Patents

Literature

163 results about "Force convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forced convection is a method of heat transfer in which external means influence the motion of the fluid. There, external sources such as pumping, fans, suction devices, etc. are useful in generating the fluid motion. This method is very valuable because it can efficiently transfer heat from a heated object.

Convective accelerometer

InactiveUS20050257616A1Simple designLow costAcceleration measurementFluid speed measurementAccelerometerHomeland security

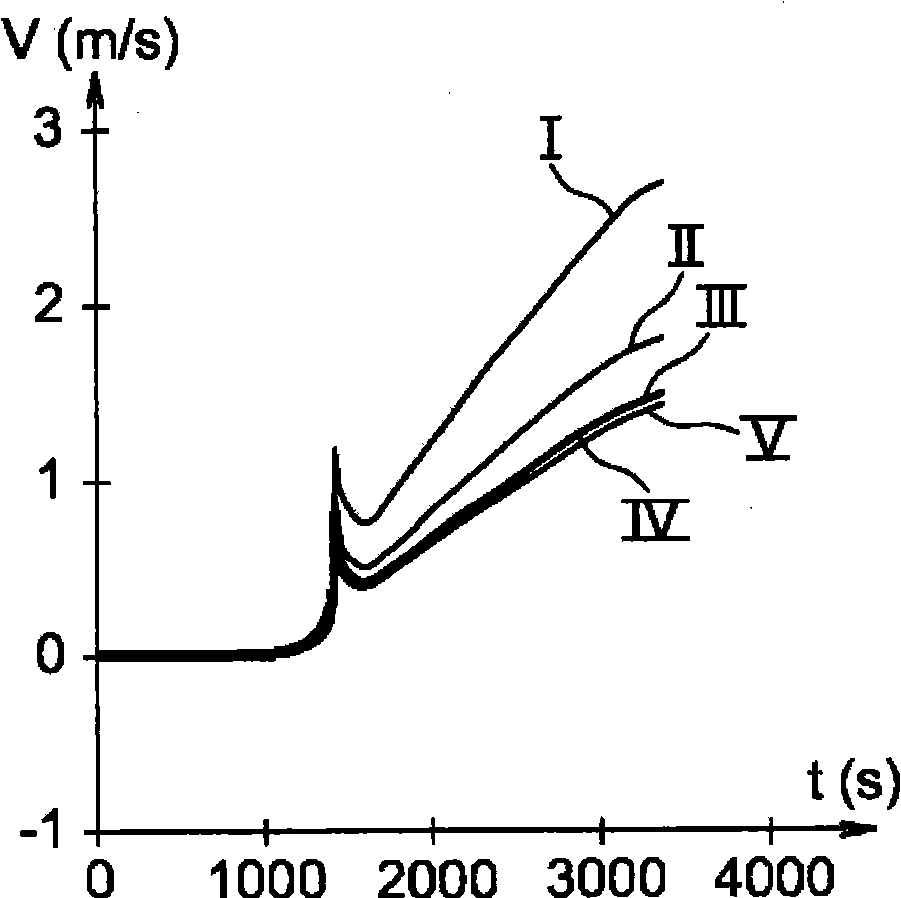

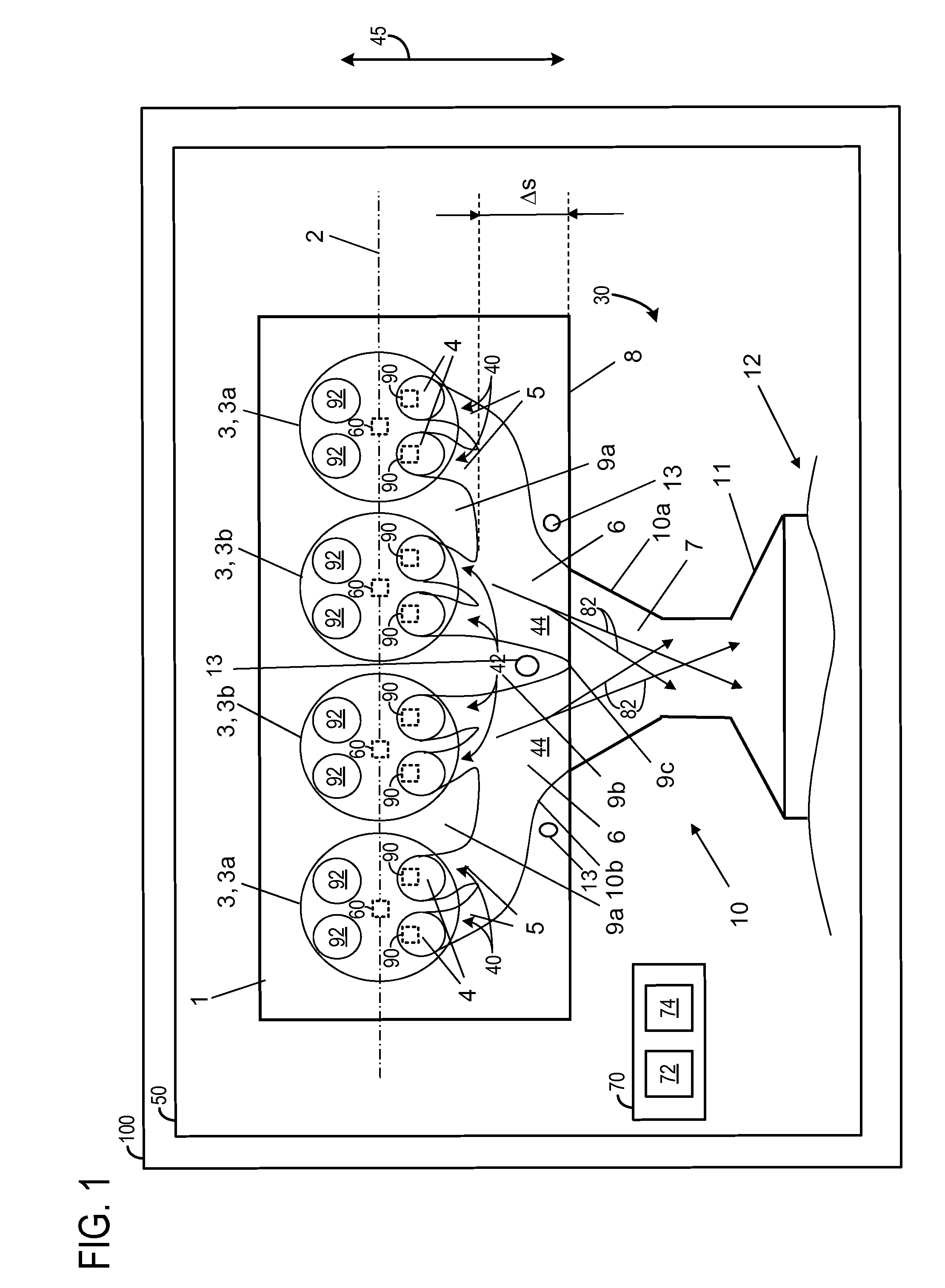

A convective accelerometer capable of measuring linear or angular acceleration, velocity, or angle of inclination is provided. The accelerometer comprises sensing elements that are sensitive to convection located inside a sealed housing containing a liquid agent. Applied external acceleration causes forced convection of the liquid agent, which produces variations in an electric current produced by the sensing elements that are proportional to the applied acceleration or angle of inclination. The accelerometer has a small size, extremely wide frequency and dynamic ranges, high sensitivity, simple design and is suitable for mass production. The device has a wide range of application, such as stabilization and control systems, homeland security, and oil exploration.

Owner:MET TECH INC

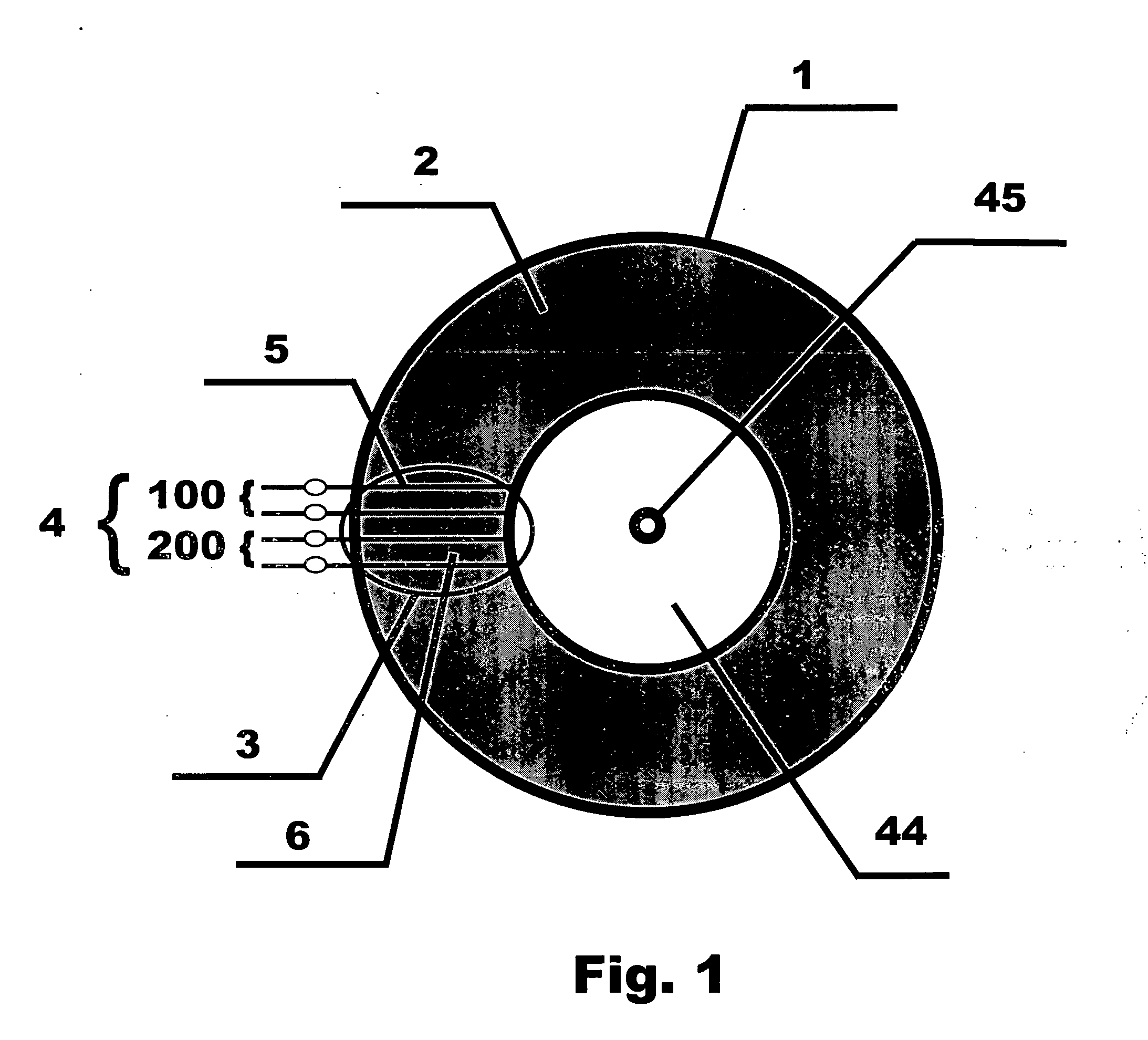

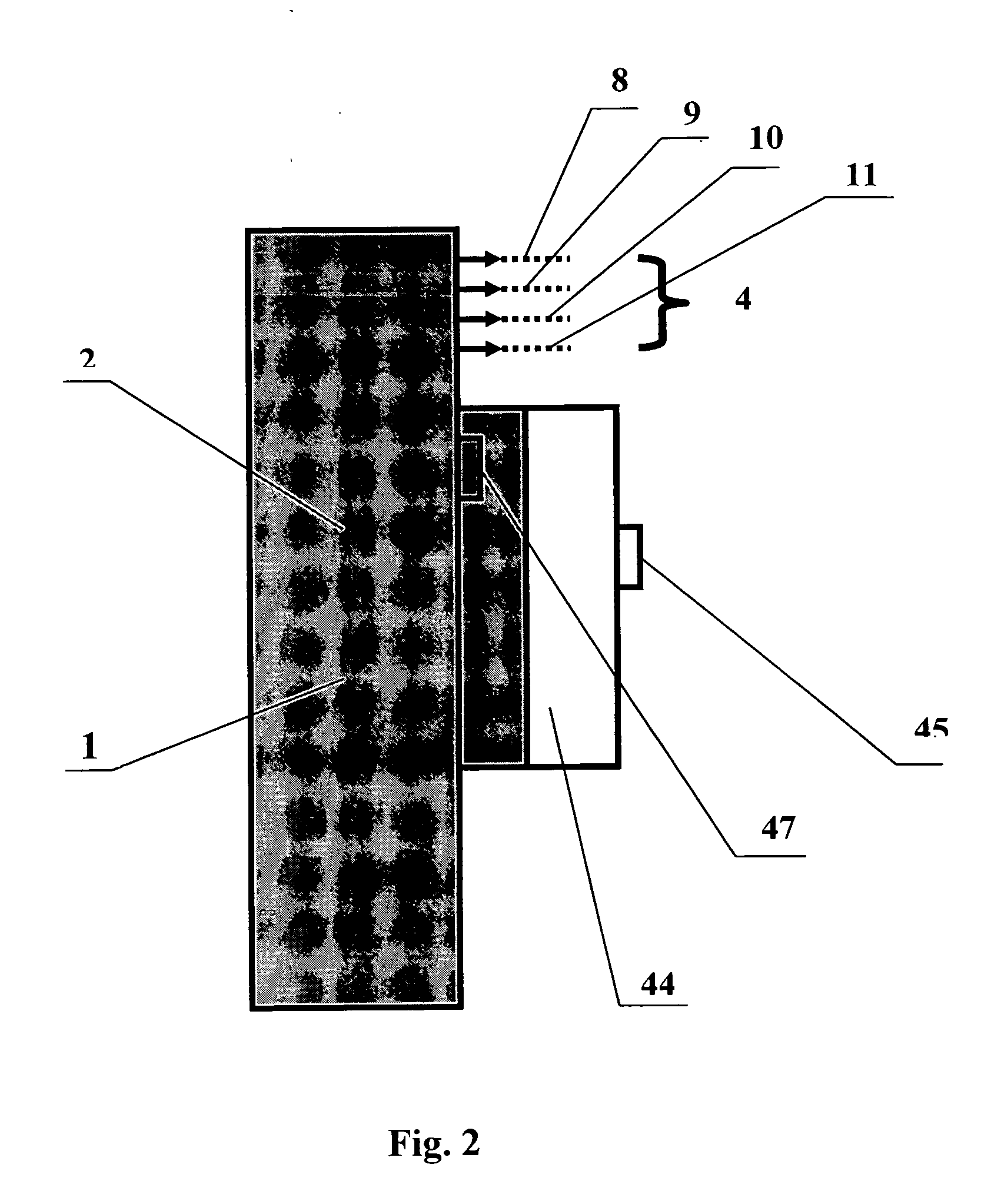

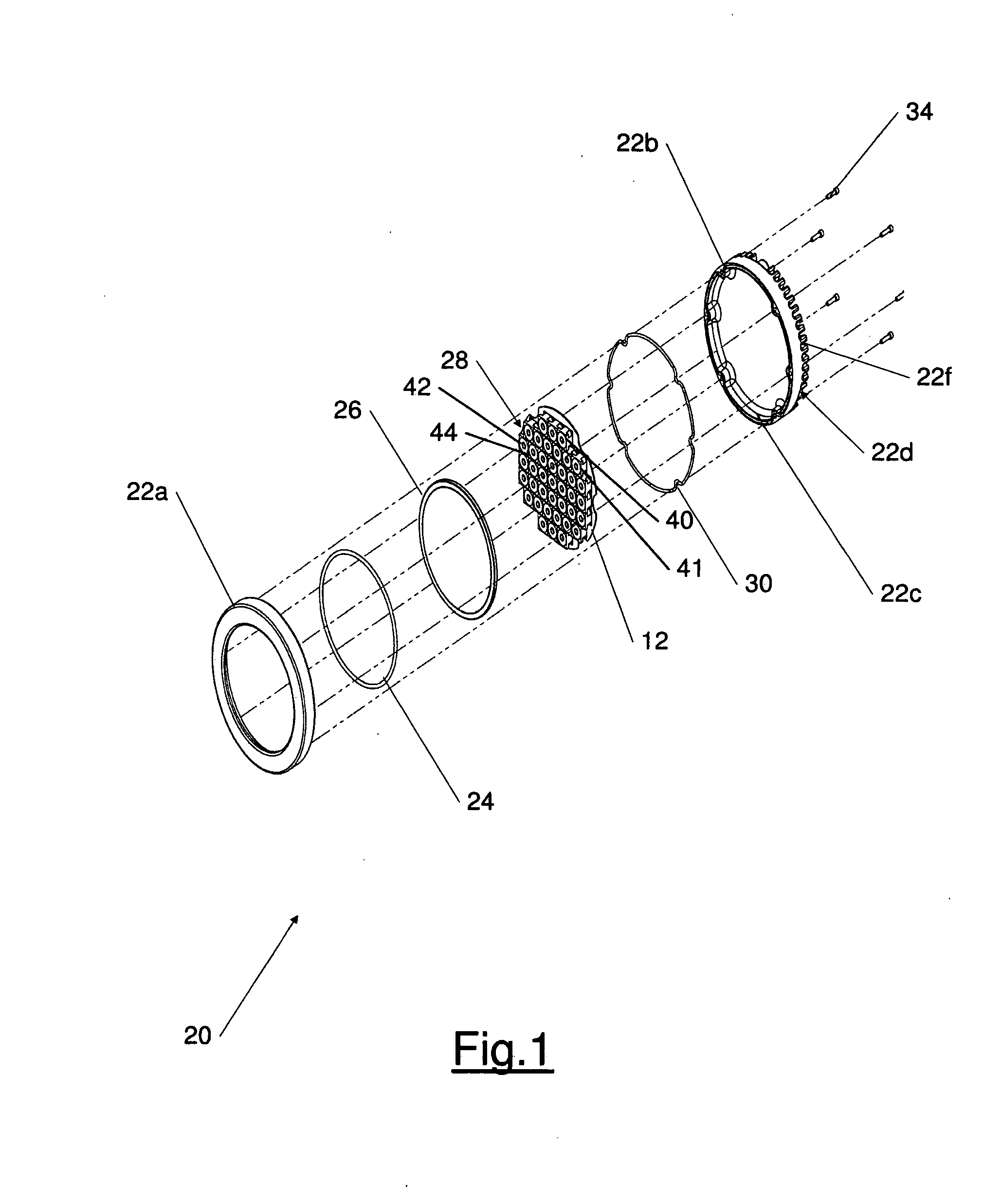

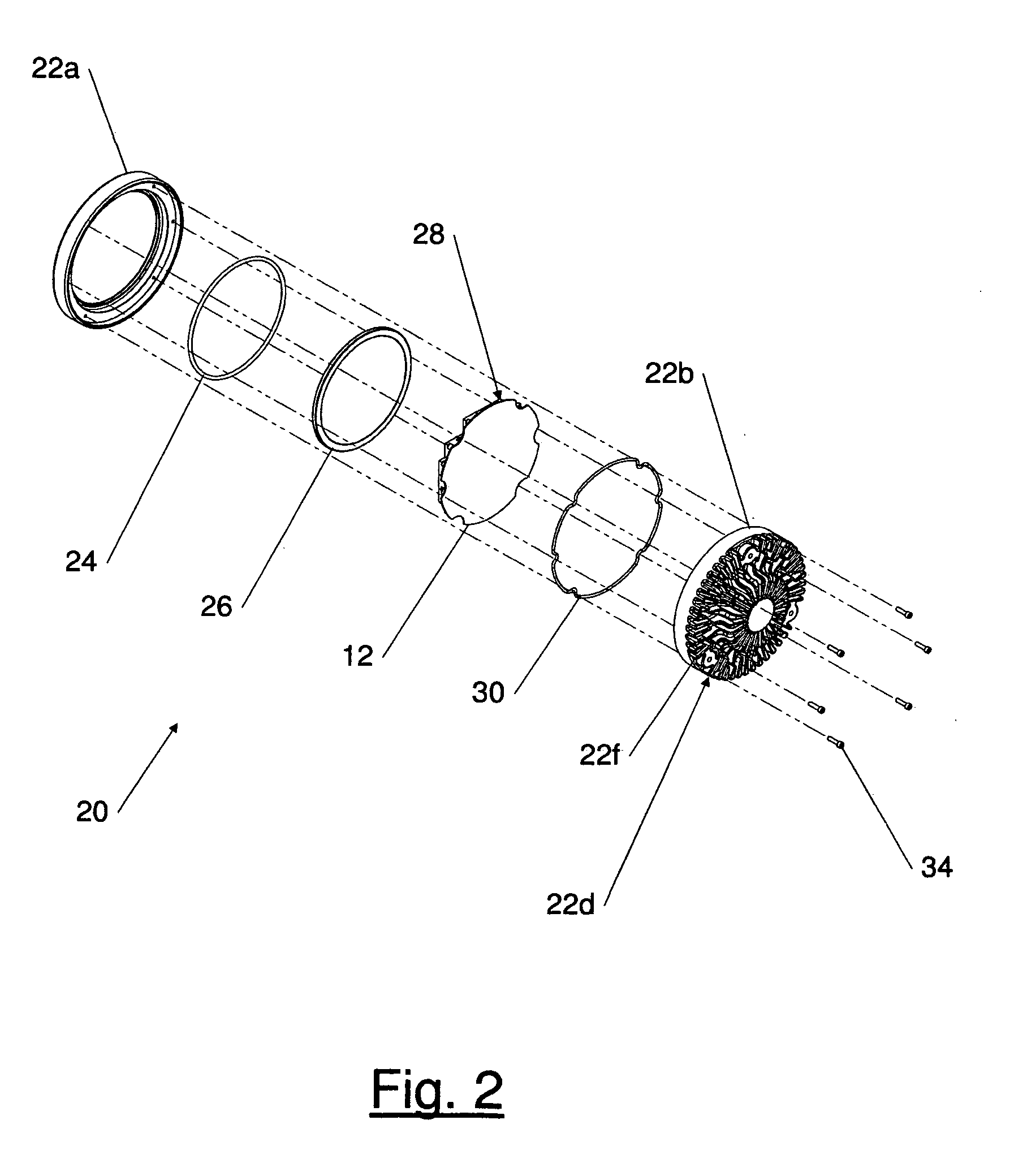

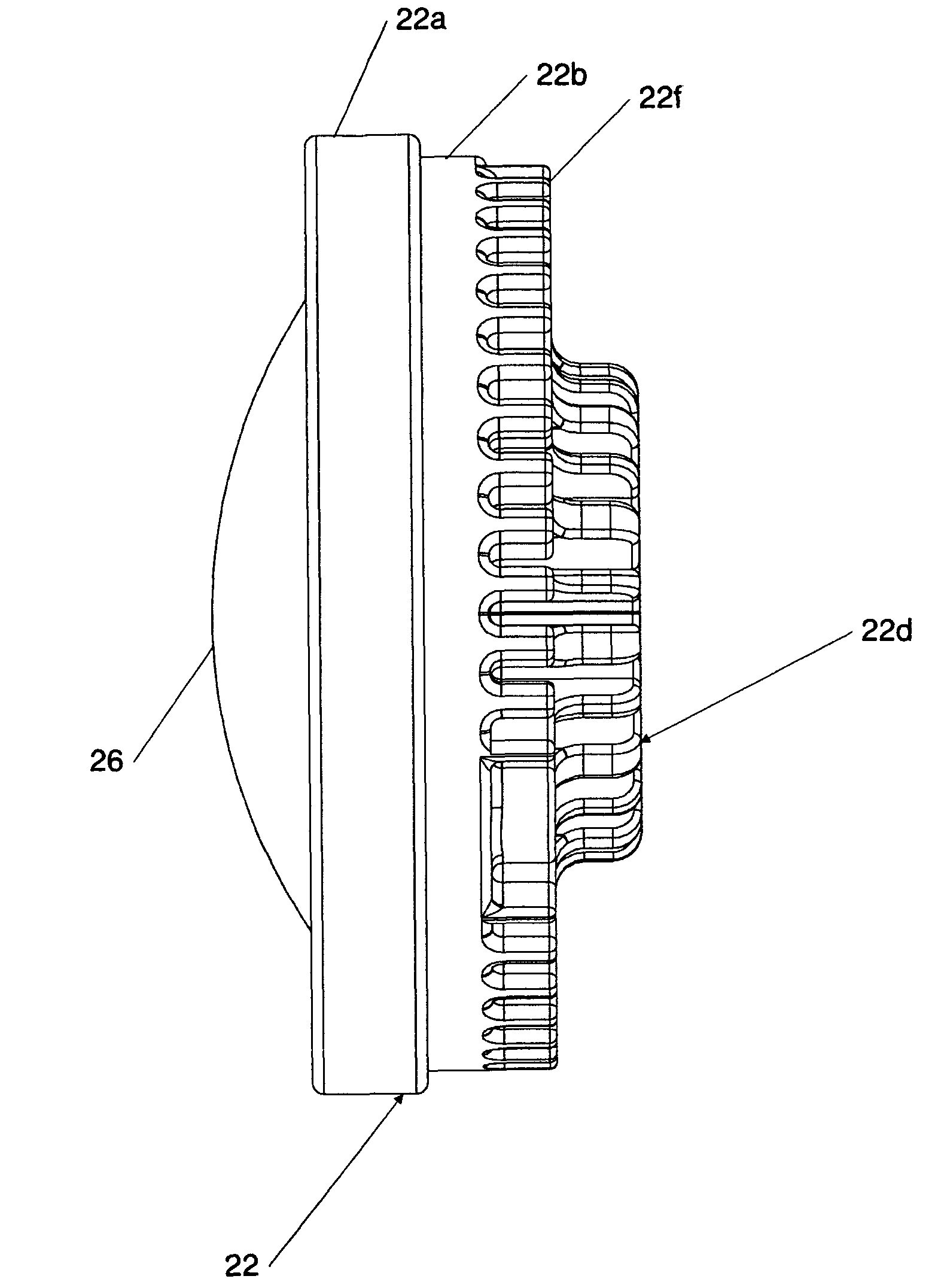

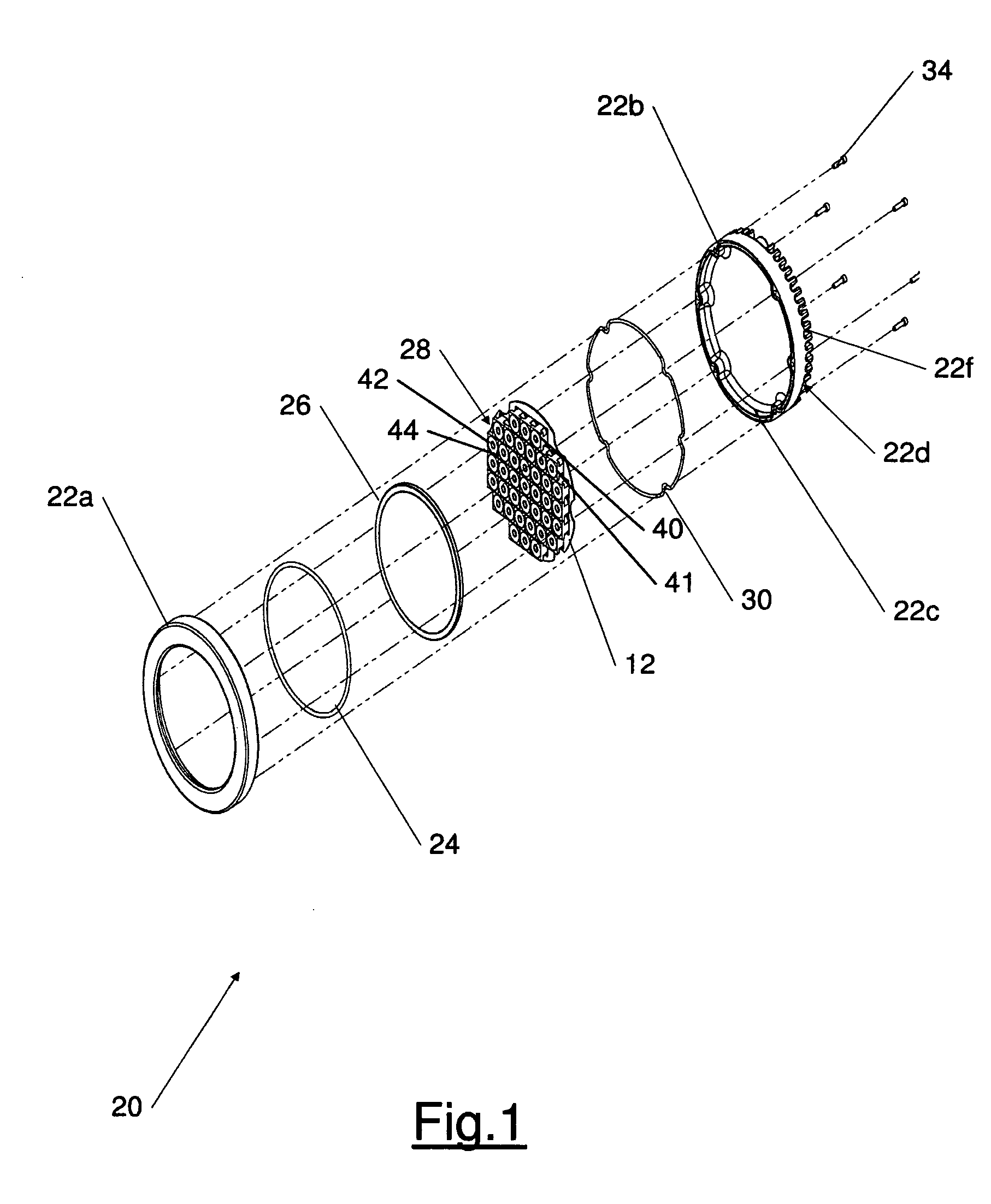

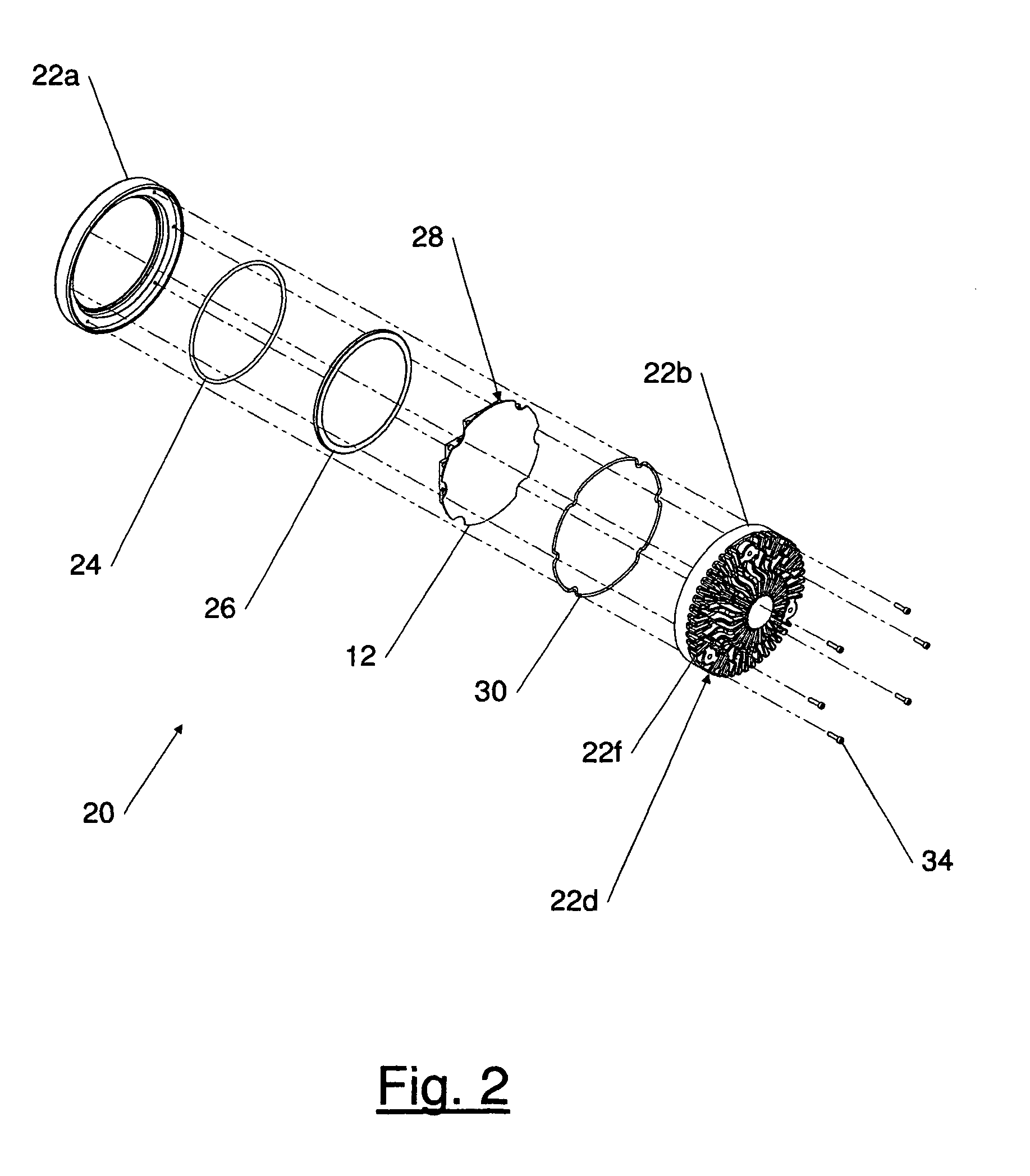

All-LED visible light and IR light headlamp

A headlamp for a vehicle (air, land or sea) providing a planar array of infrared (IR) light-emitting diodes (LEDs) and visible light LEDs, and arranged and mounted within a housing so as to provide for cooling of the LEDs without forced convection, by conducting heat from the LEDs to protruding cooling fins. A switch system is also provided, for enabling either the visible light or the infrared light, and for selecting a high-beam or low-beam pattern. The beam pattern is provided in some embodiments so as to meet US Federal Motor Vehicle standards.

