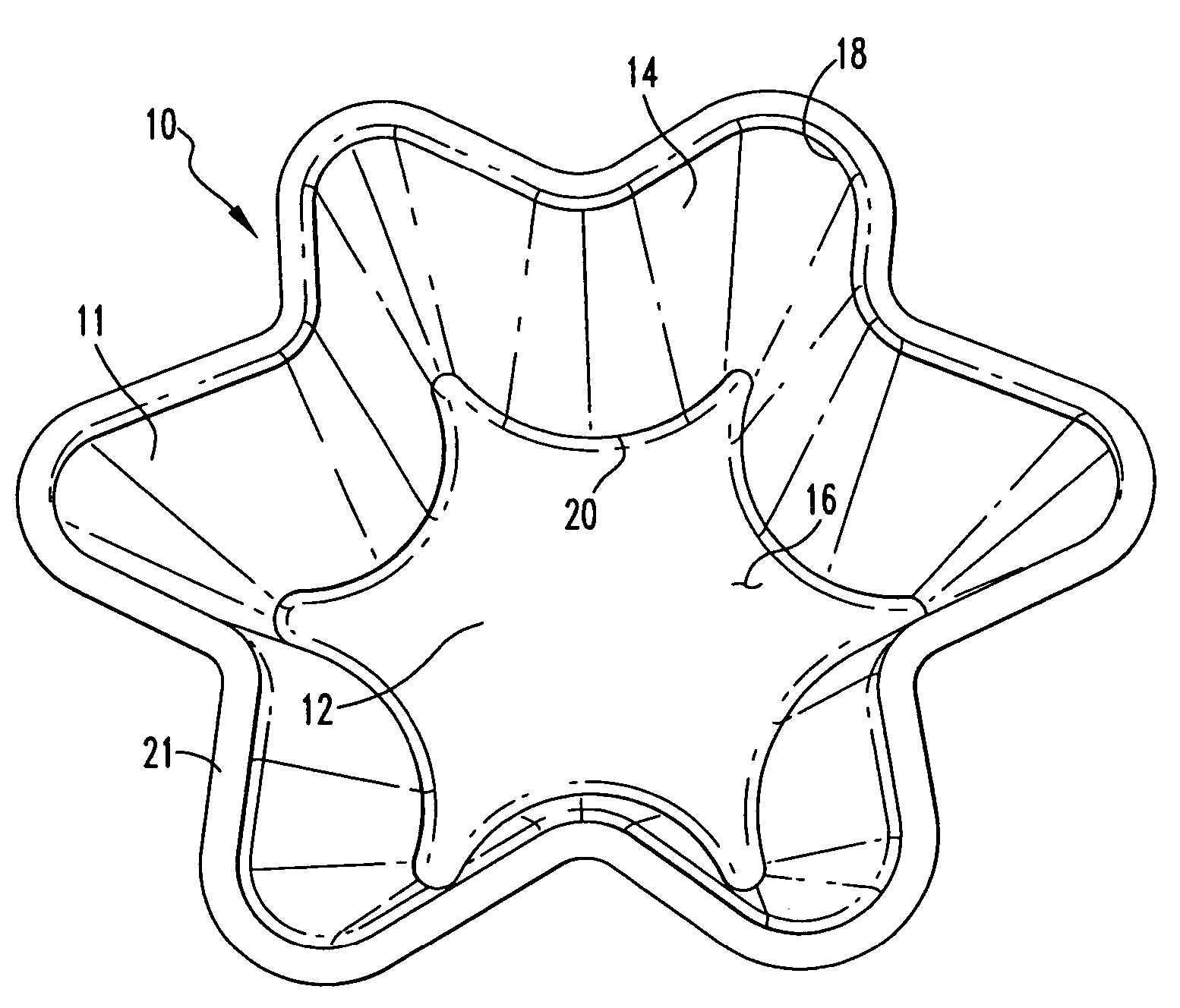

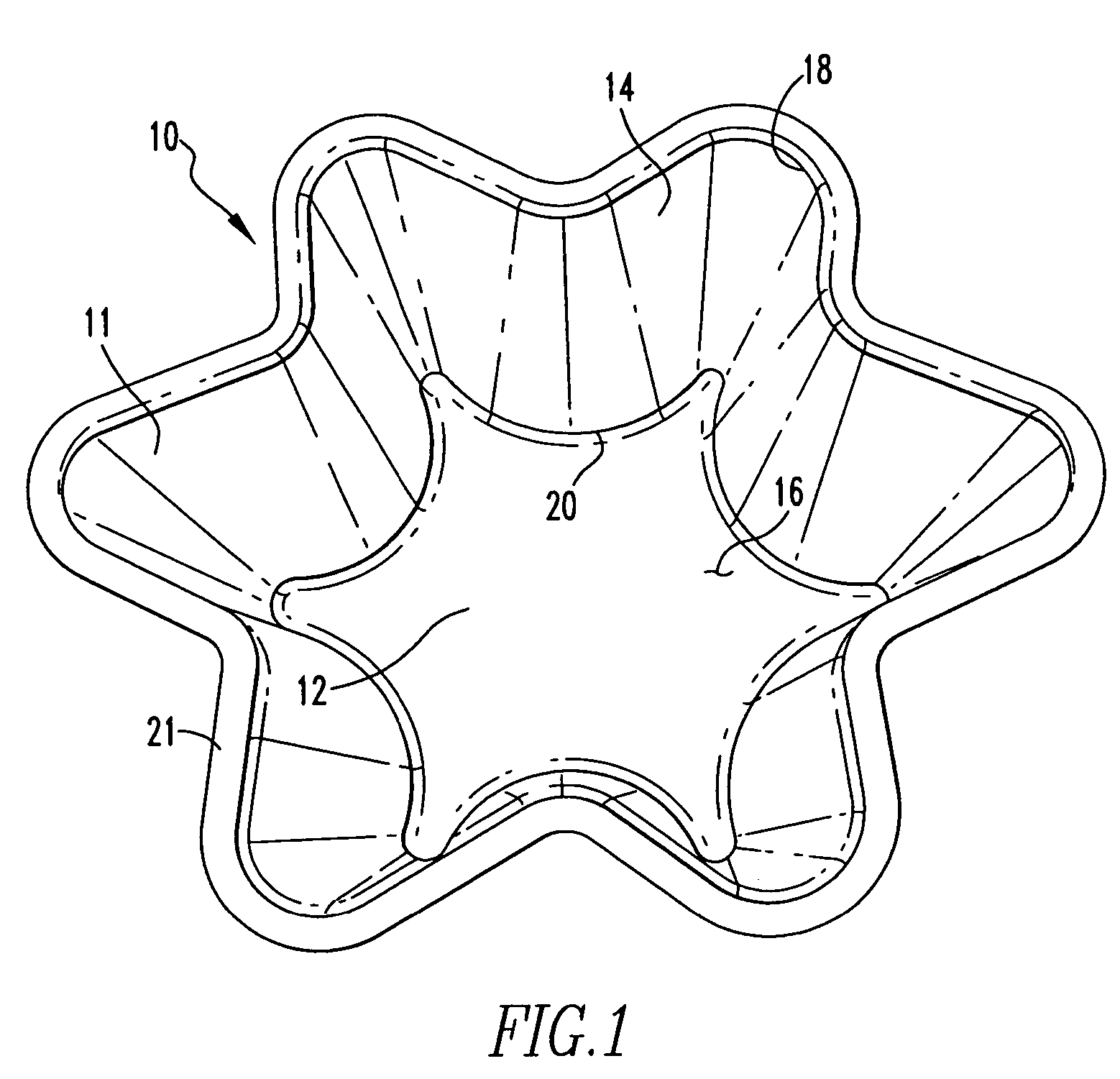

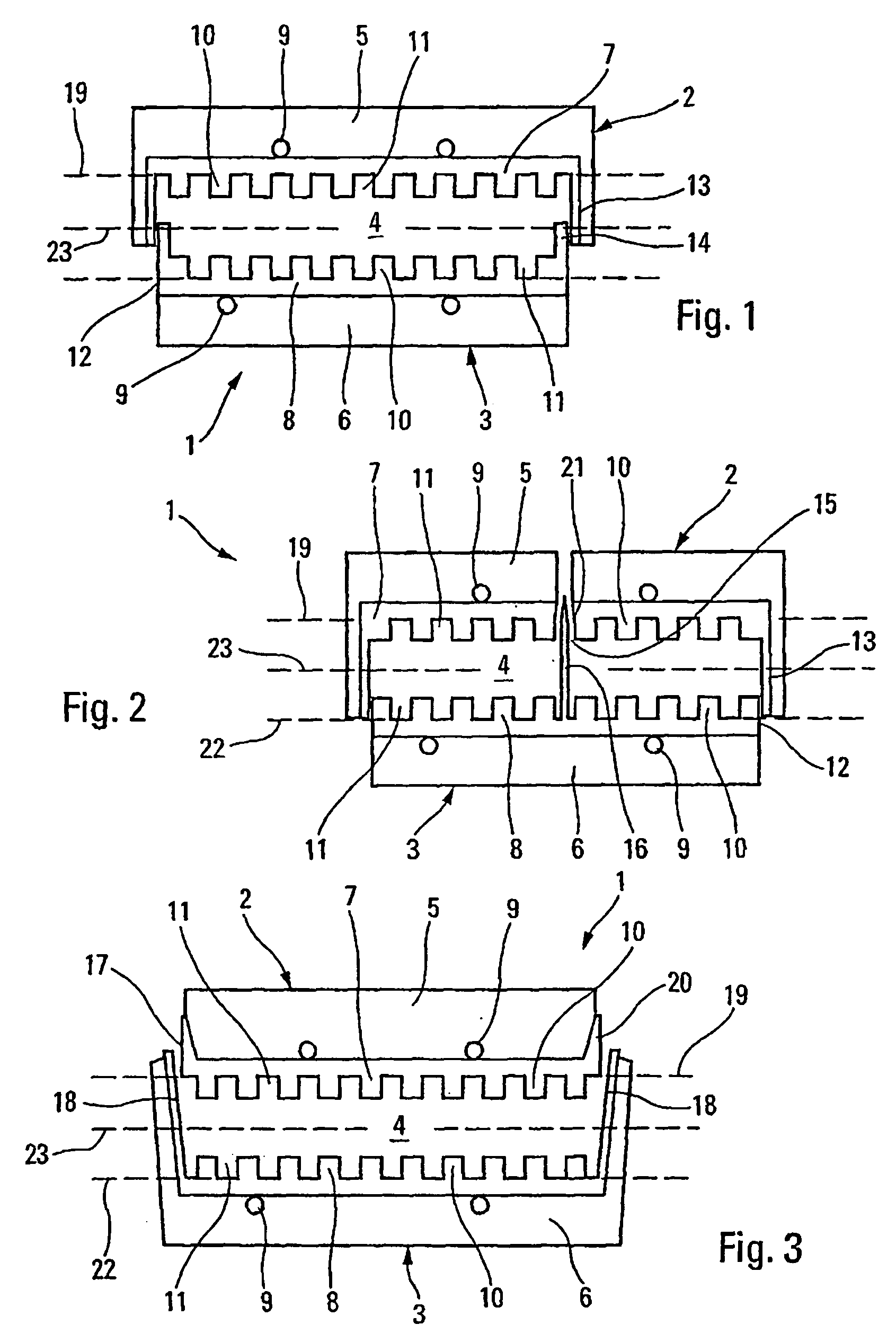

Limited Overflow Waffle Iron

The inventive waffle iron has two baking sub-assemblies pivotable with respect to each other from an open position and a closed proximate position in which they define a baking chamber. At any position of the baking sub-assemblies between the closed proximate position and the closed offset position thereof, wherein they are offset from each other by a product expansion, a peripheral element of a baking sub-assembly slides along a corresponding peripheral element of the other baking sub-assembly in such a way that the variable volume baking chamber is formed.

Owner:SEB SA

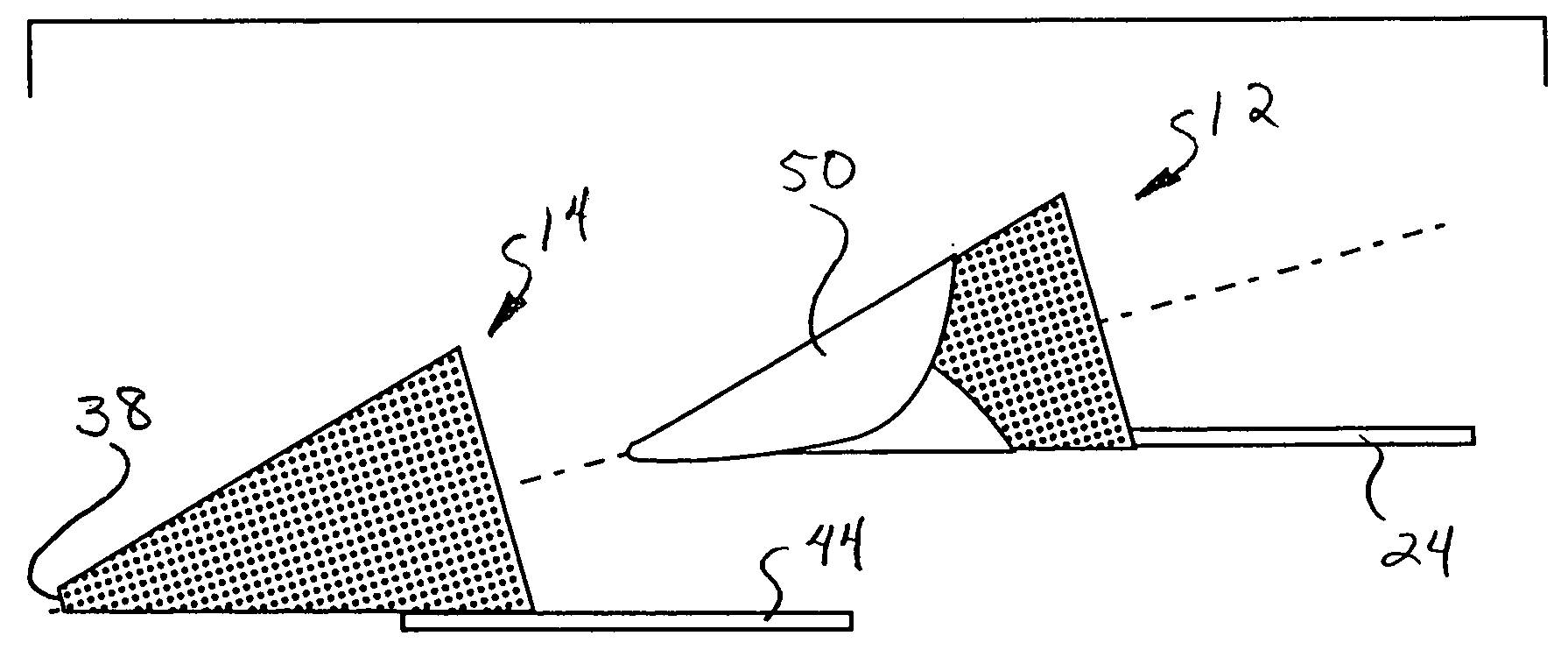

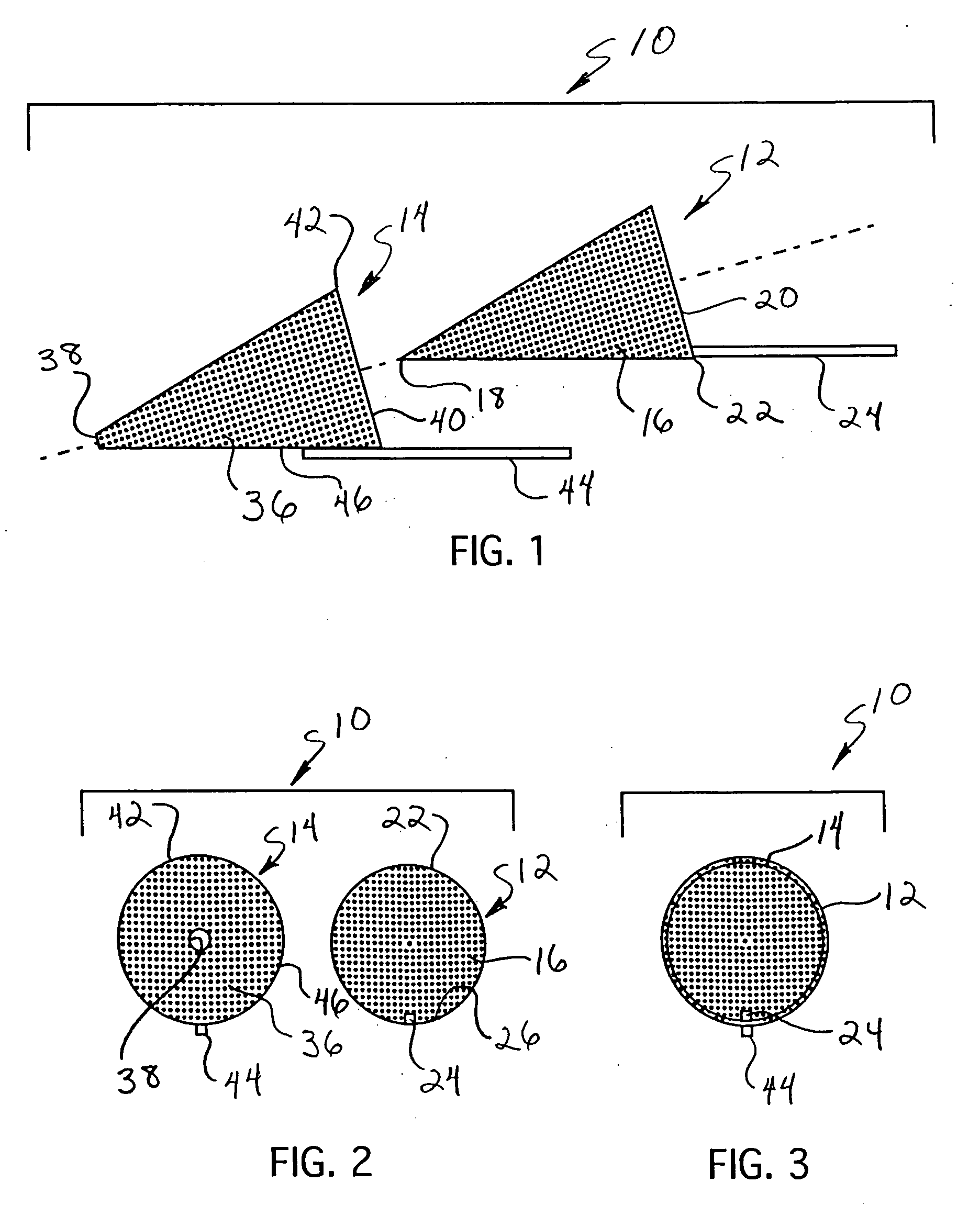

Cone-shaped tortilla molds and method of cooking conical tortilla shells

The apparatus and method for making conical tortilla shells involves a pair of conical molds with a plurality of apertures therethrough. The first mold has a closed apex at one end, and a widened end at the other, and a handle mounted to the inside at the opening of the first mold, and the second mold has a narrow open apex at one end, and a widened end at the other end, with a handle mounted to the exterior at the opening, to allow the handles to be grasped by a user. In the method, a tortilla is wrapped in a conical shape around the first mold and the molds are put together with the tortilla between them, and with the handles placed together to that the molds and tortilla between them may be manipulated as a unit by a user in cooking the tortilla.

Owner:TAMINICH NICKOLAS G

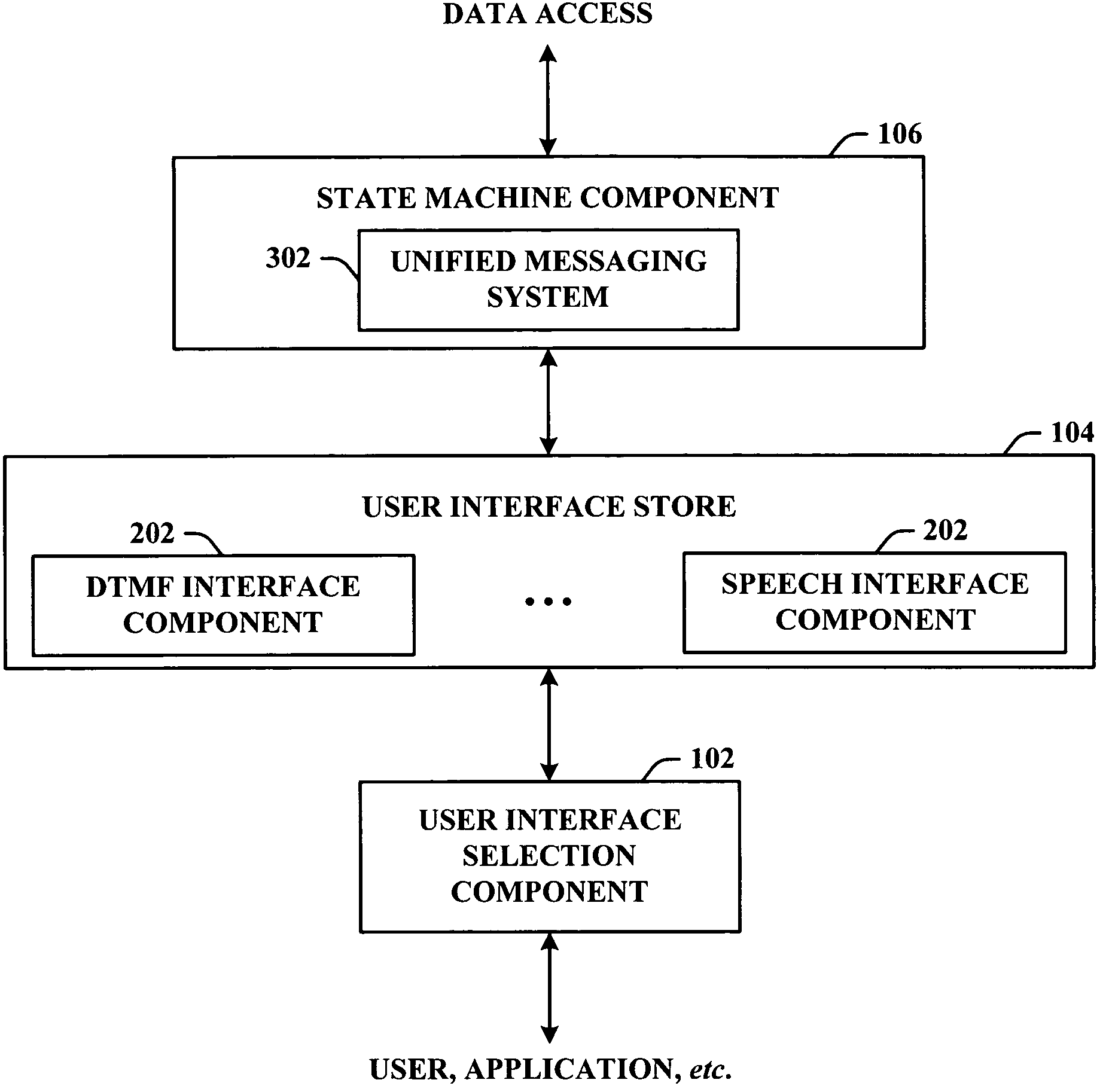

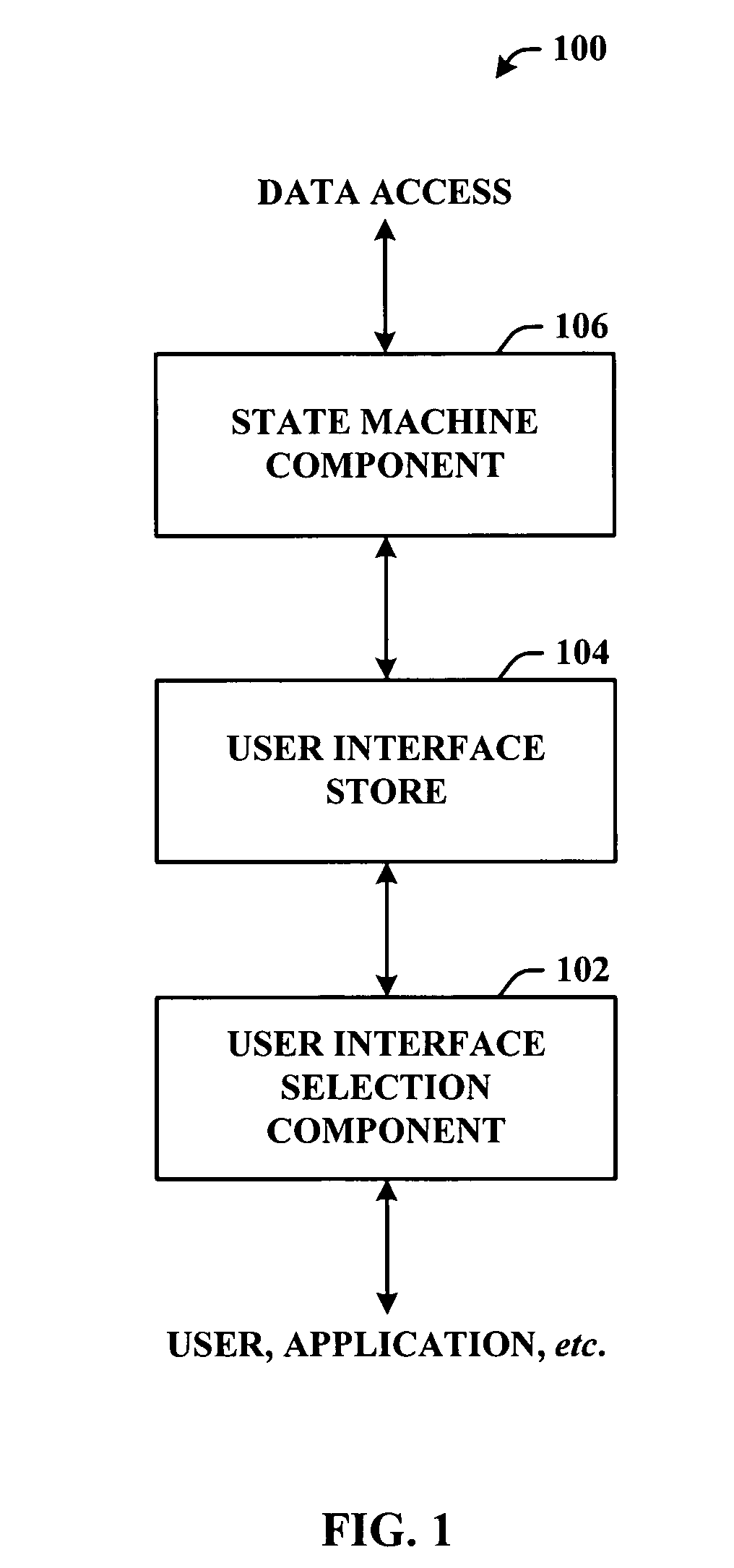

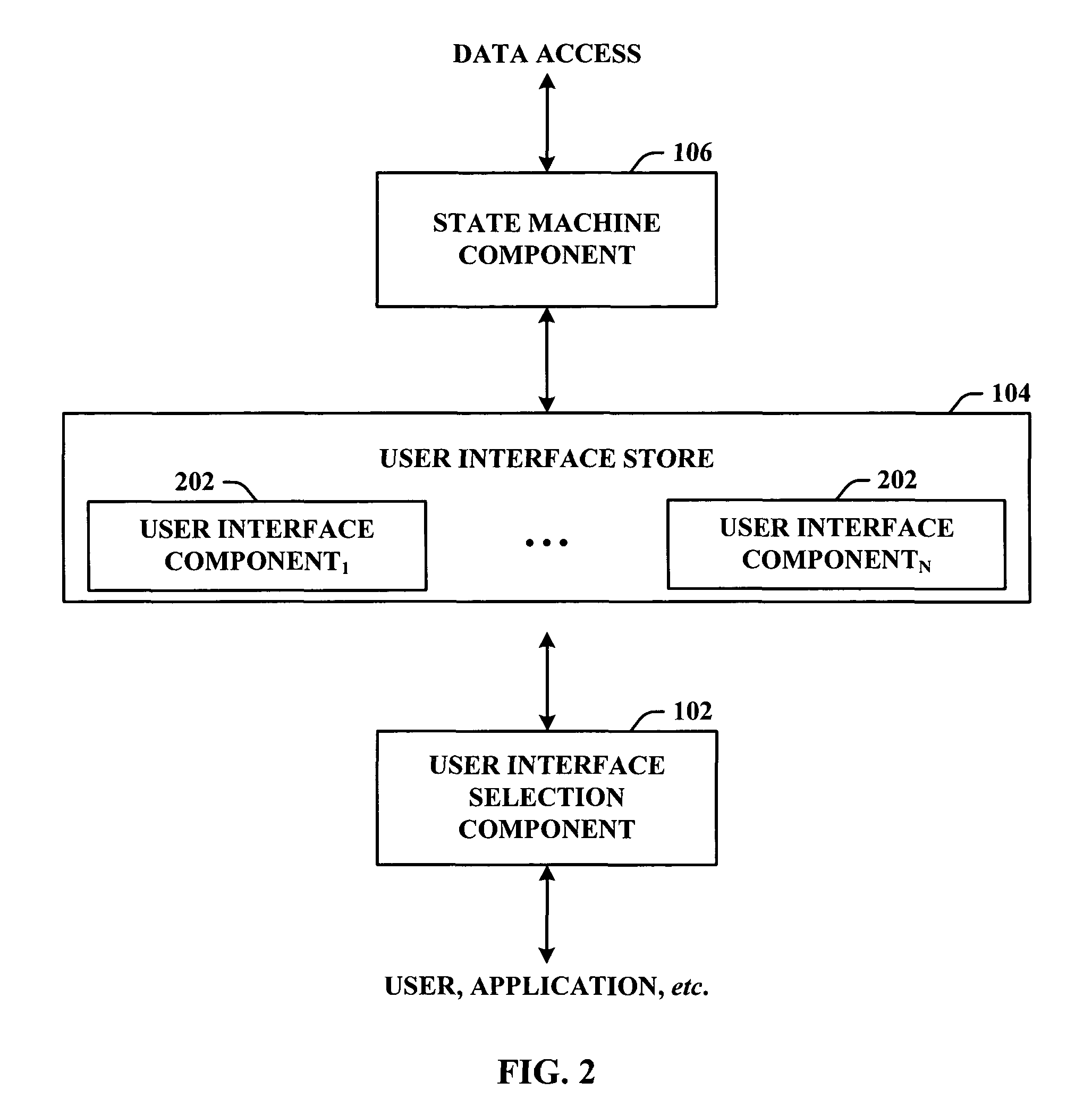

Selectable state machine user interface system

InactiveUS7912186B2Facilitate accepting or canceling calendar itemsAutomatic call-answering/message-recording/conversation-recordingSpecial service for subscribersMultiple user interfaceState switching

A system that concurrently provides multiple user interface (UI) mechanisms that facilitate control of an application state machine (e.g., unified message system). More particularly, the invention can create two relatively distinct user experiences, one via dual tone multi-frequency (DTMF) navigation and another through speech recognition navigation of a unified message system. In accordance therewith, one single underlying state machine can be used. Navigation and flow control (e.g., state transitions) in the state machine can be leveraged by multiple UI mechanisms that actively co-exist. The invention introduces speech recognition features together with other input mechanisms to drive the UI of an application state machine (e.g., unified messaging system). The speech recognition UI can be designed to provide a natural navigation through the application independent of a DTMF UI.

