Patents

Literature

144results about "Oven doors/gates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

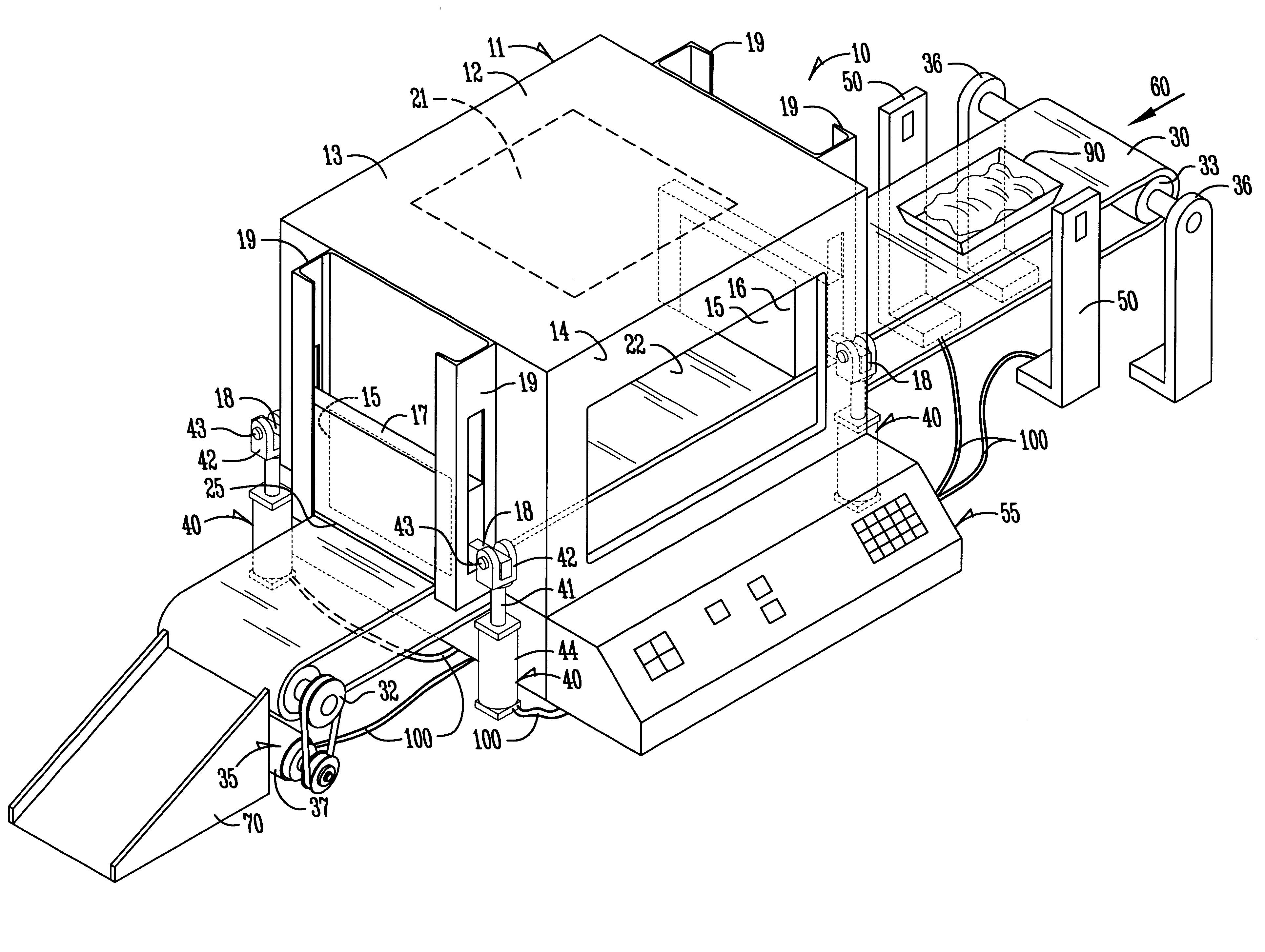

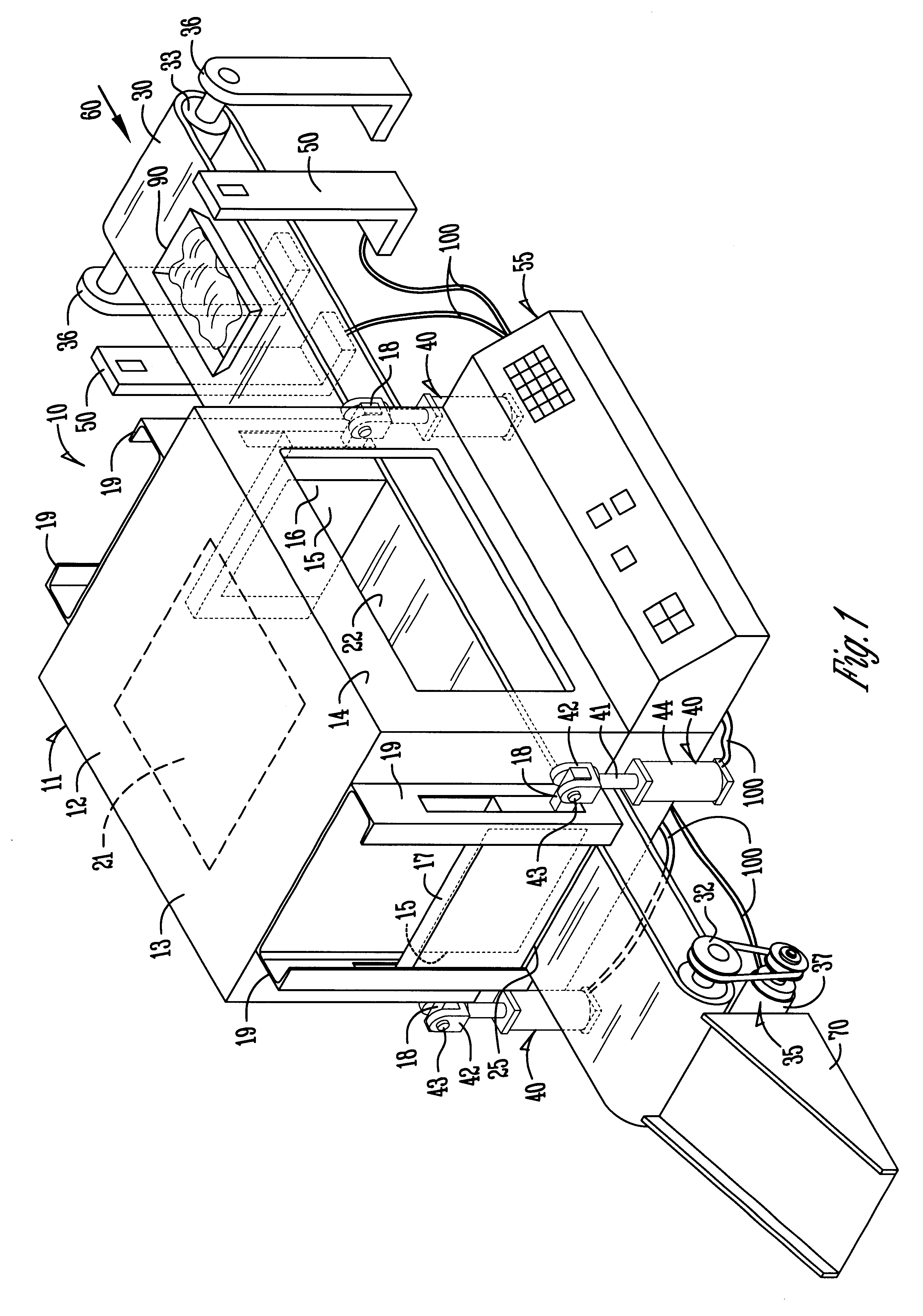

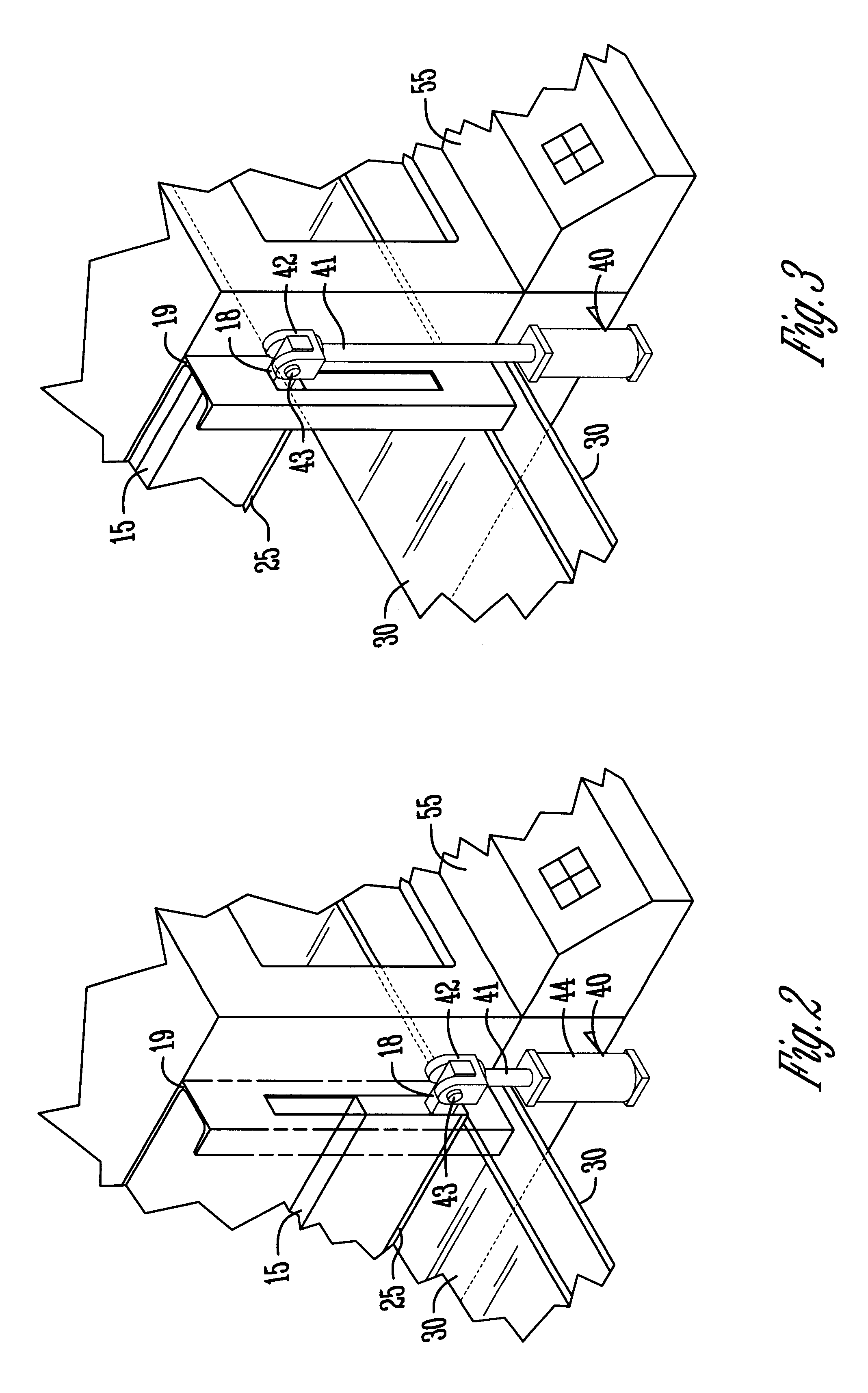

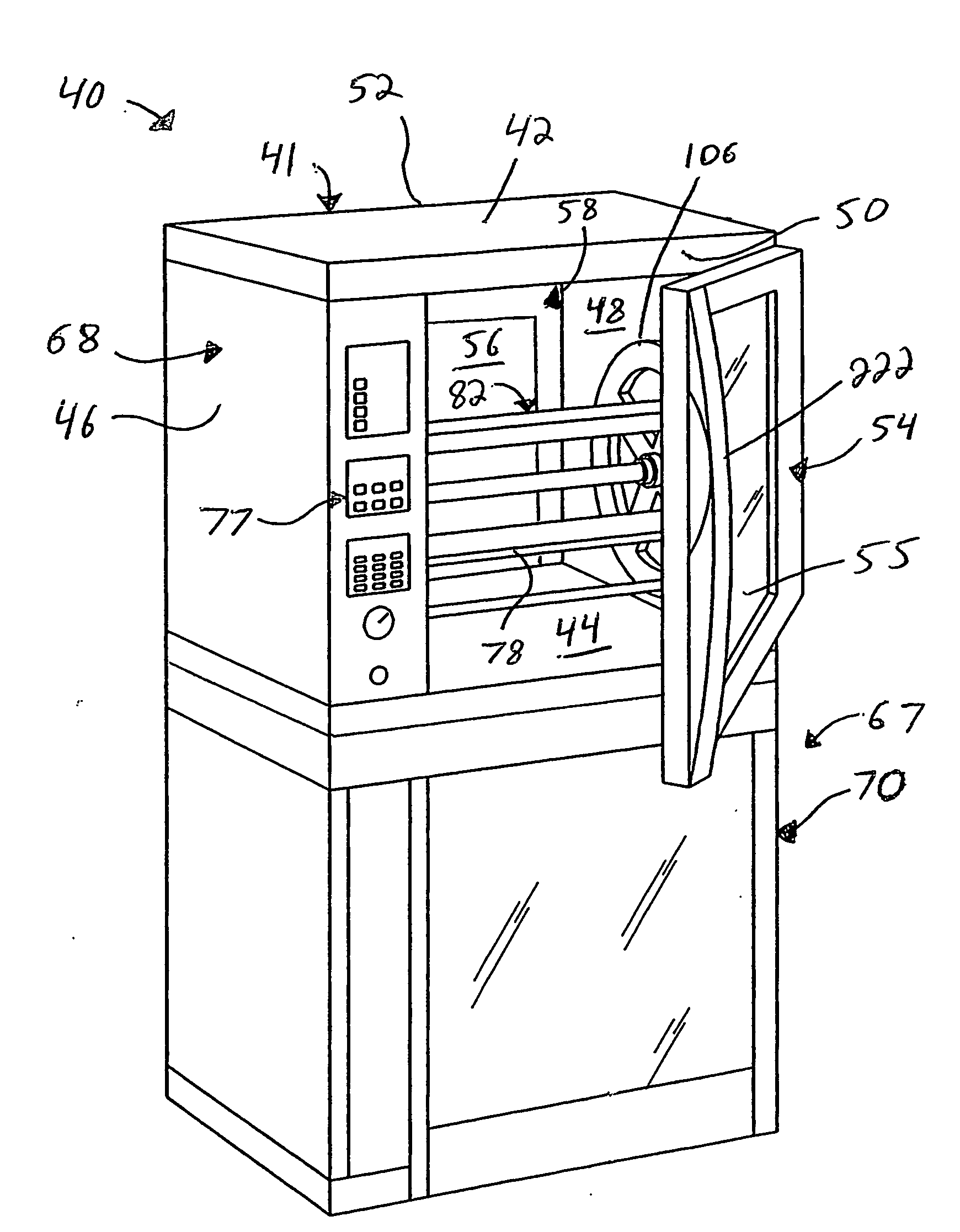

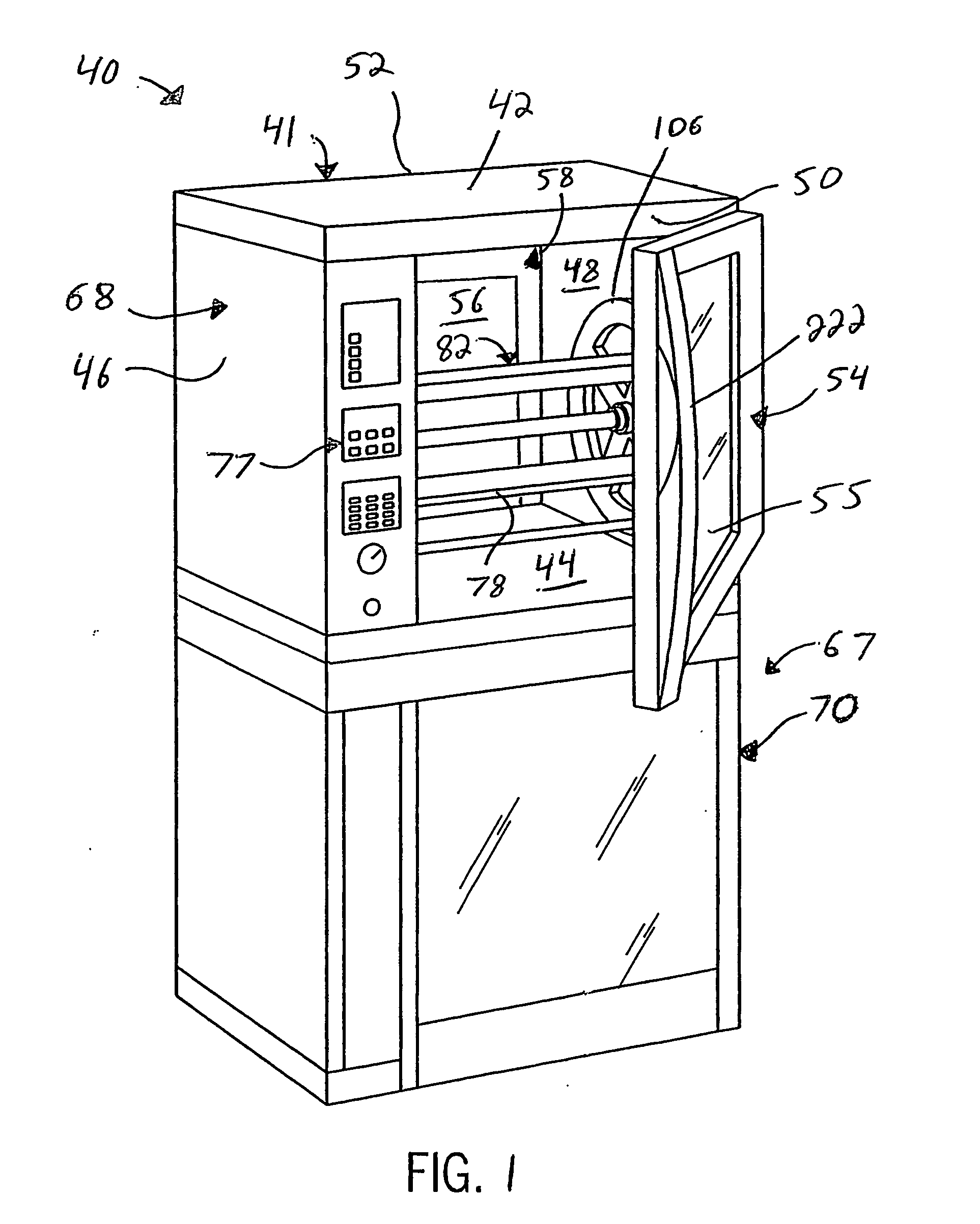

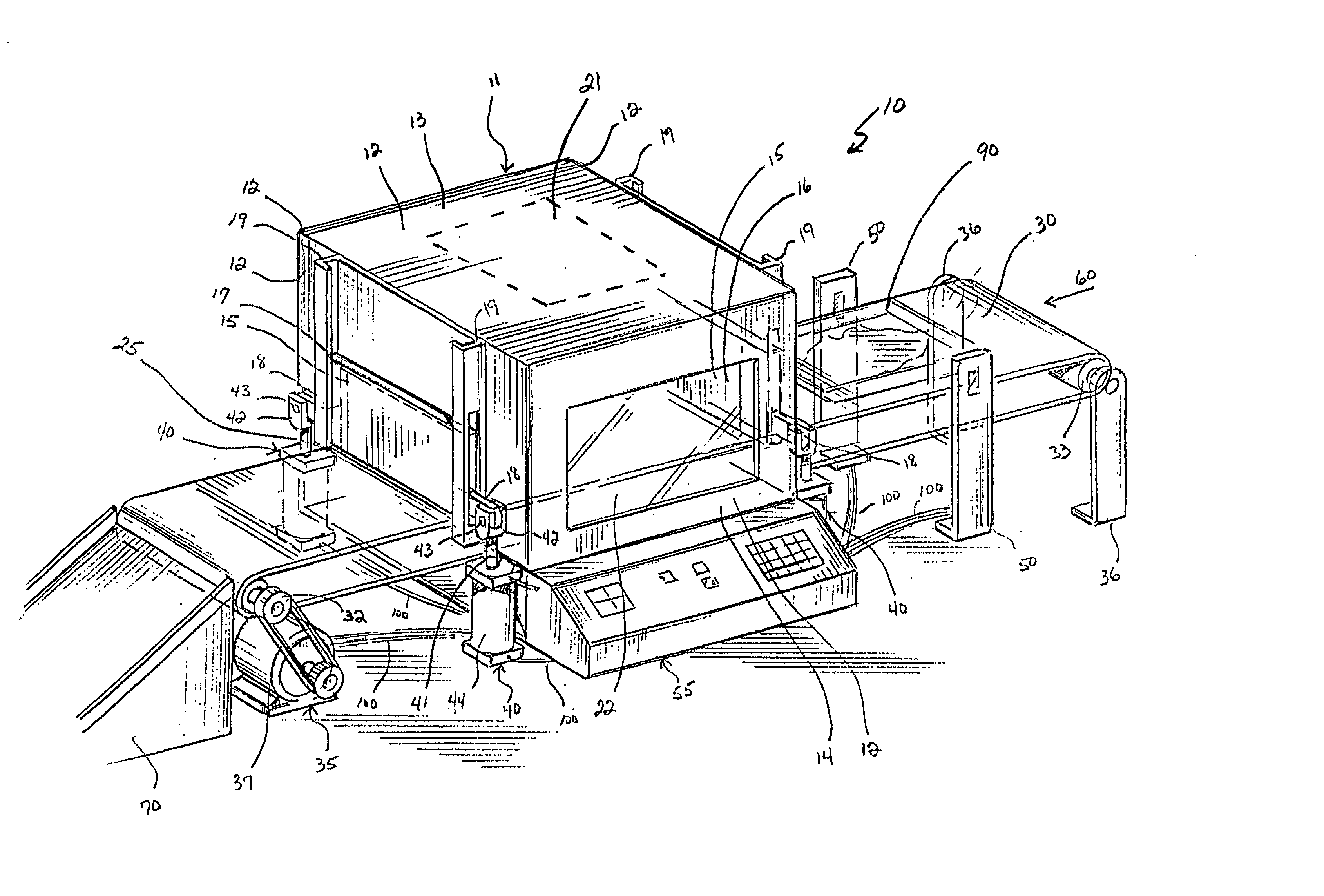

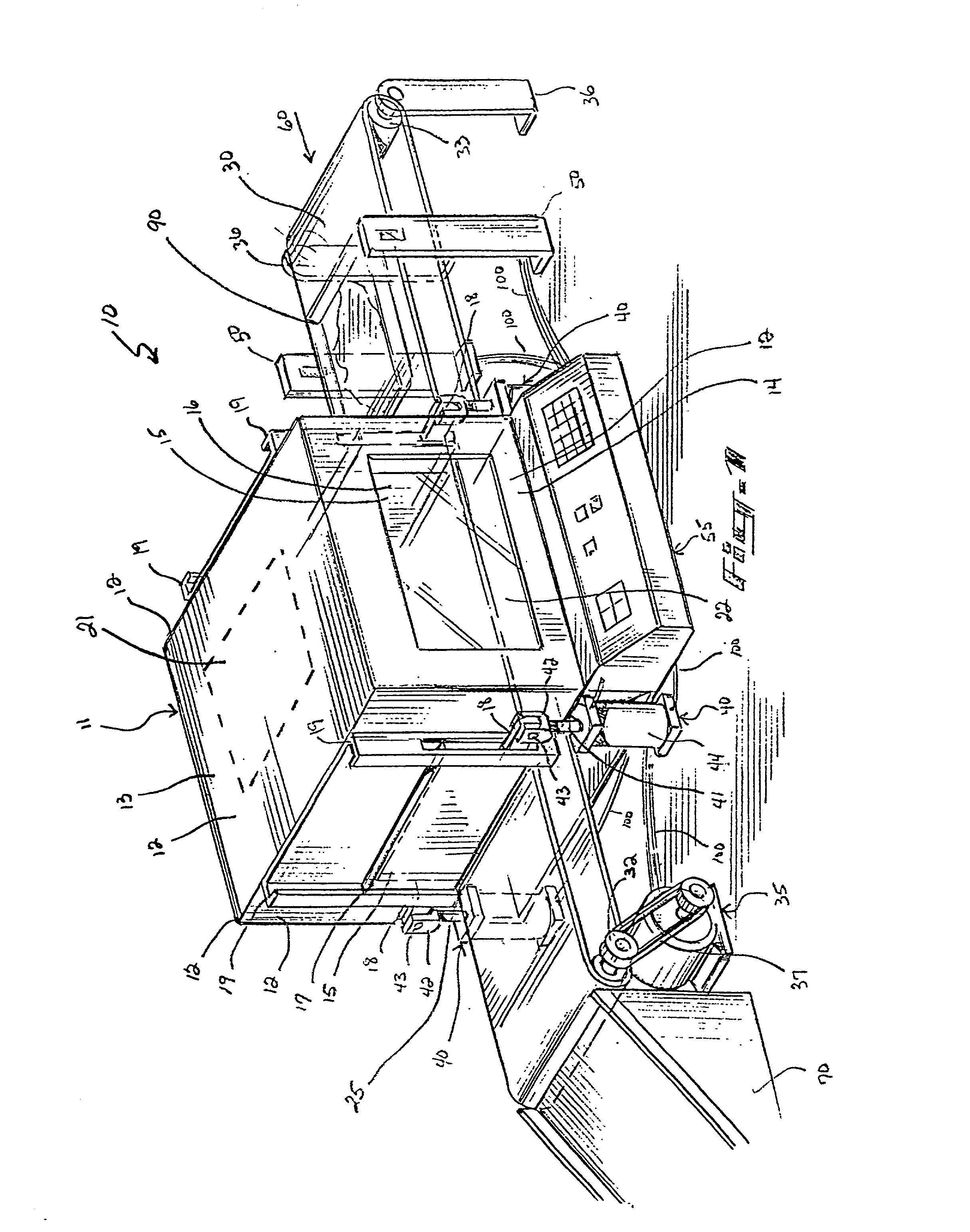

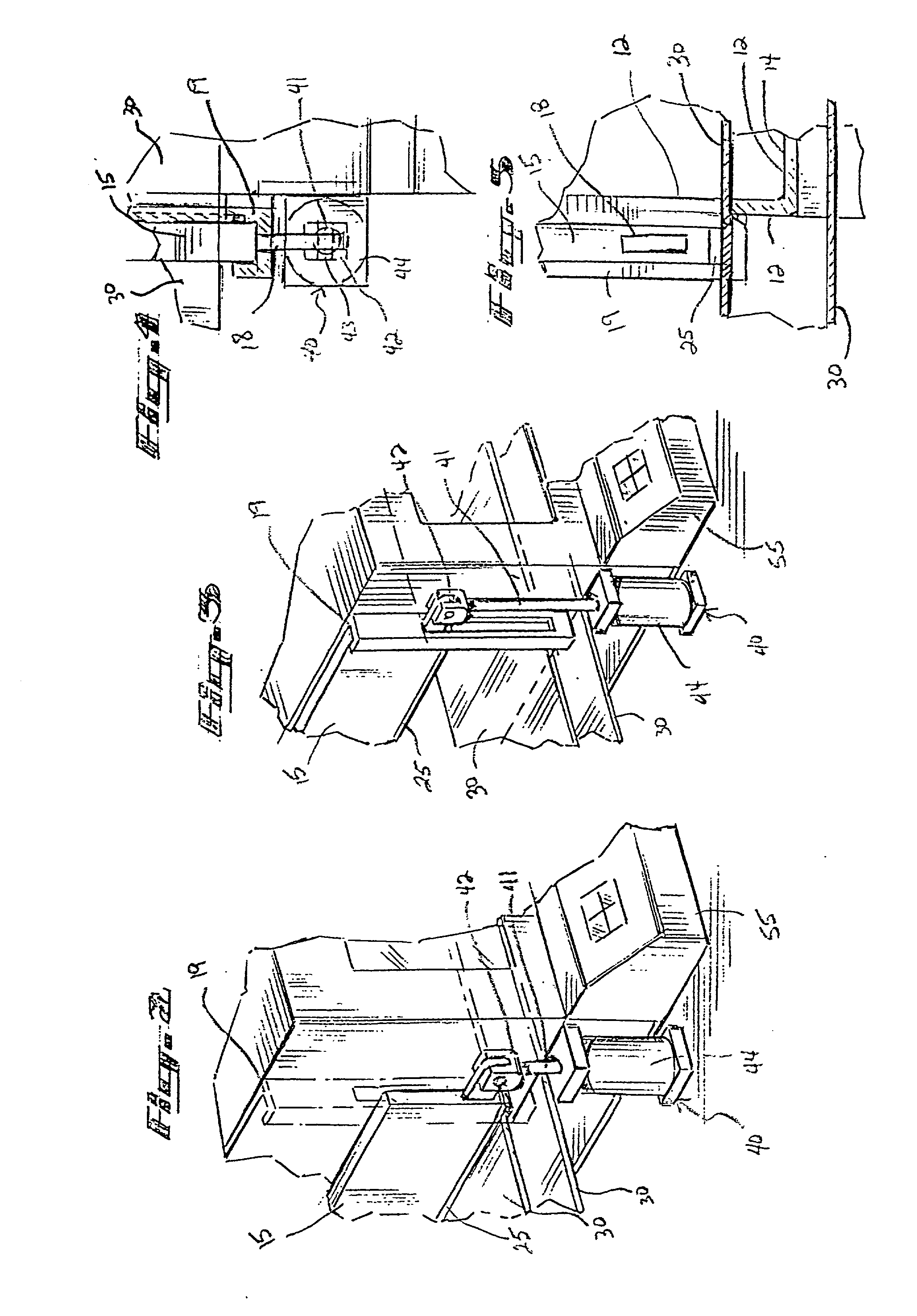

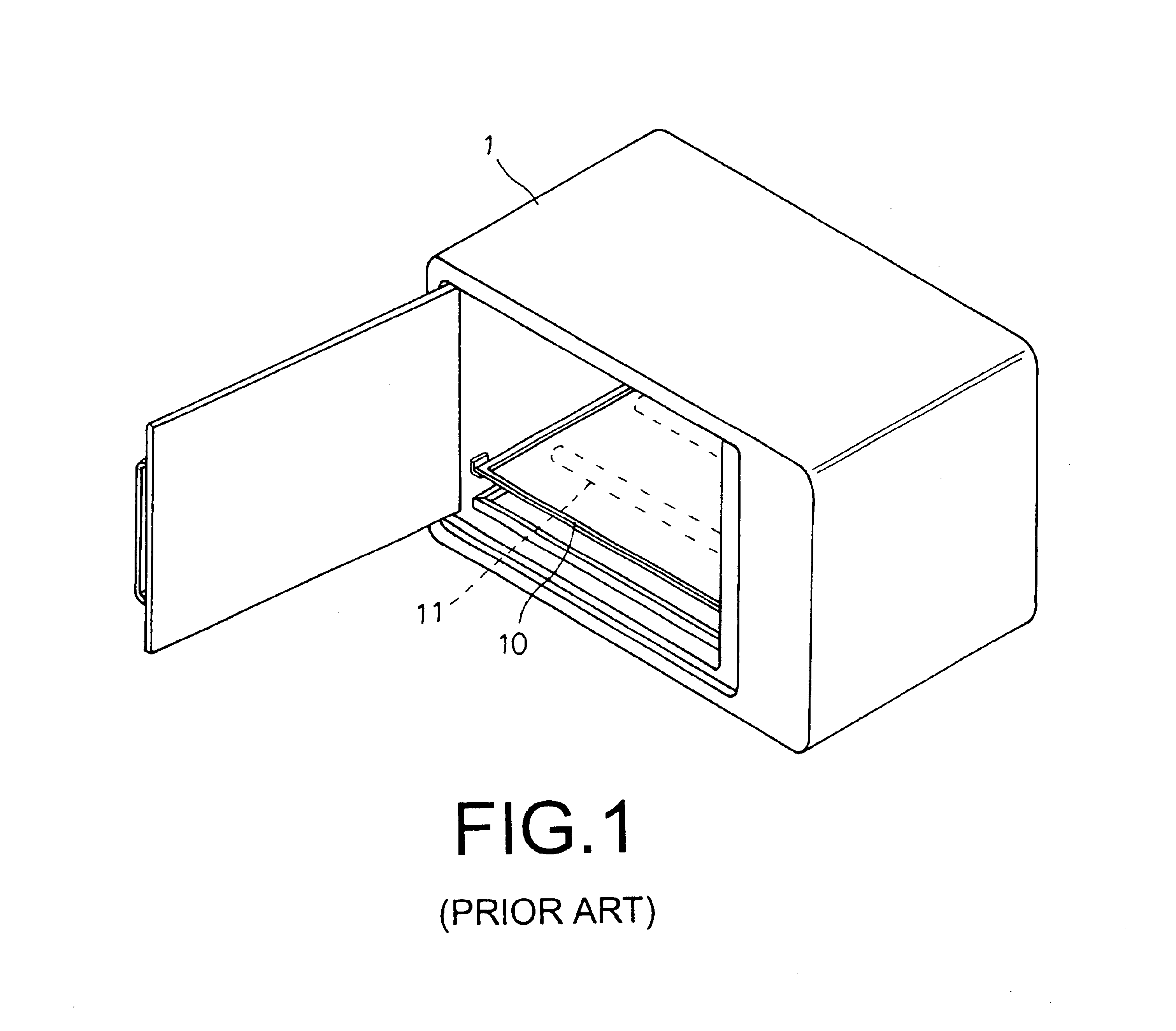

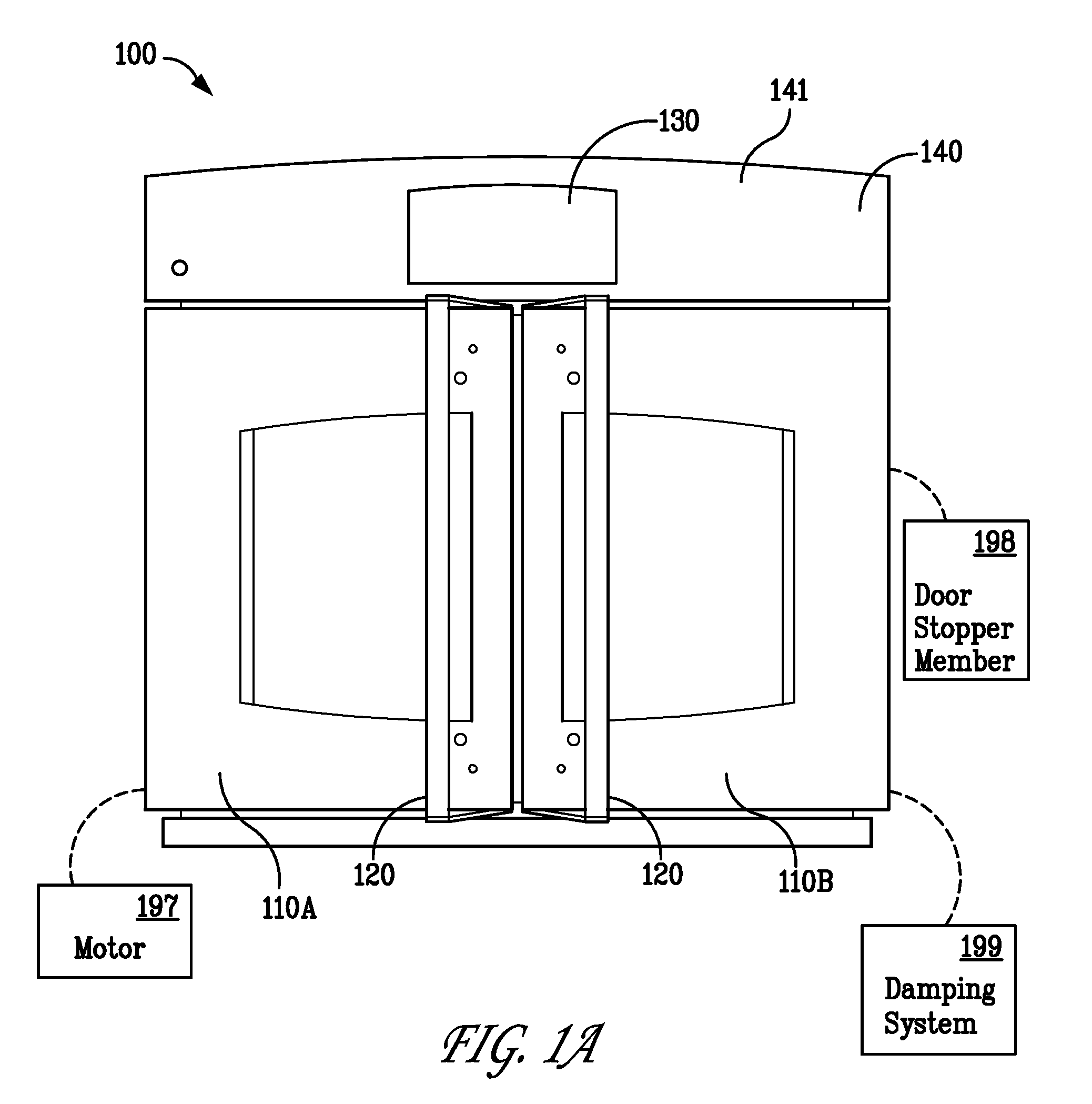

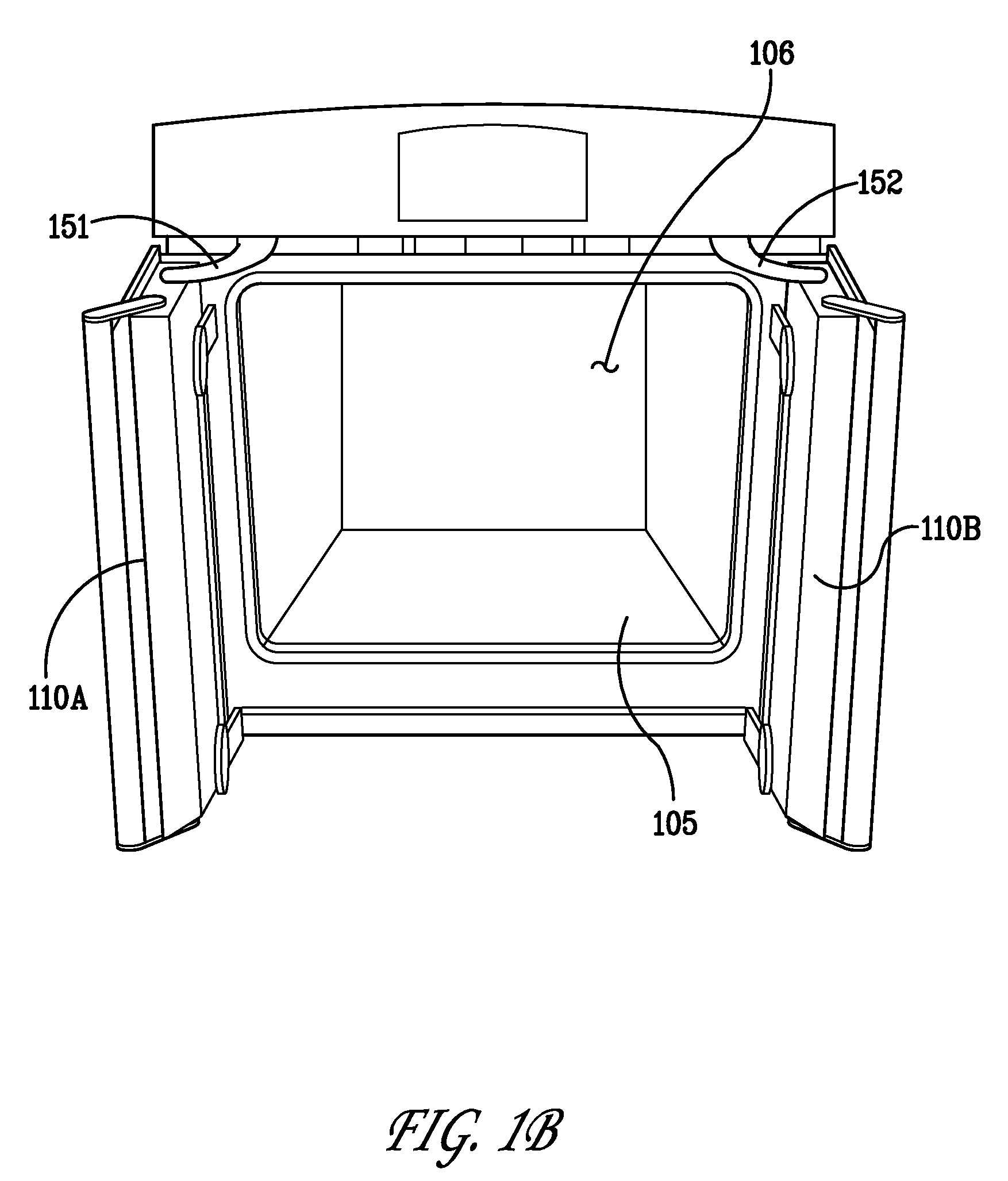

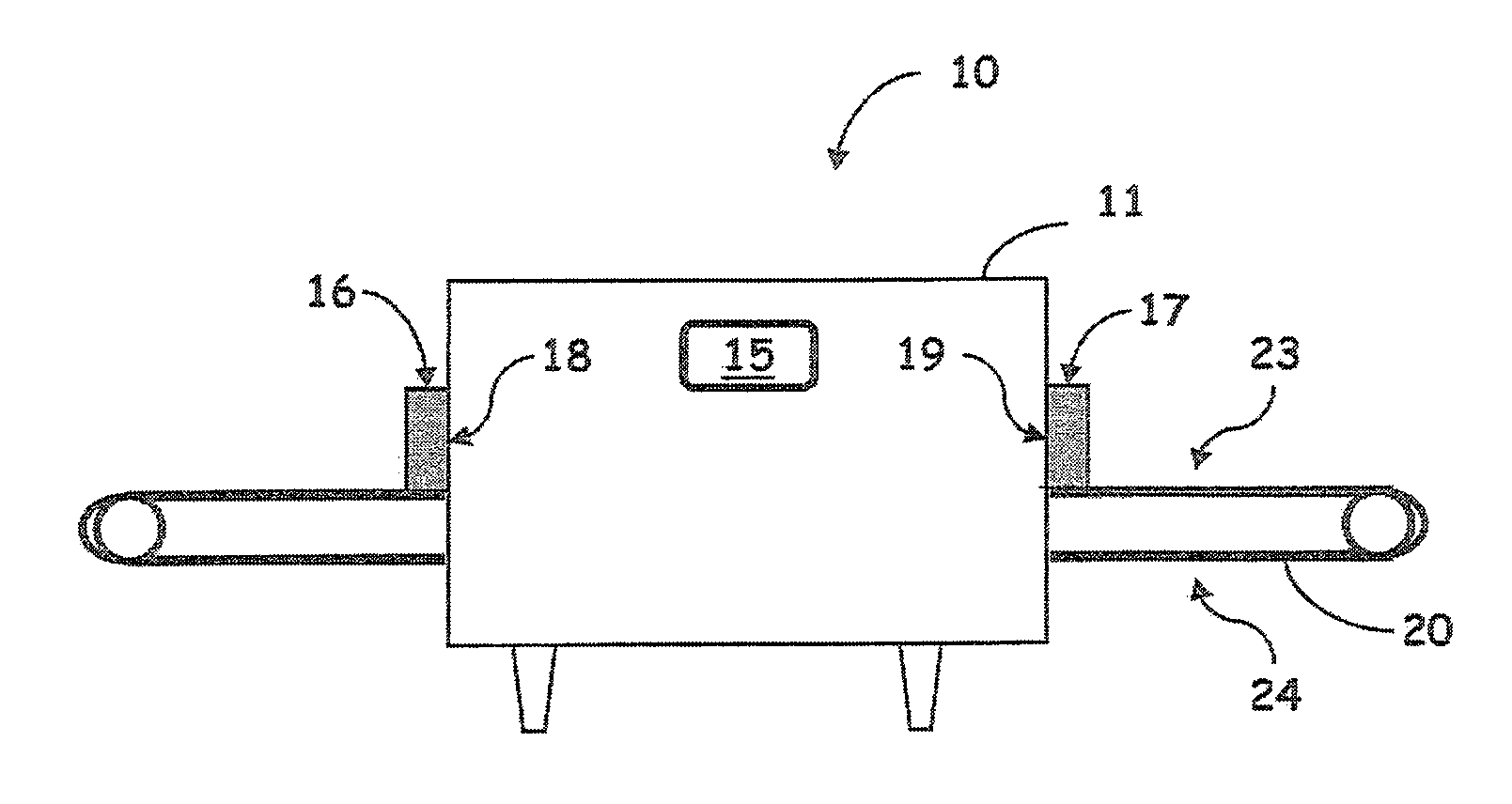

Conveyorized oven with automated door

InactiveUS6713741B2Amount of heat lossImprove throughputOven doors/gatesMicrowave heatingMicrowave ovenConveyor belt