Owner:IBIS TEK

Heater elements with enhanced cooling

ActiveUS20130062333A1Improve cooling effectSpeed up coolingMuffle furnacesSemiconductor/solid-state device detailsForced convectionEngineering

A heater assembly with enhanced cooling pursuant to various embodiments described herein makes use of fluidic flow in the insulation or in the space used for insulation. By creating a natural convection or forced convection flow, the heater cools down faster, it can operate at lower temperatures and / or higher temperature precision, and it can improve temperature controllability by generating higher heat loss rates.

Owner:EMAMI ARSALAN

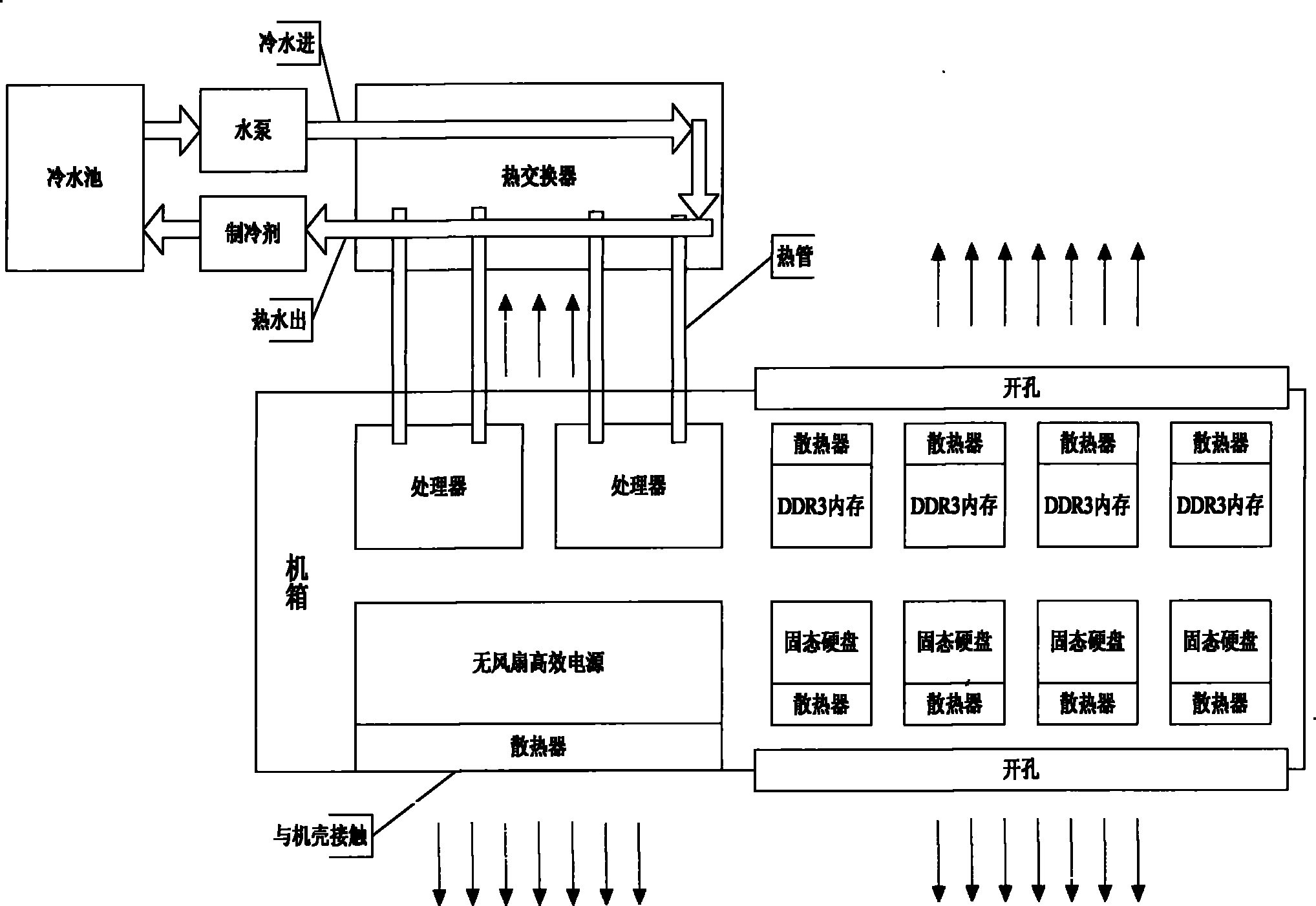

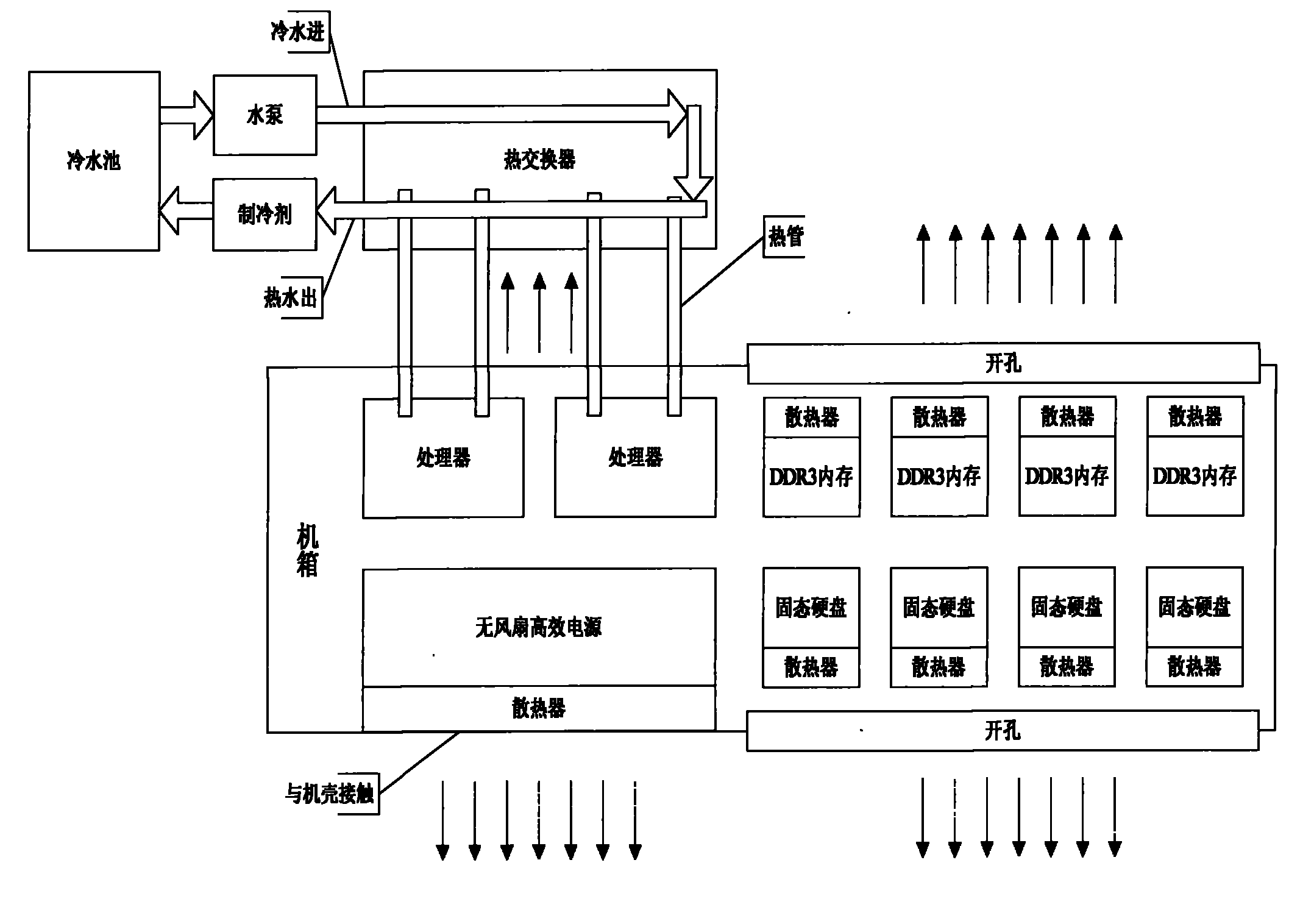

Noise-free energy-saving server

InactiveCN101893921ACancel noiseSolve the cooling problemEnergy efficient ICTPower supply for data processingFree energiesForce convection

The invention provides a noise-free energy-saving server, and the contents are as follows: 1) adopting the way with the combination of a heat pipe and liquid cooling to replace the traditional fan forced convection way for solving the heat dissipation problem of a processor and eliminating the noise of a fan; 2) using a DDR3 memory with low power consumption to reduce the noise; 3) using a solid-state disk to eliminate the noise of the hard disk; and 4) using a fanless high-efficient power supply for the power supply of a system; and the specific steps are as follows: adopting the way with the combination of the heat pipe and the liquid cooling for heat dissipation, connecting one end of the heat pipe with the processor, connecting the other end of the heat pipe with a water pipe in a heat exchanger, transferring heat produced by the processor to the water pipe in the heat exchanger according to the performance of a high heat conduction system of the heat pipe, leading cold water to flow in the water pipe, leading the heat pipe and the cold water in the water pipe to carry out heat exchange, heating the cold water, further draining hot water from the heat exchanger, refrigerating the hot water by refrigerant, then inputting into a cold water tank, and circulating in such a way for solving the heat dissipation problem of the processor, wherein the flow of the water is supported through a water pump.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

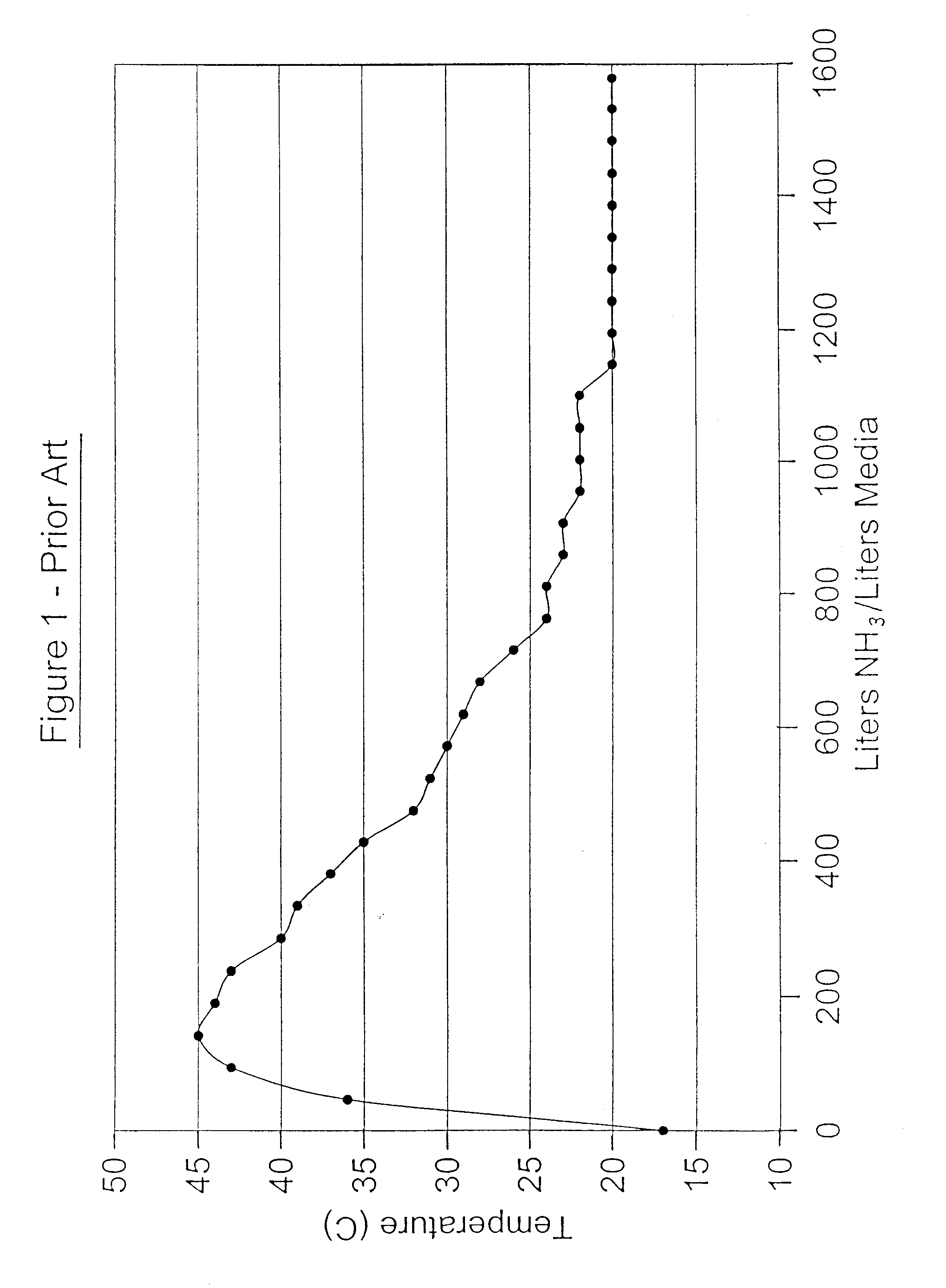

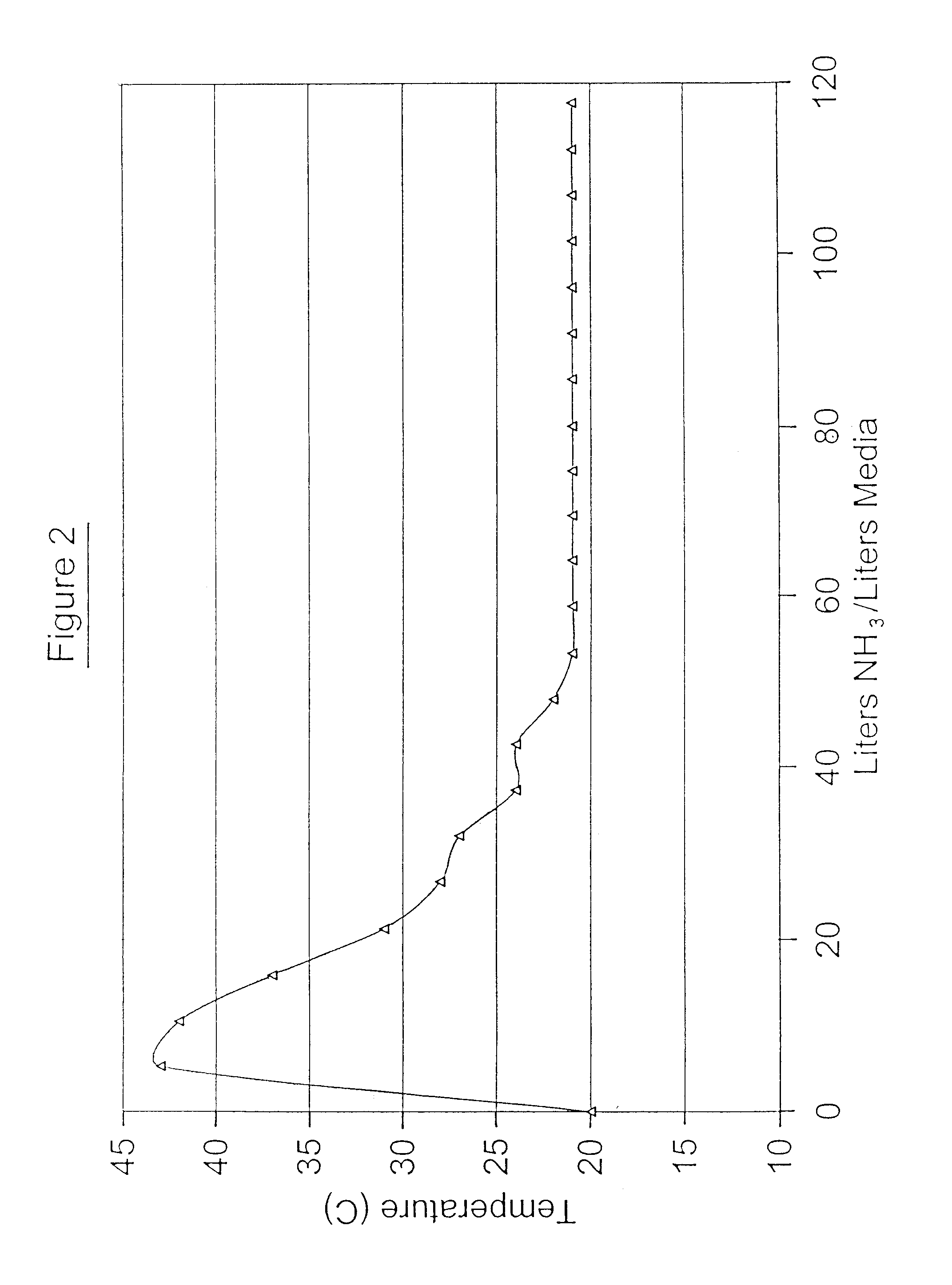

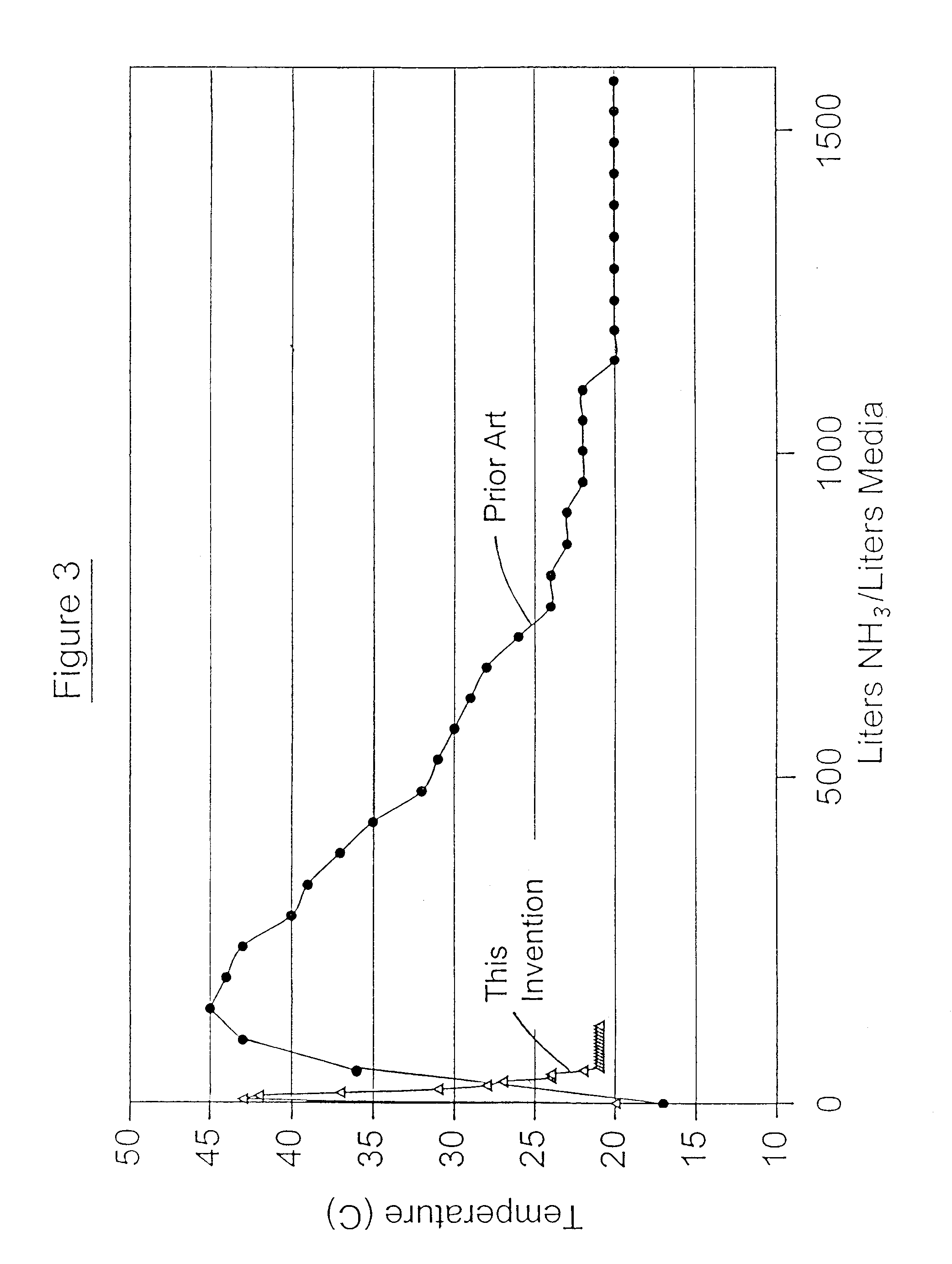

Method for rapid activation or preconditioning of porous gas purification substrates

A method is described for rapid and economical activation and / or preconditioning of gas purification substrates by providing forced convection of the preconditioning or activating gas through the pores of the substrate. The gas is pumped into the substrate-containing vessel and raised to an elevated pressure, which is maintained for a short predetermined time, followed by venting of contents of the vessel. The vessel is again pressurized with the purging gas to an elevated level, and the elevated pressure is maintained for a short predetermined time, followed by venting of the vessel. This cycle is repeated as often as needed or desired. Activation and / or preconditioning can be accomplished in a much shorter time and with much less gas usage compared to diffusion preconditioning and activation processes. This process is particularly suited for preconditioning and activation of gas purifier substrates for decontamination of gases down to <=1 ppm contaminants.

Owner:ENTEGRIS INC

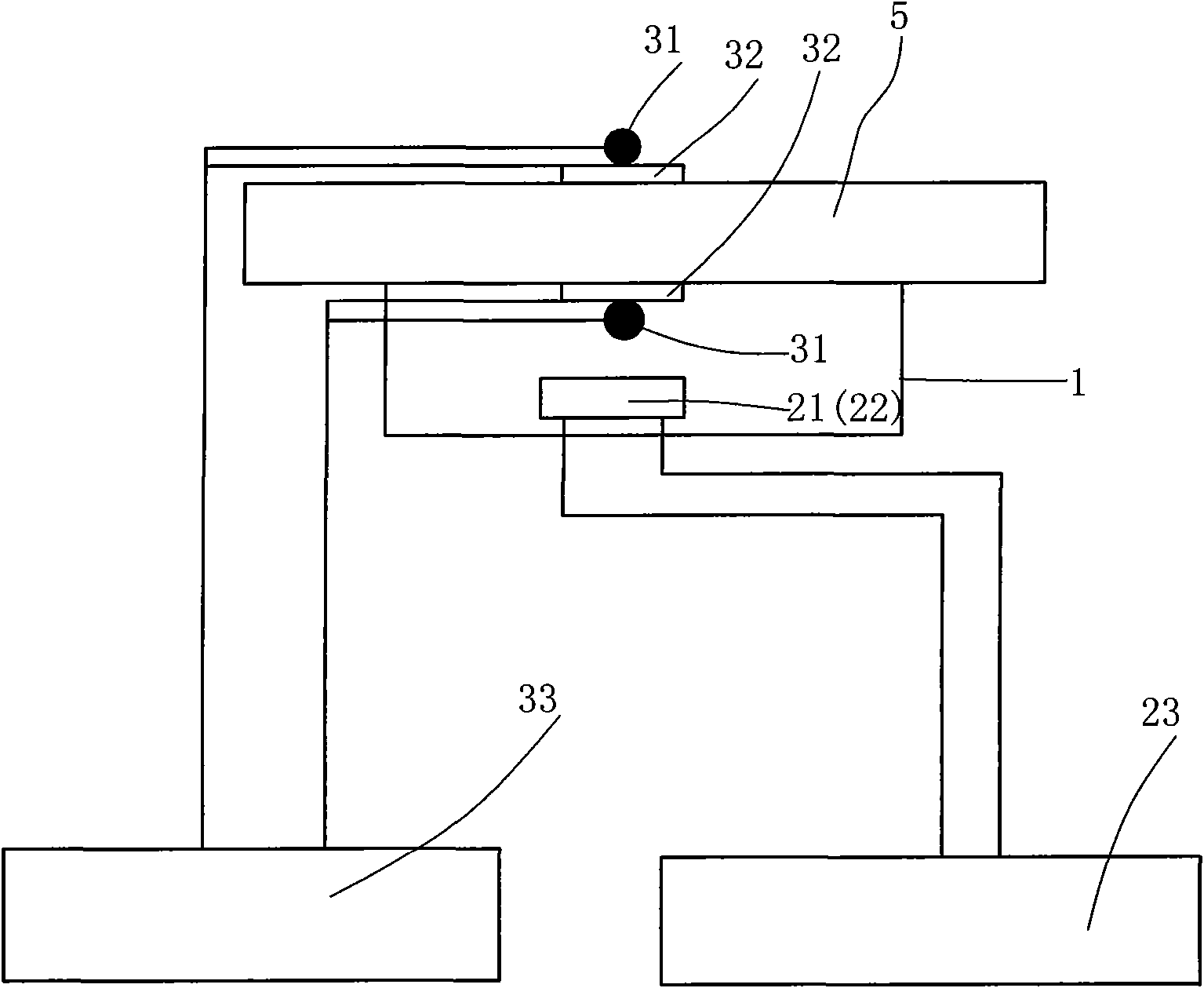

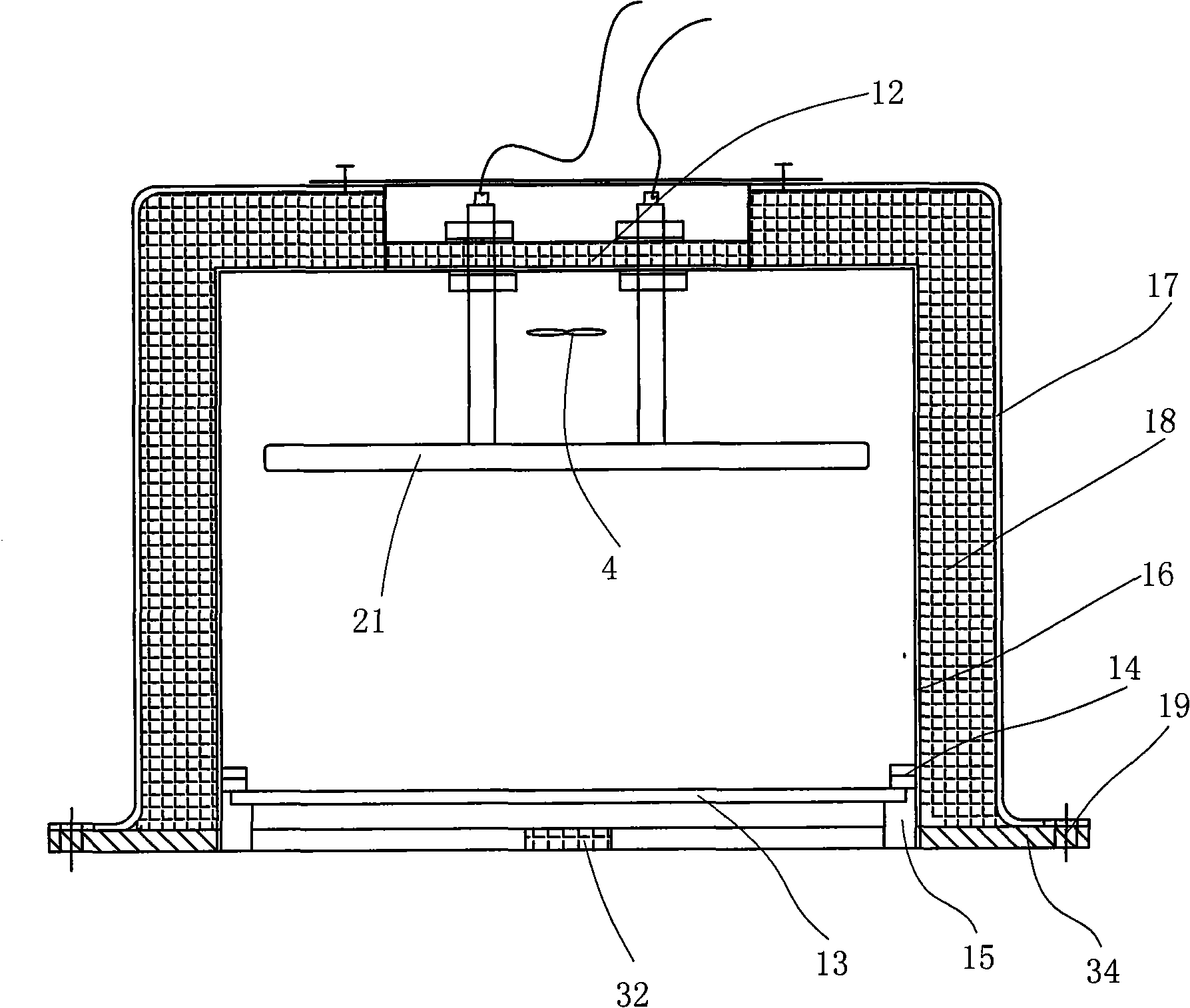

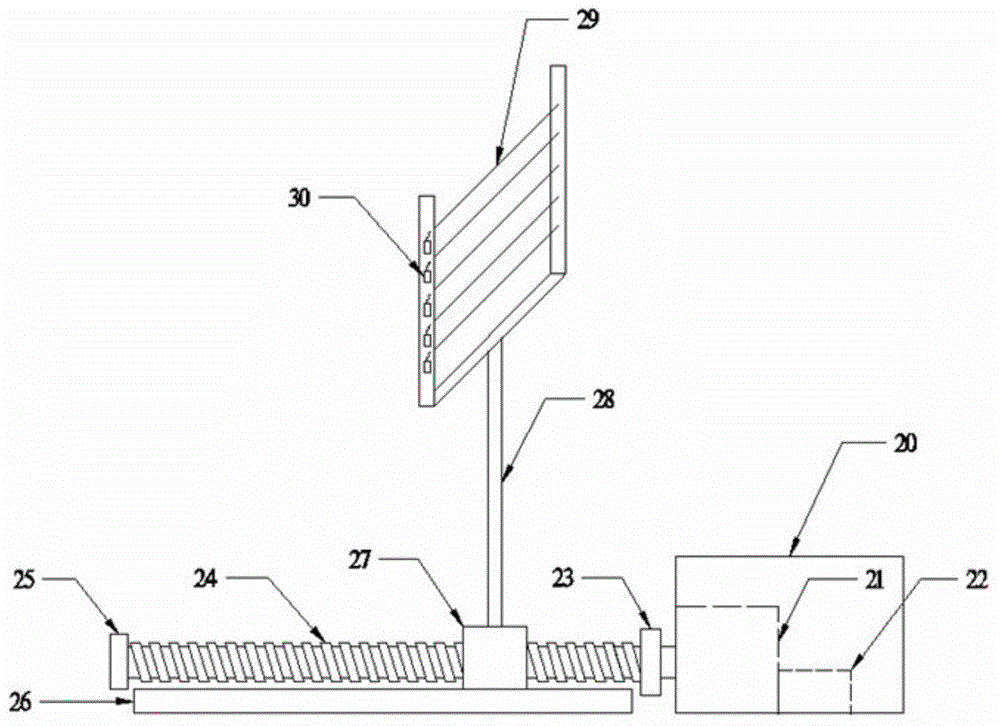

On-site detection device and detection method for heat transfer coefficients of building enclosure structures

InactiveCN101782540AAccurate measurementThere is no correction problem for 2D heat transferMaterial thermal conductivityMaterial heat developmentObservational errorHeat flow

The invention relates to an on-site detection device and a detection method for heat transfer coefficients of building enclosure structures. The device comprises a temperature difference producing device arranged on a to-be-detected enclosure structure, as well as a data acquisition device for testing and receiving temperature and heat flow of the inner and outer sides of the to-be-detected enclosure structure. The device is characterized in that the temperature difference producing device is arranged in a bucket-shaped shell; the shell and the to-be-detected enclosure structure form a cylindrical cavity; a fan used for forced convection is arranged in the shell; and the temperature difference producing device comprises heating equipment and refrigeration equipment. The detection device provided by the invention enables heat to be capable of one-dimensional conduction, thereby greatly reducing measurement errors. The device used for on-site detection has the advantages of convenient installation and use, as well as testing time free from seasonal limit.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Ceramic membrane cooling coating for LED radiator and preparation method of ceramic membrane cooling coating

InactiveCN102911535AExcellent self-cooling functionImprove Radiation PerformanceCoatingsMetallurgyFilling materials

The invention discloses a ceramic membrane cooling coating for an LED radiator and a preparation method of the ceramic membrane cooling coating. The coating comprises a liquid A and a liquid B at the weight ratio of (2:1)-(2.5:1), wherein the liquid A comprises the following materials by weight percent: 40-60 percent of silica sol, 20-40 percent of filling material, 15-20 percent of pigment, 5-10 percent of anti-anti-settling agent; and the liquid B comprises the following materials by weight percent:75-80 percent of organo siloxane, 8-10 percent of catalyst and 10-15 percent of solvent. According to the utility model, the functional coating is coated outside the LED radiator, and a high-radiance filling material is adopted. Compared with a general decorative coating, the ceramic membrane cooling coating has an excellent cooling function, provides radiative heat transfer under the condition of no forced convection and improves the problem that the radiating effect is bad in absence of forced convection. Besides, the coating has an excellent decorative function, and the radiance reaches 0.83-0.92 after a membrane is formed.