Owner:MICROSOFT TECH LICENSING LLC

Edible bread cup and method of production

Owner:BELOFF ARTHUR L

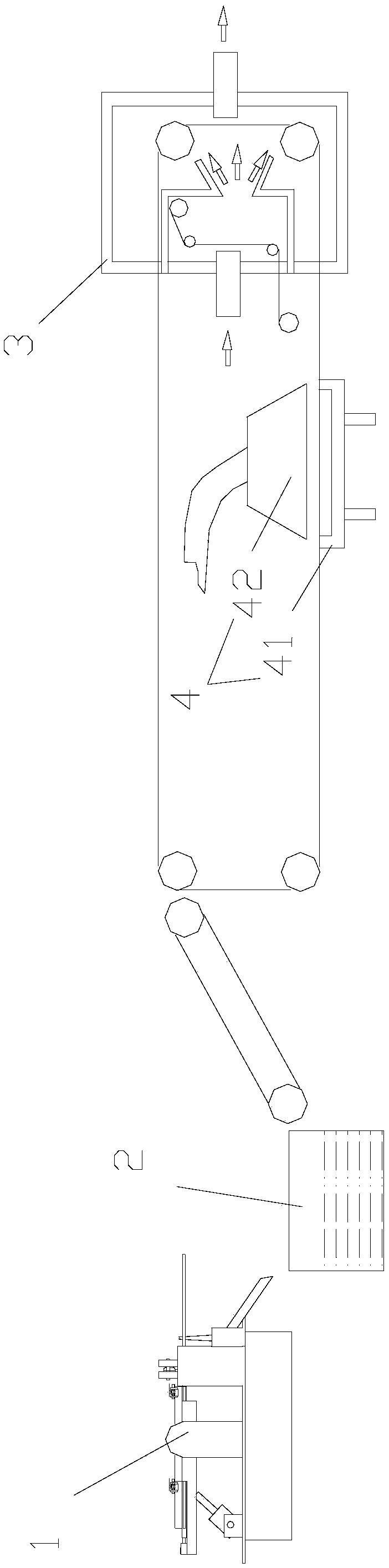

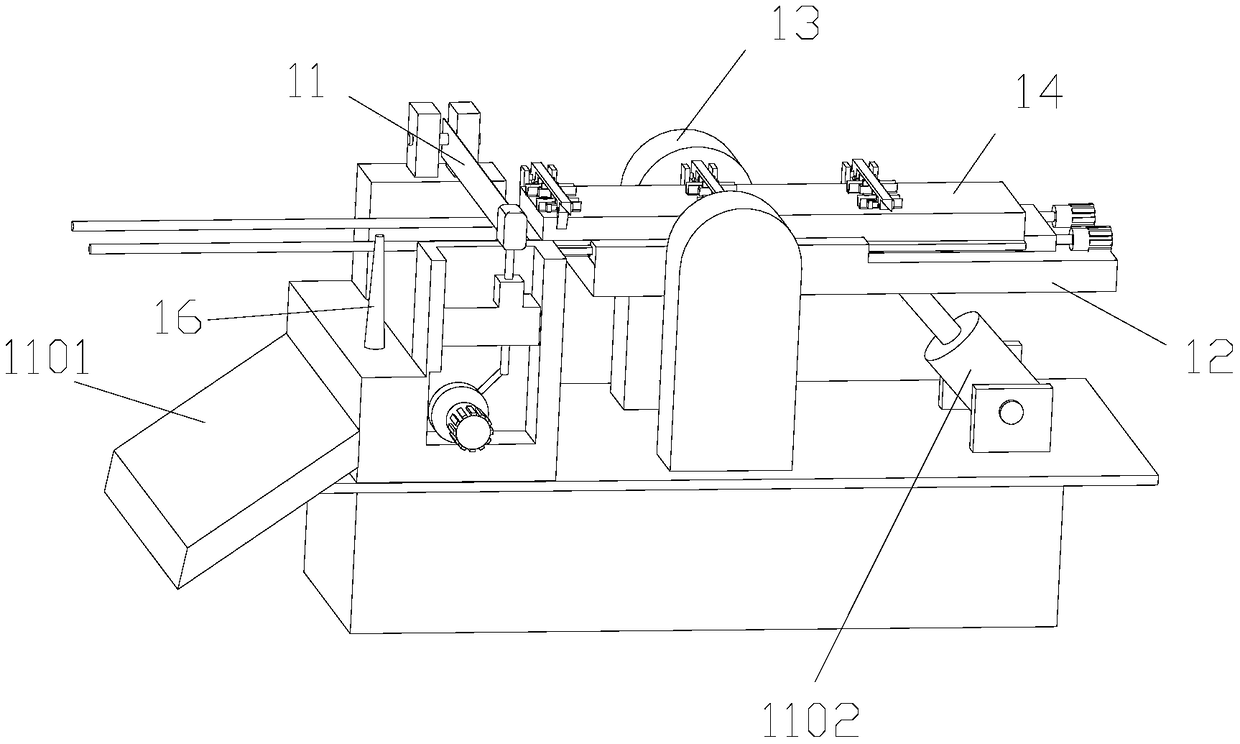

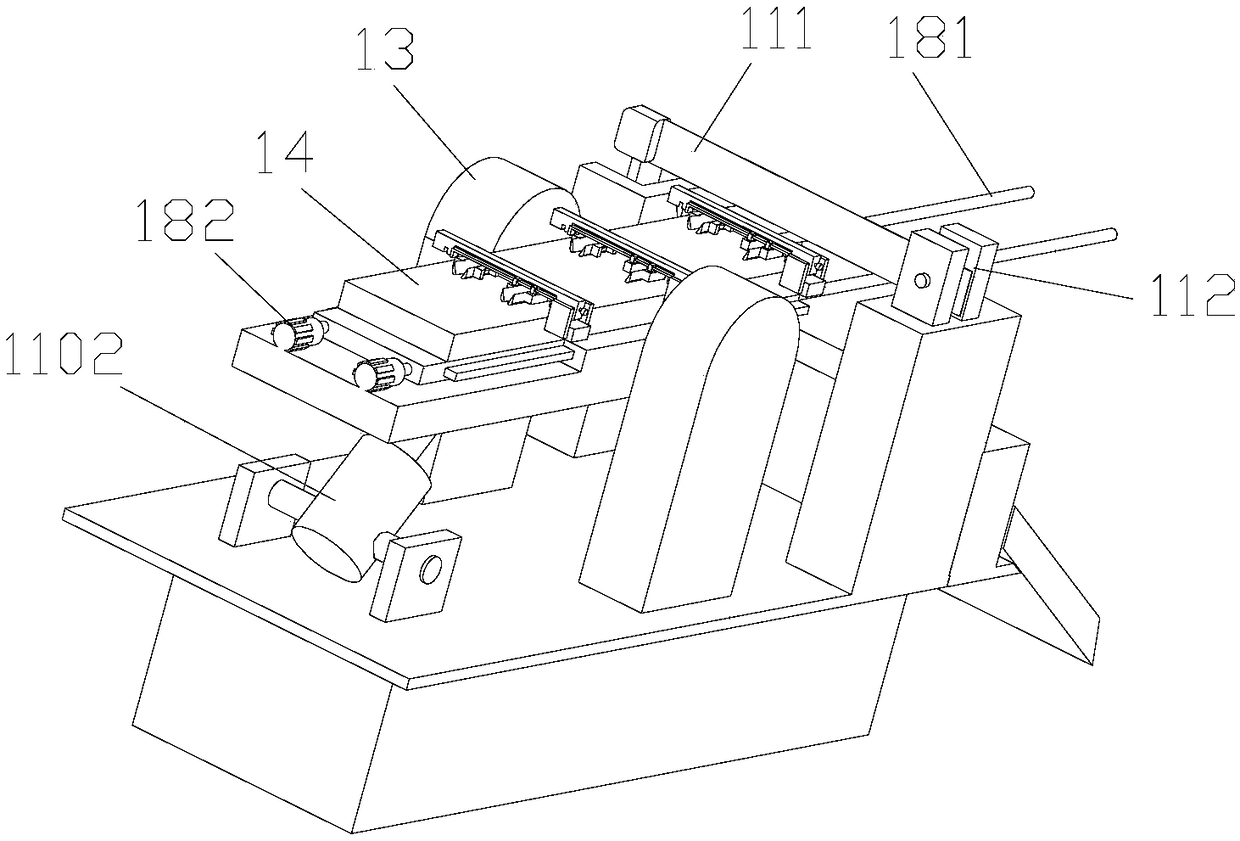

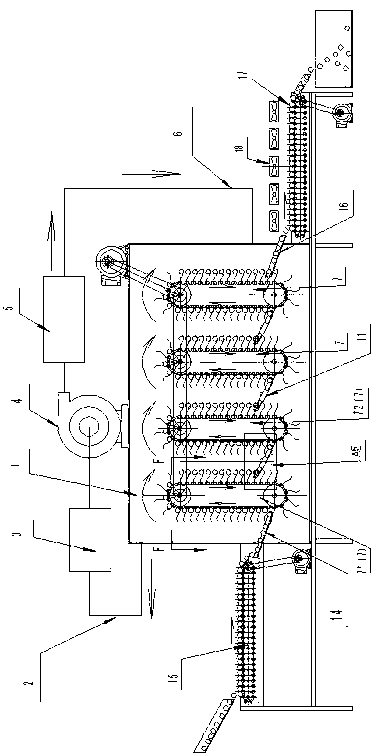

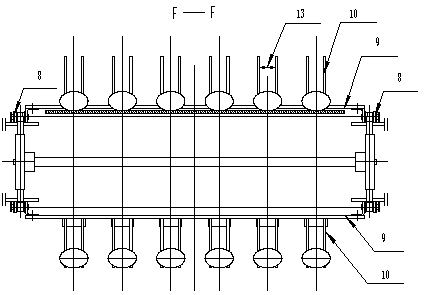

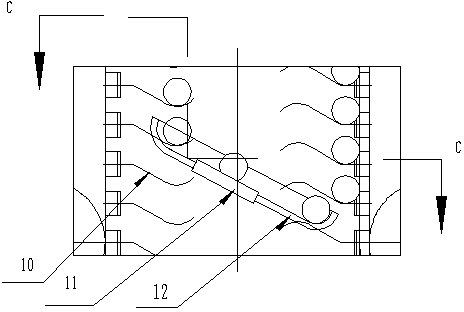

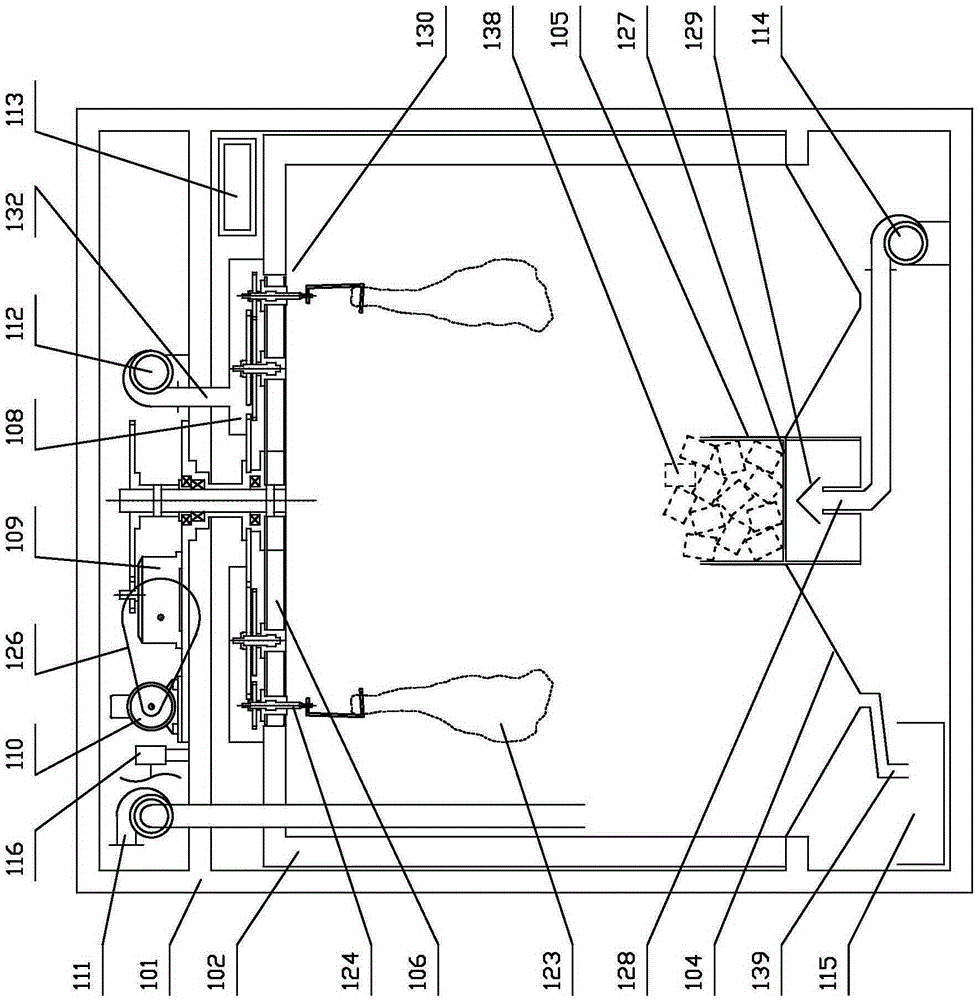

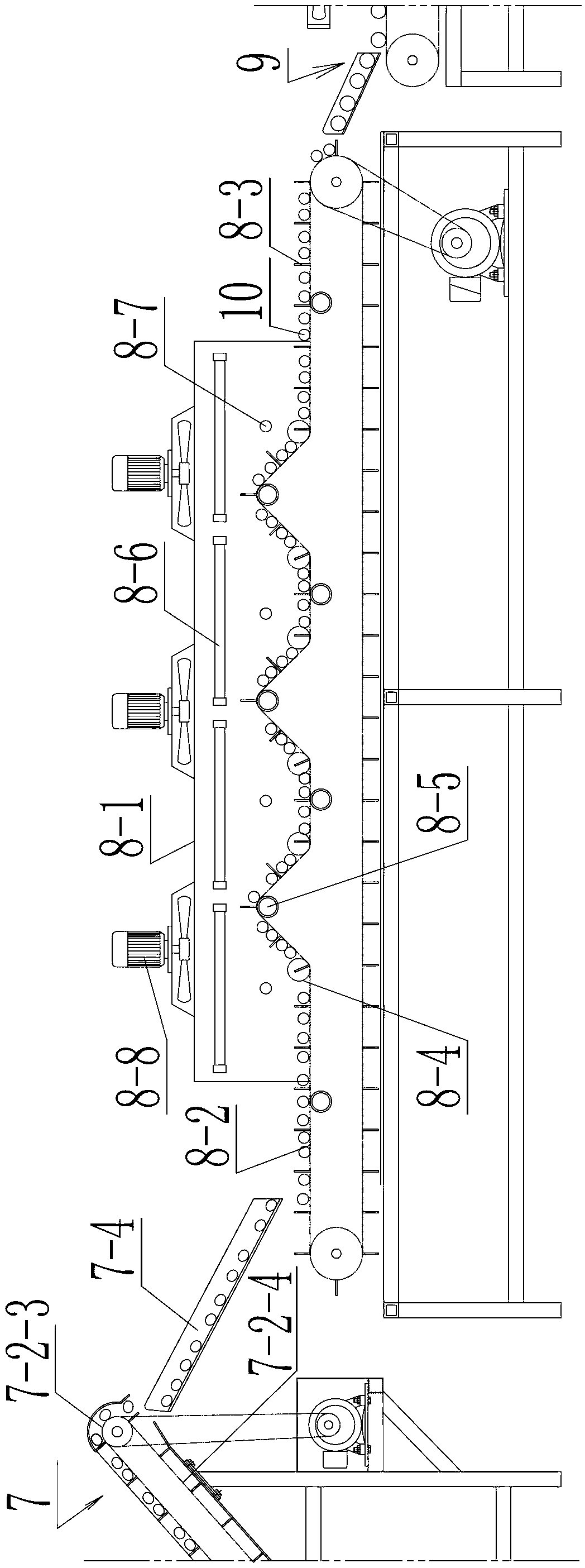

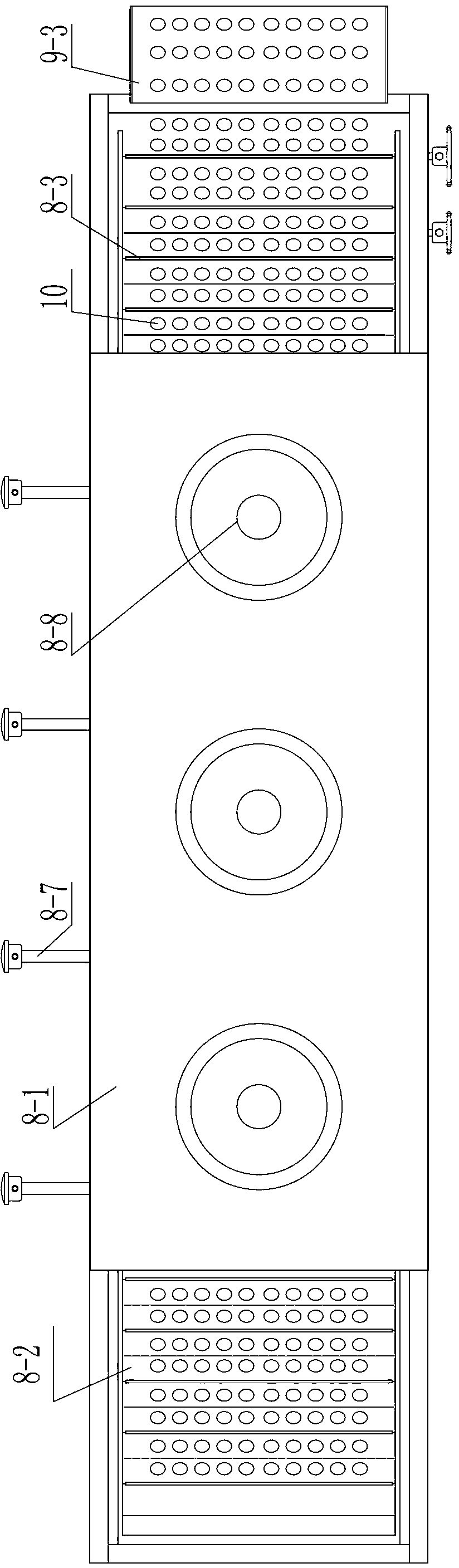

Method and device for making pizza

InactiveCN103300079AThe size is easy to controlSales realizedConveyor partsSpecial goods bakingCooking & bakingAdditive ingredient

The invention relates to a method and device for making tortillas and other like products. The method comprises the following steps: A, flour metering: a flour metering device quantitatively distributes flour; B, dough making: quantitative flour and purified water are mixed and stirred into dough in a stirring device; C, rough blank forming: the dough is put on a pressurizing chassis, and a first pressurizing device pressurizes the dough into rough blanks; D, tortilla blank forming: a second pressurizing device pressurizes the rough blanks into tortilla blanks; E, auxiliary material adding: an auxiliary material spreading device spreads a fluid auxiliary material to the tortilla blanks; F, ingredient adding: an ingredient laying device lays solid ingredients to the tortilla blanks; G, pizza baking: the tortilla blanks added with the auxiliary material and the ingredients are put in an oven to be baked; H, pizza packaging: the baked pizza is put in a pizza box; after the tortilla blanks are formed, the tortilla blanks are transmitted through the cooperative movement of a guide rail and a conveying hand plate. The method and the device have the advantages of high production efficiency and strong practicality.