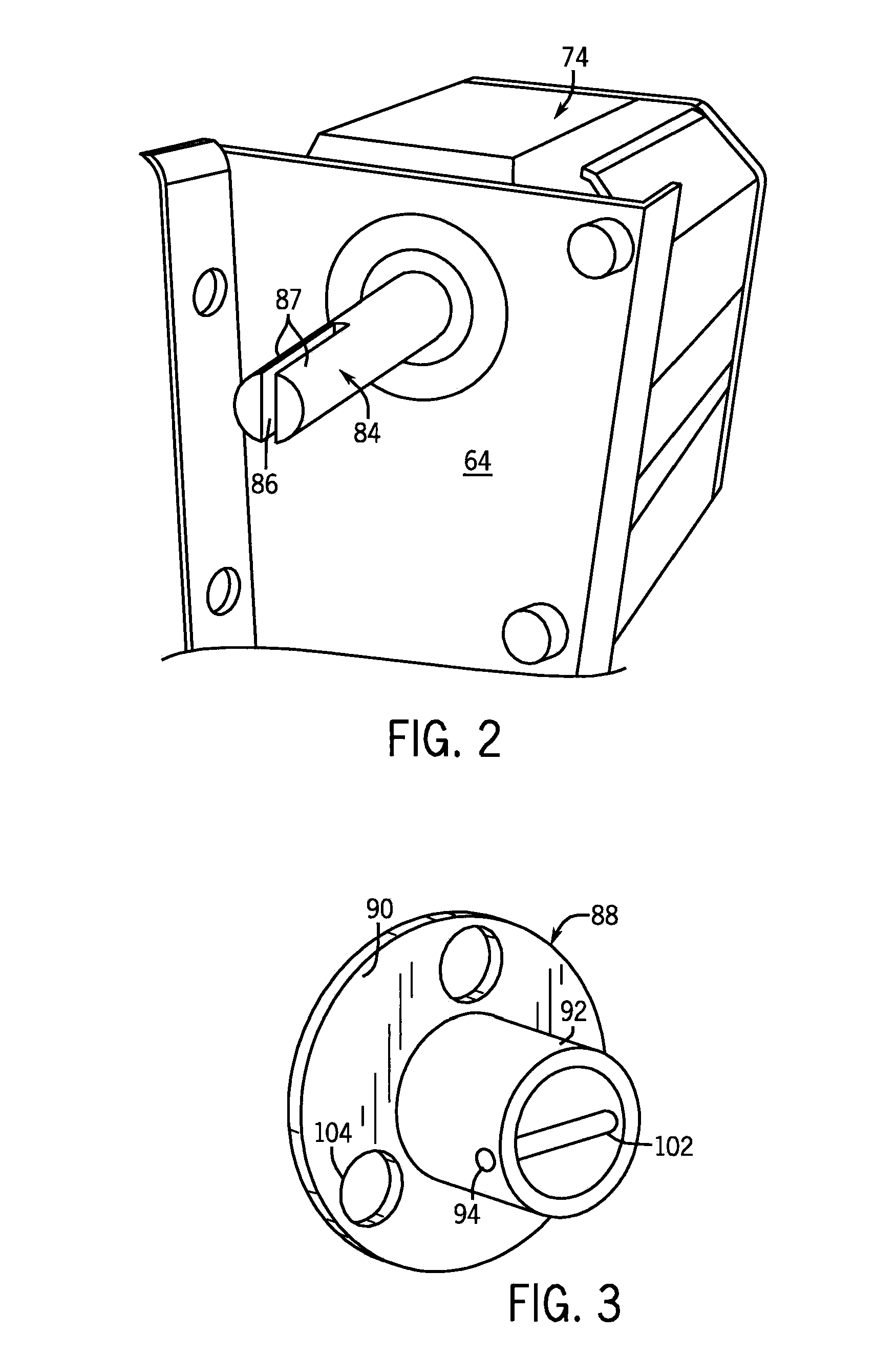

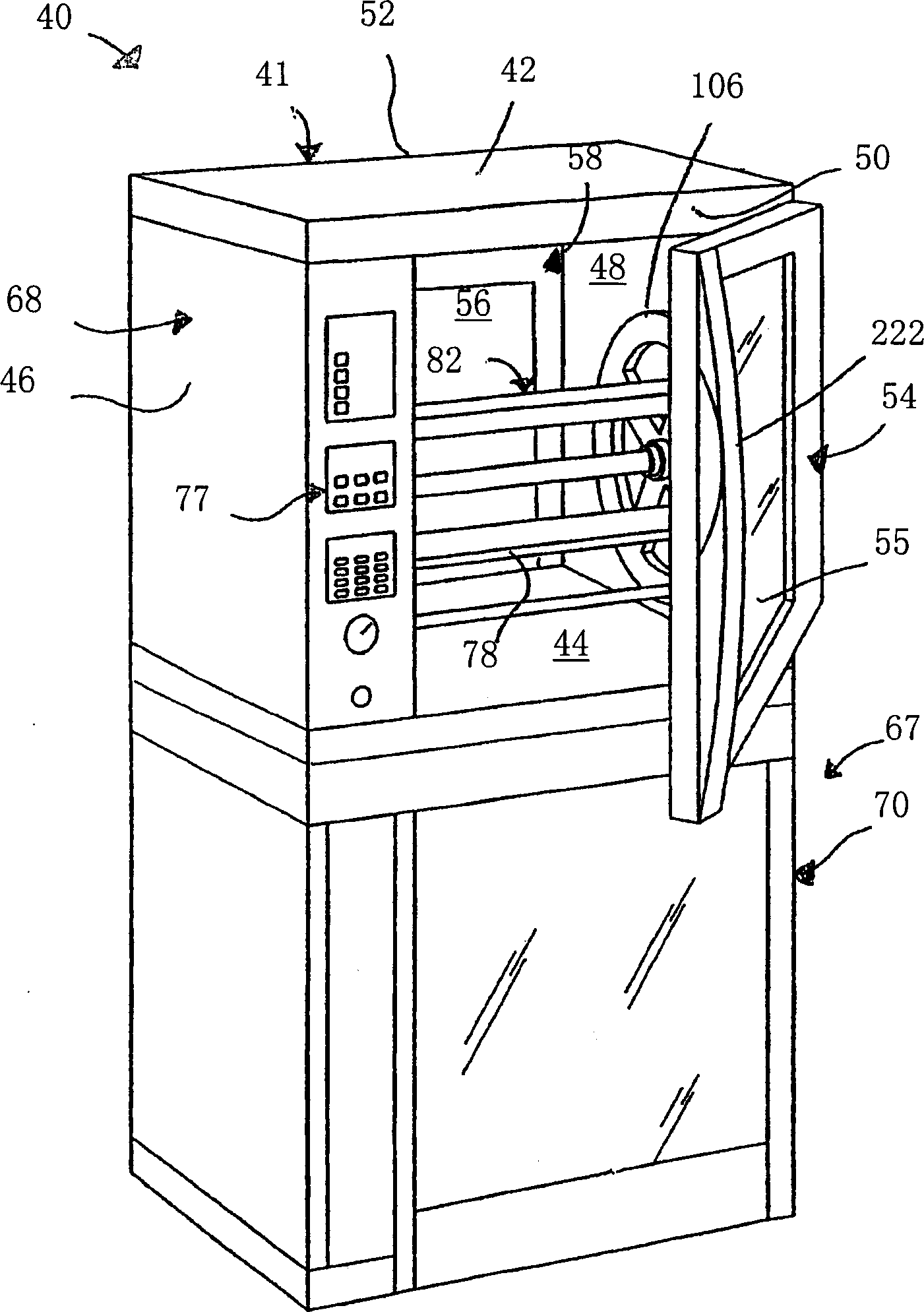

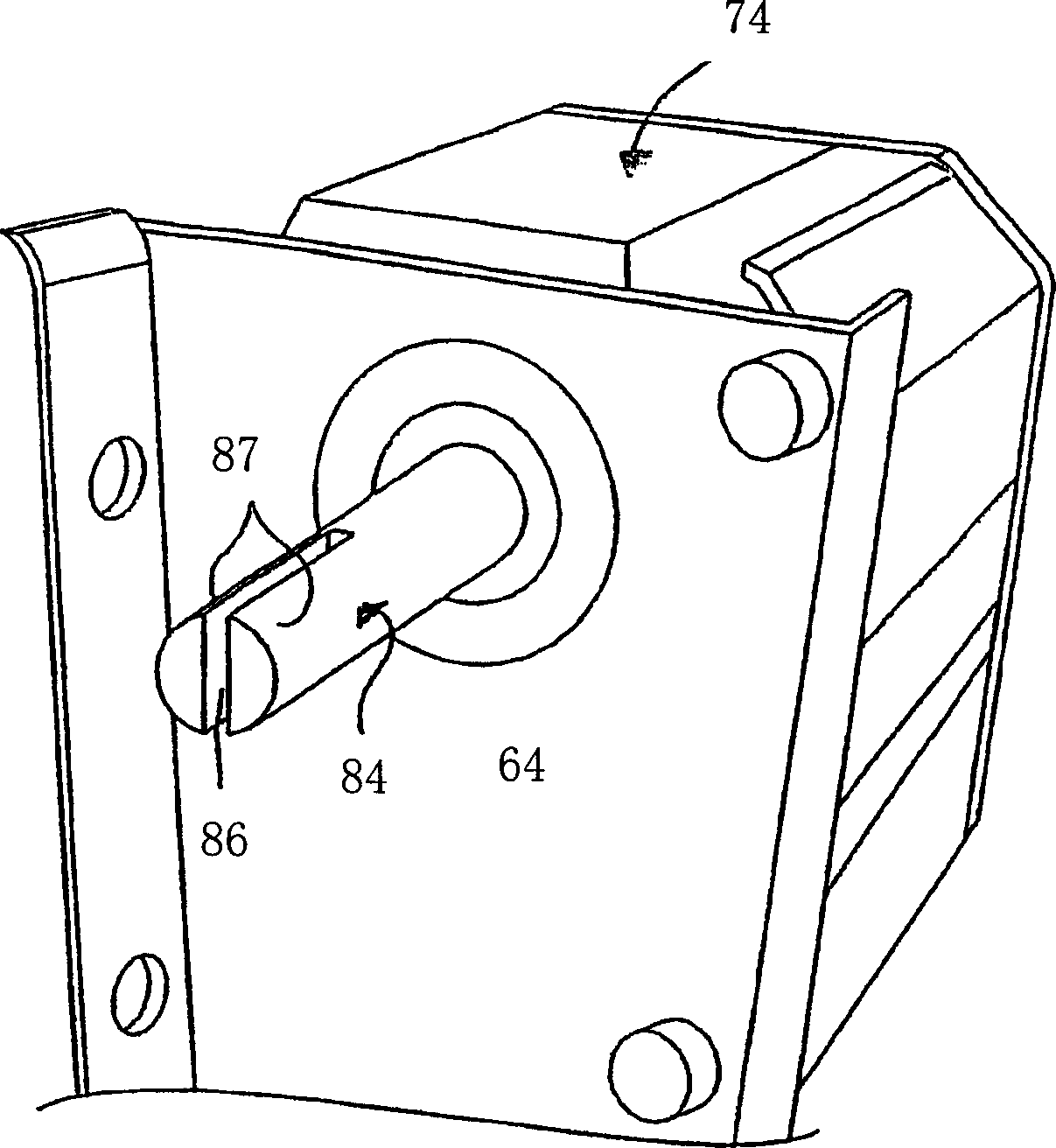

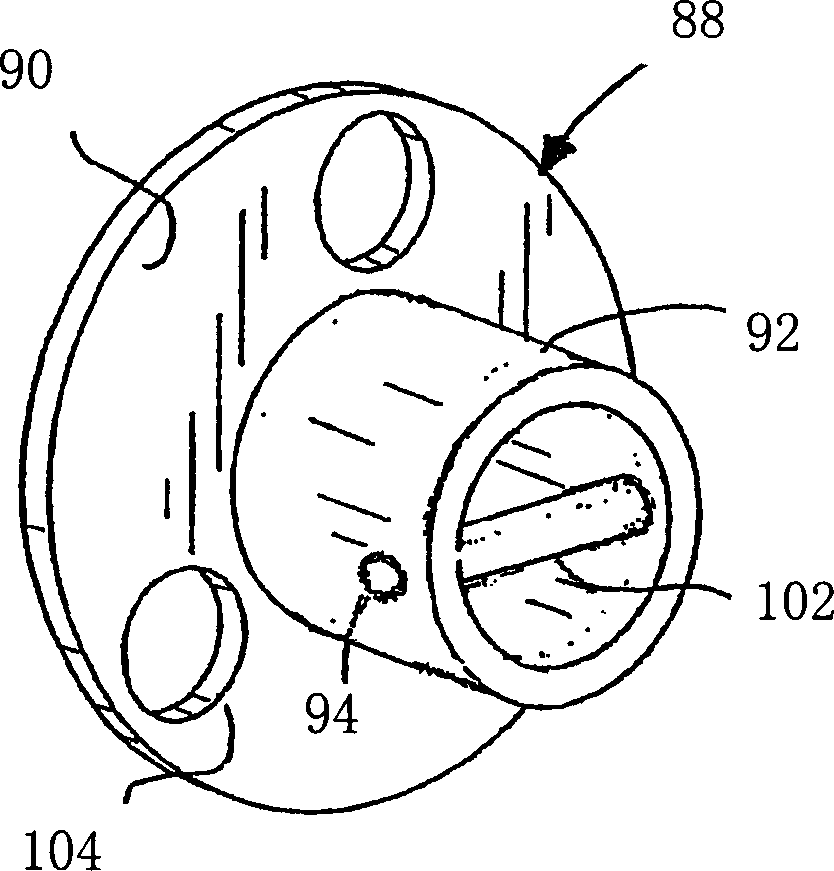

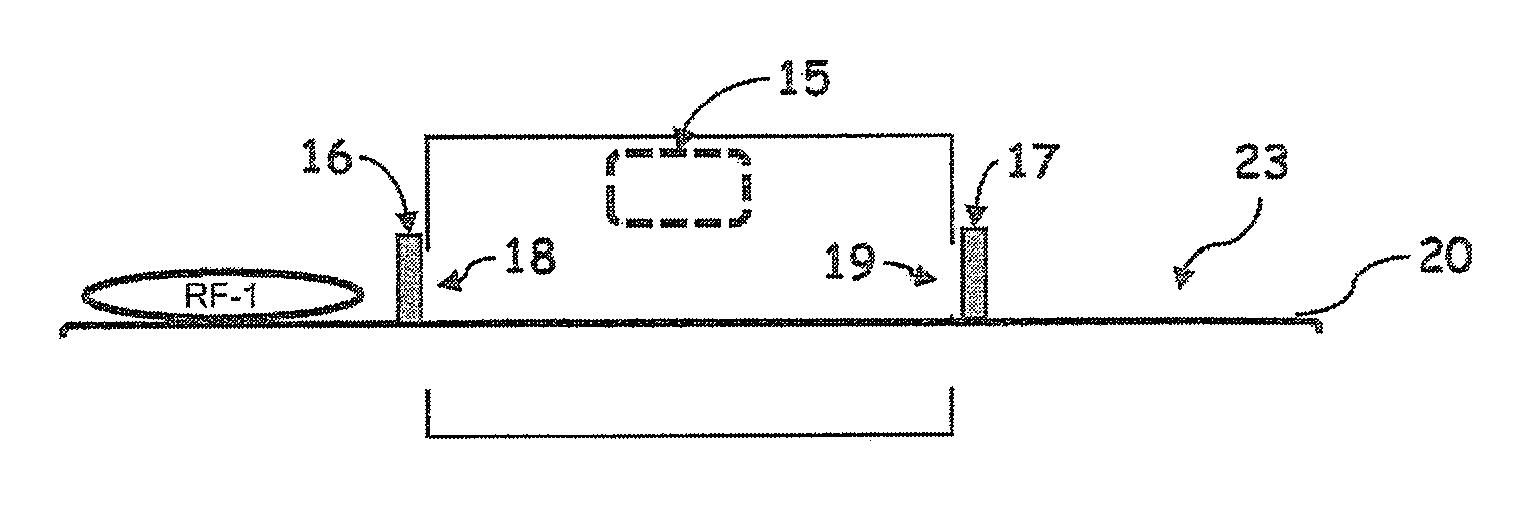

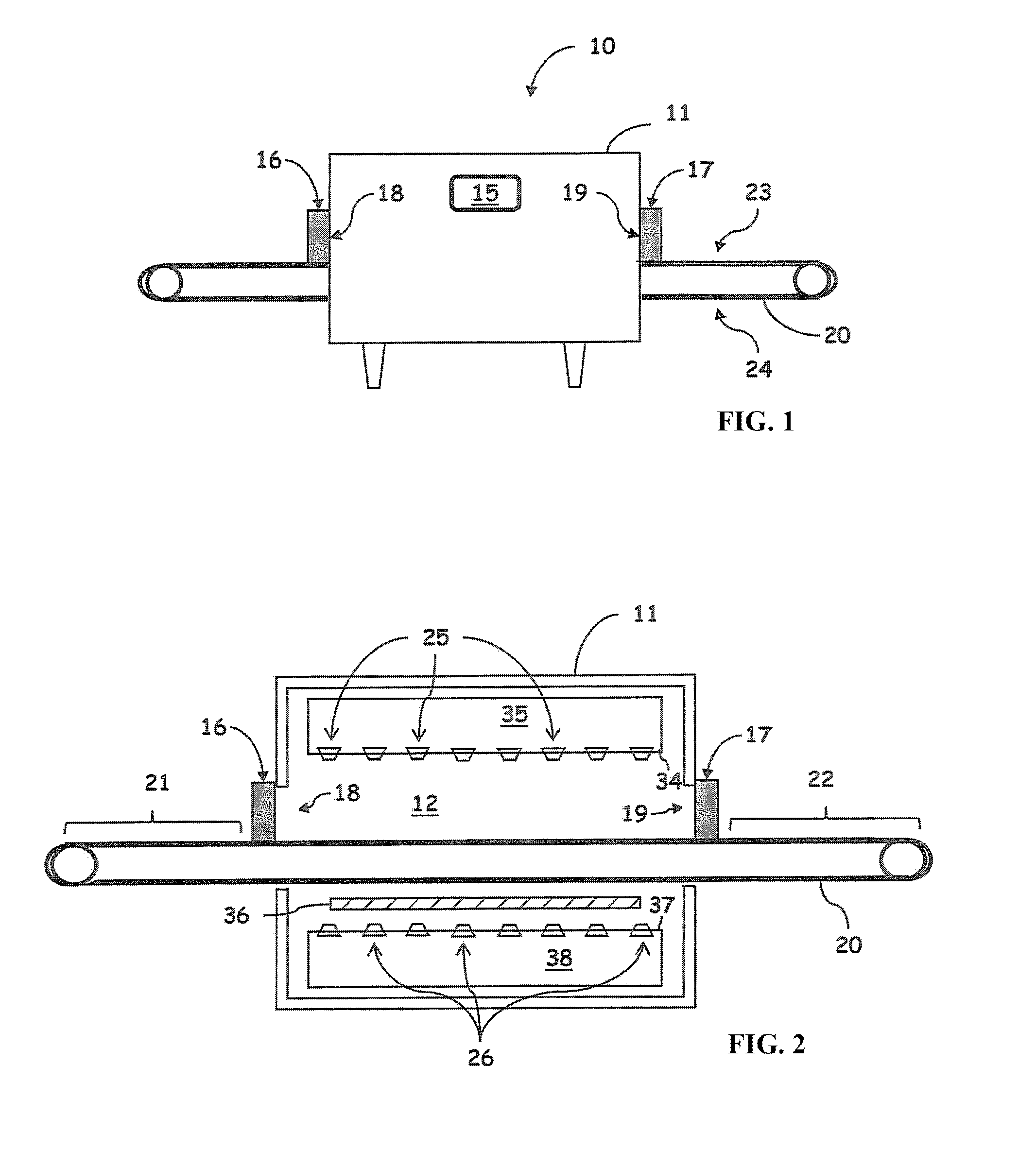

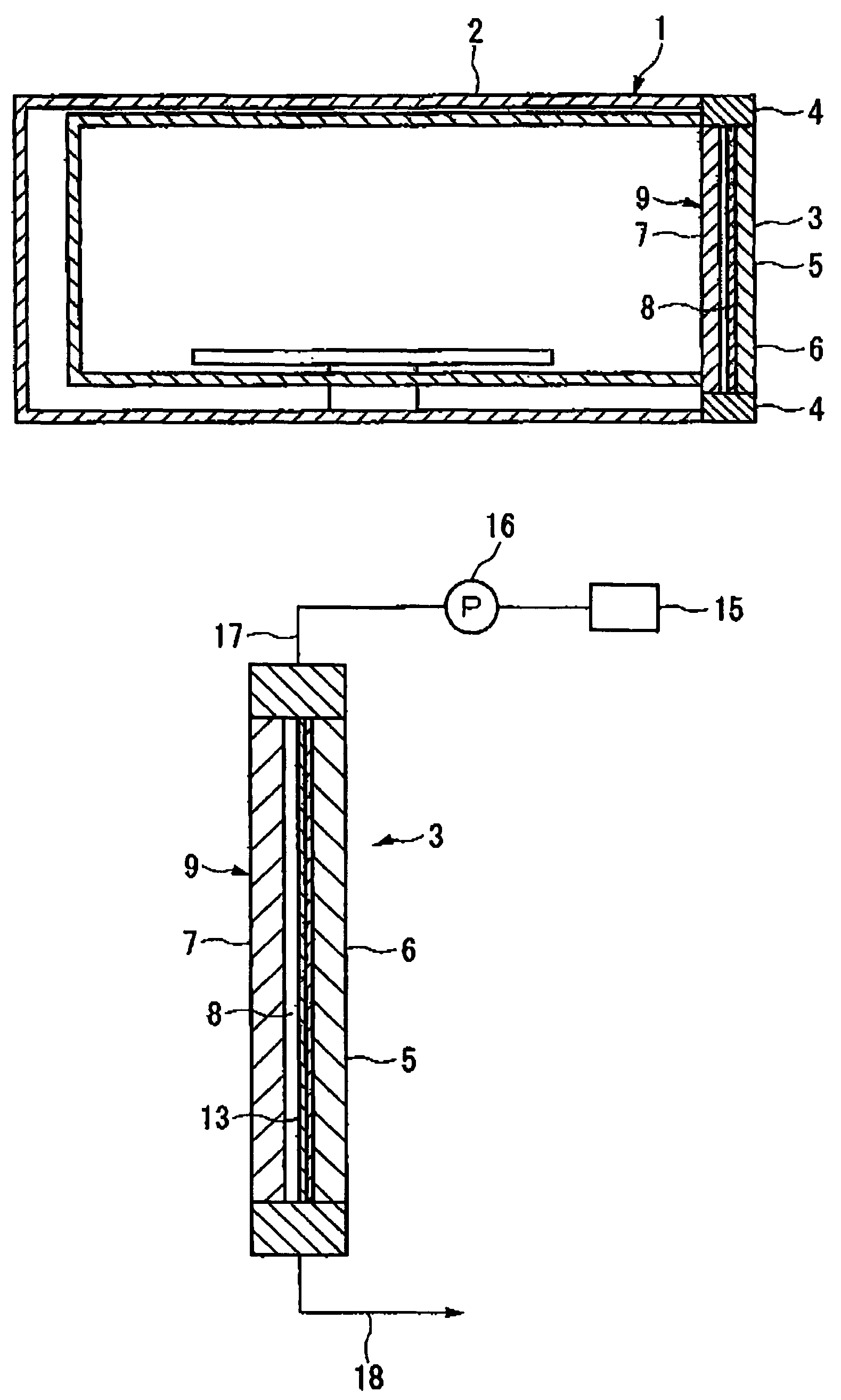

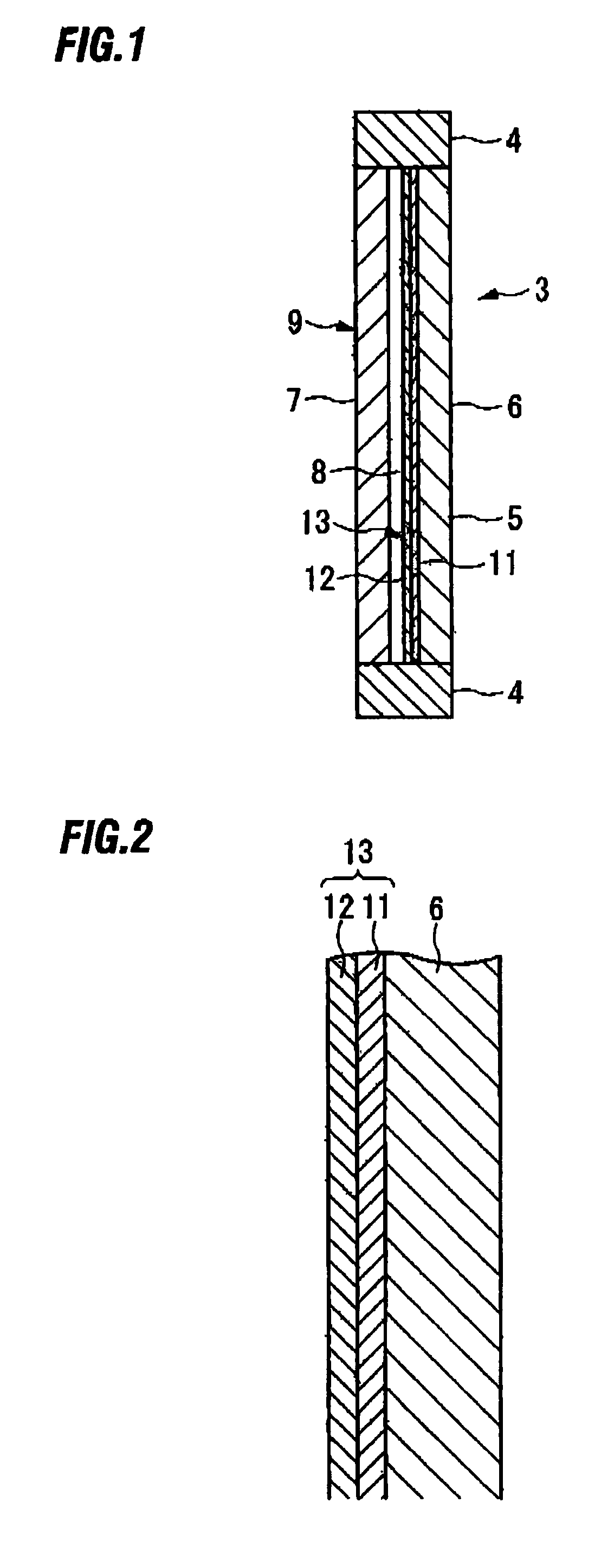

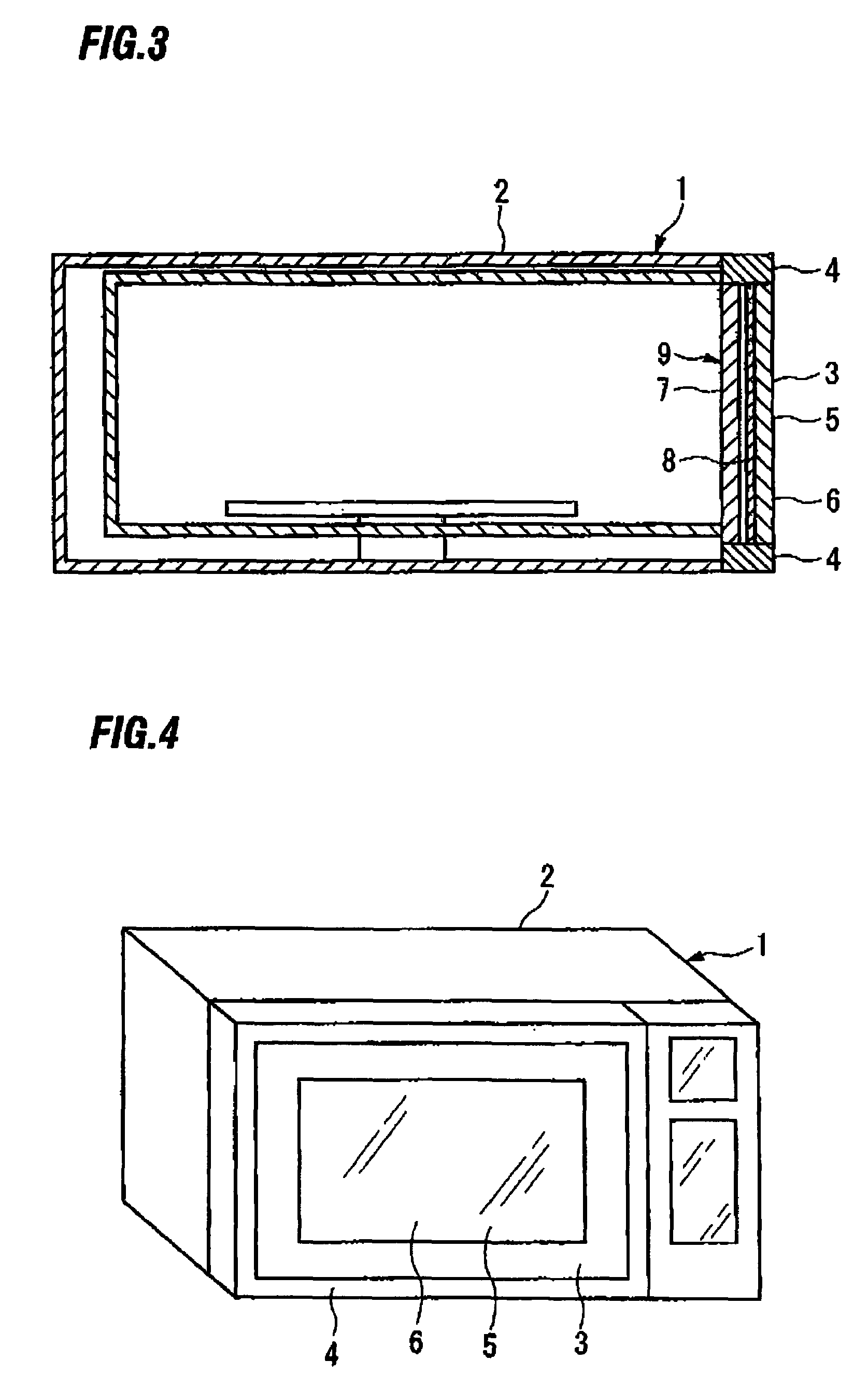

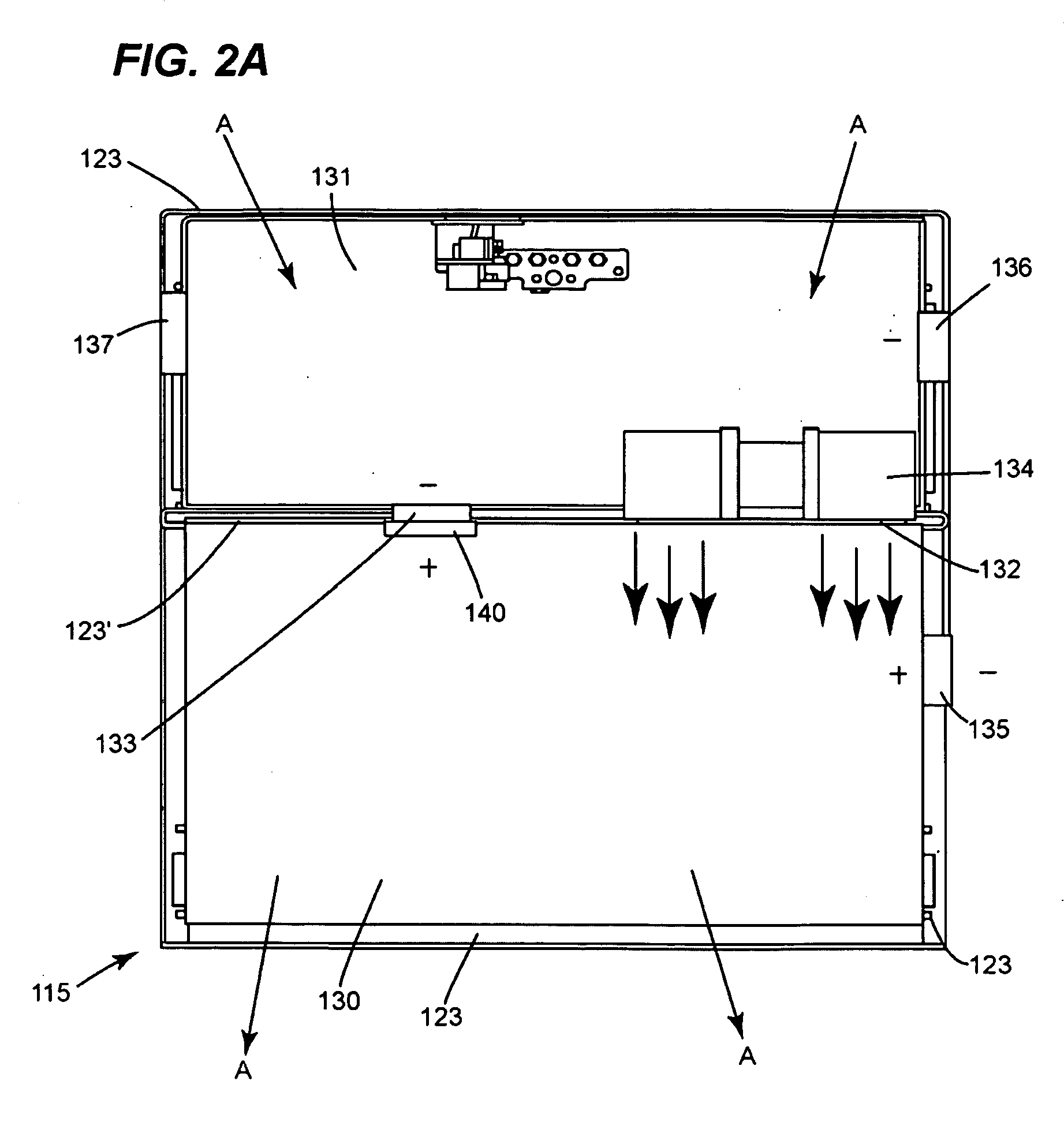

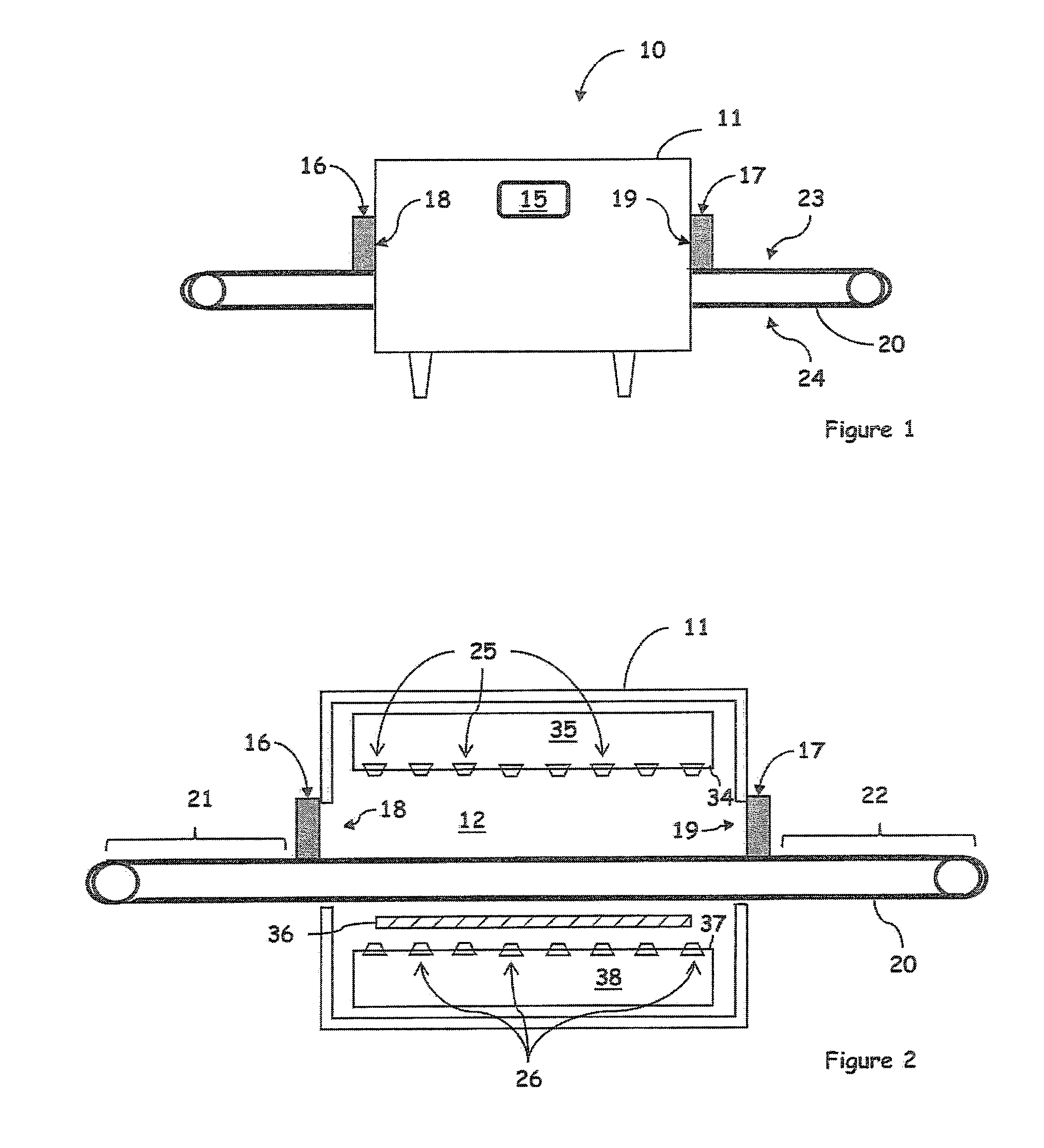

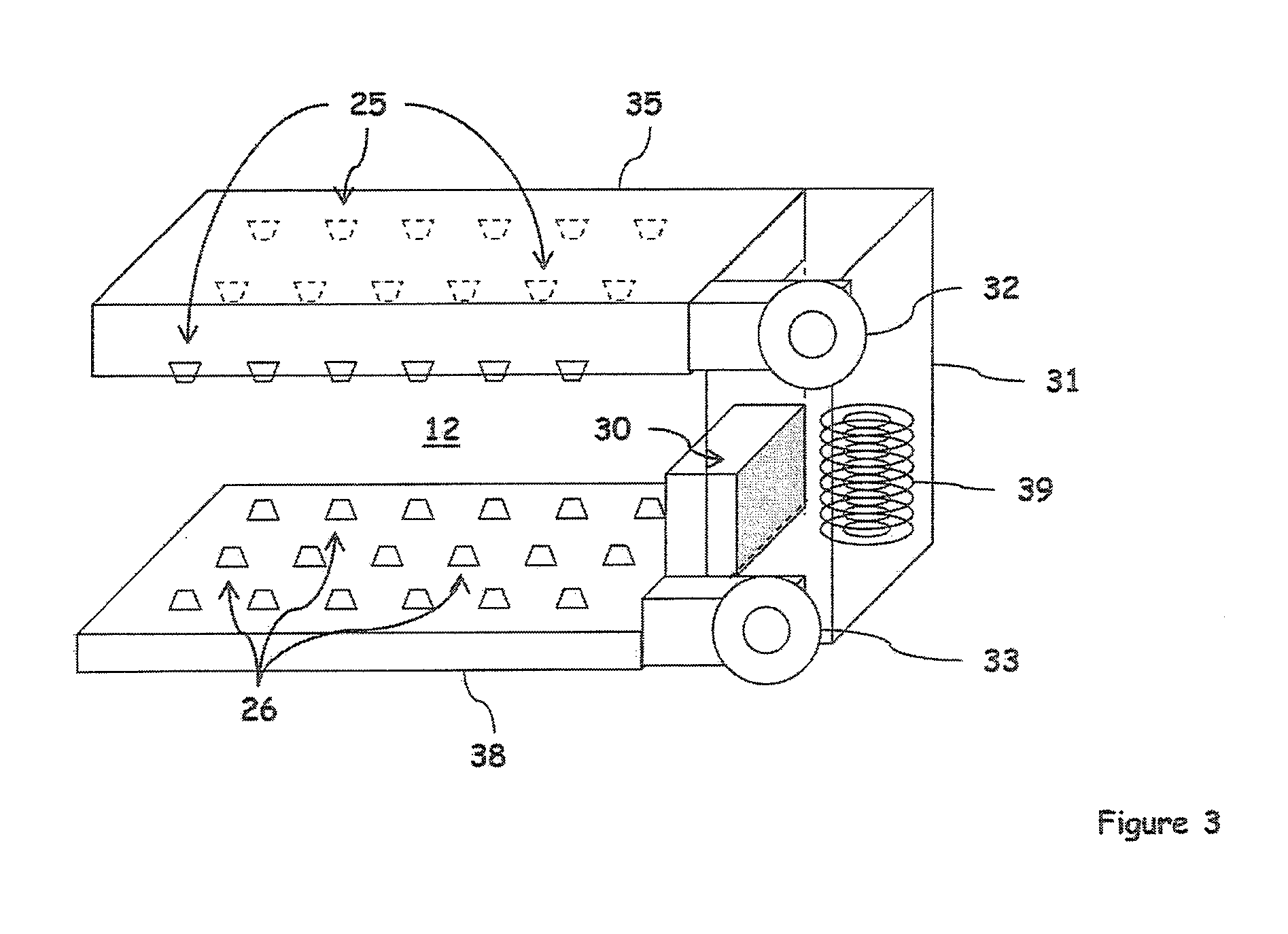

The invention is directed to an oven, and in particular, a microwave oven, having an oven cavity, two doors disposed on opposite sides of the oven cavity, and a conveyor belt passing through the oven cavity and the two doors. The two doors are preferably mechanical in design and may be operated simultaneously or in sequence. The two doors may be independently interlocked and also interlocked with each other to prevent operation of the microwave oven when either door is in an opened position. Each door may be mounted in slide rails disposed along the side of the oven cavity. The opening and closing of the two doors are preferably controlled by a programmable logic center.

Owner:ACP OF DELAWARE

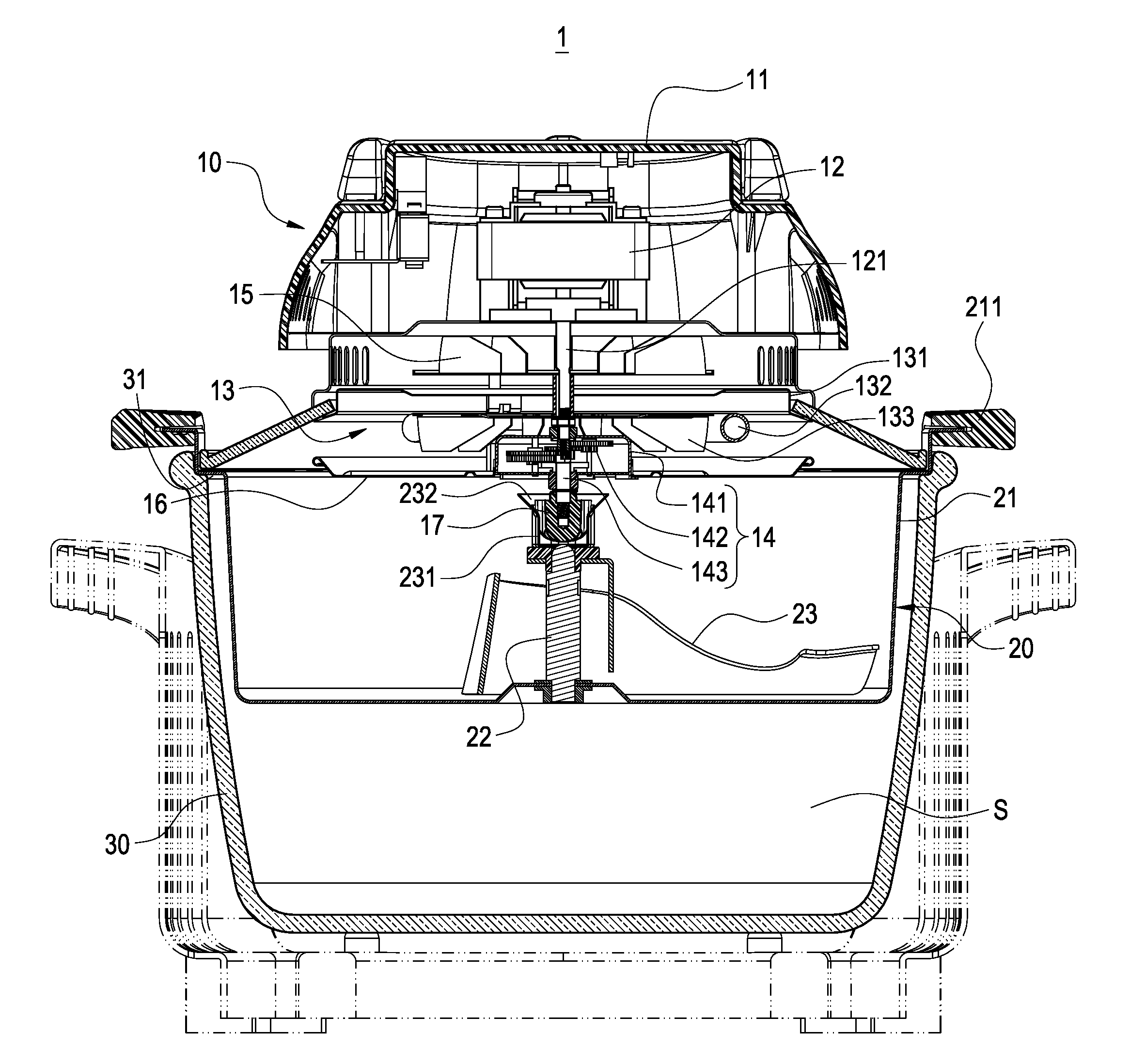

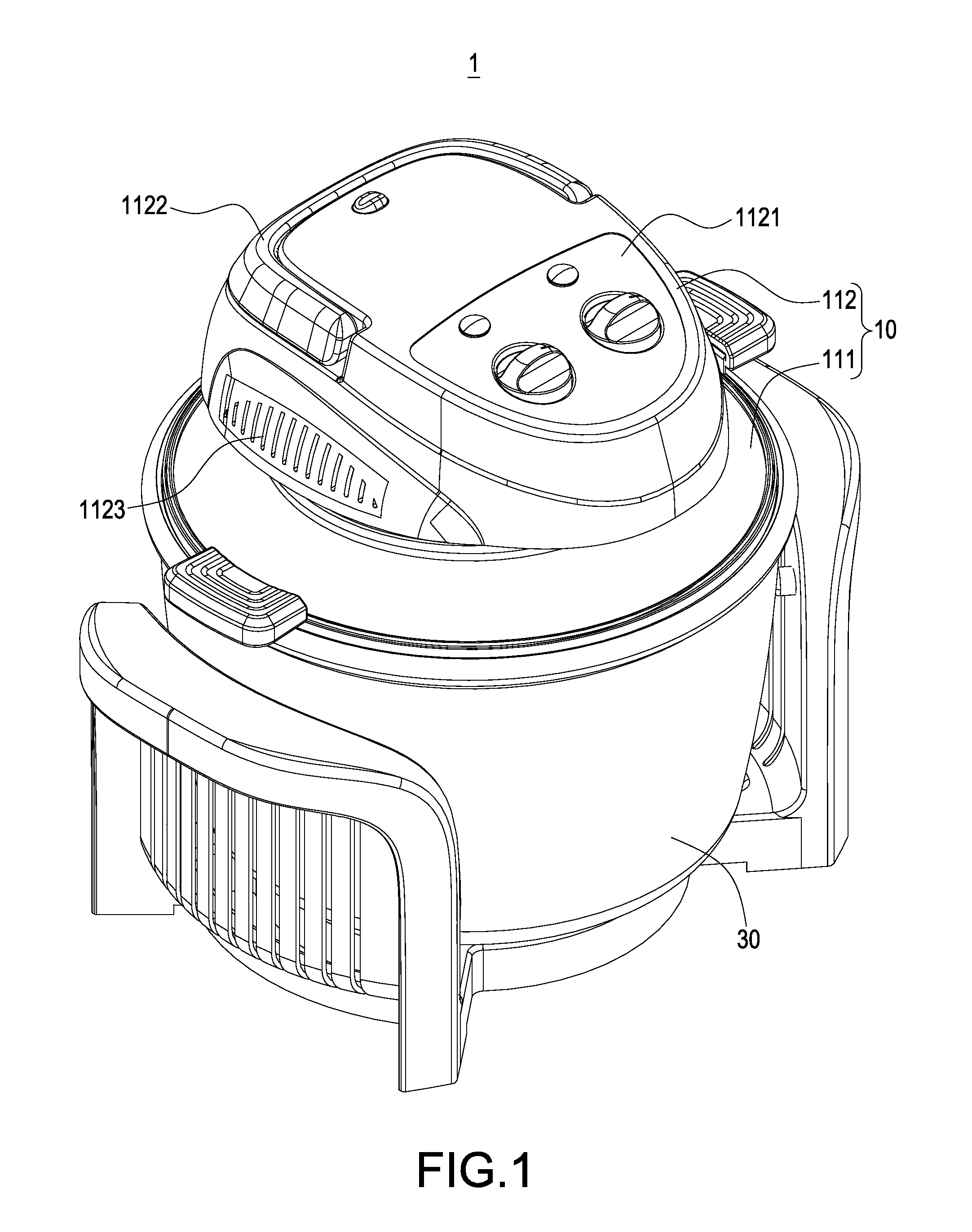

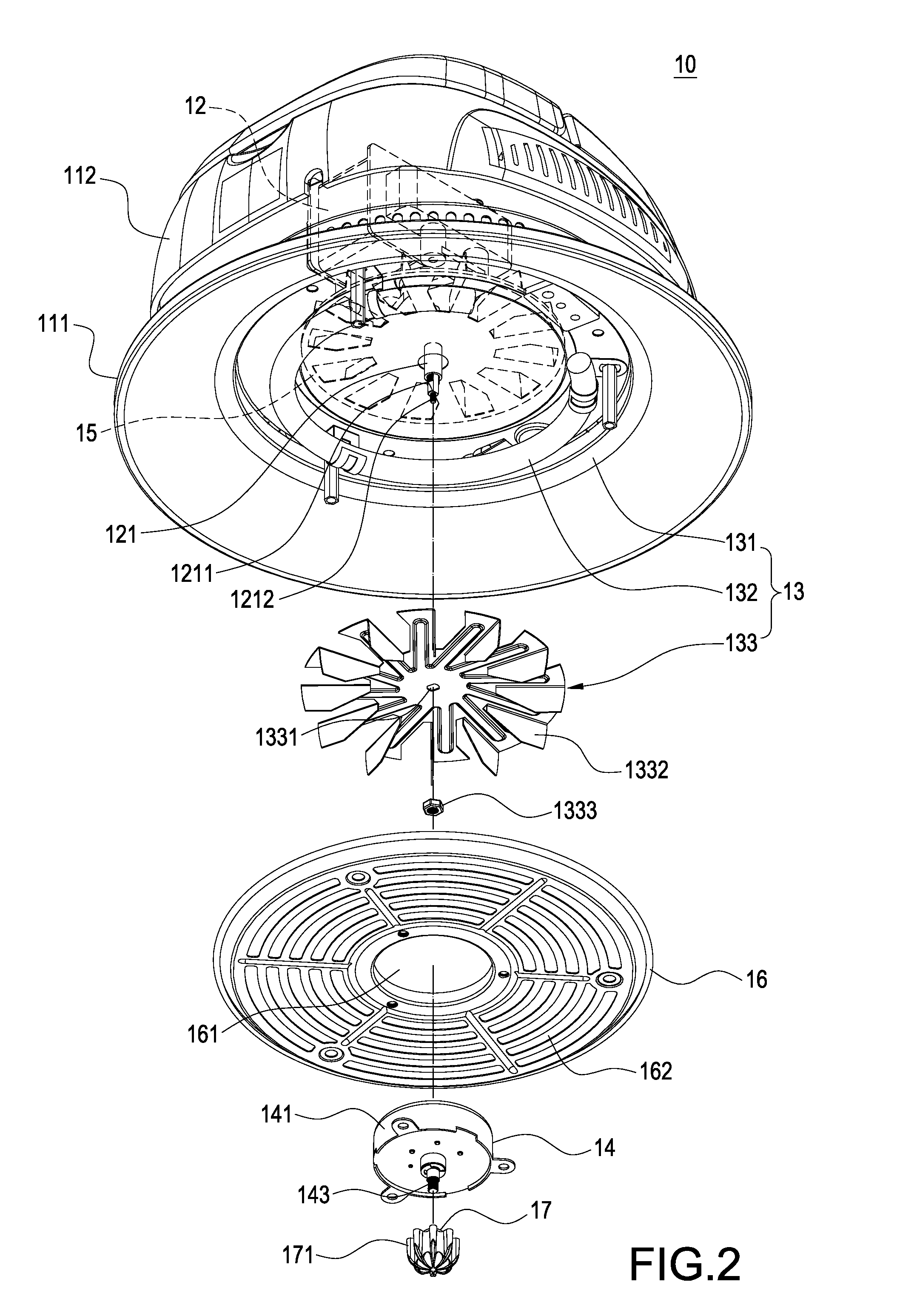

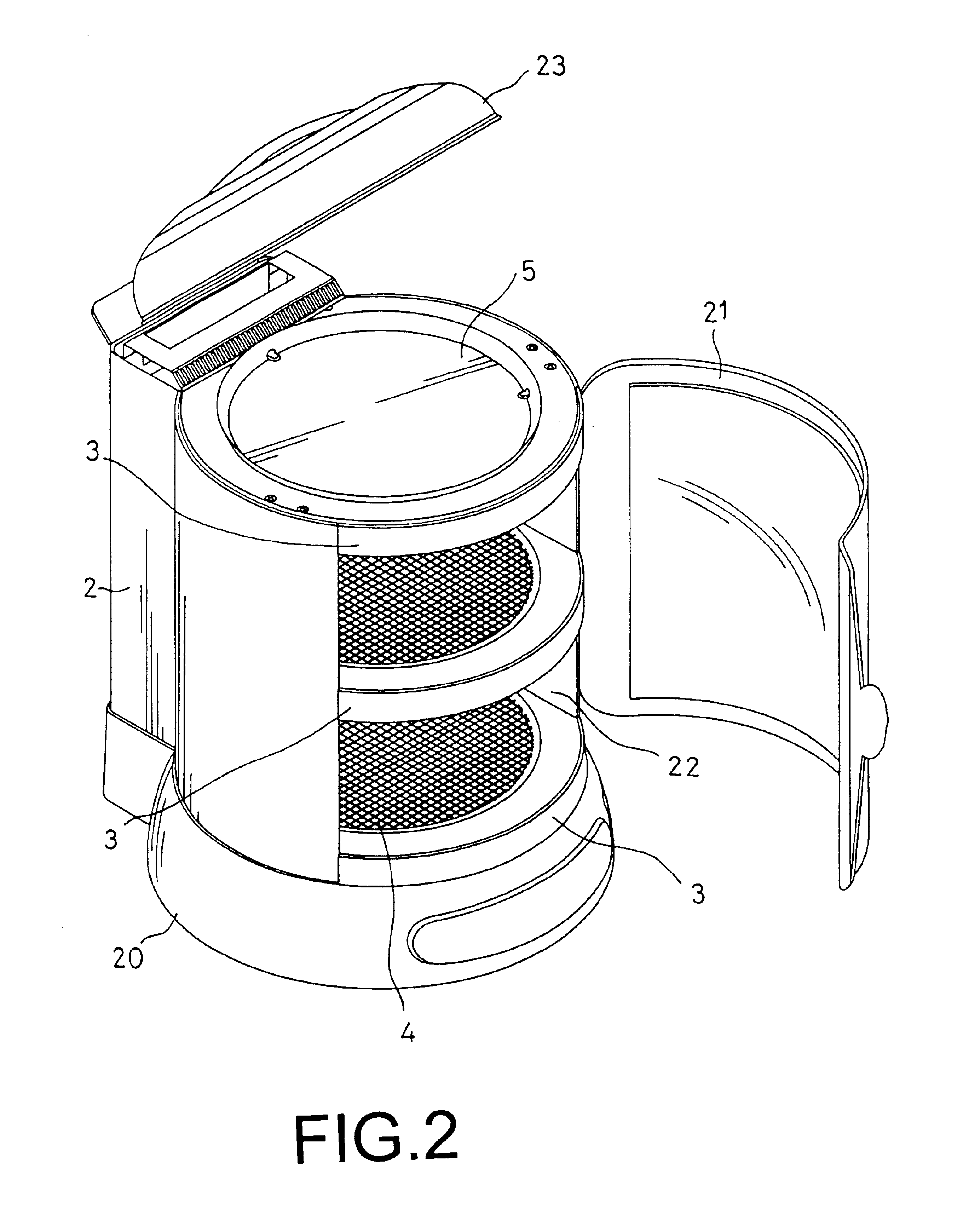

Frying-and-baking oven and heating cover assembly thereof

InactiveUS20110214574A1Improve convenienceImprove functionalityDomestic stoves or rangesDrying solid materials with heatCooking & bakingImpeller

A frying-and-baking oven includes a baking outer pot, a heating cover assembly covering the outer pot, and a frying inner pot disposed between the outer pot and the heat cover assembly. The heating cover assembly includes a cover, an actuator, a hot-air supplying module, and a speed-reducing mechanism. The actuator has a driving shaft. The hot-air supplying module has an air-blowing impeller and a heating element. The driving shaft