Owner:SOUTH CHINA UNIV OF TECH

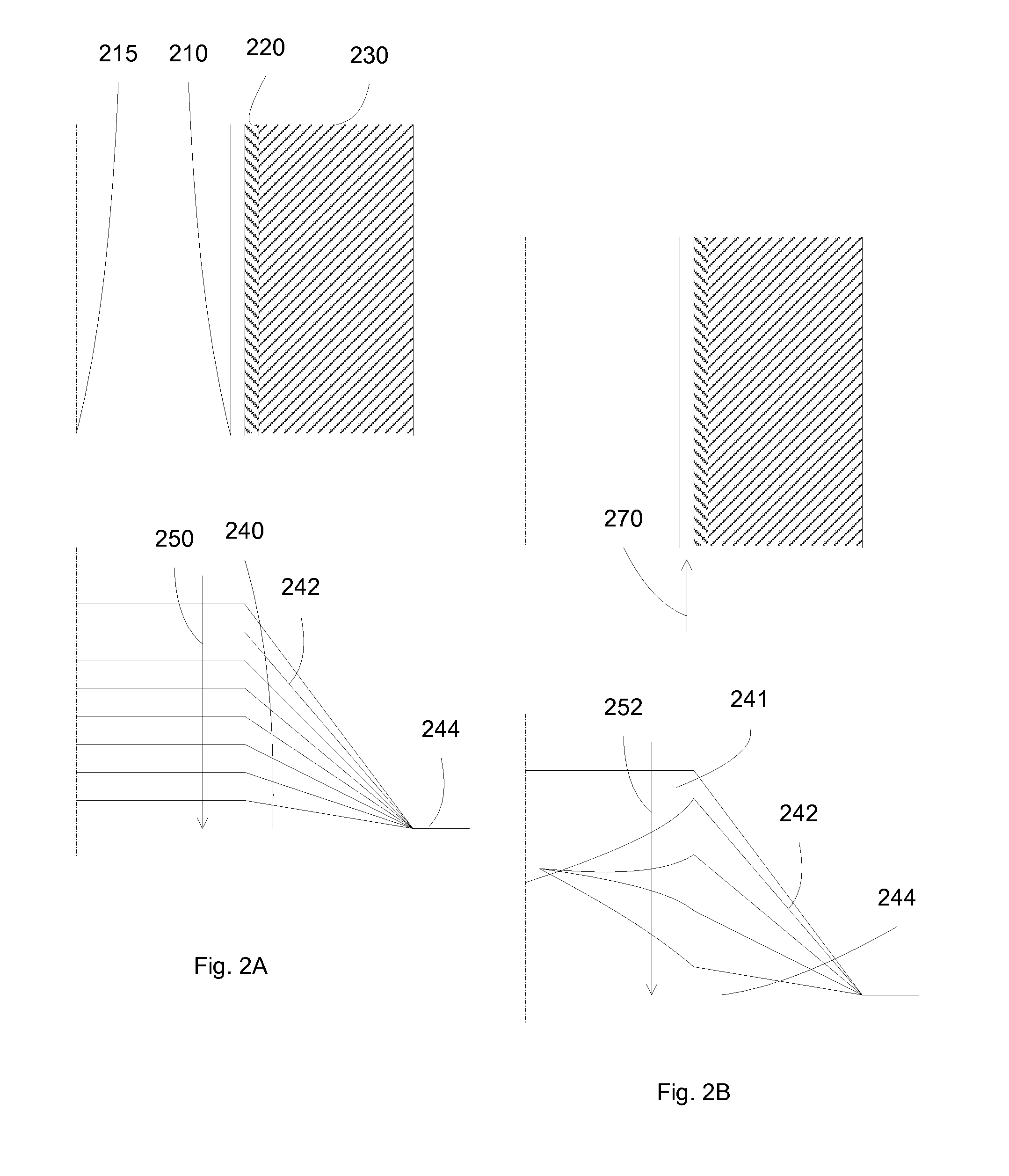

All-LED visible light and IR light headlamp

A headlamp for a vehicle (air, land or sea) providing a planar array of infrared (IR) light-emitting diodes (LEDs) and visible light LEDs, and arranged and mounted within a housing so as to provide for cooling of the LEDs without forced convection, by conducting heat from the LEDs to protruding cooling fins. A switch system is also provided, for enabling either the visible light or the infrared light, and for selecting a high-beam or low-beam pattern. The beam pattern is provided in some embodiments so as to meet US Federal Motor Vehicle standards.

Owner:IBIS TEK

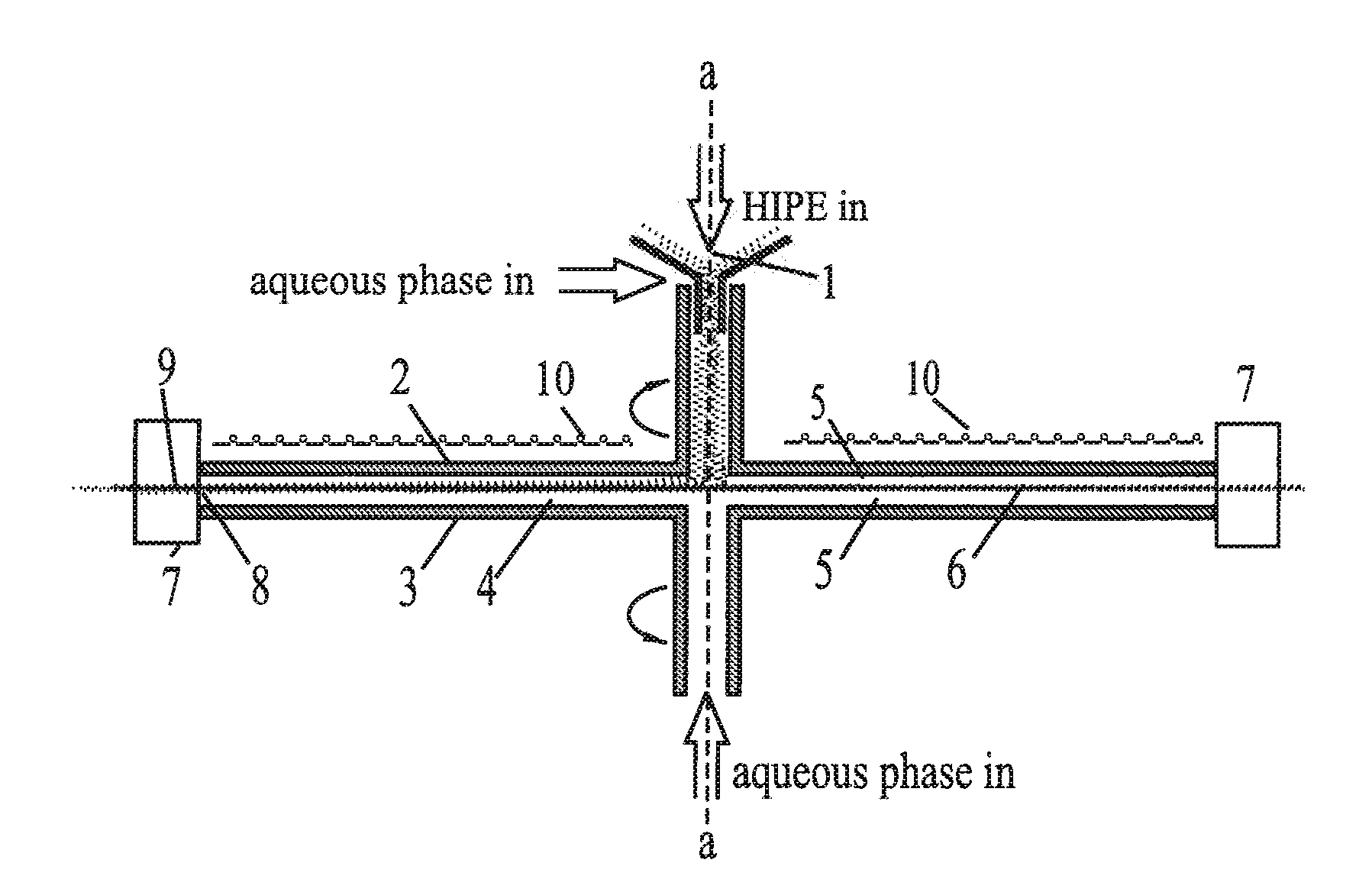

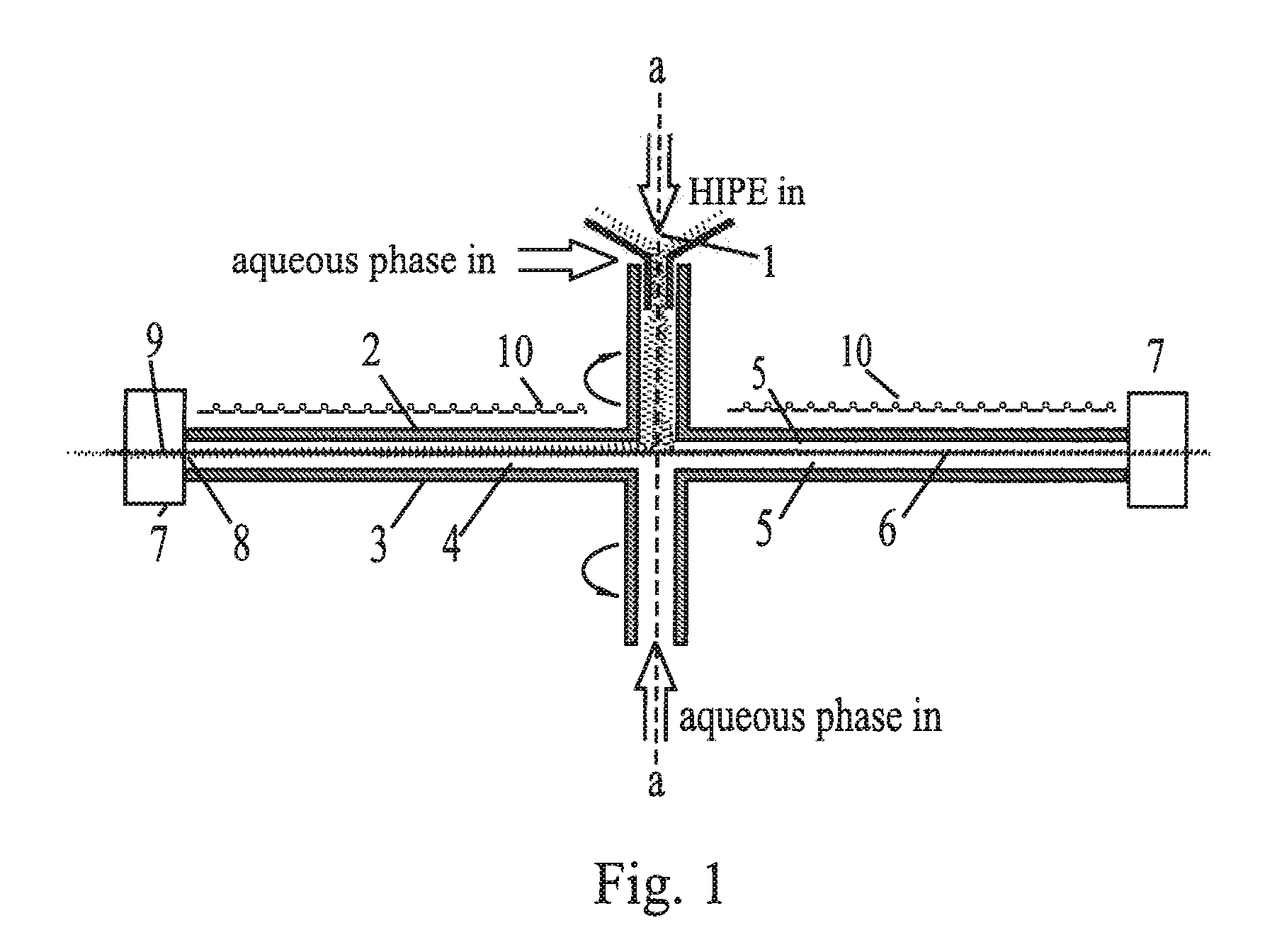

Reactors for forming foam materials from high internal phase emulsions, methods of forming foam materials and conductive nanostructures therein

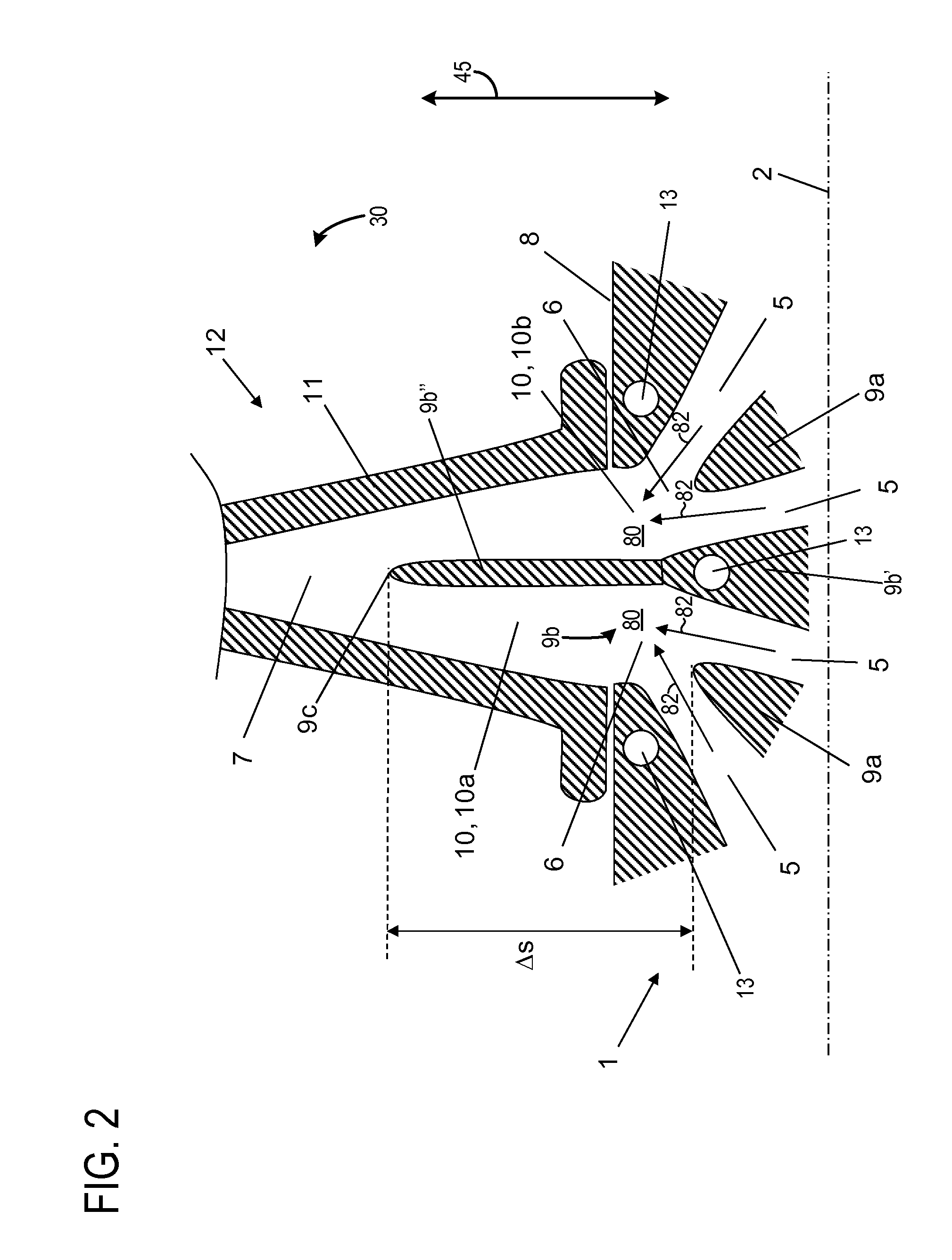

An RF inductor such as a Tesla antenna splices nanotube ends together to form a nanostructure in a polymer foam matrix. High Internal Phase Emulsion (HIPE) is gently sheared and stretched in a reactor comprising opposed coaxial counter-rotating impellers, which parallel-align polymer chains and also carbon nanotubes mixed with the oil phase. Stretching and forced convection prevent the auto-acceleration effect. Batch and continuous processes are disclosed. In the batch process, a fractal radial array of coherent vortices in the HIPE is preserved when the HIPE polymerizes, and helical nanostructures around these vortices are spliced by microhammering into longer helices. A disk radial filter produced by the batch process has improved radial flux from edge to center due to its area-preserving radial vascular network. In the continuous process, strips of HIPE are pulled from the periphery of the reactor continuously and post-treated by an RF inductor to produce cured conductive foam.

Owner:VORSANA INC

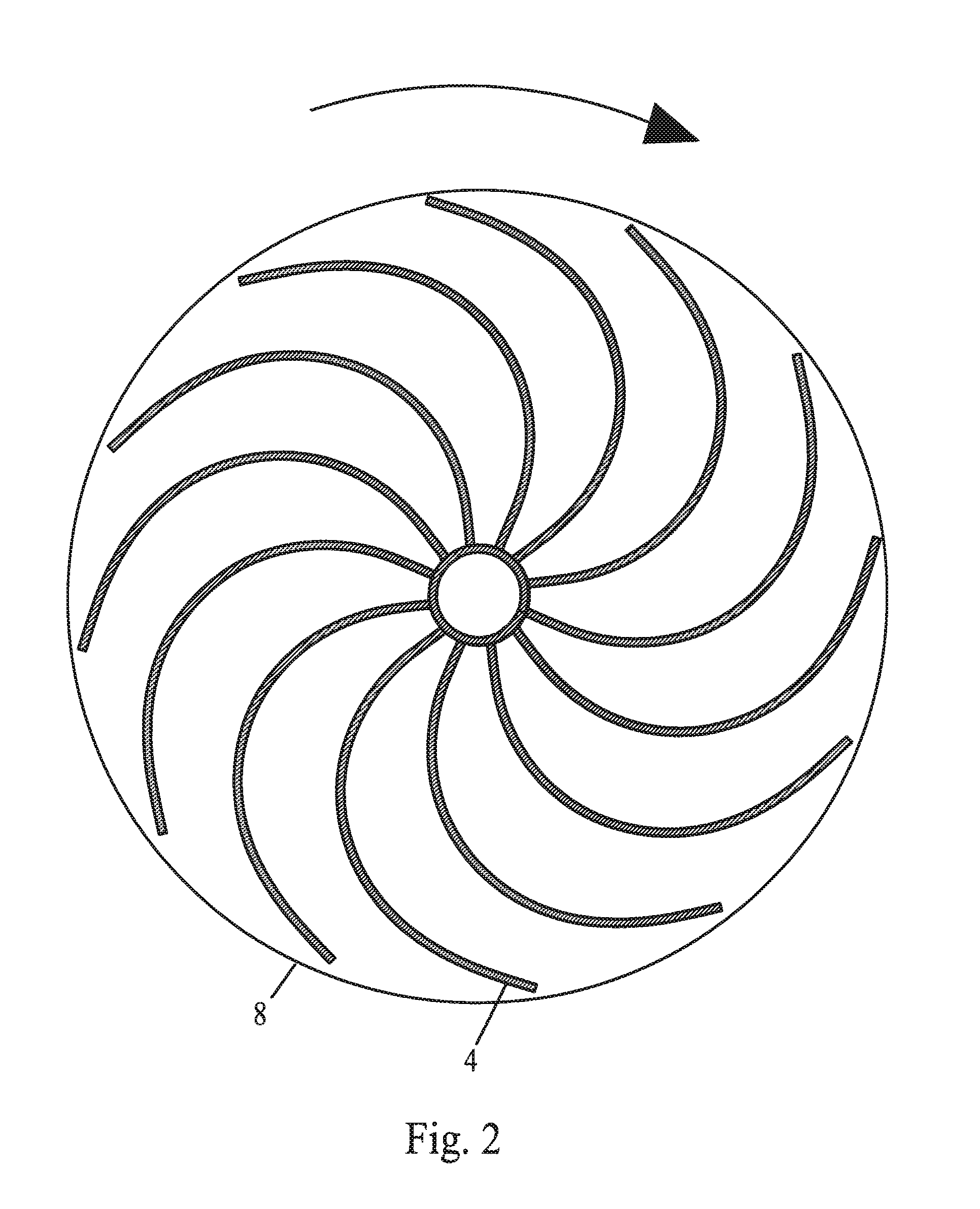

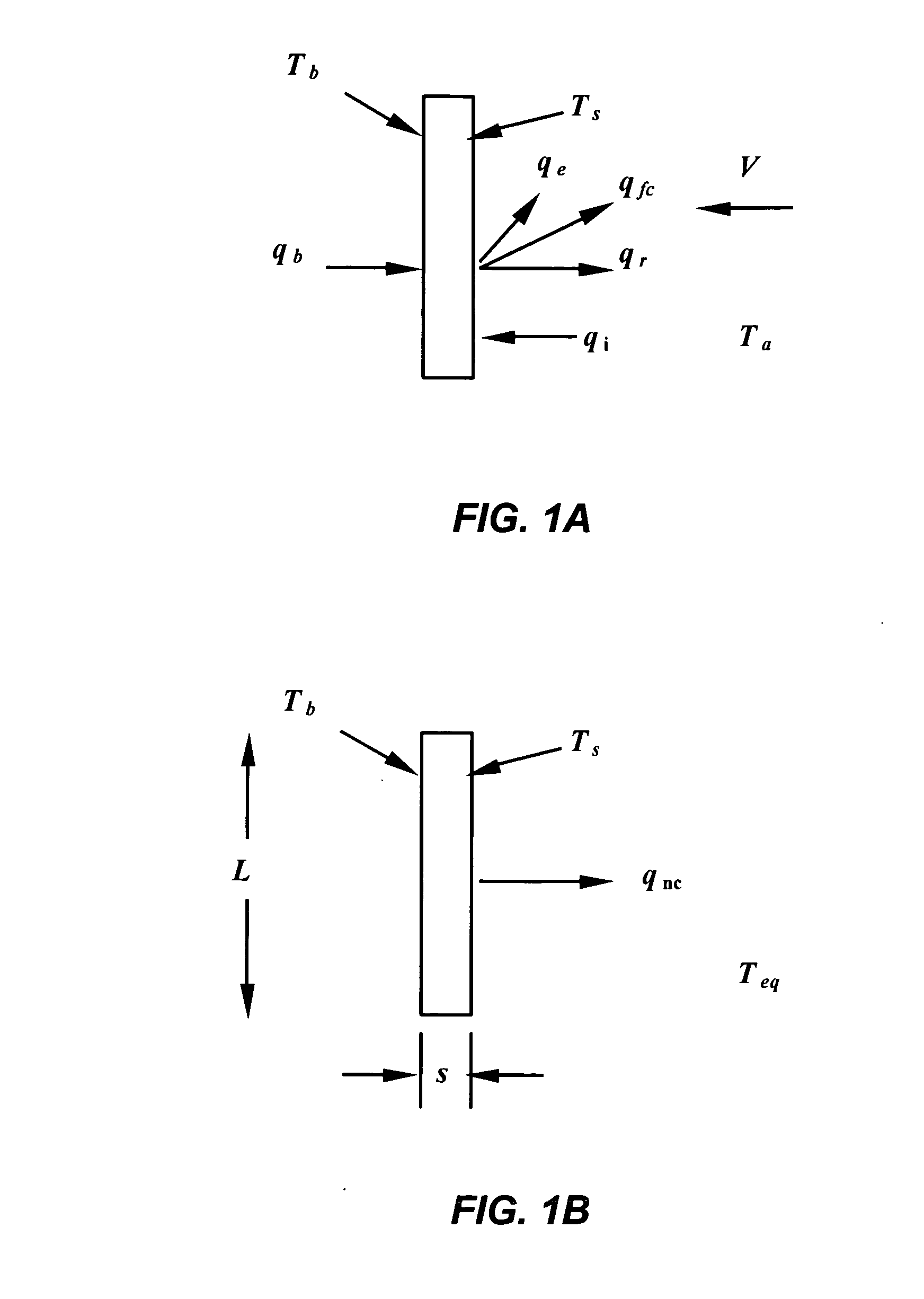

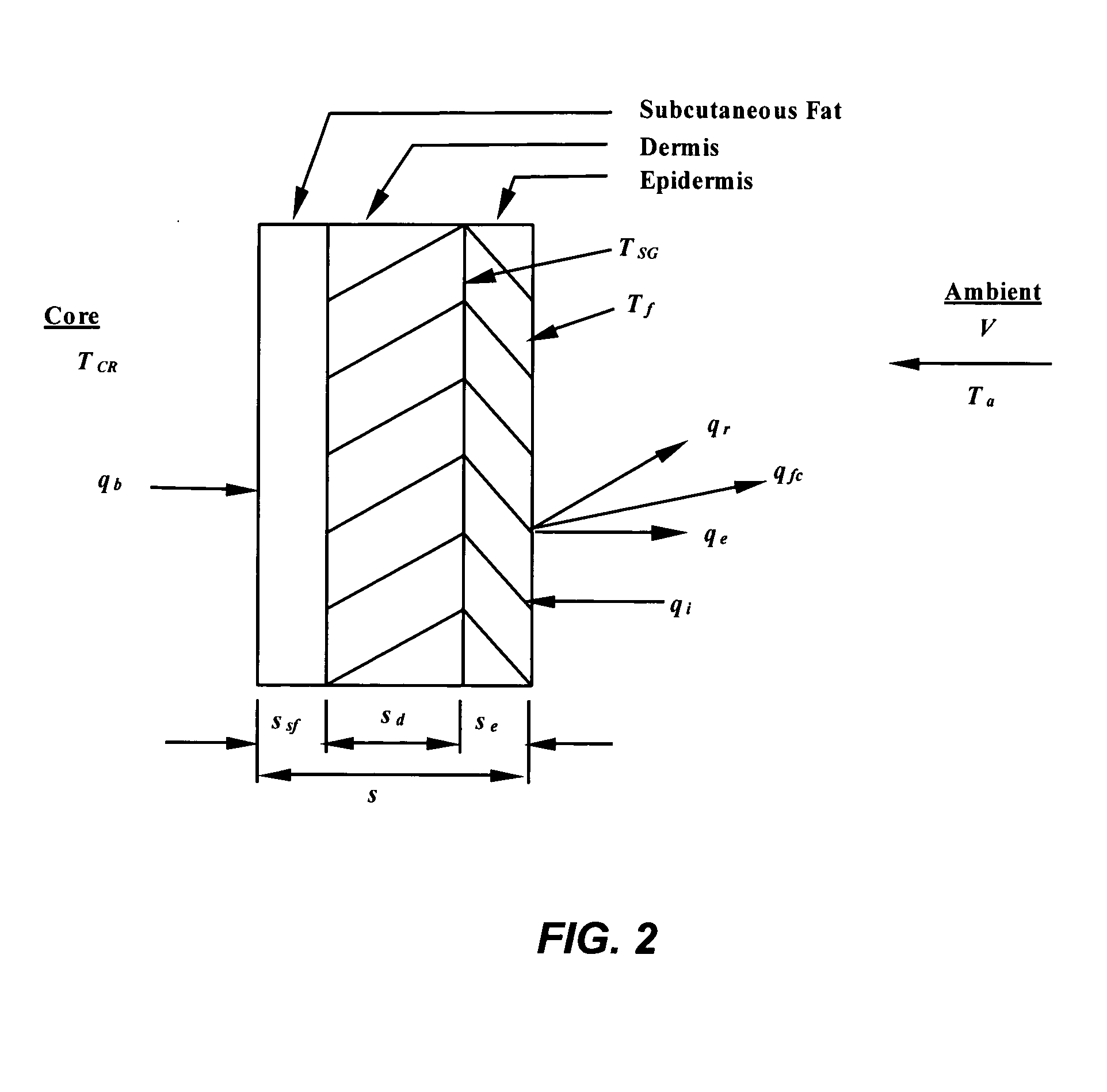

Method and system for determining wind chill temperature

The present invention includes methods, systems and computer-readable media for more accurately determining wind chill temperature, Twc, equivalent temperature, Teq, time to freeze, tf, facial temperature, Tfm+Δt, as a function of time and the altitude correction factor, Δtf / 1000. The wind chill model of the present invention accounts for the two major heat losses (forced convection, radiation) and a minor heat loss (evaporative cooling) from the facial surface and is also capable of accounting for the two major heat gains (metabolic, solar) at the facial surface due to the individual's physical activity and the presence of sunshine. The wind chill model of the present invention also provides a more accurate value for the wind velocity at head level.