Owner:SHANGHAI JINHE IND DEV CO LTD

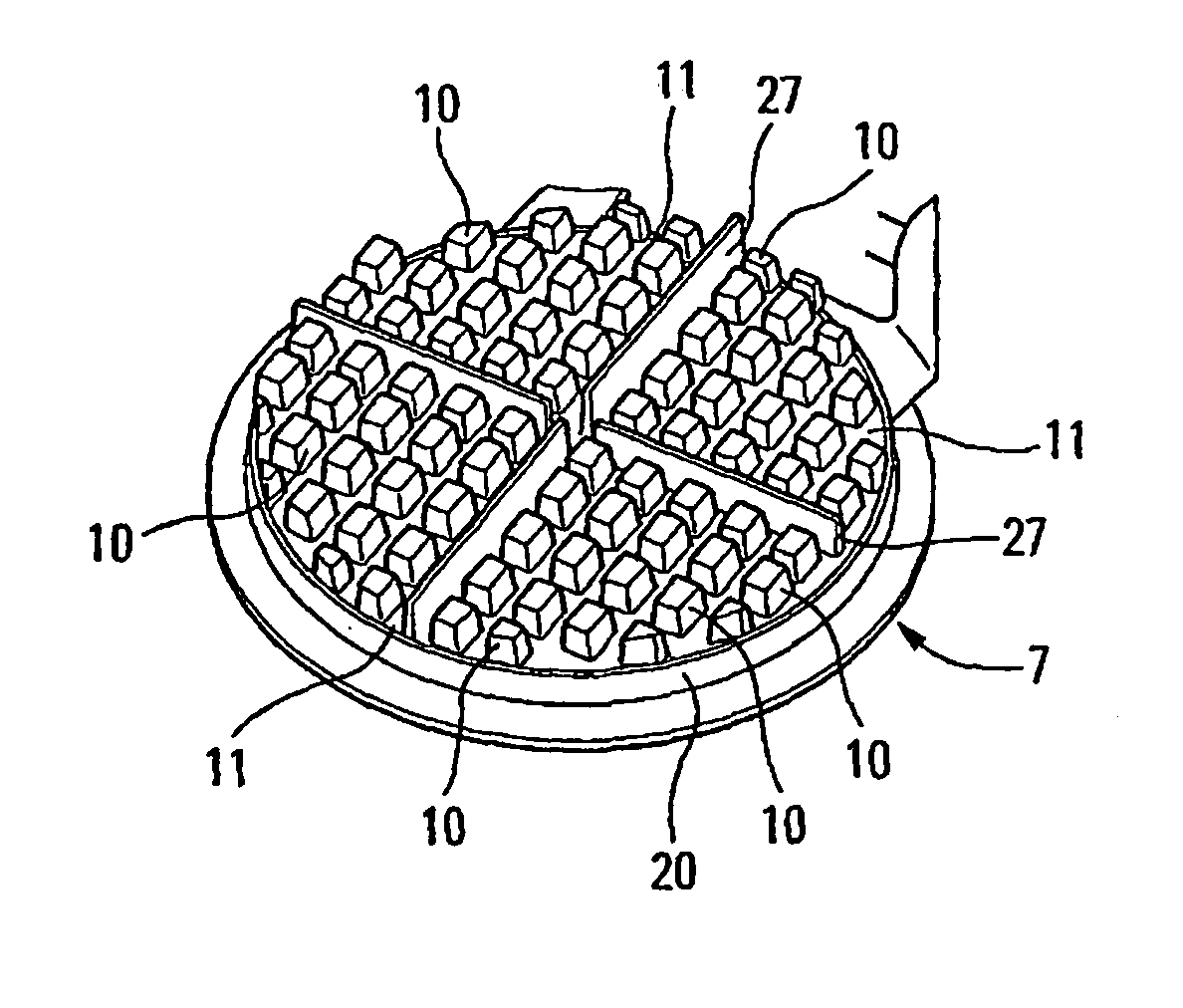

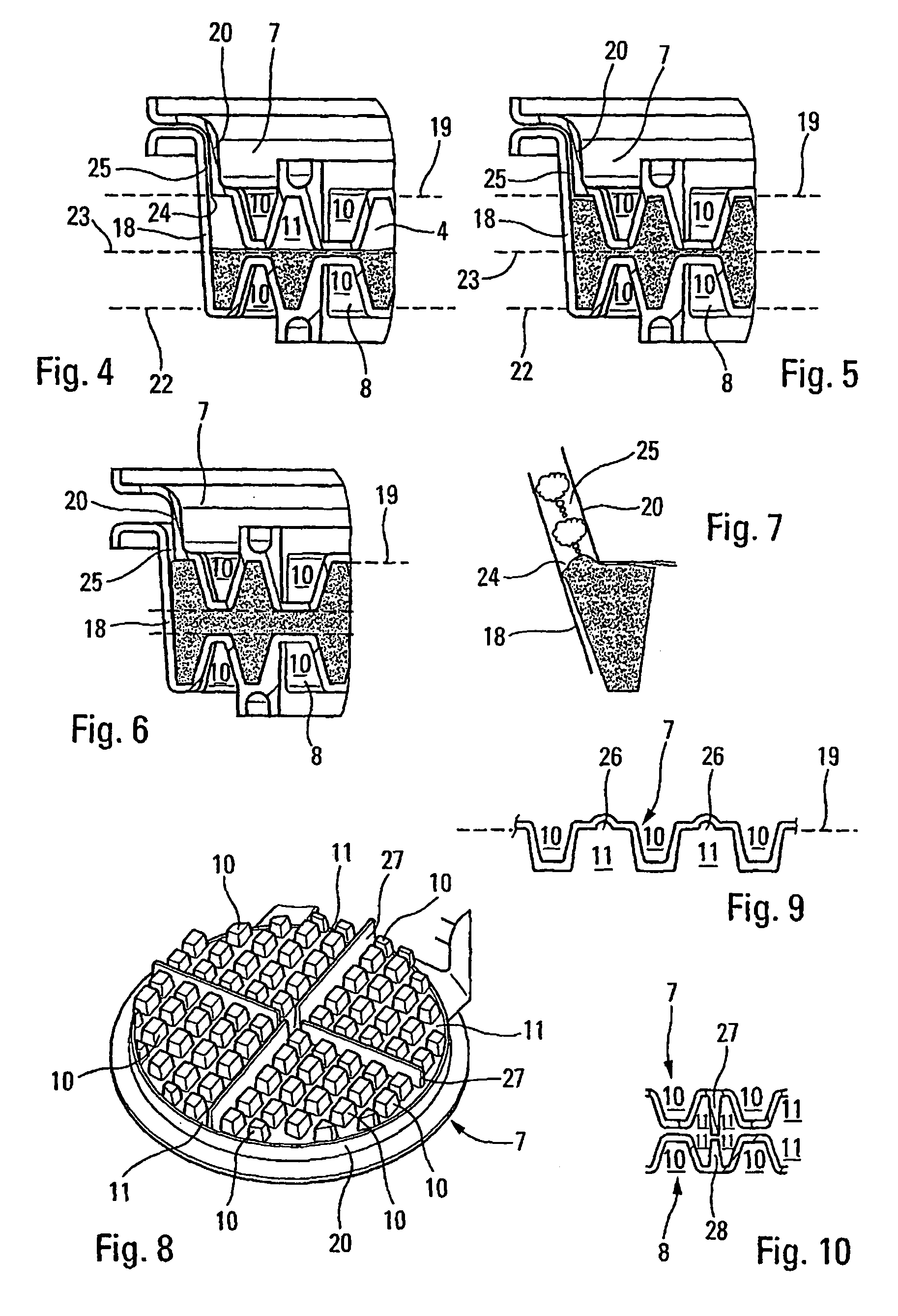

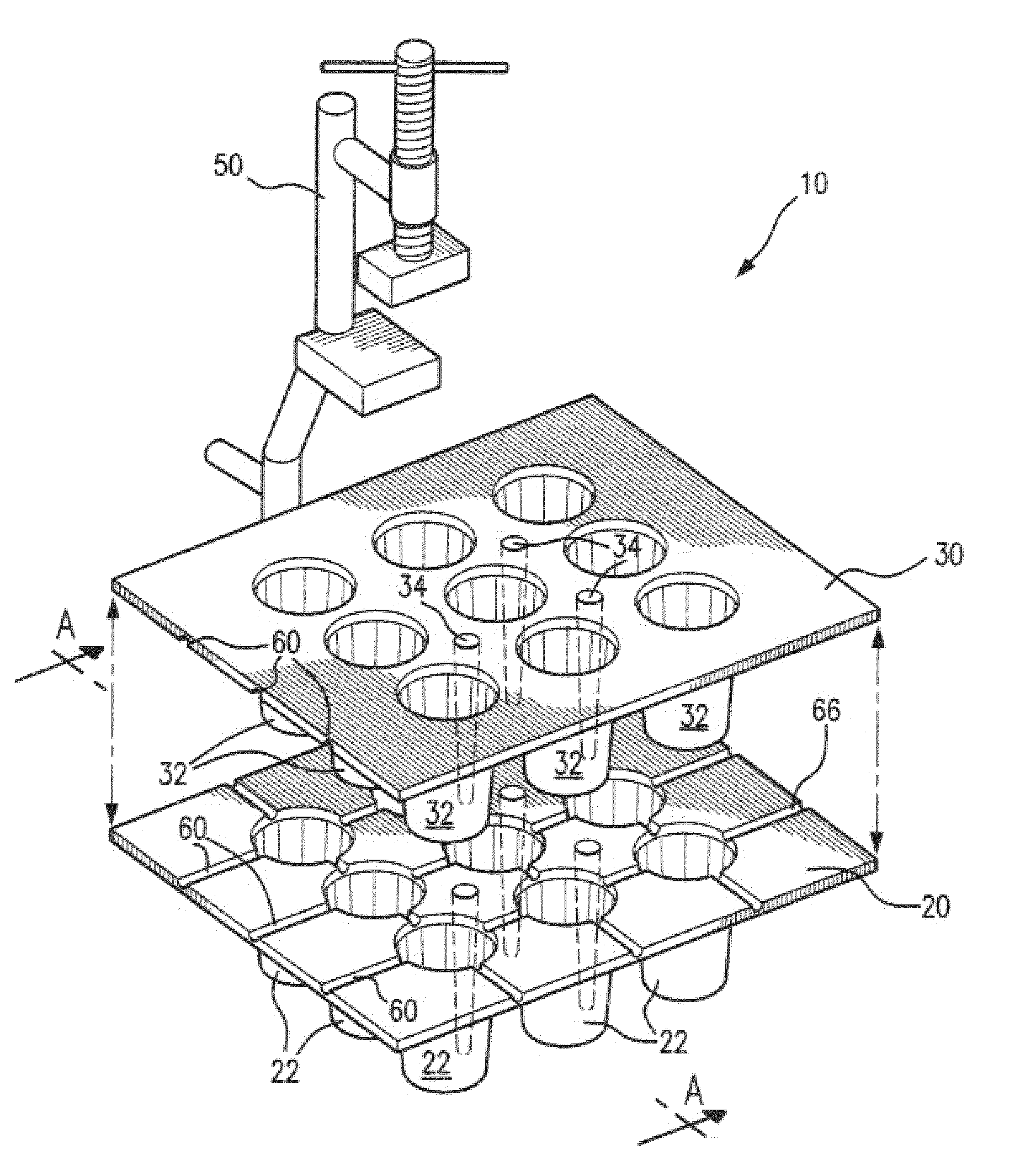

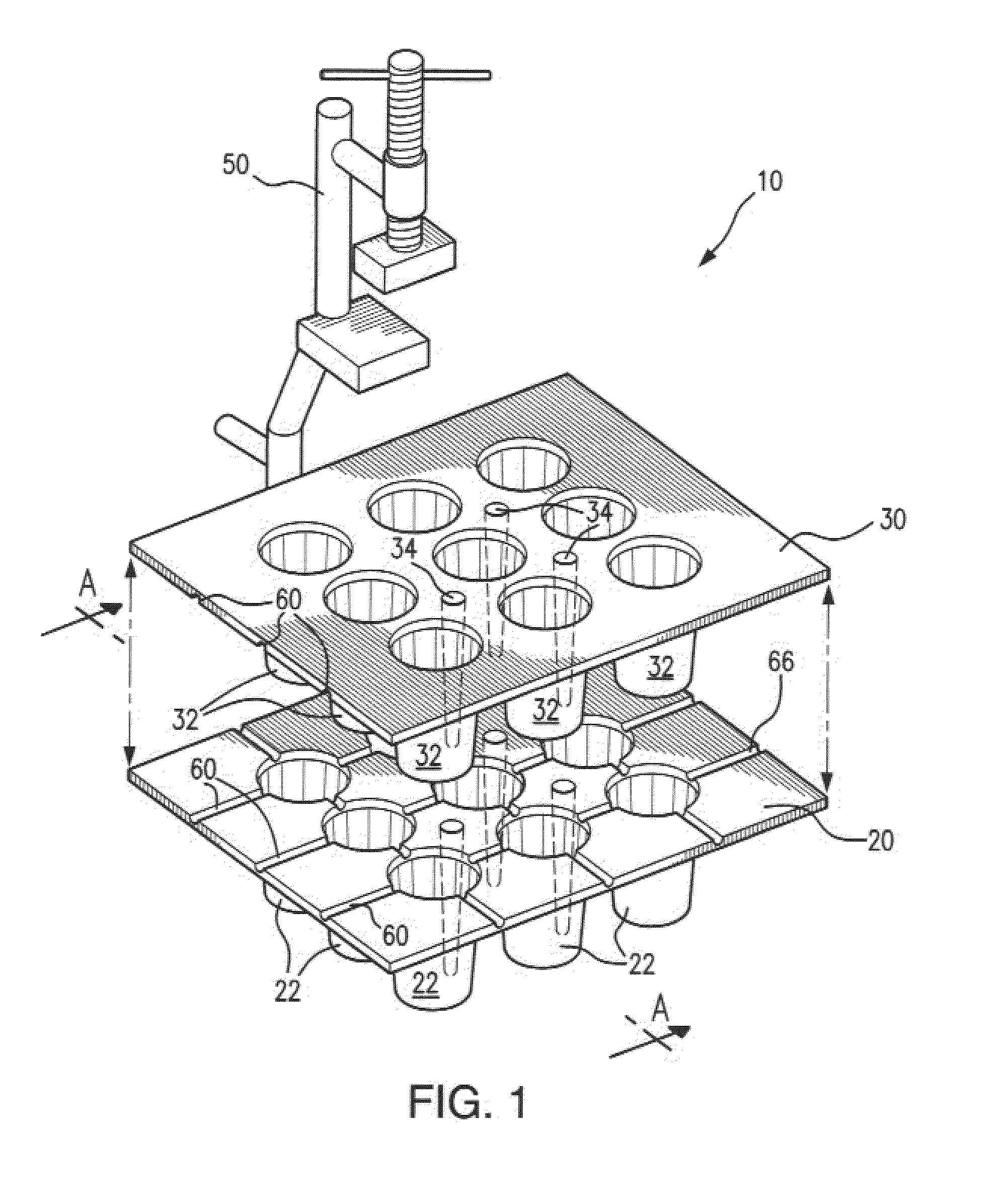

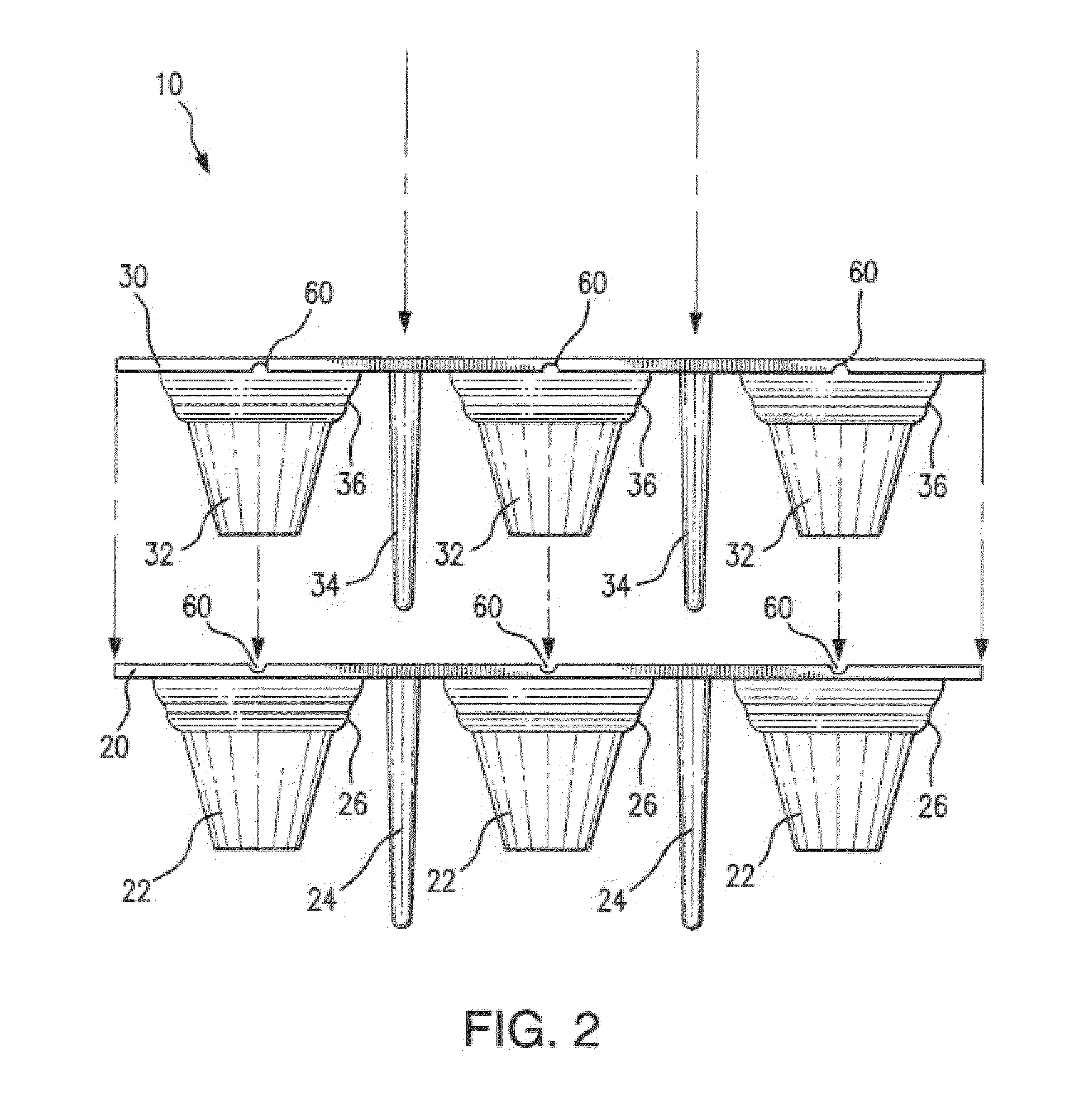

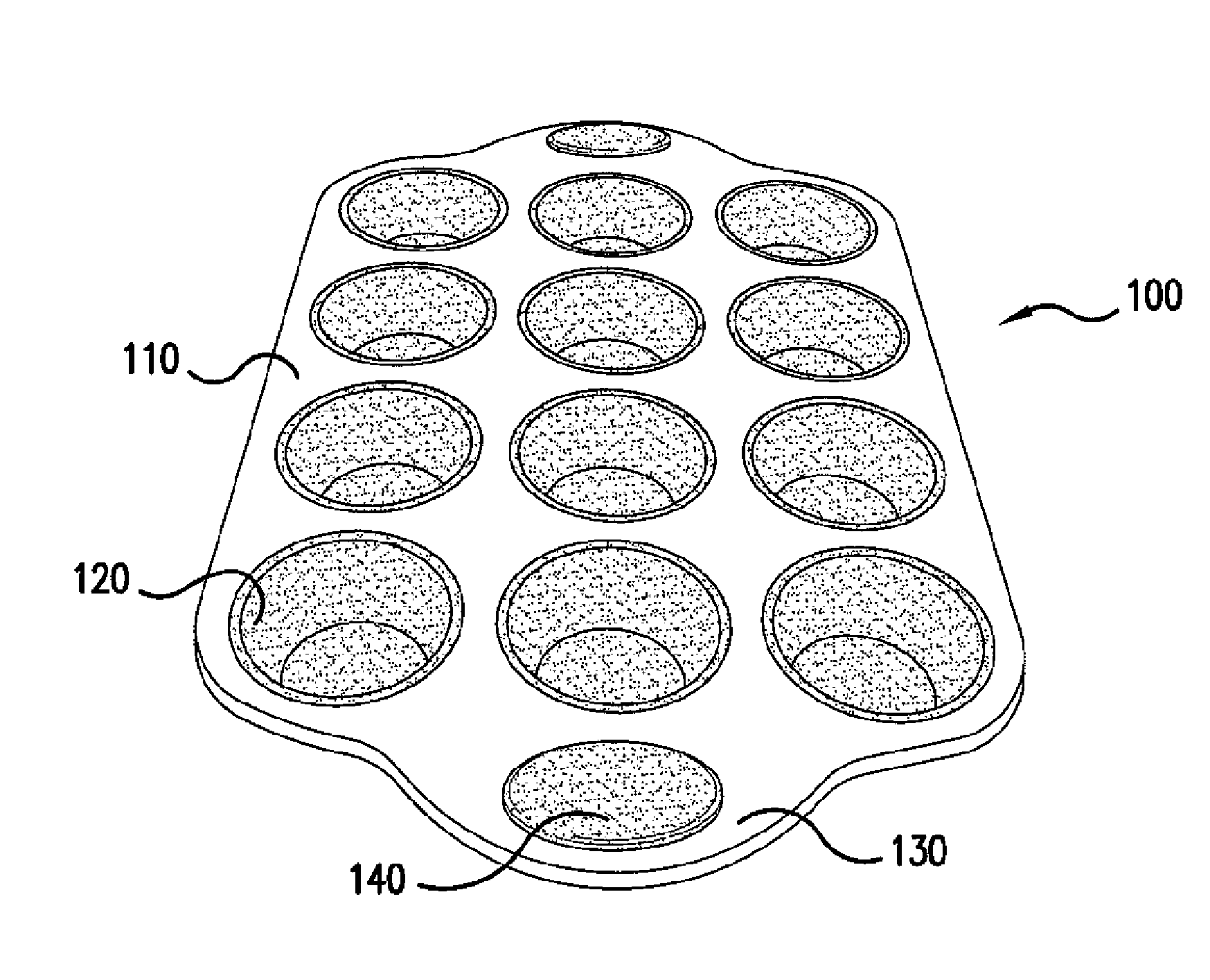

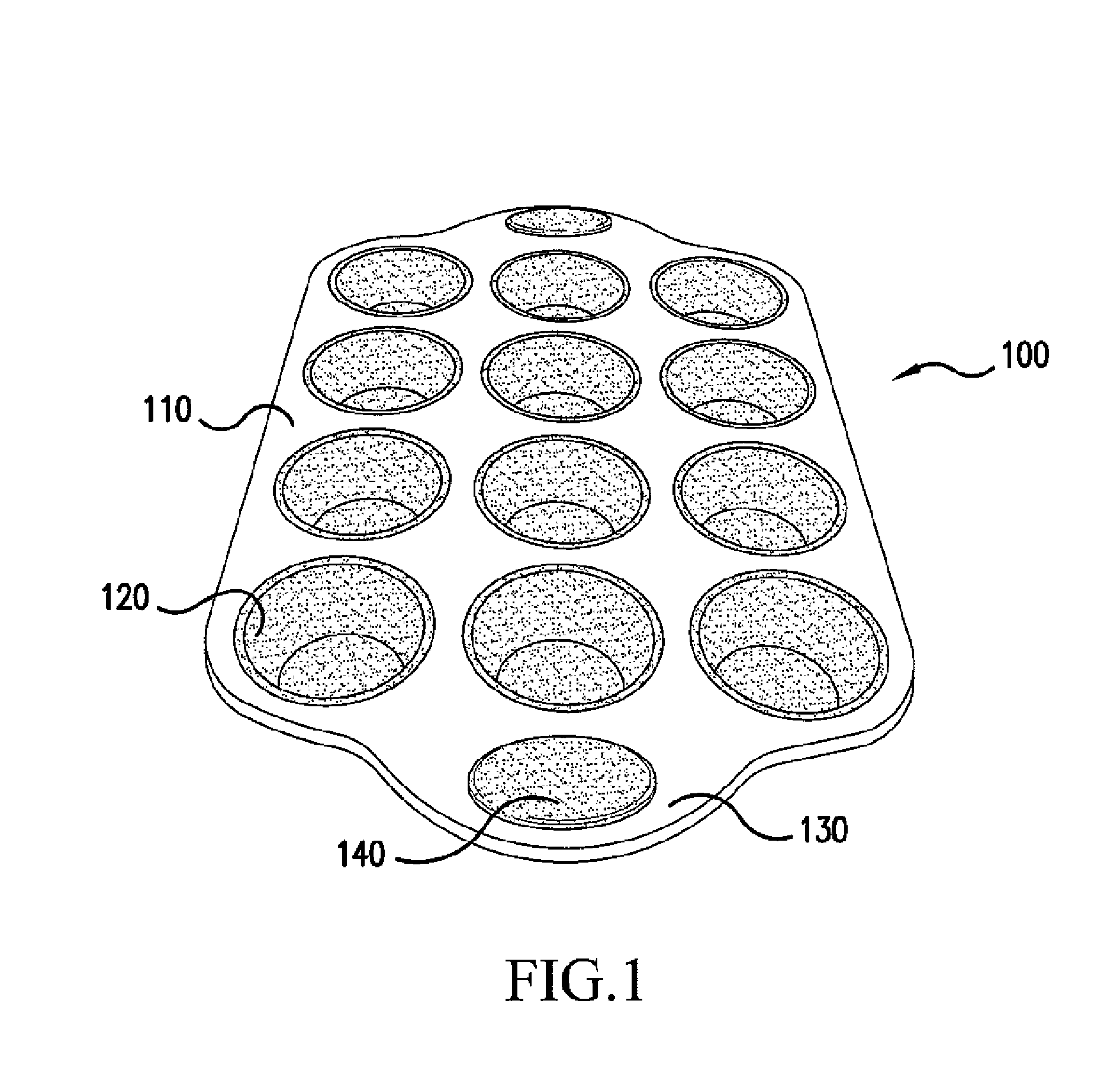

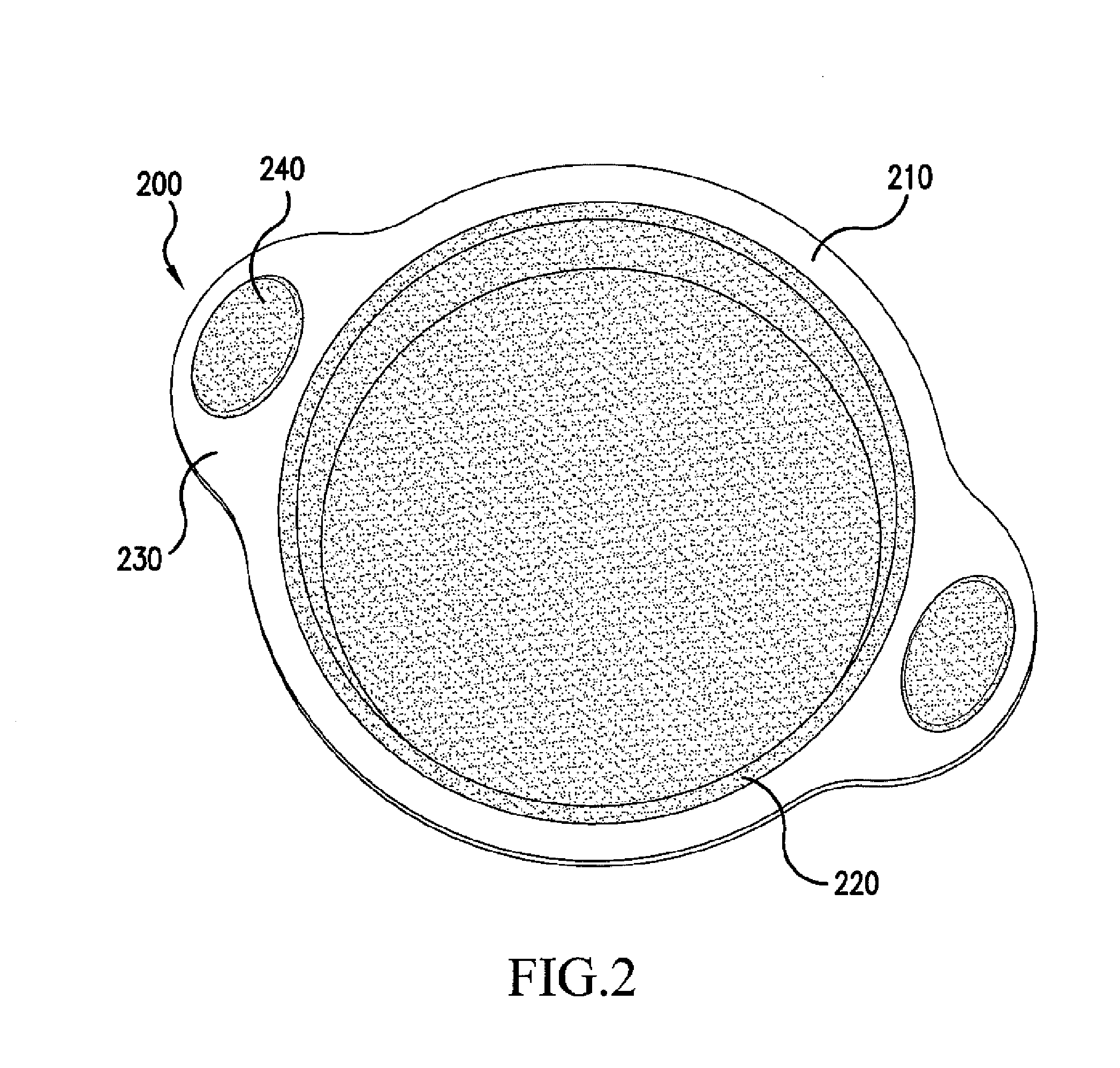

Bakeware having a flexible member and method of manufacturing same

A method for assembling a bakeware having a metal frame and at least one flexible member is provided. The method includes forming a first hole in a metal sheet, forming a sidewall extending from the first hole, the sidewall having a lower lip, bending the sidewall and lower lip partially towards the metal sheet, placing a flexible member in the first hole, and pressing the sidewall and lower lip towards the metal sheet to secure the flexible member to the metal sheet. A bakeware including a metal frame and at least one flexible member is also provided.

Owner:BRADSHAW INT

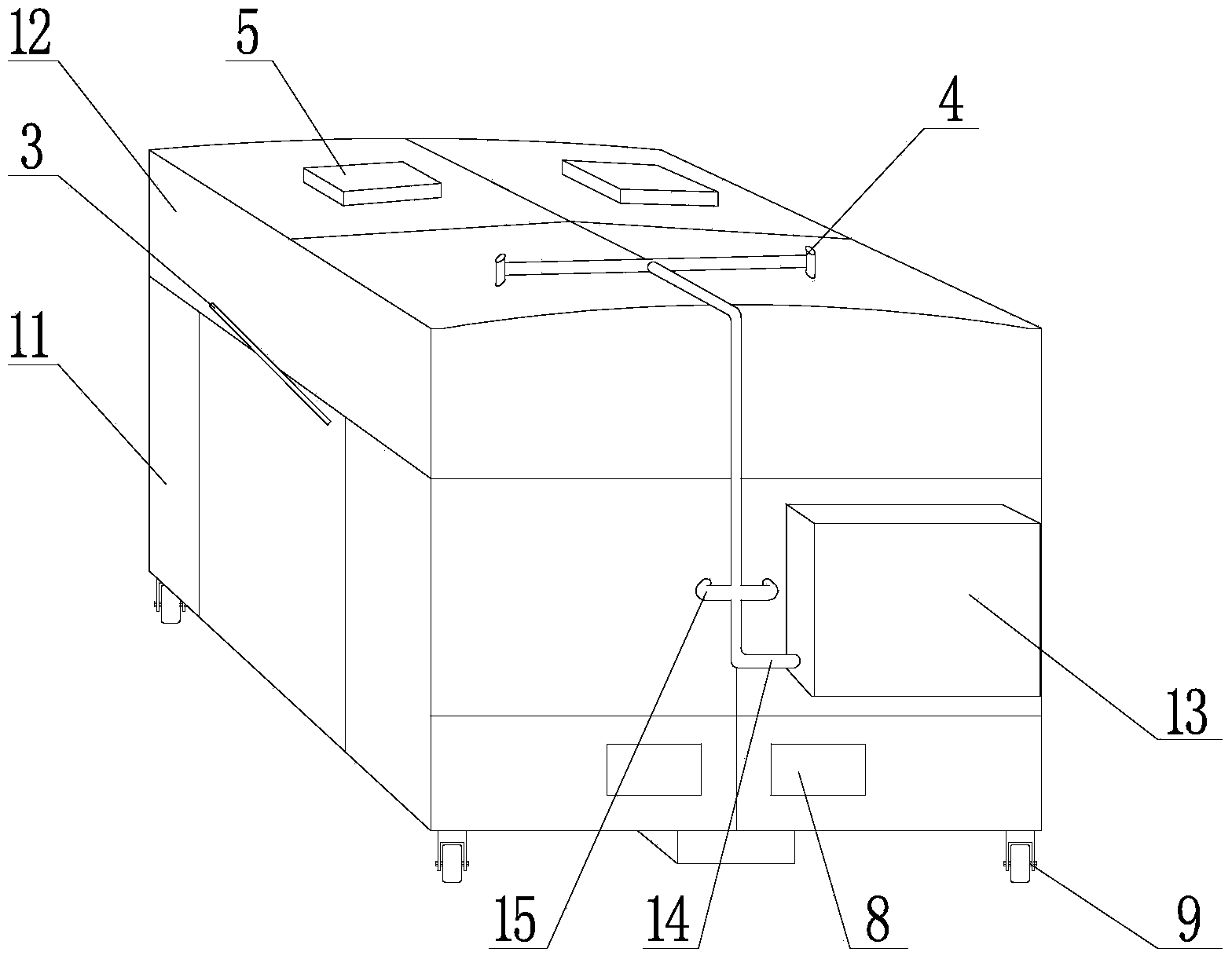

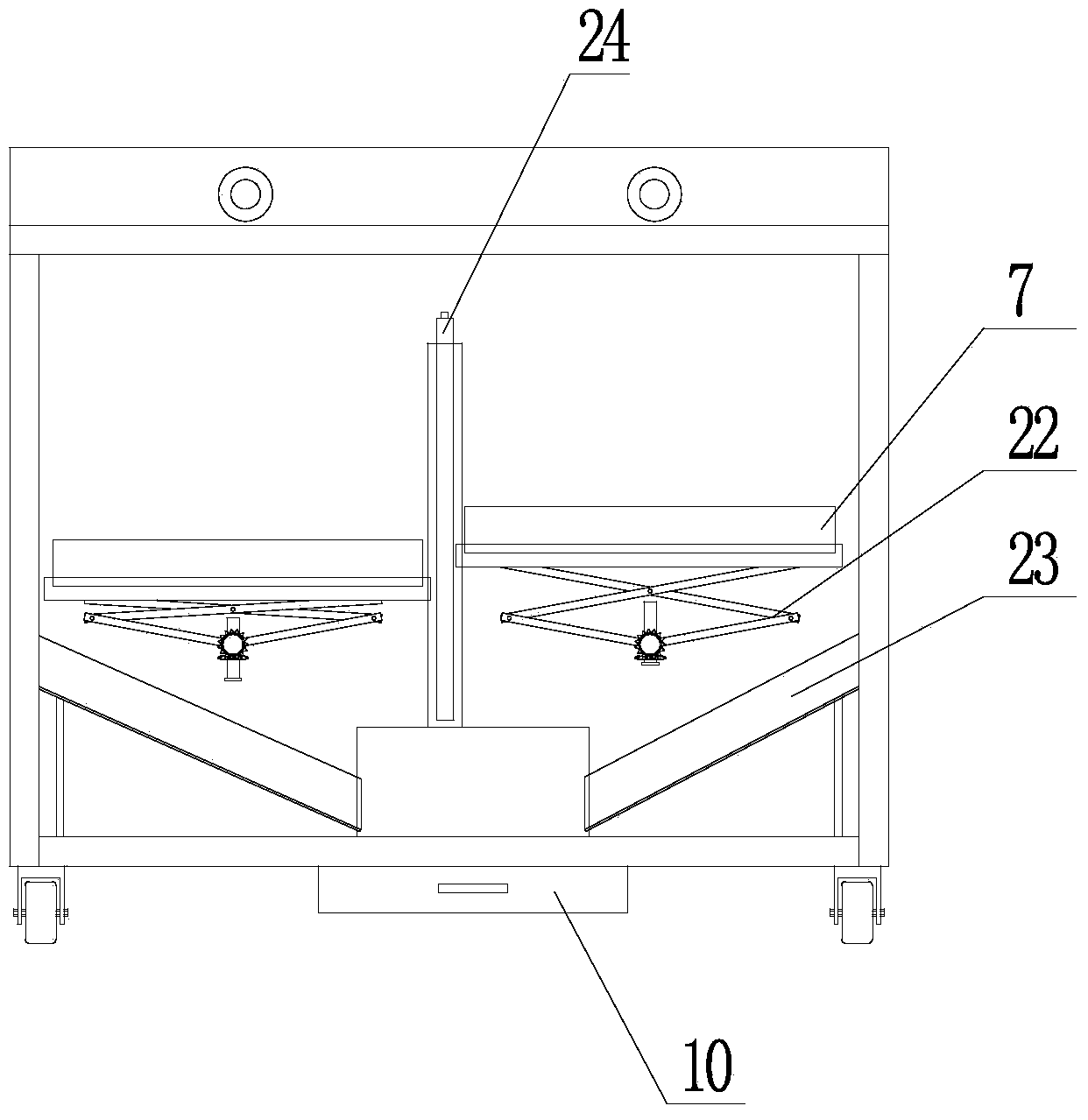

Automatic charcoal-fire sheep roasting machine

InactiveCN103651646AGuaranteed tasteKeep fresh tasteSpecial goods bakingAutomatic controlComputer module

The invention provides an automatic charcoal-fire sheep roasting machine. The automatic charcoal-fire sheep roasting machine comprises an oven, a grill, charcoal fire chambers and a control unit; the oven comprises a box body, and coaxial shaft sleeves are arranged at the upper end of the box body in pairs; a rotary shaft is arranged on the grill, the shaft head at one end of the rotary shaft is fixedly connected with a transmission device which is connected with a driving device, and the driving device is connected with the control unit; air holes are formed in the bottoms of the charcoal fire chambers which are arranged inside the box body and below the grill, and ventilation openings are formed in the positions, below the charcoal fire chambers, of the box body; the control unit comprises a rotary-shaft forward and reverse rotation motion control module, a forward and reverse rotation number control module and a master switch. The automatic charcoal-fire sheep roasting machine achieves uniform roasting heating, saves manpower, is capable of automatically controlling roasting time and short in roasting time, achieves good mouthfeel, is capable of being used for roasting multiple sheep, achieves batch roasting, saves energy, is beneficial to environmental protection, improves efficiency, reduces the number of carcinogenic substances adhering to the surfaces of the roasted sheep, guarantees cleanliness of waste gas, and has the advantages of being simple in structure, convenient to operate and low in cost.

