Rotisserie oven and hood

A meat box, rotating ground technology, applied in the directions of oven doors/flap gates, baking devices, lighting and heating equipment, etc., can solve the problems of restricting the popularity of rotary barbecue boxes and reducing sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] I

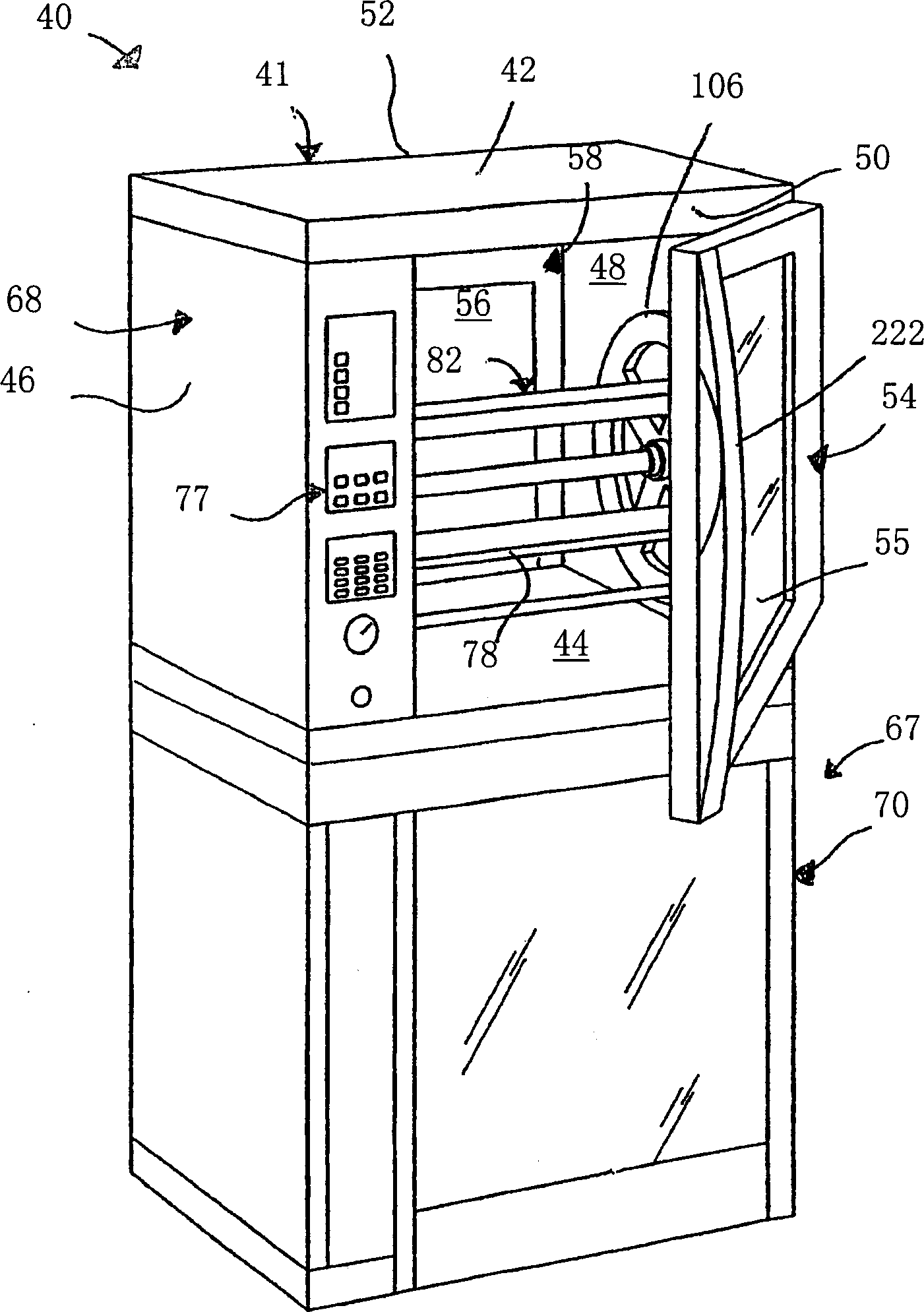

[0053] see first figure 1 A rotisserie 40 includes a housing 41 having upper and lower walls 42 and 44, opposing left and right side walls 46 and 48, and opposing front and rear walls 50 and 52 ( figure 2 shown in ). The cooking chamber 58 is formed by upper and lower walls 42 and 44, a right side wall 48 and a left side wall 64 (see FIG. 14).

[0054] Wall 64 is spaced from wall 46 which together form a lateral boundary of a cabinet 68 in which control elements of oven 40 (eg, a microprocessor or other suitable controller, not shown) are housed. Specifically, cabinet 68 houses control components (not shown) that control various aspects of oven 40, such as temperature control, cooking sequences, and clean-up functions, as will be described in detail below. Cabinet 68 also houses the motor that drives the spit assembly (see figure 2 ). The operation of the oven is controlled by the operator through a set of controls and outputs 77 located on the front wall 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com