Owner:AHMAD RASHID A +1

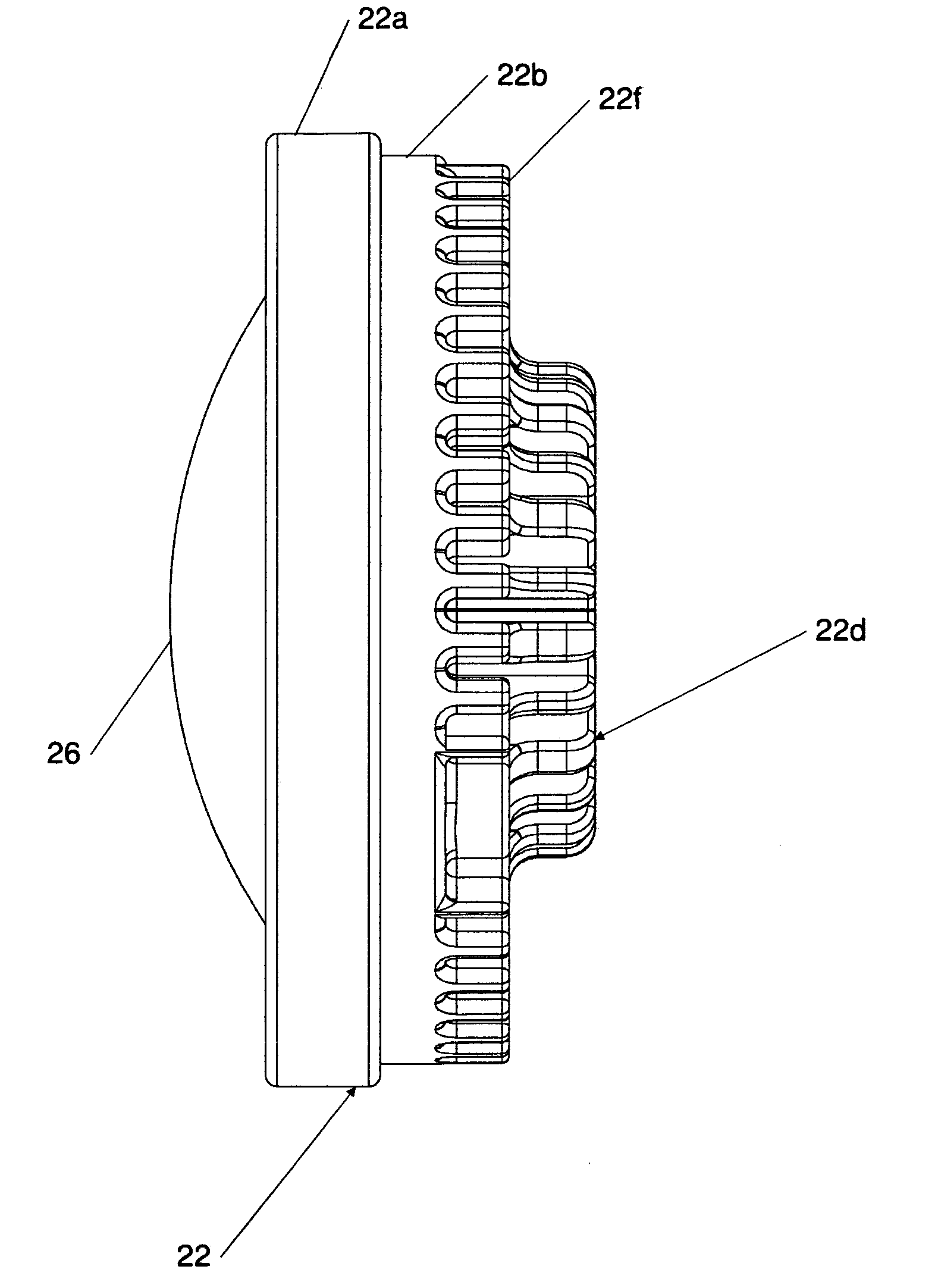

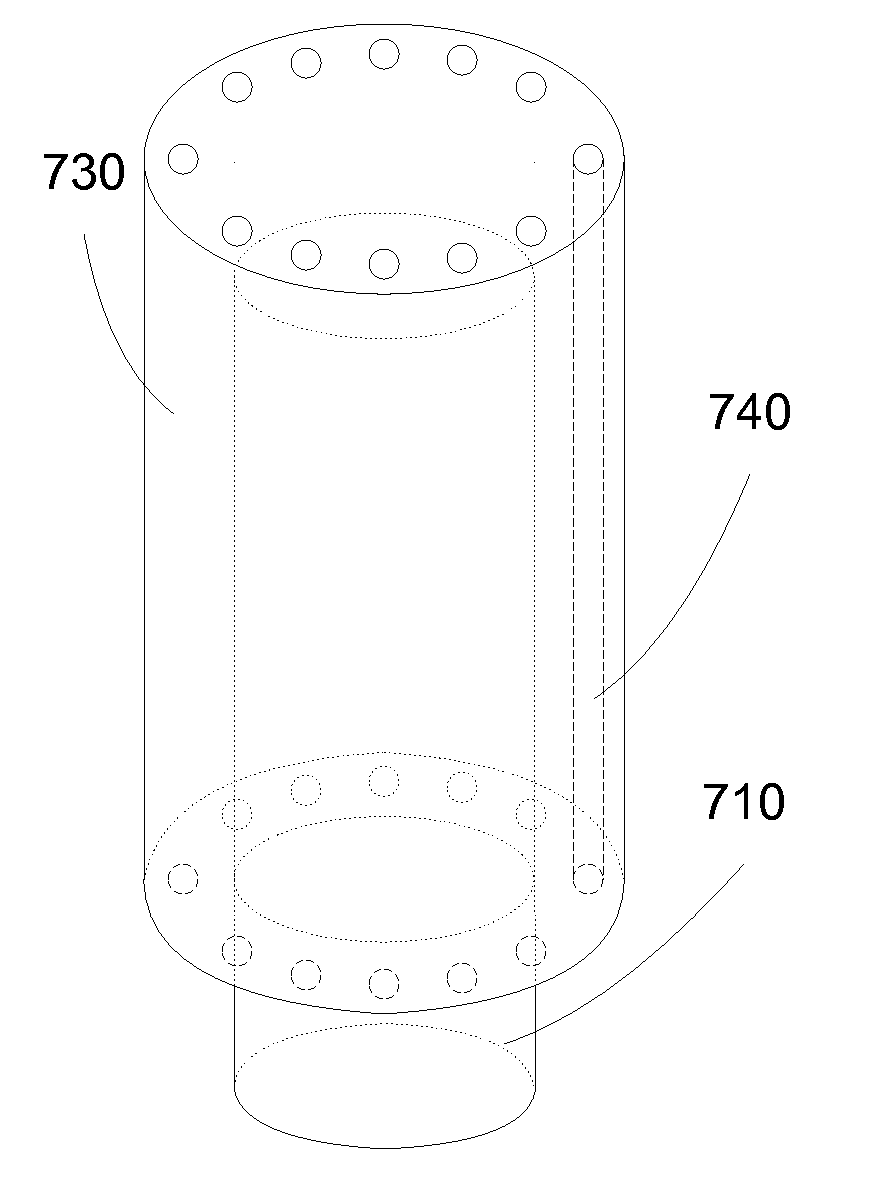

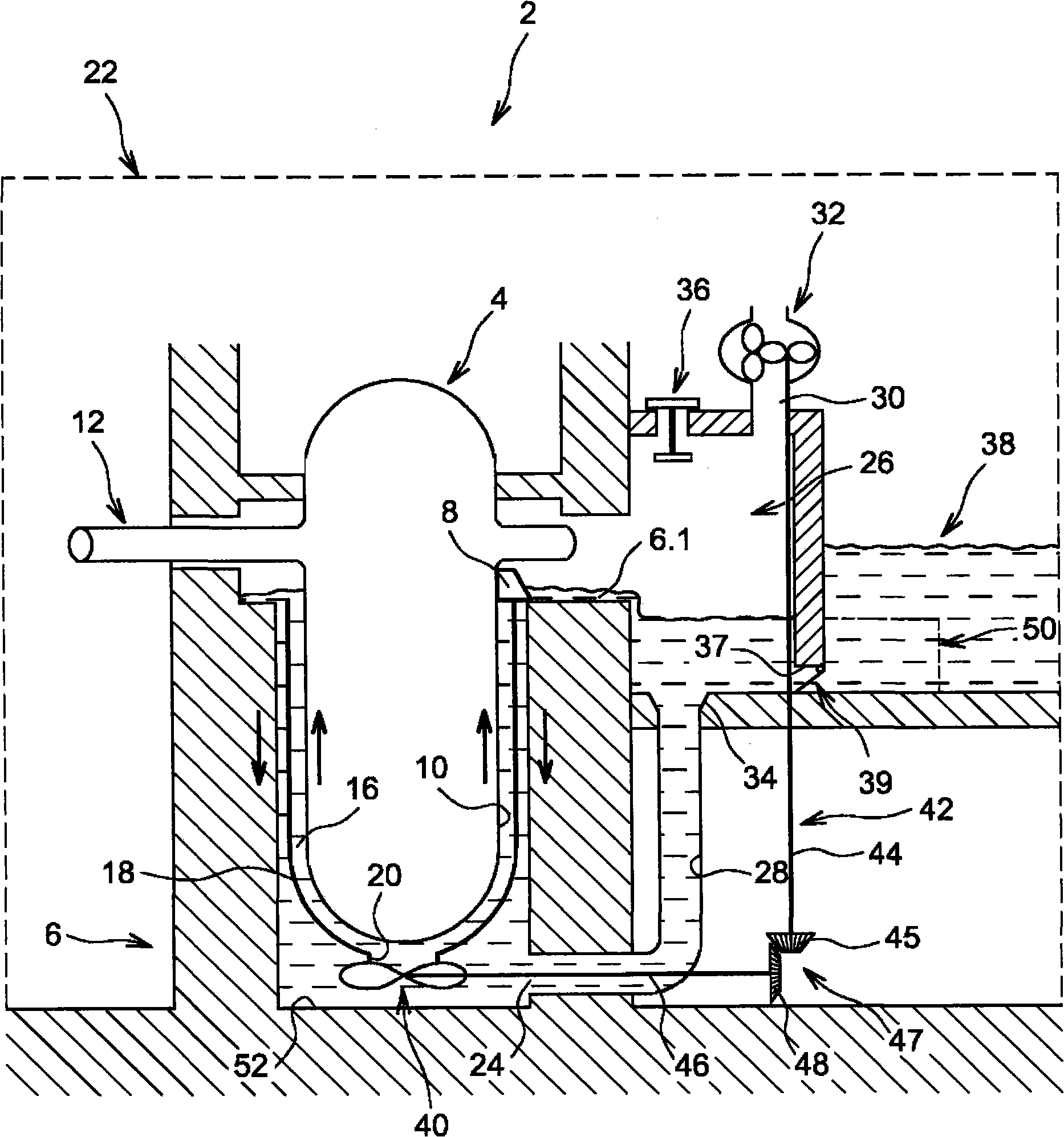

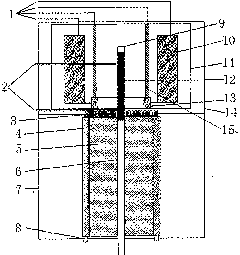

Nuclear reactor with improved cooling in an accident situation

InactiveCN101836262ARobustGuaranteed uptimeNuclear energy generationNuclear engineering problemsNuclear reactorForce convection

Nuclear reactor comprising: a reactor vessel (4) designed to hold a reactor core; a primary system for cooling the reactor; a reactor pit (6) in which the vessel (4) is placed; an annular channel (16) surrounding a lower portion of the reactor vessel (4) in the reactor pit (6), said channel (16) being intended to act as a thermal shield in normal operation and intended for the ascending flow of a liquid in the event of an accident; a reserve of liquid capable of filling the reactor pit; a reactor containment (22, not drawn); a manifold (26) for collecting the steam generated at an upper end of the reactor pit (6), said manifold being separate from the containment (22); a circulating pump (40) capable of generating a forced convection of the liquid in the annular channel (16); and a lobe pump or steam piston machine or turbine (32) for actuating the circulating pump (40) and capable of generating forced convection by means of said collected steam.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

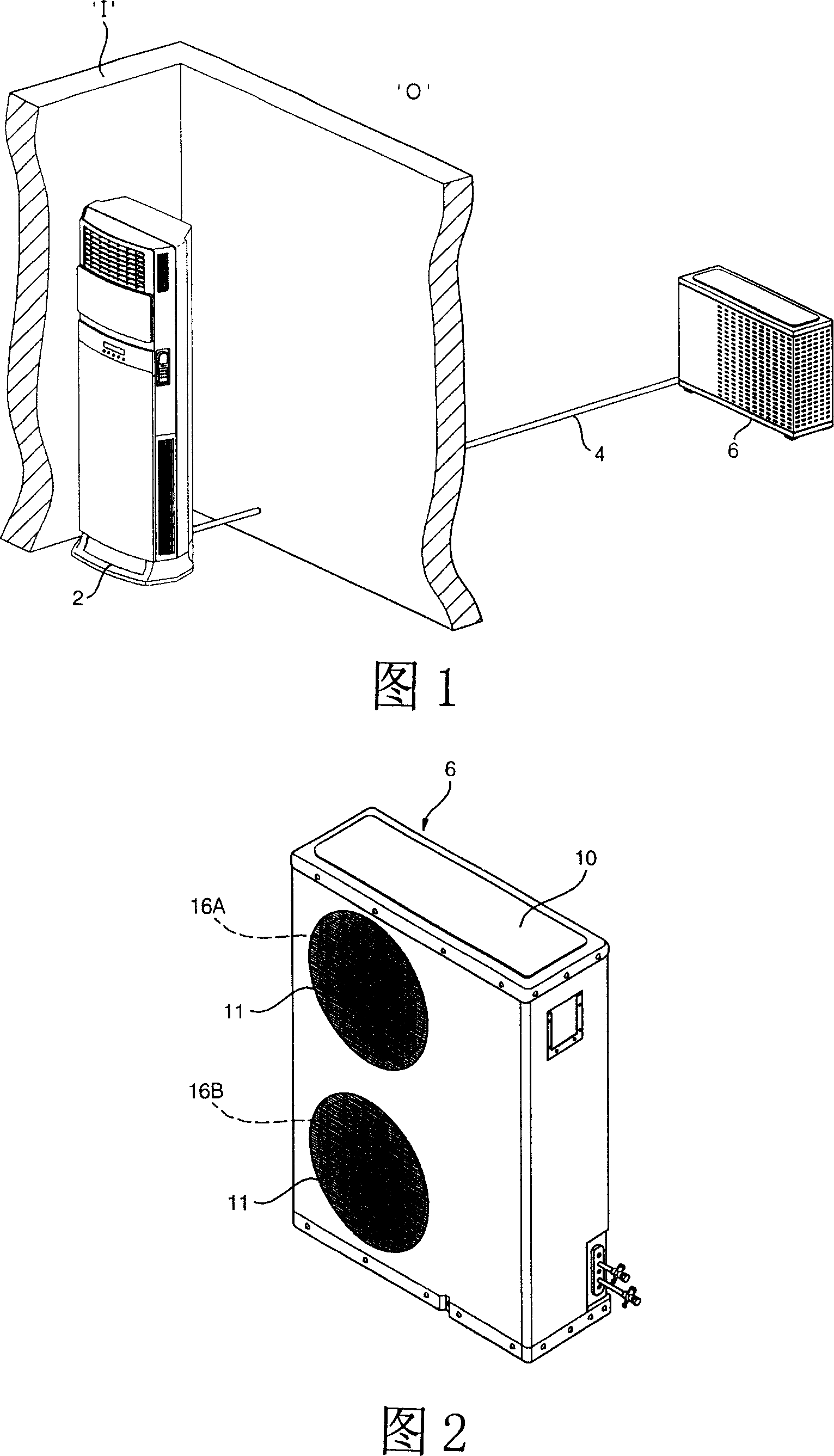

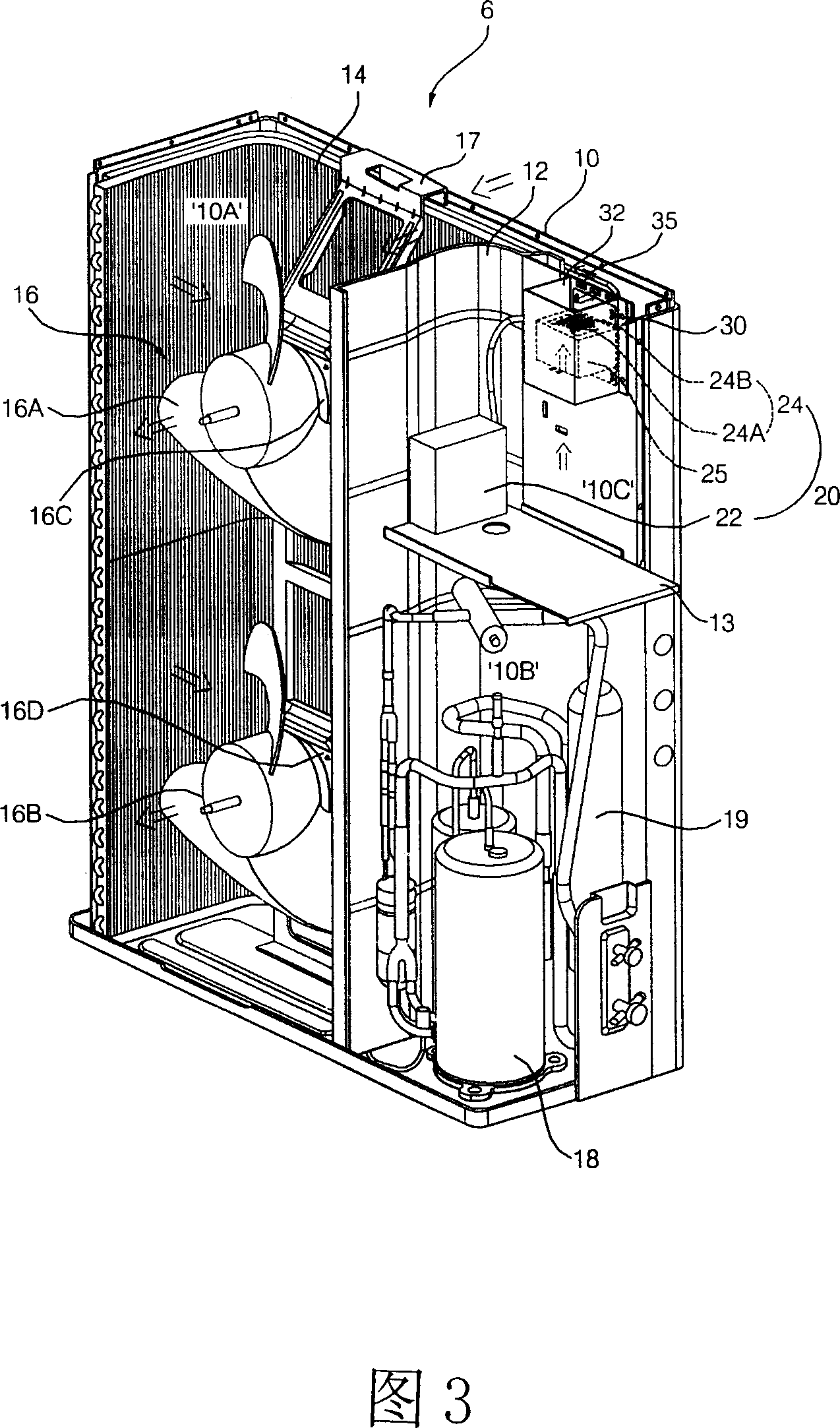

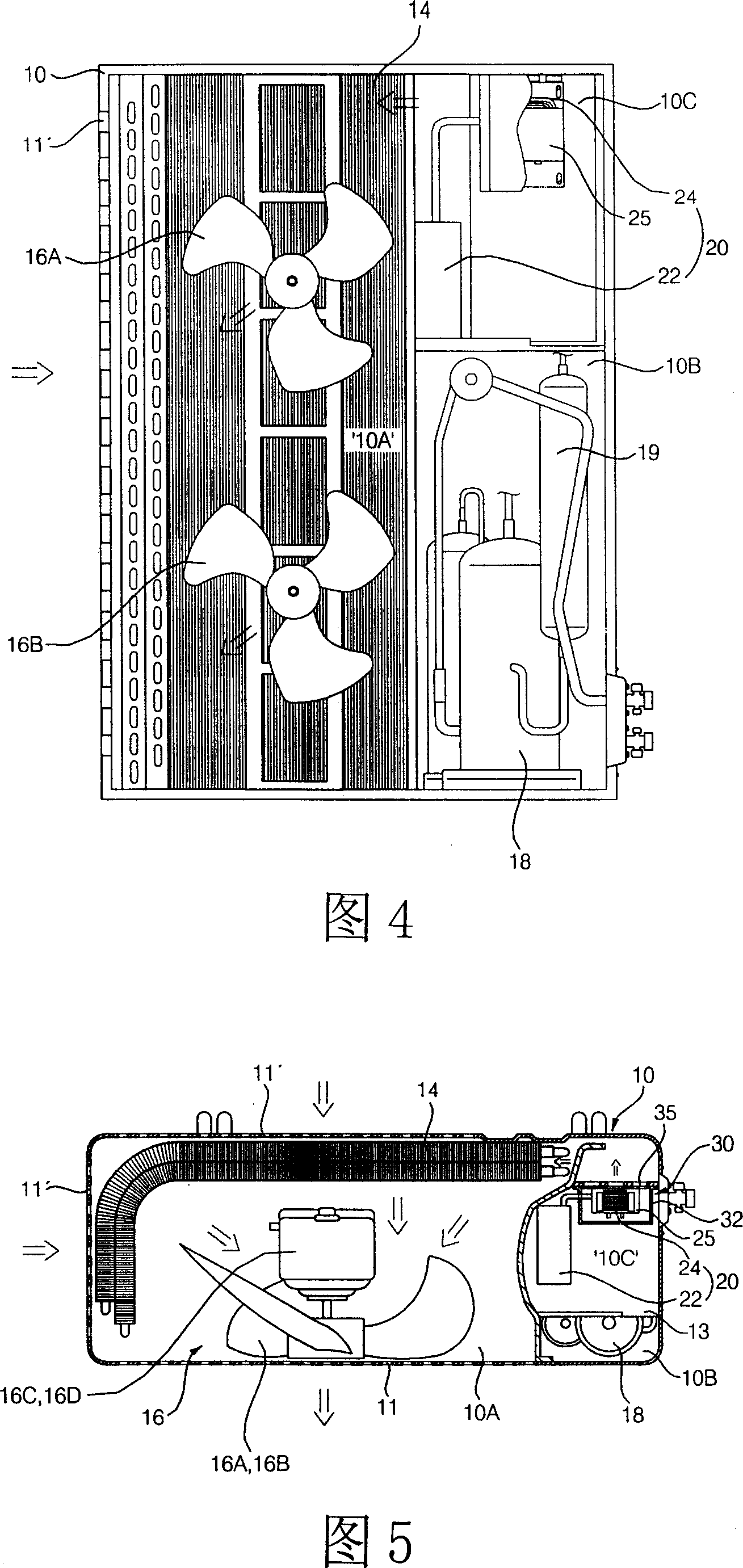

Air conditioner

InactiveCN1987264AIncrease heat releaseAvoid heat damageSpace heating and ventilation safety systemsLighting and heating apparatusForce convectionEvaporator

An air conditioner features that a heat releasing channel for its electric elements is arranged in order to use the fan to generate a forced convection for releasing heat from electric elements, or a heat exchanger for said electric elements is arranged in order to make the flowing cold medium to suck the heat from electric elements.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

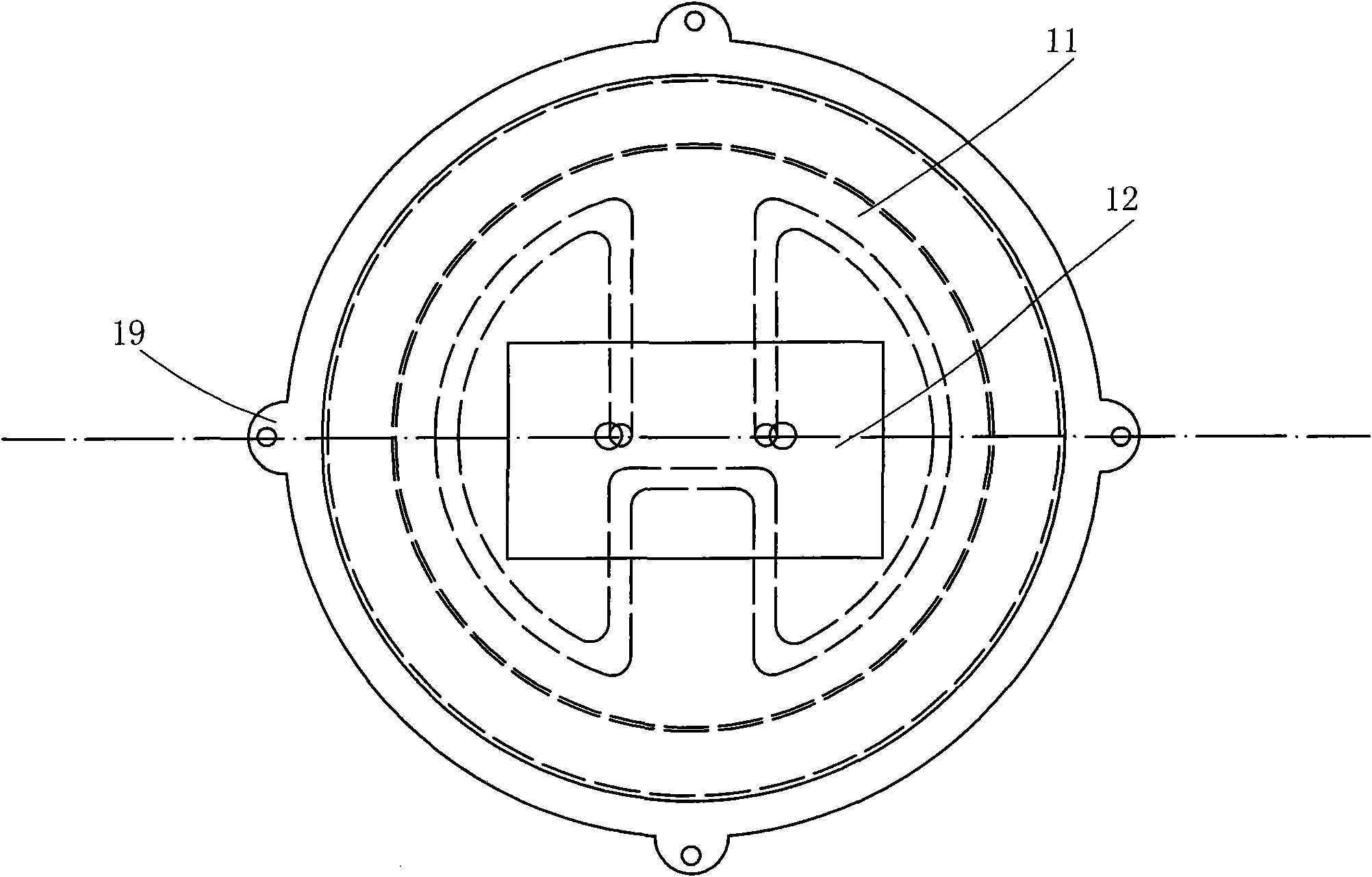

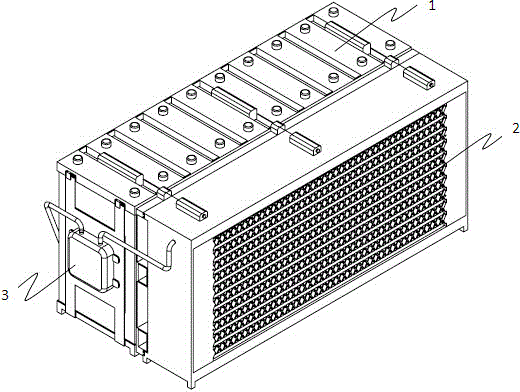

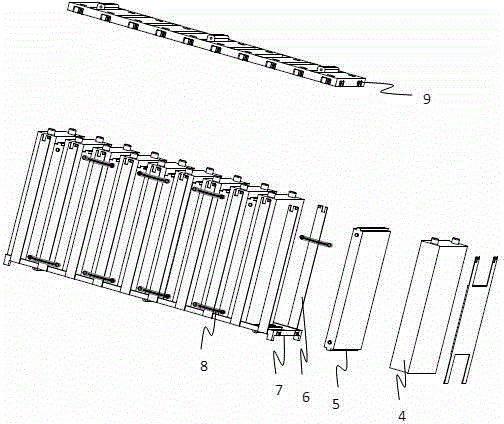

Wind-cooling and liquid-cooling integrated battery module

ActiveCN104409795AGuaranteed Temperature ConsistencyLow failure rateSecondary cellsFailure rateSelf forming

The present invention provides a wind-cooling and liquid-cooling integrated battery module, which comprises a battery pack, a heat elimination apparatus and a circulating water pump, wherein the heat elimination apparatus is arranged on one side of the battery module and is provided for heat elimination on the battery pack, and the circulating water pump is arranged on the side surface of the battery pack and is provided for forming a water circulating circuit so as to perform heat elimination. According to the wind-cooling and liquid-cooling integrated battery module of the present invention, with the liquid circulating design, the temperature uniformity of each battery in the battery module under the complex working condition can be well ensured; the X-shaped heat elimination sheets are combined to form the mesh structure, such that the heat exchange between a lot of area of air and the heat elimination sheets in the case of the air forced convection is ensured so as to take away more heat; with the integrated design, the heat elimination system is independent, each module self-forms a heat elimination system, and the modules are connected only through the power line during the battery pack application, such that the failure rate is substantially reduced; and the maintenance is further convenient, wherein the fault module can be directly replaced without change of other device in the battery pack.

Owner:HUIZHOU EPOWER ELECTRONICS

Liquid-cooled internal combustion engine with a partially integrated exhaust manifold

ActiveUS20130291811A1Short strokeMinimize thermal inertiaLiquid coolingCylinder headsCylinder headExternal combustion engine

A liquid-cooled engine and method for its operation is described wherein the engine includes a cylinder head comprising at least one coolant jacket and exhaust manifold at least partially integrated therein. In one particular example, the exhaust pipes merge in stages within the cylinder head before merging into a common exhaust gas collector outside the cylinder head. Inclusion of a coolant system according to the present disclosure allows the thermal load of the cylinder head to be controlled, which thereby allows cooling to be achieved in a targeted manner inside the cylinder head by means of liquid cooling and forced convection.