Owner:刘文山

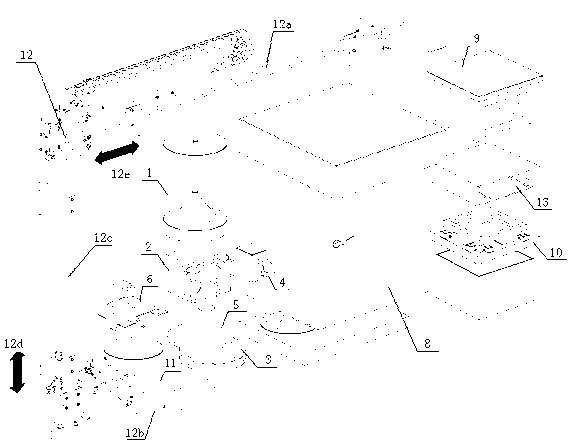

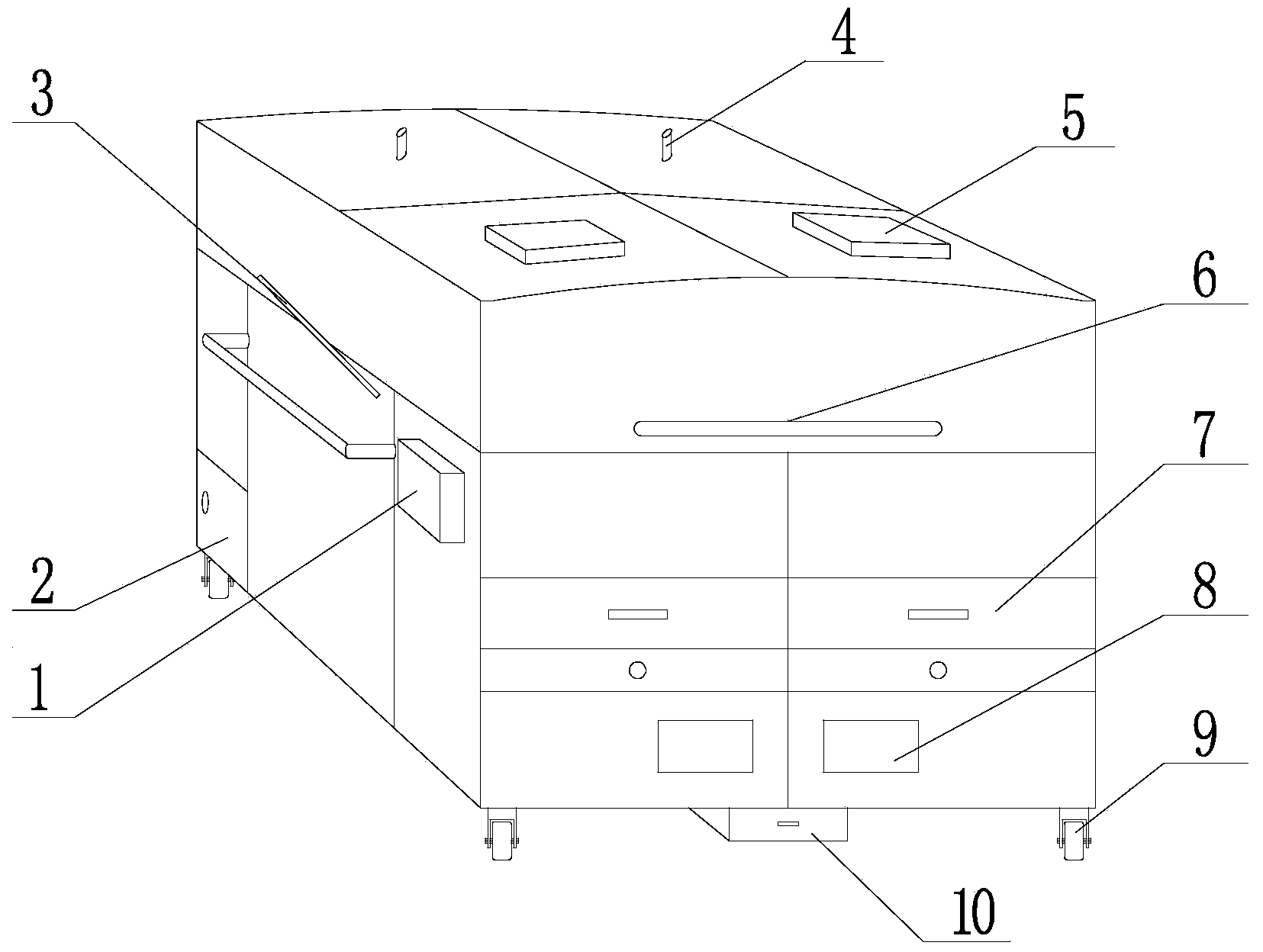

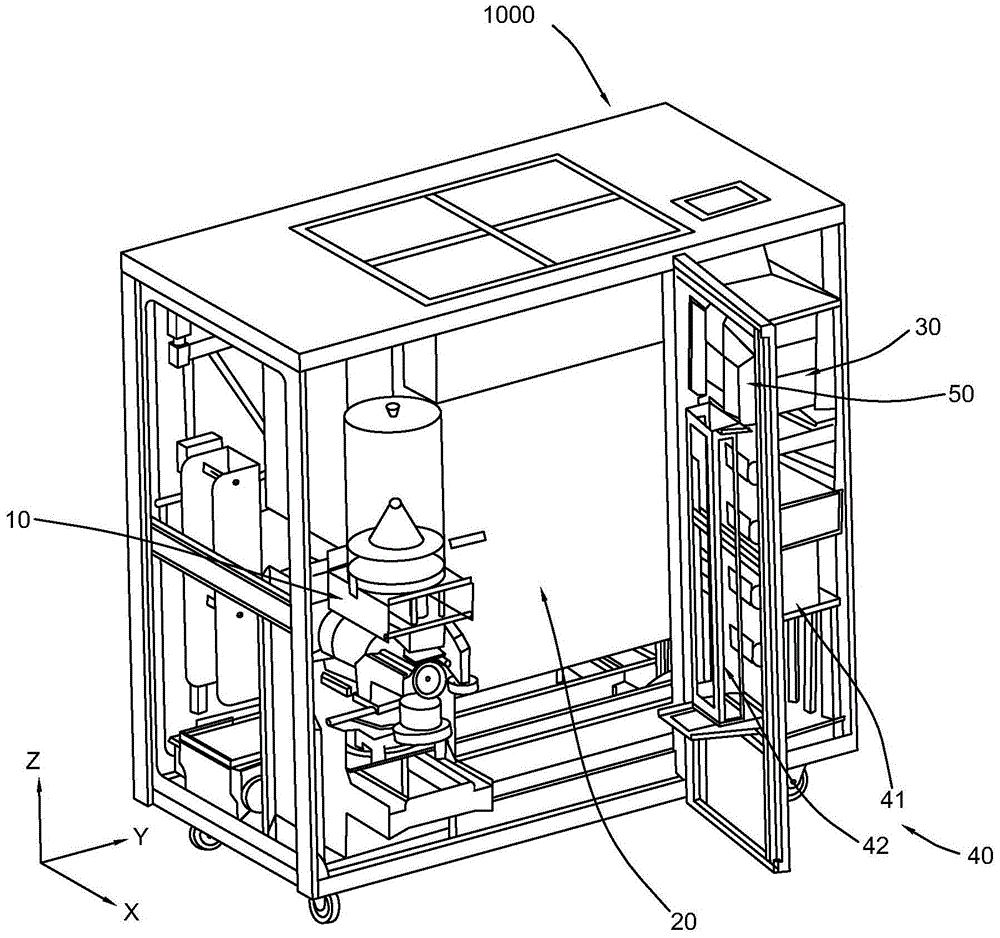

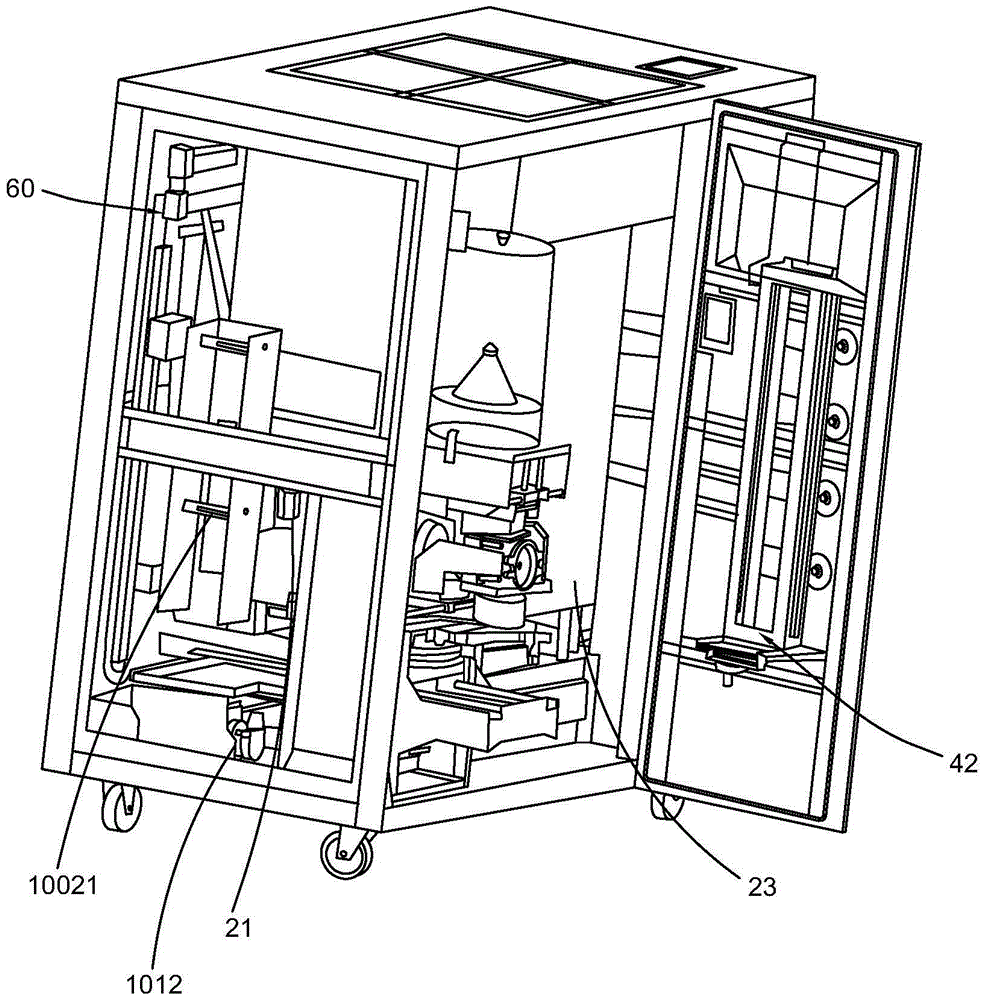

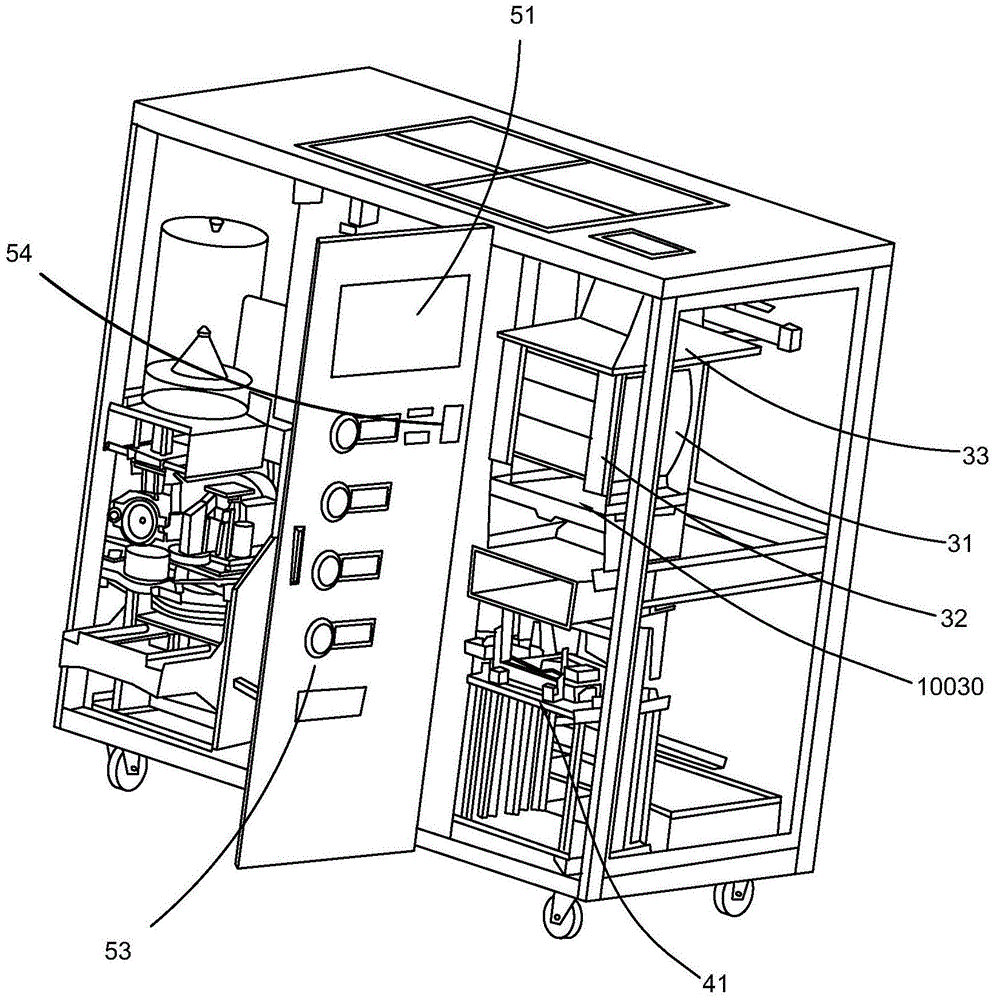

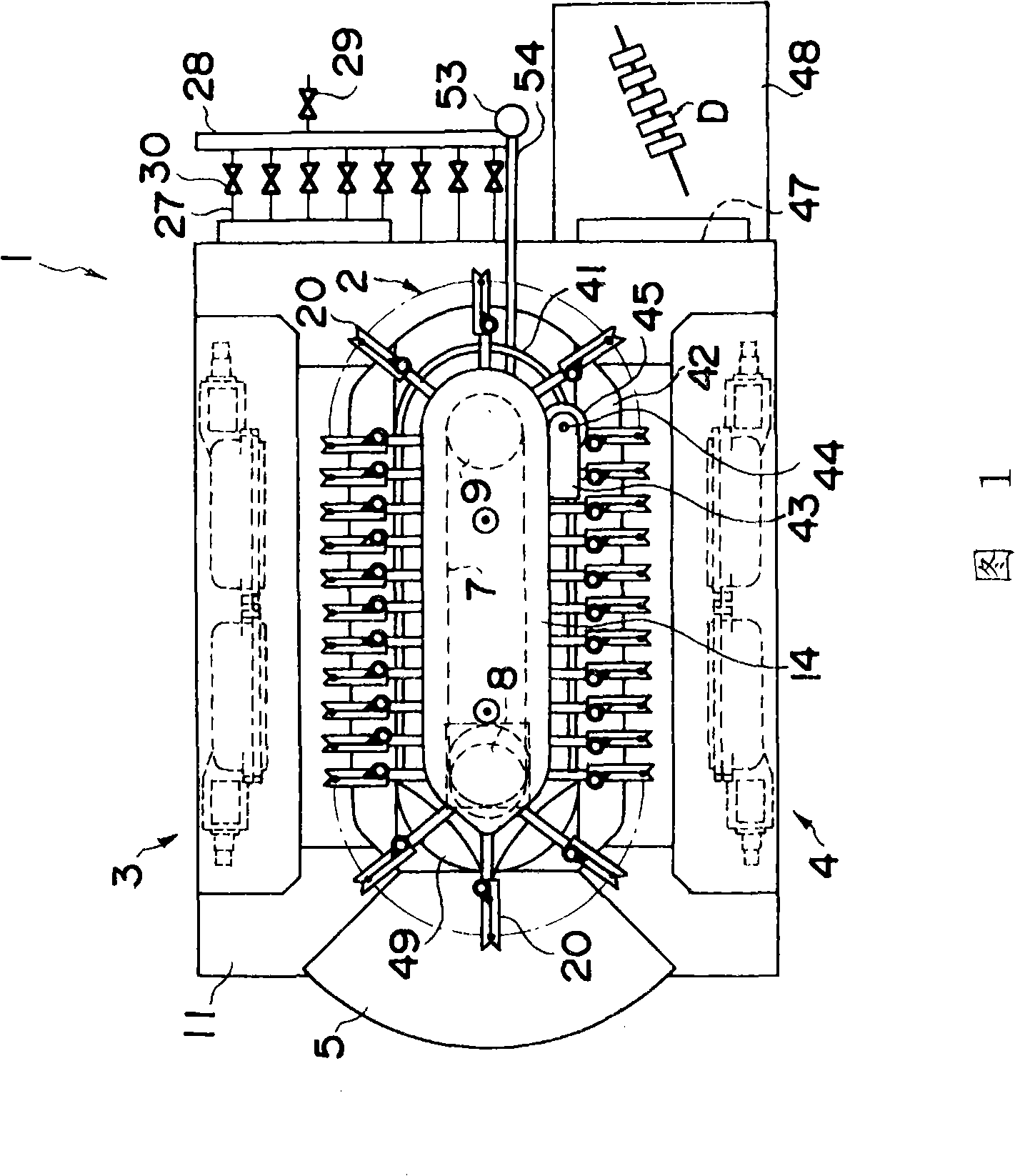

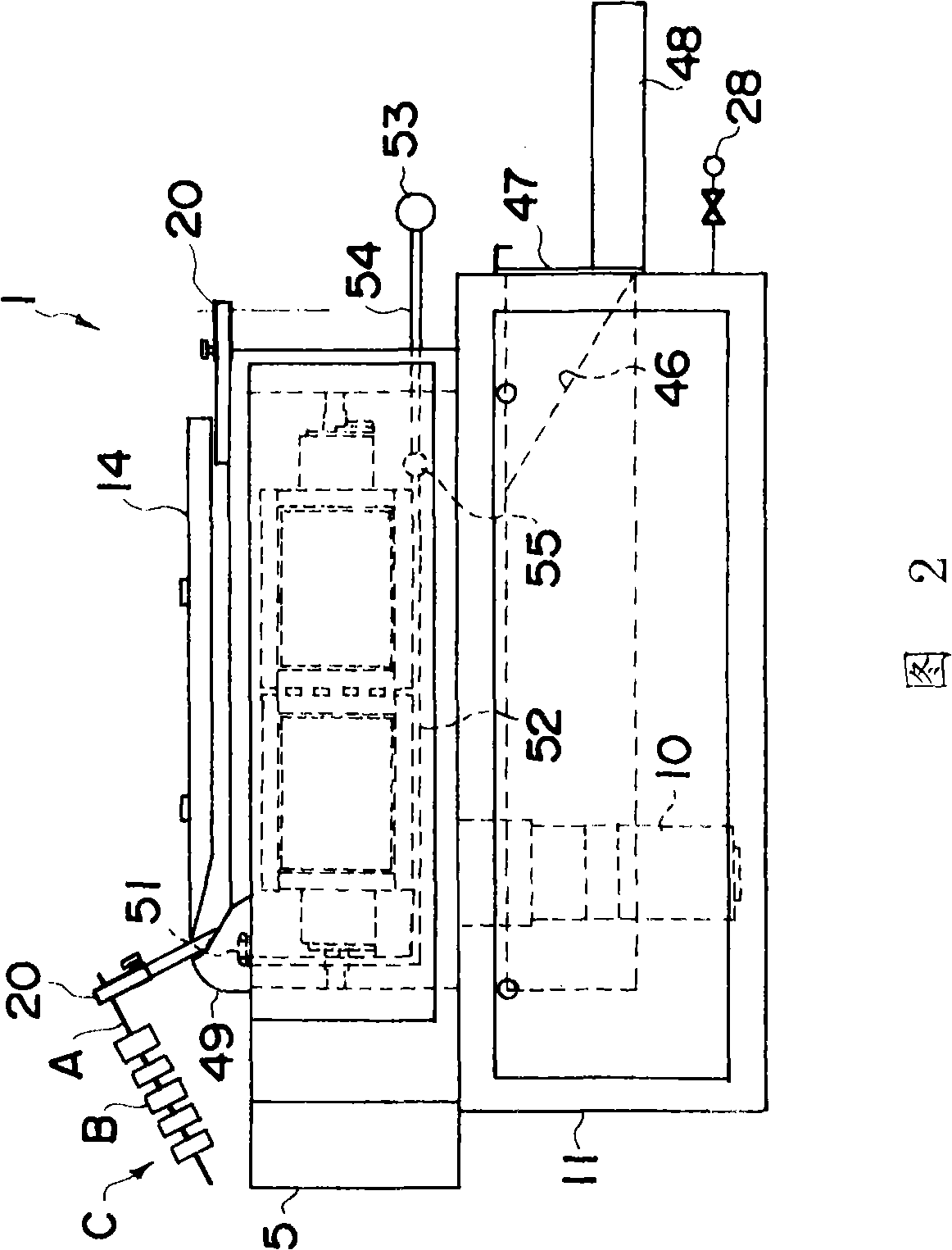

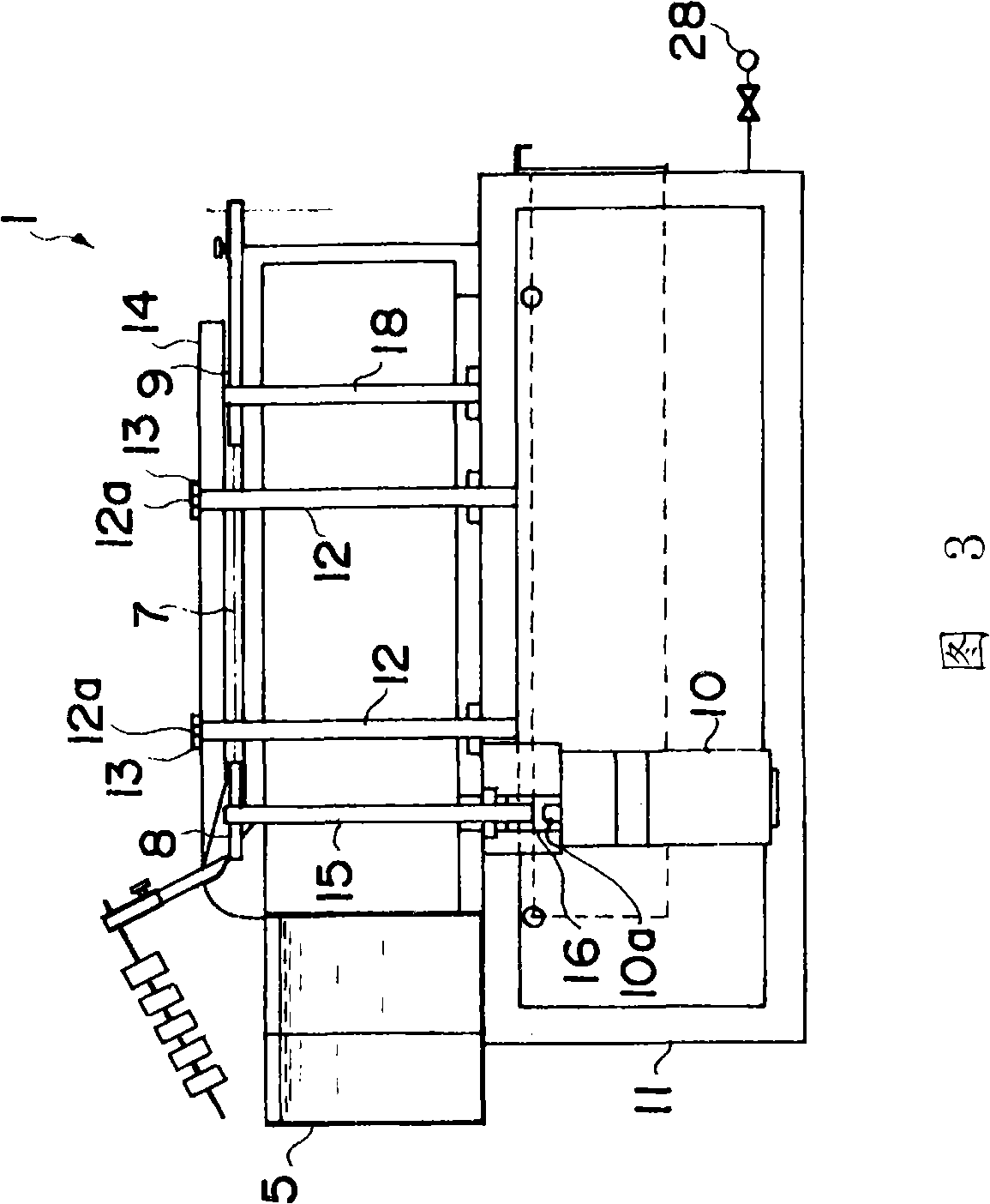

An automatic pizza maker and pizza making method

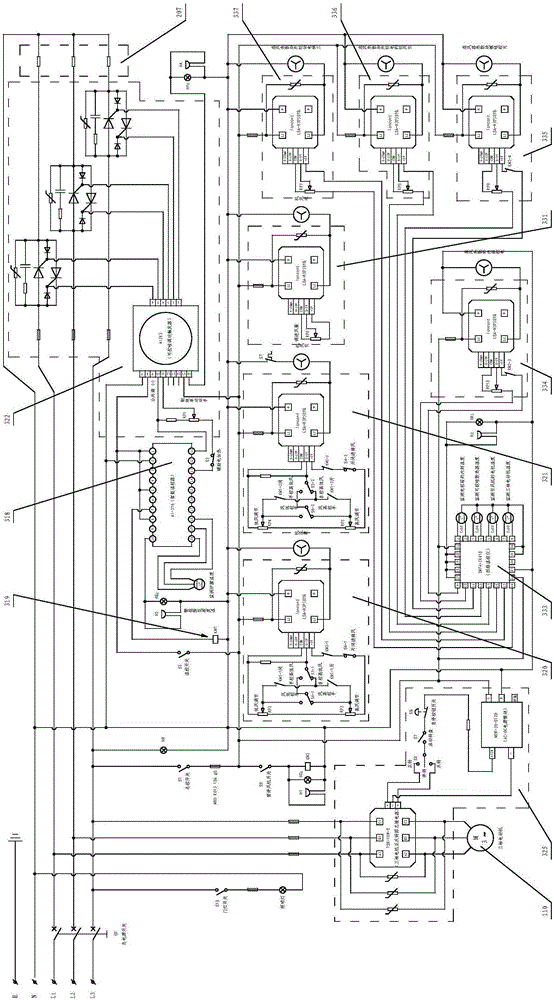

InactiveCN106170208ADough-sheeters/rolling-machines/rolling-pinsBakery productsCooking & bakingControl system

The invention provides an automatic pizza maker comprising a tank body, a flour cake making and shaping component, a material adding component, a baking component, a finished product packing component, a mechanical conveying component and a control system component. The flour cake making and shaking component, the material adding component, the baking component and the finished product packing component are located in the tank body. The material adding component is connected with the flour cake making and shaping component. The baking component is connected with the material adding component. The finished product packing component is connected with the baking component. The mechanical conveying component performs three-axis movement in the tank body. The flour cake making and shaping component, the material adding component, the baking component, the finished product packing component, and the mechanical conveying component are electrically connected with the control system component. The control system component can control the other parts of the automatic pizza making vendor to operate automatically, so that the automatic pizza making vendor completes the making of pizzas.