drives the air-blowing impeller to blow the hot airflow generated by the heating element. The driving shaft also drives a transmission shaft of the speed-reducing mechanism and in turn a stirring member to rotate at a low speed, thereby stirring food materials in the inner pot. With this arrangement, the food materials received in the inner pot can be stirred automatically and cooked sufficiently. Further, the oven can cook the food materials by baking or frying, which increases the functionality and convenience thereof.

Owner:TALL & STOUT INDAL CORP

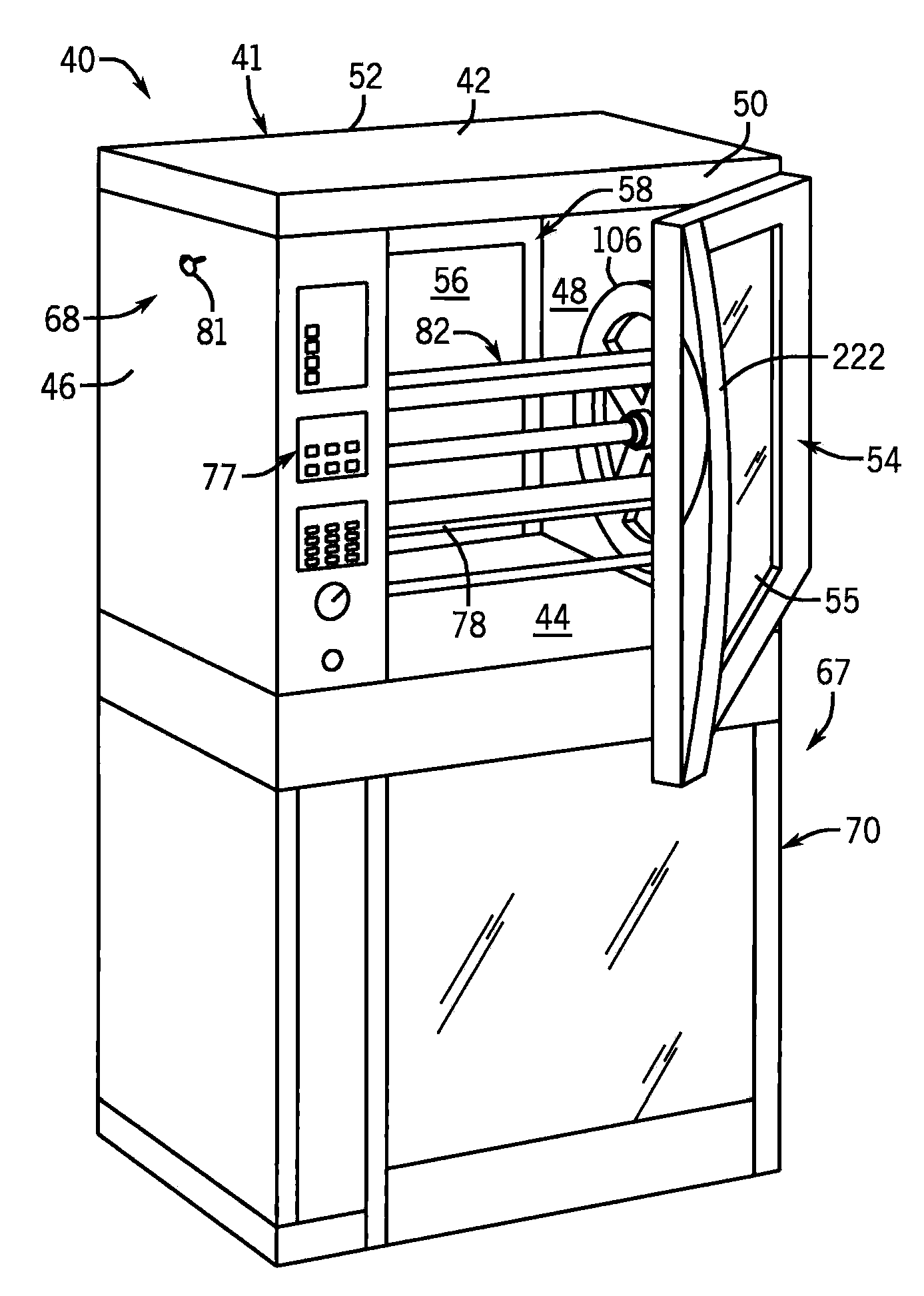

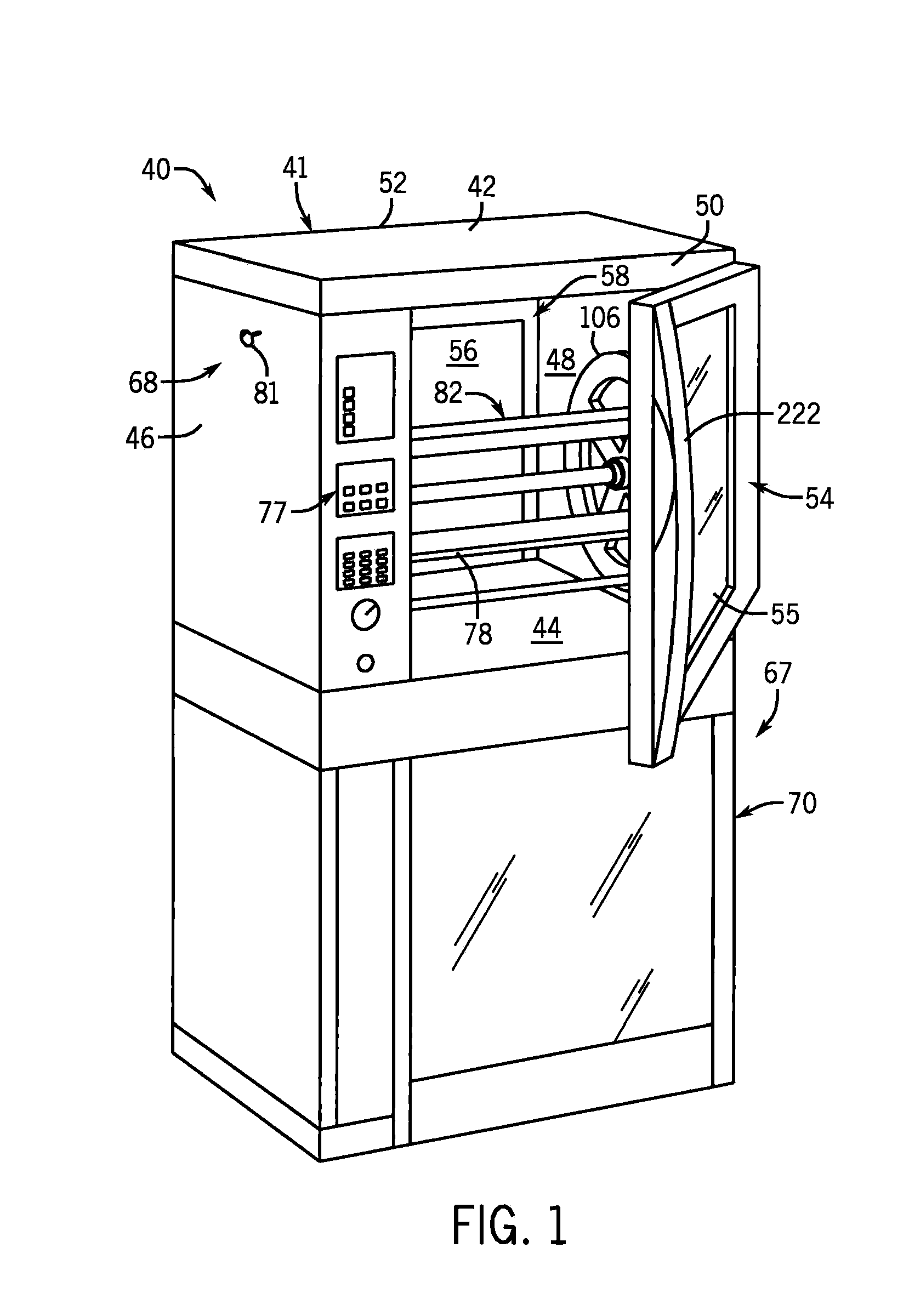

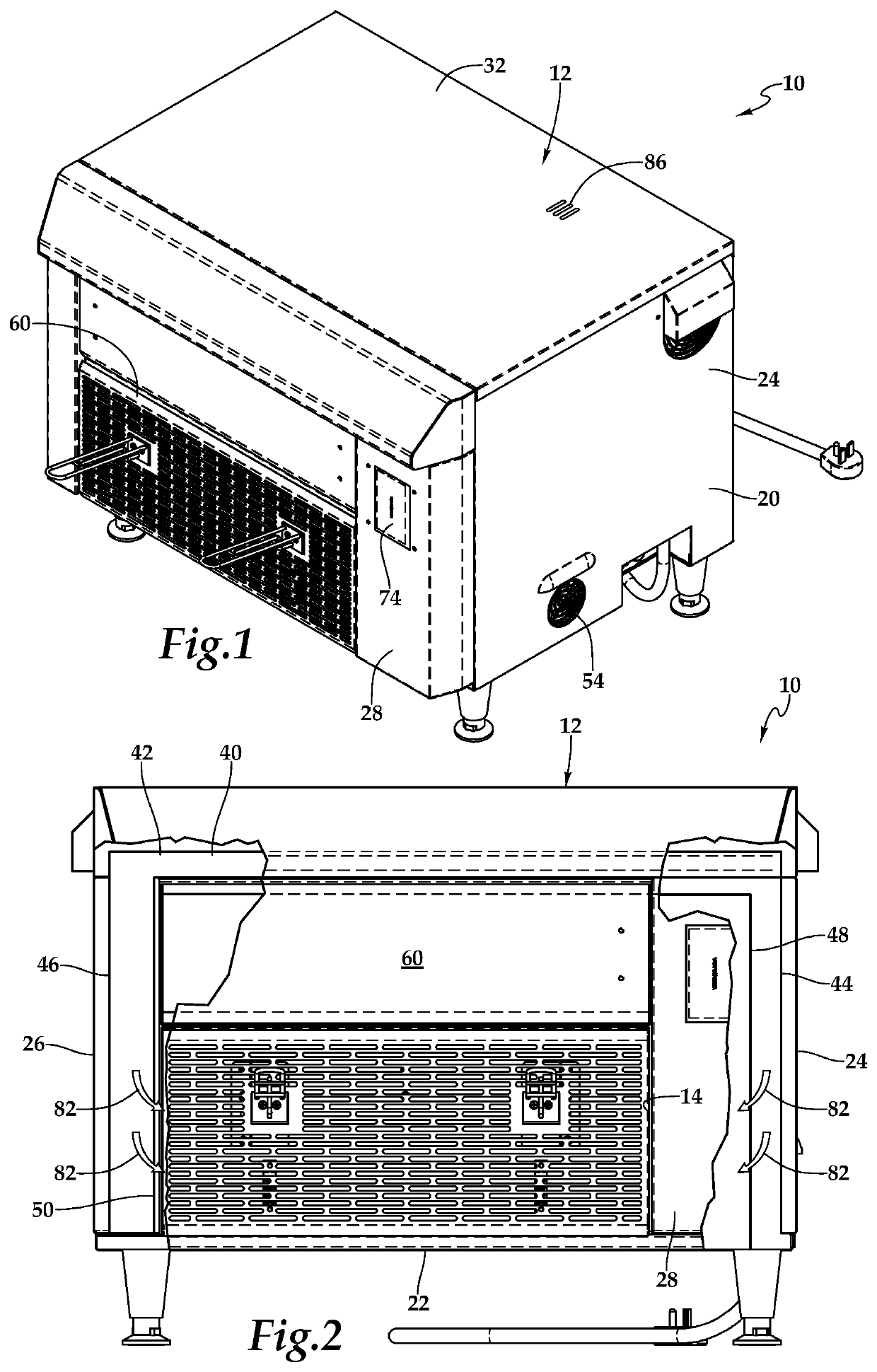

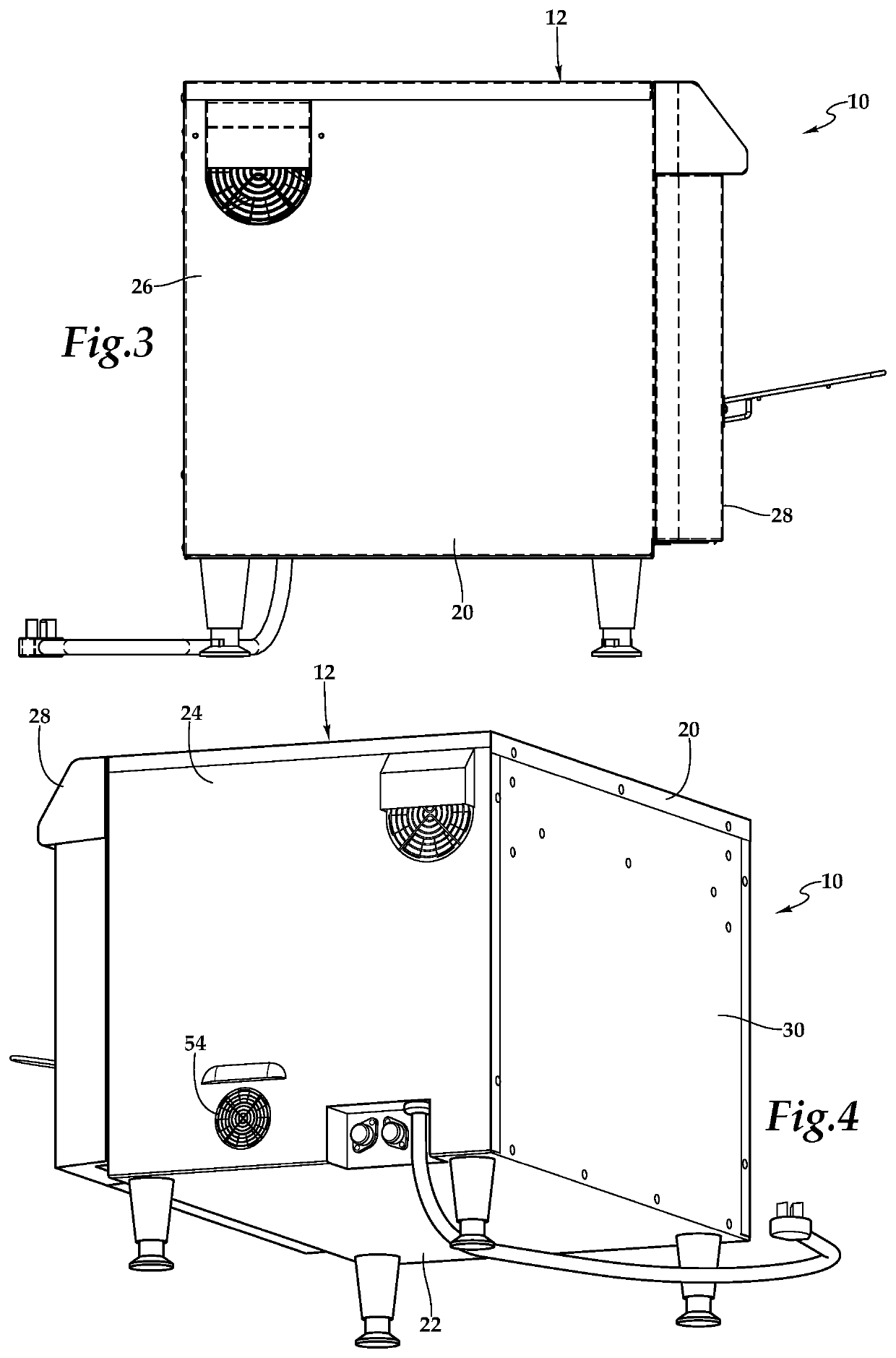

Rotisserie oven and hood

A rotisserie oven is provided having a radiating heating system in combination with a convection heating system to prepare raw meat and poultry food product inside of a cooking chamber. A spit assembly carries the food product, and includes components that are detachable to assist in cleaning. The oven further includes a steam cleaning assembly that is integrated with the convection heating system that assists in grease removal from the components inside the cooking chamber. A humidity removal system regulates the moisture level inside of the cooking chamber during food preparation. A rotisserie oven is provided of the type that includes a cooking chamber having at least one open end closed by a movable door assembly. A radiating heating system is disposed in the cooking chamber and receives electricity to produce radiating heat to cook food carried by a rotating spit assembly. A hood assembly is supported by the cooking chamber, and defines a filtration chamber that receives incoming grease-laden air from the cooking chamber and houses at least one filtration member drawing the incoming air therethrough towards a hood outlet. The hood assembly and cooking chamber move together as the rotisserie oven travels from one location to another.