Owner:FORD GLOBAL TECH LLC

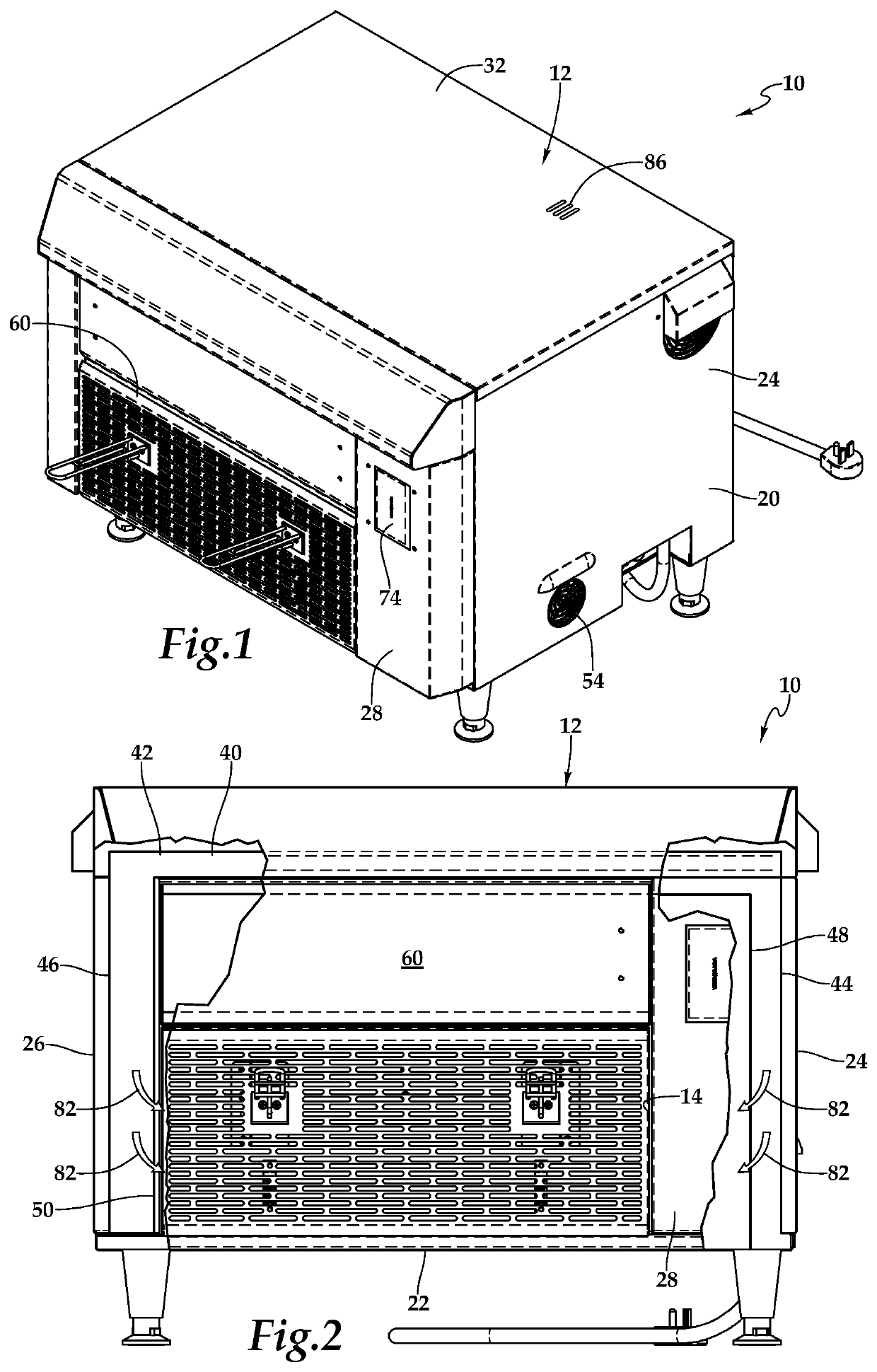

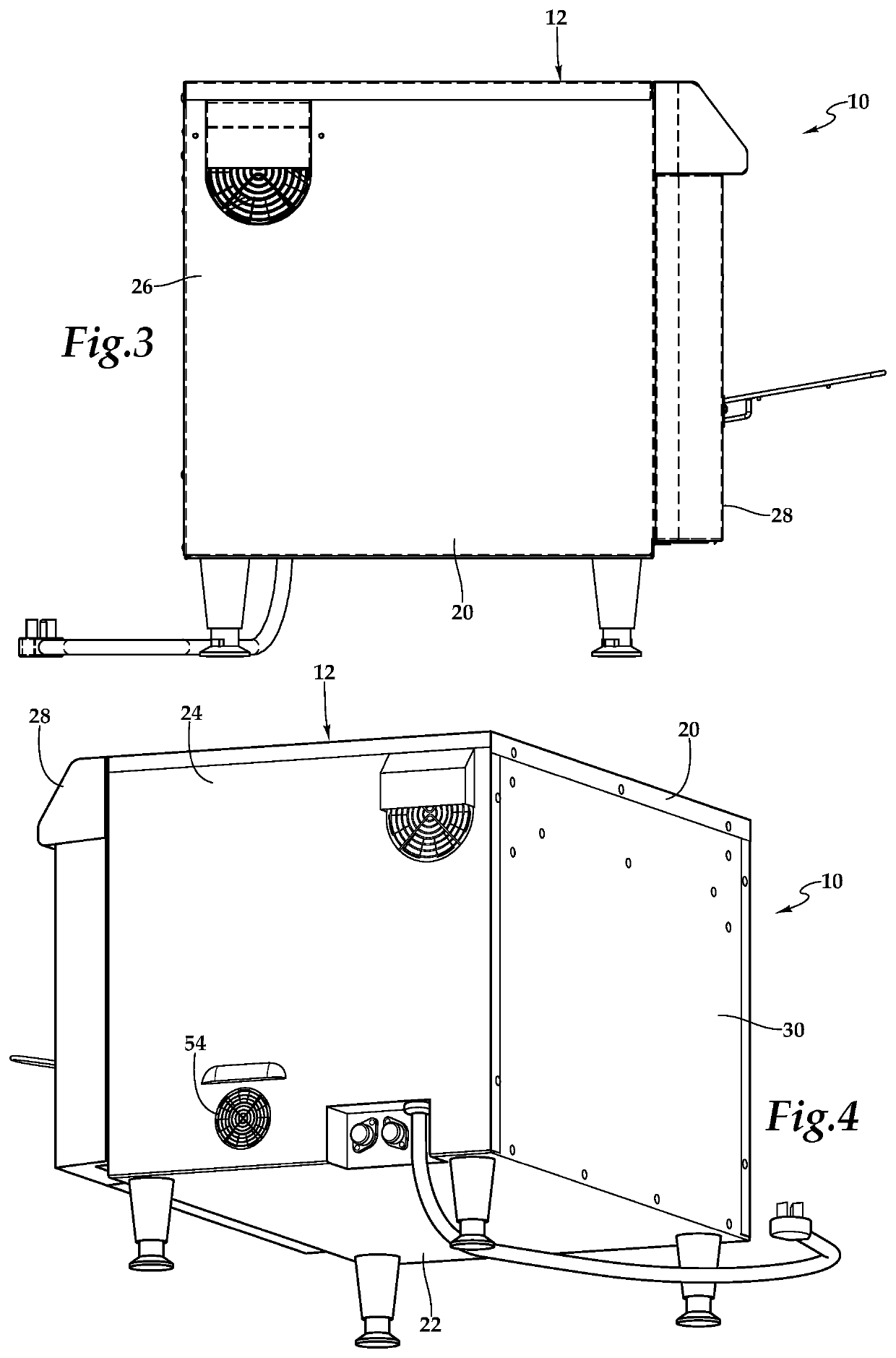

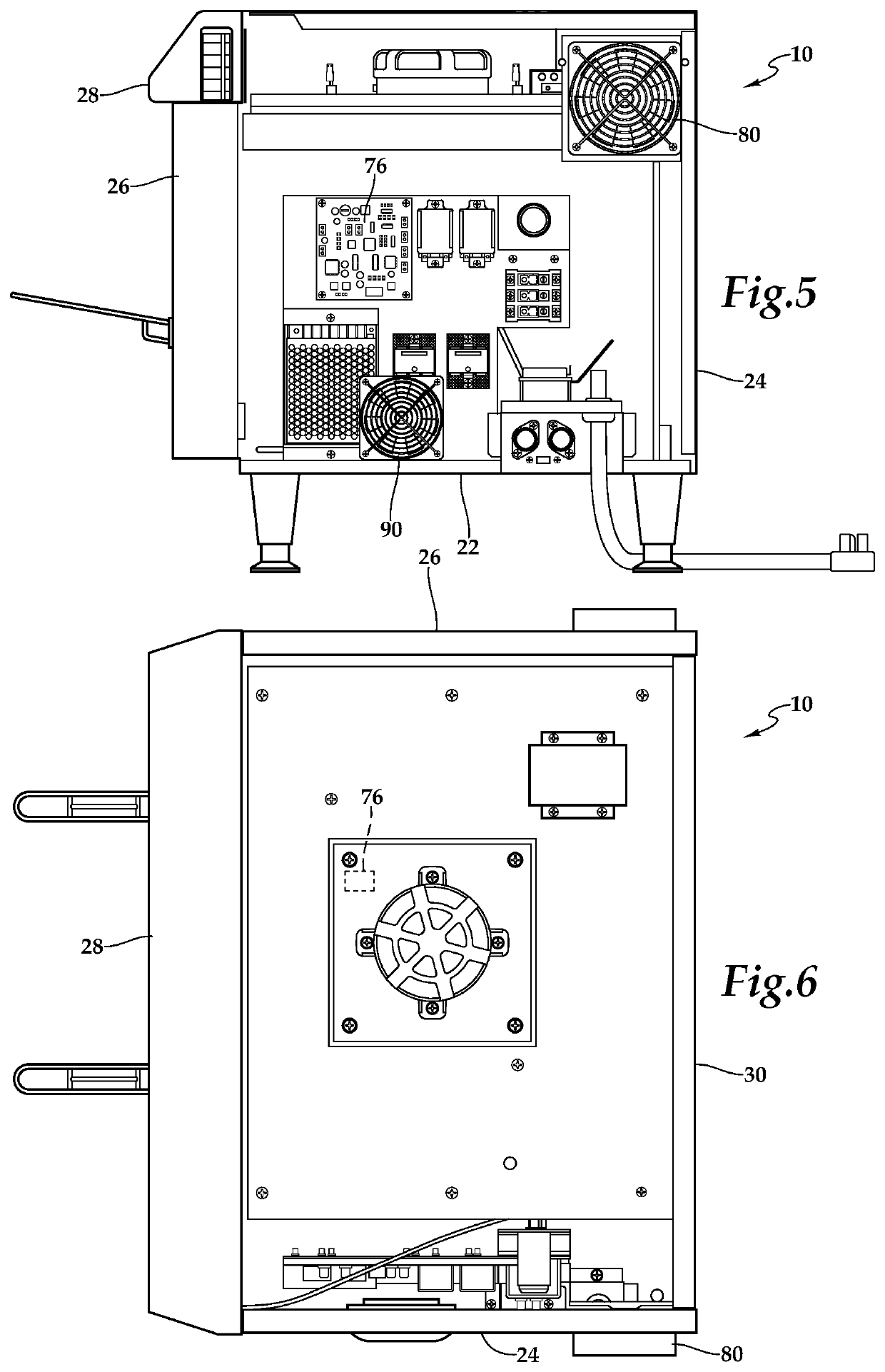

Cooking apparatus and method for use of same

ActiveUS10746412B1Improve performanceImprove usabilityDomestic stoves or rangesOven air-treatment devicesForce convectionProcess engineering

A cooking apparatus and method for use of the same are disclosed that utilize forced convection and radiant heating cooking. In one embodiment, the cooking apparatus includes an oven housing defining a cooking chamber, a circulation chamber, and a catalyst chamber. The catalyst chamber is superposed to the circulation chamber and the circulation chamber is superposed to the cooking chamber. Heating elements are located in the cooking chamber and the circulation chamber. An airflow circulation loop is located between the cooking chamber and the circulation chamber. An exhaust airflow path is provided from the circulation chamber to the catalyst chamber to an exterior of the oven housing. A fan subassembly is located within the oven housing and the fan subassembly circulates convection air along the airflow circulation loop with a portion of the convection air being diverted into the exhaust airflow path.

Owner:HIX CORP

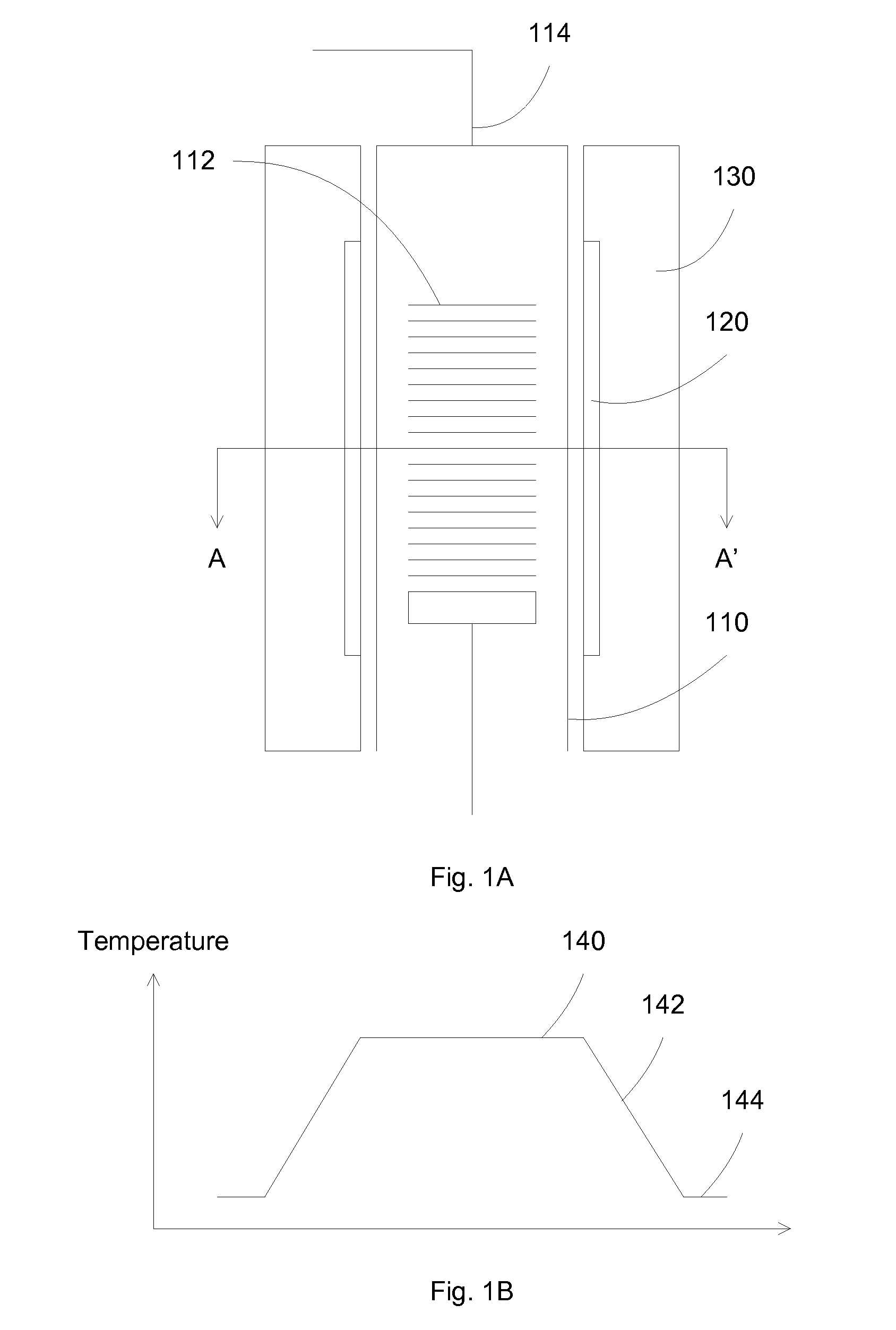

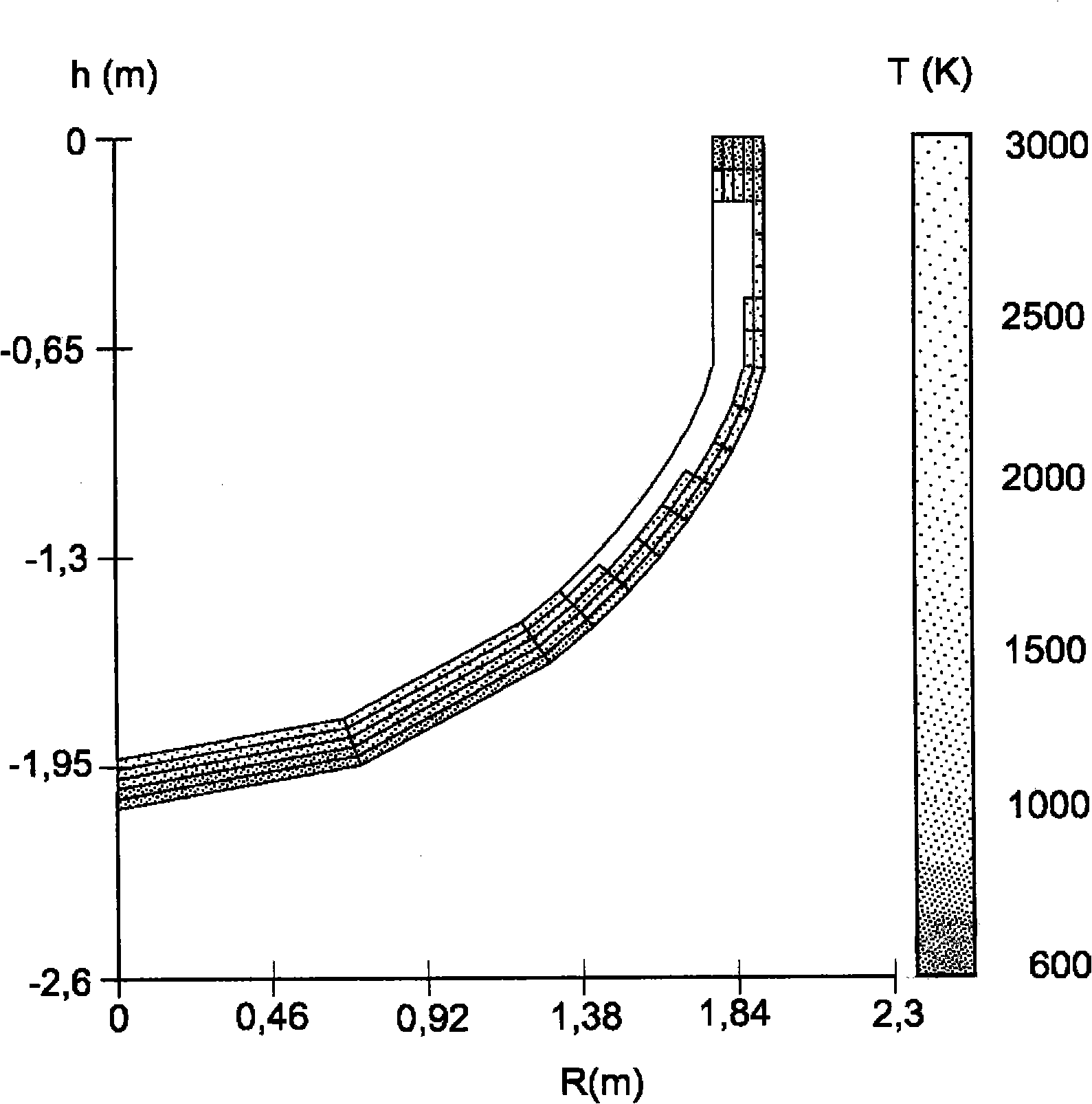

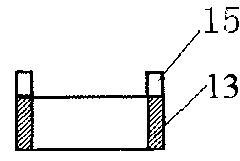

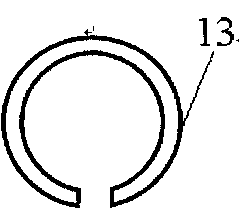

Device for directionally solidifying by locally and forcibly heating with resistance at high gradient

The invention relates to a device for directionally solidifying by locally and forcibly heating with resistance at high gradient, comprising an upper oven and a lower oven. A crucible, a resistance ring, a tungsten cylinder and a shielding layer are arranged in sequence from the center of the upper oven to the outside of the upper oven, and the crucible, the resistance ring and the tungsten cylinder are arranged in the shielding layer; power leads are respectively connected to the upper surfaces of both the tungsten cylinder and the resistance ring; the power lead of the tungsten cylinder and the power lead of the resistance wire are respectively and independently connected with a power supply and are used for wholly heating the sample in the crucible through the tungsten cylinder and partially and forcibly heating the sample in the crucible through the resistance ring which is arranged on the lower part of the crucible; and two thermocouples are respectively on the upper part and the lower part of the tungsten cylinder and are respectively used for measuring the temperature of the tungsten cylinder and the resistance ring. The device can wholly heat the sample and locally and forcibly heat the sample to ensure that the sample obtains the high-temperature gradient and can be fully melted on the front edge of the solid / liquid interface and can reduce the burning loss of the low melting point elements. In addition, the device can be used for more materials of different size and can eliminate the forced convection of the melt, which is caused by the traditional induction heating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

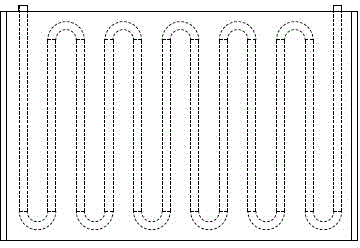

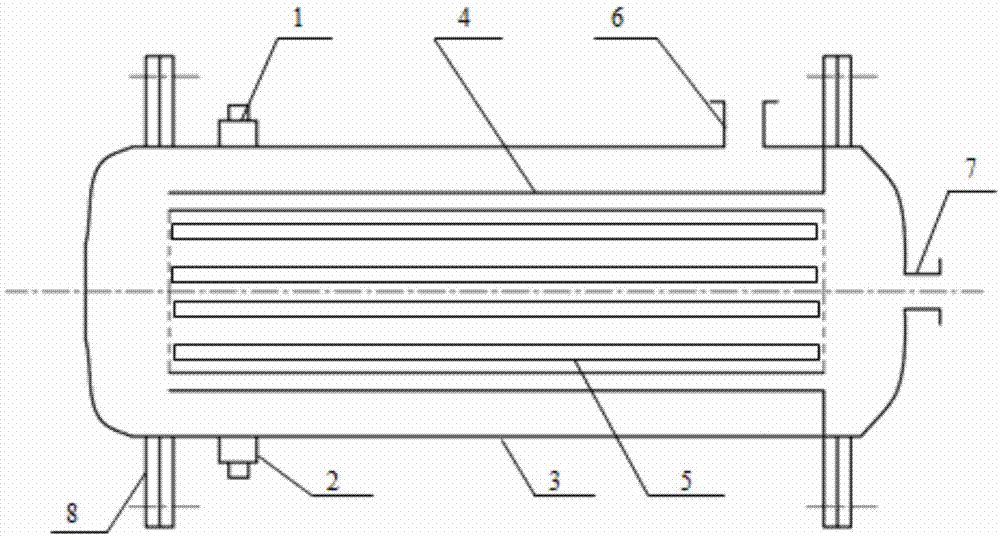

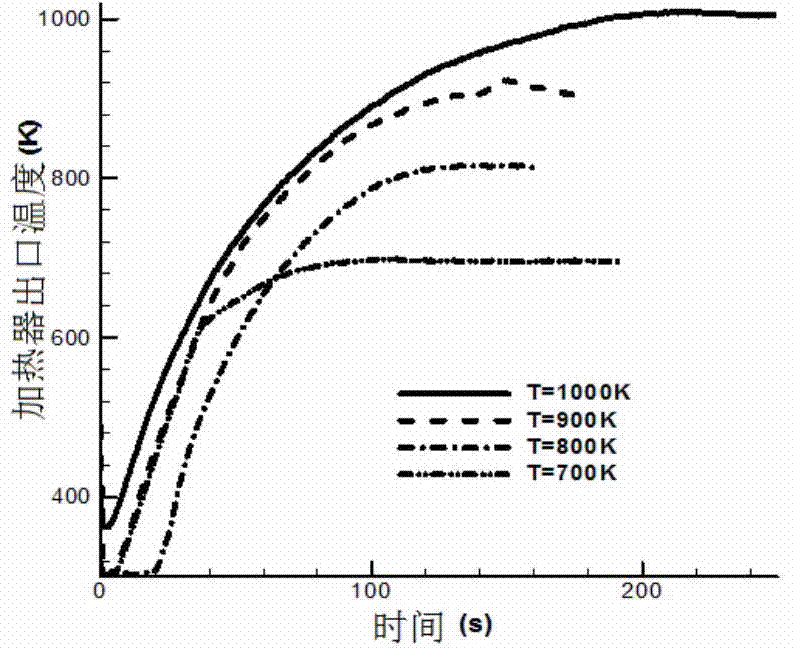

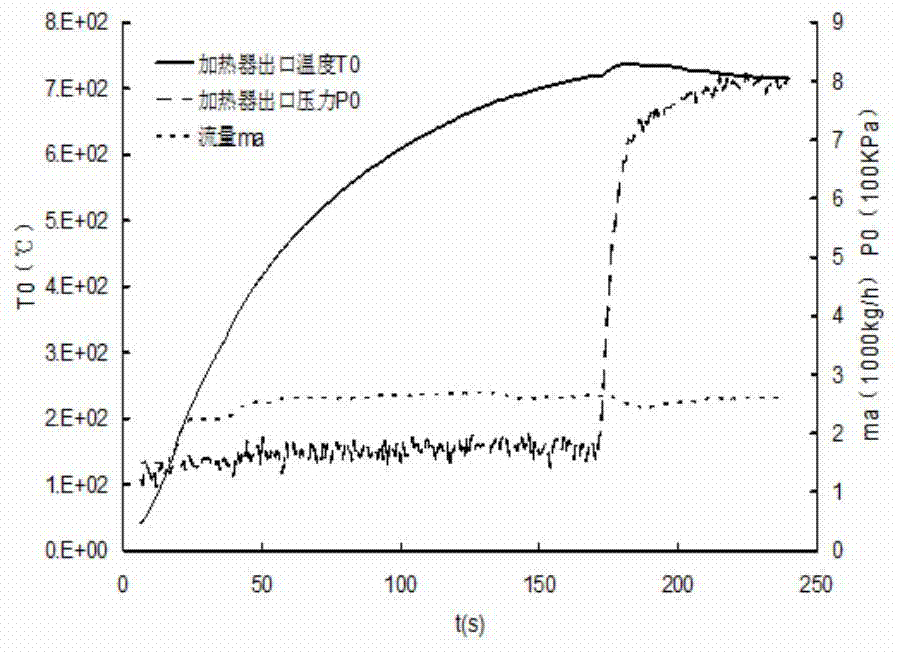

Resistive heater used for engine combustion chamber experiment system

InactiveCN104748371ASimple structureExtend stable running timeAir heatersCombustion chamberEngineering

The invention discloses a resistive heater used for an engine combustion chamber experiment system. The resistive heater is used for simulating the high temperature, high pressure and high Mach number in supersonic speed and hypersonic speed flying states and the oxygen component in gas and performing experiment research, free of pollution to experiment working media, on hypersonic speed combustion chamber performance so that related problems caused by incoming flow pollution can be evaluated. According to the resistive heater, thin-wall tube heating bodies serving as heating elements are made of high-temperature-resistive alloy steel, an inner barrel and the thin-wall tube heating bodies are fixed inside a heater shell, and the thin-wall tube heating bodies, the inner barrel and the heater shell together form a heating gas duct. When voltage of 380 V is loaded on the thin-wall tube heating bodies, the thin-wall tube heating bodies emit heat, cold air which is heated flows inside and outside through thin-wall tubes for forced-convection heat exchanging, and the outlet temperature can reach 1000 K. The experiment can be performed inside supersonic speed and hypersonic speed air tunnels very close to actual flying conditions. The resistive heater is simple in structure, long in stable operation time and low in operation cost and works continuously.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fuel strut injector

InactiveCN106247407AImprove thermal protection performanceSimple structureContinuous combustion chamberForce convectionEngineering

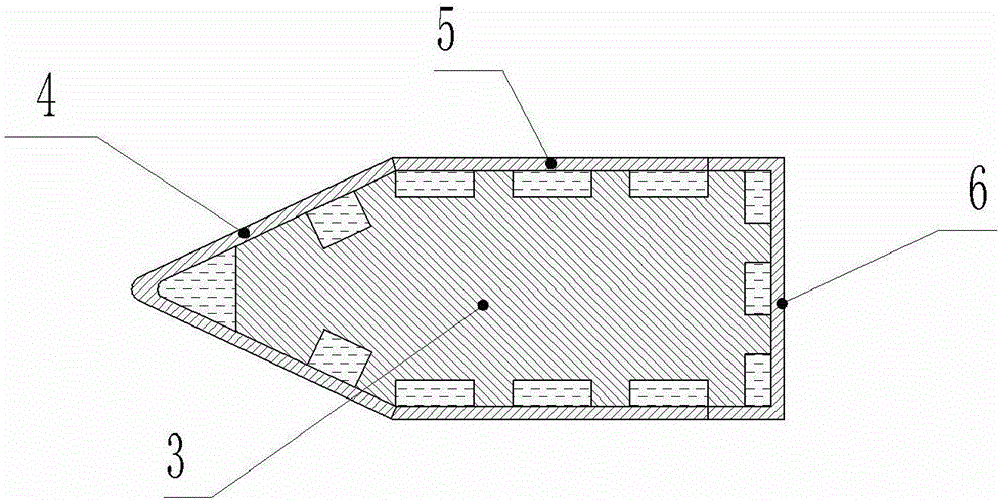

The invention discloses a fuel strut injector. Fuel of a scramjet engine and a combined circulatory power engine is adopted as a cooling agent, the cooling agent flows in a cooling channel for cooling a strut and is sprayed into a combustion chamber for being subjected to mixing combustion together with fuel gas, and therefore long-time normal work of the strut can be realized. The front edge of the strut is of a rounding wedge-shaped structure, and a flowing channel is located on the inner side of the front edge of the strut; a plurality of channel inlets are formed in each of the inner side of a front part of the strut and the inner side of a rear wall of the strut, a plurality of fuel spraying holes are formed in each of side wall surfaces of the strut, a liquid collection cavity is formed in the bottom of the strut and communicates with the flowing channel and the cooling channel, and the cooling agent enters the channel inlets, flows to the bottom of the strut along the channel, is gathered in the liquid collection cavity and finally is sprayed out of the strut through the fuel spraying holes; and the cooling agent absorbs heat in the channel in a flowing heat exchange mode of forced convection before being sprayed into the combustion chamber, and therefore the temperature of the strut can be lowered, and the fuel can be preheated. The strut injector is simple in structure, the thermal protection effect on the strut is good, and the strut can realize the function of injecting the fuel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

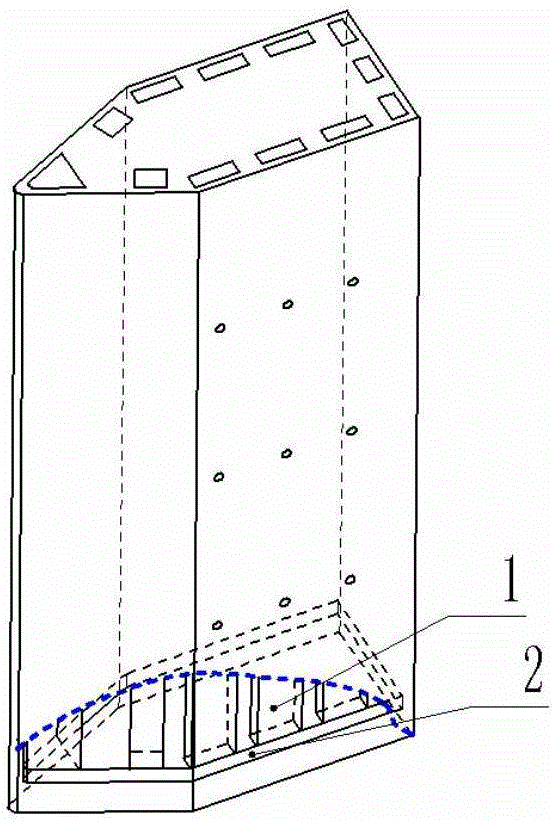

Energization wire combustion experiment device capable of automatically igniting and collecting smoke and method

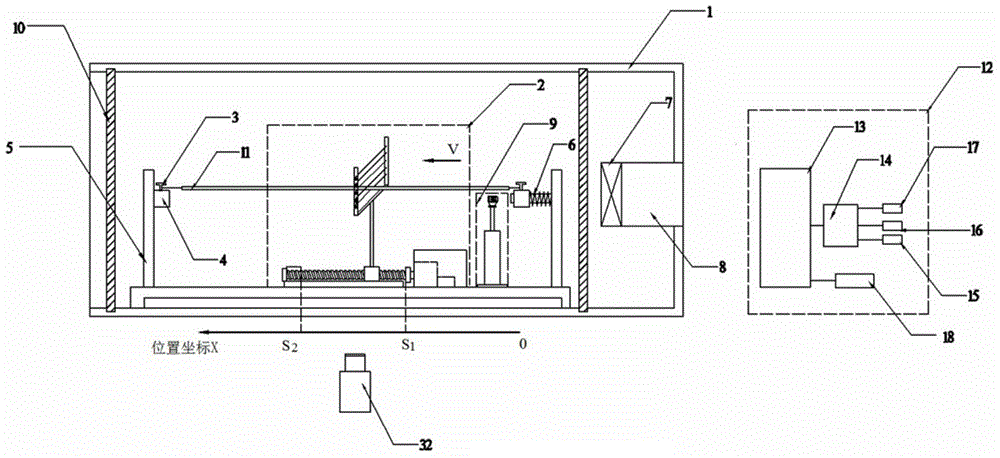

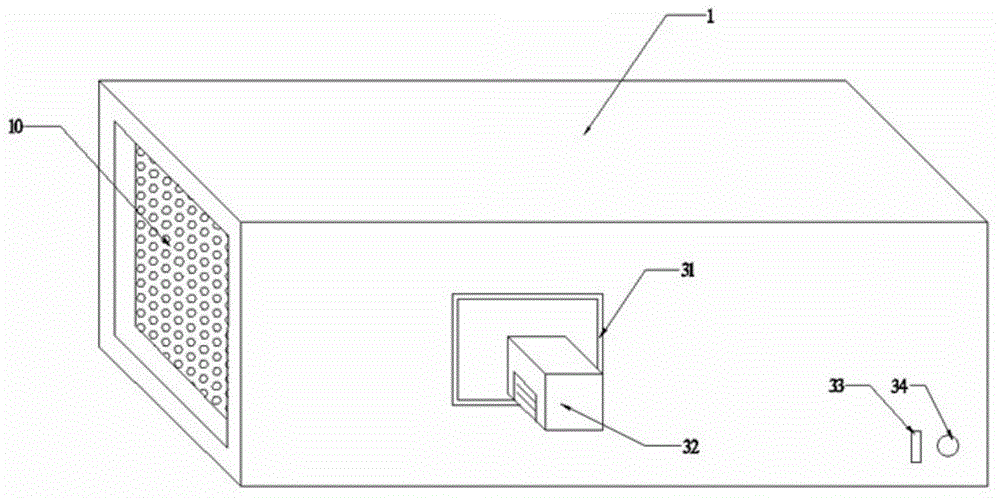

ActiveCN105004580ATimely detectionTimely preventionChemical analysis using combustionWithdrawing sample devicesCombustion chamberForce convection

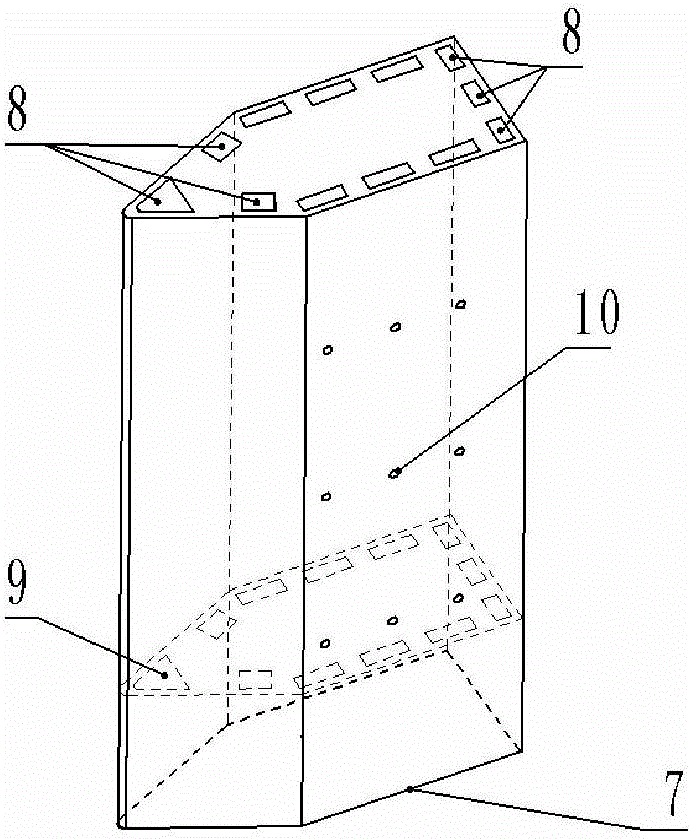

The invention discloses an energization wire combustion experiment device capable of automatically igniting and collecting smoke and a method. The device comprises two parts of a combustion chamber and a control center; a sample platform is arranged in the combustion chamber, the middle of the sample platform is provided with an automatic smoke particle collecting device, one end of the sample platform is provided with an automatic igniting device, a sample wire is fixed on the sample platform, and a control circuit of the sample wire is connected with a relay; the two ends of the combustion chamber are provided with forced convection generation devices, the combustion chamber is a cuboid, an opening is formed in the left end of the combustion chamber, a circular air inlet is formed in the right wall face, a draught fan is arranged at the circular air inlet, the front wall face of the combustion chamber is provided with a rectangular observation window, a camera is fixed at the edge of the window, and the lower right corner of the front wall face of the combustion chamber is provided with a draught fan switch and an air speed adjusting knob. According to the device and the method, the shape and distribution of smoke particles at different height of dynamic flames in the fire spreading process can be obtained, and cable fires can be detected and prevented in time.