Owner:SHANGHAI JINHE IND DEV CO LTD

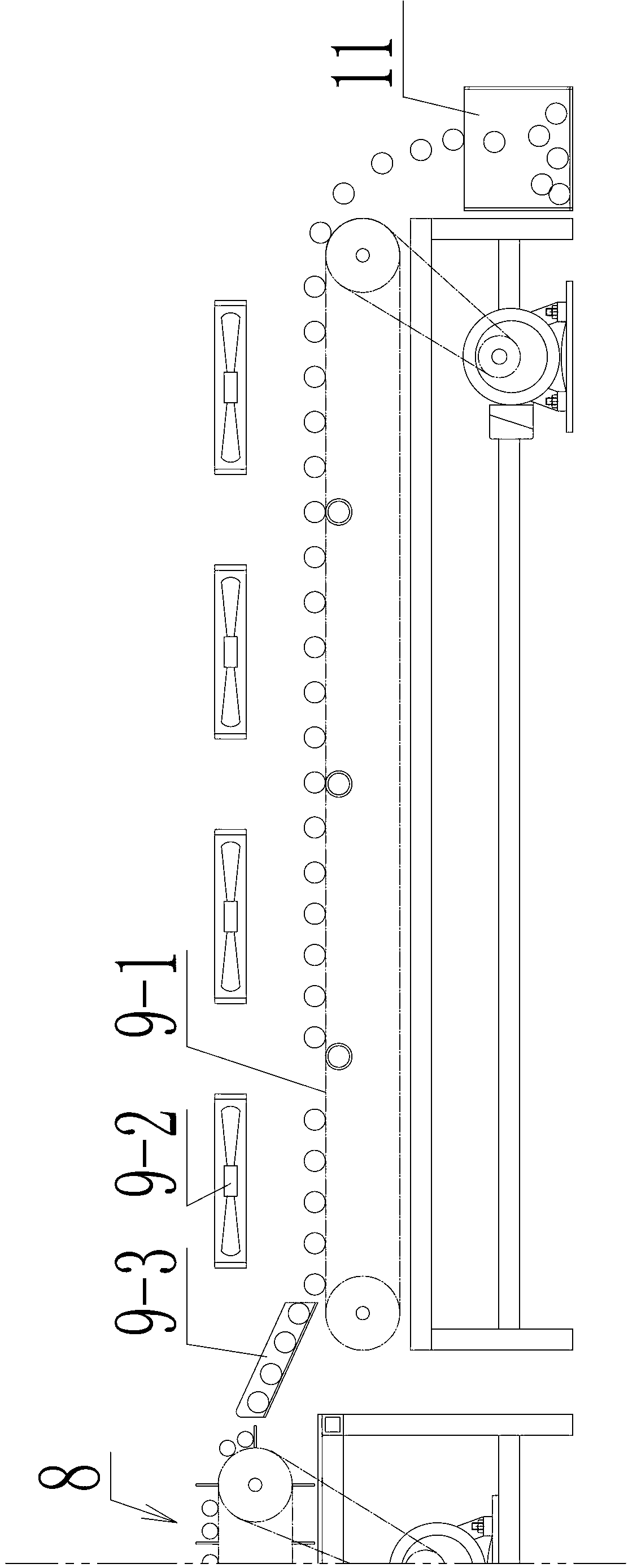

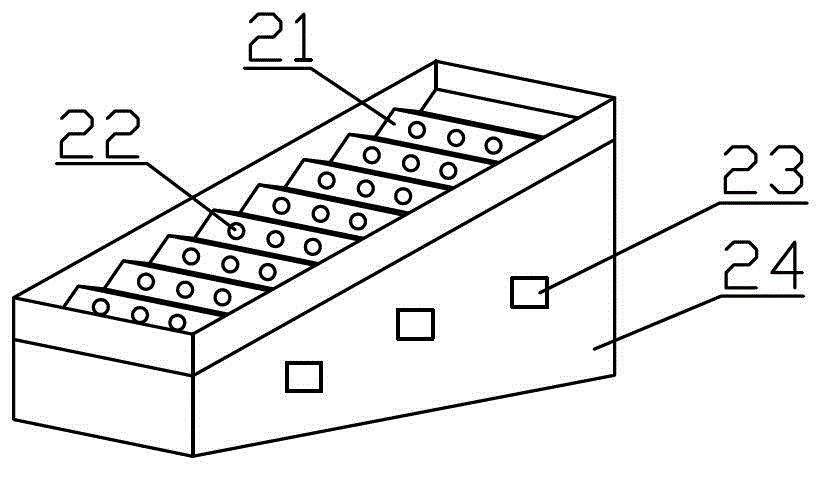

Roasted eel continuous processing production line system and roasted eel processing method

ActiveCN109007647AImprove fluidityImprove processing efficiencyFood ingredient as flavour affecting agentNatural extract food ingredientsEngineeringMouth shape

The present invention discloses a roasted eel continuous processing production line system. According to sequences of a process flow, the roasted eel continuous processing production line system successively comprises a slicing mechanism, a deodorizing pool, an air-drying device and a roasting device; the slicing mechanism is used for synchronous cutting of a plurality of eels in the same row along the length direction and can enable the cut eel blocks to slide into the deodorizing pool for deodorizing treatment; the air-drying device comprises a conveying device, a blowing device, an air-drying bin and filtering device; the conveying device is used for feeding the deodorized eel blocks into the air-drying bin; a conveying belt presents a mouth-shaped circulation structure and enters and exits the air-drying bin horizontally; the eel blocks can be turned over in the air-drying bin; and the roasting device is located on a conveying path of the conveying device and used for roasting theair-dried eel blocks. The present invention also discloses a processing method of the roasted eels. The roasted eel continuous processing production line system is strong in production and processingcontinuity, can realize continuous cutting of the eels, can conduct automatic turning-over in the air-drying stage, is high in air-drying cleaning degree and realizes circular material feeding.

Owner:FUJIAN FUMING FOOD

Barbecue string producing device

Owner:HIBIKI CO LTD +1

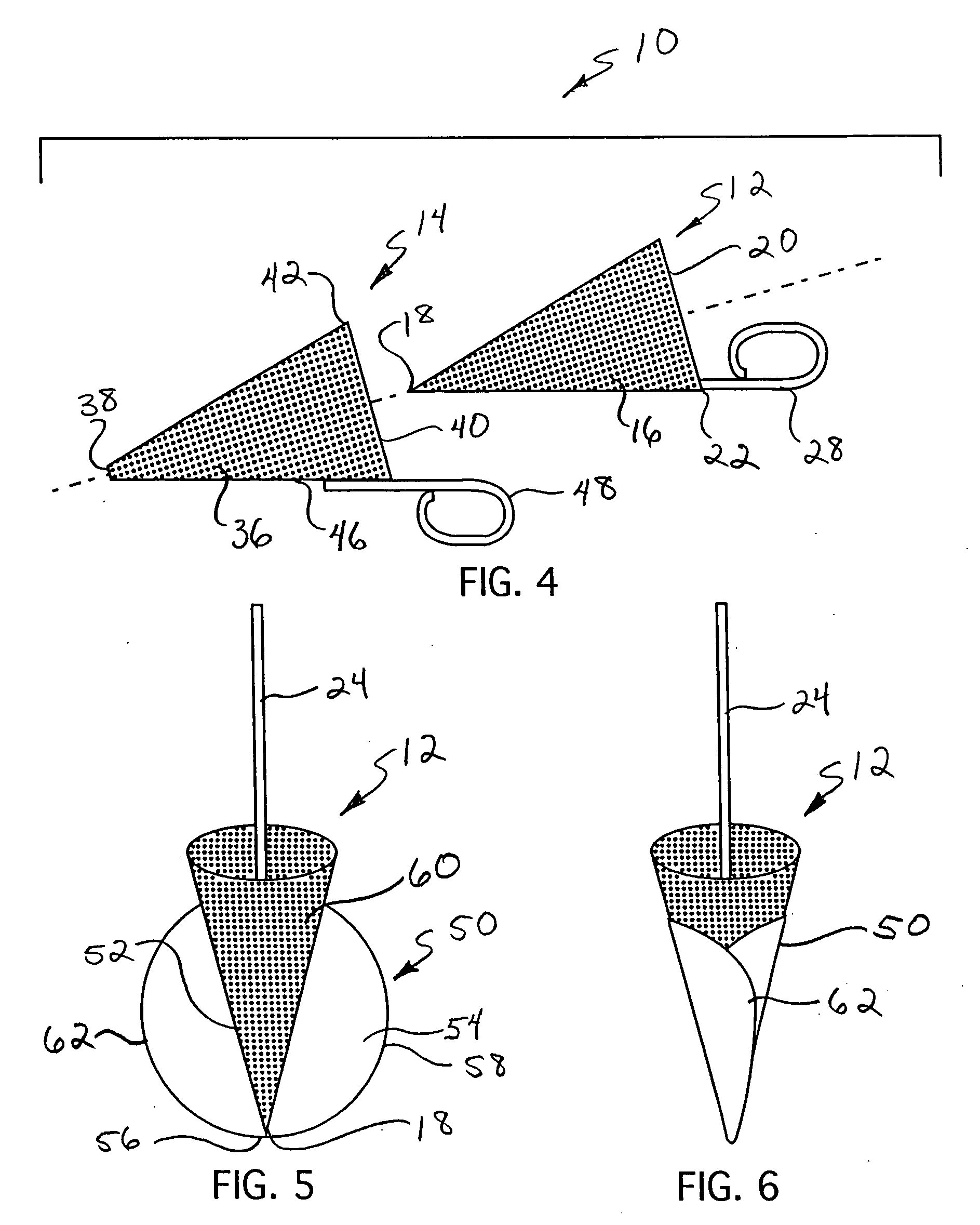

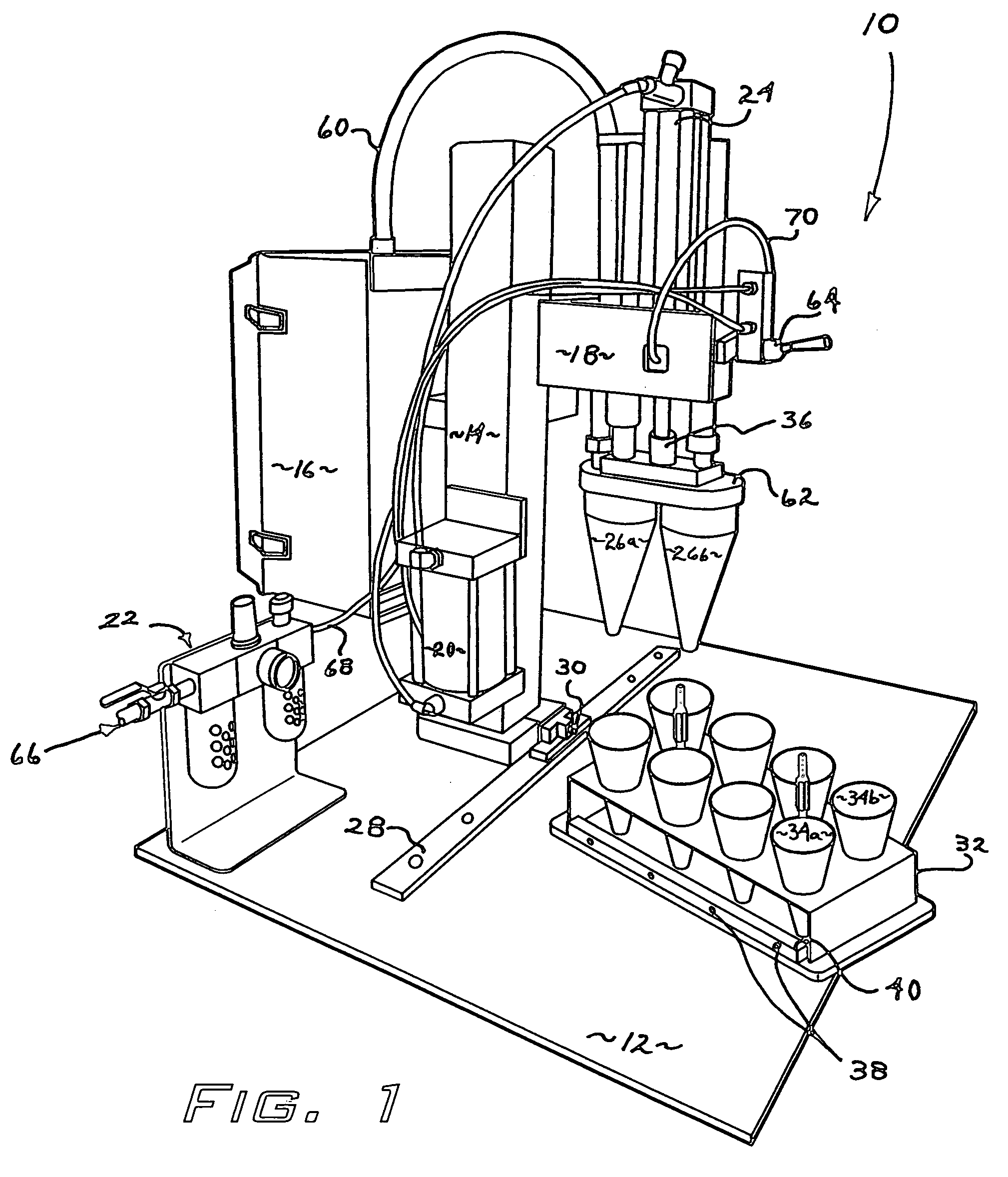

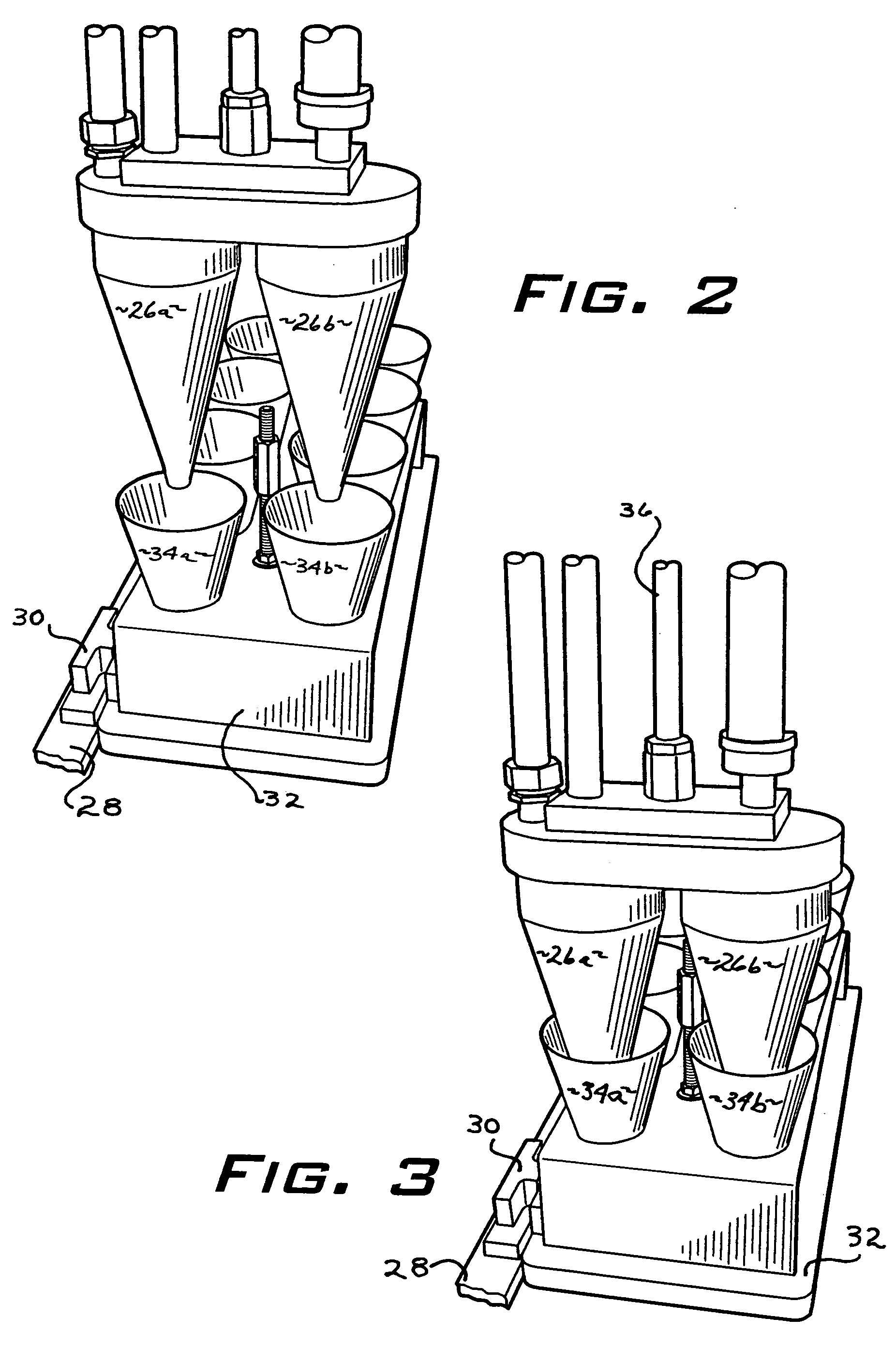

Edible container apparatus and method of manufacture

A method and apparatus are provided for forming and baking an edible cone-shaped container, the container being of a bread dough provided with a light, flaky texture by the inclusion of solid flaked fat pieces in the dough mixture and the cone formed by an initial forming and cooking step followed by multiple baking steps.

Owner:CONICS FOODS

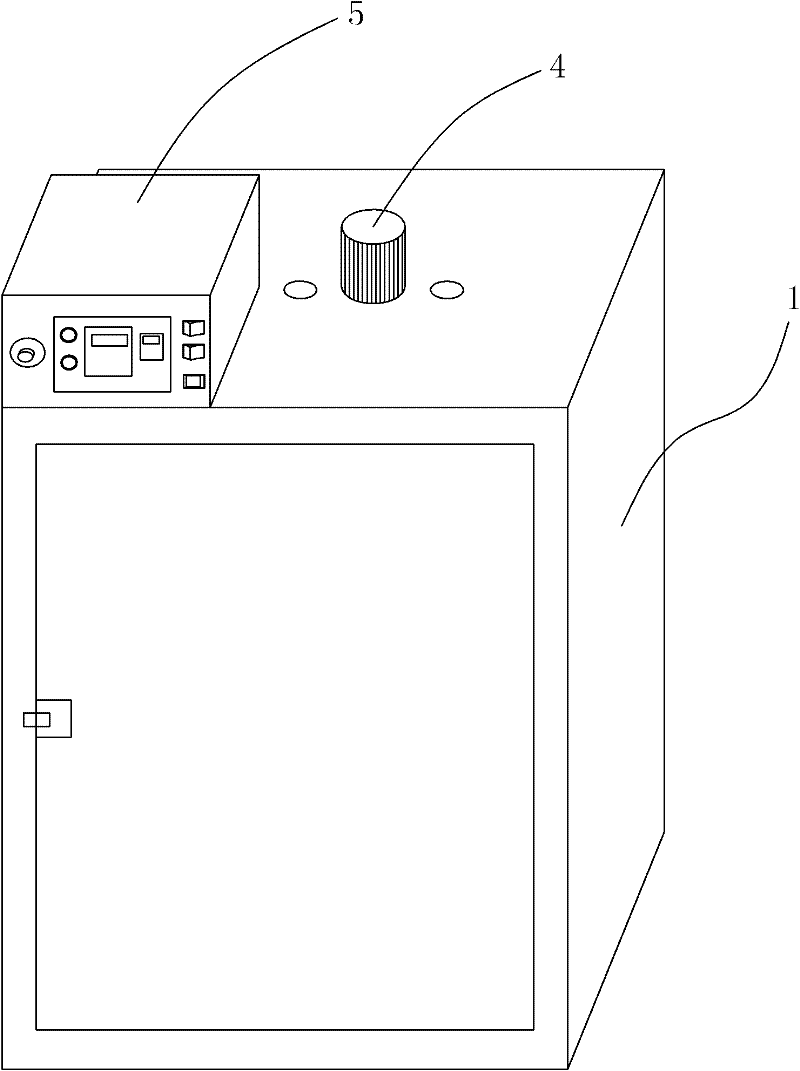

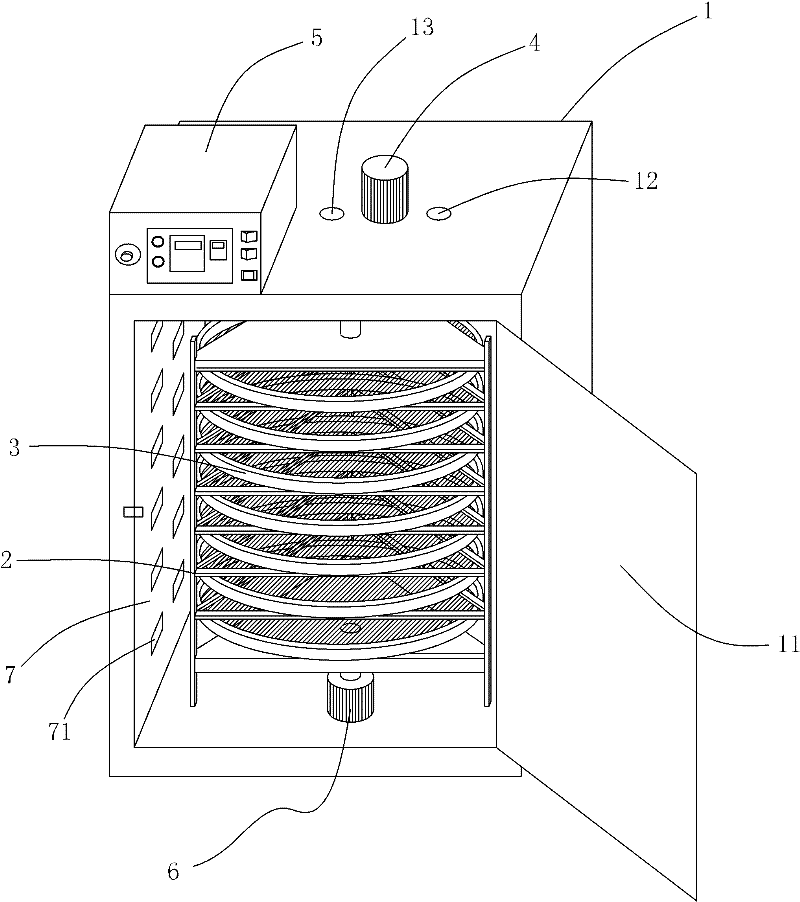

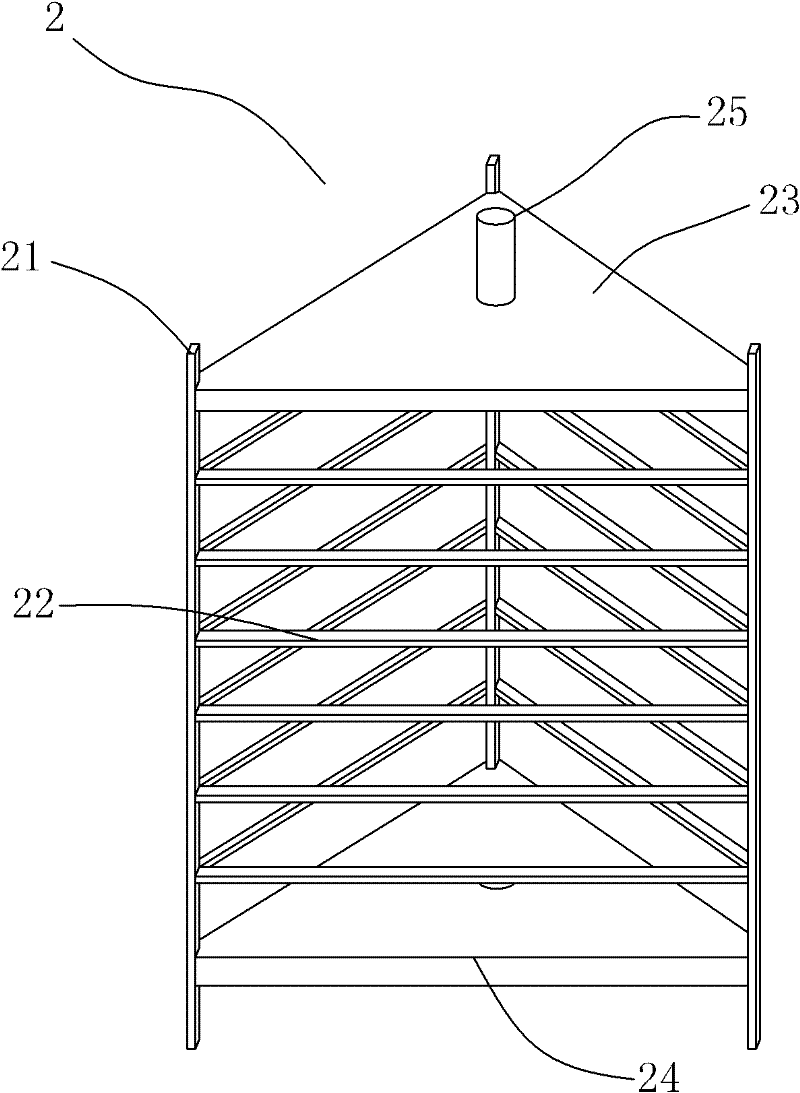

A kind of baked egg, baked egg case and baking method thereof

The invention discloses a baked egg, an egg baking box, and a method for baking the baked egg. The baked egg comprises an egg shell and an egg core which does not have the fishy smell of a fresh egg when eaten, wherein the egg shell of the baked egg totally coats the egg core in a crack-free state; the egg core comprises an egg white which is a tough body and an egg yolk which is a loose body; and the egg white totally coats the egg yolk in the crack-free state. The egg baking box comprises a box body, a grill, a plurality of baking trays for accommodating livestock and poultry eggs, and a heater, wherein a wall body at the front end of the box body can be opened; the grill is provided with a plurality of slots along the vertical direction and can be arranged in the box body along the vertical axis of the grill in a rotating mode; each baking tray is inserted into the corresponding slot of the grill in a pull-out mode; and the heater is arranged in the box body. The method comprises a high-temperature heating section and a low-temperature heating section. The baked egg has the characteristics of good mouthfeel, high elasticity and toughness, and the like; the egg baking box has the characteristics of simple structure and the like, and is convenient to operate; and the method has the characteristics of unique process, simple flow control and the like, and is easy to implement.

Owner:陈杉荣

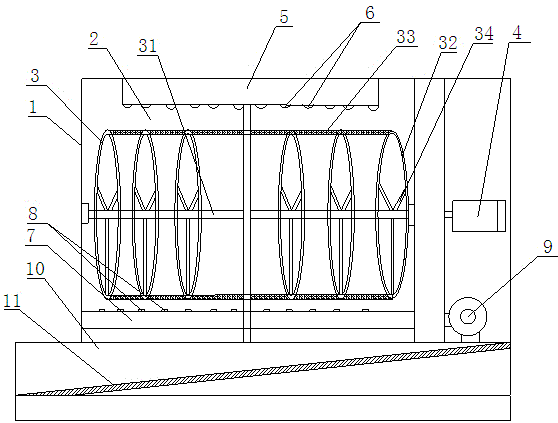

Rotary oven

InactiveCN104054762ASpray evenlyGreat tasteBaking ovenSpecial goods bakingEngineeringMaterial distribution

The invention discloses a rotary oven, which comprises an oven body, wherein a transparent mobile door is formed in the oven body; a baking rotating drum is arranged in the transparent mobile door and driven to rotate through a motor; a seasoning adding pipe is arranged at the top of the oven body above the baking rotating drum; a plurality of material-distribution holes are uniformly formed in the seasoning adding pipe; a spraying and blow pipe is arranged at the bottom of the baking rotating drum; a plurality of nozzles directly facing an baking object are arranged on the spraying pipe; a blower is arranged at the tail end of the spraying and blow pipe. According to rotary oven disclosed by the invention, the seasoning adding pipe is arranged, the material-distribution holes are uniformly formed in the seasoning adding pipe, the seasoning is added from the seasoning adding pipe, and then sprayed on food in the baking rotating drum through the material-distribution holes, the spraying and blow pipe is arranged at the bottom of the baking rotating drum, the nozzles directly facing the baking object are arranged on the spraying and blow pipe, and air sprayed from the spraying pipe reversely blows the seasoning, so that the seasoning is sprayed on the food uniformly, and the food is tasty and delicious.

Owner:江勇汉

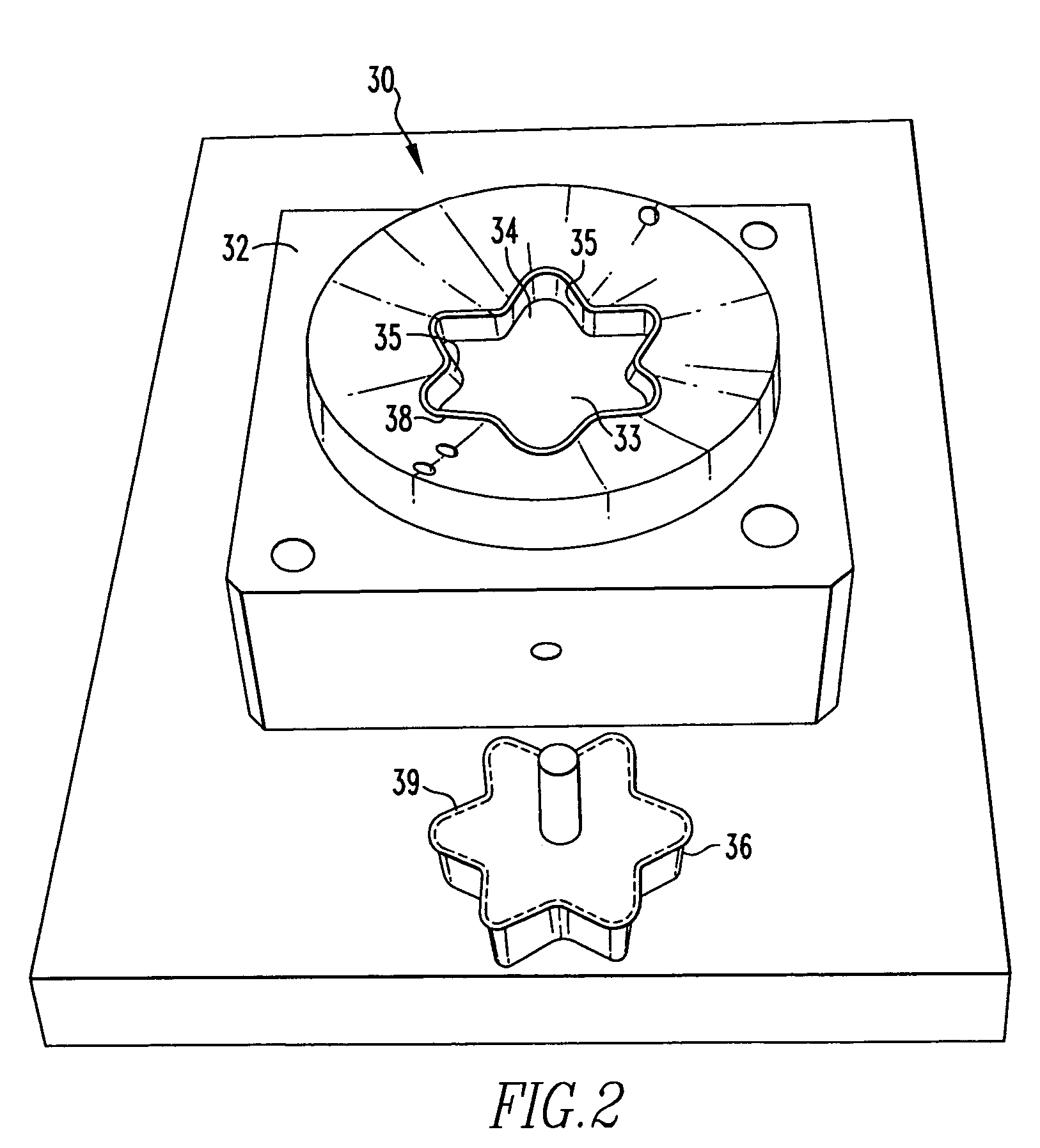

Process for making a silicone mold and baking a food product therein

The present invention relates to a process for baking a food product utilizing a confectionery mould made from silicone. The confectionery mould is obtained by mixing and reacting a crosslinkable silicone, especially methyl-vinyl siloxane (VMQ), and a peroxide as a cross-linking agent.