Owner:SWANK PHILIP D +5

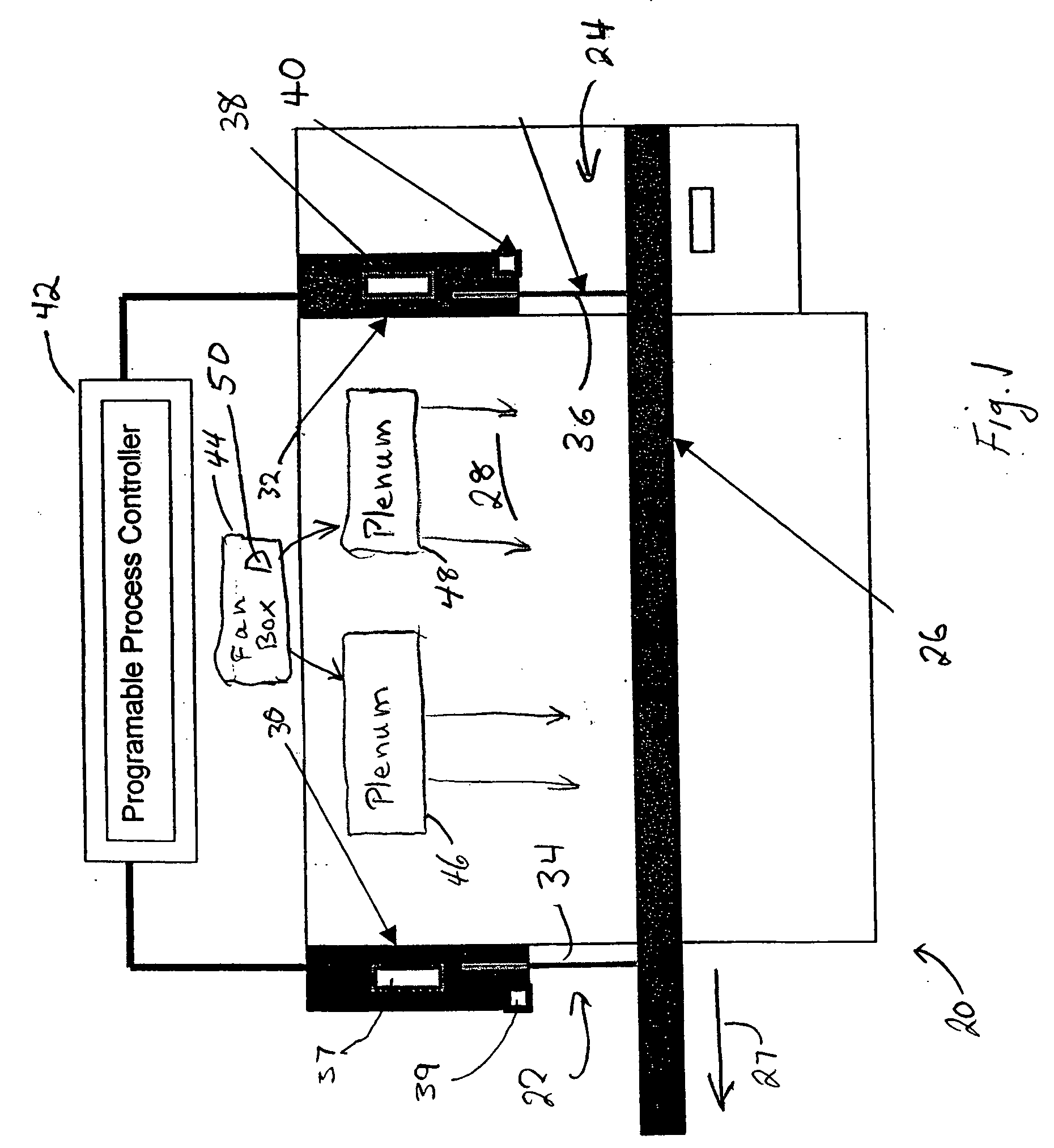

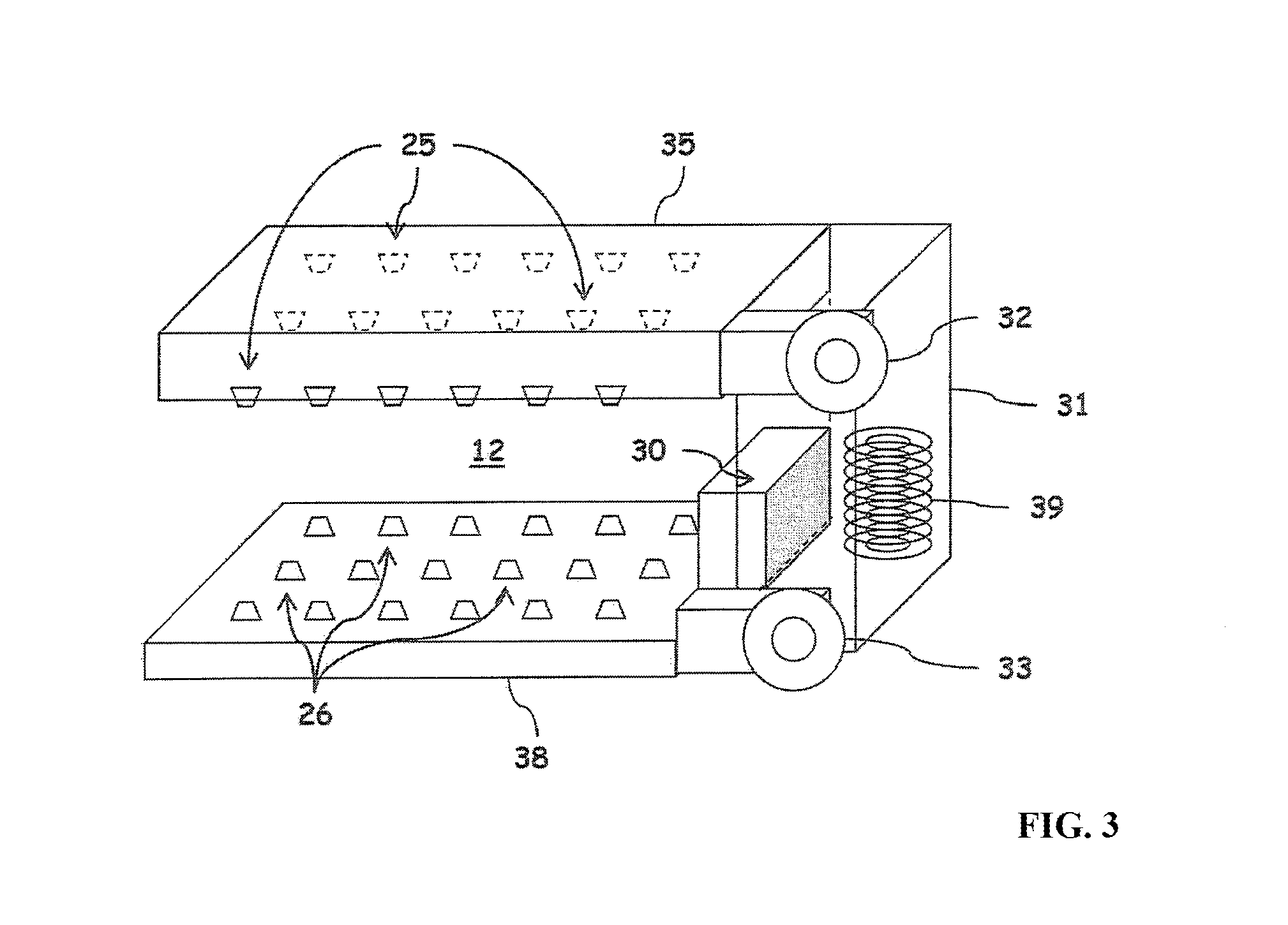

Conveyor oven with energy saving baffle mechanism and method

InactiveUS20050132899A1Reduce cavitiesReduce heat lossFood processingOven doors/gatesProcess engineeringFood products