Owner:UNIV OF SCI & TECH OF CHINA

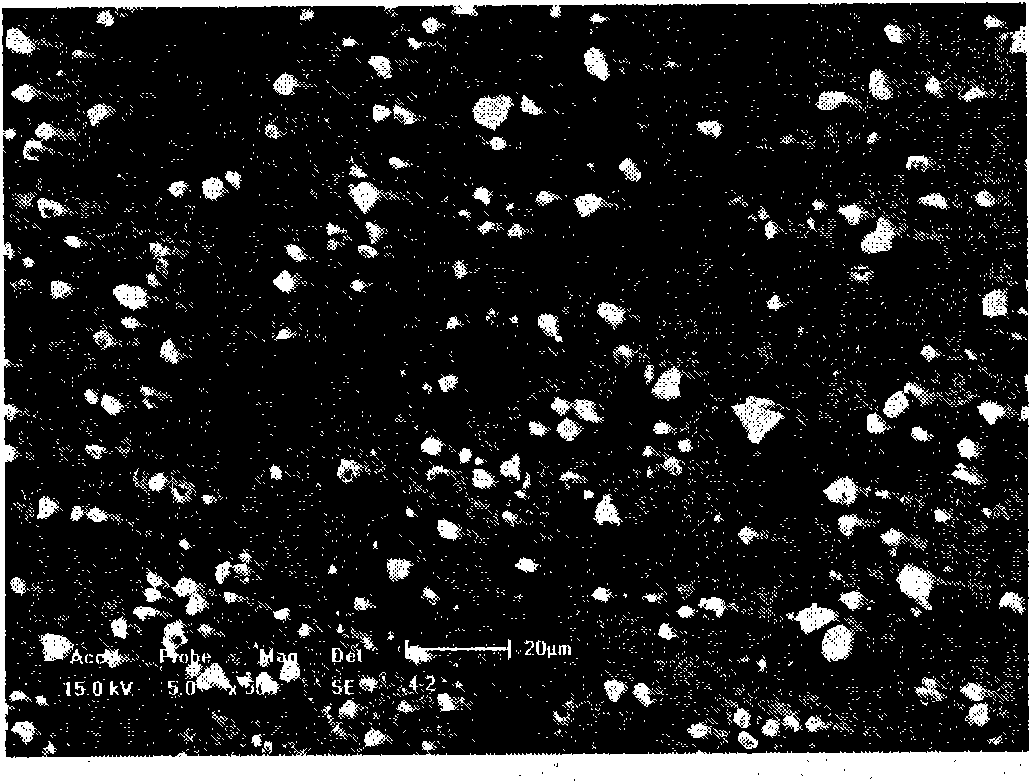

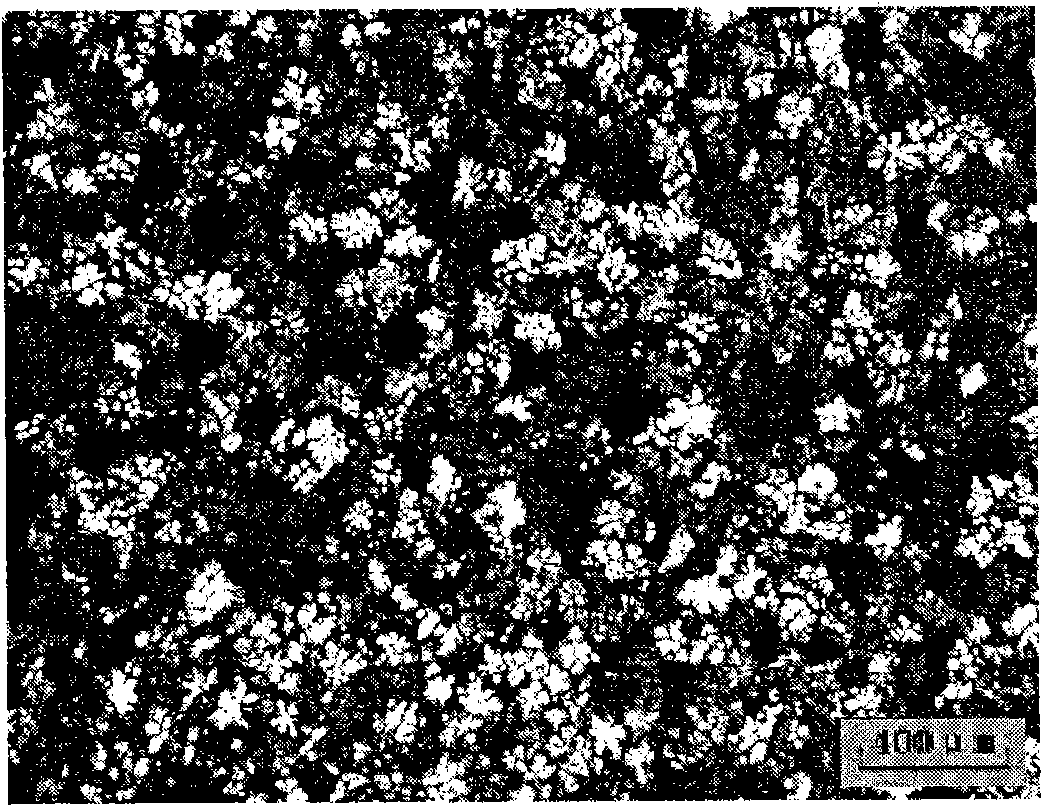

Grain refiner for magnesium alloy and preparation method thereof

The invention discloses a grain refiner for magnesium alloy and a preparation method thereof. The grain refiner comprises the components in percentage by weight: 95 to 98 percent of Al, 2 to 5 percent of C and less than or equal to 0.2 percent of impurities. The preparation method comprises the following steps of: mixing aluminum powder, carbon powder, MgCO3 powder and a magnesium alloy NO.2 solvent uniformly by using a ball mill, drying to prepare preformed powder, preheating an intermediate frequency furnace, packing the preformed powder by using an aluminum foil, placing the pack in the intermediate frequency furnace, pouring aluminum solution to cover the preformed powder, and heating the reaction materials by applying an intermediate frequency magnetic field to make the aluminum solution form stable forced convection; and after keeping the temperature, casting the reaction materials into an ingot to prepare the grain refiner for the magnesium alloy. The method has the advantages of adequate reaction, high carbon yield, enlargement of production scale and suitability for industrial production.

Owner:NORTHEASTERN UNIV

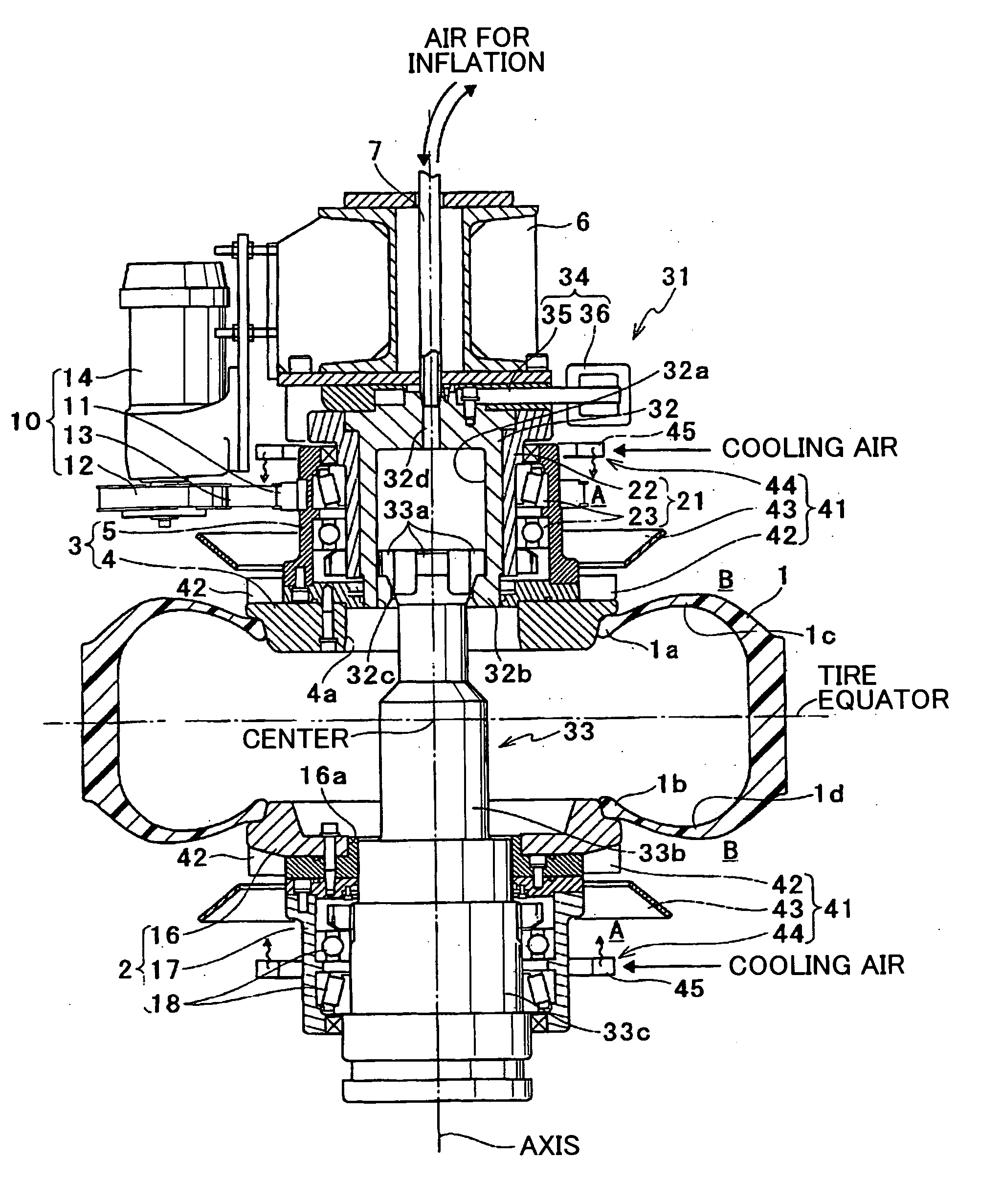

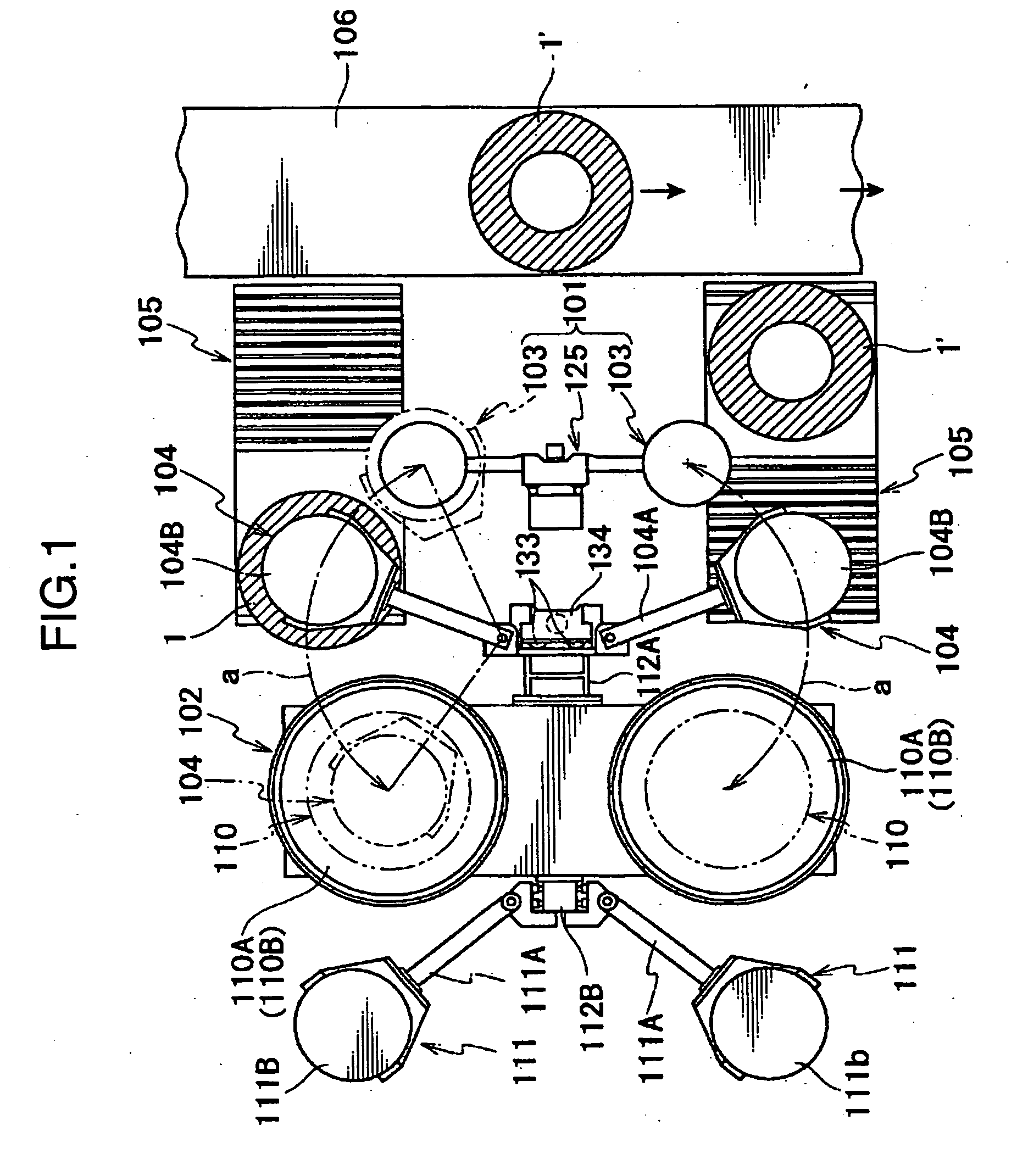

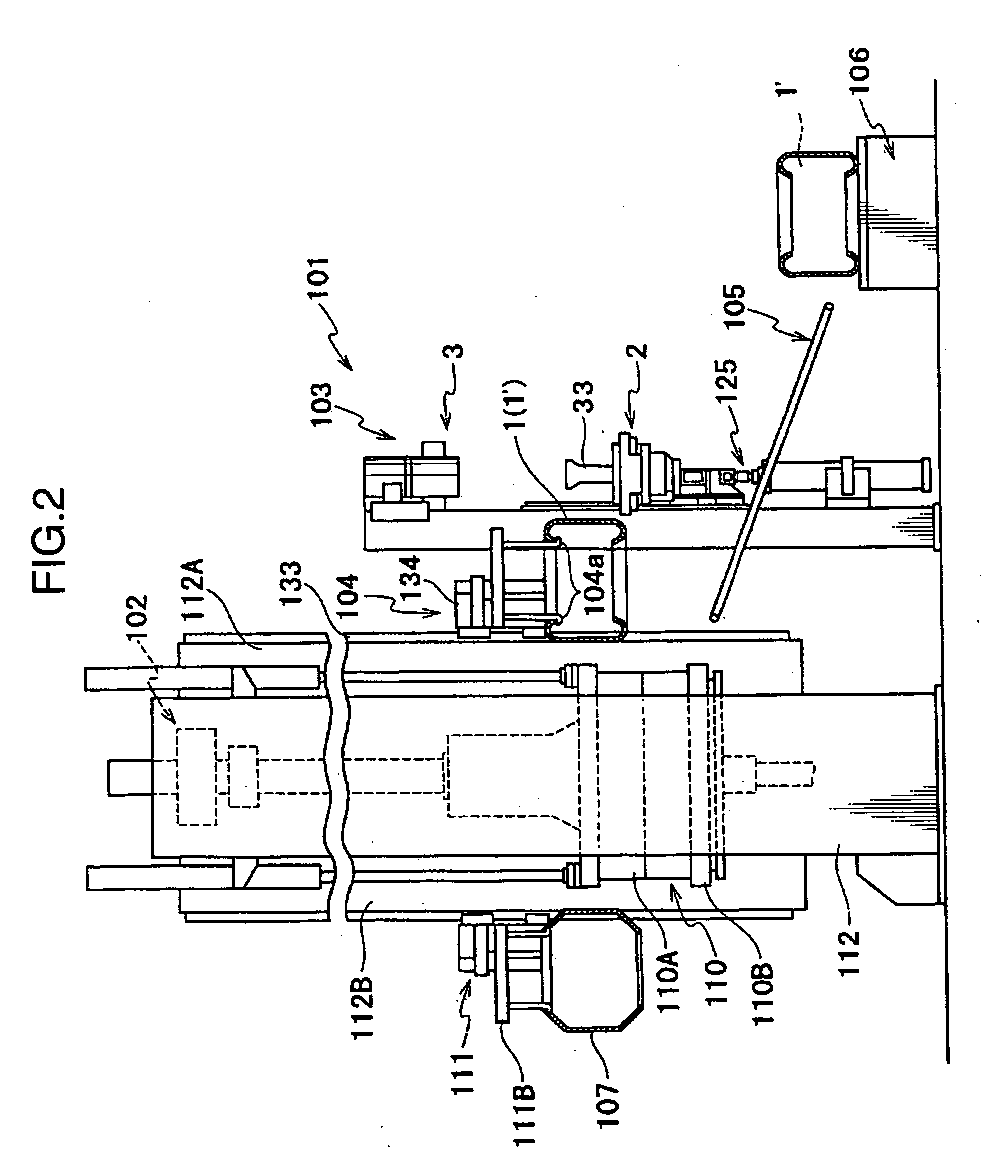

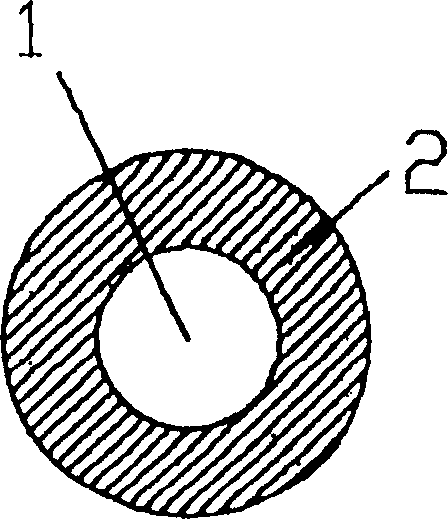

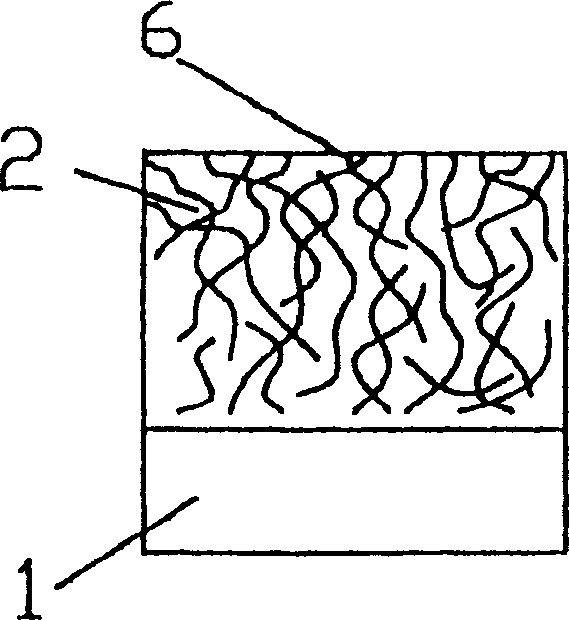

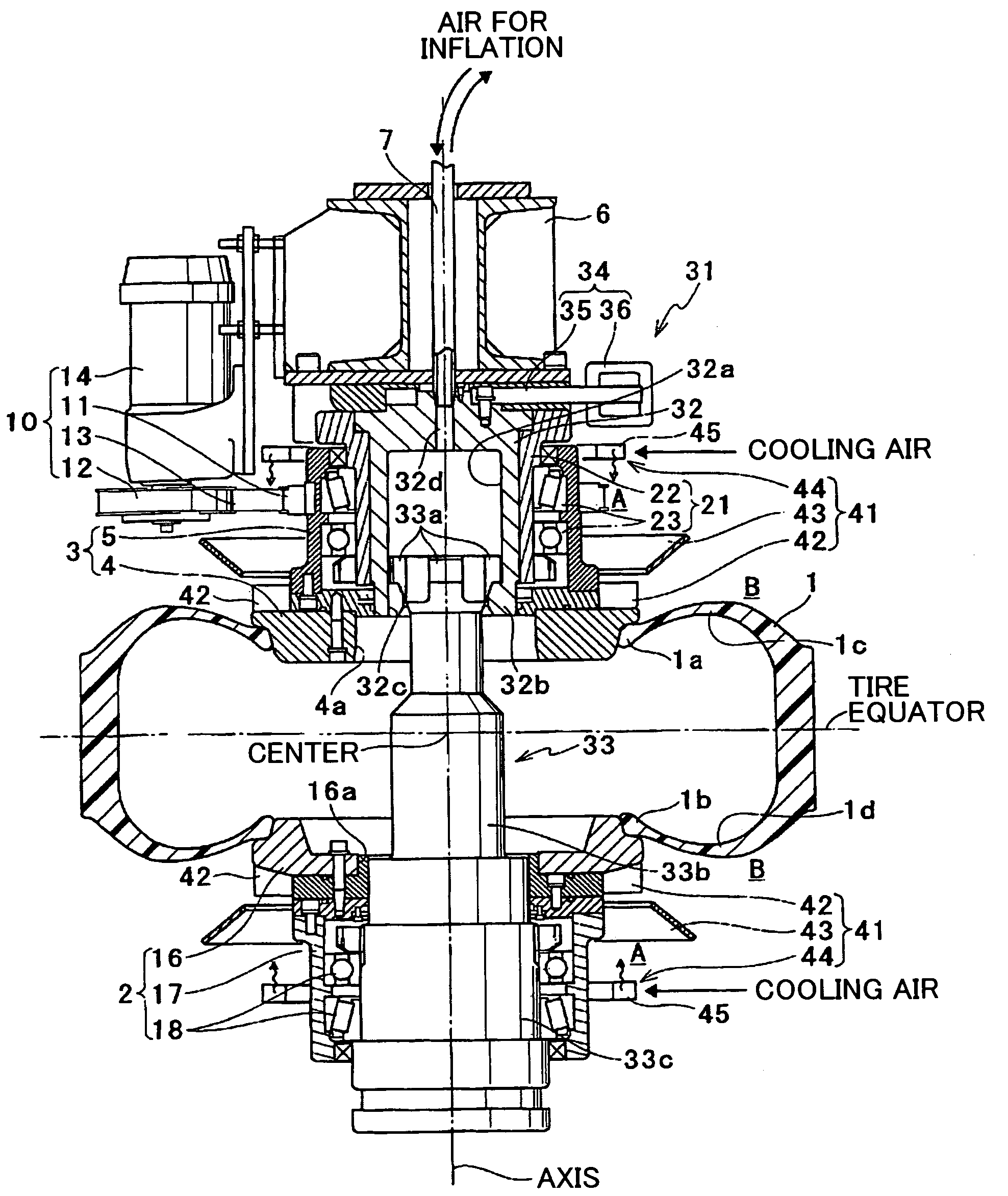

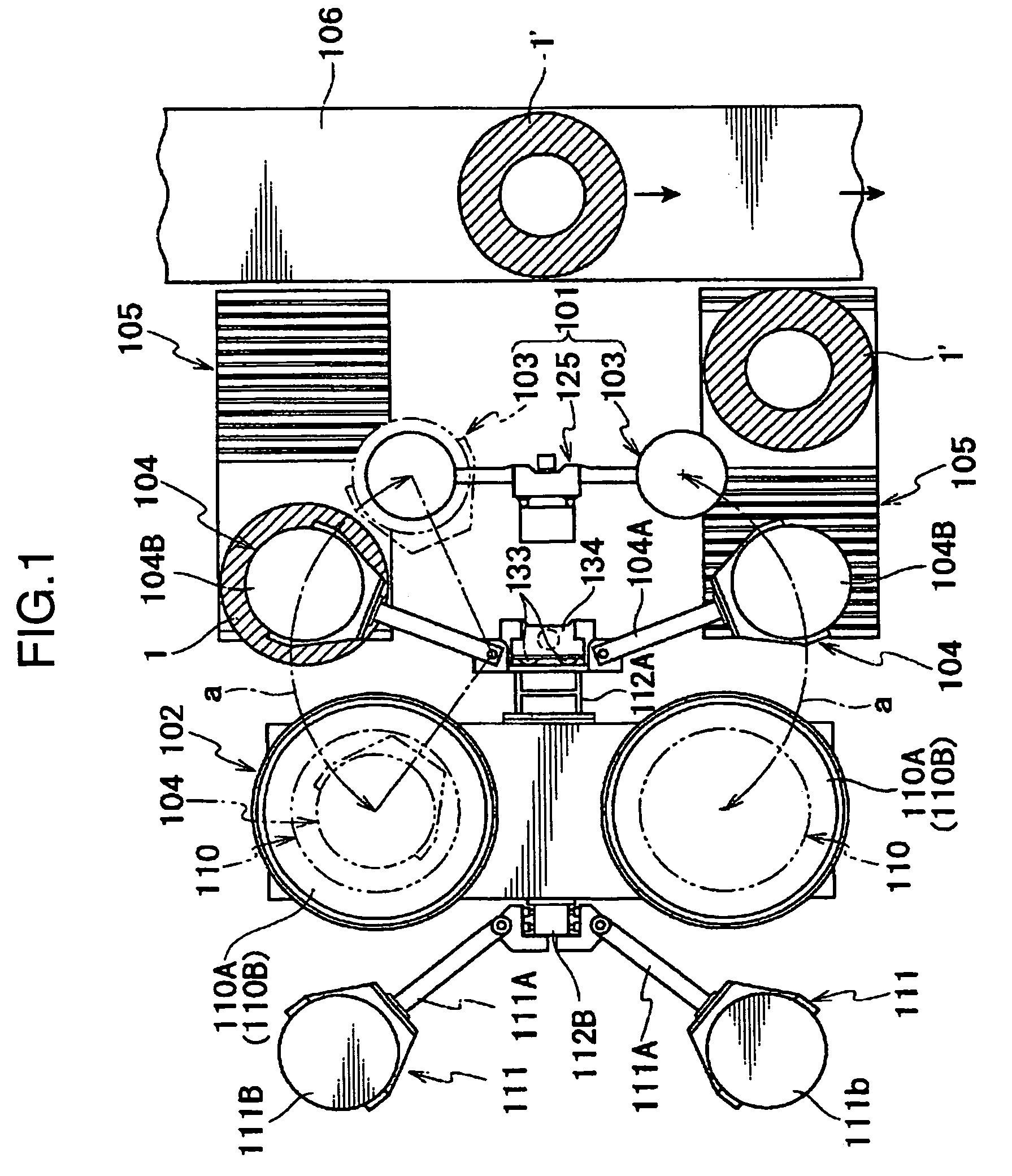

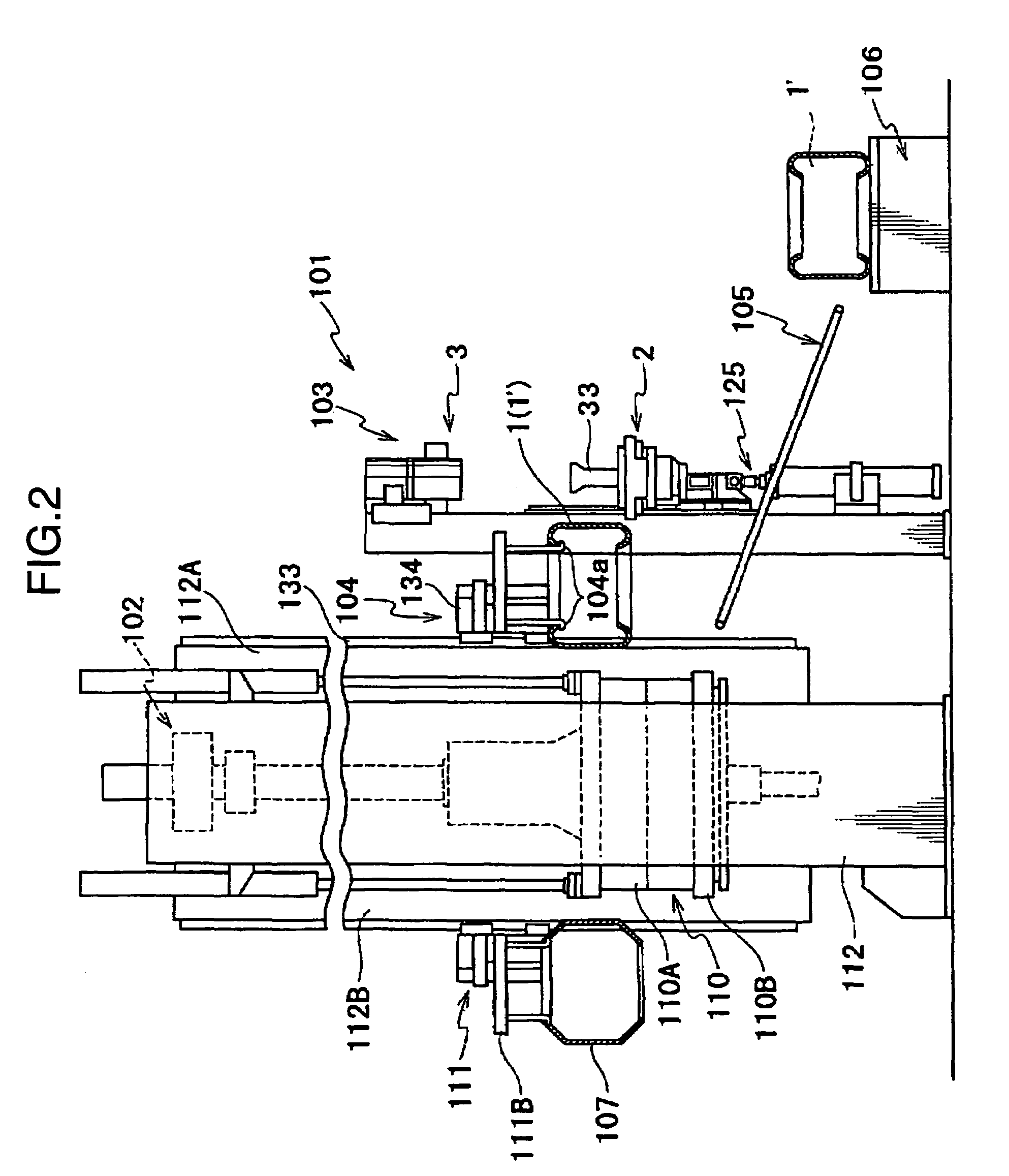

Post cure inflator and vulcanized tire cooling method

InactiveUS20060099285A1Increasing size of apparatusIncrease in part cost costTyresBeltsForce convectionEngineering

A post cure inflator for expansion-cooling a vulcanized tire is provided with a vulcanized-tire holding mechanism for holding the vulcanized tire and a rotating mechanism for rotating the vulcanized tire at a high speed via the vulcanized-tire holding mechanism such that a forced convection becomes more dominant than a natural convection in an air flow around the vulcanized tire.