Owner:SAR HLDG INT

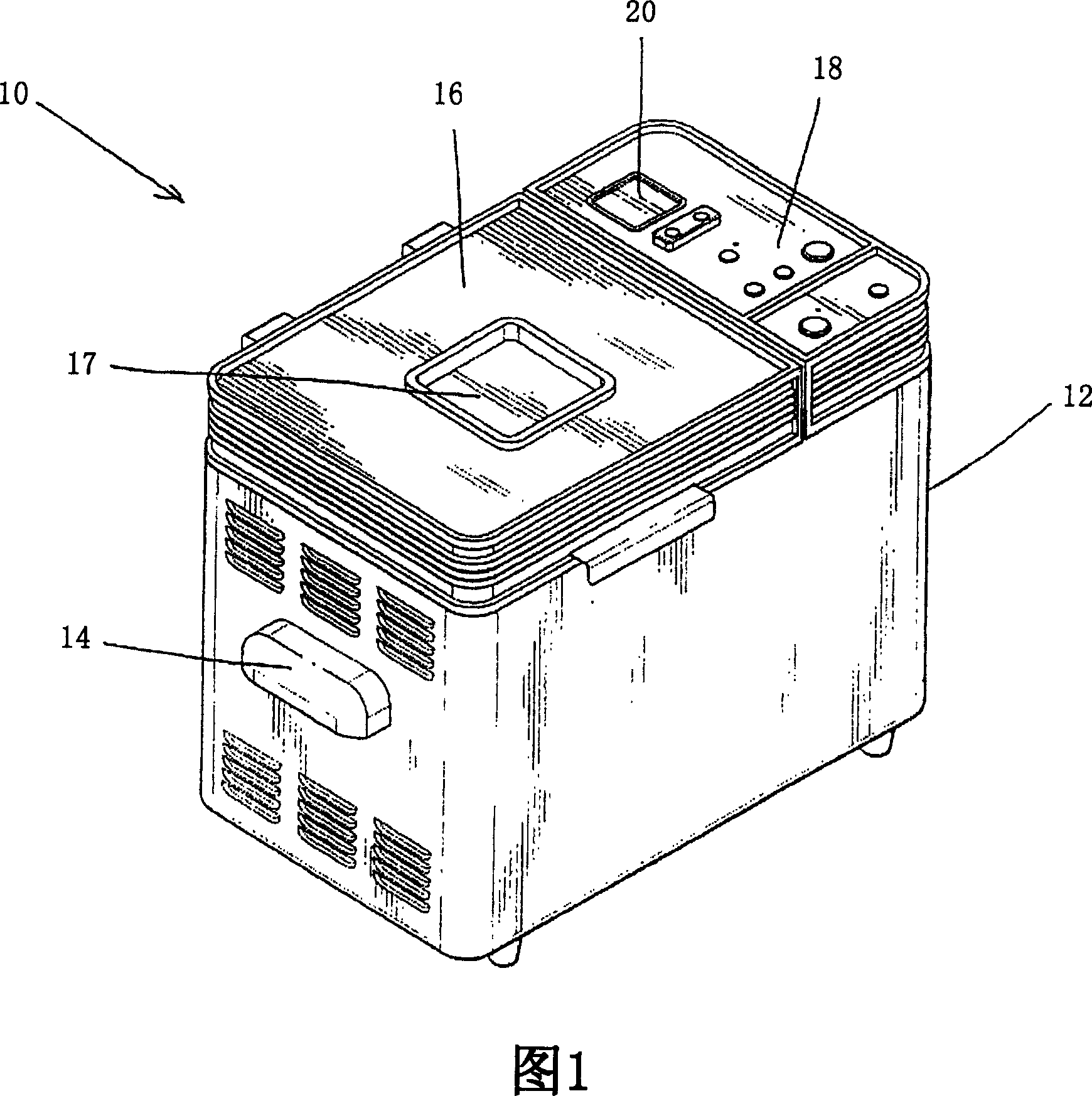

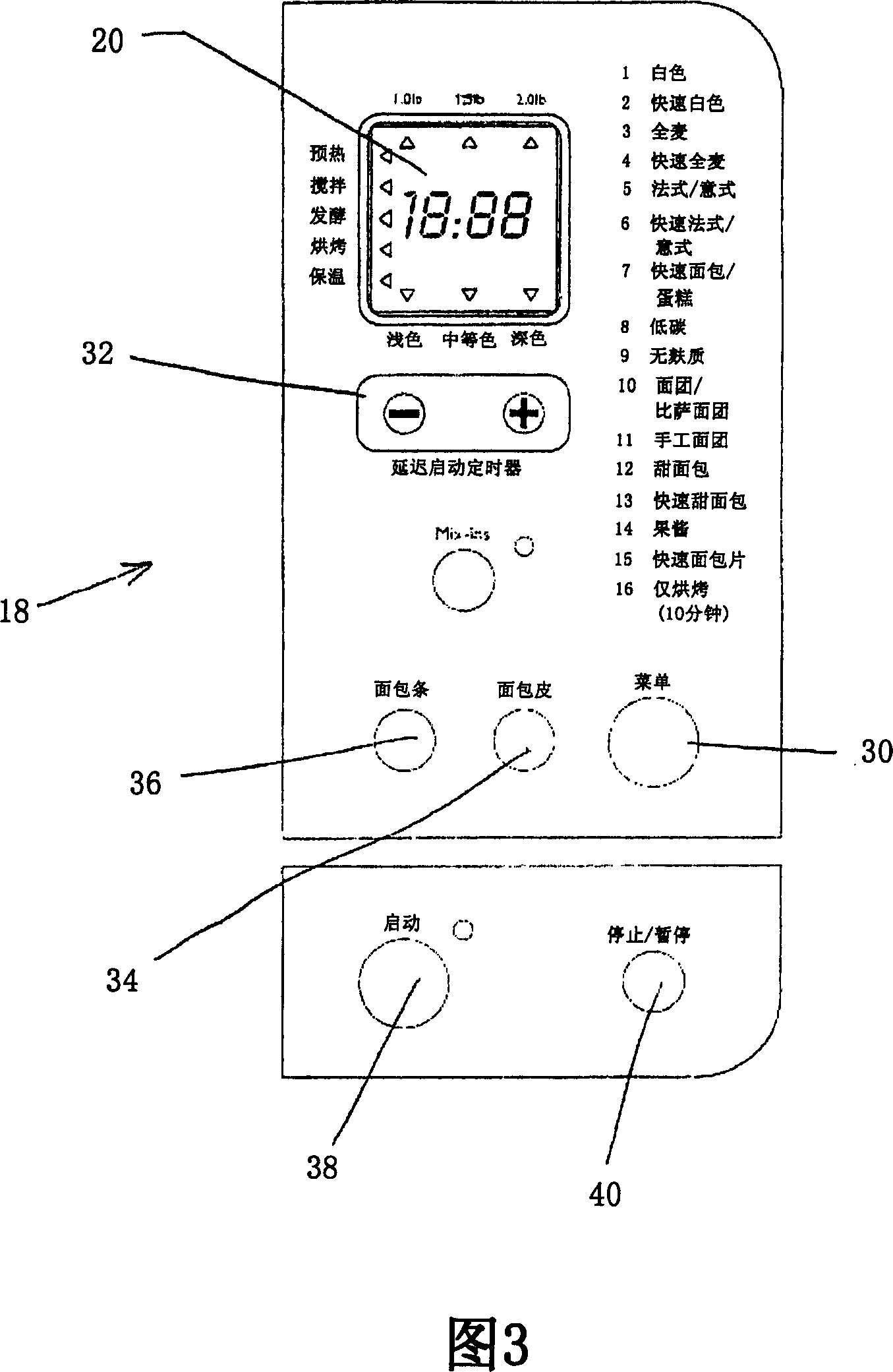

Bread machine with automatic control

InactiveCN101073327AEasy to operateChallengingBread-toastersSpecial goods bakingAutomatic controlEngineering

The invention is concerned with the bread maker, which is with the active coping that the user can open it selectively and the observation window that the user can observe the processing of making bread. It is: the active baking plate and the stirring vane that is in the selective roasting chamber using for preserve and mix the raw materials; the controlling panel that lays near the active coping and is with the pressing button in order that the user is easy to operate the making of bread; the LCD display in the controlling panel shows the program selection and the roasting moment; the user can programming the bread maker in order to make any kind of bread, the moment of the preheating, the mixing, the fermentation, the roasting and the heat preservation that need not the intervention from the user.

Owner:CONAIR CORP

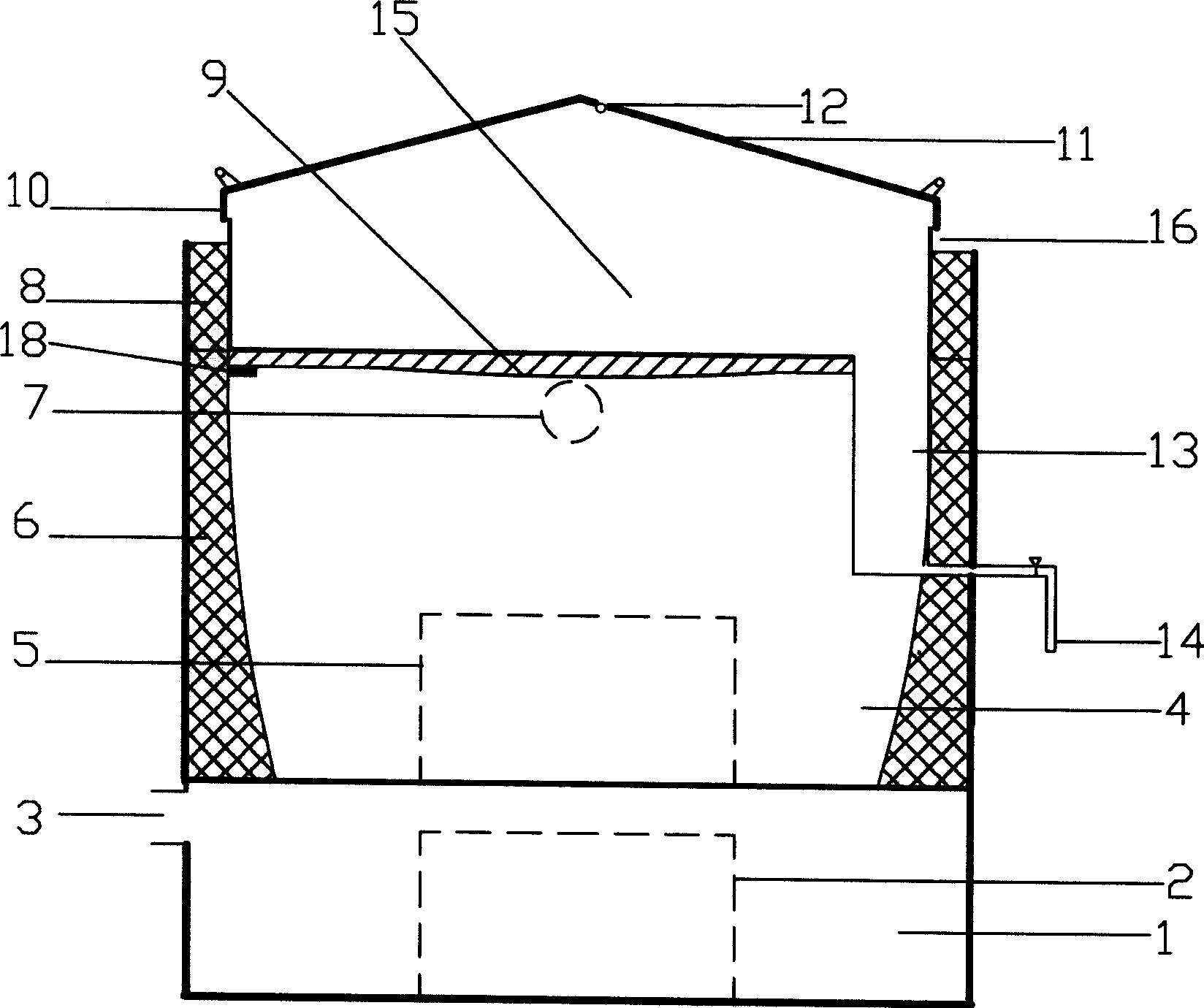

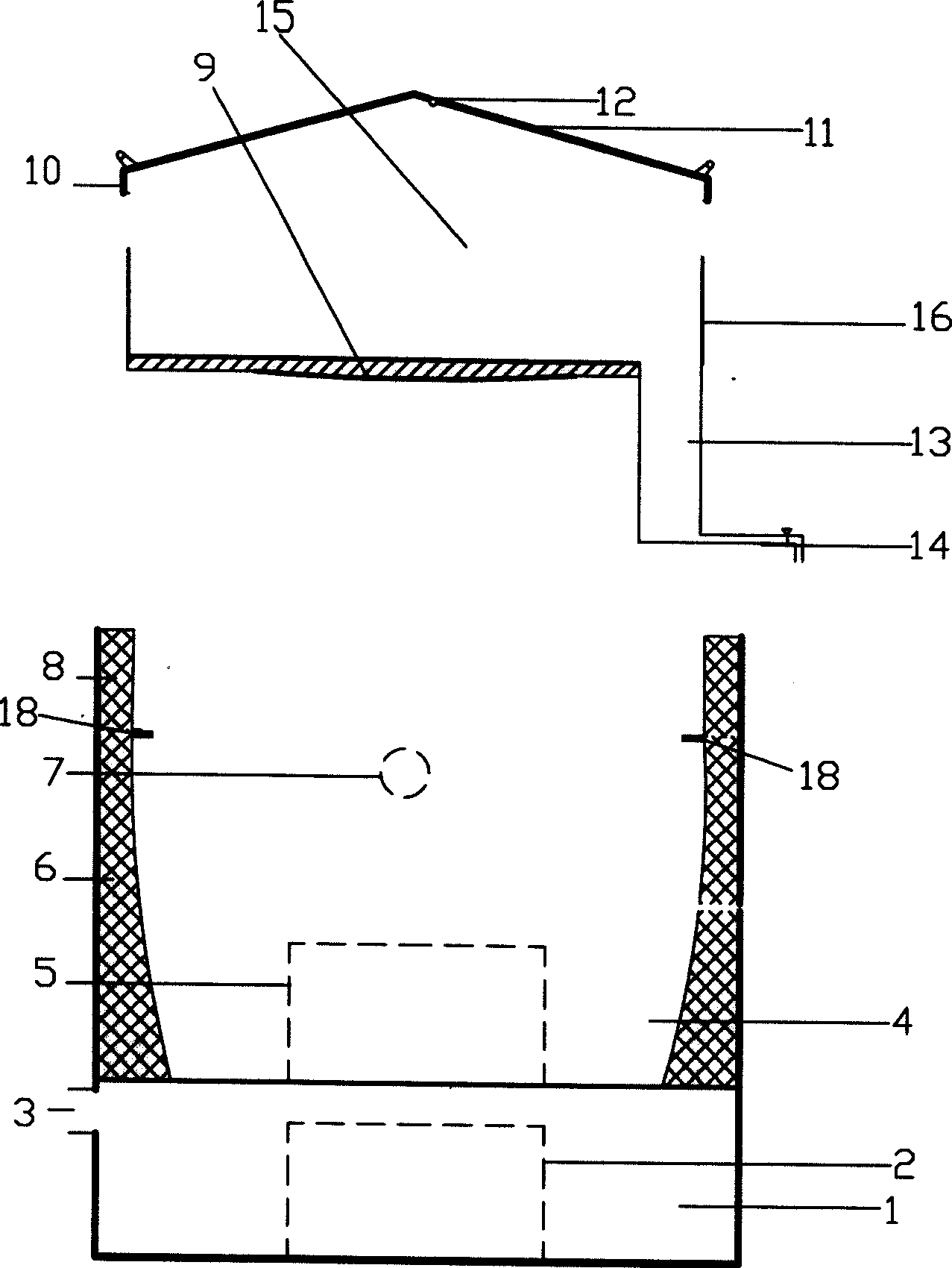

Method for processing steamed and baked bread and special-purpose equipment stove for steaming and baking

InactiveCN101461410AThe taste is mellow and strongRich dining tableBakery productsSpecial goods bakingEngineeringSponge cake

The invention relates to a method for processing food, especially for steaming and baking bun. The method comprises: making the leavened dough into steamed bread blanks, steamed stuffed bun blanks, dumpling blanks, steamed sponge cake blanks or pie blanks; and putting them into a special steaming-baking stove equipment to steam and bake by specific steps. The bun made in the invention has the crack layer of about 2 mm, is more soft and crisp than baked bun, and is more puffed, tender, aromatic and pliant than steamed bun; is salutary and safe, and protect the nutrition of the materials perfectly. The invention further provides an integrally designed special enclosed steaming-baking stove for processing the steamed-baked bun, which comprises oven chamber, heating device, steam griddle supporter, steam griddle heat preservation ring and steam griddle; achieves the advantages of , simple, practical and energy saving; can steam, bake and perform the steaming and baking synchronously, especially can guarantee the quality of the steamed-baked buns.

Owner:刘姝婧

Egg body baking and producing device

ActiveCN103210965AShorten the lengthEvenly bakedSpecial goods bakingCooking & bakingProcess engineering

The invention provides an egg body baking and producing device which comprises a baking chamber, wherein the baking chamber is internally provided with a transporter for inputting and outputting egg bodies one by one, a hot gas discharging pipeline is arranged on the baking chamber, and discharged hot gas is output through a fan after being dewatered by a dewatering device, and enters the bottom of the baking chamber through a hot gas inlet pipe after heat of hot gas is absorbed by an air heat exchanger, so that the circulating heating of air can be realized, and egg bodies can be baked. The device not only can be used for evenly heating the egg bodies, but also is small in volume and high in baking efficiency.

Owner:福州闽台机械有限公司

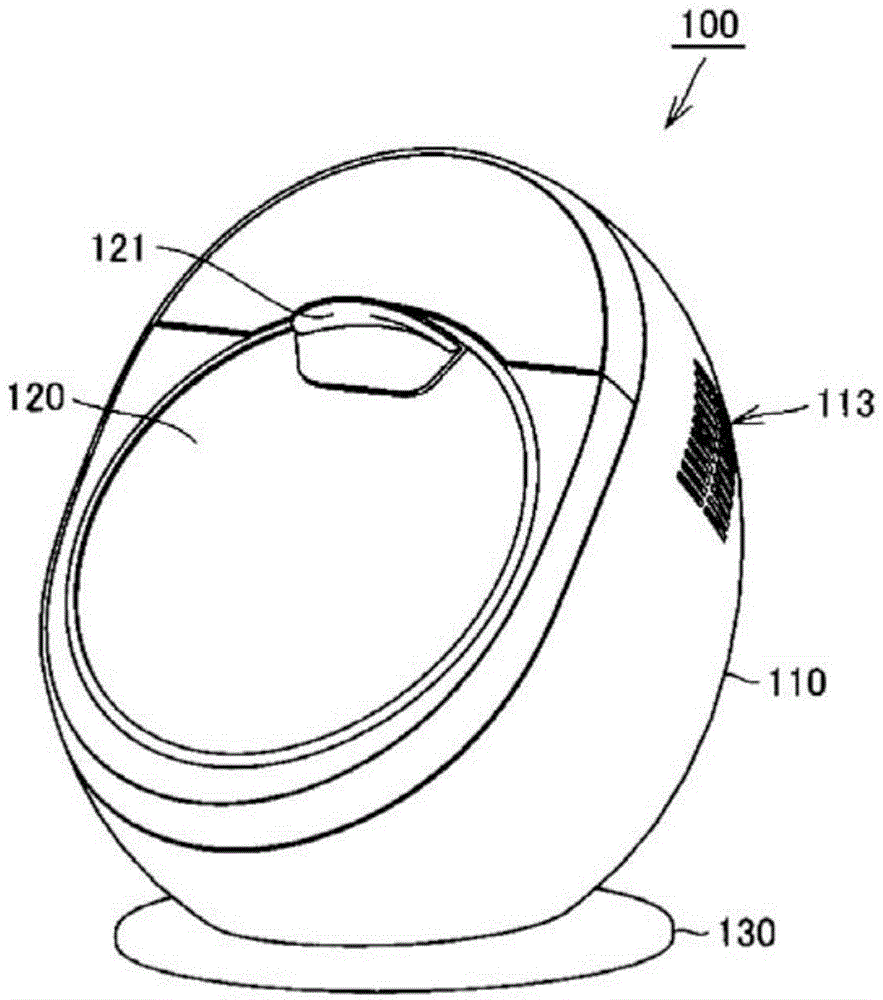

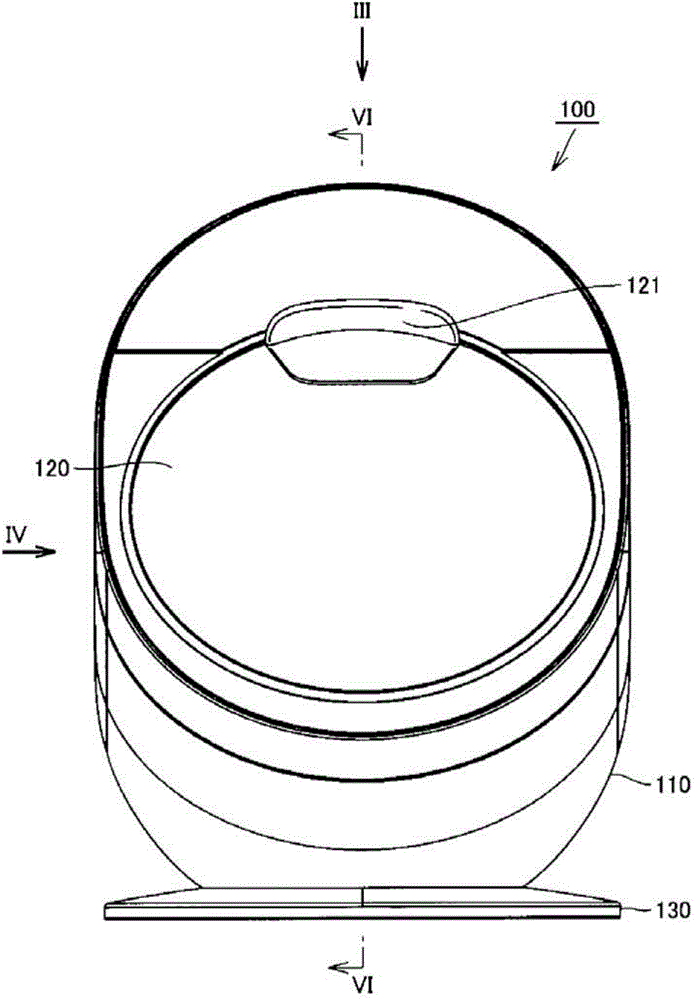

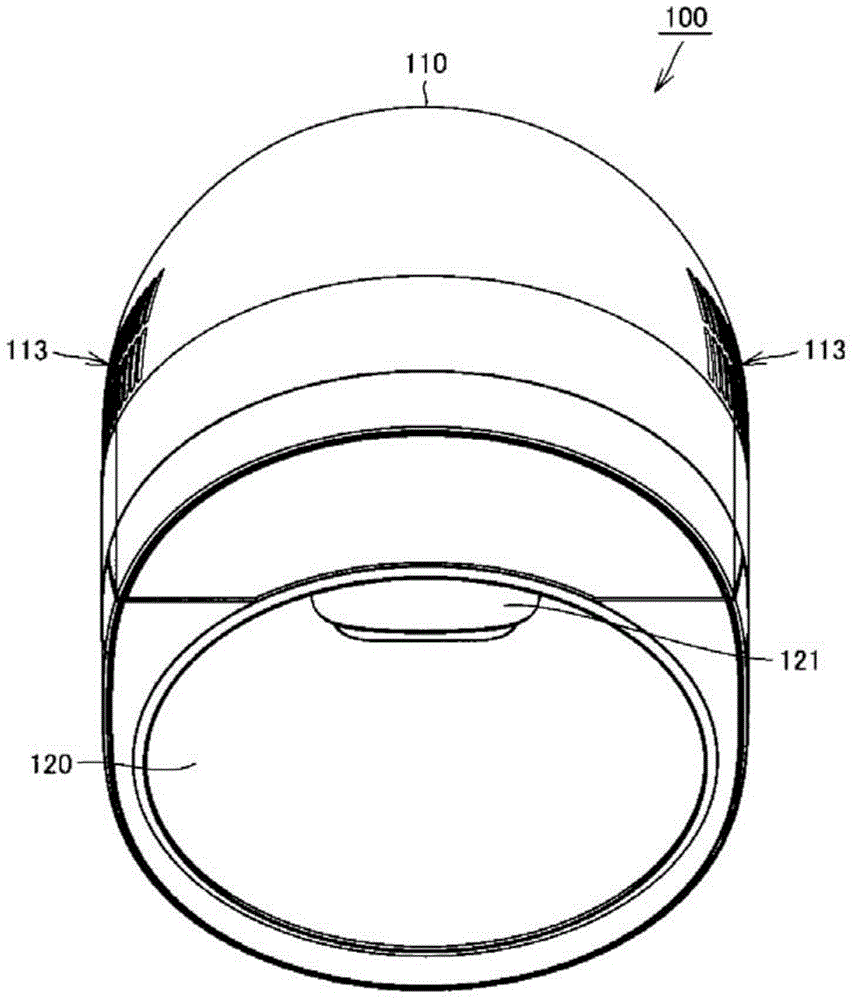

Heating cooker

InactiveCN104797178AHeating evenlyDomestic stoves or rangesLighting and heating apparatusEngineeringPerpendicular direction

This heating cooker is provided with: a housing; a container (150), which is housed in the housing in a state wherein the center axis of the container is tilted at a predetermined angle with respect to the perpendicular direction, and which contains a subject to be heated; a hot air blowing mechanism that blows hot air to the inside of the container (150); and a drive mechanism that rotates the container with the center axis at the center.