Owner:LINCOLN FOODSERVICE PRODS

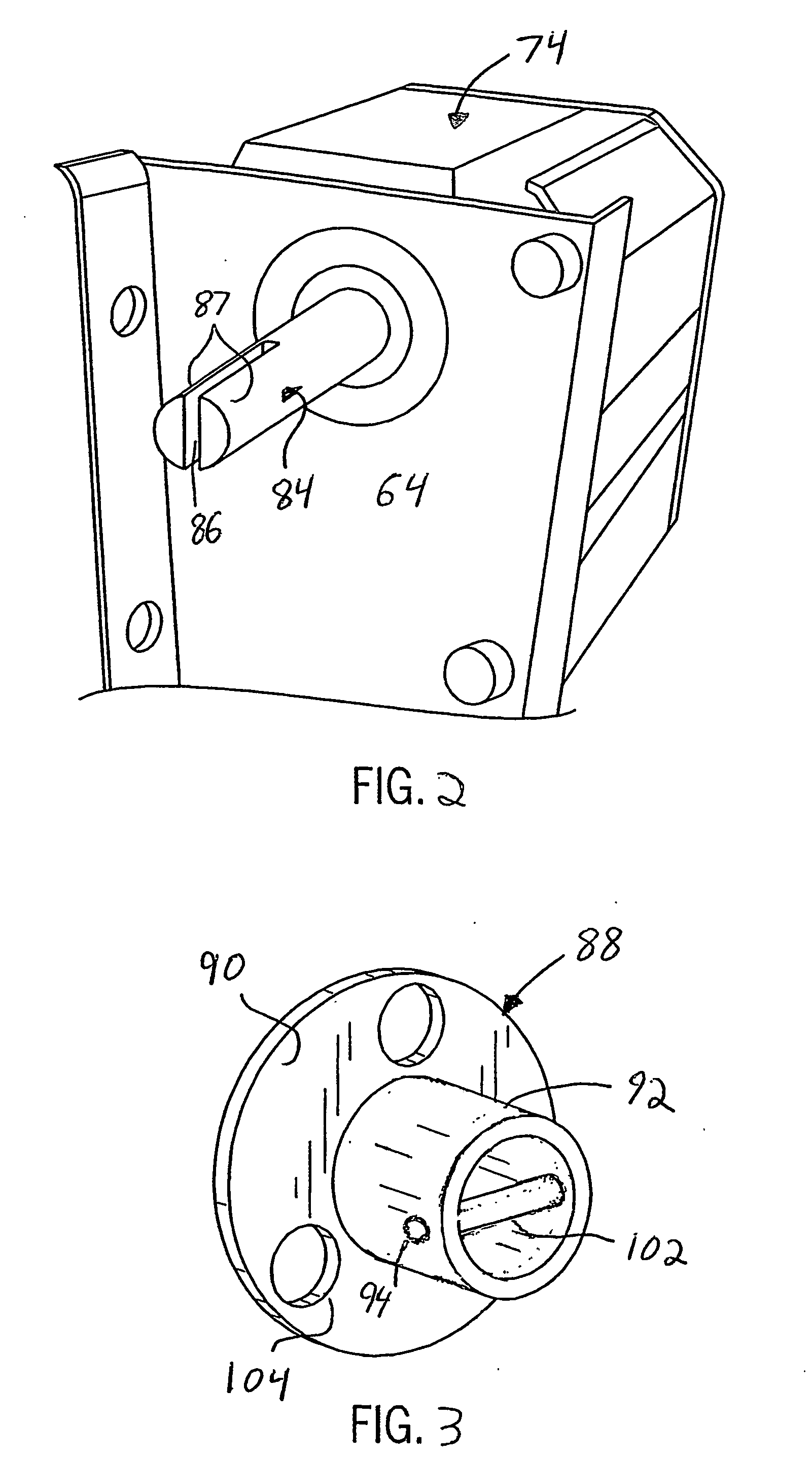

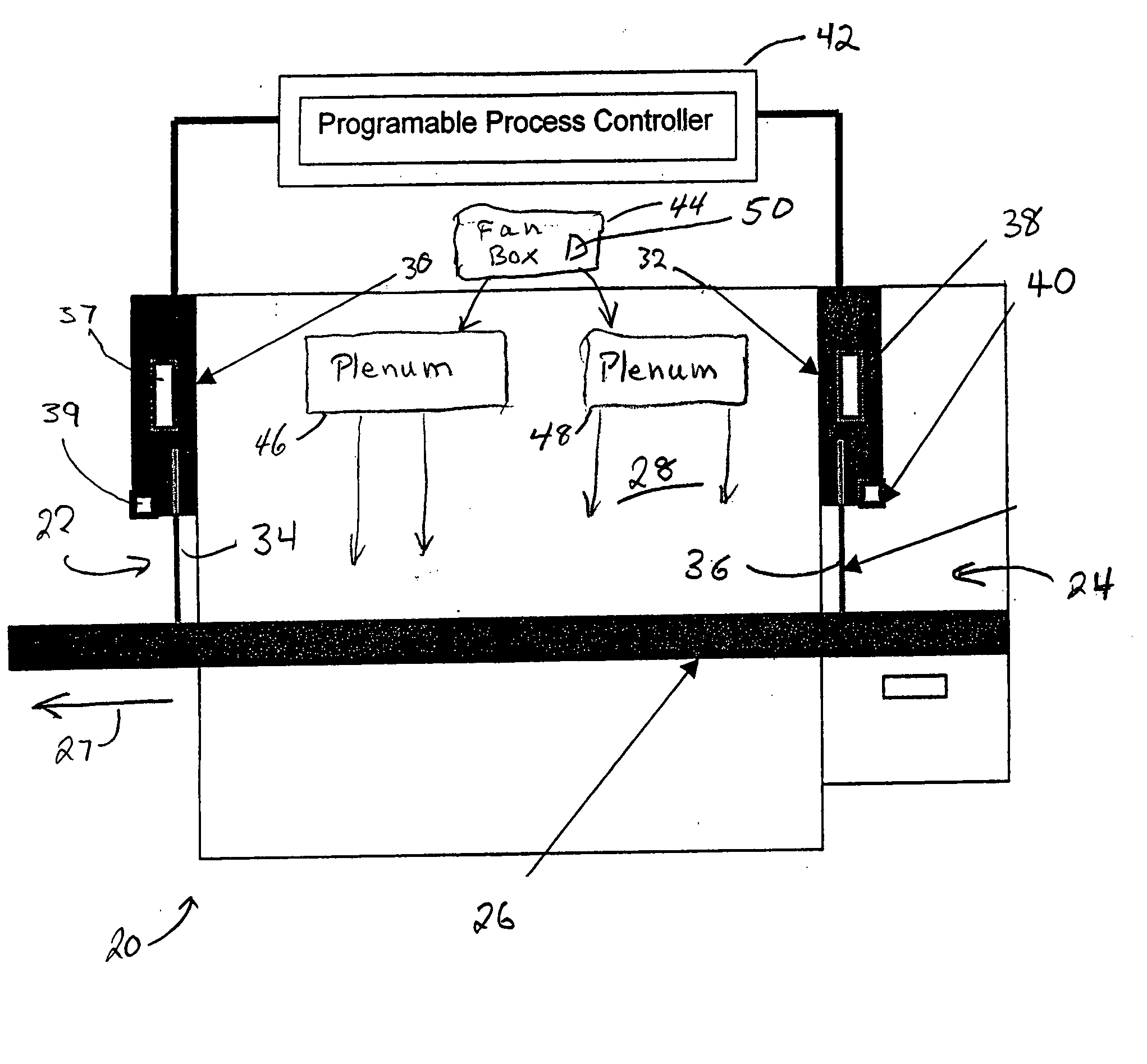

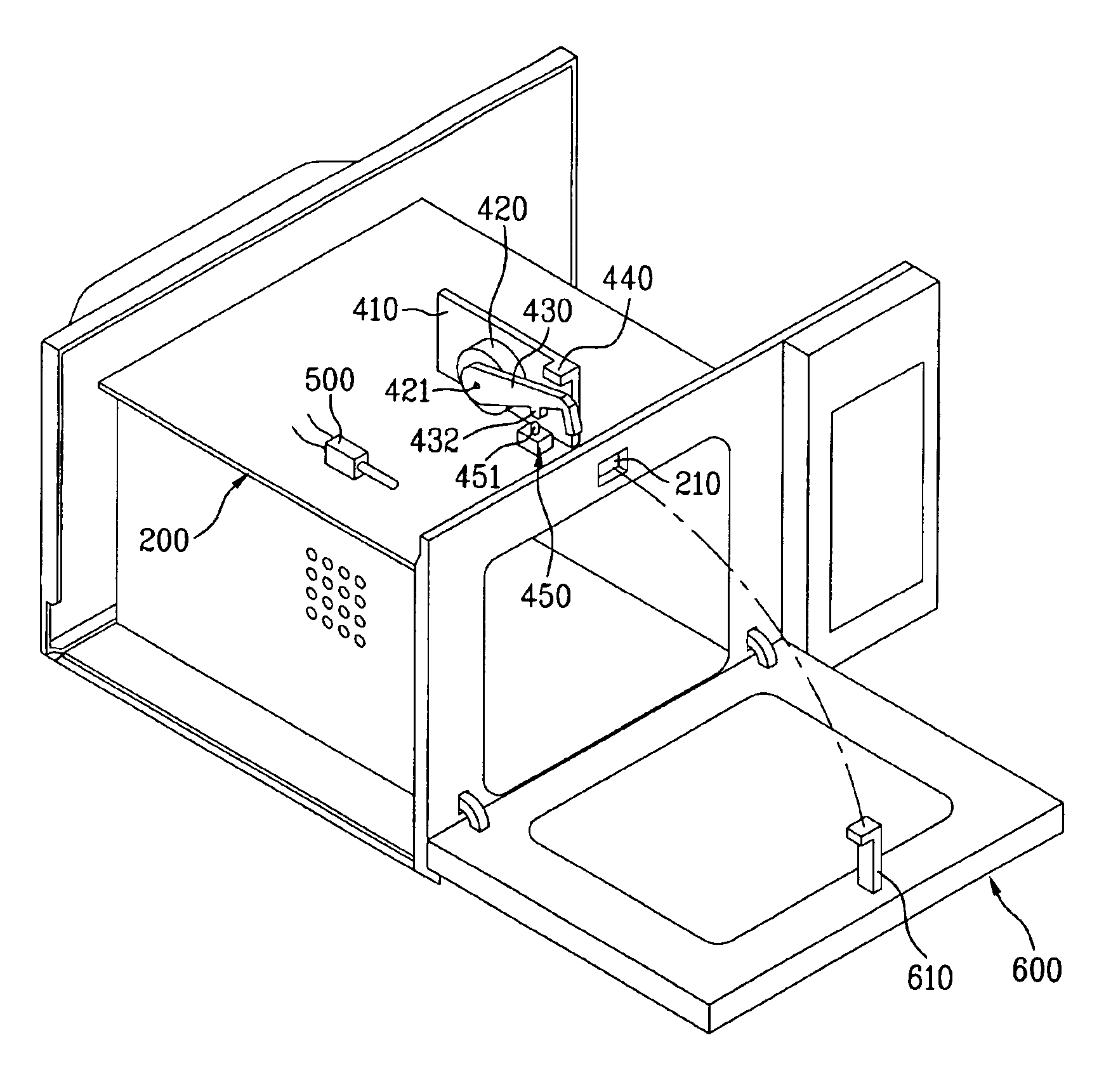

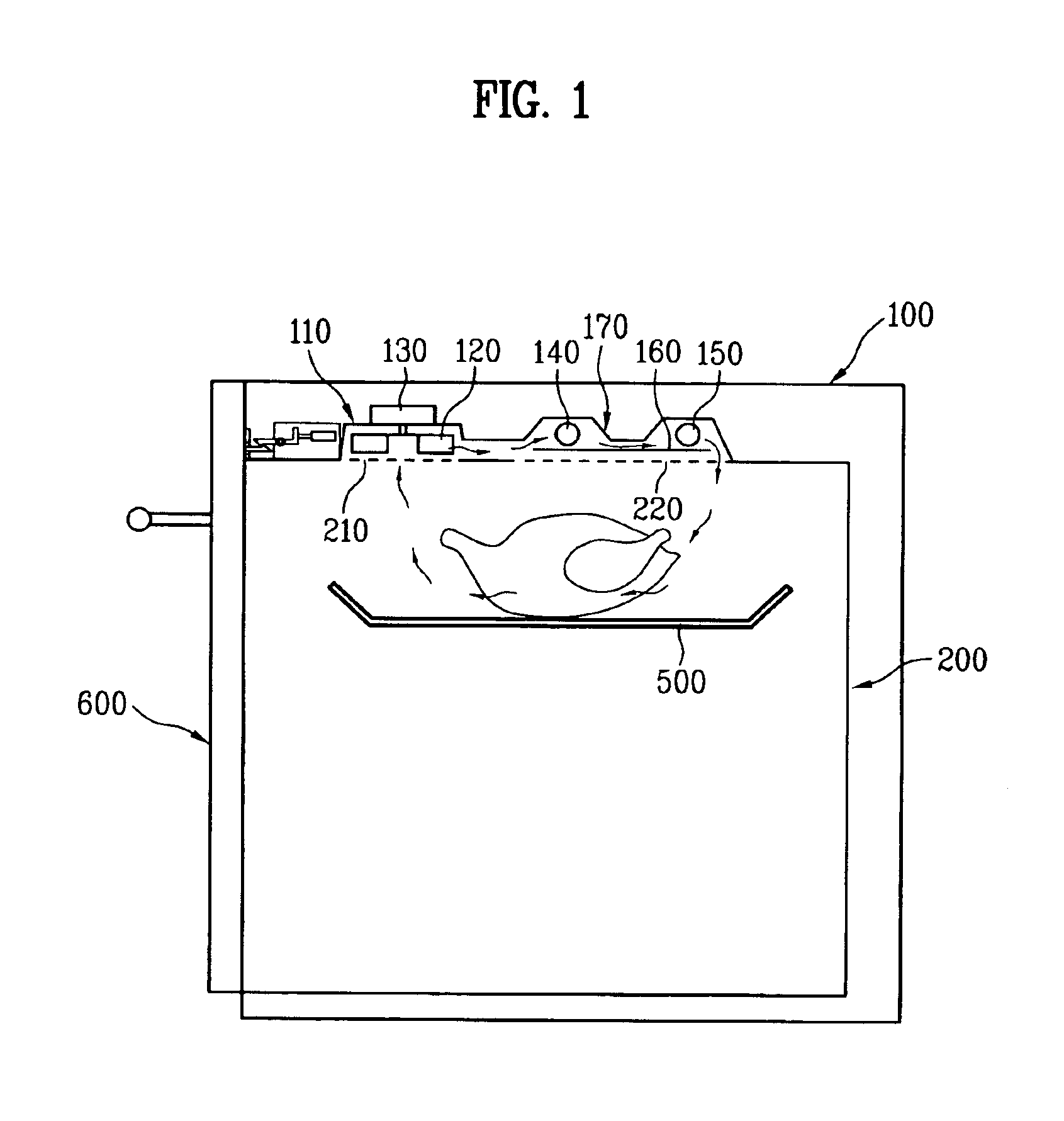

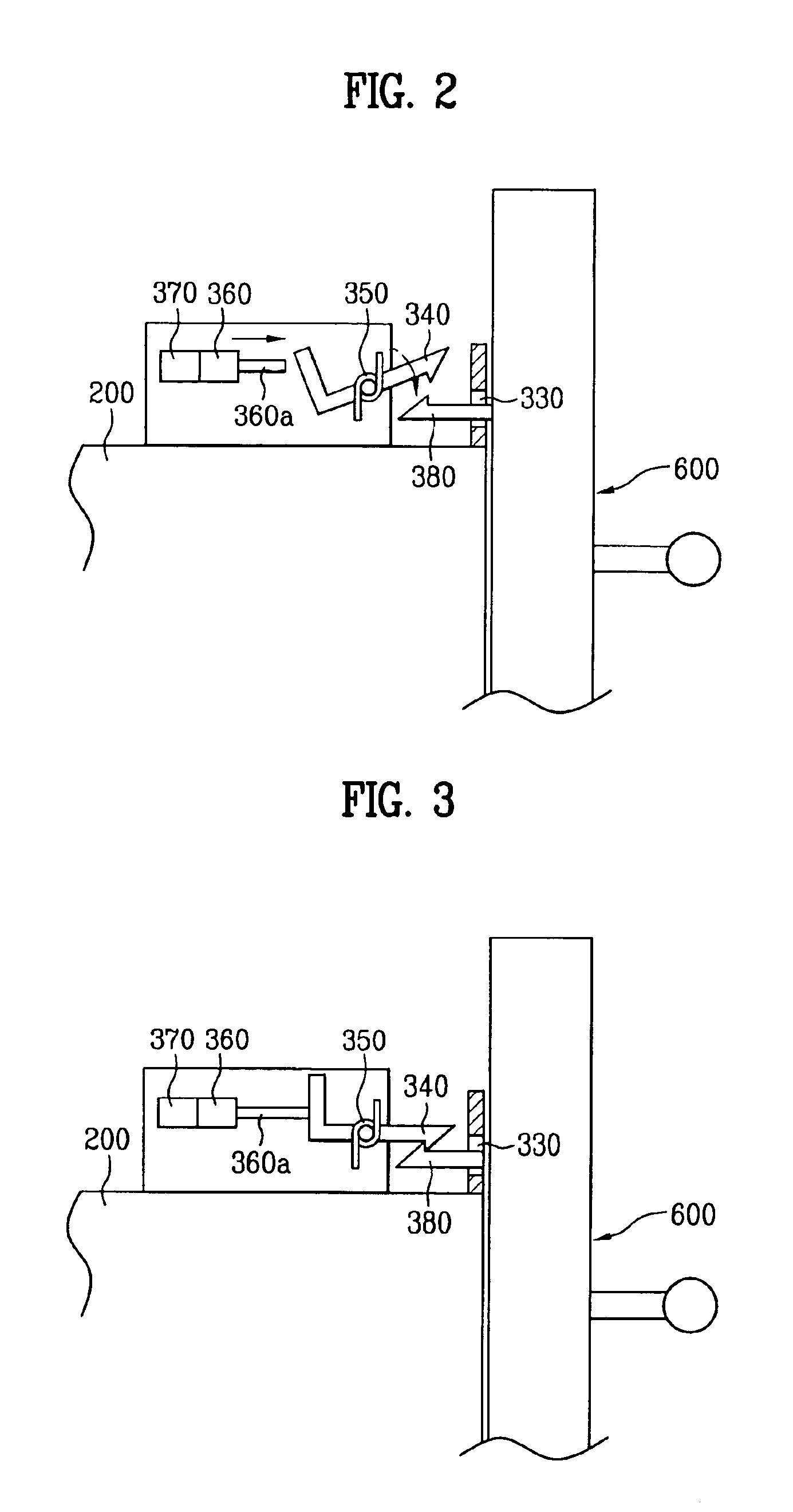

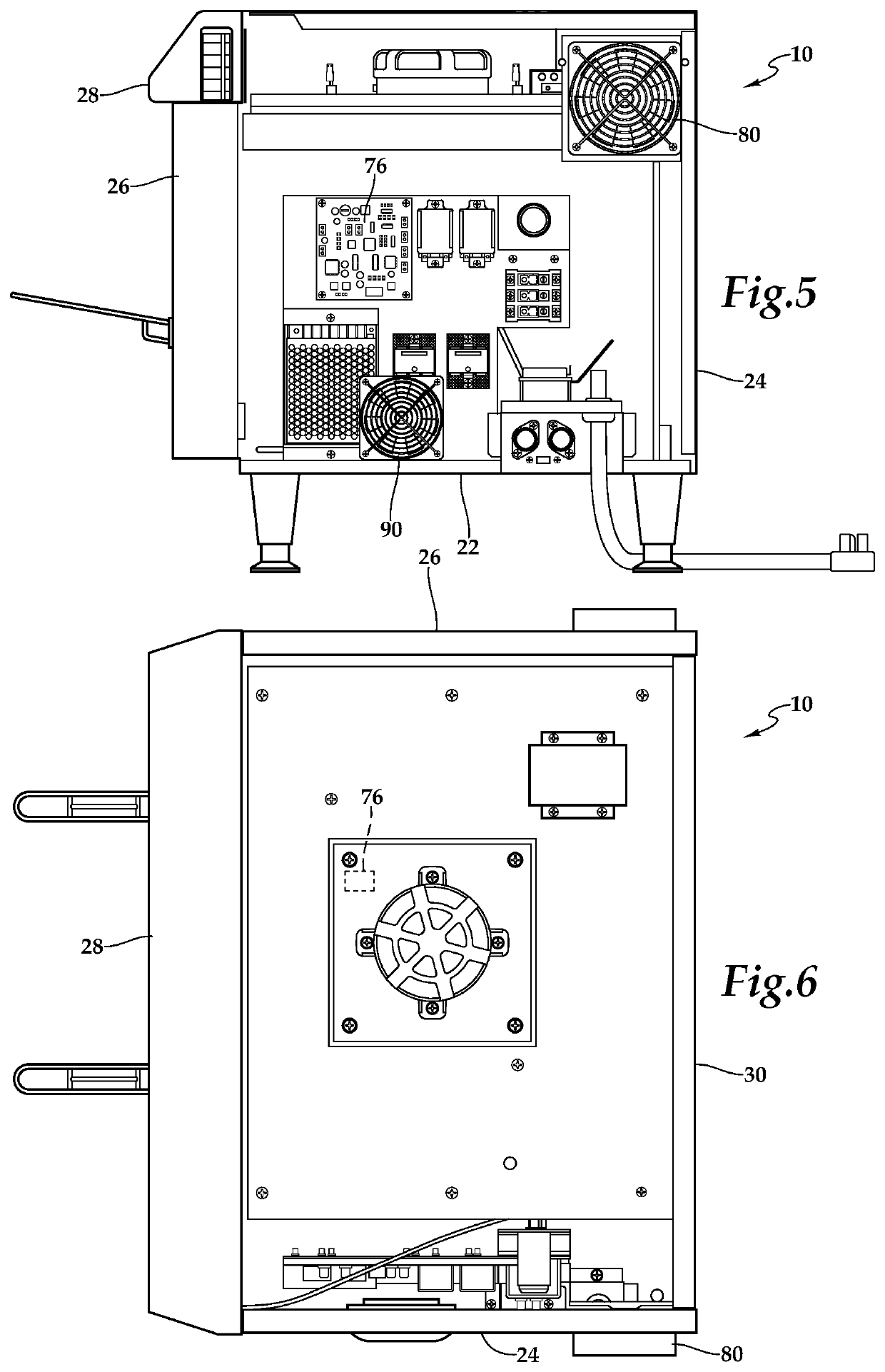

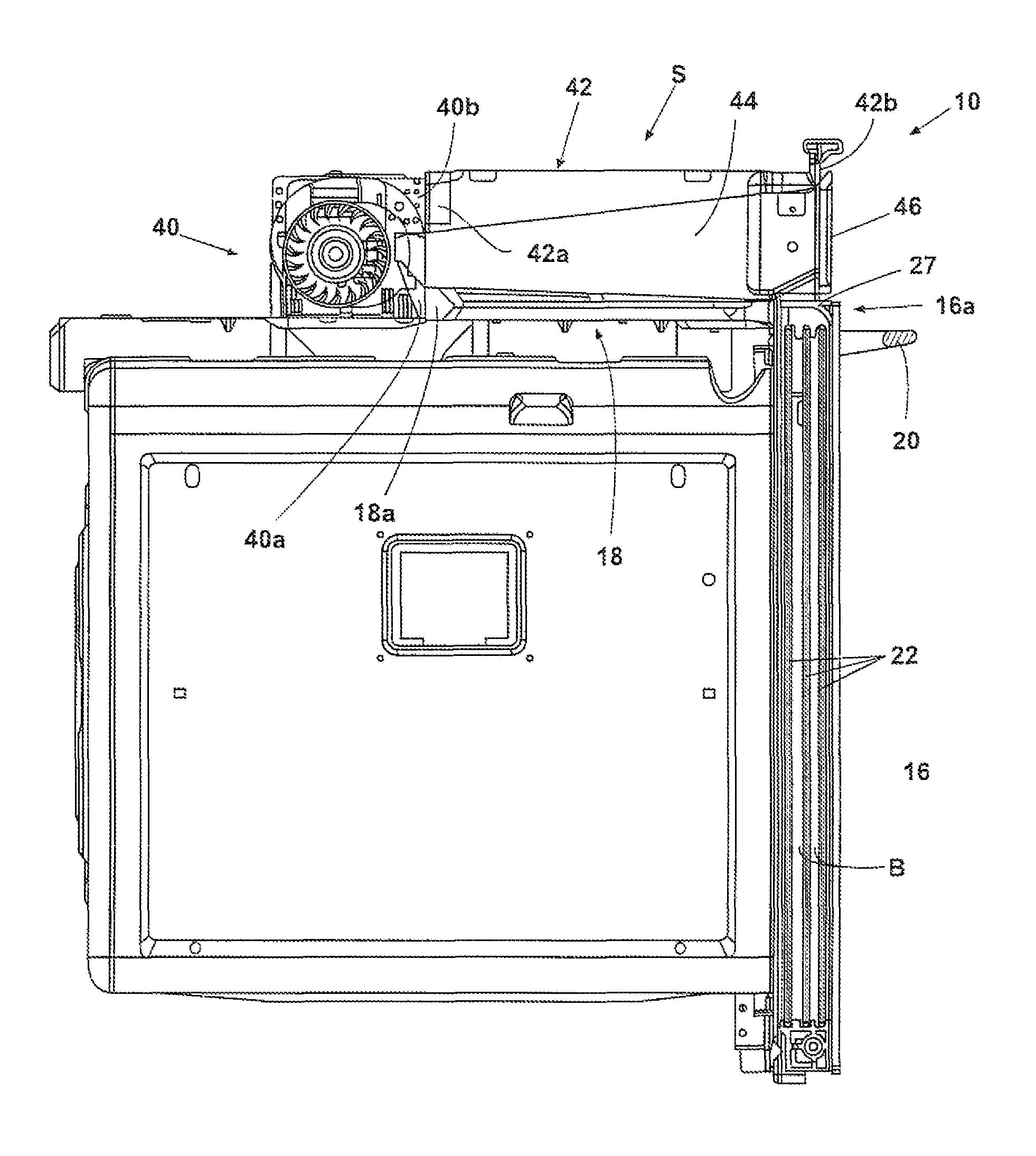

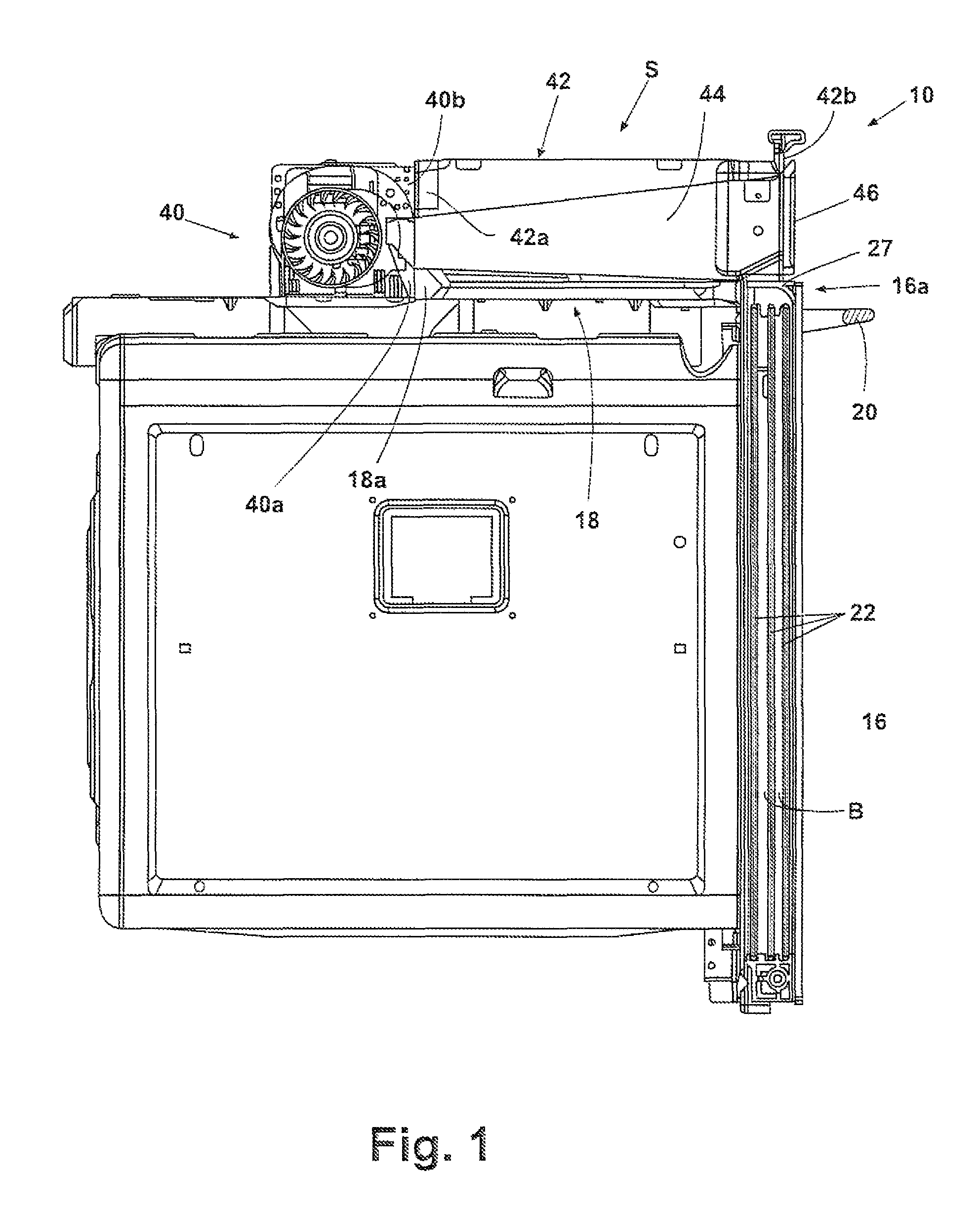

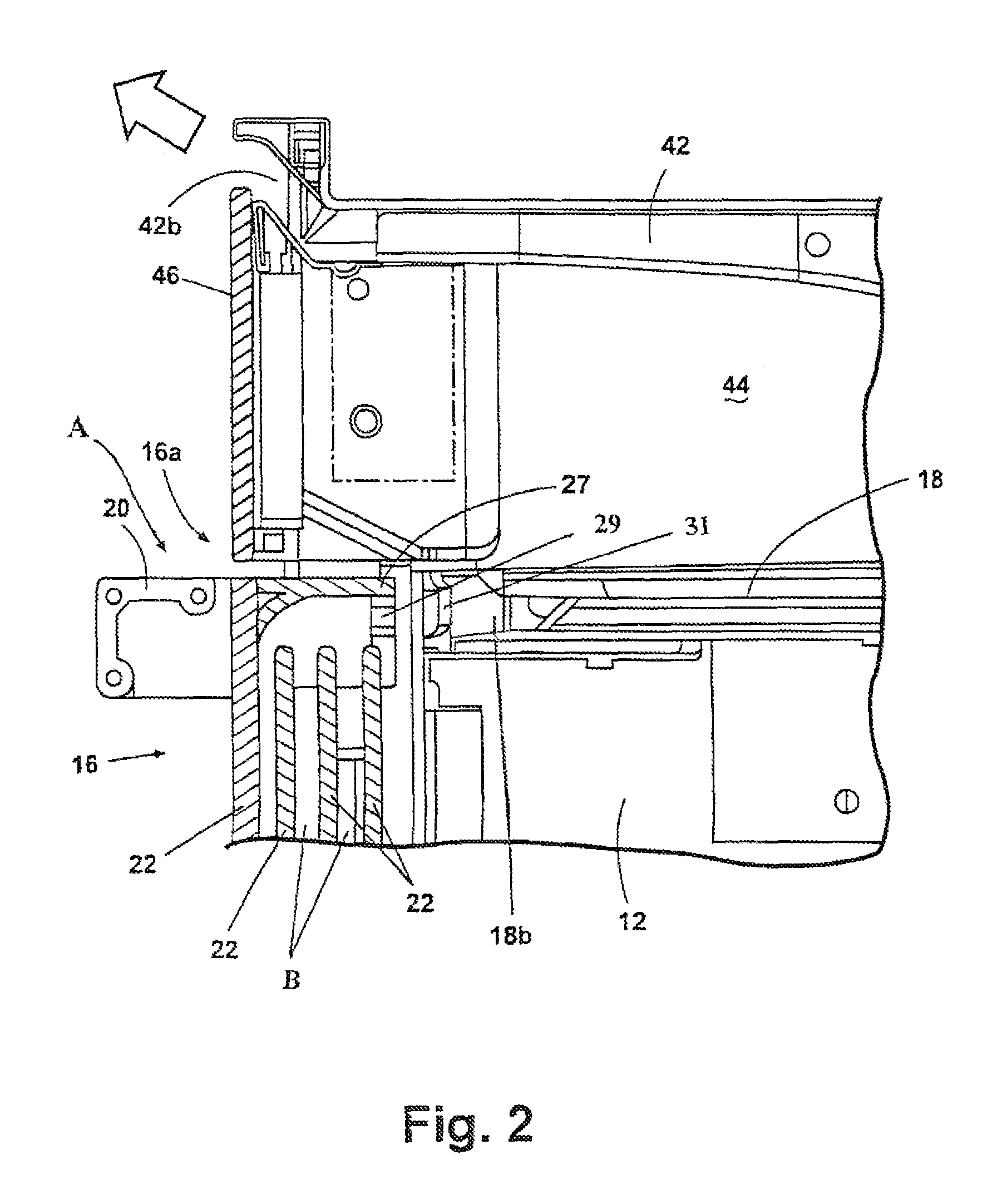

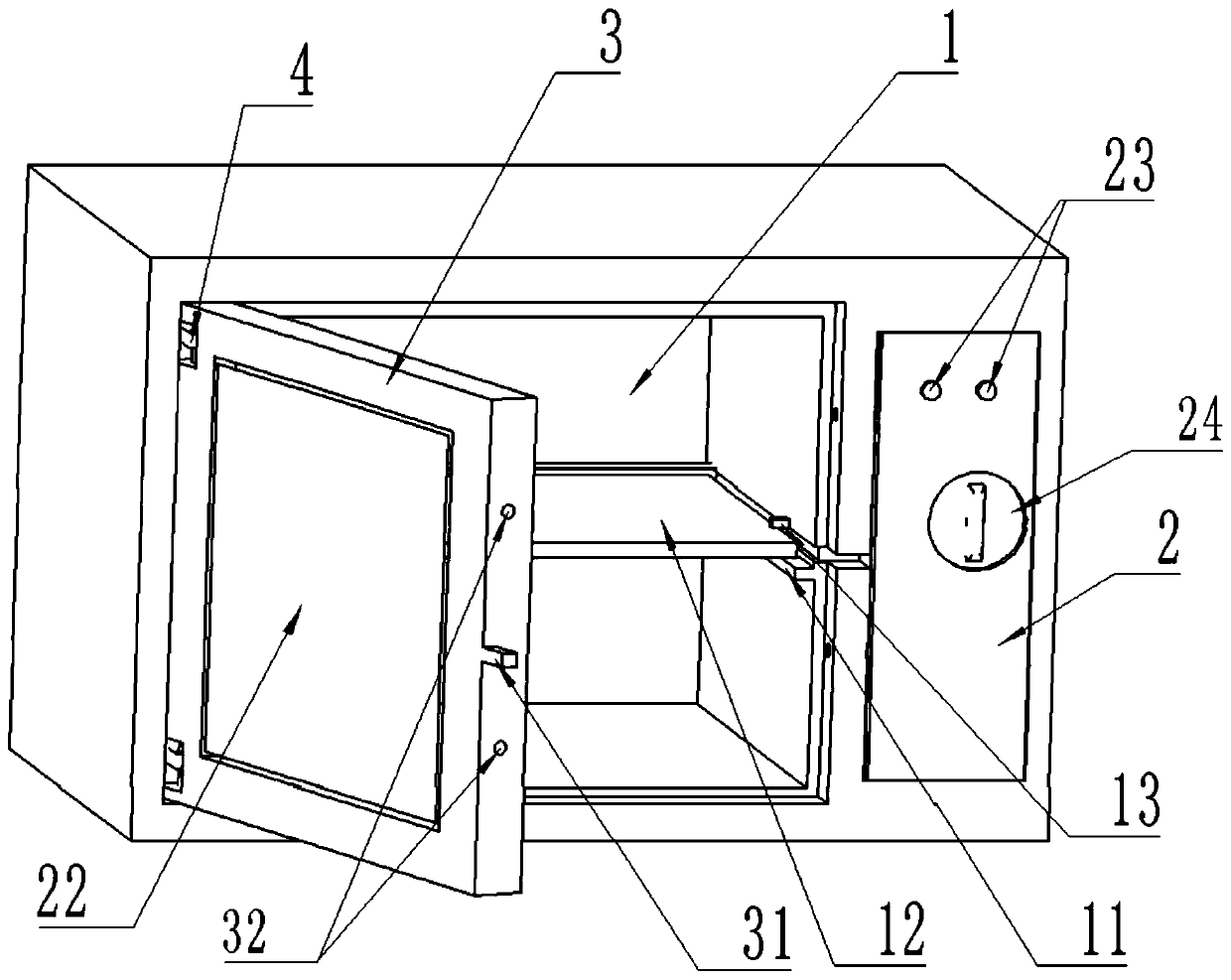

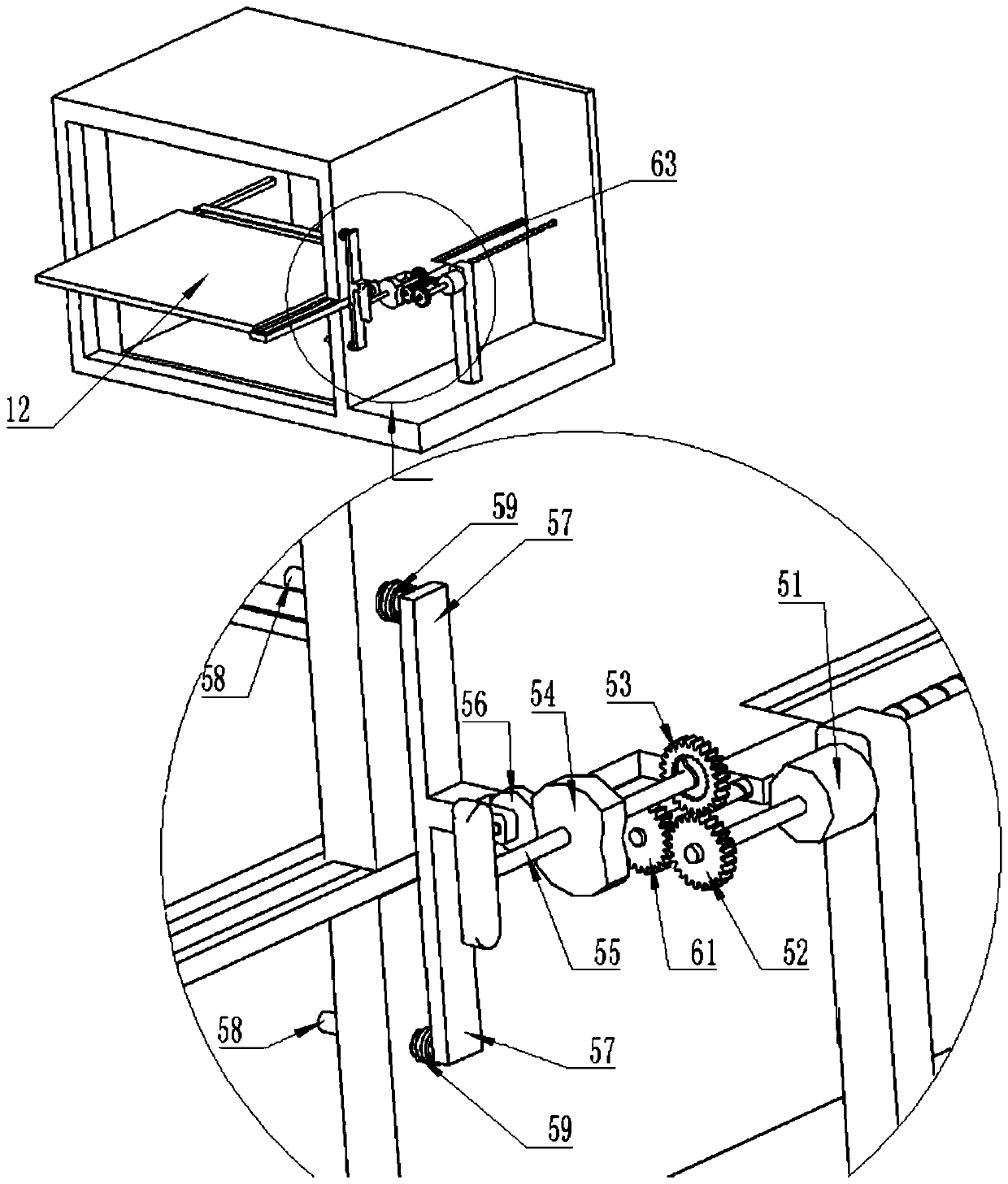

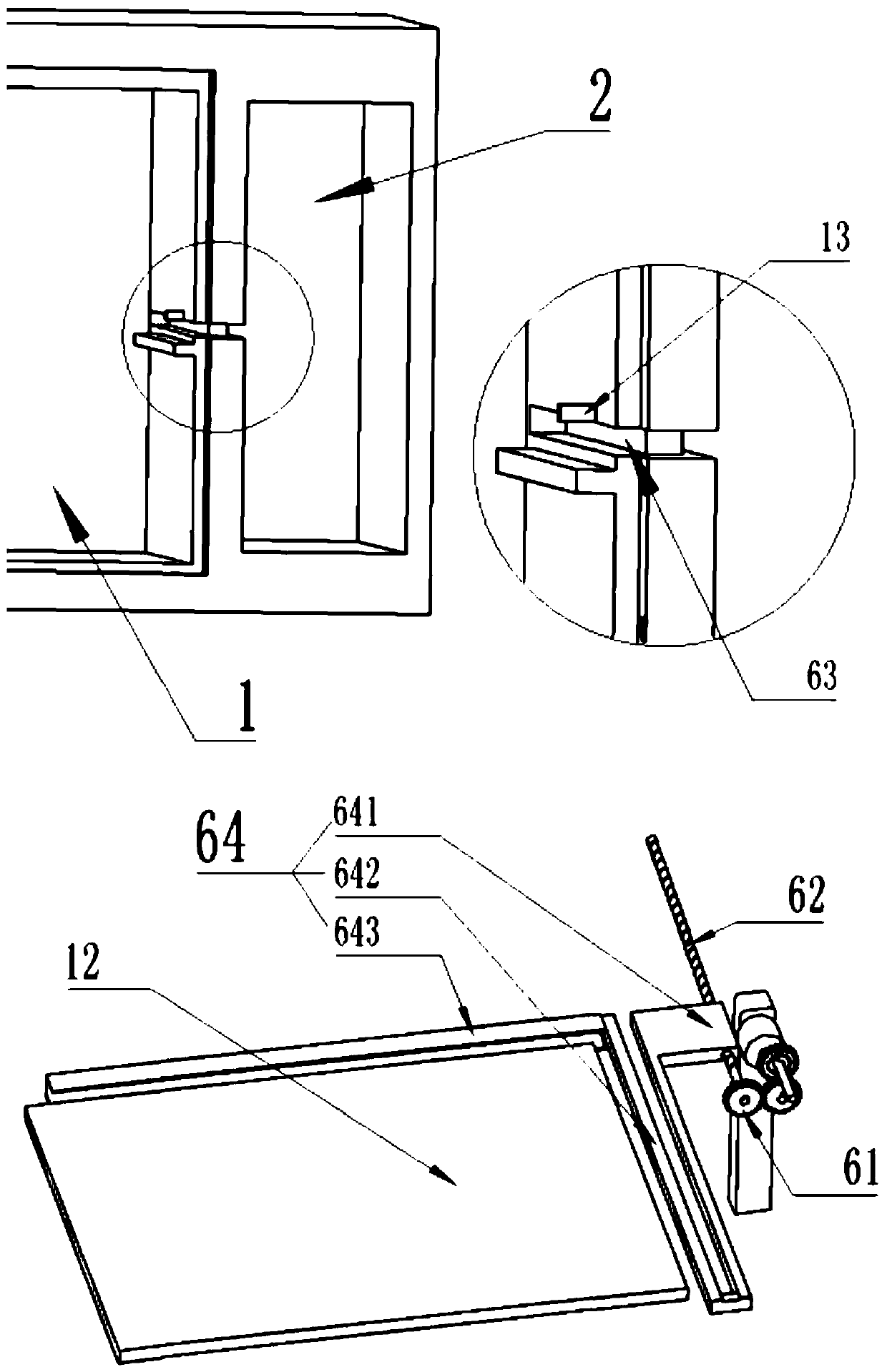

Conveyorized oven with automated door

InactiveUS20020088800A1Improve throughputAmount of heat lossOven doors/gatesMicrowave heatingMicrowave ovenEngineering

The invention is directed to an oven, and in particular, a microwave oven, having an oven cavity, two doors disposed on opposite sides of the oven cavity, and a conveyor belt passing through the oven cavity and the two doors. The two doors are preferably mechanical in design and may be operated simultaneously or in sequence. The two doors may be independently interlocked and also interlocked with each other to prevent operation of the microwave oven when either door is in an opened position. Each door may be mounted in slide rails disposed along the side of the oven cavity. The opening and closing of the two doors are preferably controlled by a programmable logic center.

Owner:ACP OF DELAWARE

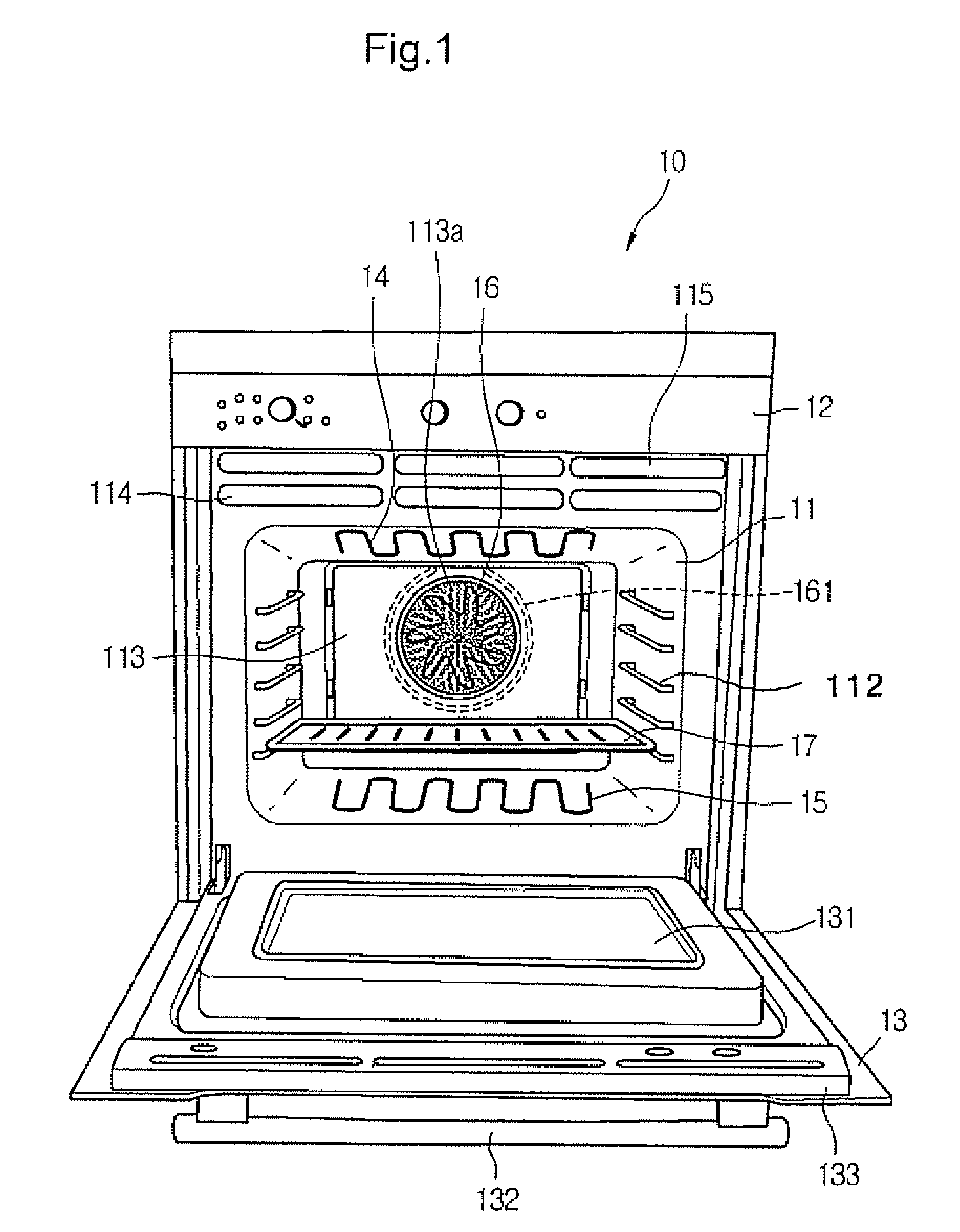

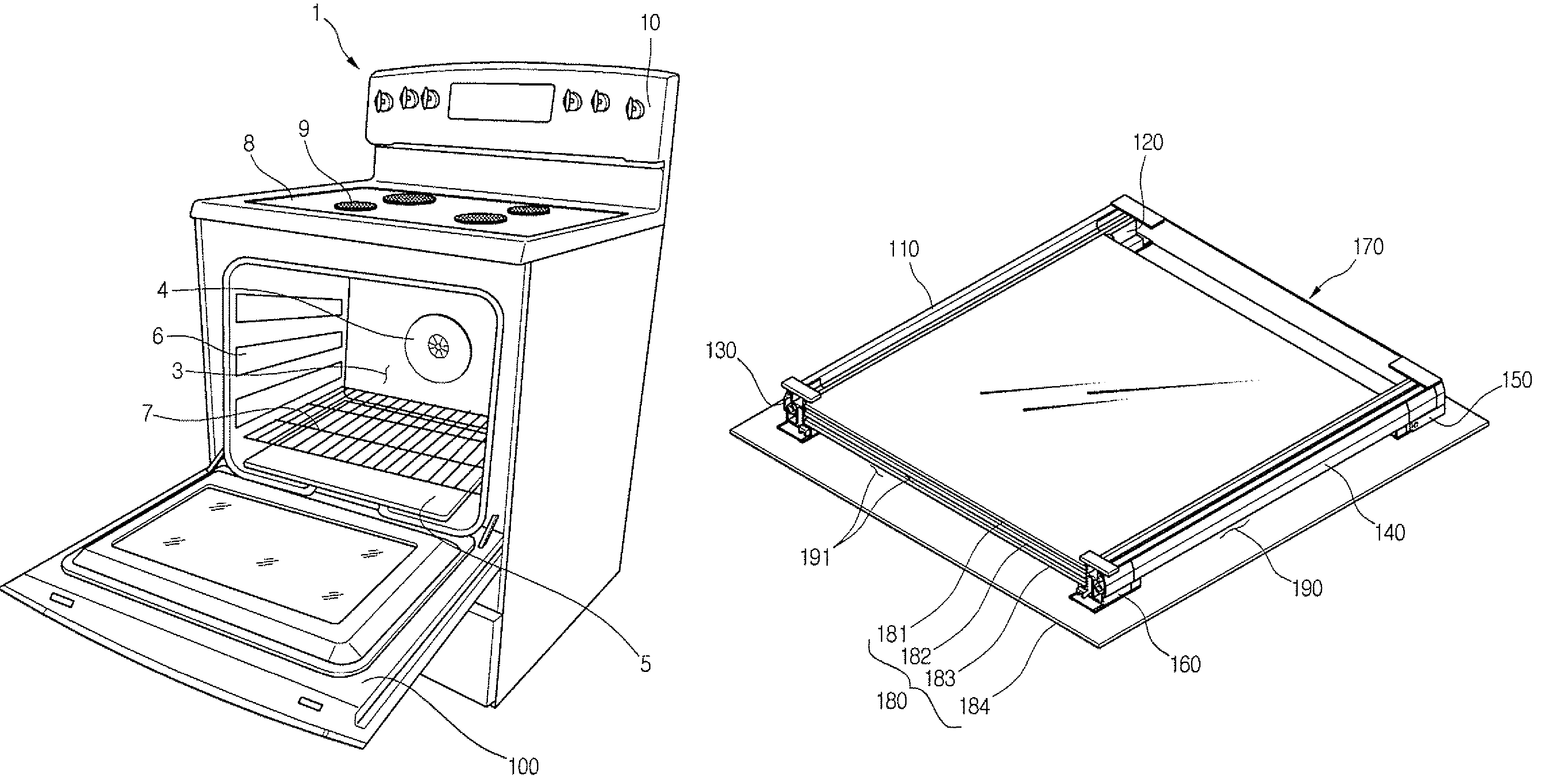

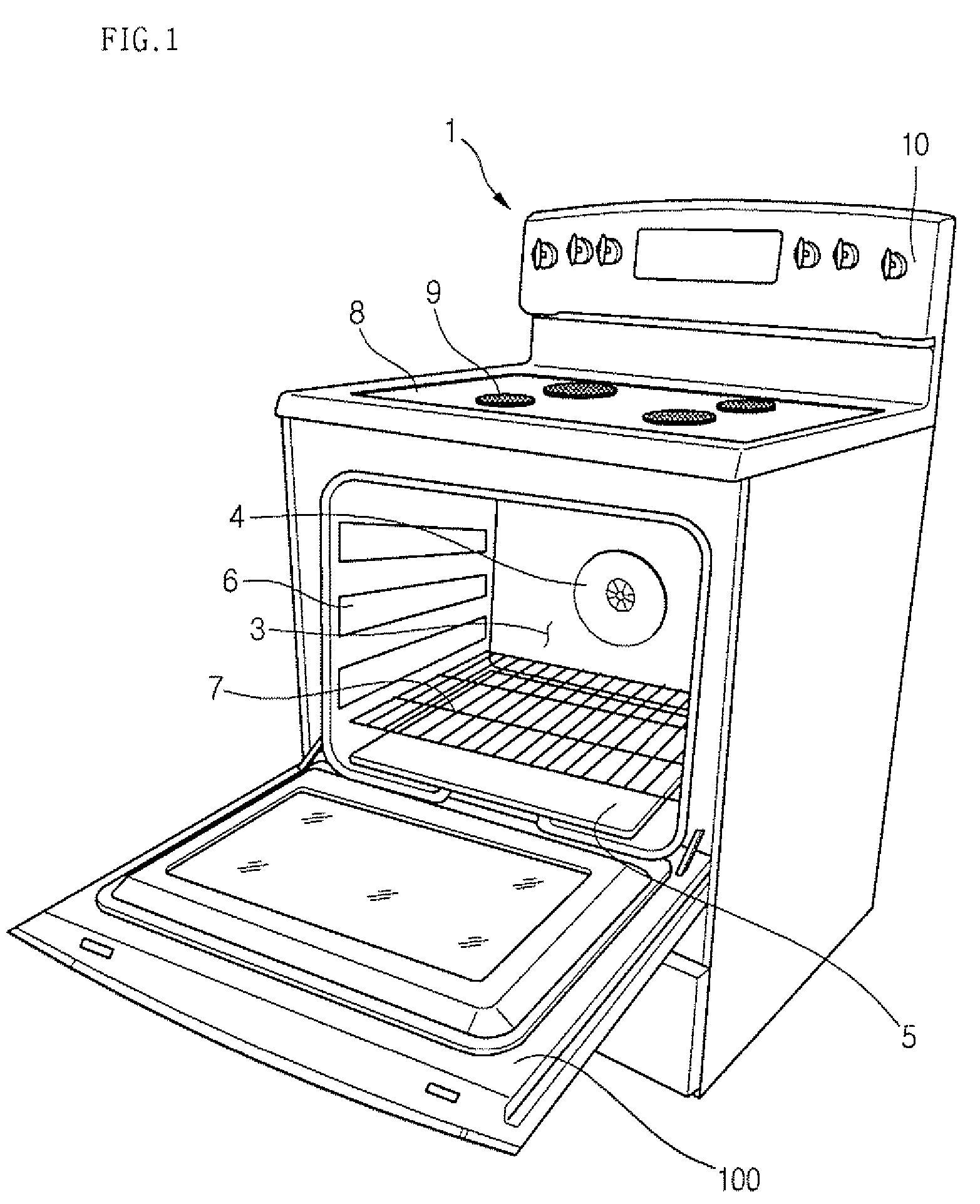

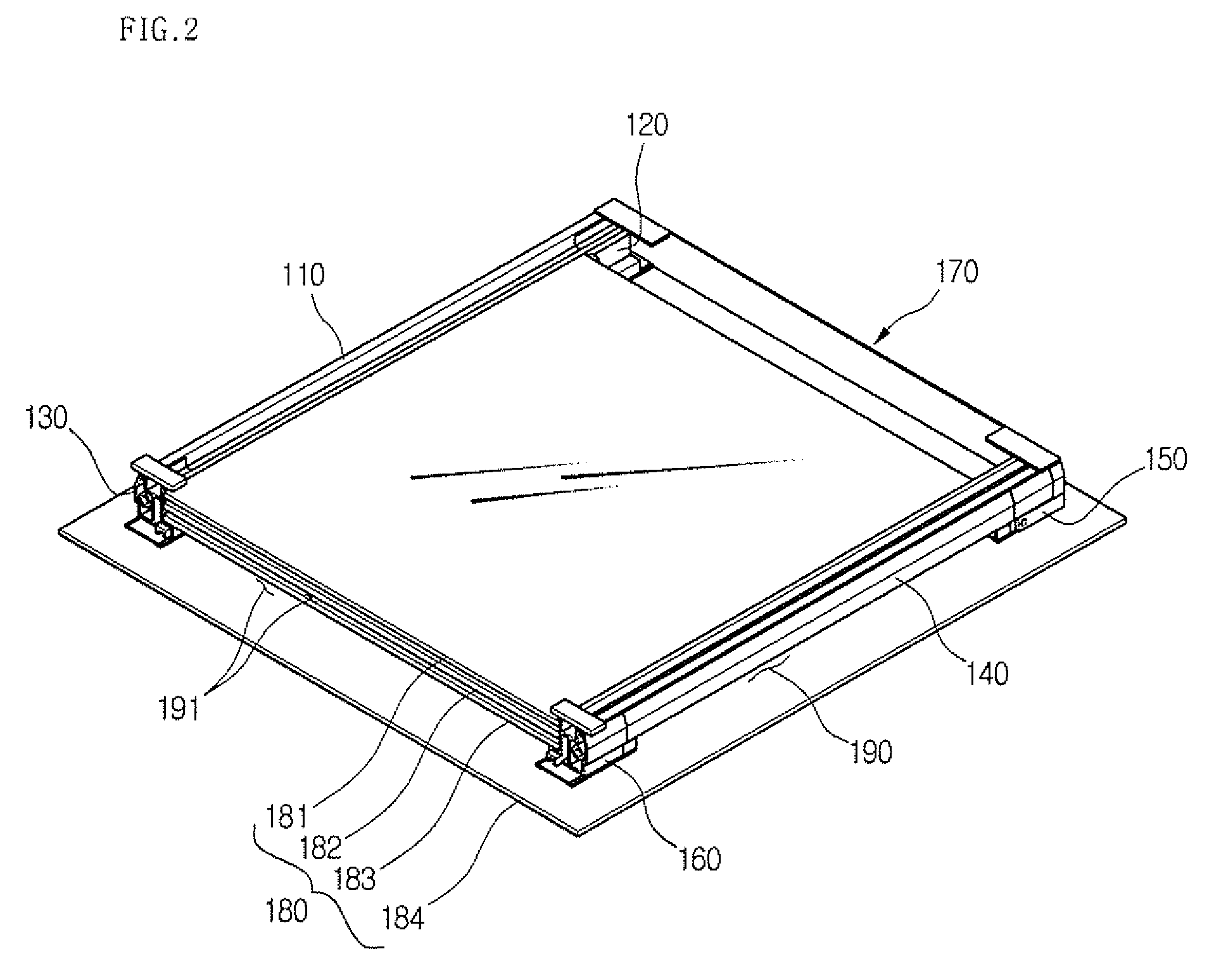

Electric oven

ActiveUS7060940B2Simple structureAvoid componentsDoors for stoves/rangesDomestic stoves or rangesMechanical engineeringIngested food

Owner:LG ELECTRONICS INC

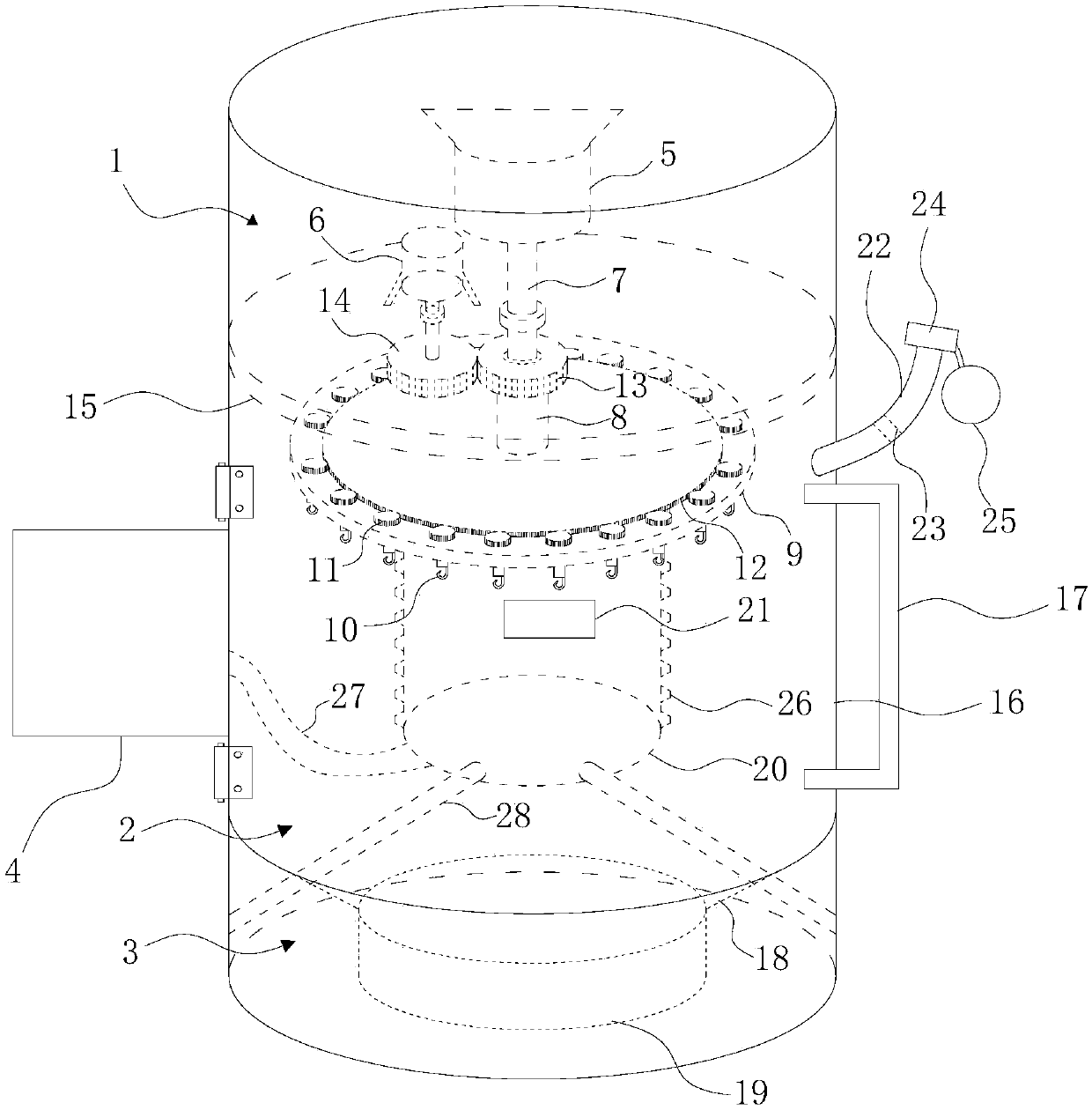

Rotisserie oven

A rotisserie oven is provided having a radiating heating system in combination with a convection heating system to prepare raw meat and poultry food product inside of a cooking chamber. A spit assembly carries the food product, and includes components that are detachable to assist in cleaning. The oven further includes a steam cleaning assembly that is integrated with the convection heating system that assists in grease removal from the components inside the cooking chamber. A humidity removal system regulates the moisture level inside of the cooking chamber during food preparation.

Owner:ALTO SHAAM

Rotisserie oven and hood

A rotisserie oven is provided having a radiating heating system in combination with a convection heating system to prepare raw meat and poultry food product inside of a cooking chamber. A spit assembly carries the food product, and includes components that are detachable to assist in cleaning. The oven further includes a steam cleaning assembly that is integrated with the convection heating system that assists in grease removal from the components inside the cooking chamber. A humidity removal system regulates the moisture level inside of the cooking chamber during food preparation. A rotisserie oven is provided of the type that includes a cooking chamber having at least one open end closed by a movable door assembly. A radiating heating system is disposed in the cooking chamber and receives electricity to produce radiating heat to cook food carried by a rotating spit assembly. A hood assembly is supported by the cooking chamber, and defines a filtration chamber that receives incoming grease-laden air from the cooking chamber and houses at least one filtration member drawing the incoming air therethrough towards a hood outlet. The hood assembly and cooking chamber move together as the rotisserie oven travels from one location to another.

