Baked bun maker

The technology of a bun making machine and a bun roller is applied in baking, disc dough forming, baking workshop and other directions, which can solve the problems of smoke pollution, low processing efficiency, waste of resources, etc., and achieve uniform product quality, high processing efficiency, The effect of no smoke pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

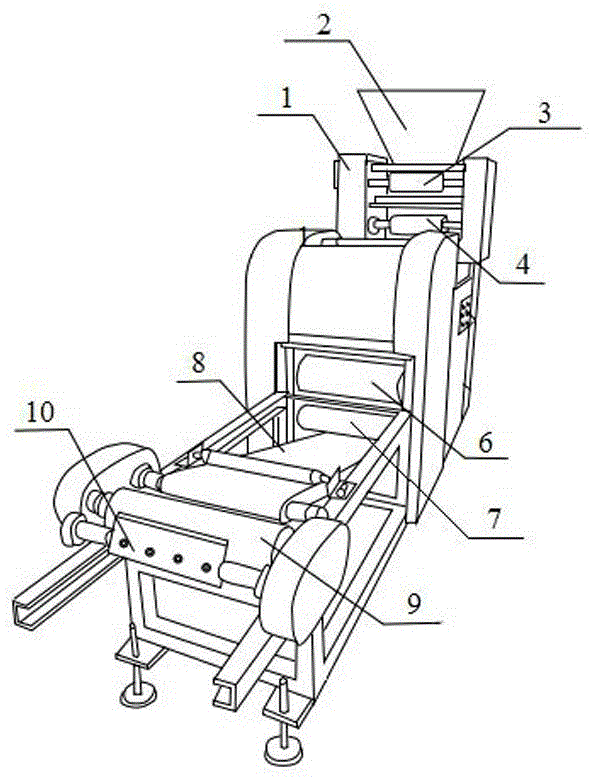

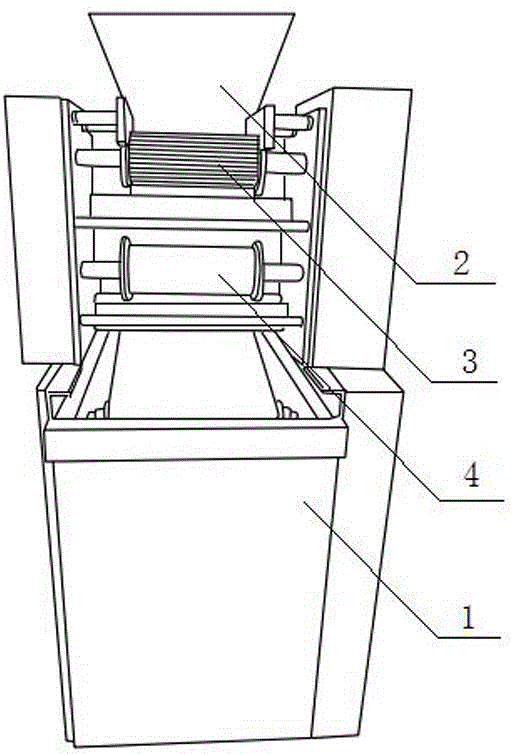

[0015] Such as figure 1 , 2 The steamed bun machine shown comprises a frame 1 and a noodle-pressing mechanism installed on the frame, a steamed bun mechanism, a cutting mechanism, a transmission device, and a temperature control device, and the noodle-pressing mechanism includes a feed hopper 2 , the first-stage pressing face roller 3, the second-stage pressing face roller 4, the raw dough conveyor belt 5, the discharge opening of the feed hopper 2 is less than the length of the first-stage pressing face roller 3, and the first-stage pressing face roller 3 and the two-stage pressing surface roller 4 both sides are all provided with width-limiting sides; Described steamed bun mechanism comprises upper steamed bun roll 6 and lower steamed bun roll 7 and finished product conveyor belt 8; 9 and a cutter 10; the transmission device is connected to the noodle pressing mechanism, the steamed bun mechanism and the cutting mechanism; the temperature control device is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com