Owner:SHARP KK

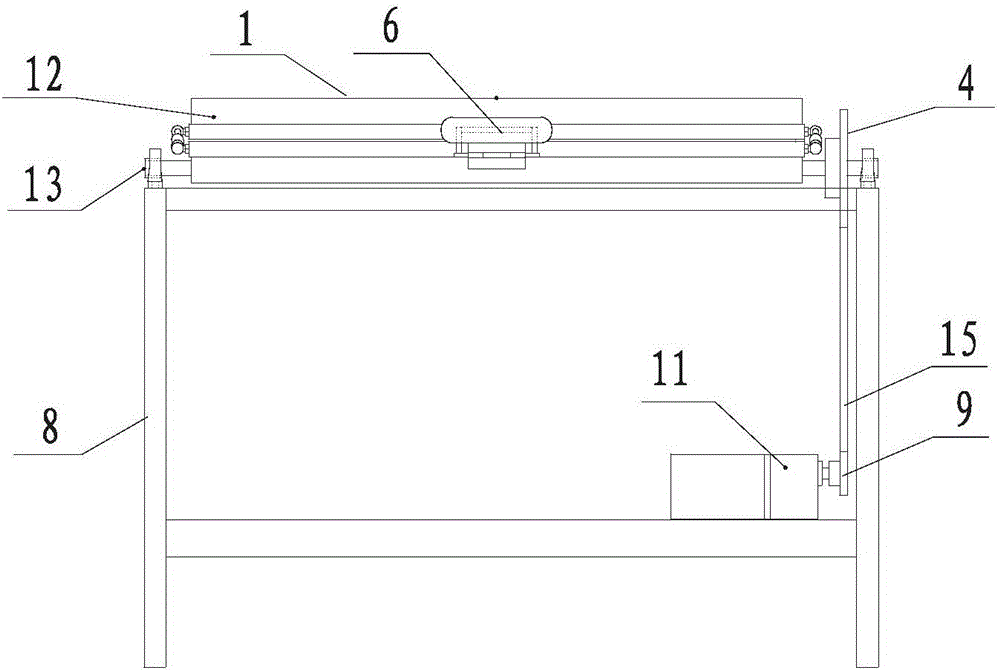

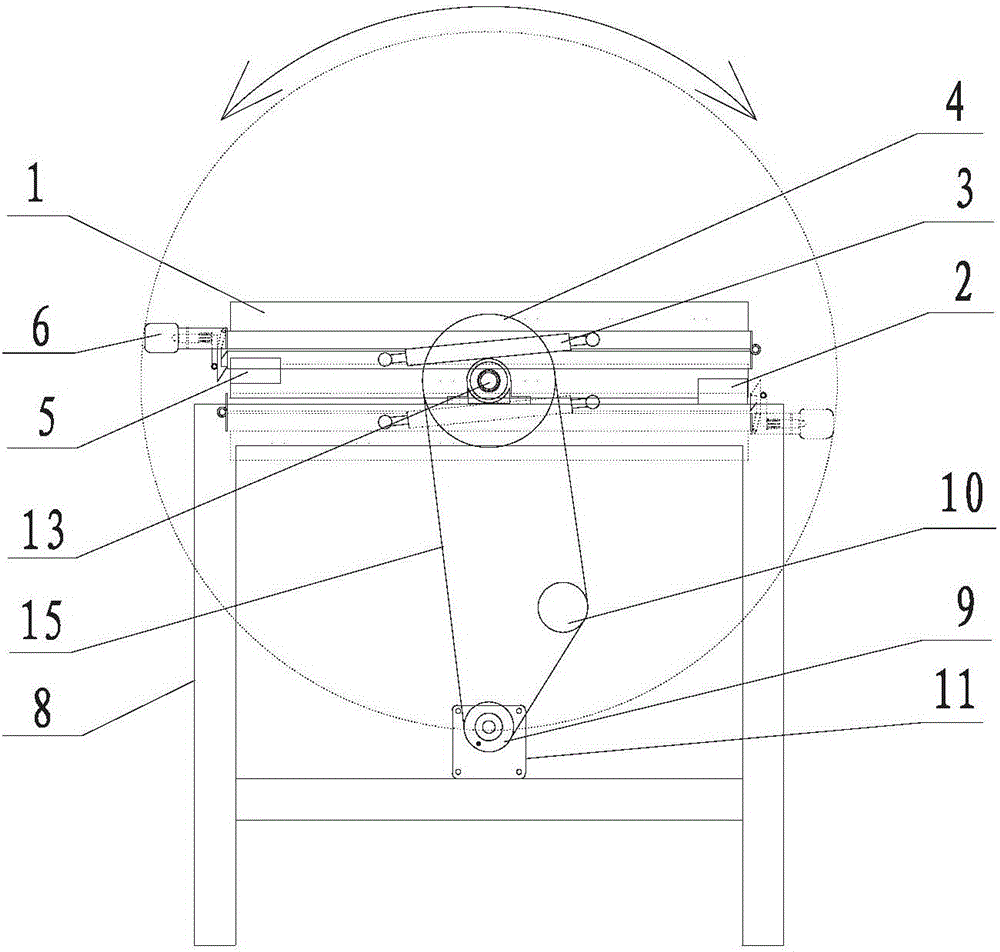

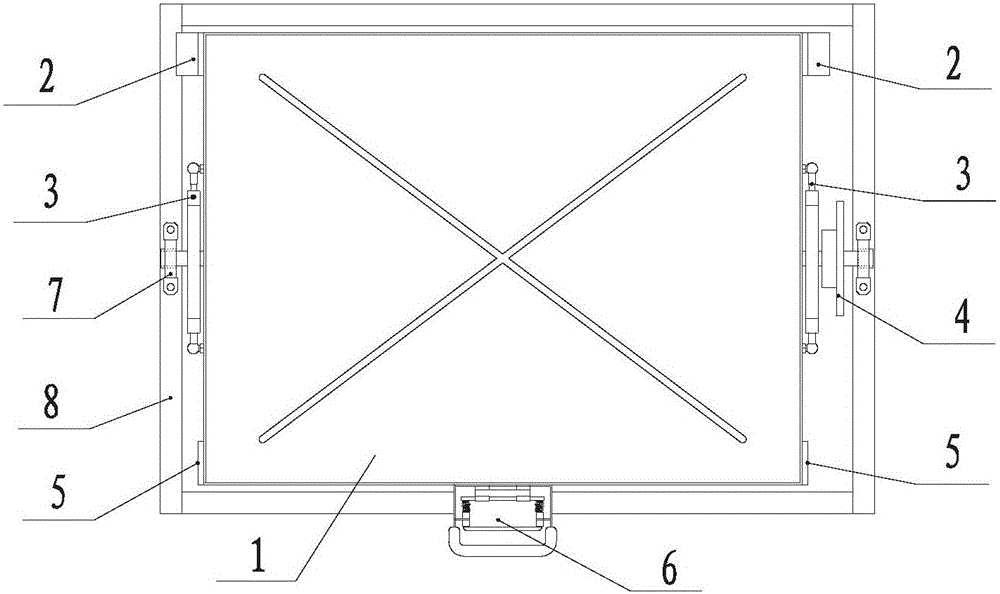

Full-automatic overturning type electric baking pan

The invention relates to an electric baking pan for food baking, particular to a full-automatic overturning type electric baking pan comprising an electric baking pan body, a clutch unit, a main body frame, a rotating shaft, and a drive unit. Two ends of the rotating shaft can be installed on the main body frame rotatably; and one end of the rotating shaft is connected with the drive unit installed on the main body frame. The electric baking pan body is fixedly arranged on the rotating shaft and can overturn with the rotating shaft. The clutch unit is arranged between the electric baking pan body and the main body frame and is used for controlling the freedom of the electric baking pan body. The provided full-automatic overturning type electric baking pan has the following beneficial effects: the structure is simple; the electric baking pan can be overturned automatically; the manpower and cost can be saved; and the full-automatic food baking can be realized.

Owner:贾连波

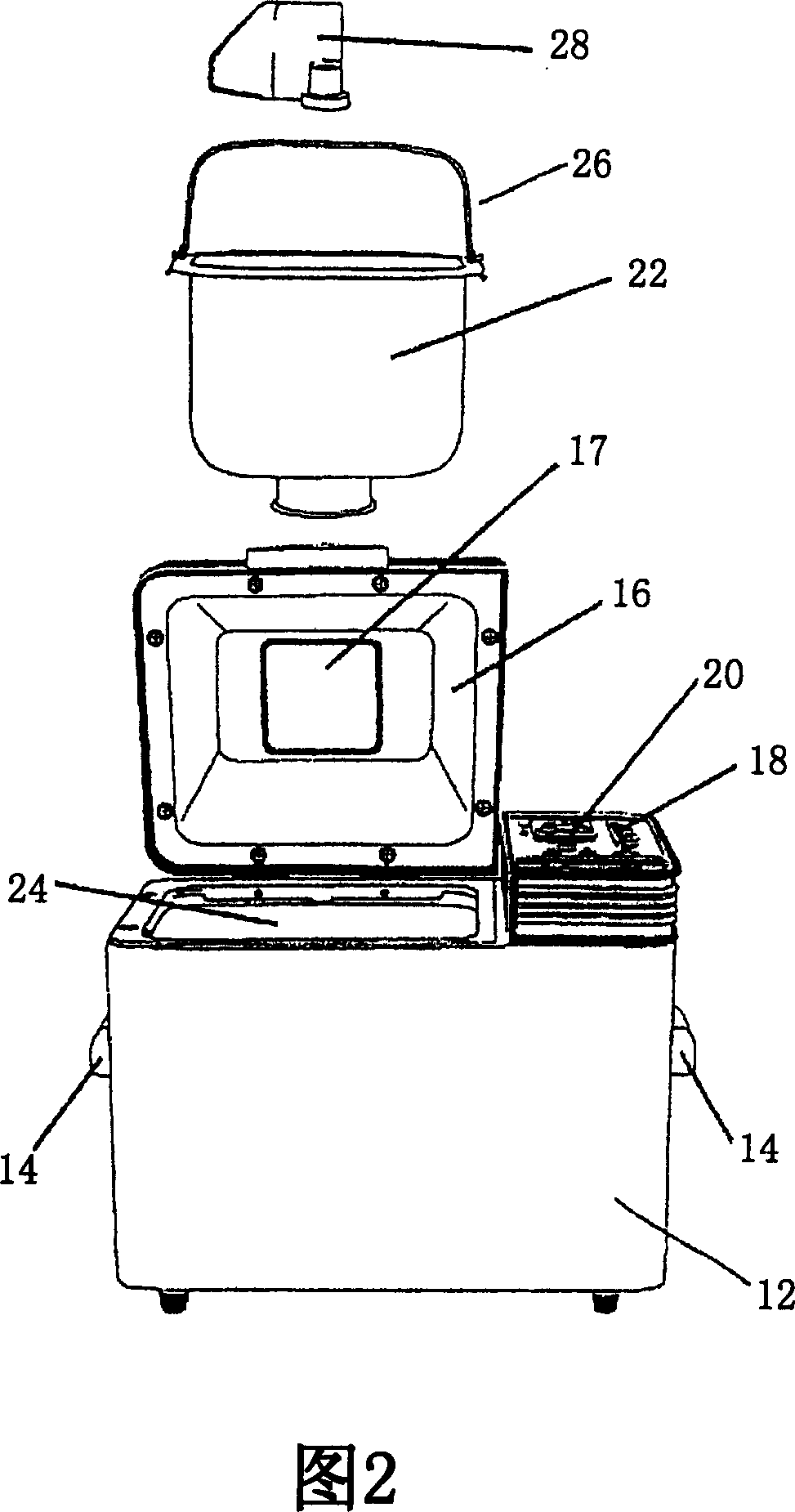

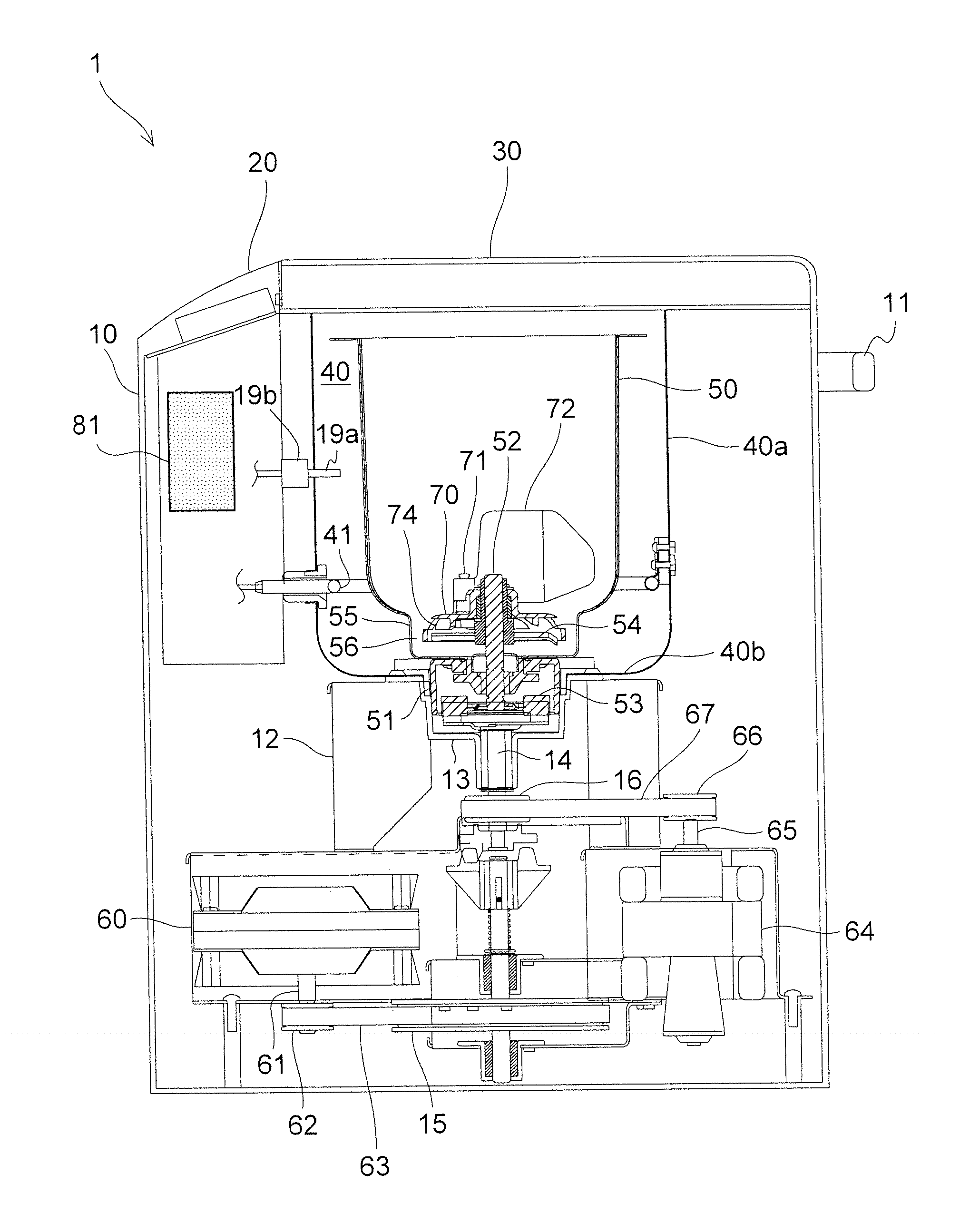

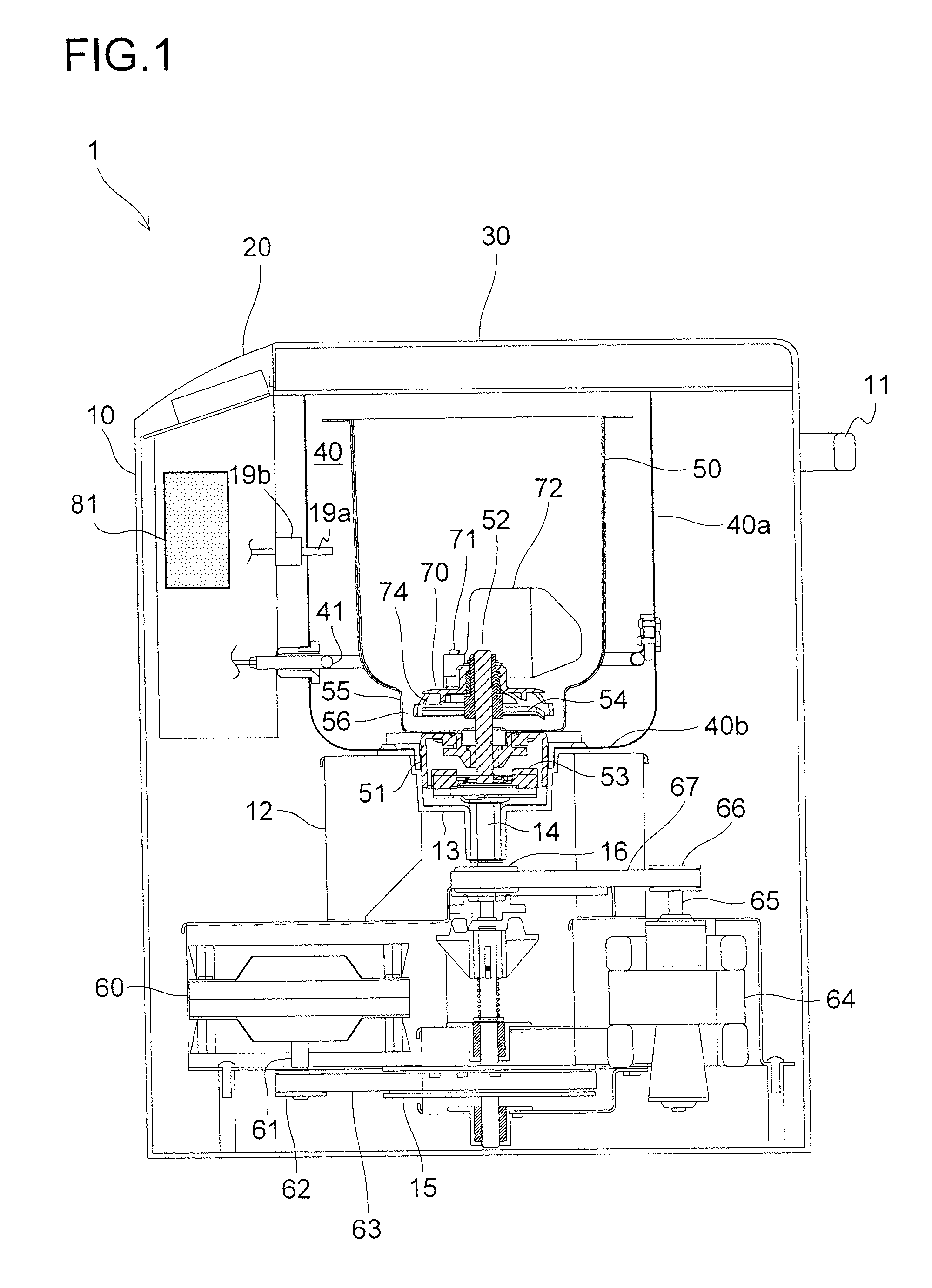

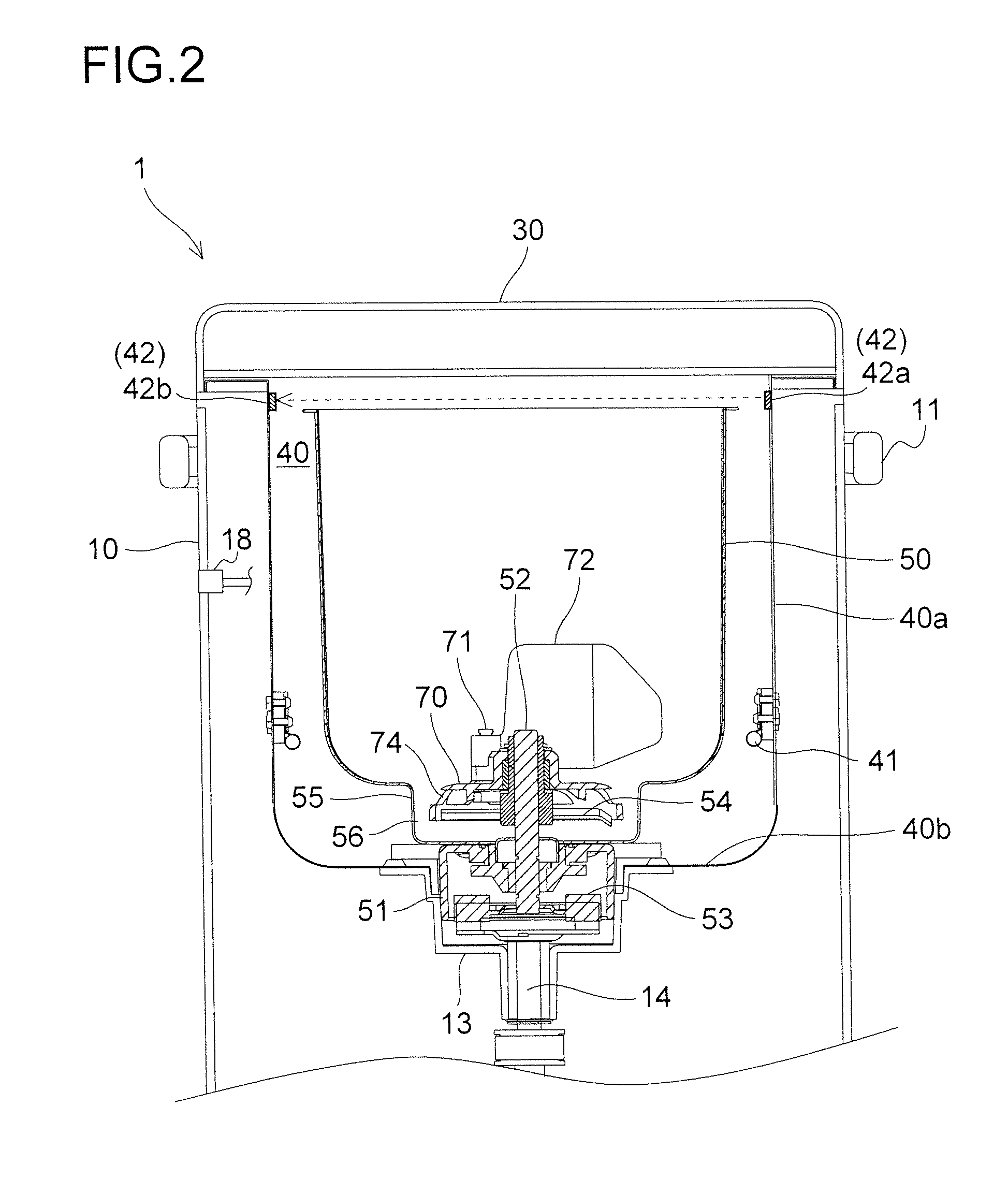

Automatic bread maker

InactiveUS20110174169A1Reduce the possibilityMinimize excessive risingKitchen fruit stoningFruit coringEngineeringMechanical engineering

An automatic bread maker comprises a container in which bread ingredients are fed; a body for accommodating the container; a control unit for carrying out bread-making steps in a state in which the container is accommodated in the body; and a rise detector for detecting that dough has risen to a prescribed height from an upper surface of the container in a state in which the container is accommodated in the body.

Owner:SANYO ELECTRIC CO LTD +1

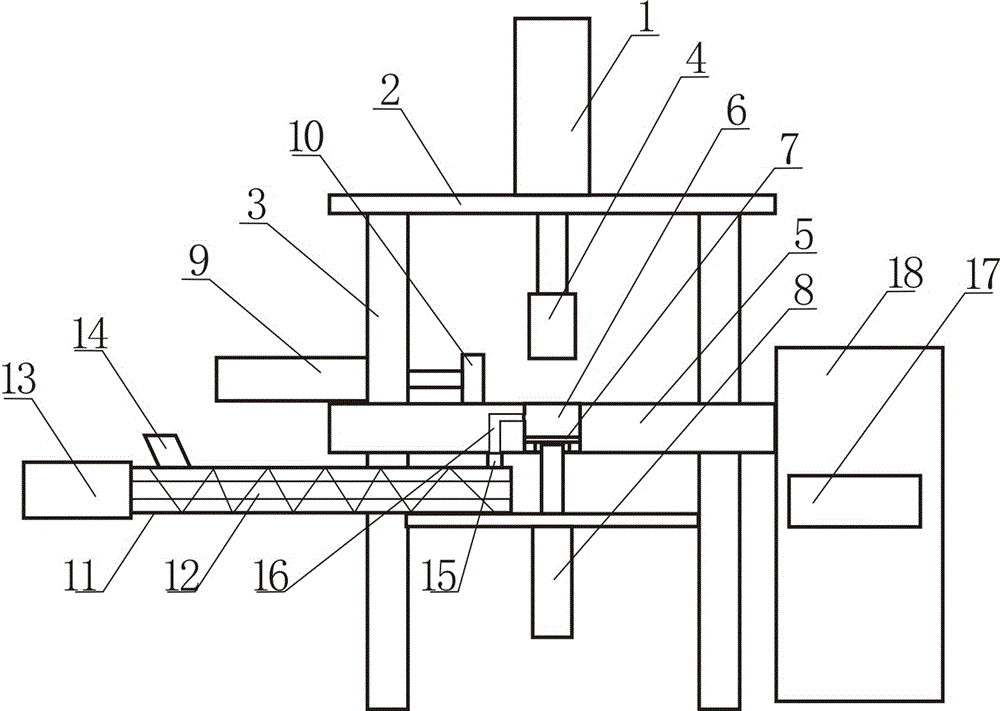

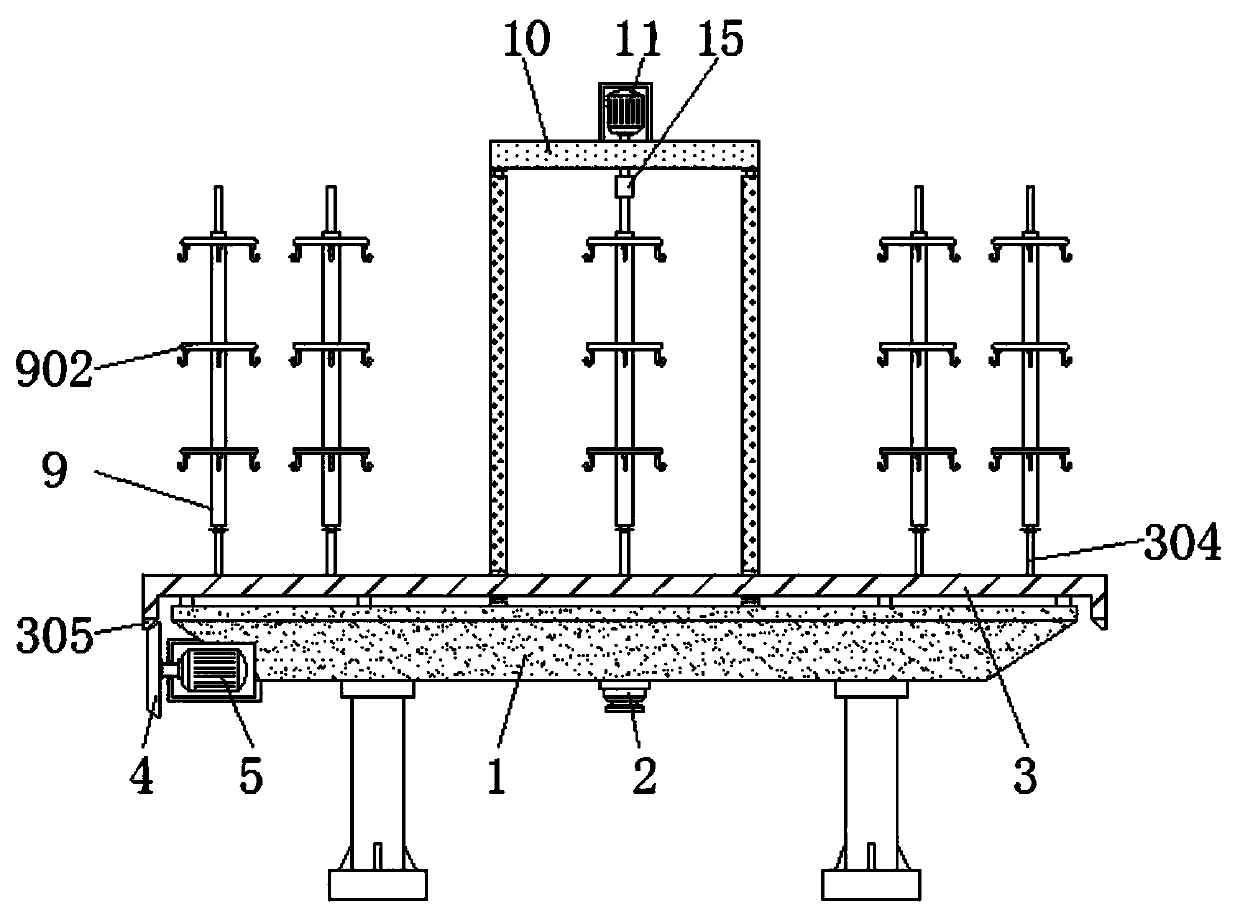

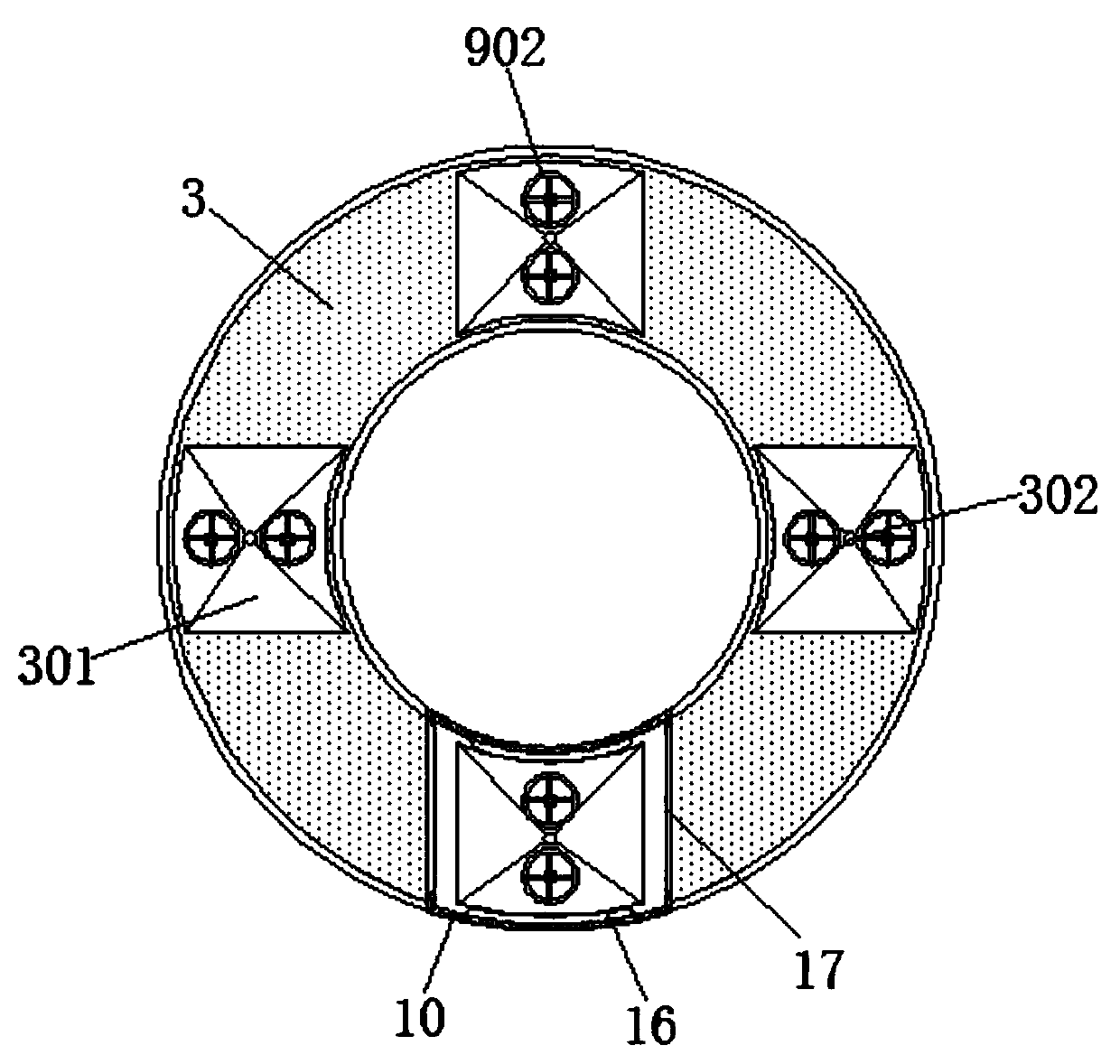

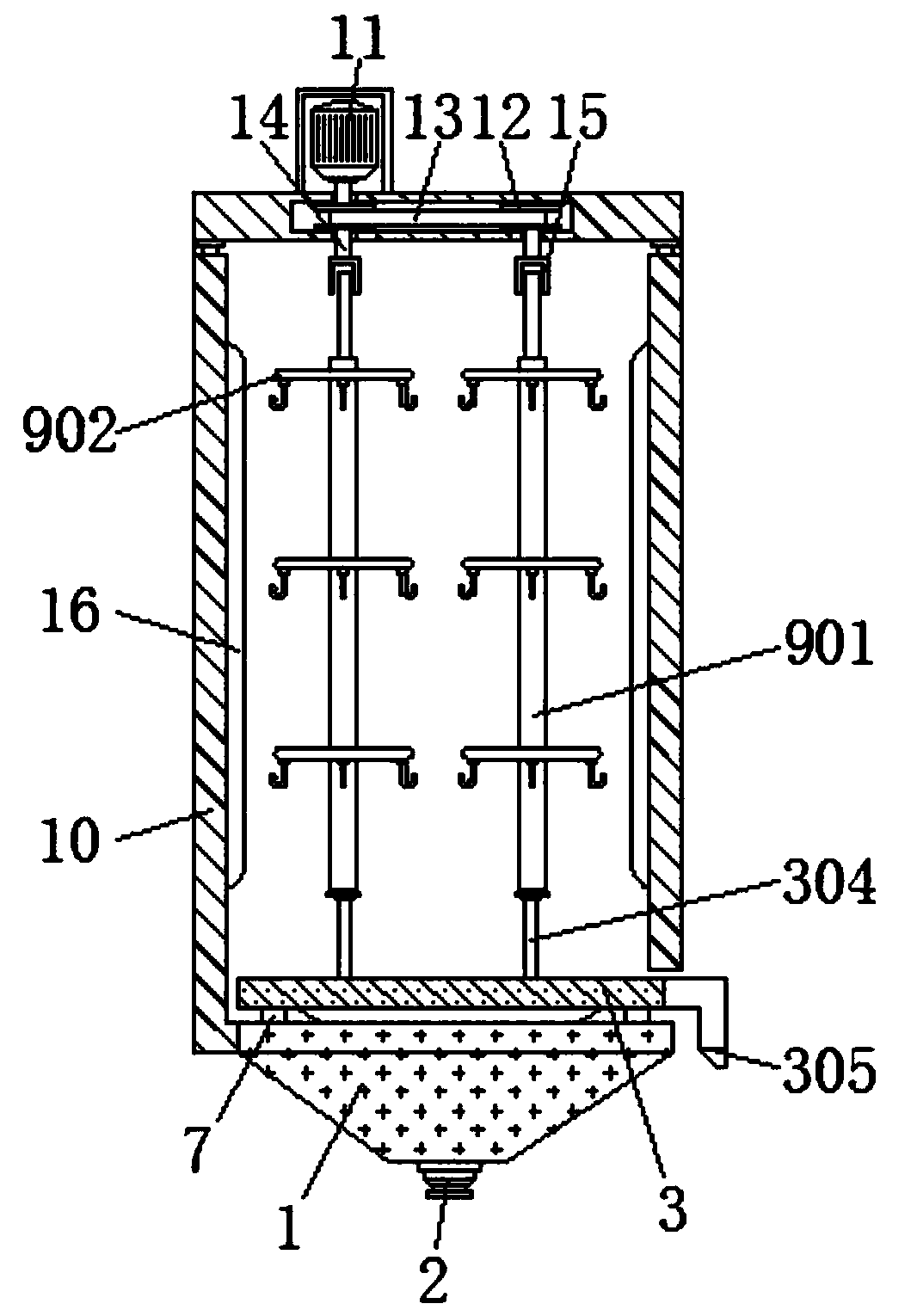

Commercial charcoal fire full-automatic lamb leg roasting furnace

InactiveCN105248492AUniform extrusion forceNot easy to evaporateClimate change adaptationBaking ovenCooking & bakingFurnace temperature

The invention discloses a commercial charcoal fire full-automatic lamb leg roasting furnace and belongs to the field of food baking equipment. The commercial charcoal fire full-automatic lamb leg roasting furnace is characterized by solving problems that (1) charcoal fire intensity a present charcoal fire automatic lamb leg roasting furnace has to be manually adjusted, so food cannot be baked by optimal baking fire; (2) during the baking, blood in blood vessels of the lamb leg cannot be discharged and fat oil cannot be easily eliminated; (3) and the present charcoal fire automatic lamb leg roasting furnace has low energy utilization rate, unstable roasted lamb leg, inadequate high quality and low automatic degree as well as labor use waste. To solve the above problems, a cylindrical sealed hearth is employed; the top of the hearth is provided with a cylindrical rotating disc; the periphery of the rotating disc downwardly extends tens of output shafts synchronously rotating; the output shafts rotate and drive a lamb leg invertedly hung on the output shafts to synchronously revolve and rotate surrounding a charcoal fire furnace in the center of the bottom of the hearth, so all sides of the lamb leg can be evenly baked; and the charcoal fire intensity can be automatically adjusted according to changes of furnace temperature detected by an intelligent circuit and control of rotating speed of an air blower and an induced draft fan.