Owner:ALTO SHAAM

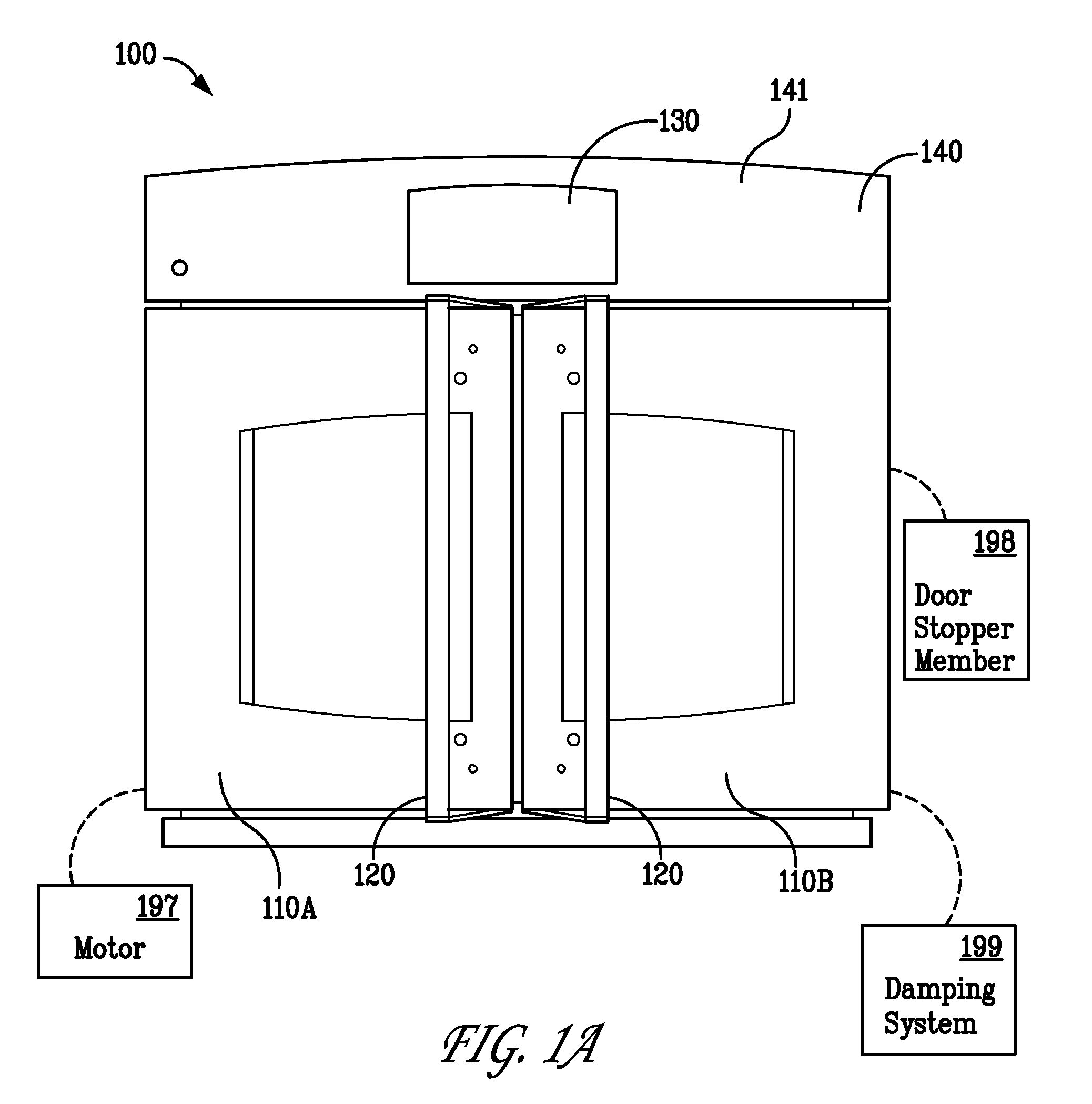

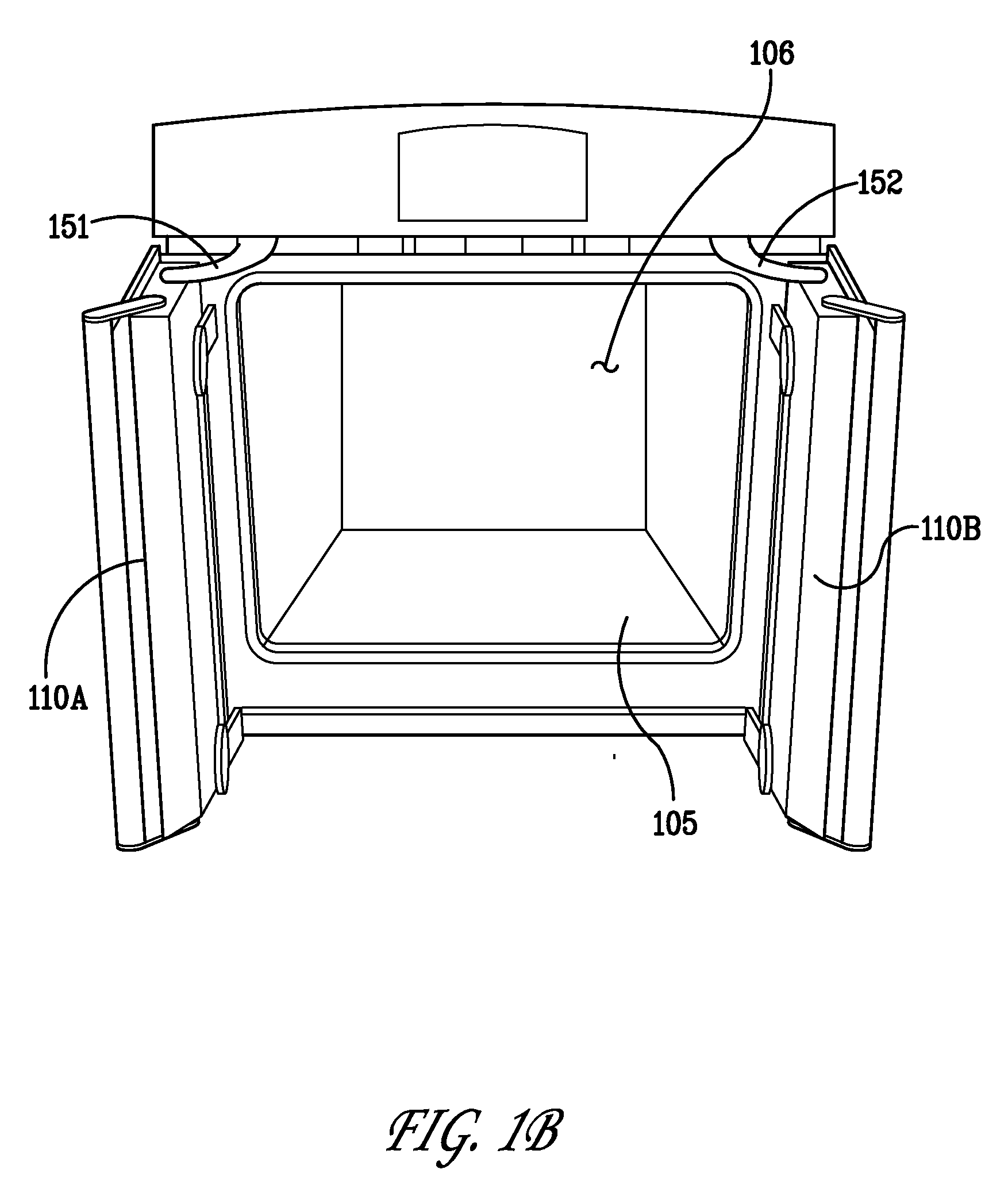

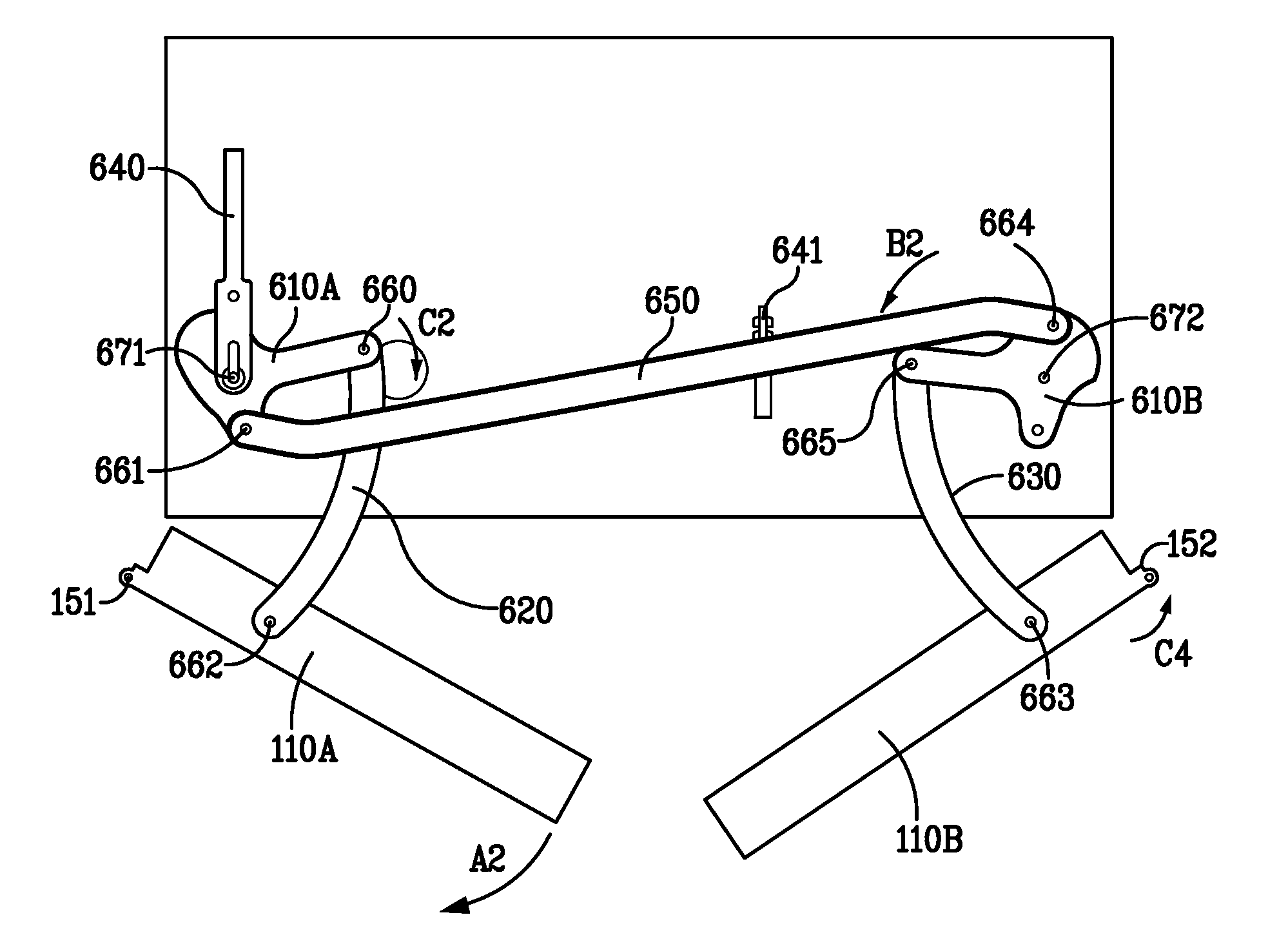

Door coupling system

ActiveUS20100139169A1Overcome disadvantagesWing operation mechanismsDoors for stoves/rangesEngineeringCoupling system

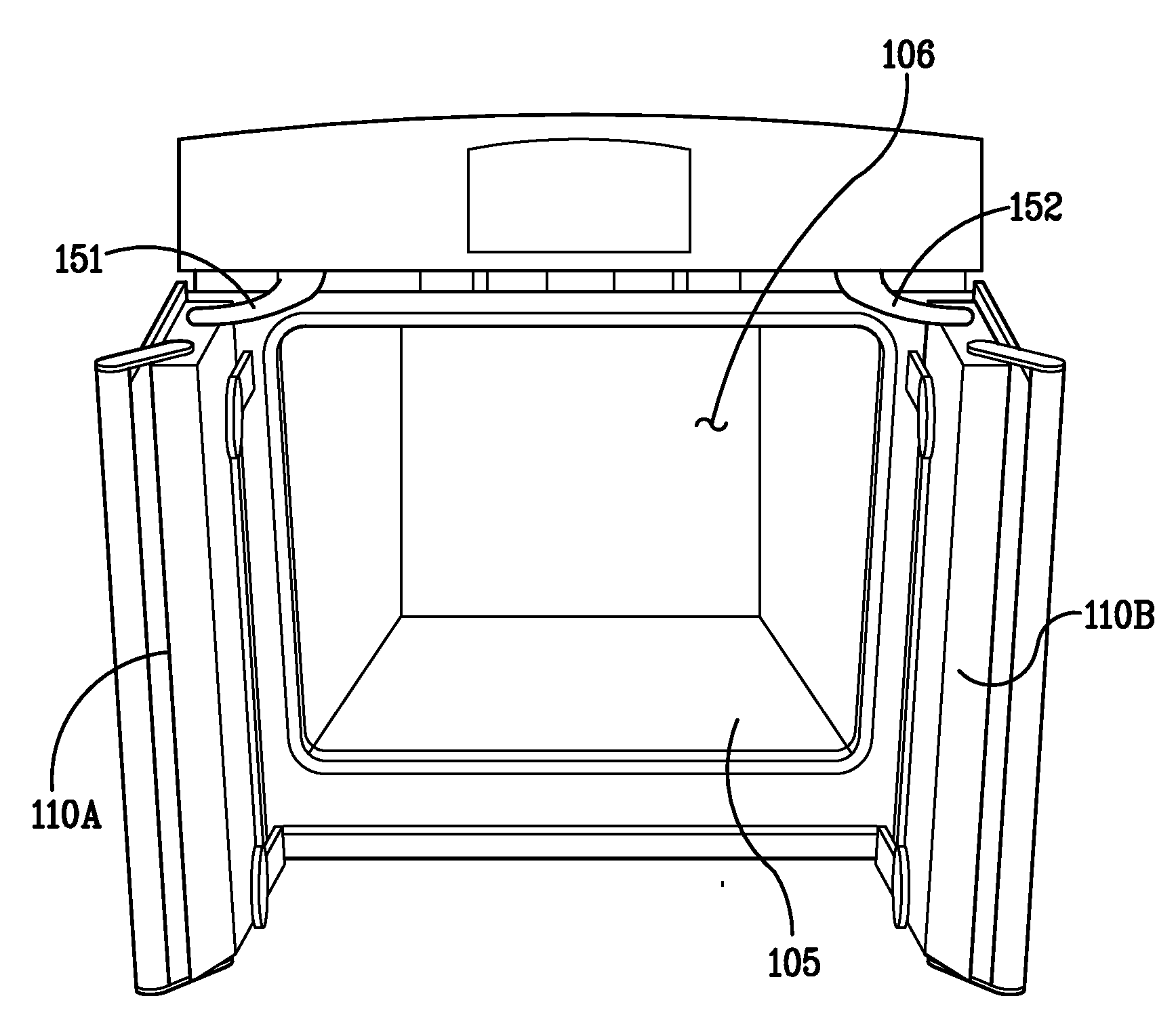

An apparatus including a frame forming an internal cavity, the frame having an opening for accessing the internal cavity, a first door and a second door mounted to the frame and a door coupling mechanism for effecting a substantially simultaneous movement of the first door and second door relative to the frame, the door coupling mechanism including a first door link, a second door link and at least one ternary link, the first door link being rotatably coupled to the first door and the at least one ternary link, the second door being rotatably coupled to the second door and the at least one ternary link.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Safety device of electric oven

ActiveUS6930284B2Prevent openingDoors for stoves/rangesDomestic stoves or rangesElectric machineEngineering

Owner:LG ELECTRONICS INC

Oven provided with aperture for air entry into its cavity

ActiveUS9157640B2No longer cooledDomestic stoves or rangesDoors for stoves/rangesEngineeringAmbient air

An oven comprises a housing or structure presenting a plurality of inner walls and outer walls, the inner walls defining an oven cavity in which means are provided for cooking foods, the means comprising a grill for browning the foods, the oven also comprising a door for closing the cavity. At least one aperture is present in at least one of the walls of the oven cavity, or in the door, for selective connection to the environment external to the oven, such as to interceptably introduce fresh ambient air into the cavity, controllable interceptor means being provided at the aperture to enable this selectivity in introducing the ambient air into the cavity.

Owner:WHIRLPOOL CORP

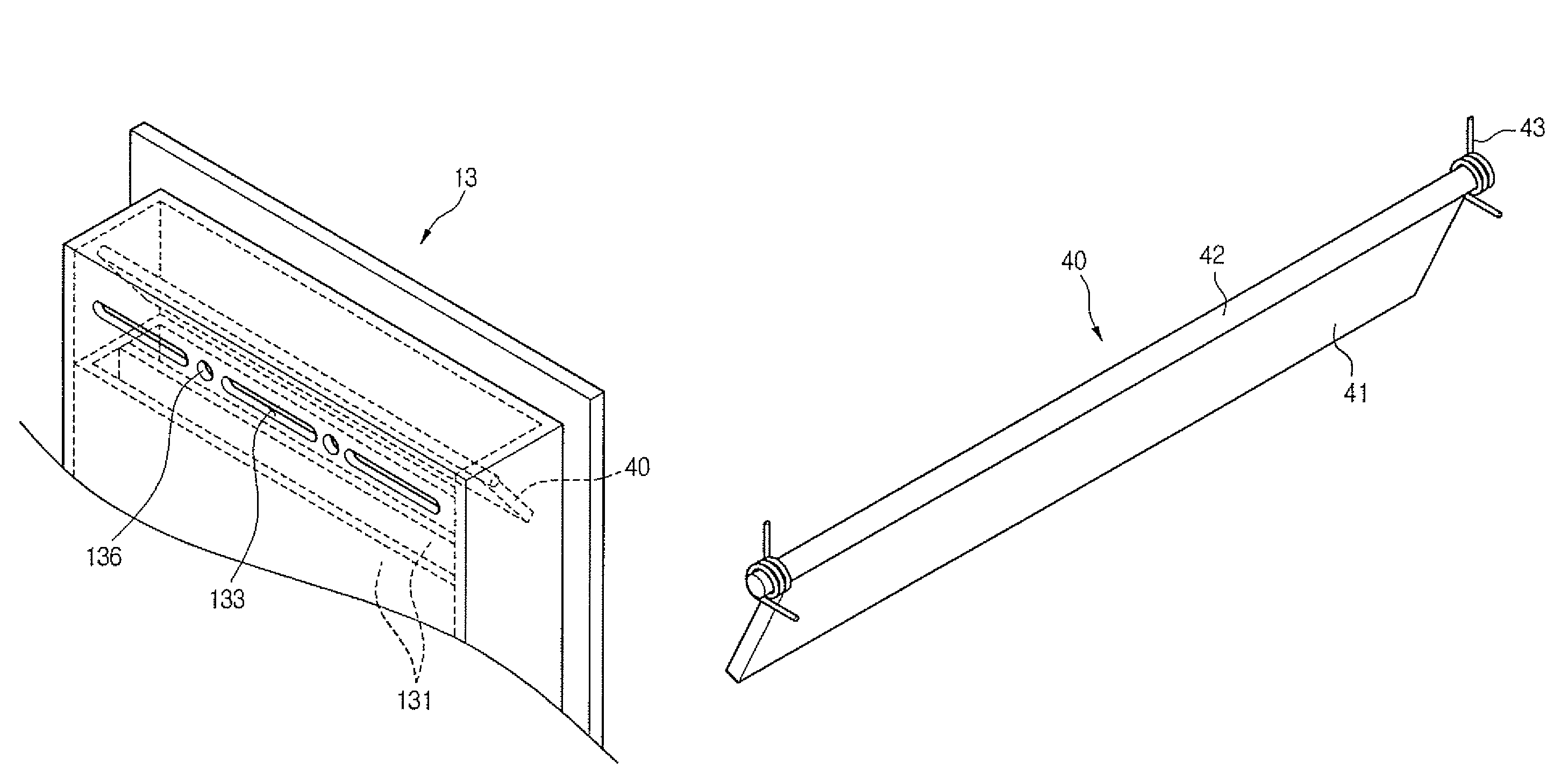

Conveyor oven

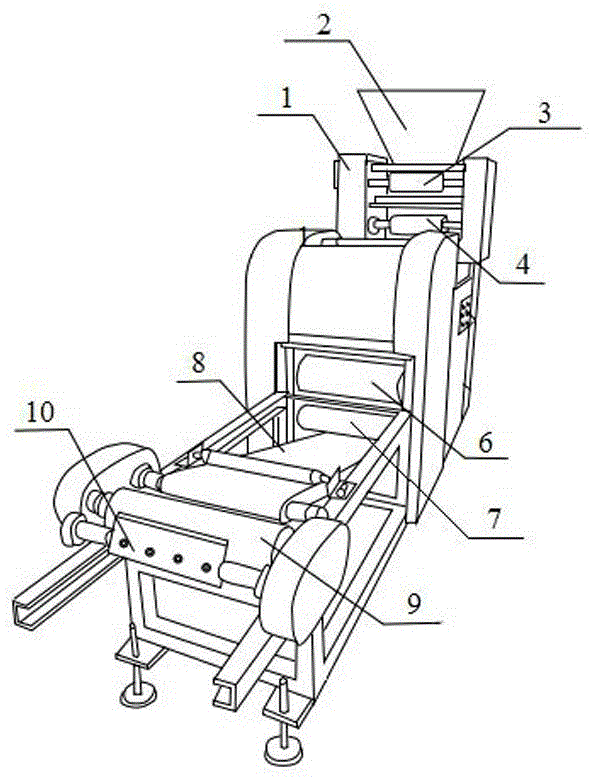

A conveyor oven is disclosed. The conveyor oven includes a housing, a conveyor belt, a first and second doors, and a heat source. The housing includes a cavity and a first and second openings. The conveyor belt is configured to receive and transport food items in and out of the cavity through the first and second openings. The conveyor belt includes a loading section and an unloading section for food. The first and second doors cover first and second openings, respectively, in order to prevent heat within the cavity from escaping through the first and second openings during operation. Configured to provide different cooking times and thermal profiles to various types of food items, the heat source provides heat to the cavity for heating up any food item placed on a portion of the conveyor belt located within the cavity.

Owner:OVENTION

Electric oven

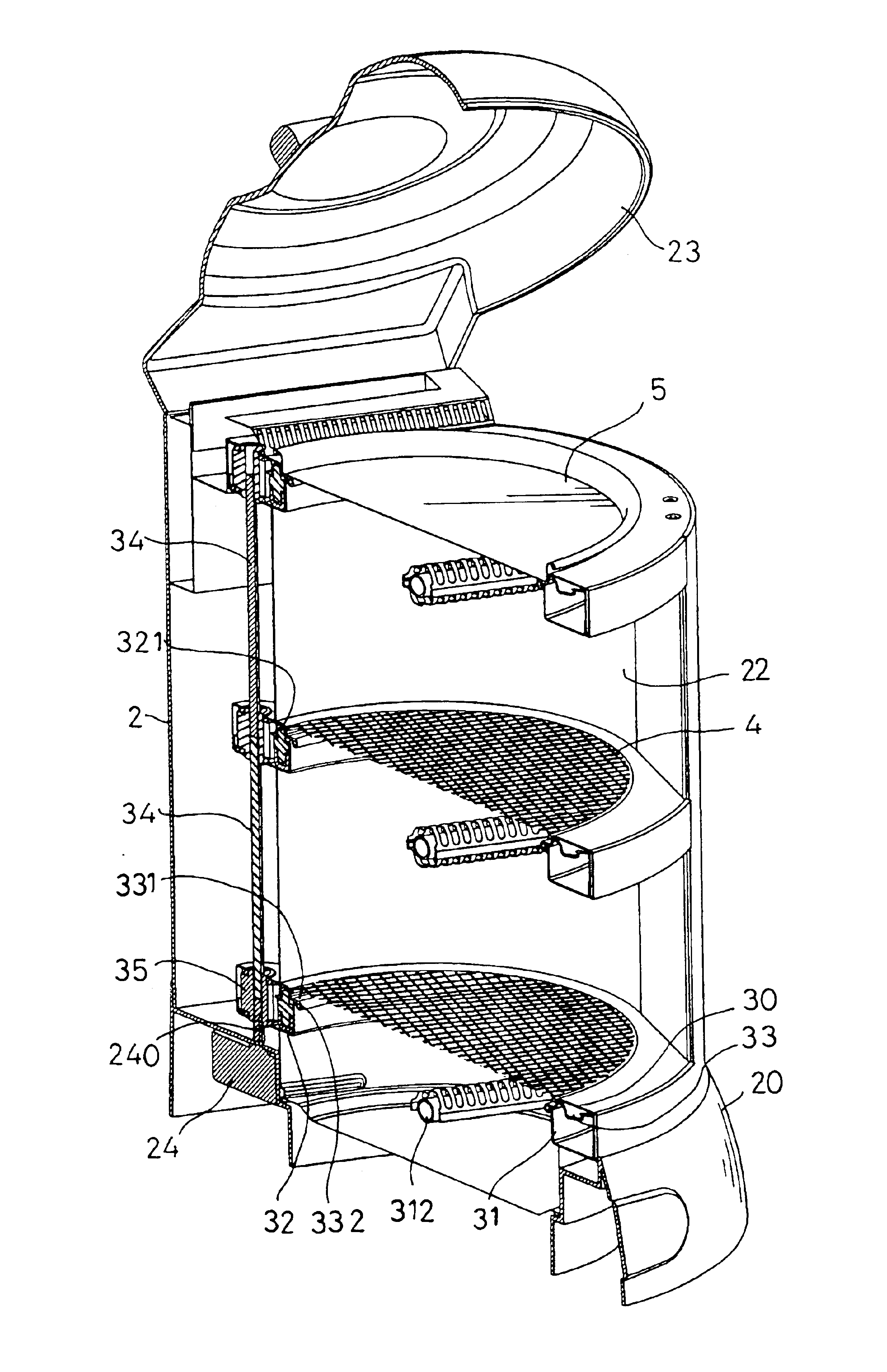

An electric oven includes a housing having a door at a front, a chamber in an interior and a motor at a bottom; rotating devices installed in the housing and each consisting of an upper frame, a lower frame, roller seat assemblies, a gear wheel, a driven shaft and a driven gear; and, net racks capable of being rested on the gear wheels. In using, the motor is actuated to turn the driven shafts and gears to synchronously rotate the gear wheels to make the net racks rotated accordingly for roasting food articles evenly. The rotating devices designed to be located in multiple layers can be placed with various food articles, thus enabling one single electric oven to roast the various food articles at the same time. A pan can be rested on the rotating device that is positioned at a top layer for frying, roasting, boiling and deep-frying.

Owner:LEE MING TSUNG

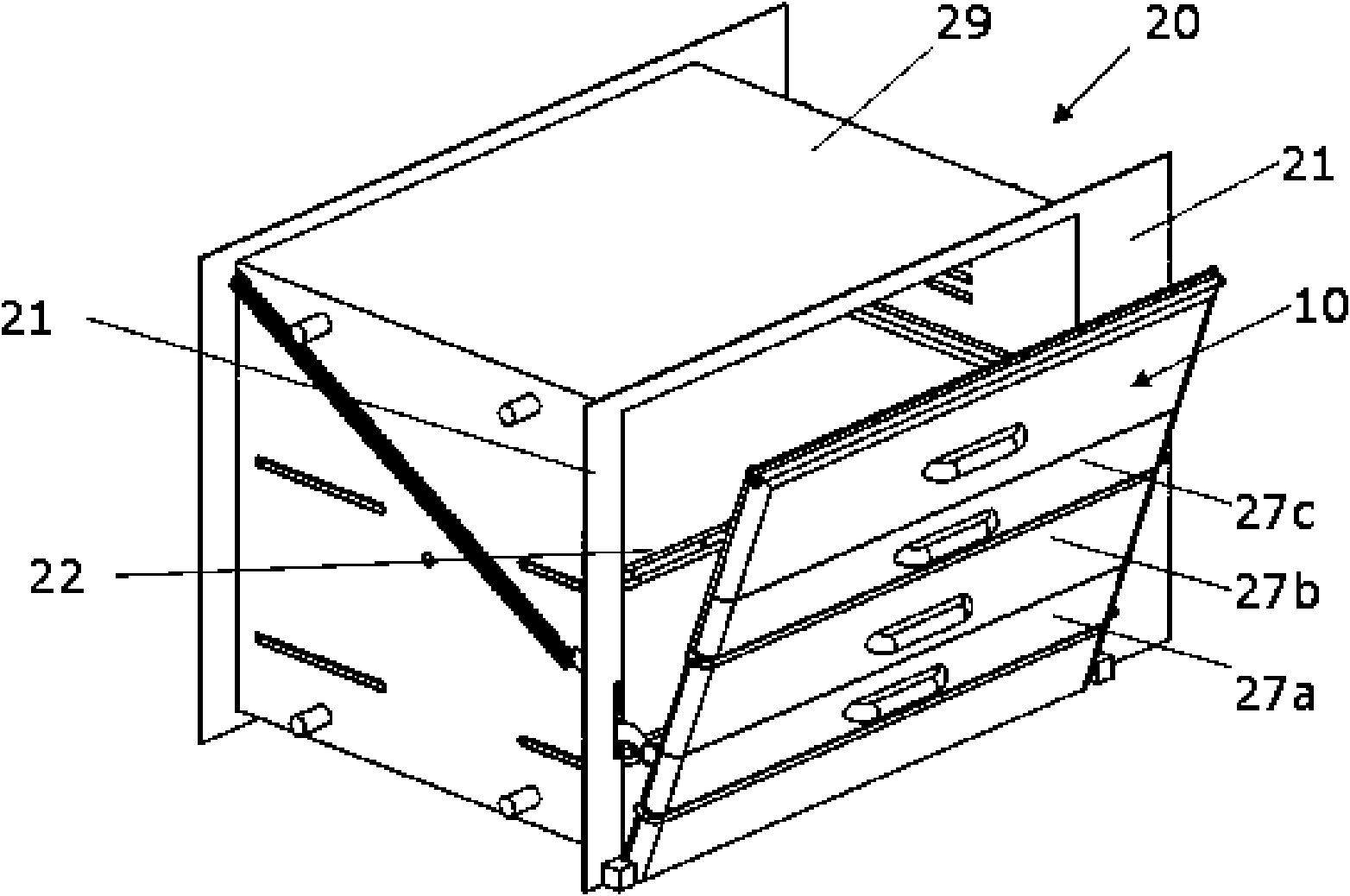

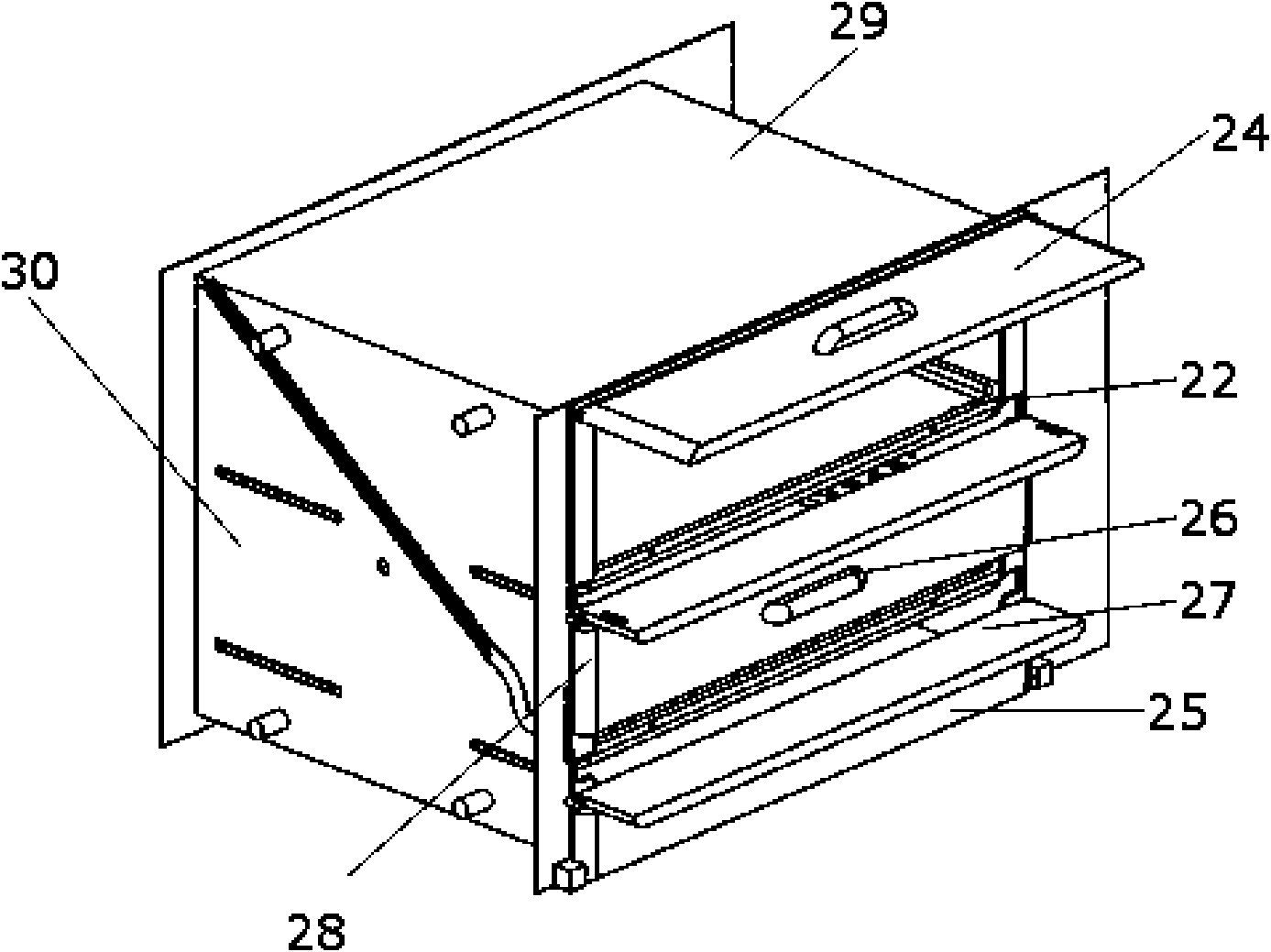

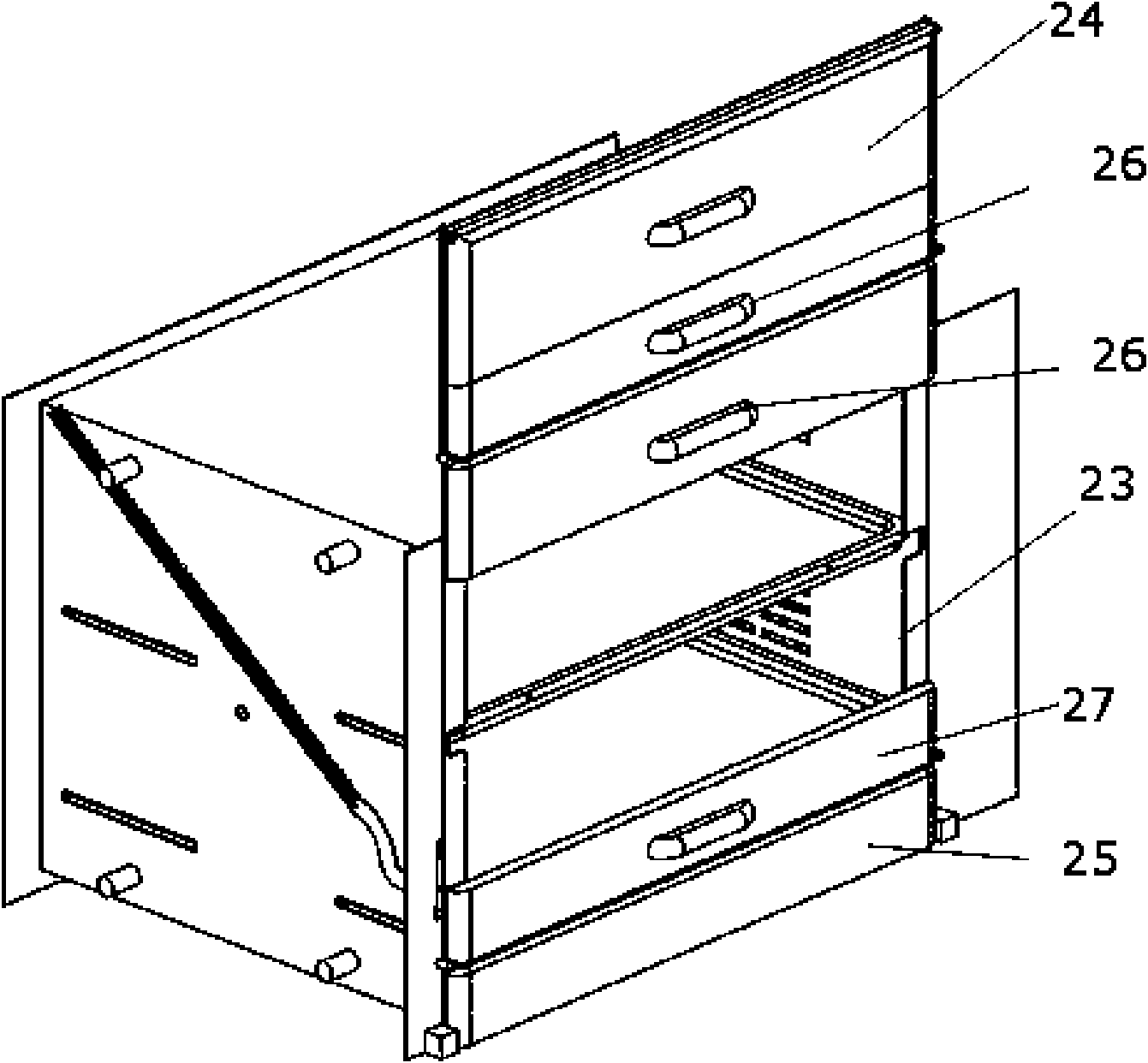

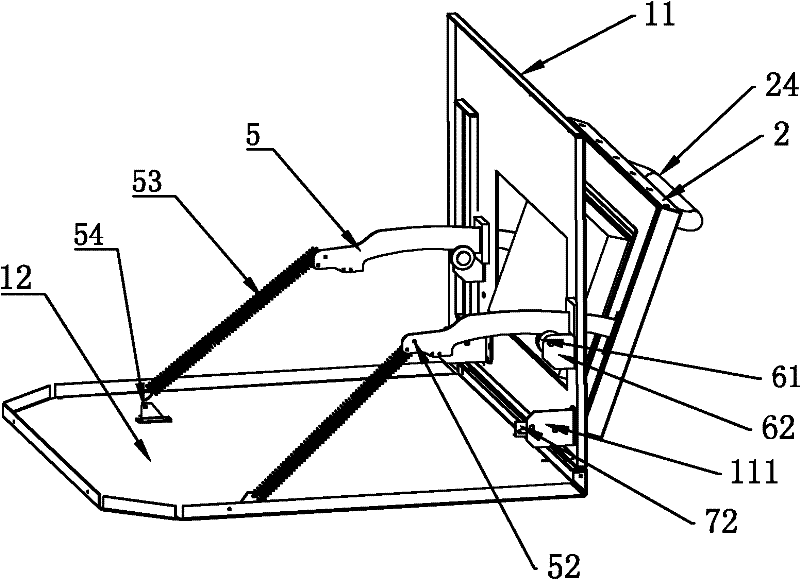

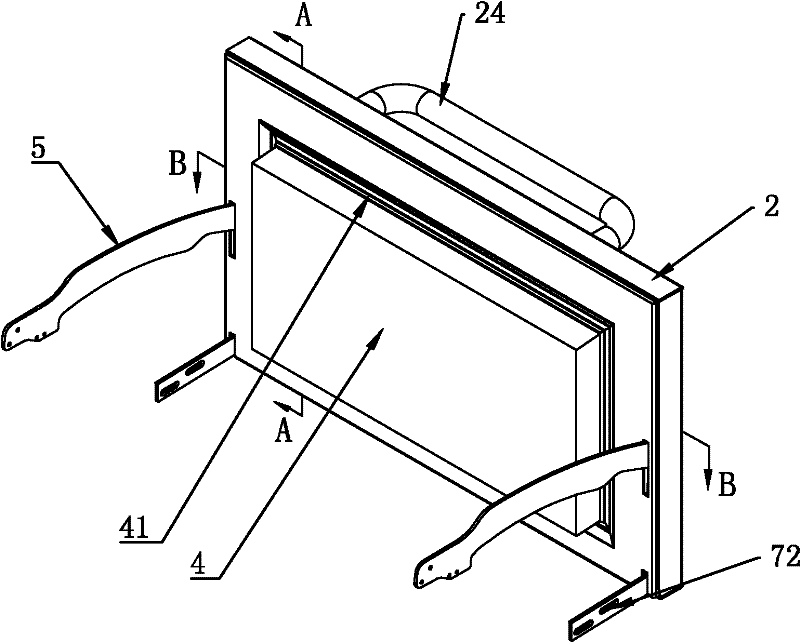

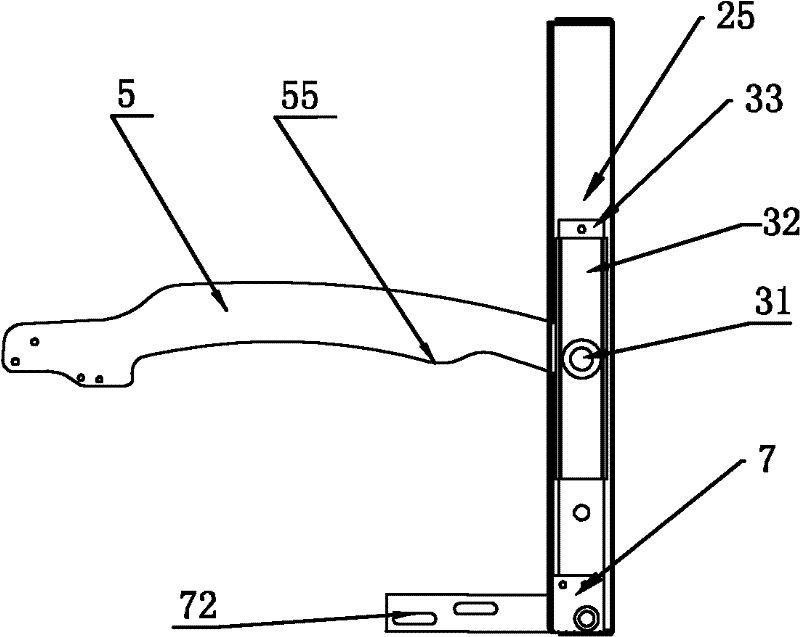

Oven door

The invention provides an oven door. The lower part of the oven door is hinged to a frame on two sides of a front opening of an oven part. The oven door comprises a U-shaped door frame, a slidable door frame, an upper door plate, a lower door plate and a plurality of openable doors, wherein the lower part of the U-shaped door frame is hinged to the frame on the two sides of the oven part; the slidable door frame is slidably sleeved on the U-shaped door frame; the upper door plate is arranged at the upper end of the slidable door frame; the lower door plate is fixedly arranged at the lower end of the U-shaped door frame; the plurality of openable doors are selectively opened or closed and are arranged between the upper door plate and the lower door plate; and a door handle is arranged on the upper door plate and each openable door respectively. The corresponding openable door can be opened as required and the whole door does not need to be opened, so that the heat loss of an oven provided with the oven door can be effectively reduced, and the baking efficiency of the oven is improved; in addition, only the corresponding openable door needs to be opened when food is taken out, and hands can be prevented from touching the high-temperature inner wall and baking pipe of the oven, so that the safety is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Door coupling system

