Commercial charcoal fire full-automatic lamb leg roasting furnace

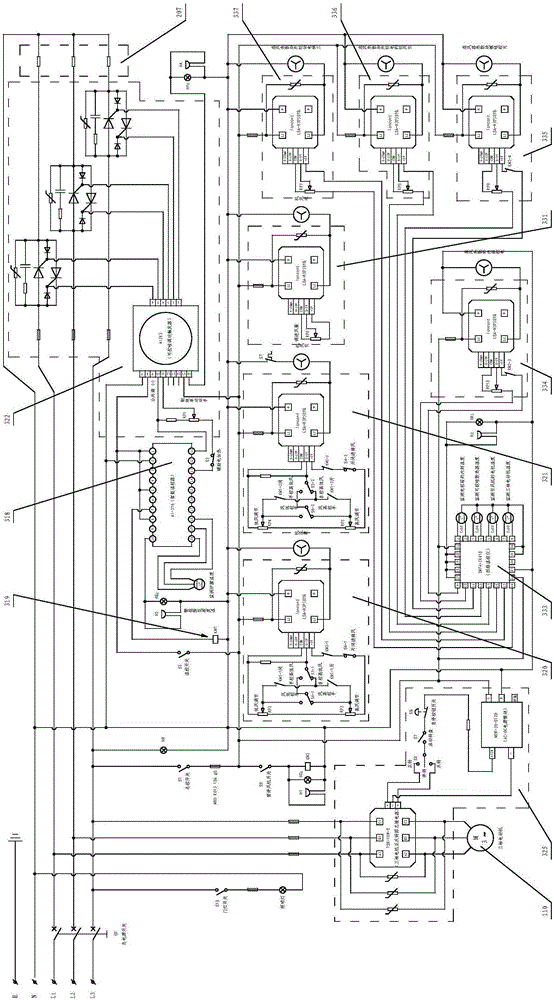

A fully automatic, charcoal-fired furnace technology, applied in food ovens, special commodity baking, baking, etc., can solve problems such as difficulty, low energy utilization rate, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