Owner:徐东钦

Method for making convenient wontons and dumplings

InactiveCN101623066APreserve the flavorKeep tendonsDough treatmentPreservation by heat treatmentCooking & bakingFood material

The invention relates to a method for making convenient wontons and dumplings, which comprises the following steps: wrapper making, stuffing making, forming, dehydration, sterilization, cooking, and packaging. The dehydration, sterilization and cooking step comprises the following steps: placing the formed wontons and dumplings into a baking oven; setting the oven temperature between 120 and 160 DEG; setting the baking time between 8 and 20 minutes; and directly carrying out the dehydration, sterilization and cooking. Because the formed wontons and dumplings are directly dehydrated, sterilized and cooked, the fresh fragrant characteristics of food materials self are completely retained. The baking process ensures that the wontons and dumplings have fragrance similar to that of fried food, and overcomes the defects of high grease and dryness heat of the fried food at the same time. After the wontons and dumplings are mixed with boiling water, the pliability of wrappers are completely retained because of one-time soaking, and the wontons and the dumplings have sufficient chewing force and good mouthfeel.

Owner:郑建伟 +1

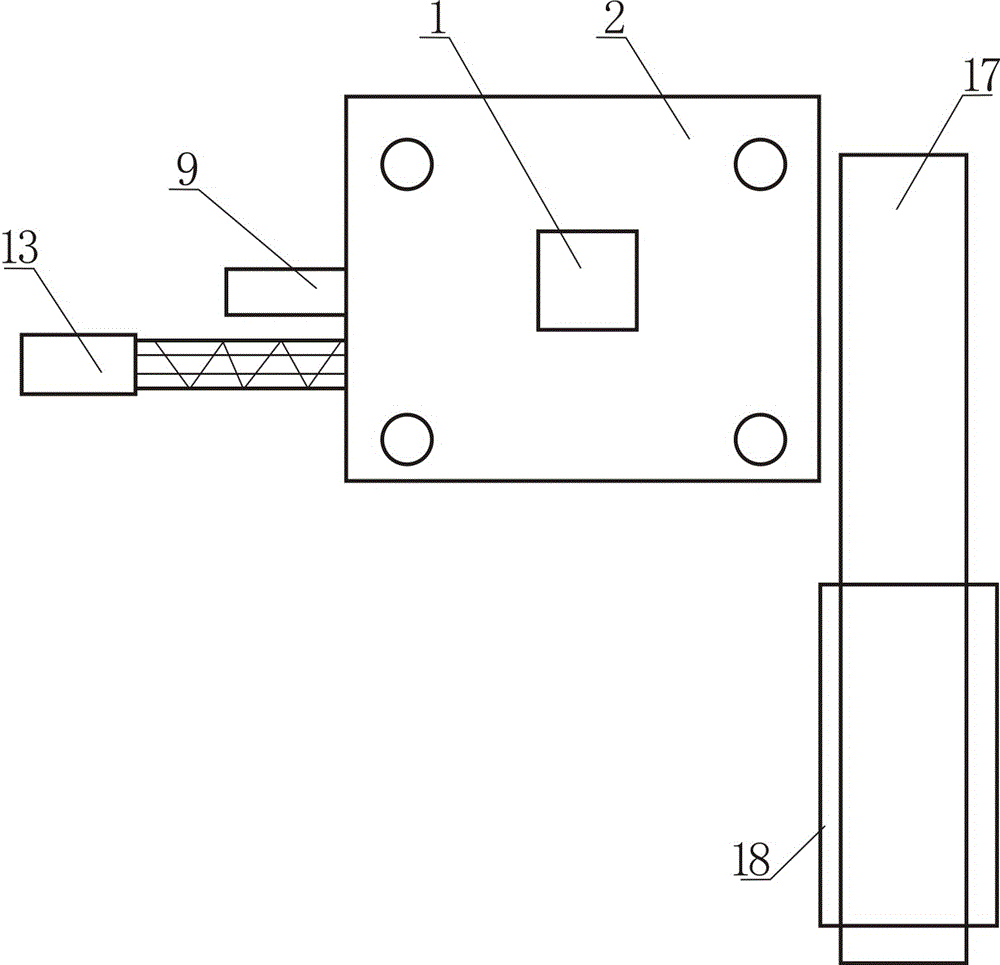

Cookie filling molding and roasting machine

InactiveCN106723243AWith compression moldingFunctionalFood shapingSpecial goods bakingCompression moldingConveyor belt

The invention discloses a cookie filling molding and roasting machine. The cookie filling molding and roasting machine comprises a supporting frame, a pressing air cylinder, a mold head, a mold cylinder, a movable template, a lifting air cylinder, a shaping and supporting working table, a horizontal pushing air cylinder, a push plate, a conveyer belt and a drying oven, wherein the horizontal pushing air cylinder is arranged on the shaping and supporting working table; the push plate is arranged at the end part of a piston rod of the pressing air cylinder, and is located on the shaping and supporting working table; the conveyer belt is arranged on one side of the shaping and supporting working table; the horizontal pushing air cylinder is used for pushing the push plate; the push plate is used for pushing compression molded cookie filling to the conveyer belt; and the conveyor belt is used for conveying the compression molded cookie filling into the drying oven, and the drying oven is used for baking the compression molded cookie filling to obtain cooked cookie filling. The cookie filling molding and roasting machine disclosed by the invention has double functions of performing compression molding and baking the compression molded cookie filling to obtain the cooked cookie filling; and the lifting air cylinder is utilized for upwards lifting the movable template, so that the compression molded cookie filling can be conveniently ejected out of the mold cylinder, and the cookie filling molding and roasting machine has the characteristic of being high in working efficiency.

Owner:高州市创盟科技有限公司

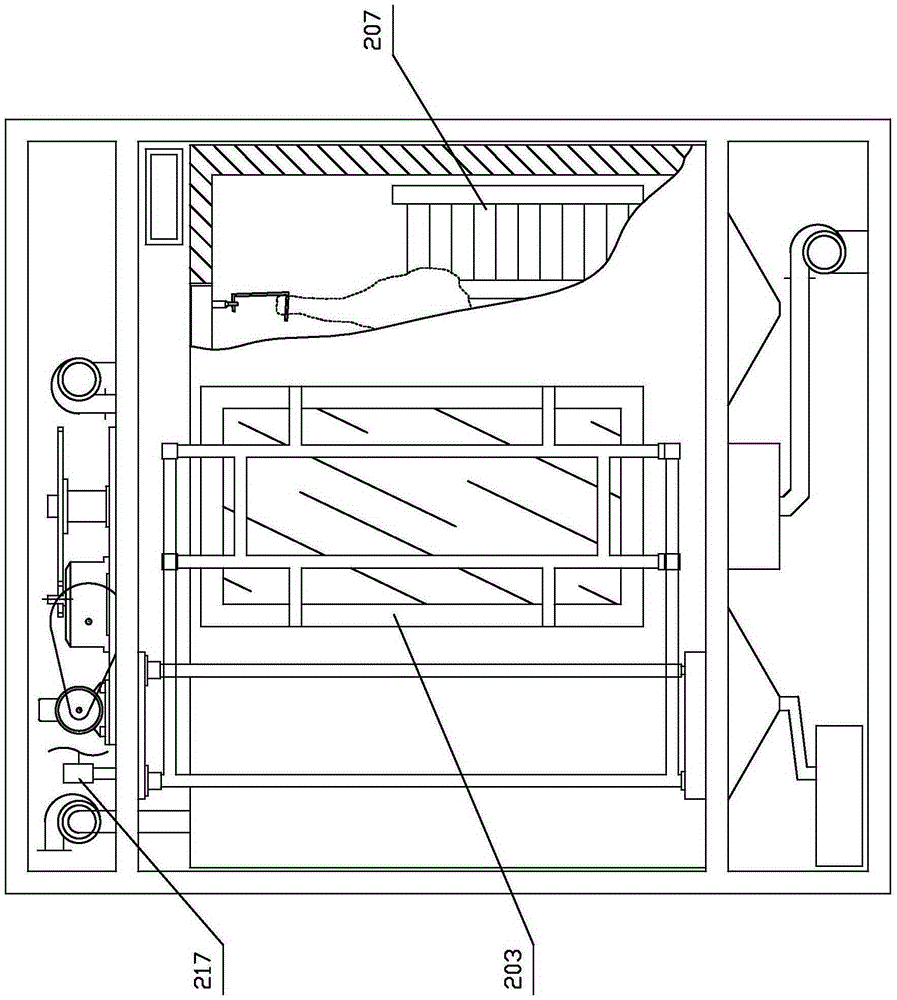

Continuous egg product baking manufacturing machine

ActiveCN103229788AAchieve continuous bakingEvenly bakedSpecial goods bakingCooking & bakingEgg product

The invention relates to a continuous egg product baking manufacturing machine which is characterized by comprising a baking device. The baking device comprises a baking conveying line, a baking heat-preserving cover covered outside part of or all of the baking conveying line and more than one group of baking heating assemblies located in the baking heat-preserving cover and arranged along the conveying direction of the baking conveying line. The continuous egg product baking manufacturing machine can be used for continuous baking.

Owner:福州闽台机械有限公司

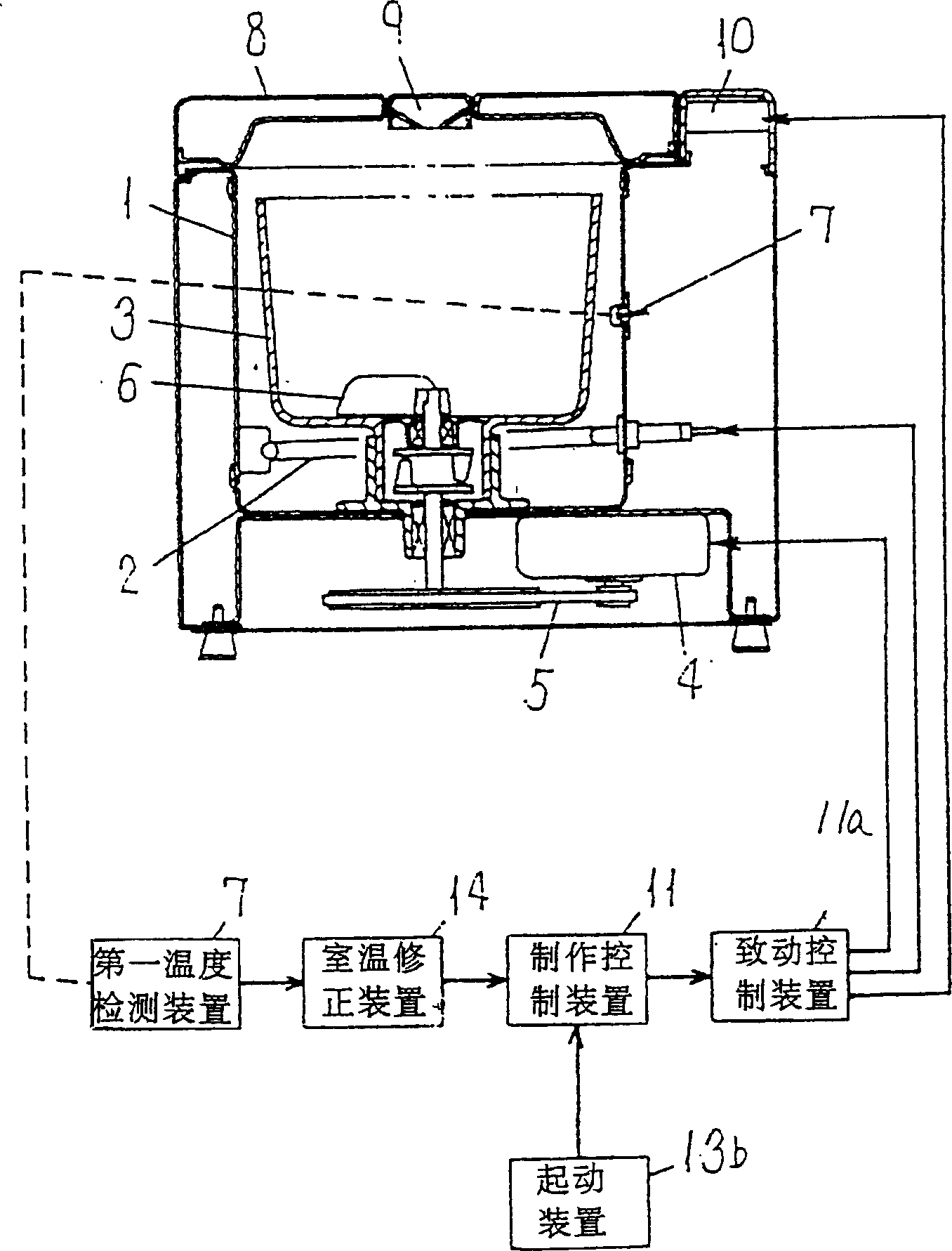

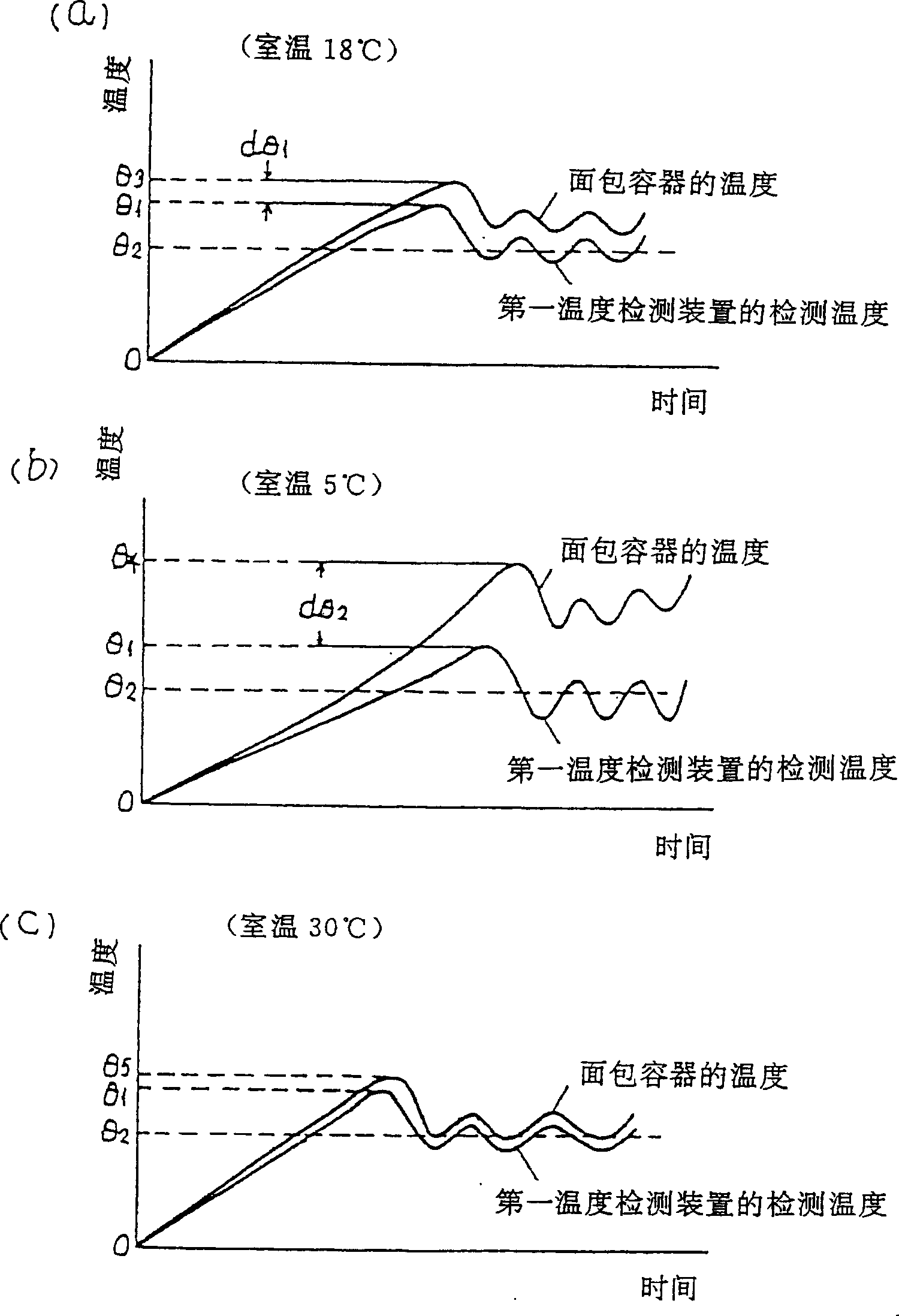

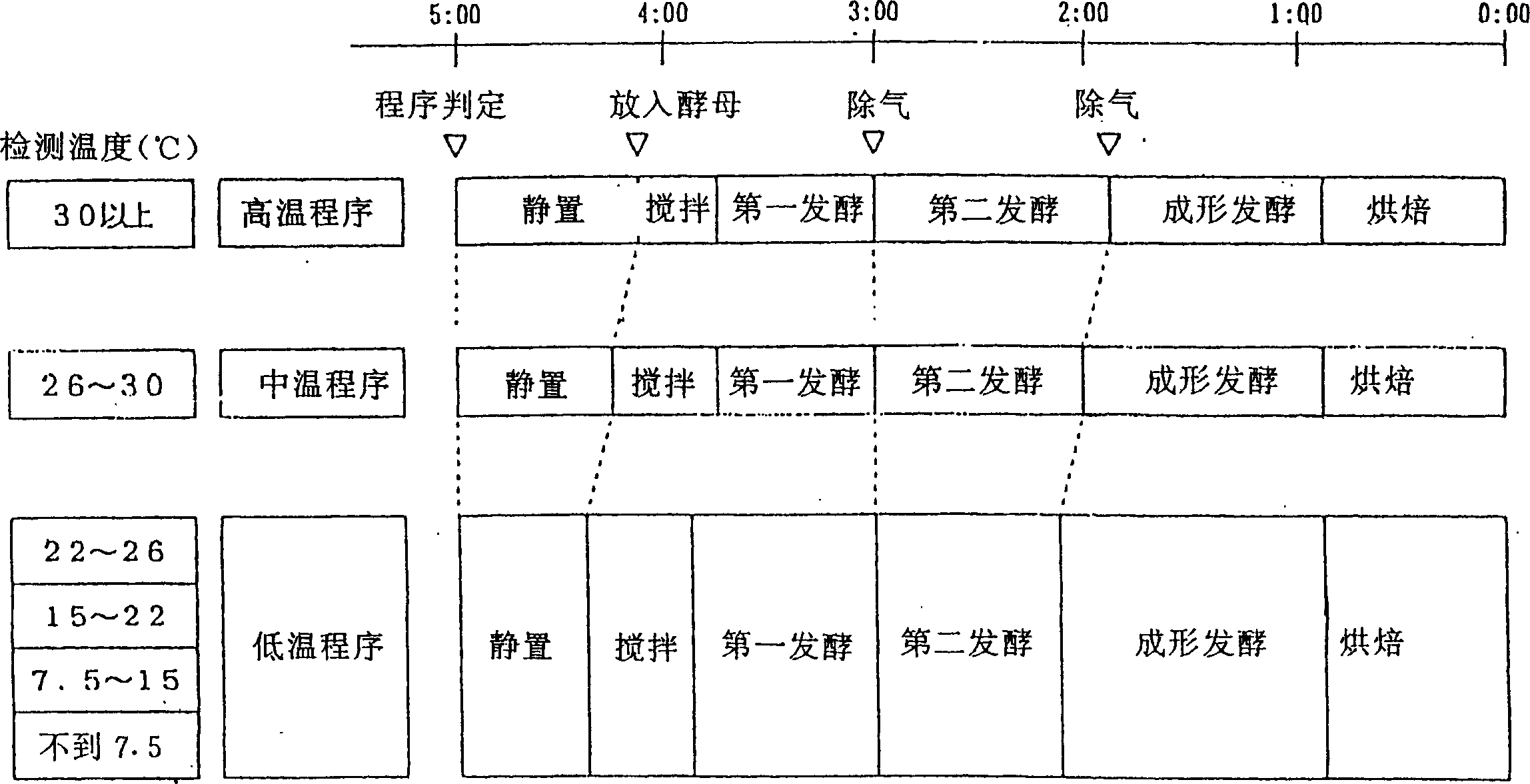

Automatic bread producing machine

InactiveCN1846583AGood correction valueReasonable temperature controlBread-toastersSpecial goods bakingTemperature controlRoom temperature

An automatic bread machine, which detects the temperature in the baking room to control the temperature of the bread container in the baking room, which can prevent the temperature of the bread container from being incorrectly detected due to the influence of the room temperature, and make the finished bread in good shape. It includes: a first temperature detection device (7) for detecting the temperature in the baking chamber (1); a room temperature correction device (14) for correcting the temperature measured by the detection device (7) according to the room temperature; The process control temperature is compared to control the production control device of the heating capacity of the heater (2) in each process.

Owner:PANASONIC CORP

Roaster for roasting whole lamb

The invention discloses a roaster for roasting a whole lamb, belonging to a roaster. The structure comprises a roaster body, an electric heating pipe, an inserted link, an inserted link exploratory hook, an inserted link rotation driving device and a roasting tray, wherein the front side of the roaster body is provided with a front door; an inspection window is arranged on the front door; the top part of the roaster body is provided with an air outlet while the side of the lower part is provided with an air inlet; an electric controller and a display are arranged on the roaster body of the upper part of the front door; the electric heating pipe is electrically connected with the electric controller and the display; a layer of refractory bricks are respectively arranged on the top surface, bottom surface, left surface, right surface and back surface of the roaster body; the inserted link is tipsily arranged on a base of the roaster body; one end of the inserted link is connected with the inserted link rotation driving device, the other end of the inserted link is connected with the inserted link exploratory hook; the lower part of the inserted link is provided with the roasting tray; and the top surface of the roasting tray is tipsily arranged in the direction of the inserted link. The roaster provided by the invention has the following characteristics that a lamb body is heated uniformly, the grease is unlikely to drop on charcoals, harmful gas and food pollution are avoided, the smoking time to lamb in a charcoal roasting process is reduced and the like.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI +1

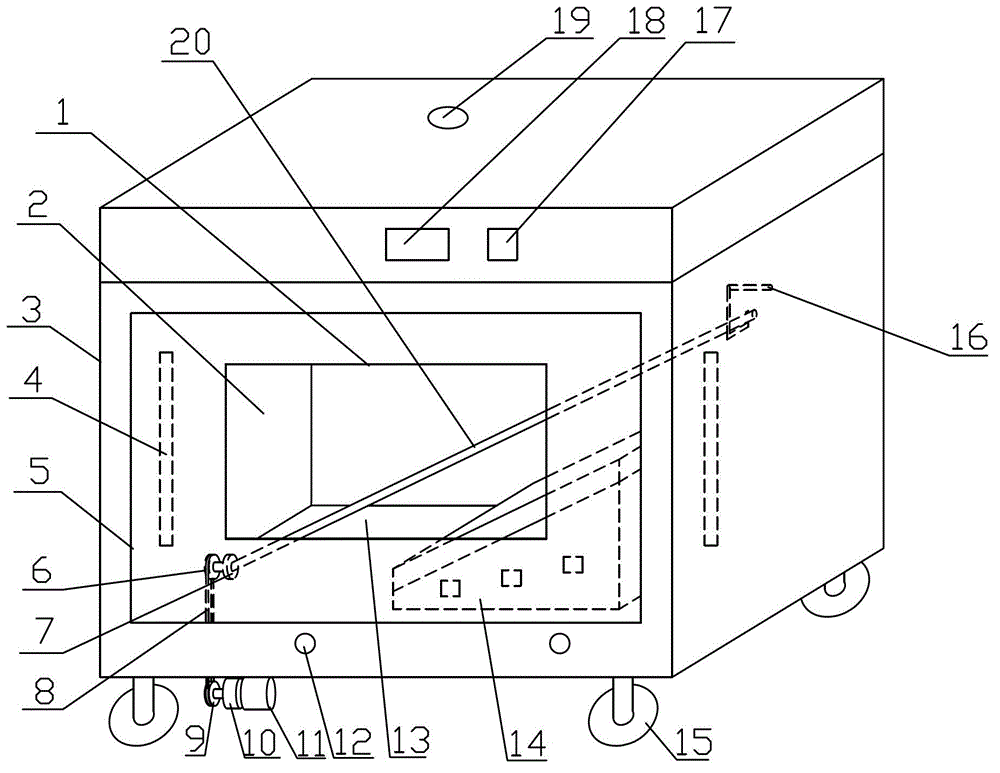

Baking device for pressed spicy salted duck processing convenient for centralized loading and unloading

ActiveCN109832307AConvenient centralized loading and unloadingEasy accessCharging/discharging ovensSpecial goods bakingDrive wheelGear wheel

The present invention discloses a baking device for pressed spicy salted duck processing convenient for centralized loading and unloading. The baking device comprises a supporting bracket, a first motor, a second motor and baking lamps, a material discharge opening is formed in a lower side of the supporting bracket, besides, a drive plate is arranged at an upper side of the supporting bracket, abevel gear is arranged a left side of the supporting bracket, connecting grooves are formed in the supporting bracket, besides, insides of the connecting grooves are provided with connecting rings, vertical shafts are arranged under driving wheels, besides, the vertical shafts are located inside a baking oven, besides, lower sides of the vertical shafts are connected with clamping pieces, the baking lamps are located inside the baking oven, and besides, the baking oven is provided with oven doors. The baking device for the pressed spicy salted duck processing convenient for the centralized loading and unloading can hang pressed spicy salted ducks needing to be baked in batches on baking brackets, thus is convenient for the drive plate to drive the pressed spicy salted ducks on the baking brackets successively into the baking oven to be baked, reduces labor intensity of workers and at the same time can also prevent the workers from being harmed by high temperatures in the baking oven during the work process.

Owner:HUNAN UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com