ActiveUS8226180B2Wing operation mechanismsDoors for stoves/rangesCoupling systemElectrical and Electronics engineering

Owner:HAIER US APPLIANCE SOLUTIONS INC

Fire door of microwave baking box

InactiveCN102200309ASimple structureSimple processDoors for stoves/rangesDomestic stoves or rangesCooking & bakingMicrowave oven

A fire door of a microwave baking box, which solves problem of easy leakage of microwave and steam, comprises an oven front plate equipped with a fire door opening, an oven base plate, a door housing arranged on the opening, an automatically reset system between the door housing and the oven body, wherein the automatically reset system includes a slide block assembly, a rotating shaft assembly and a hinge system. The fire door with a good seal effect can hold an extension spring and close automatically. The invention has a simple structure and technology, and is suitable for both microwave oven and microwave baking box. In addition, the fire door can avoid microwave leakage and steam leakage caused by deformation under high temperature, and is extensively applicable, safe and reliable.

Owner:济南佳泰电器有限公司

Electric oven

ActiveUS7847219B2Avoid it happening againDoors for stoves/rangesDomestic stoves or rangesForeign matterEngineering

An electric oven includes a door and a compartment having an internal space that is selectively closed by the door. The door has a cooling air opening oil a surface facing the compartment, and the compartment has an intake opening configured to receive air exhausted through the cooling air opening. A shield element prevents foreign matter from entering into the door through the cooling air opening.

Owner:LG ELECTRONICS INC

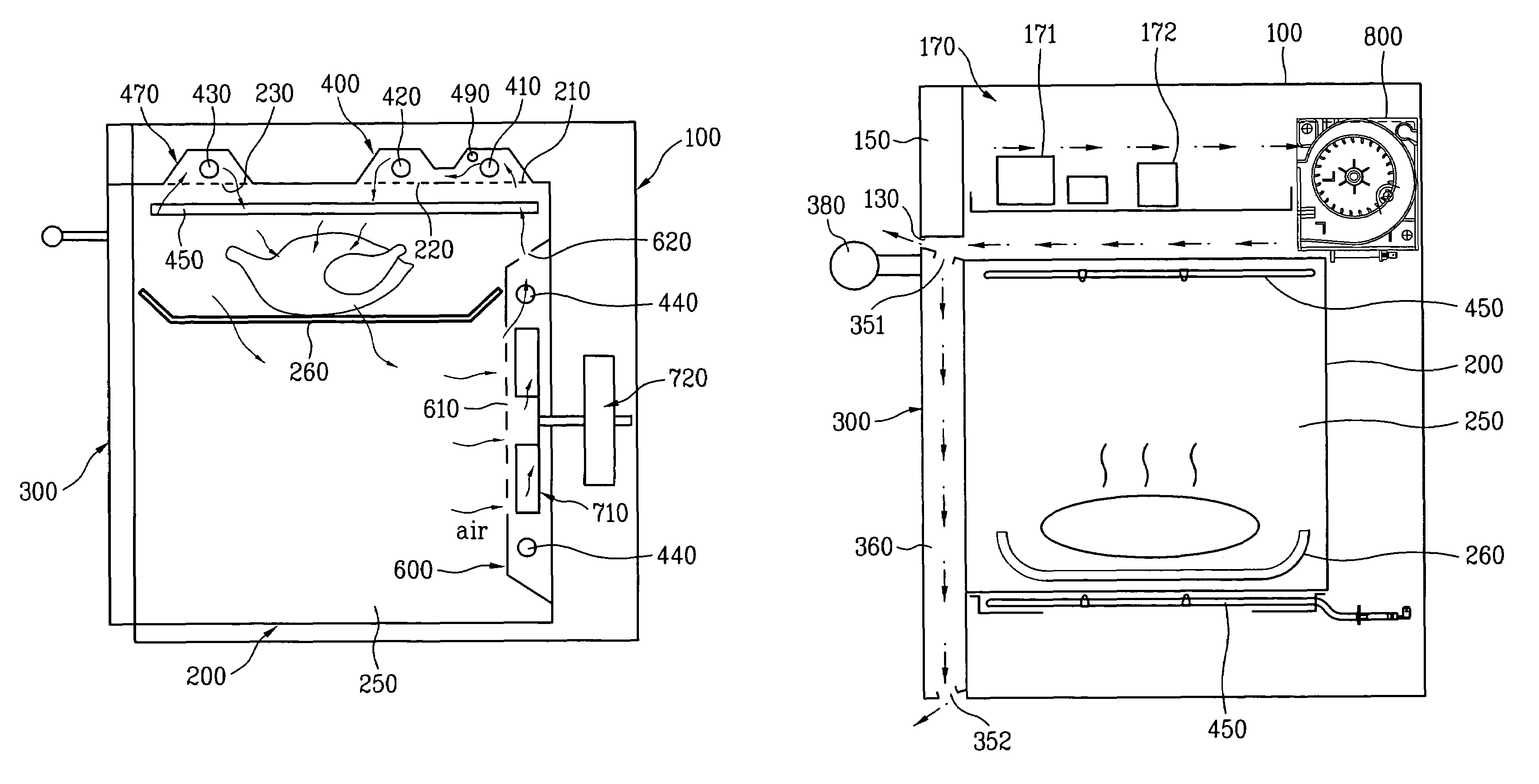

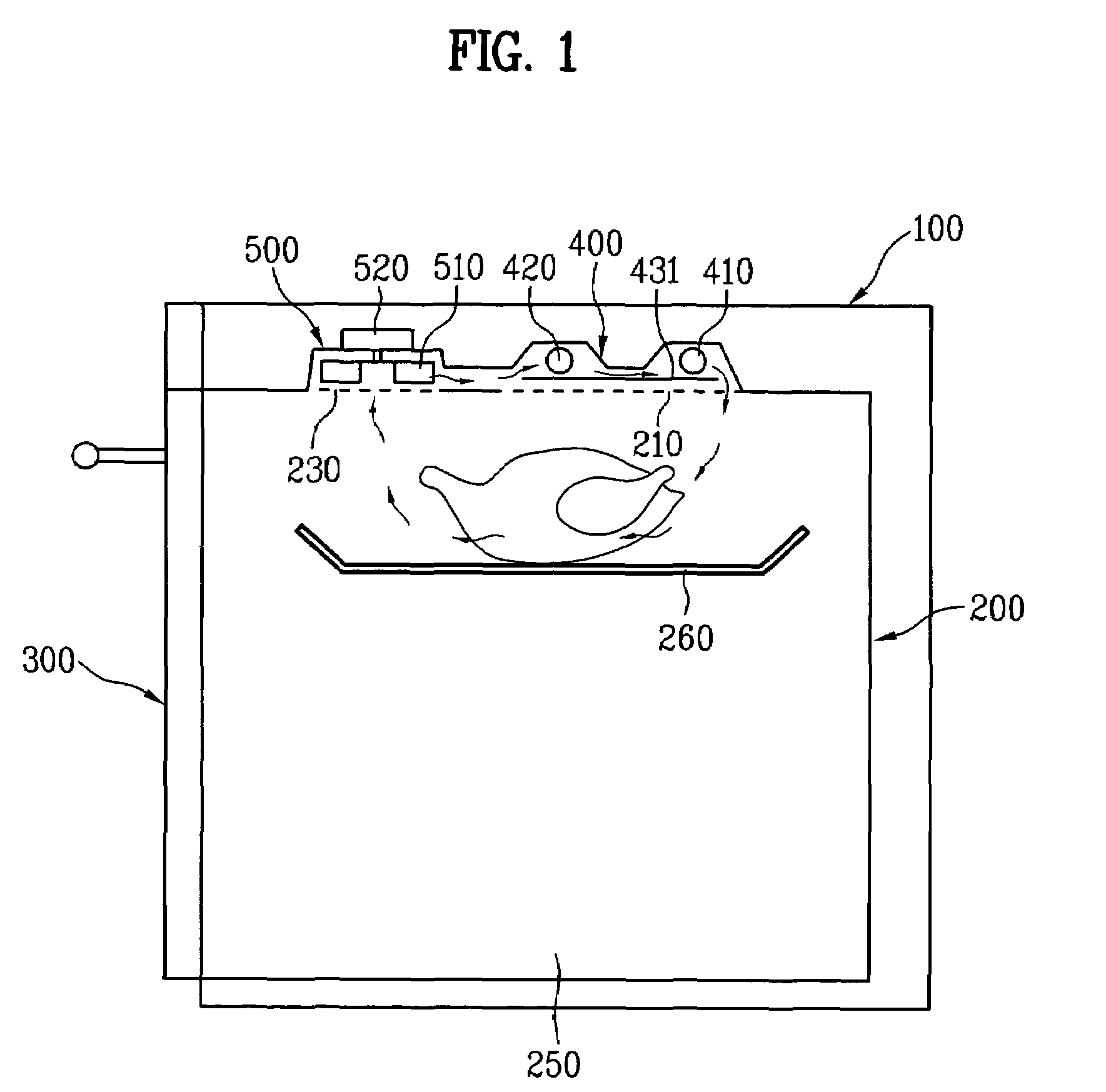

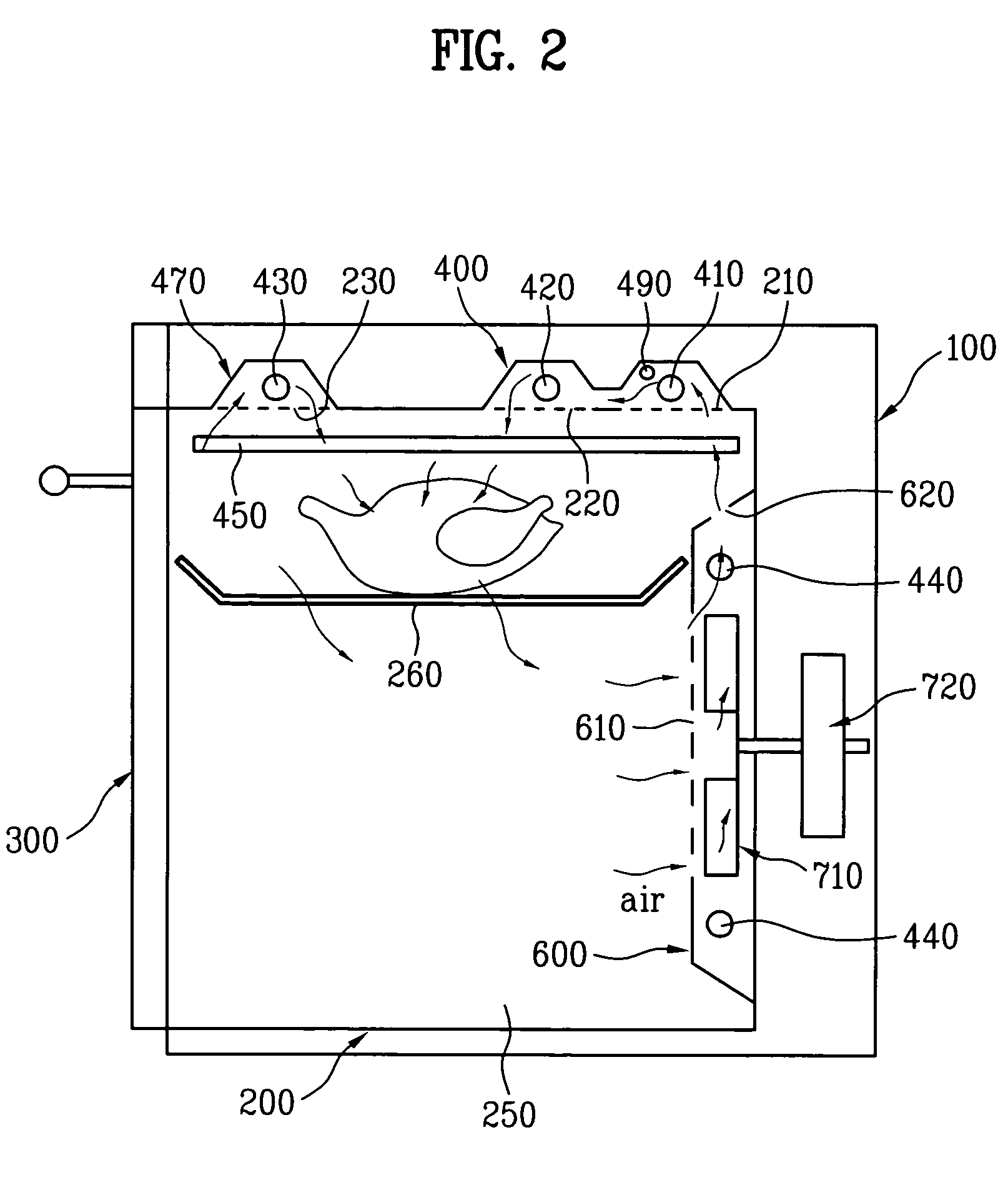

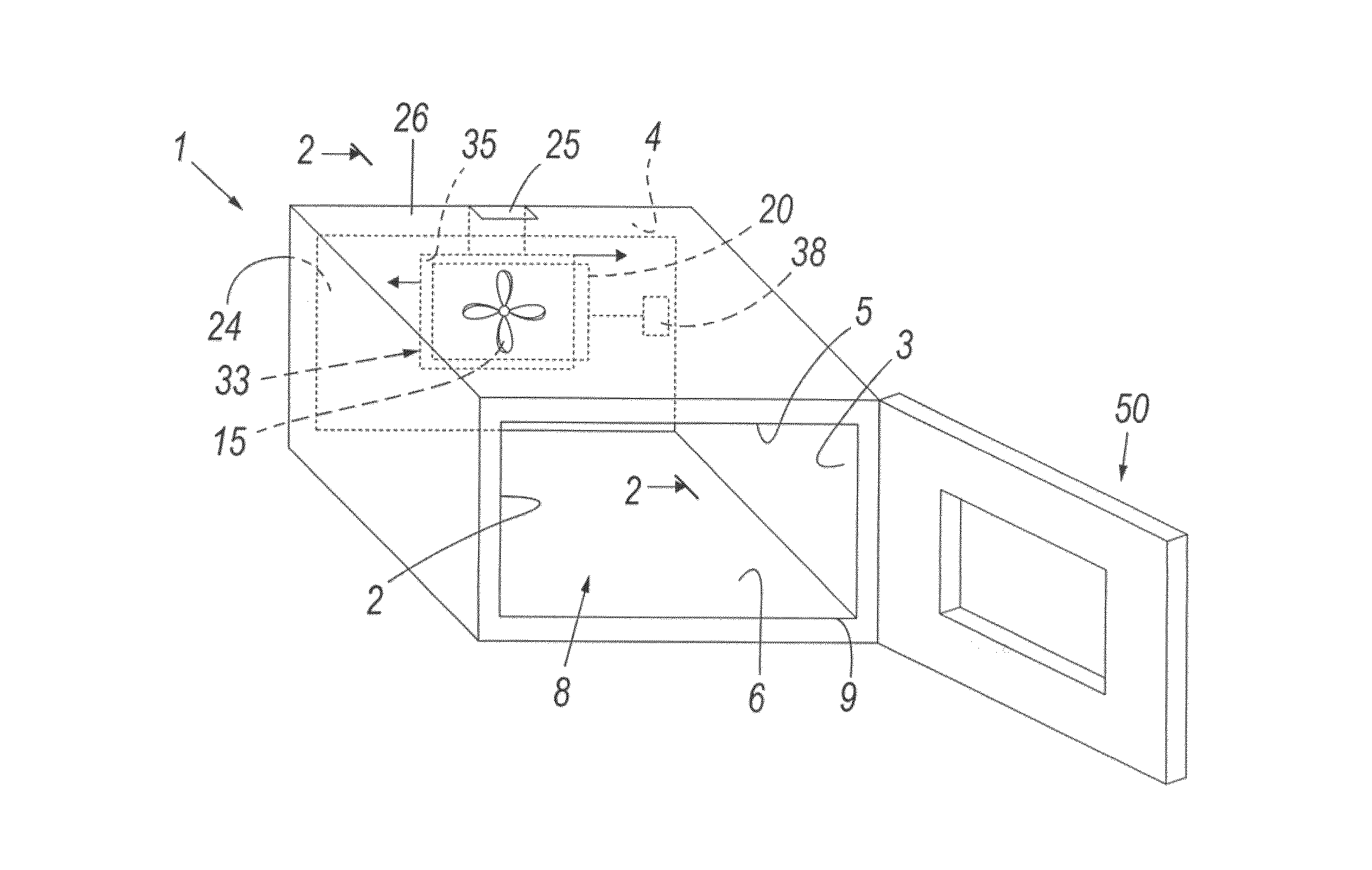

Cooking apparatus and method for use of same

ActiveUS10746412B1Improve performanceImprove usabilityDomestic stoves or rangesOven air-treatment devicesForce convectionProcess engineering

A cooking apparatus and method for use of the same are disclosed that utilize forced convection and radiant heating cooking. In one embodiment, the cooking apparatus includes an oven housing defining a cooking chamber, a circulation chamber, and a catalyst chamber. The catalyst chamber is superposed to the circulation chamber and the circulation chamber is superposed to the cooking chamber. Heating elements are located in the cooking chamber and the circulation chamber. An airflow circulation loop is located between the cooking chamber and the circulation chamber. An exhaust airflow path is provided from the circulation chamber to the catalyst chamber to an exterior of the oven housing. A fan subassembly is located within the oven housing and the fan subassembly circulates convection air along the airflow circulation loop with a portion of the convection air being diverted into the exhaust airflow path.

Owner:HIX CORP

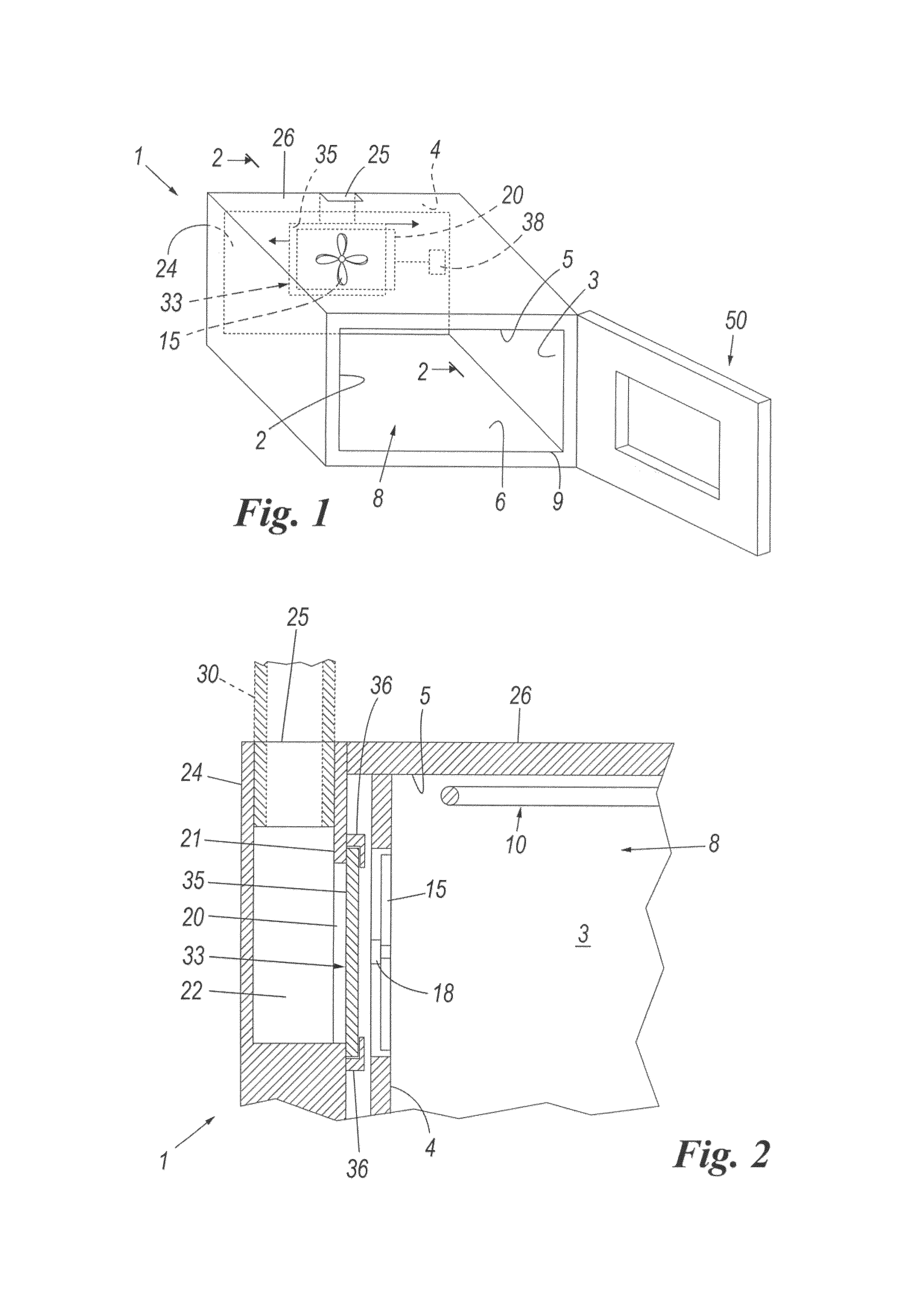

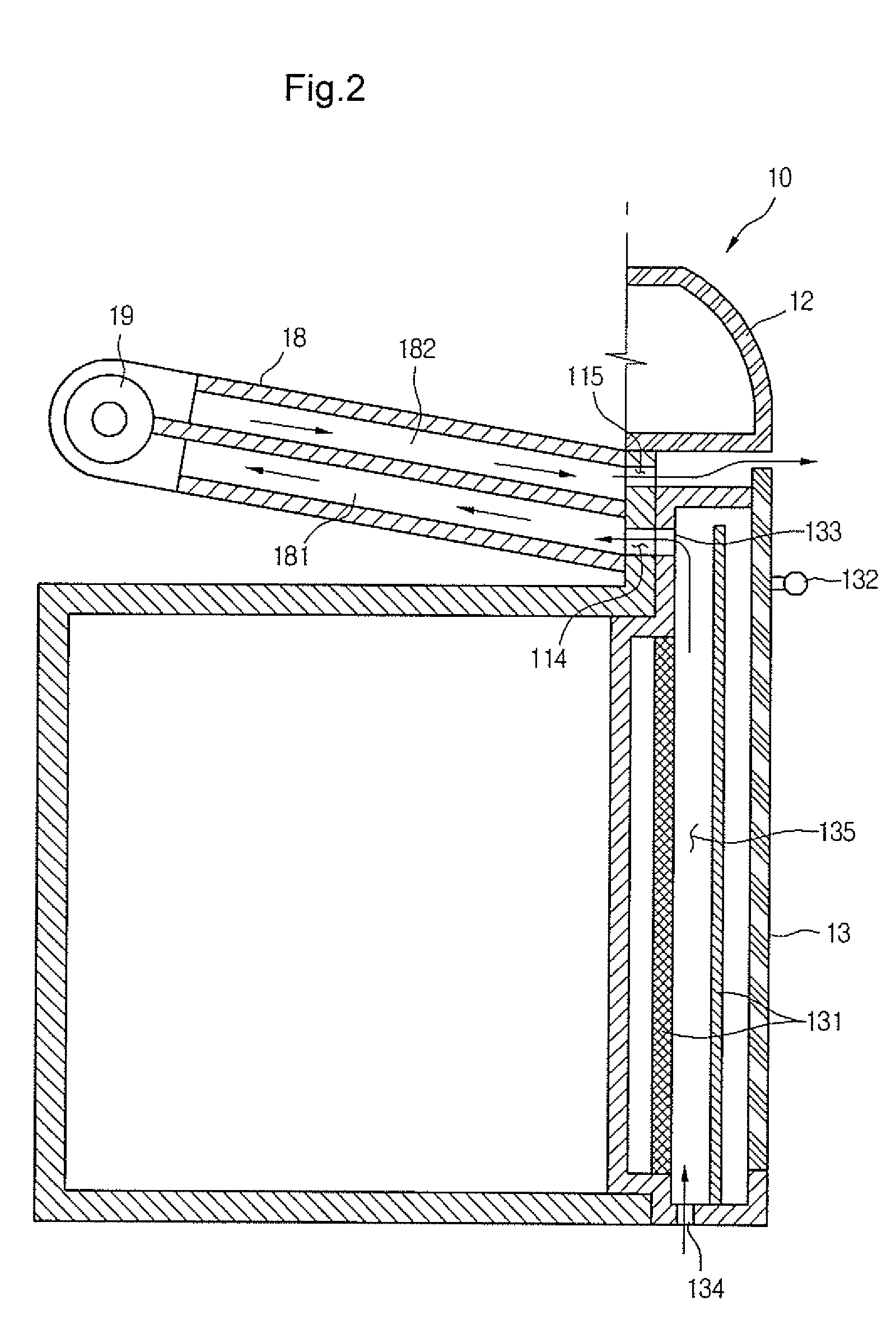

Built-in oven with an improved cooling system

ActiveUS8039775B2Reduce condensationDoors for stoves/rangesDomestic stoves or rangesEngineeringMechanical engineering

A built-in oven has a door, a control panel positioned above the door and a cooling system including a fan-motor assembly for drawing cooling air around the outside surface of the oven and an exhaust duct for discharging air to the ambient. The cooling system comprises a cooling air supply duct above the top side of the oven and with an intake opening below the control panel, and an exhaust duct positioned above the supply duct so that its exhaust opening is placed above the control panel, the fan-motor assembly being mounted between the supply duct and the exhaust duct.

Owner:WHIRLPOOL CORP

Heating cooking device

InactiveUS7294811B2Improve heat resistancePrevent oxidationDoors for stoves/rangesDomestic stoves or rangesHeat resistanceTransparent conducting film

A heating cooking device includes a housing having a wall portion; a first base material provided in at least a portion of the wall portion; and optionally a second base material formed on the first base material; a heat ray reflector formed on the conductive base material, including a first transparent conductive film formed on the first base material and a second transparent conductive film that is provided on the first transparent conductive film, where the second transparent conductive film has a higher heat resistance than that of the first transparent conductive film.

Owner:FUJIKURA LTD

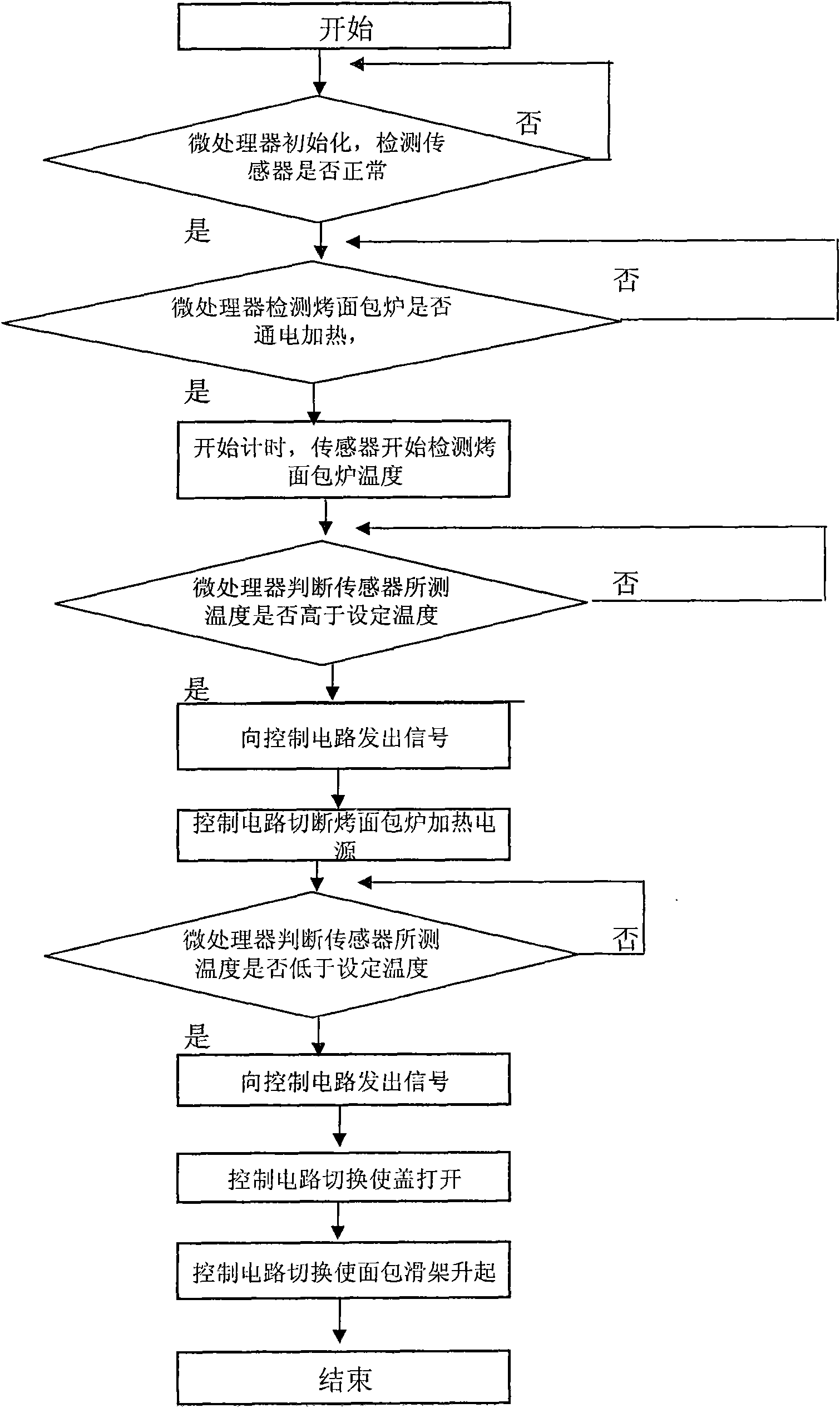

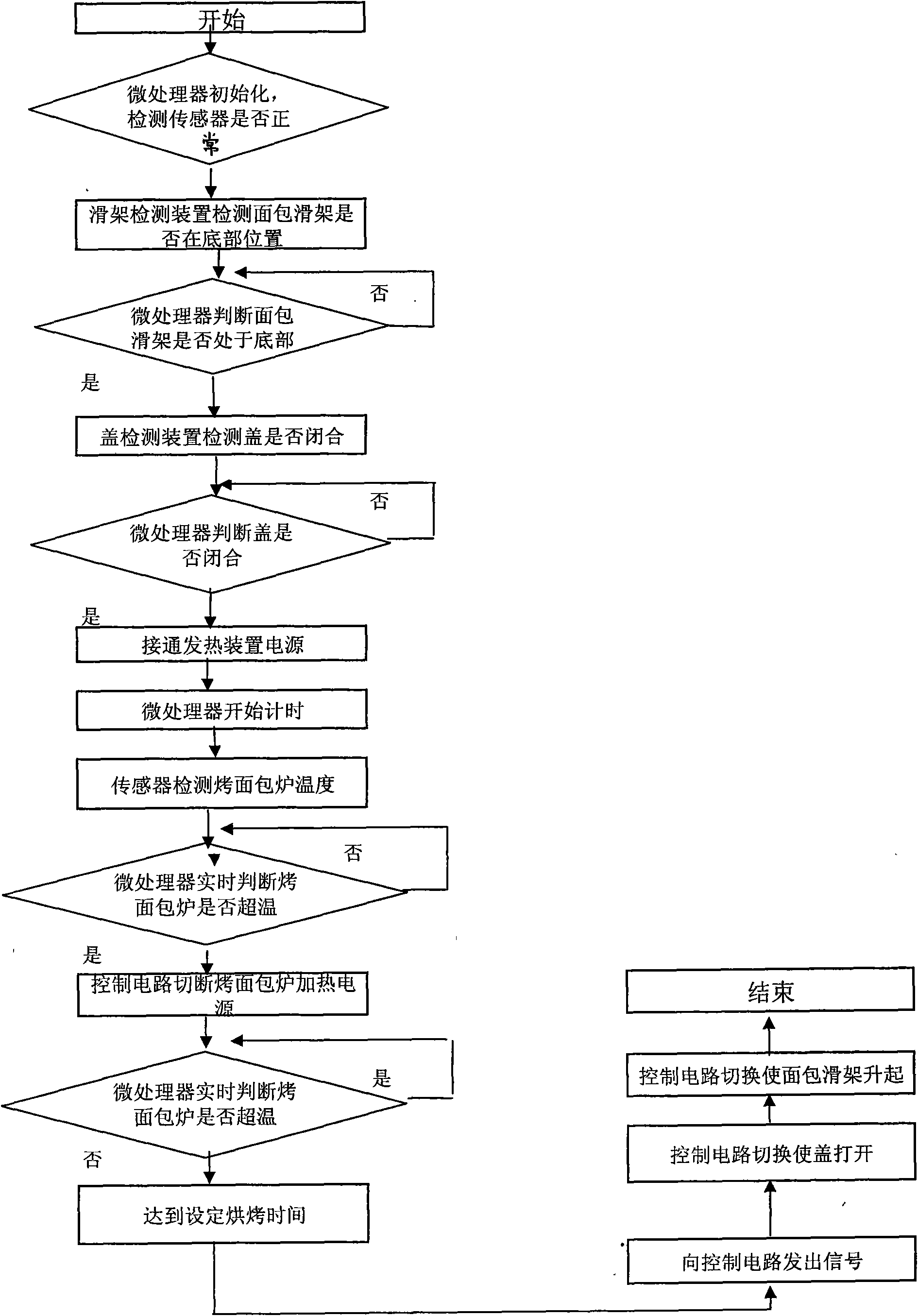

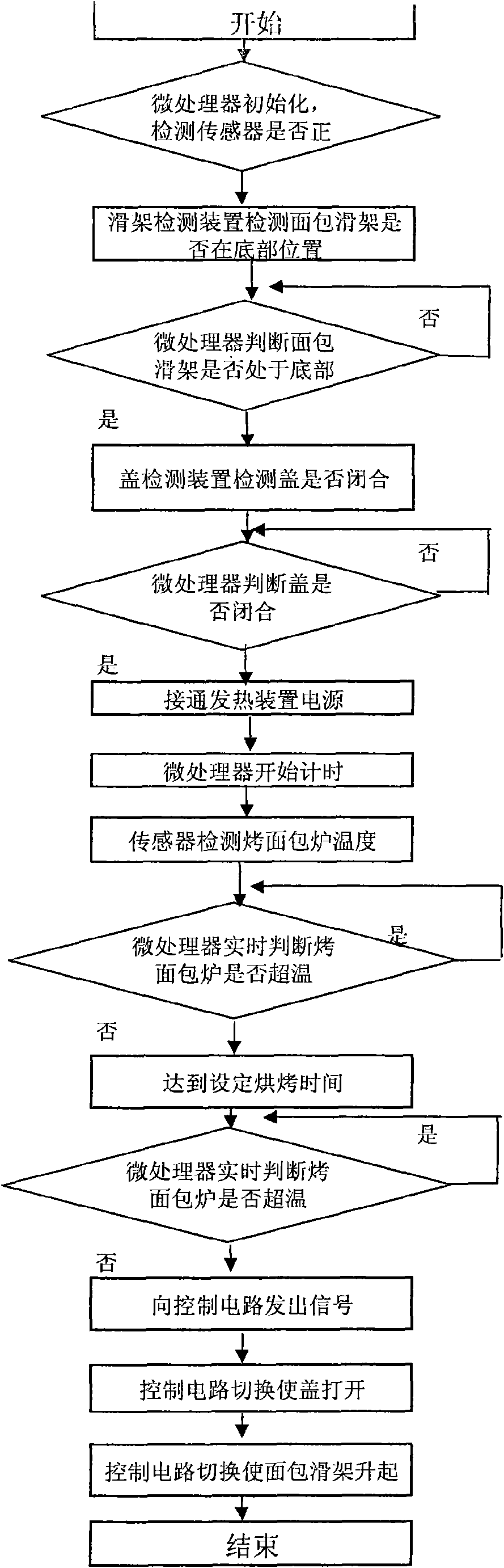

Control device with fire prevention function for toaster cover and application method thereof

InactiveCN101576741AAvoid safety accidentsTemperatue controlOven doors/gatesControl signalControl circuit

The invention discloses a control device with fire prevention function for a toaster cover and an application method thereof. The device comprises a cover sliding guide or a cover opening / closing mechanism, and a power switch, a cover switch and a control circuit which are arranged in the toaster; the control circuit is internally provided with a microprocessor, and the output port of the control circuit is connected with a triode, the control circuit is also connected with a sensor. The invention detects if the temperature of the toaster is within normal predetermined temperature range by arranging the sensor on the base or the stander of the toaster; if the control circuit detects that the temperature of the toaster exceeds the predetermined temperature value, the control circuit produces a control signal, and the circuit controlling the action of the cover keeps the cover to be closed all the time; only when the sensor of the toaster detects that the temperature recovers to the lower predetermined temperature value, even if the bread in the toaster is on fire, the cover is closed all the time till the fire is extinguished, and then the cover can be opened normally, thereby effectively avoiding the happening of safe accidents.