Owner:KOBE STEEL LTD +1

Method for processing waste gas treating ultraviolet lamp and waste gas treating method

InactiveCN1607035AGood effectImprove cleanlinessDispersed particle separationCatalyst activation/preparationFiberDecomposition

Owner:NAT CHUNG SHAN INST SCI & TECH +1

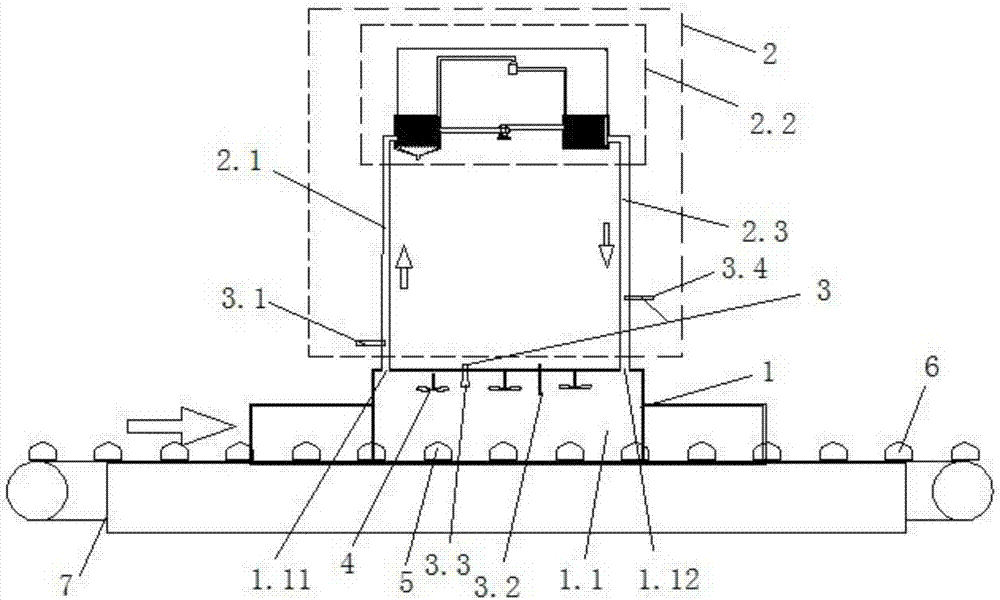

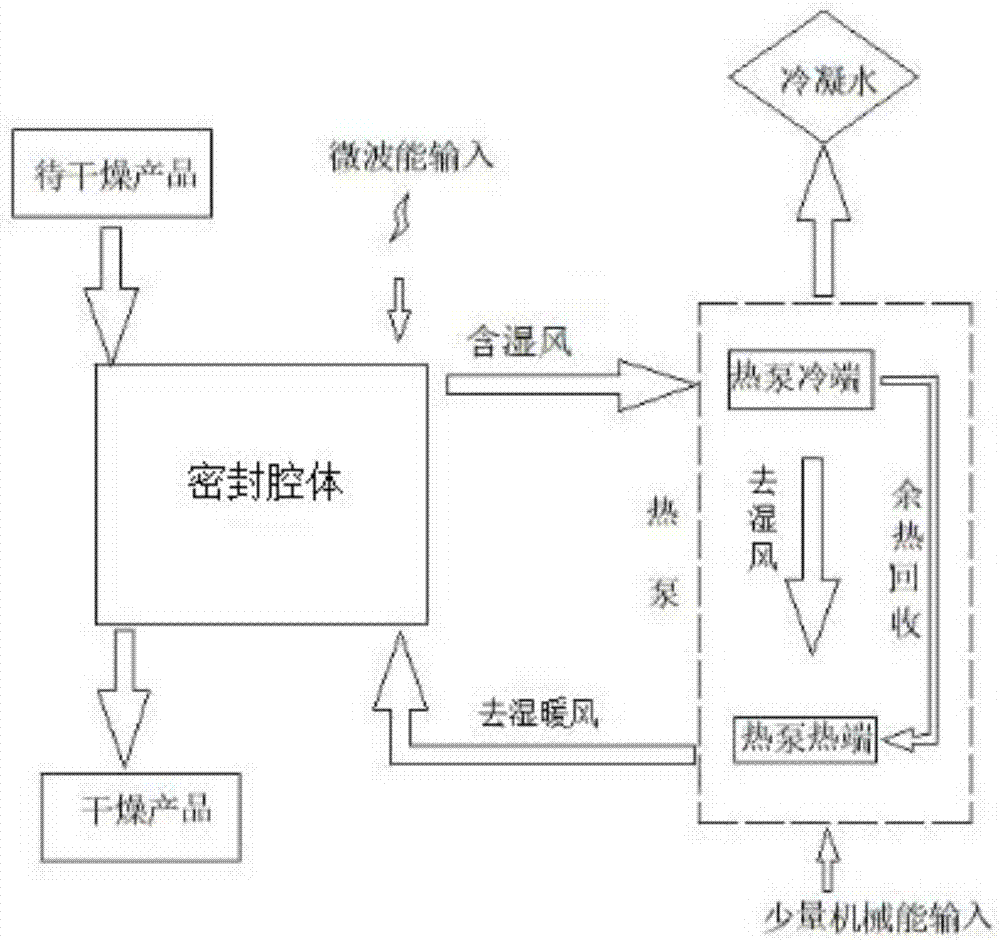

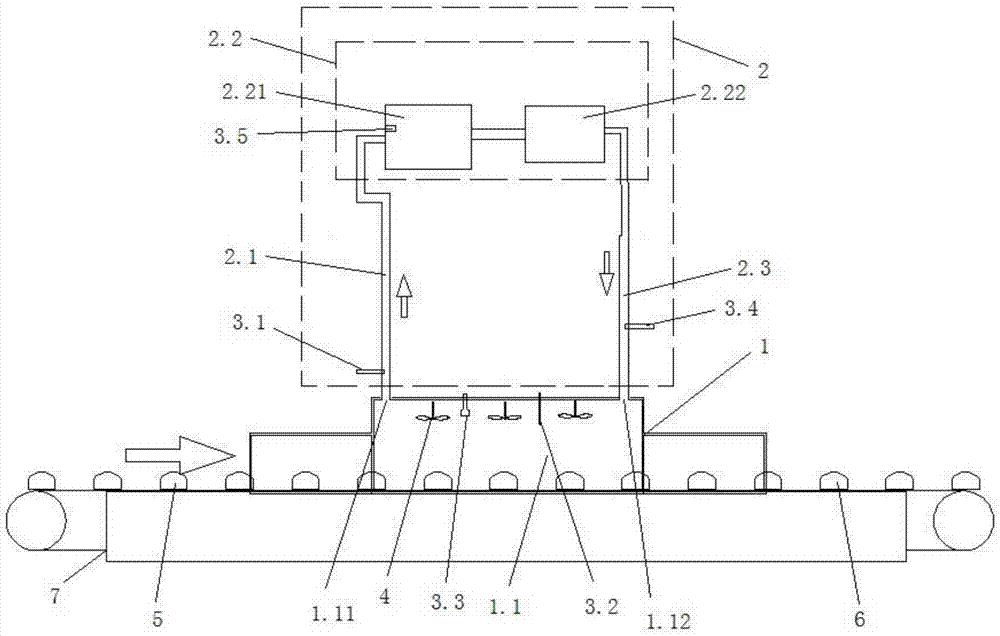

Microwave drying method and device adopted by same

PendingCN107314621ATemperature controlMaintain evaporation rateDrying solid materials with heatDrying gas arrangementsForce convectionProcess engineering

The invention provides a microwave drying method. The microwave drying method comprises the following steps: placing a product to be dried in a sealing cavity of microwave drying equipment; performing microwave drying through the microwave drying equipment emitting microwaves and meanwhile performing forced convection on a gas in the sealing cavity; and monitoring the temperature of the gas in the sealing cavity and the surface temperature of the product to be dried, and at the same time performing post-treatment on the gas in the sealing cavity and enabling the gas after post-treatment to return to the sealing cavity in a cyclic manner. According to the microwave drying method and the device adopted by the same, the temperature and humidity of the gas medium in the sealing cavity are controlled on the basis of the conventional microwave drying technology, meanwhile the essence of the material drying principle is well utilized, so that the purpose of performing microwave drying by efficiently utilizing microwaves is achieved, and technological problems that materials are excessively dried, deformed, burned and denatured during the microwave drying process are effectively avoided; meanwhile, the microwave drying process is enhanced in an energy-saving manner through approaches such as complete moisture circulation and reutilization and cavity heat preservation. The invention further discloses the device adopted by the method, parts are easy to obtain, and the implementation is easy to realize.

Owner:湖南源创高科工业技术有限公司

Heating device capable of realizing rapid heating through liquid and steam vacuum circulation

PendingCN109579295ATo achieve the purpose of indoor heatingSuitable for home heatingSteam generation heating methodsFeed water supplyCold airElectricity

The invention relates to a heating device capable of realizing rapid heating through liquid and steam vacuum circulation. The heating device comprises a steam boiler, a steam outlet pipe, a liquid return pipe and a heat exchange mechanism, wherein an electric heating panel is installed in the steam boiler; the steam outlet pipe is installed at the top end of the steam boiler, and the liquid returnpipe is installed at the lower end of the steam boiler; and the electric heating panel heats liquid heat exchange media in the steam boiler, the liquid heat exchange media boil and produce steam, thesteam enters an inner cavity of a steam heat exchange core body of the heat exchange mechanism under the vacuum condition, the steam transfers heat to the pipe wall of the heat exchange core body andconducts the heat to heat exchange fins, indoor cold air makes contact with the heat exchange fins and is constantly heated, after heat exchange, the hot steam forms condensed water and reaches a collecting pipe through an inclined flat heat exchange pipe, finally the hot steam circularly returns back into the steam boiler through the liquid return pipe, the heat of the electric heating panel iscircularly reciprocated for forced convection and rapidly transferred into indoor air, the purpose of indoor heating is achieved, greening and environment protection are achieved, the environment is protected, and the heating device is very suitable for home heating.

Owner:东莞旭光五金氧化制品有限公司

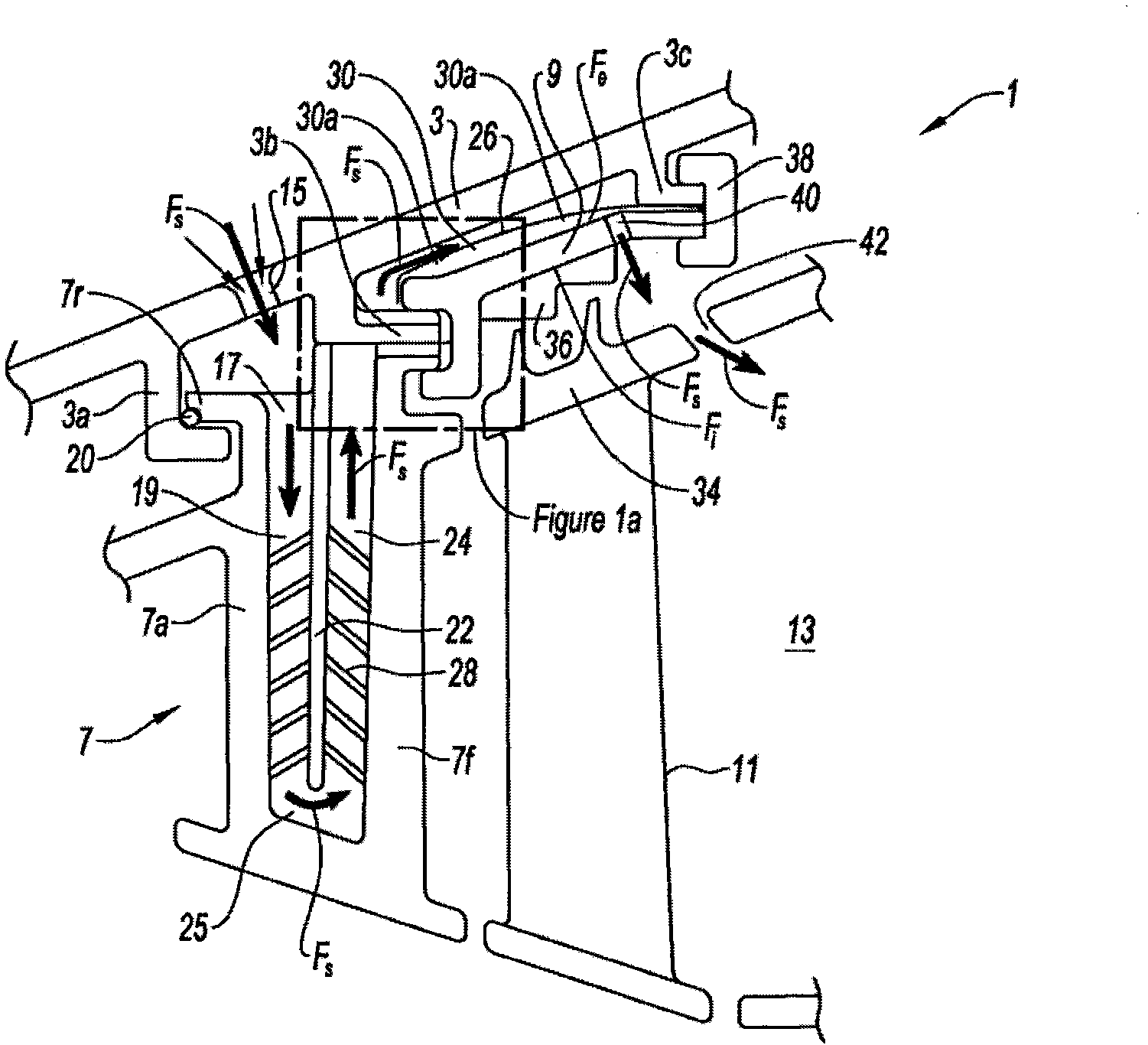

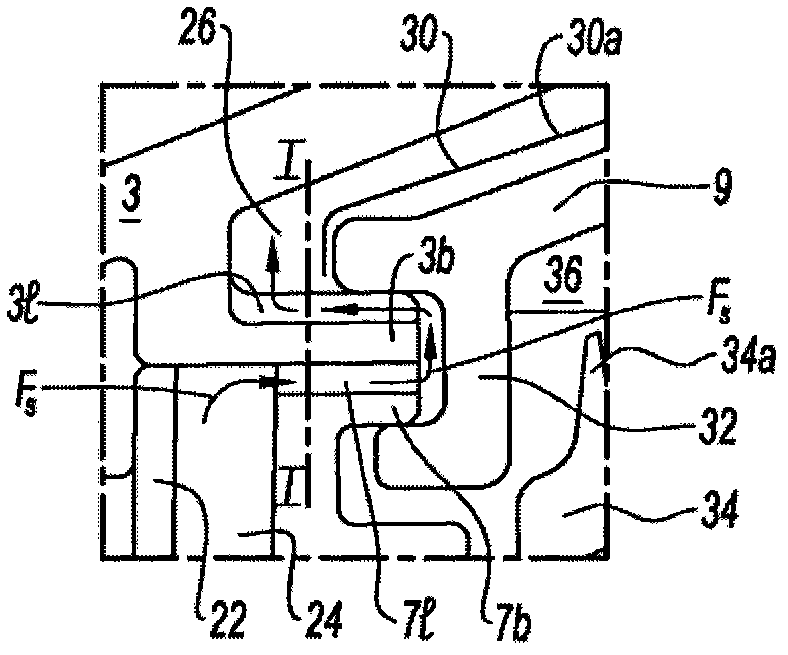

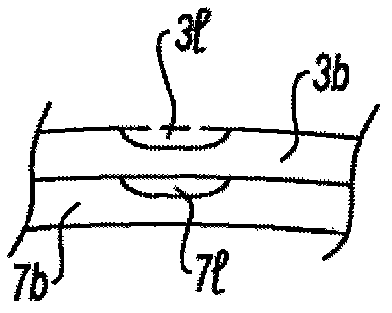

Method for cooling turbine stators and cooling system for implementing said method

The invention relates to a method and system for cooling turbine engine turbines (1), said method and system comprising: at least one pair of parts to be cooled, said pair consisting of a stator, upstream from the stator valve (7), and a sealing ring mounting (9) of a downstream movable blade rotor (11) that is adjacent to the stator (7); a turbine housing (3); and an outlet path (13). Said system in particular comprises: at least one opening (15) in the housing (3) facing at least one part (7, 9) to be cooled; and an air circuit producing a forced convection (19, 24, 26, 30) in connection with said parts (7, 9) and at least one downstream outlet (56) in the path (13) so as to draw in and transport an ambient air flow (Fs).

Owner:TURBOMECA SA

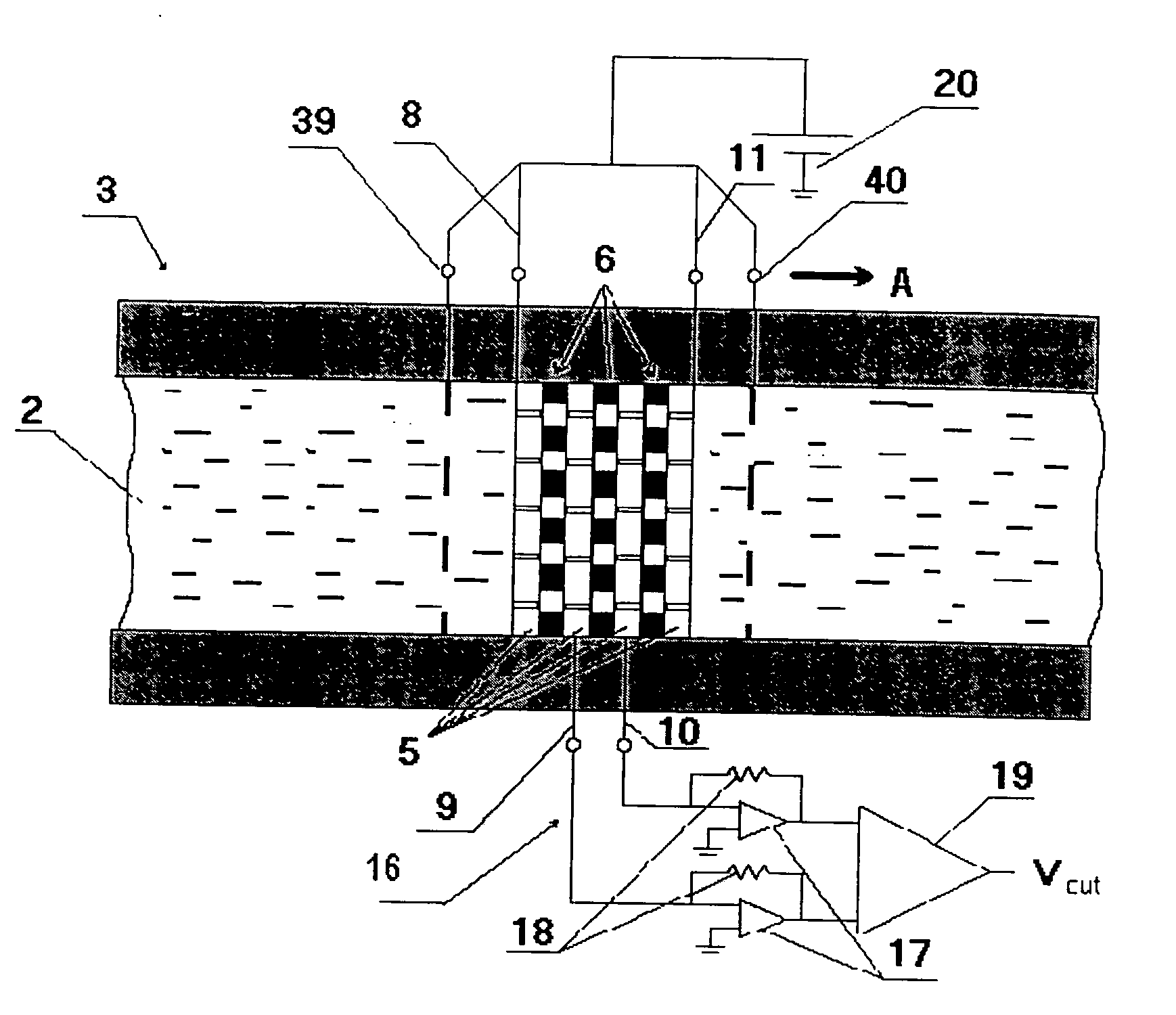

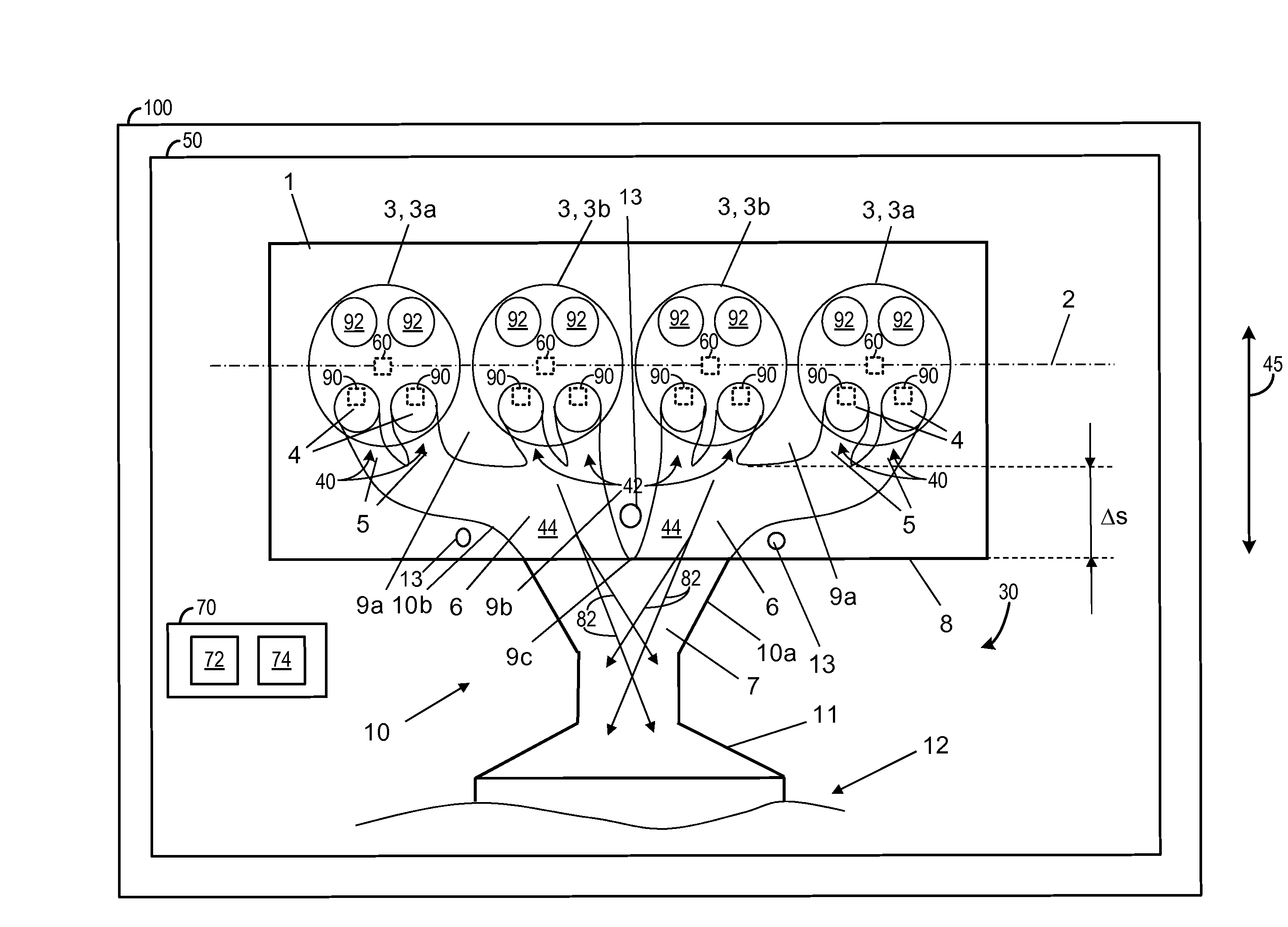

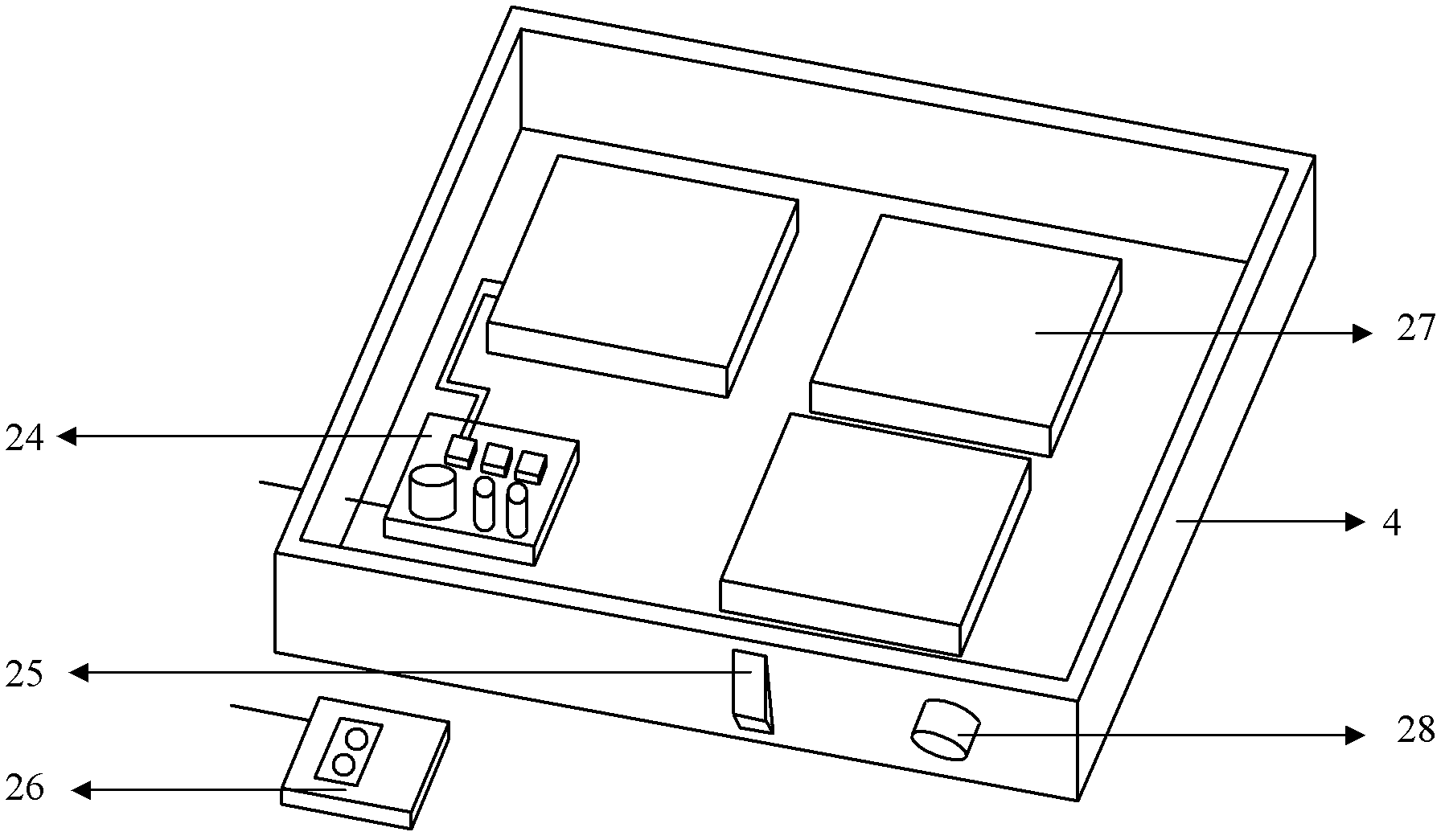

Experimental apparatus for diffusion flames in forced convection environment

InactiveCN102322739ADoes not affect forced convection environmentIncandescent ignitionFurnace typesDiffusion flameCombustion