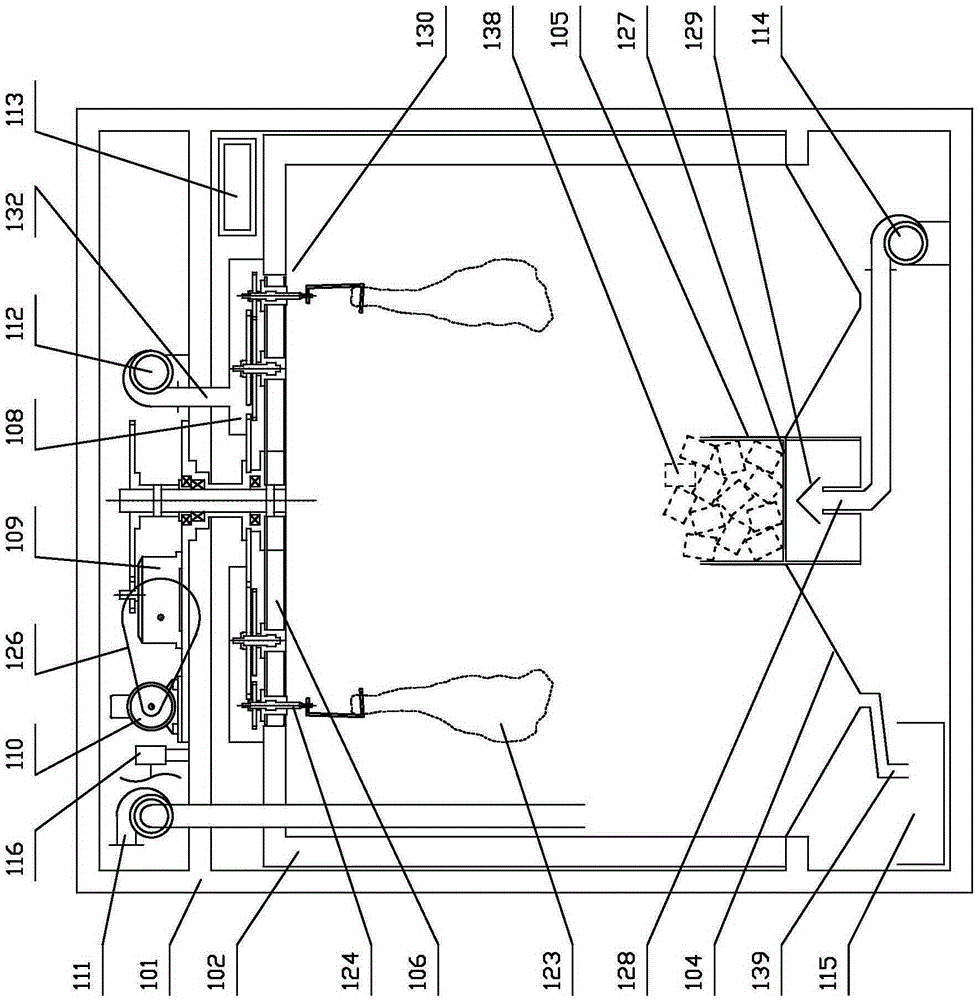

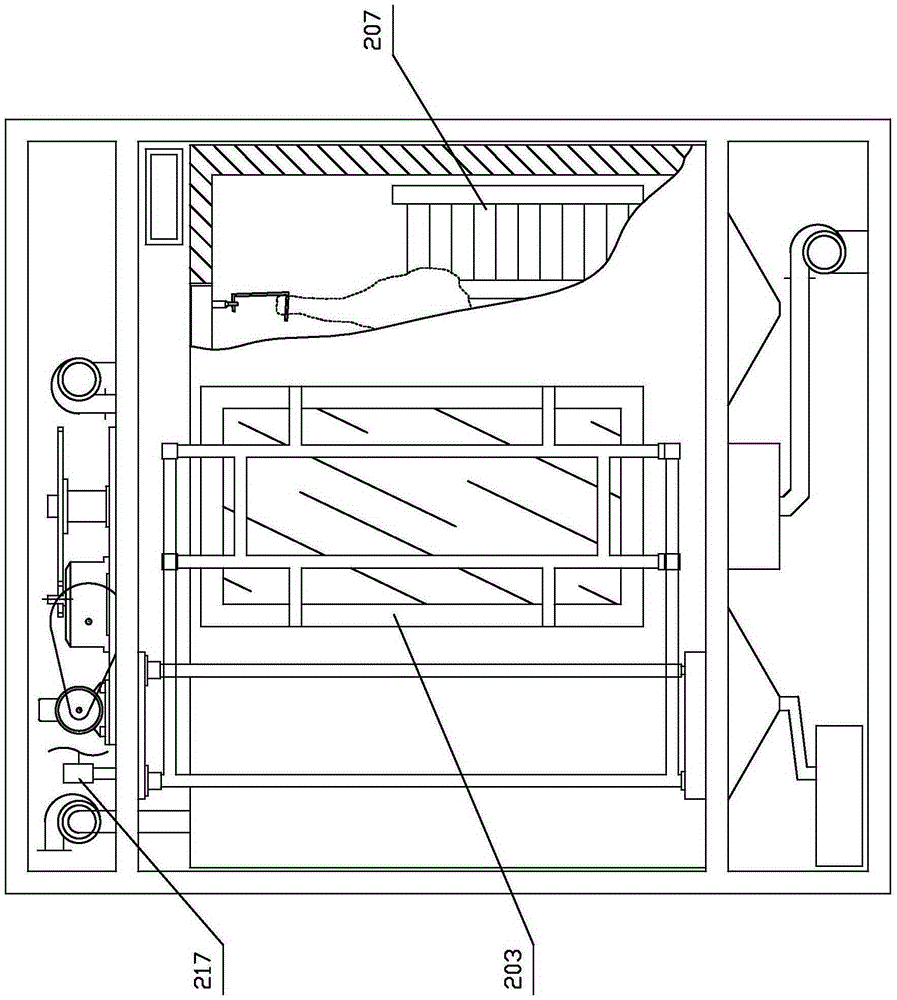

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] See figure 1 and figure 2 As shown, the commercial charcoal-fired full-automatic lamb leg oven disclosed by the present invention comprises: a body of furnace frame 101, which is the load-bearing frame of the whole body of furnace; The hearth door 203 on the wall, the annular funnel type oil receiving tank 104 and the charcoal stove 105 at the bottom of the hearth are formed by the rotating disk 106 at the top of the hearth; the electric heating tube group 207 is installed on the inside of the cylindrical furnace wall 102; the rotating disk 106 and The revolution and rotation mechanism 108 formed by it is installed on the top of the furnace and the top of the furnace body frame 101; what is installed on the top of the furnace body frame 101 is also a worm gear reducer 109, a three-phase motor 110, an induced draft fan 111, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com