Owner:SHENZHEN CRASTAL TECH CO LTD

Fan apparency arrangement for an appliance

ActiveUS20100051244A1Self-cleaning stoves/rangesOven air-treatment devicesChange positionsPressure difference

A fan apparency arrangement for an appliance is disclosed. The appliance has a chamber with a first port and a second port. The arrangement includes a fan for moving air in or out of the chamber, and a sail switch disposed adjacent to the second port. When activated, the fan moves air in or out of the chamber through the first port to create a pressure difference between an inside and an outside of the chamber. The pressure difference causes the sail switch to change position and signal that the fan is activated. An appliance incorporating such a fan apparency arrangement is also disclosed.

Owner:HAIER US APPLIANCE SOLUTIONS INC

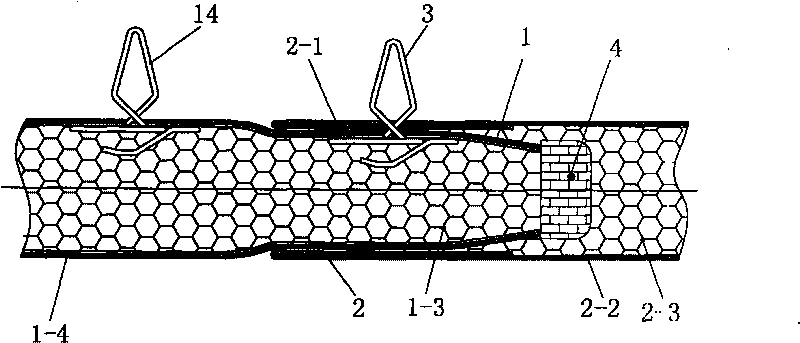

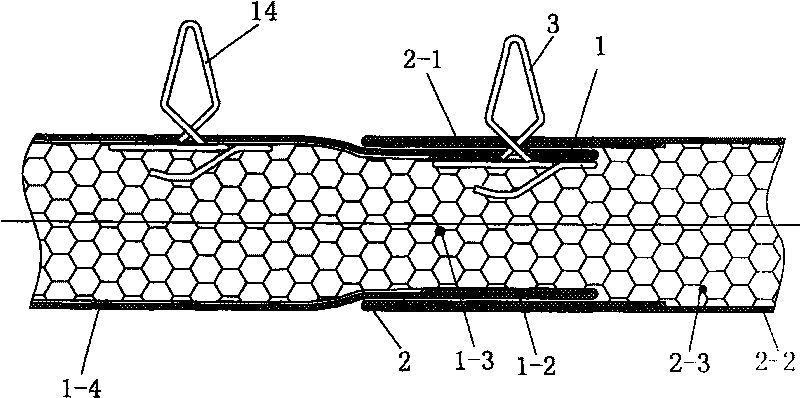

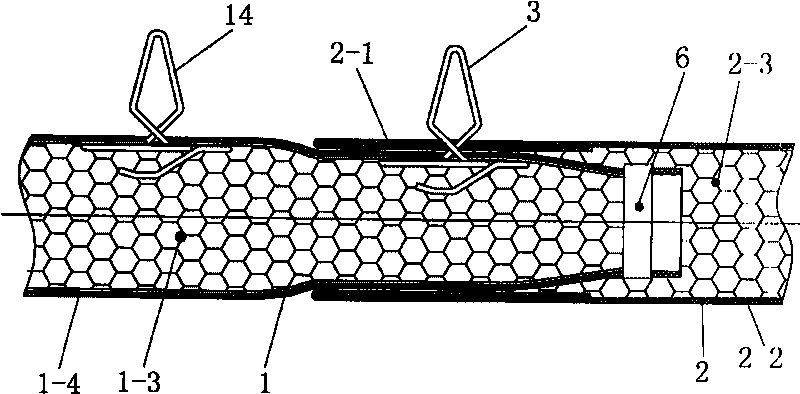

Liner with connecting structure from beginning to end

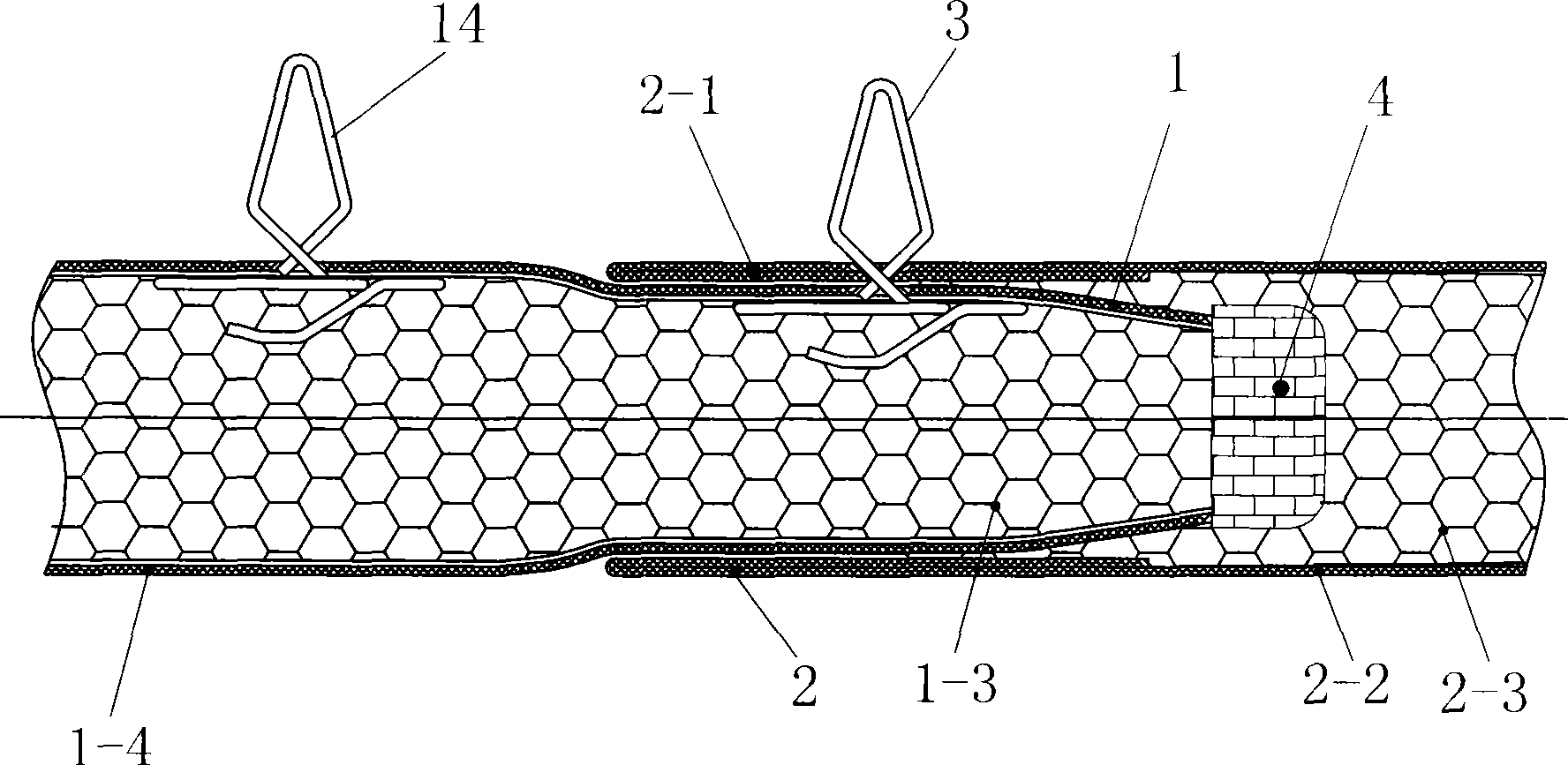

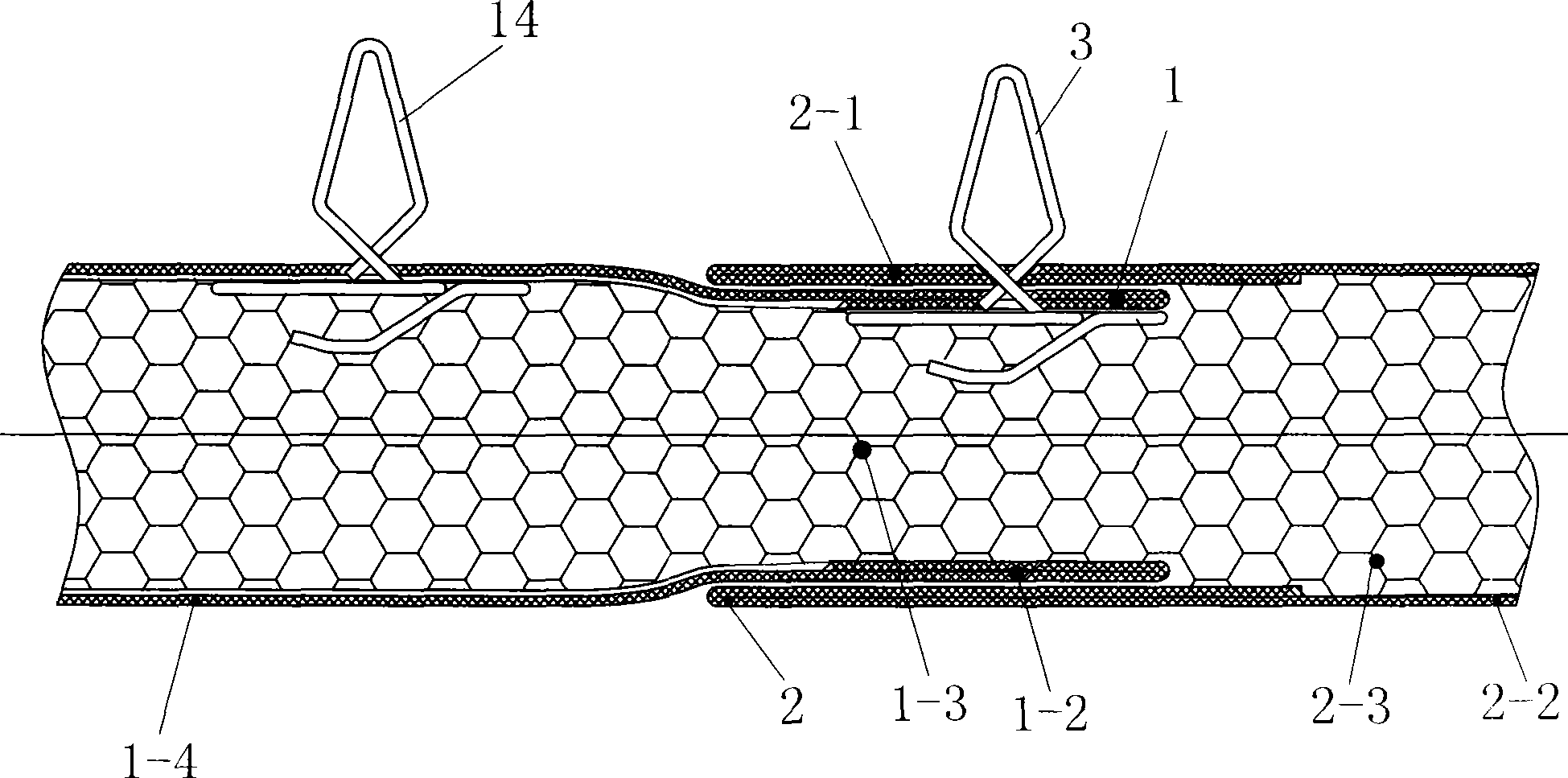

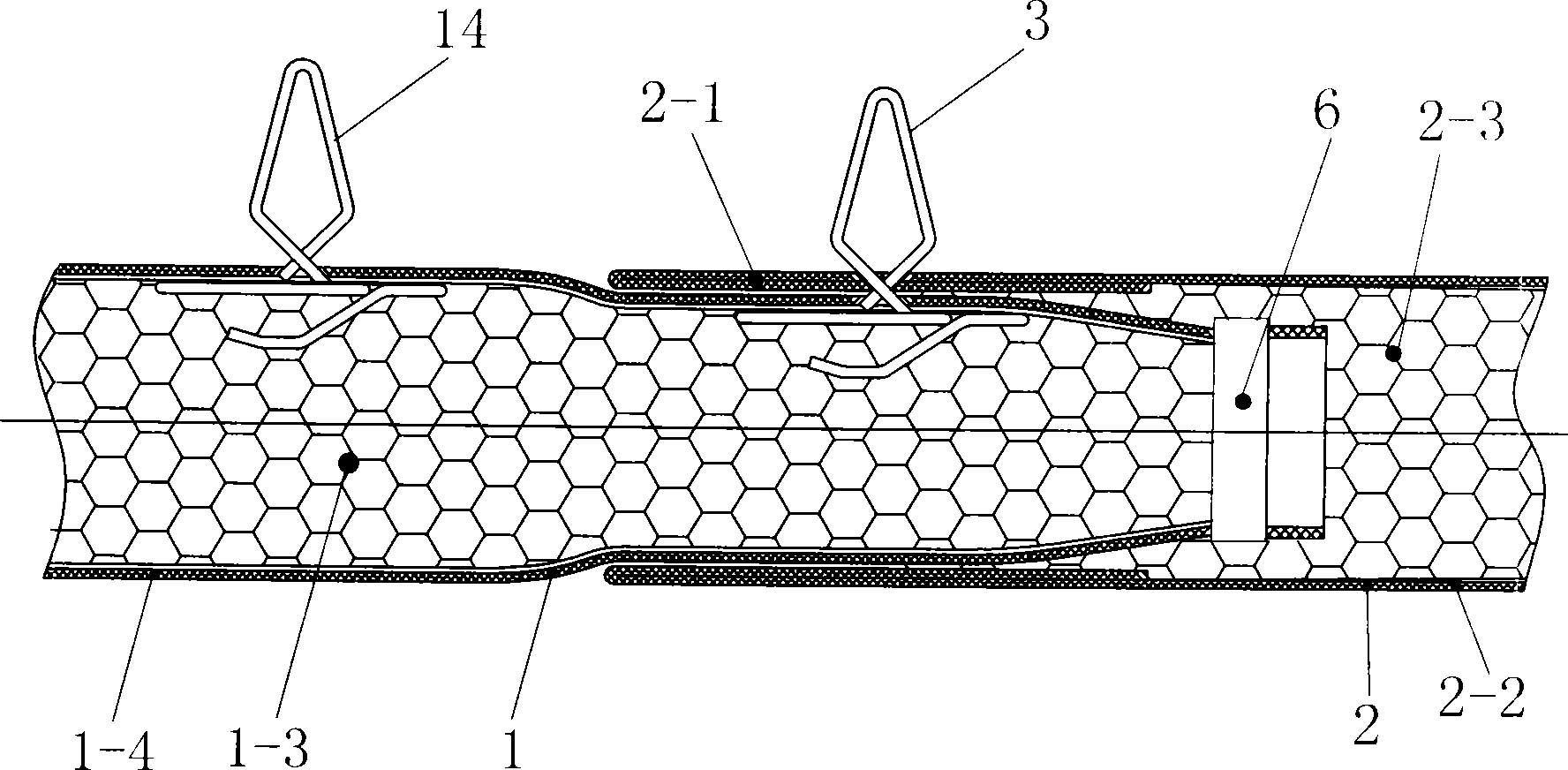

The invention relates to a liner with better sealing performance and convenient installation and use, in particular to a furnace door liner with a structure connected end to end. The furnace door liner comprises a female head and a male head, wherein, the male head extends in the female head; and a spring clip penetrates through the adjacent side wall of the female head and the male head. Both the female head and the male head are formed by a glass-fiber tube and a mesh tube shaped framework arranged in the glass-fiber tube; and the mesh tube shaped framework is clamped in the first double-layer part of the female head. The spring clip is formed by a paper clip shaped horizontal base and a diamond meshing clip vertically arranged on the horizontal base, and a free end is formed on the horizontal base; the horizontal base penetrates through the first double-layer part of the female head and the side wall of the male head in sequence from the outside to the inside through the free end, so that the horizontal base of the spring clip is placed in the mesh tube shaped framework of the male head, and meanwhile, the diamond meshing clip of the spring clip protrudes outwards from the glass-fiber tube of the male head. A high-temperature resistant adhesive tape is bound at the tail end of the male head or a metal restricted opening is fixed at the tail end of the male head.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

Liner with connecting structure from beginning to end

ActiveCN101438719BAvoid Disengagement SituationsGuaranteed air tightnessOven doors/gatesGlass fiberAdhesive belt

The invention relates to a liner with better sealing performance and convenient installation and use, in particular to a furnace door liner with a structure connected end to end. The furnace door liner comprises a female head and a male head, wherein, the male head extends in the female head; and a spring clip penetrates through the adjacent side wall of the female head and the male head. Both thefemale head and the male head are formed by a glass-fiber tube and a mesh tube shaped framework arranged in the glass-fiber tube; and the mesh tube shaped framework is clamped in the first double-layer part of the female head. The spring clip is formed by a paper clip shaped horizontal base and a diamond meshing clip vertically arranged on the horizontal base, and a free end is formed on the horizontal base; the horizontal base penetrates through the first double-layer part of the female head and the side wall of the male head in sequence from the outside to the inside through the free end, so that the horizontal base of the spring clip is placed in the mesh tube shaped framework of the male head, and meanwhile, the diamond meshing clip of the spring clip protrudes outwards from the glass-fiber tube of the male head. A high-temperature resistant adhesive tape is bound at the tail end of the male head or a metal restricted opening is fixed at the tail end of the male head.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

Conveyor Oven

ActiveUS20130213380A1Prevent escapeDomestic stoves or rangesLighting and heating apparatusEngineeringConveyor belt

A conveyor oven is disclosed. The conveyor oven includes a housing, a conveyor belt, a first and second doors, and a heat source. The housing includes a cavity and a first and second openings. The conveyor belt is configured to receive and transport food items in and out of the cavity through the first and second openings. The conveyor belt includes a loading section and an unloading section for food. The first and second doors cover first and second openings, respectively, in order to prevent heat within the cavity from escaping through the first and second openings during operation. Configured to provide different cooking times and thermal profiles to various types of food items, the heat source provides heat to the cavity for heating up any food item placed on a portion of the conveyor belt located within the cavity.

Owner:OVENTION

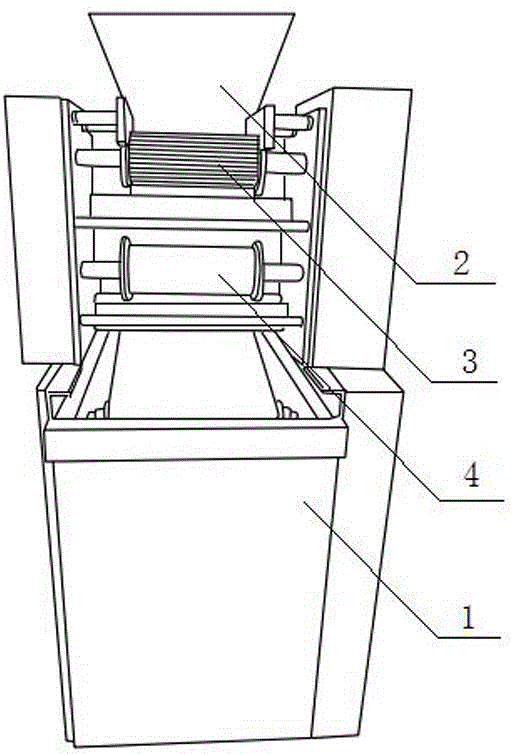

Baked bun maker

ActiveCN104542765AGuaranteed smoothNo pollution in the processOven doors/gatesBaking plantsBatch productionEngineering

The invention discloses a baked bun maker comprising a rack as well as a dough pressing mechanism, a baked bun making mechanism, a cut-off mechanism, a transmission device and a temperature control device mounted on the rack and connected sequentially. The dough pressing mechanism comprises a feed hopper, a primary dough pressing roller, a secondary dough pressing roller and a dough conveying belt, a discharge outlet of the feed hopper is smaller than the primary dough pressing roller in length, and width limiting edges are arranged on both sides of each of the primary dough pressing roller and the secondary dough pressing roller; the baked bun making mechanism comprises an upper baked bun making roller, a lower baked bun making roller and a finished product conveying belt; the cut-off mechanism comprises a cutter roller and a cutter rotating oppositely; the transmission device is connected with the dough pressing mechanism, the baked bun making mechanism and the cut-off mechanism; the temperature control device is connected with the upper baked bun making roller and the lower baked bun making roller of the baked bun making mechanism. The baked bun making mechanism adopts two stages of heating rollers rotating vertically and relatively to bake both sides of the baked bun in sequence, and quality uniformity of finished products is guaranteed by regulation of the rotation speed and temperature; manual intervention is not required, one-time batched production is realized, processing efficiency is high, and smoke contamination is avoided.

Owner:南通弘铭机械科技有限公司

Cam electric door opening device

The invention relates to the technical field of oven doors, in particular to a cam electric door opening device. The cam electric door opening device includes a main cabin, an auxiliary cabin, a doorbody, a hinge, an opening and closing mechanism and a pull plate mechanism; and a square groove is formed in the connection position between the main cabin and the door body, so that the whole door body is embedded in the main cabin. According to the cam electric door opening device, use of a clear handle is abandoned, pulling of a door holder and a tray is advantageously realized by a motor, a potential safety hazard that it is prone to occurring personnel being scalded is prevent when a user pulls out a grill by hands to take cooked items, and the more reasonable combination structure with apull plate is realized.

Owner:安徽冠东科技有限公司

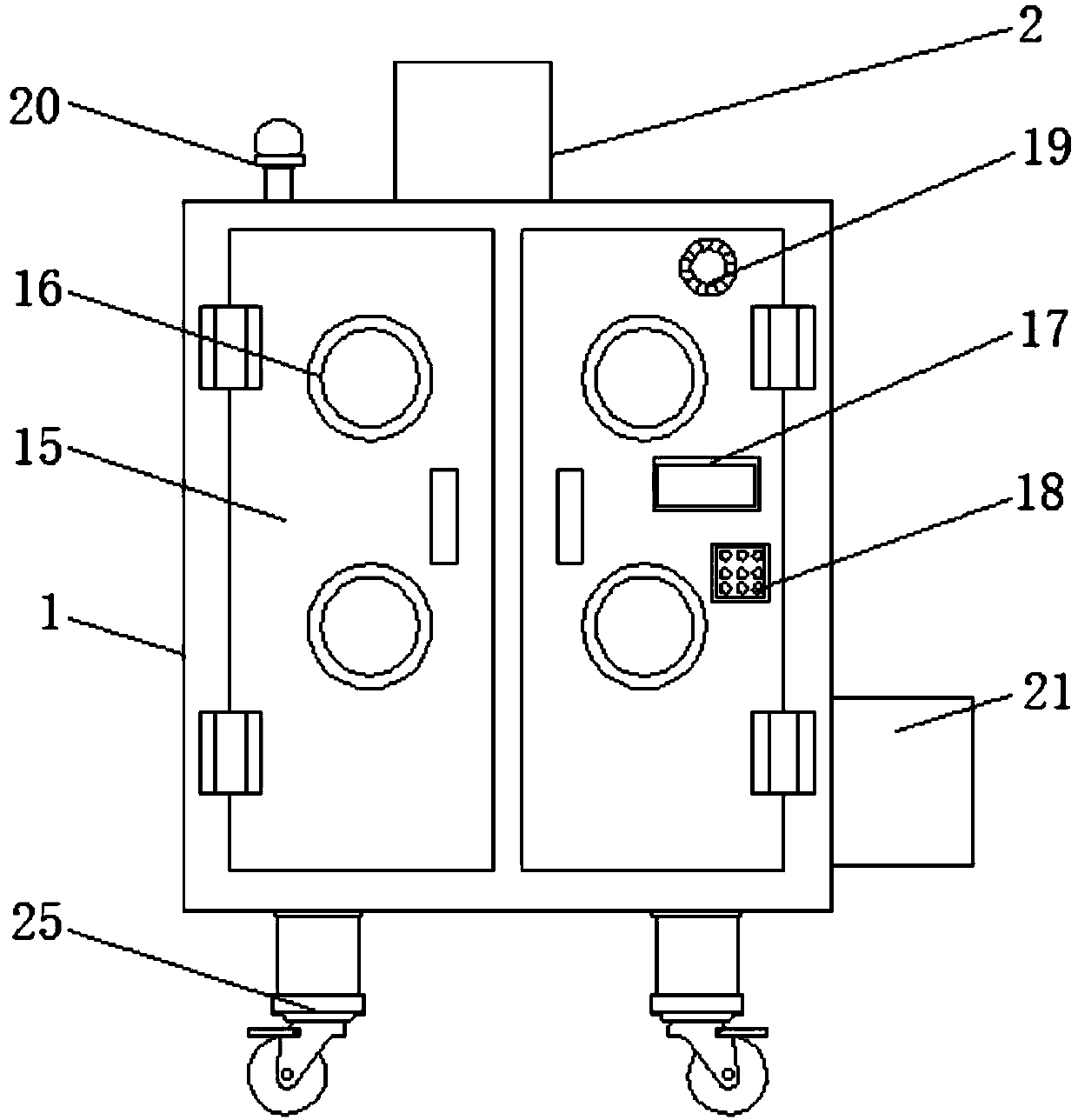

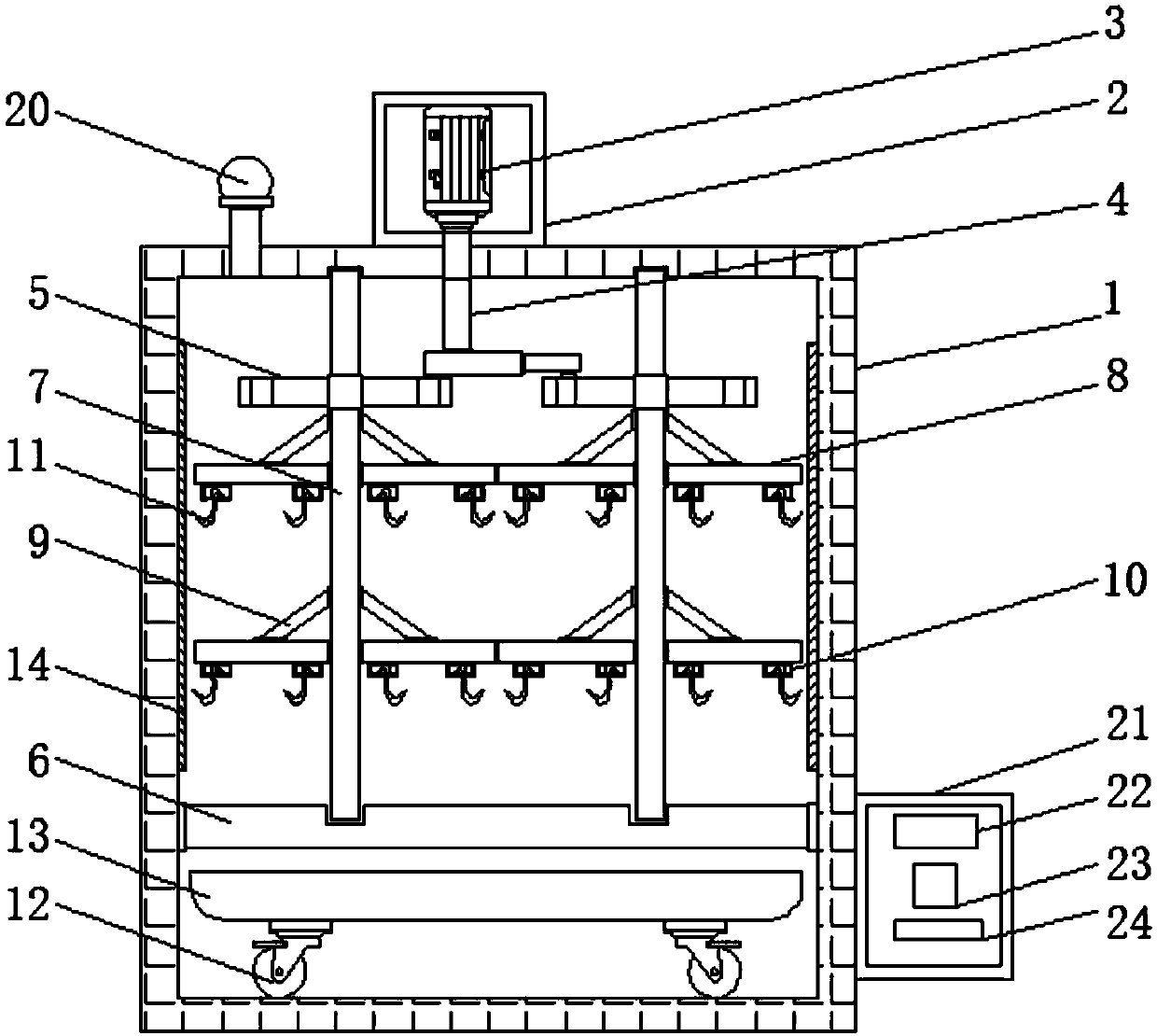

Duck roasting machine

InactiveCN107927015AQuality improvementEvenly heatedDispersed particle filtrationOven doors/gatesMotor driveEngineering

The invention relates to the technical field of food processing equipment, in particular to a duck roasting machine. The duck roasting machine comprises a machine body, a heating device, a rack, driving device and a control device, wherein the machine body is provided with a power chamber, a duck roasting chamber and an oil collecting chamber, the rack and the driving device are arranged in the machine body, the rack comprises a tray, a main rotary shaft and an auxiliary rotary shaft, a plurality of hooks are connected on the periphery of the tray through bearings, a main rotary motor is connected with the main rotary shaft, an auxiliary rotary motor is connected with the auxiliary rotary shaft, the main rotary motor drives the tray to rotate around the main rotary shaft, the auxiliary rotary motor drives the hooks to rotate, the heating device roasts ducks, and the control device controls the working states of the main rotary motor, the auxiliary rotary motor and the heating device. The duck roasting machine can rotate ducks automatically, manual turning is not required, ducks are uniformly heated, the quality of roasted ducks is improved, and the labor intensity of workers is reduced.

Owner:柳州市鼎福通用机械厂

Oven

ActiveUS7655885B2Improve cooling effectReduce heatDomestic stoves or rangesDoors for stoves/rangesEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

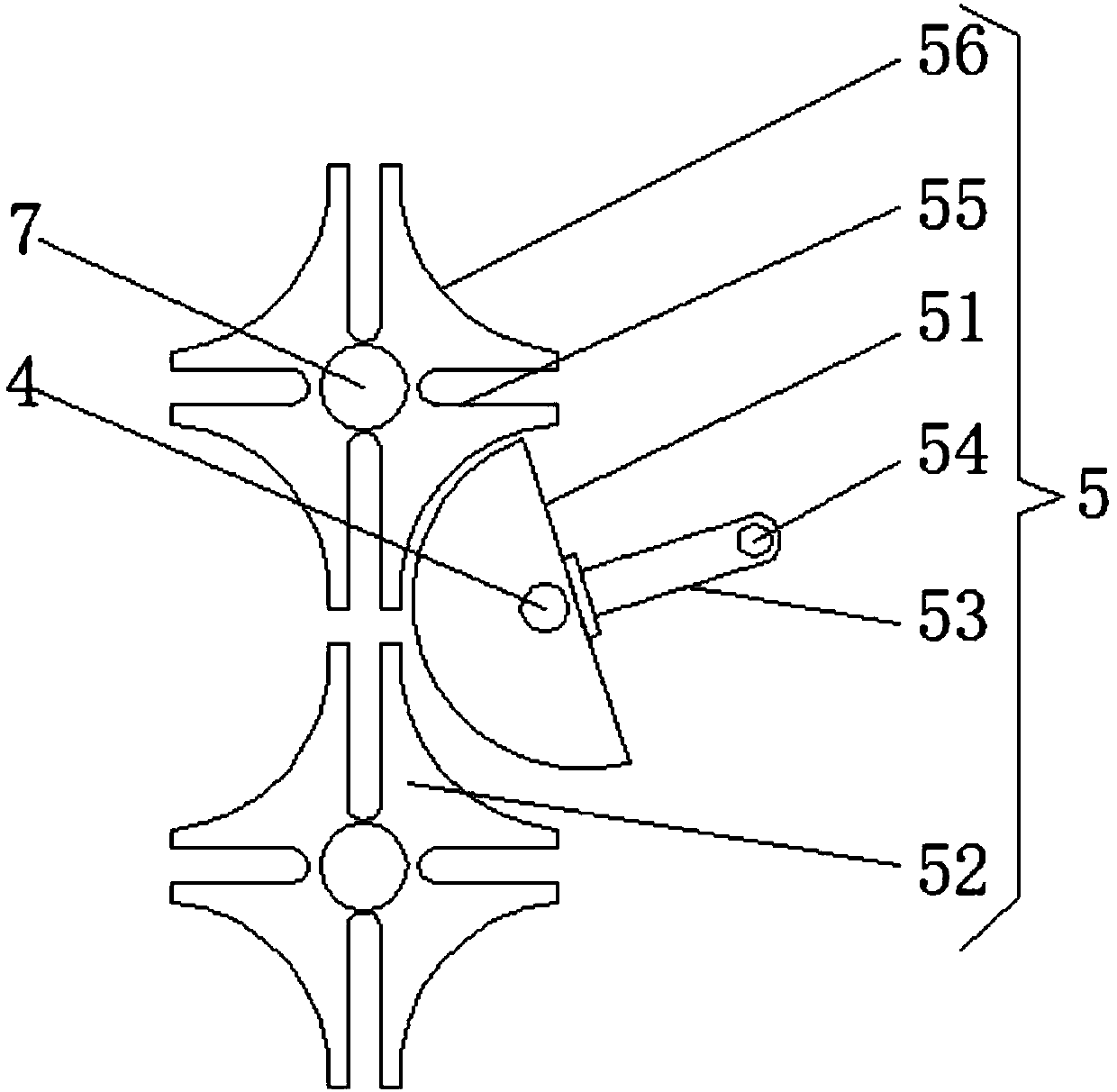

Intelligent duck roasting box based on internet of things control

InactiveCN107927016AIncrease the number ofExpand your baking spaceOven doors/gatesEngineeringInternet of Things

The invention discloses an intelligent duck roasting box based on internet of things control, and relates to the technical field of intelligent duck roasting boxes. The intelligent duck roasting box comprises a box body, a motor box is fixedly connected at the top of the box body, a motor is fixedly connected at the top of the inner wall of the motor box, a movable rod is fixedly connected with one end of an output shaft of the motor, one end of the movable rod far away from the motor penetrates the motor box and the box body and extends into the box body, one end of the movable rod extendinginto the box body is fixedly connected with a rotating device. According to the intelligent duck roasting box based on internet of things control, the top of a semicircular plate is fixedly connectedwith the bottom of the movable rod, roasting space is widened, number of roasted ducks can be increased, roasting efficiency is greatly improved, a lot of energy is saved, fixed plates are fixedly connected on two sides of the surface of a rotating rod, so that the roasted ducks can be comprehensively roasted, roasting efficiency is greatly improved, and the quality of finished products can be improved.

Owner:ZHONGSHAN DEGAOXING INTPROP CENT LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com