Owner:UNIV OF SCI & TECH OF CHINA

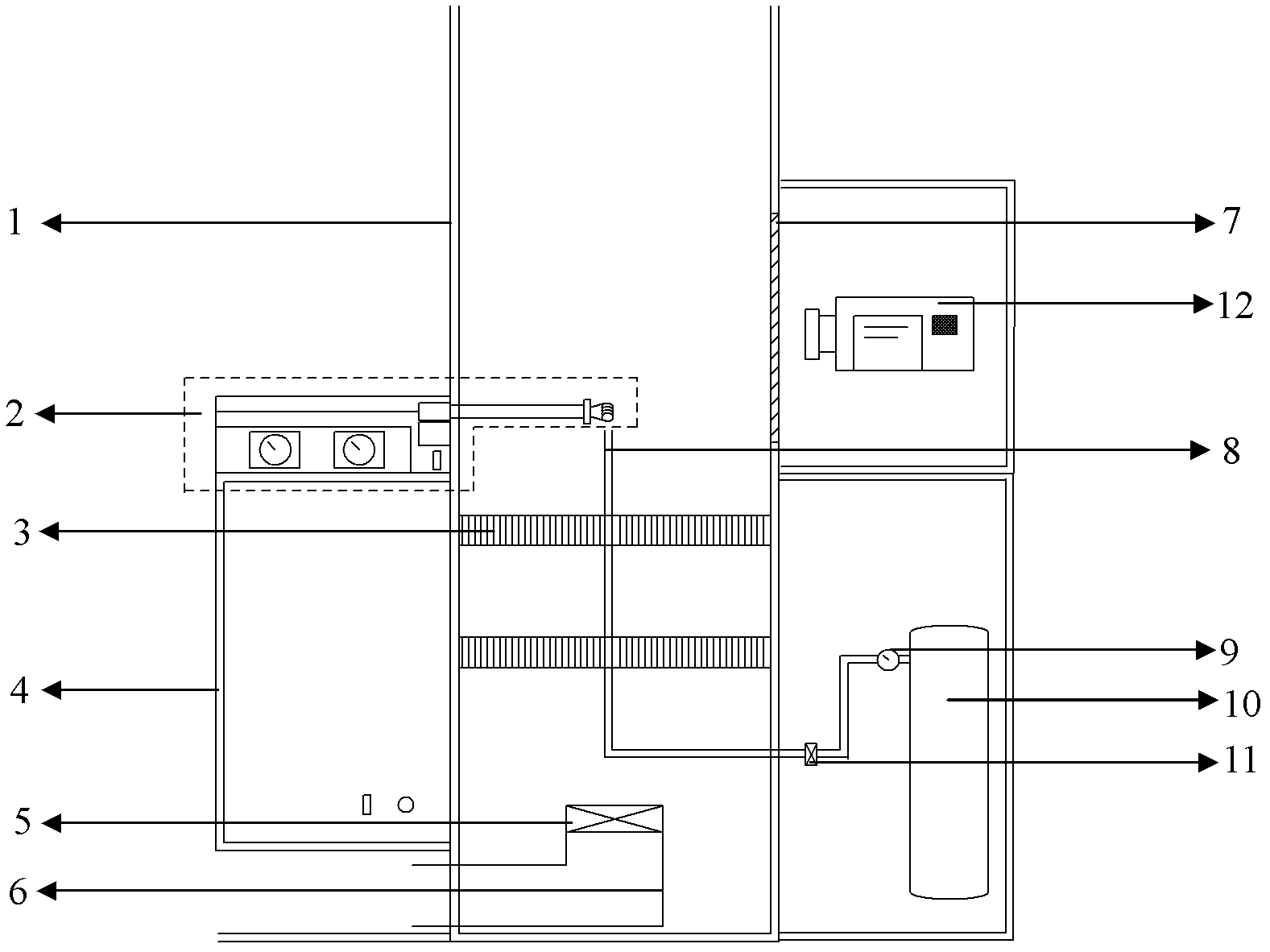

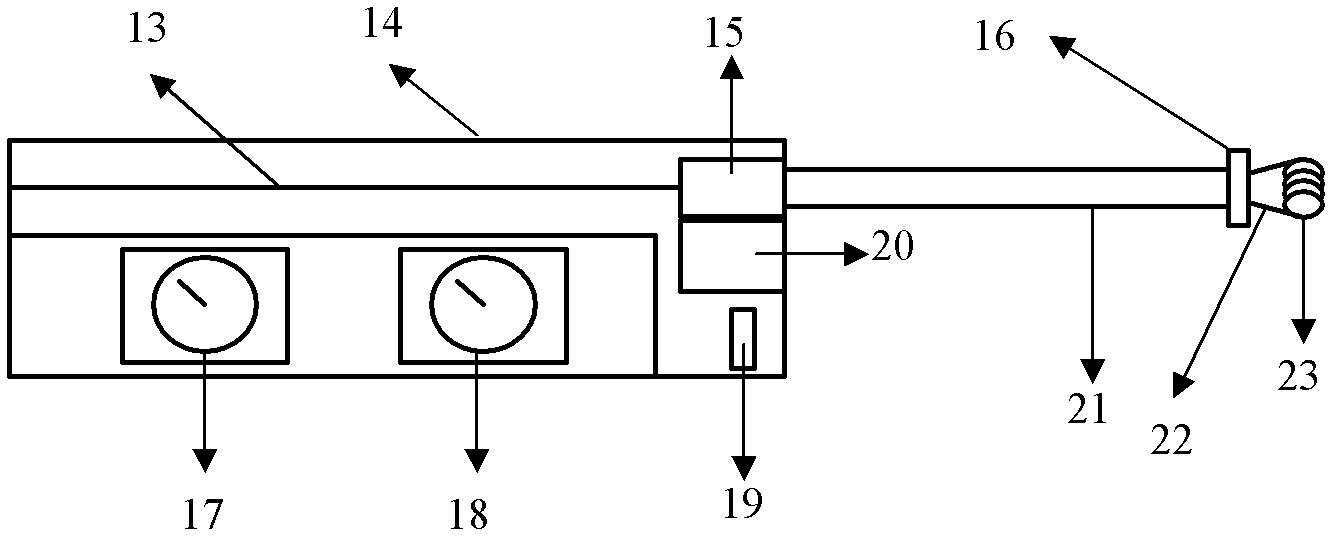

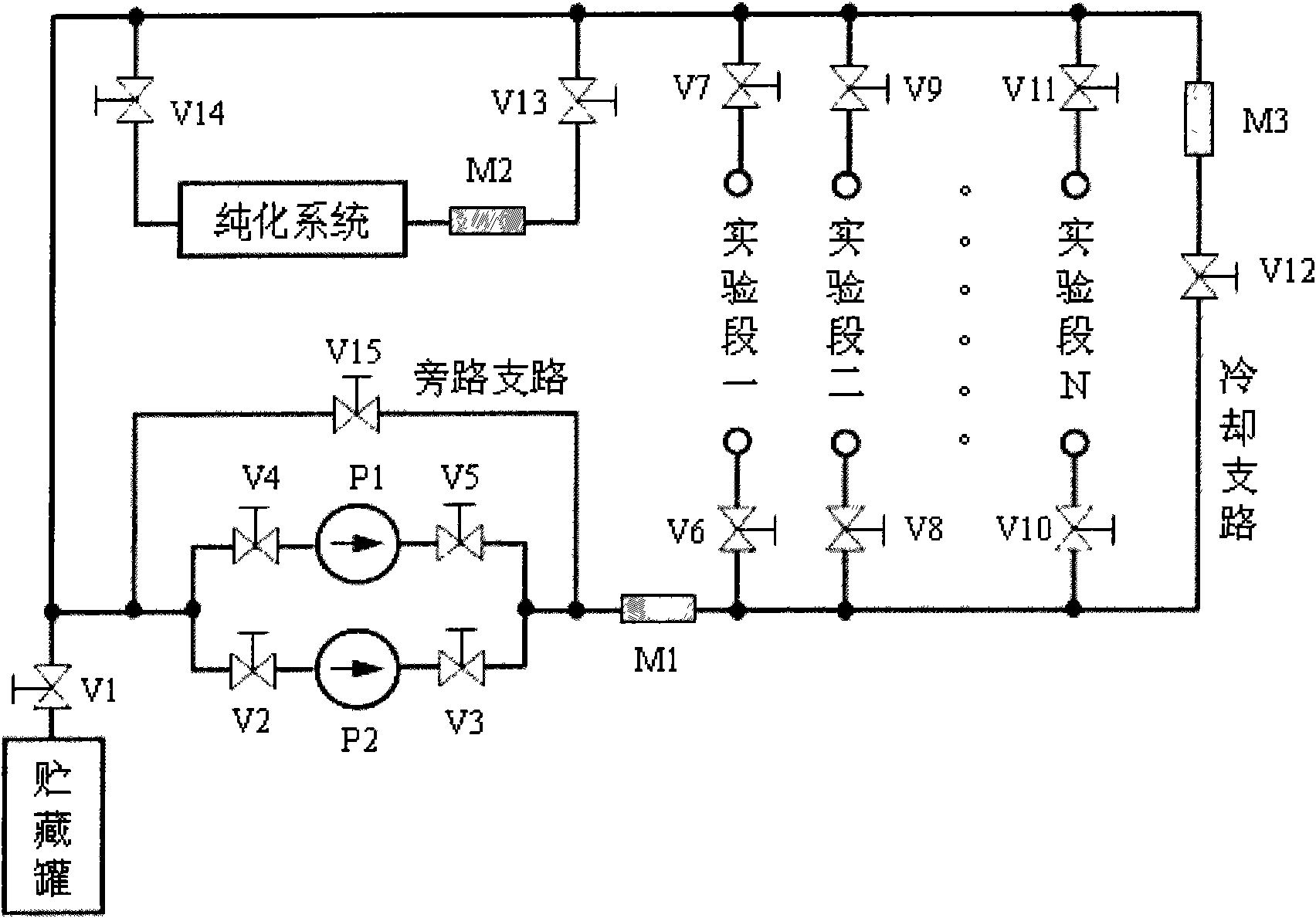

Forced convection multifunctional liquid medium experimental loop

InactiveCN101581657ACarry out experimental researchWeather/light/corrosion resistanceFlow propertiesLiquid mediumMeasurement device

The invention discloses a forced convection multifunctional liquid medium experimental loop which mainly comprises a storage tank, a power pump, a valve, a flow meter, an experimental section, a medium pipeline, a purifying system, a heating system, a heat insulation system and the like. The power pump is utilized as a power source for driving a liquid medium to flow; the flow meter measures the flow rate of the liquid medium in the device in real time; the valve controls the flow direction and the flowing or static state of the medium in the device; the flow rate of the medium in the loop is controlled in multiple positions by virtue of a bypass valve and the power pump as well as the flow meter; and after the experiment is over, all the media are collected in the storage tank by depending on the elevation angle of the pipeline and the gravity action of the liquid medium. A plurality of circuit branches and experimental section junctions in the loop can be combined, the required experimental sections can be extended according to specific experimental requirements, and corresponding experimental environment (such as a temperature field, a stress field, a magnetic field, a flow field and the like) can be constructed in the loop of the liquid medium. The forced convection multi-functional liquid medium experimental loop can be widely applied to the fields of industrial application and scientific research projects for developing relevant researches on key technical problems.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

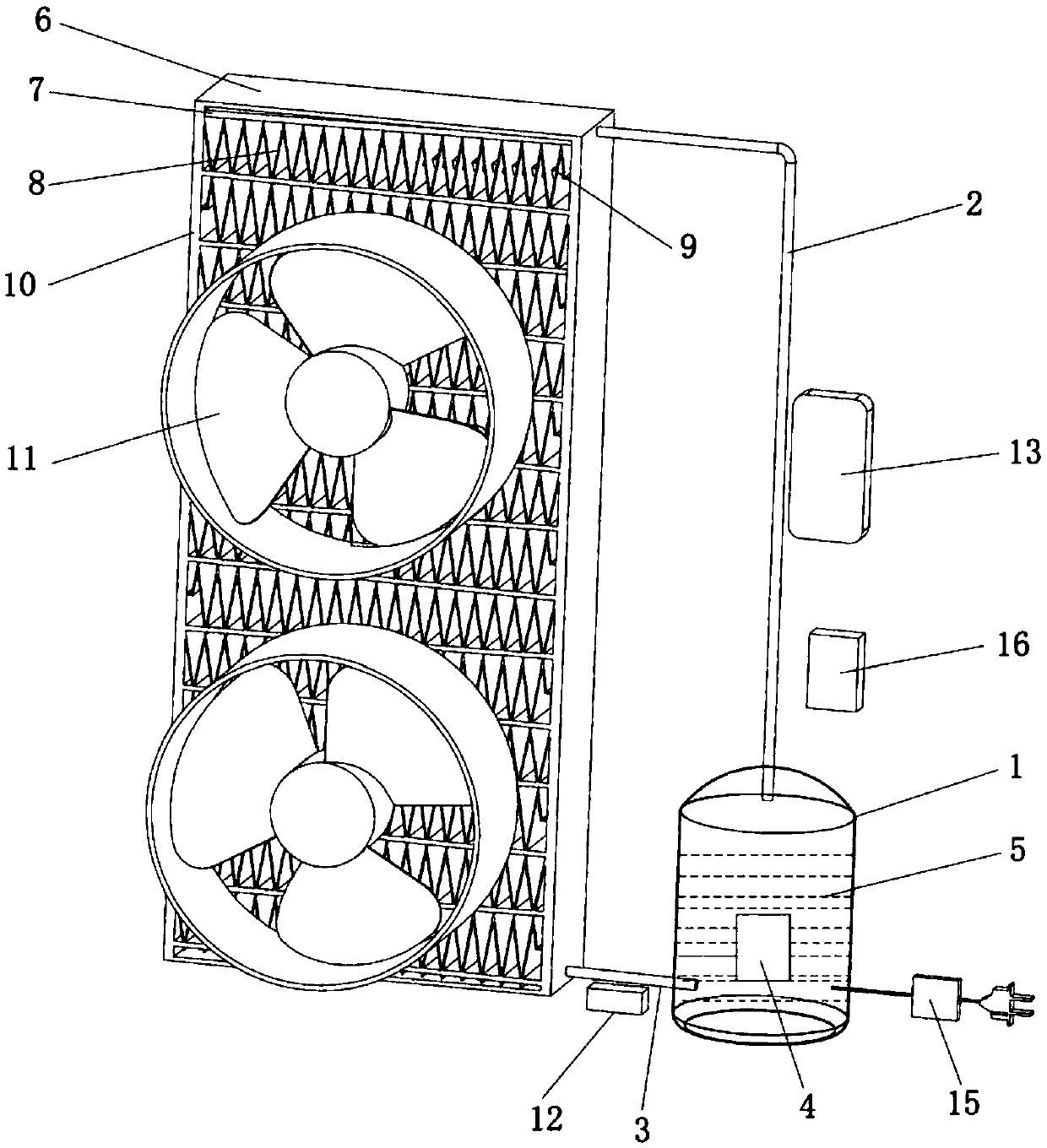

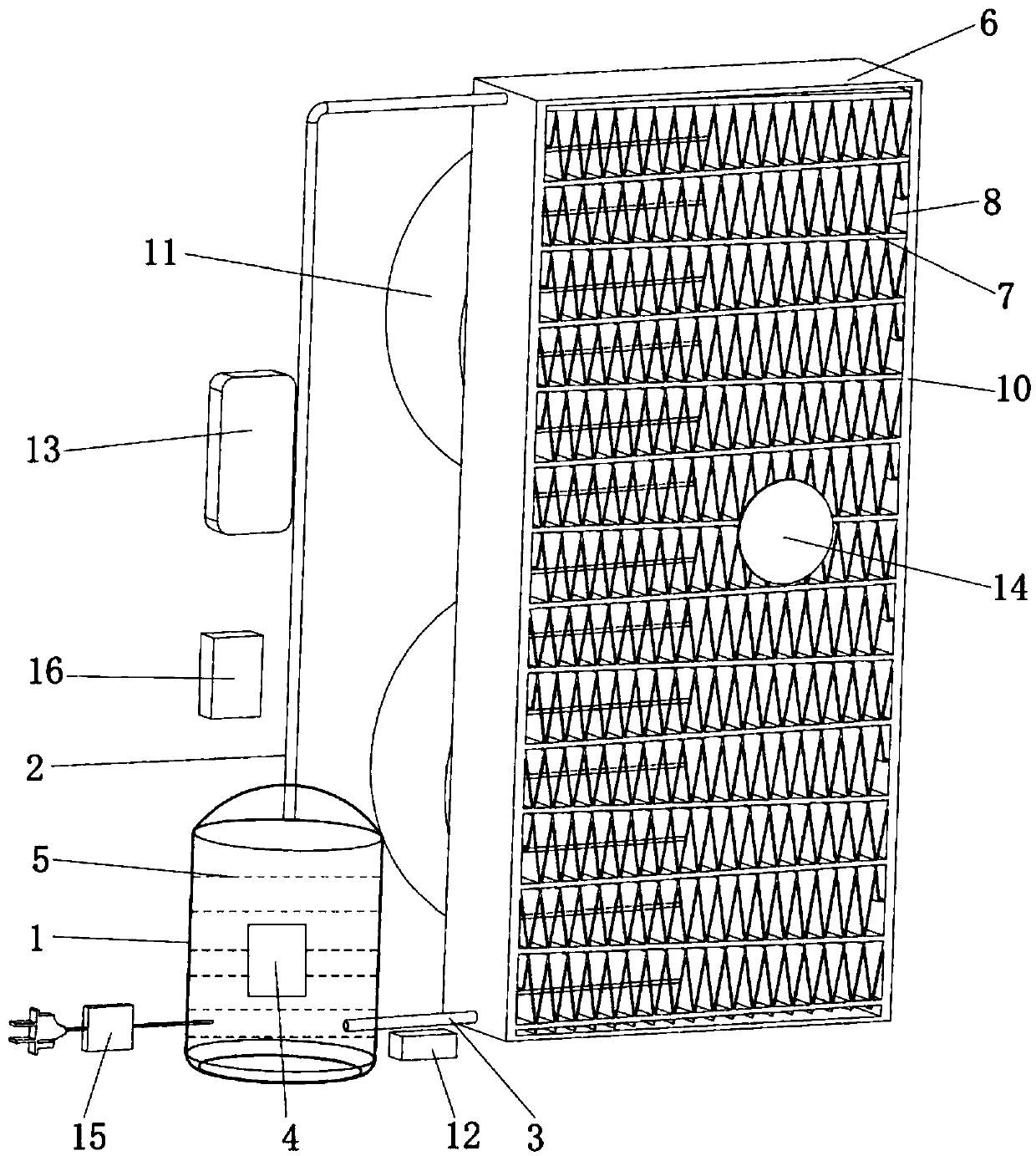

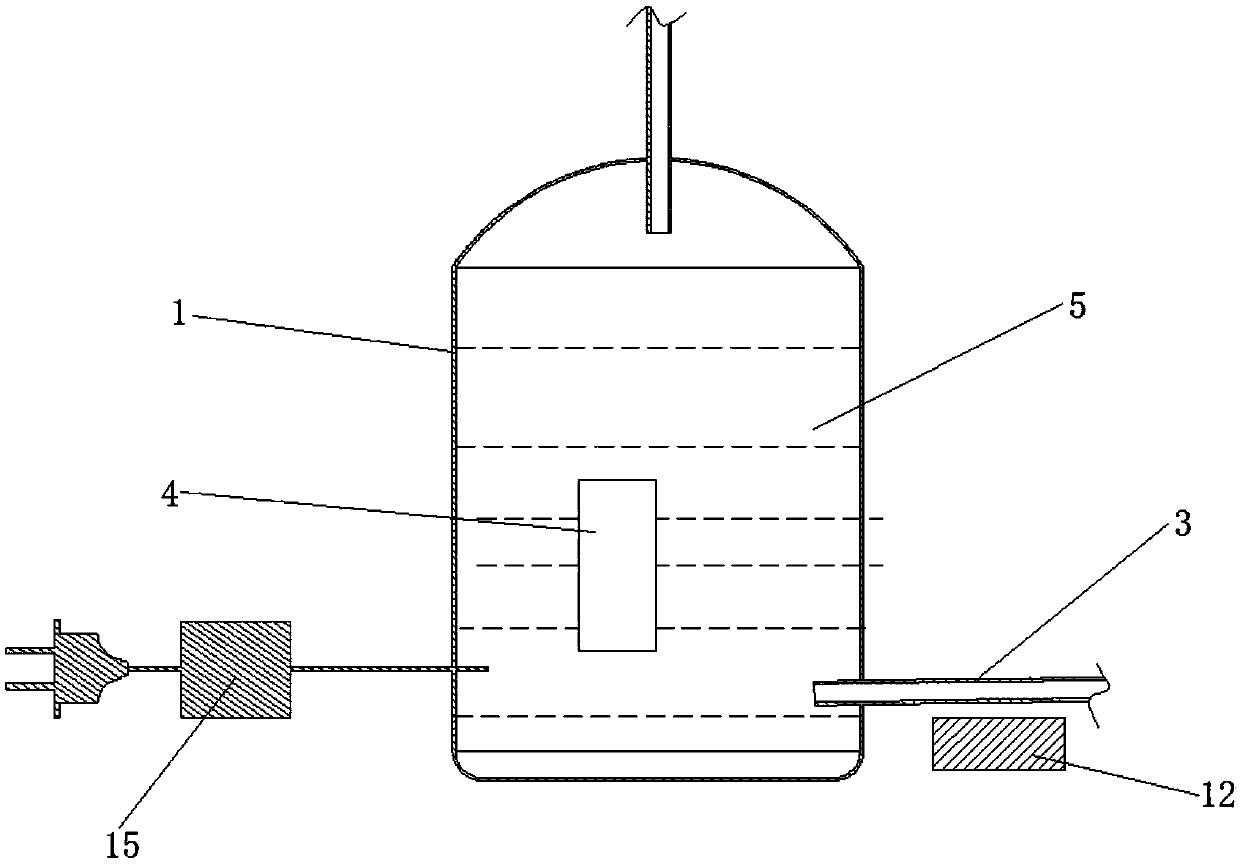

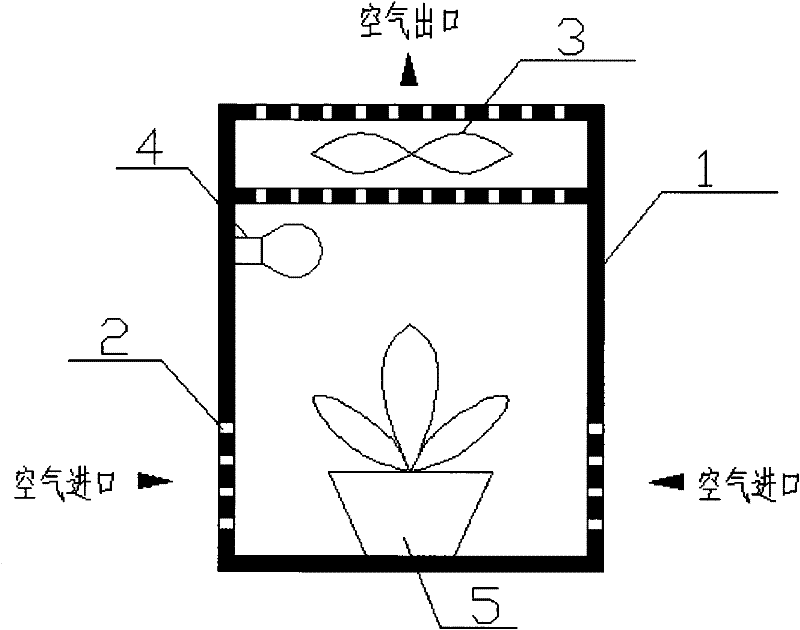

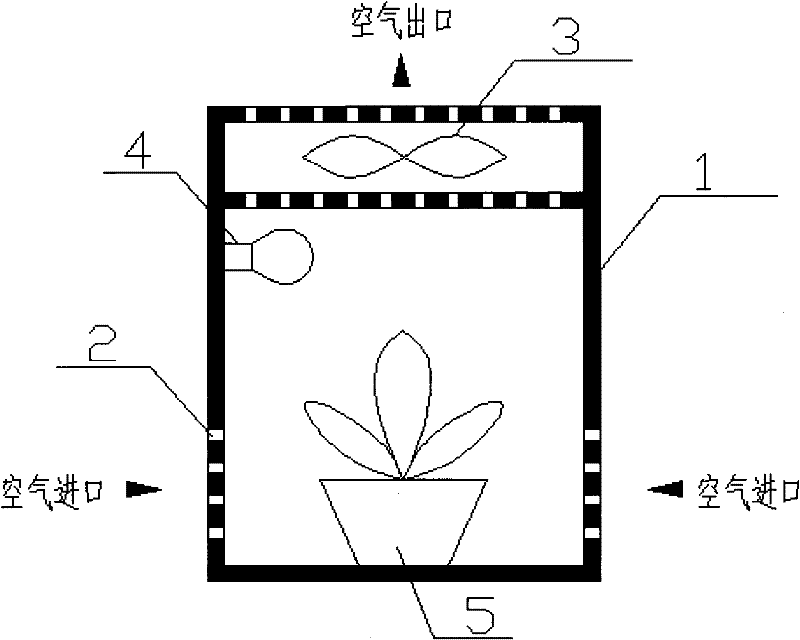

Photosynthesis-based forced convection air purification device

InactiveCN102246672AEnsure photosynthesisDoes not affect restLighting and heating apparatusGreenhouse cultivationForce convectionEngineering

The invention relates to an air purification device, in particular to a photosynthesis-based forced convection air purification device. In the device, a shell which is provided with an air vent and is provided with a lamp bulb and a built-in fan is used as a core, and sufficient illumination is provided by utilizing the lamp bulb so as to ensure the leading position of the photosynthesis of plants; and the effect of forced convection between the plants and air is improved by the driving of the fan to accelerate the speed of purifying the air.

Owner:NANJING INST OF TECH

Post cure inflator and vulcanized tire cooling method

Owner:KOBE STEEL LTD +1

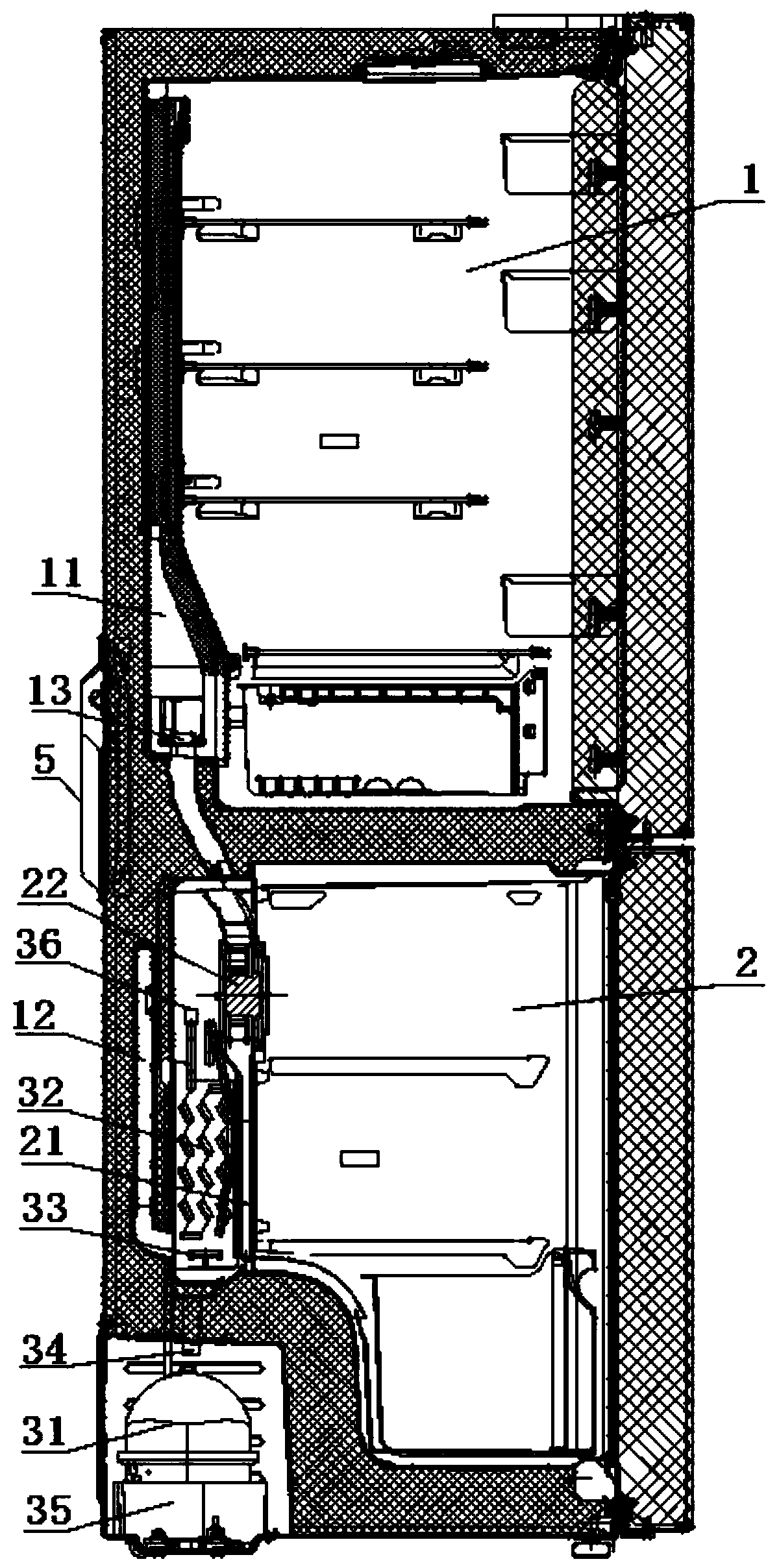

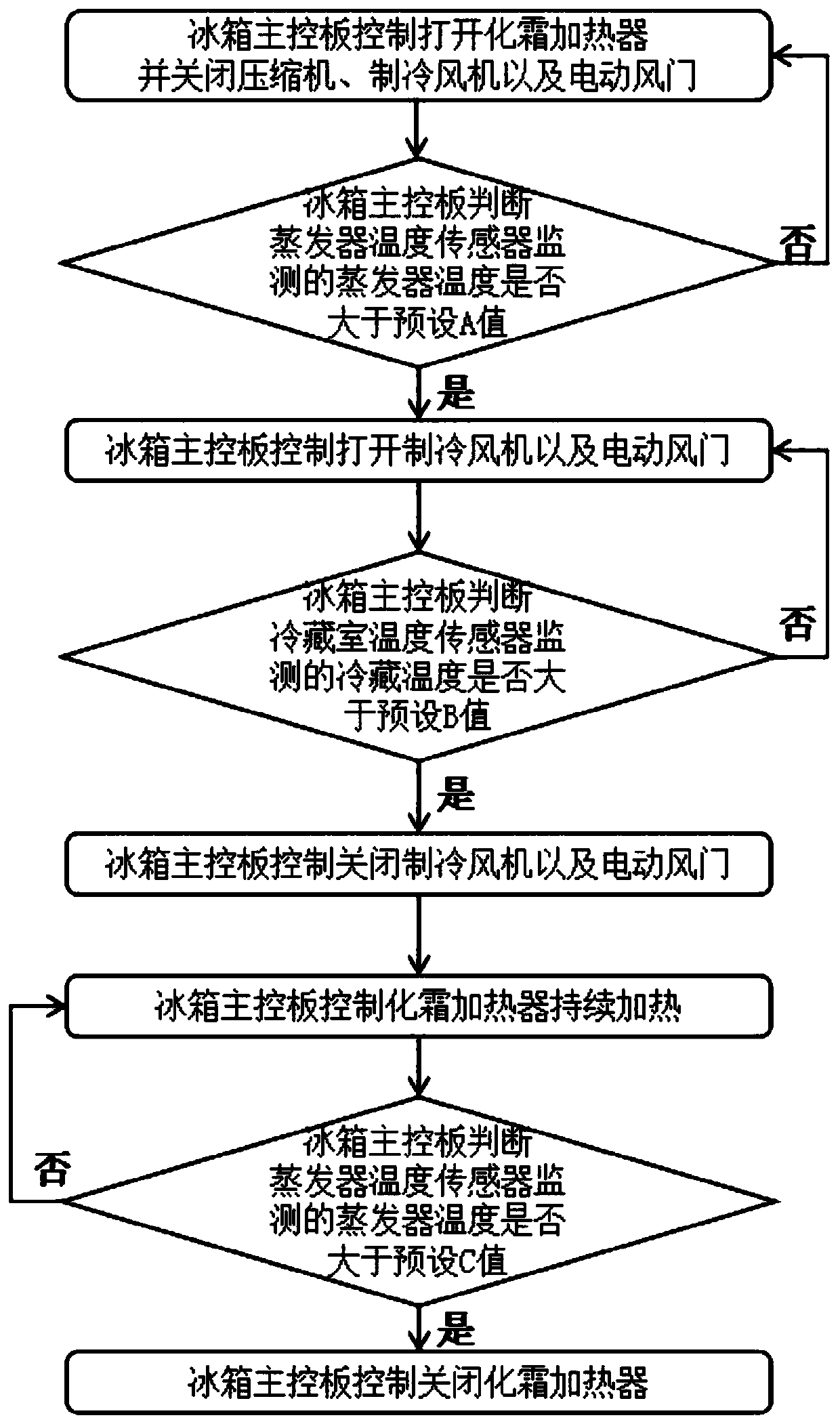

Air cooled refrigerator defrosting and humidifying device and control method thereof

PendingCN110440502AShorten heating timeImprove the preservation effectLighting and heating apparatusDomestic refrigeratorsHeating timeHigh humidity

The invention discloses an air cooled refrigerator defrosting and humidifying device and a control method thereof, and relates to the technical field of refrigerators. The air cooled refrigerator defrosting and humidifying device comprises a refrigerator body, a refrigerating chamber, a freezing chamber, a refrigerating system, an air circulating system and a defrosting and humidifying system; therefrigerating system comprises a compressor, an evaporator, a capillary tube, a filter and a condenser; the compressor is mounted inside a compressor chamber below the refrigerating chamber; and theevaporator is communicated with the compressor, and is mounted inside an evaporator chamber on the rear side of the refrigerating chamber. The air cooled refrigerator defrosting and humidifying deviceprovided by the invention uses the principle that when solid frost on the evaporator is changed to be in a liquid state, heat is absorbed and the temperature is not changed; when defrosting is performed, the main control panel of the refrigerator controls a refrigerating blower to blow moist air produced by defrosting into the refrigerating chamber for moistening; by using a forced convection method, high humidity air is blown into the refrigerating chamber, the defrosting and heating time is shortened, so that when the system inside a single-system air cooled refrigerator enters into a defrosting period, the relative humidity average value is increased to 80 percent from 40 percent, and the fruit and vegetable fresh-keeping effect of the refrigerating chamber is improved greatly.

Owner:CHANGHONG MEILING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com